Porous pipe method large-diameter high-pressure jet grouting pile construction method

A technology of high-pressure rotary jetting pile and construction method, which is applied to sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of small pile diameter, low pile work efficiency, large soil squeeze effect, etc., and improve the pile forming efficiency. , saving engineering cost, and expanding the effect of pile diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

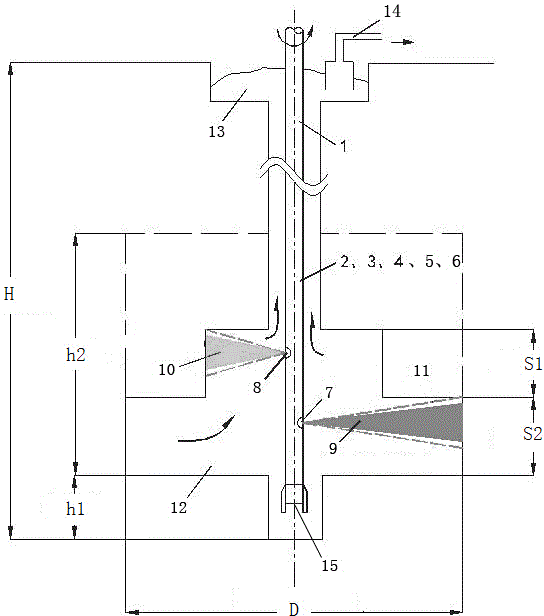

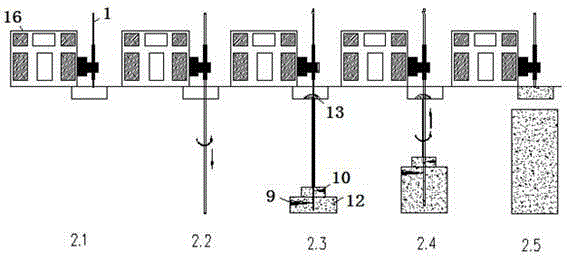

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] The invention provides a large-diameter high-pressure rotary grouting pile construction method (RJP construction method) with a porous pipe method. Through the reasonable arrangement and optimization of the jet flow of high-pressure water, compressed air, and ultra-high-pressure solidified liquid (cement slurry, etc.), the In the process of lifting piles, the high-pressure water flow and compressed air jet flow at the upper end and the ultra-high pressure solidified liquid jet flow and compressed air jet flow at the lower end are used for joint relay cutting, so that the pile diameter of the high-pressure rotary grouting pile can reach 2.2~3.5m, and the pile-forming efficiency is improved. Substantially improved. In conjunction with the accompanying drawings, the specific description is as follows:

[0020] Such as figure 1 , as shown in 2, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com