Construction method for enhancing earthwork compactness of small-span #-shaped beam inner lime sand pile

A construction method and compaction technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of small area, large filling earthwork thickness, high construction cost, etc., and achieve simple mechanical structure, convenient operation, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

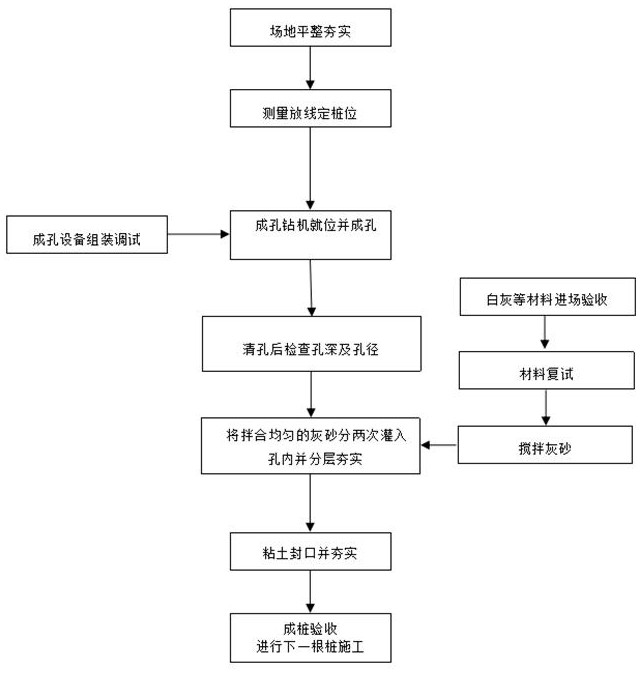

[0016] Such as figure 1 As shown, a construction method for enhancing earthwork compaction by lime-sand piles in a small-span well-shaped beam includes the following steps.

[0017] S100~The site is leveled and compacted; the atrium backfill soil between the ground beam and the ground beam of the independent foundation atrium backfill soil is reinforced with a spiral mechanical hole-forming lime-sand pile, and the surface of the atrium soil of the independent foundation is 300mm thick The surface layer soil shall be rammed artificially with a tamping machine, and the lack of soil shall be filled with silty sand to the design fill level after tamping.

[0018] S200~Measuring and setting out positioning piles; according to the layout plan of the lime-sand piles, after the site is leveled, use the total station and meter ruler to release the construction pile positions of each pile, insert bamboo sticks and sprinkle white ash marks. The layout of the gray-sand piles is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com