Large diameter cement soil pile construction method

A technology of cement-soil pile and construction method, which is applied in construction, sheet pile wall, foundation structure engineering, etc. Non-uniformity and other problems, to achieve the effect of reducing the amount of external transportation, improving the bearing capacity of the pile body, and being easy to mix evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

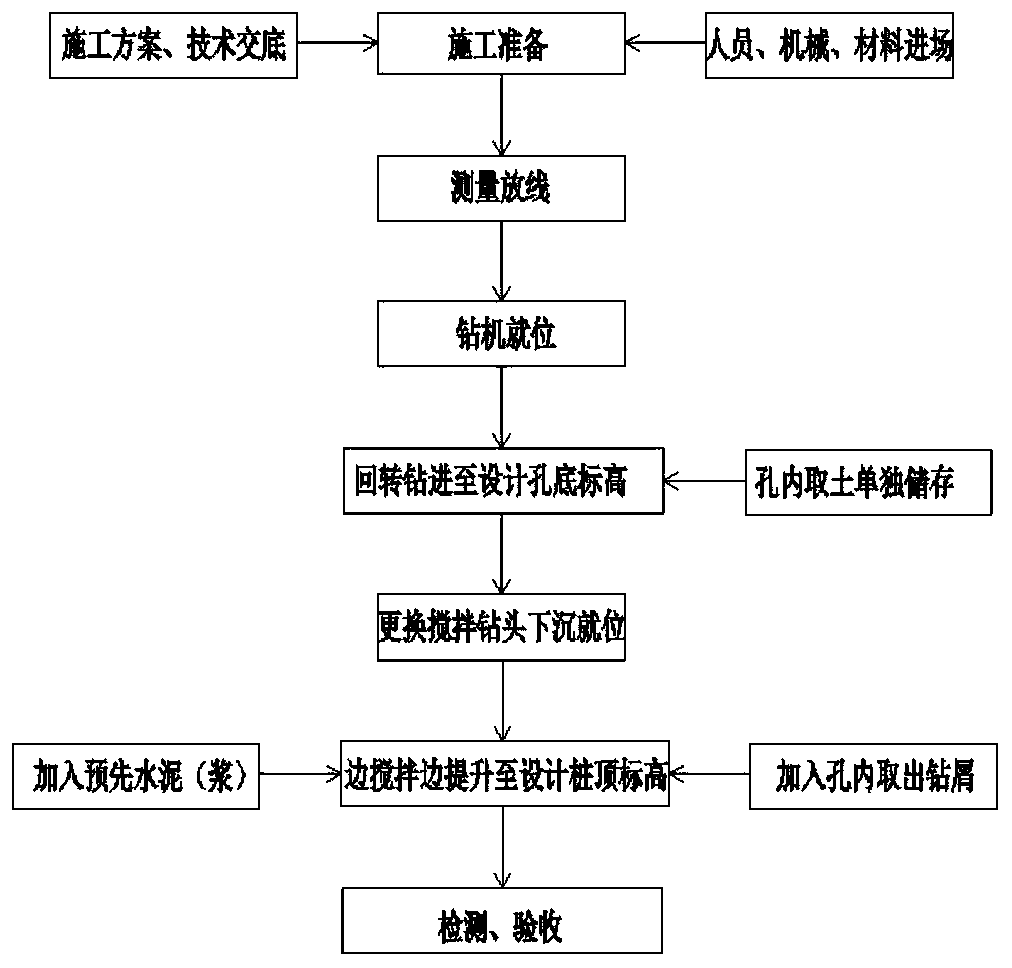

[0020] In conjunction with the accompanying drawings.

[0021] The rotary drilling rig is used to rotate the soil to form a hole, and the soil is taken one by one to form the hole to the design pile bottom elevation, and then the drilling is stopped, and then cement slurry or cement mortar is injected into the bottom of the hole, and the rotary drilling rig bit is replaced with a mixing bit and placed at the bottom of the hole. Stir at the bottom of the hole, and then add backfill material in batches into the hole. The backfill material can be drilled slag or sand and pebbles taken when the hole is formed, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com