Patents

Literature

33results about How to "Easy to mix evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brucite granular fertilizer and its preparation method

InactiveCN1785914AReduce pollutionNo wasteMagnesium fertilisersFertiliser formsSpherical granuleWater soluble

The present invention relates to a brucite granule fertilizer and its preparation method. Said preparation method includes the following steps: mixing brucite, natural magnesium sulfate and light calcined magnesium, using water or 5% (mass) of citric acid solution as binding agent, mixing all the materials, granulating drying and packaging so as to obtain spherical granules whose diameter is 2-4mm, in which water content is less than or equal to 1%, hardness is 1.5-4kg / sq.cm, disintegration rate is greater than or equal to 90%, citric-soluble MgO mass content is 53-62% and water-soluble MgO mass content is 3-5%.

Owner:大连爱思凯矿产有限公司

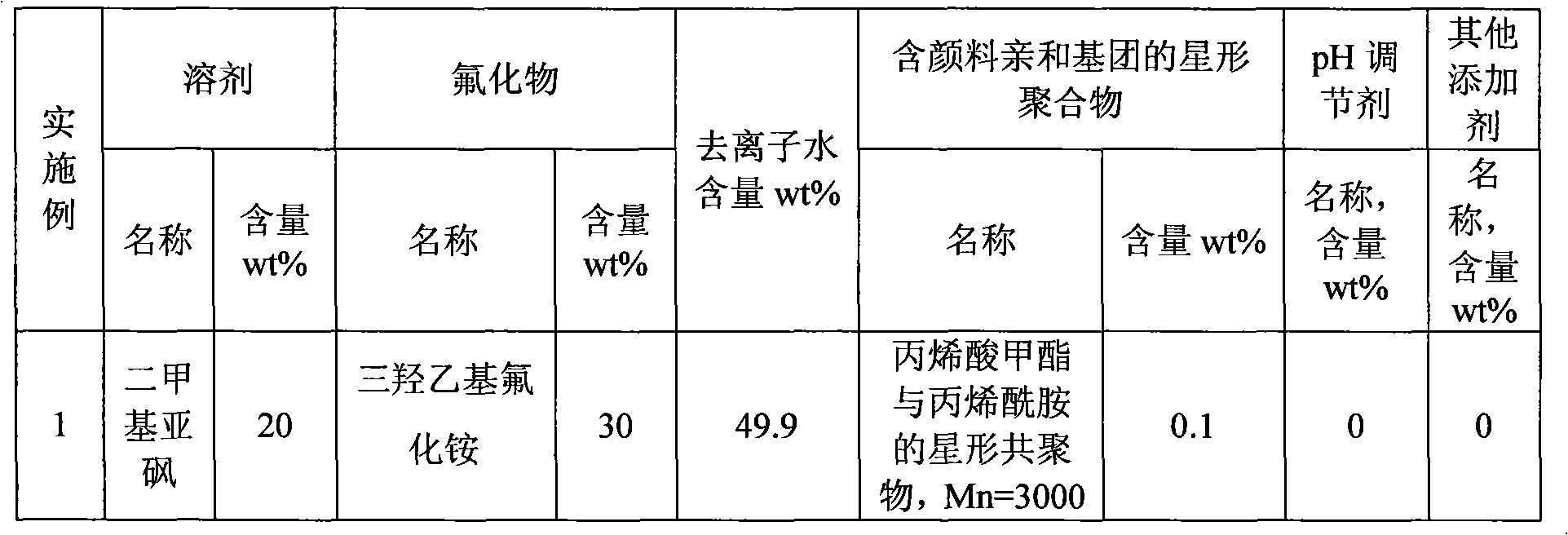

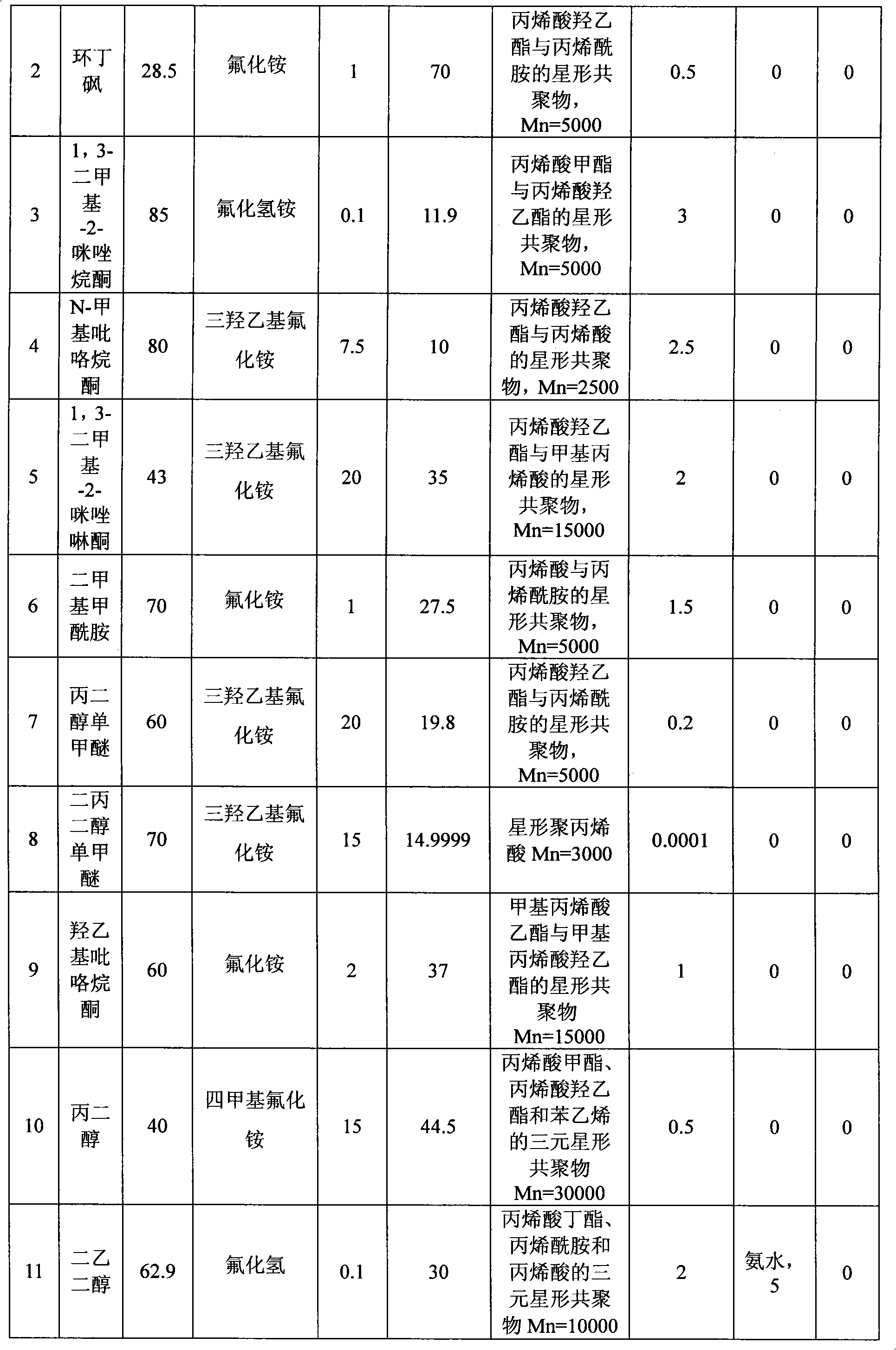

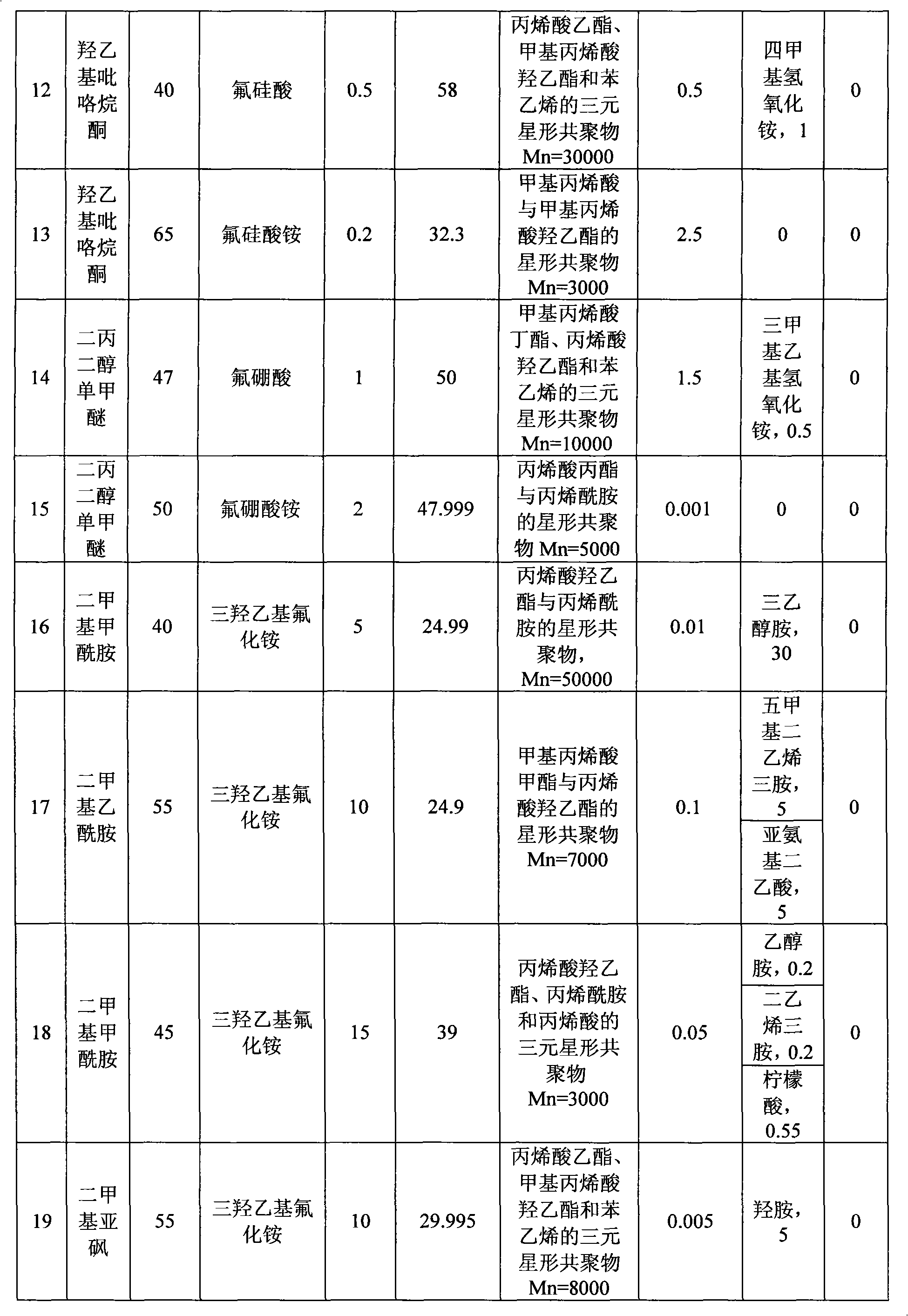

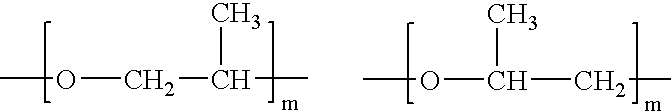

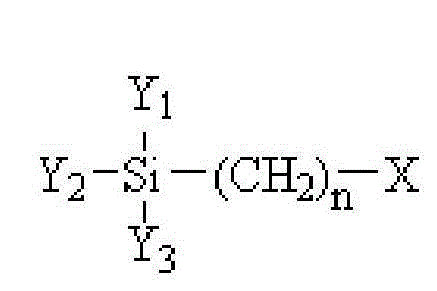

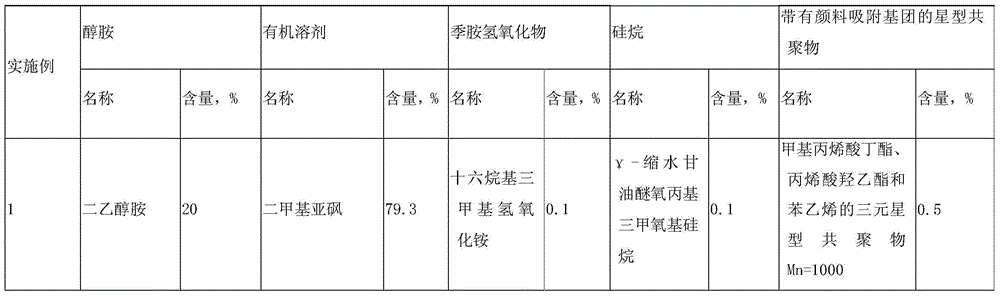

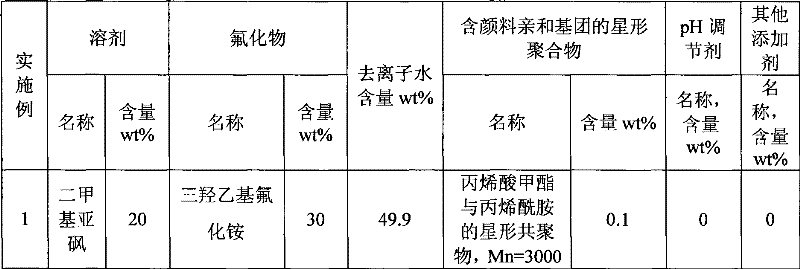

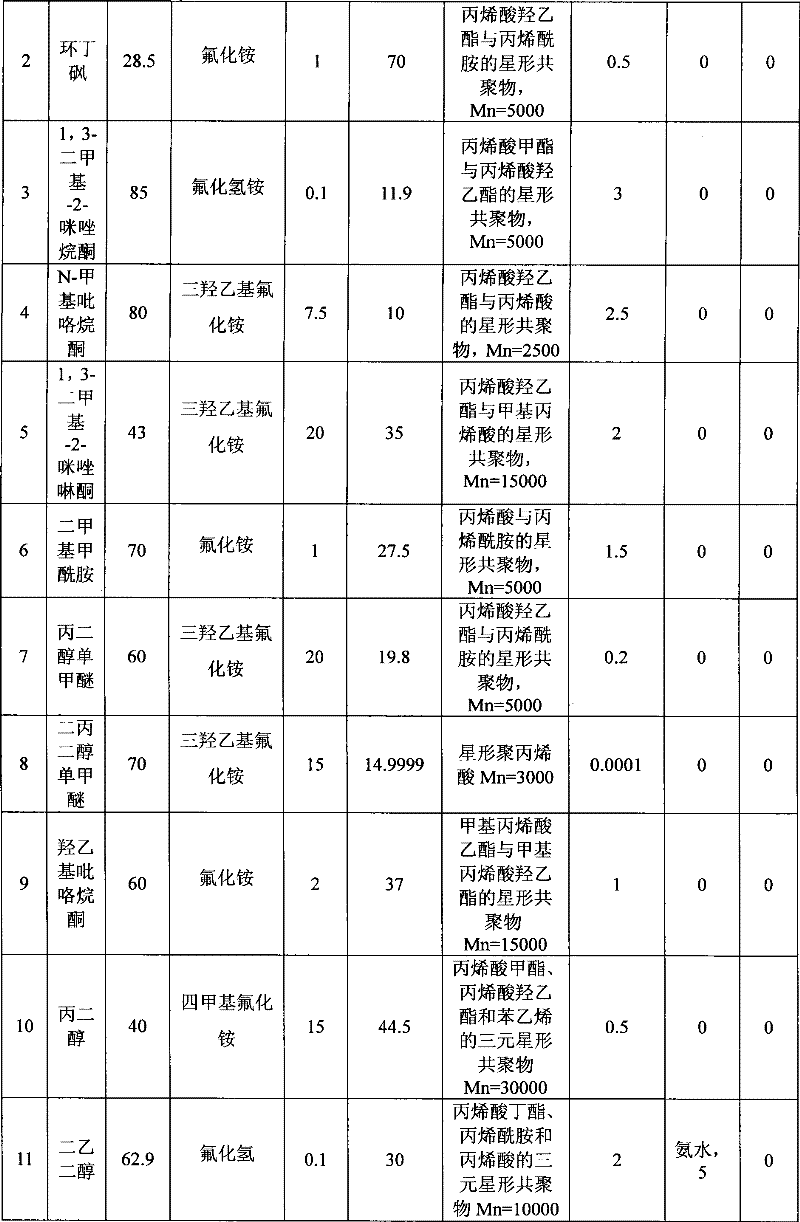

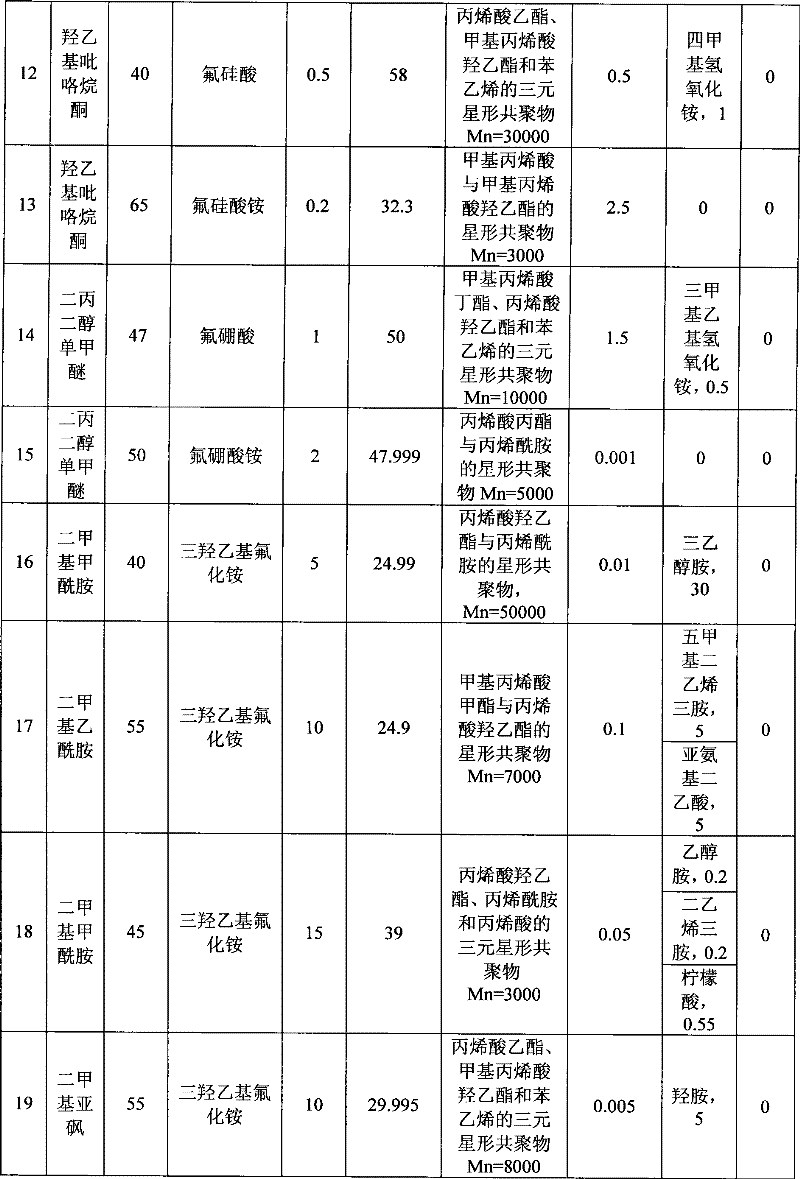

Plasma etching residue cleaning solution

ActiveCN101666984AReduce corrosion rateImprovement cannot control metal at the same timeDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSolventFluoride

The invention discloses plasma etching residue cleaning solution, which comprises a solvent, water, fluoride, and a star polymer containing pigment affinity groups. The plasma etching residue cleaningsolution can effectively remove photoresist residues after plasma etching, can simultaneously inhibit corrosion of metal (in particular aluminum) and non-metals in high efficiency, and has larger operating windows for cleaning and rinsing.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

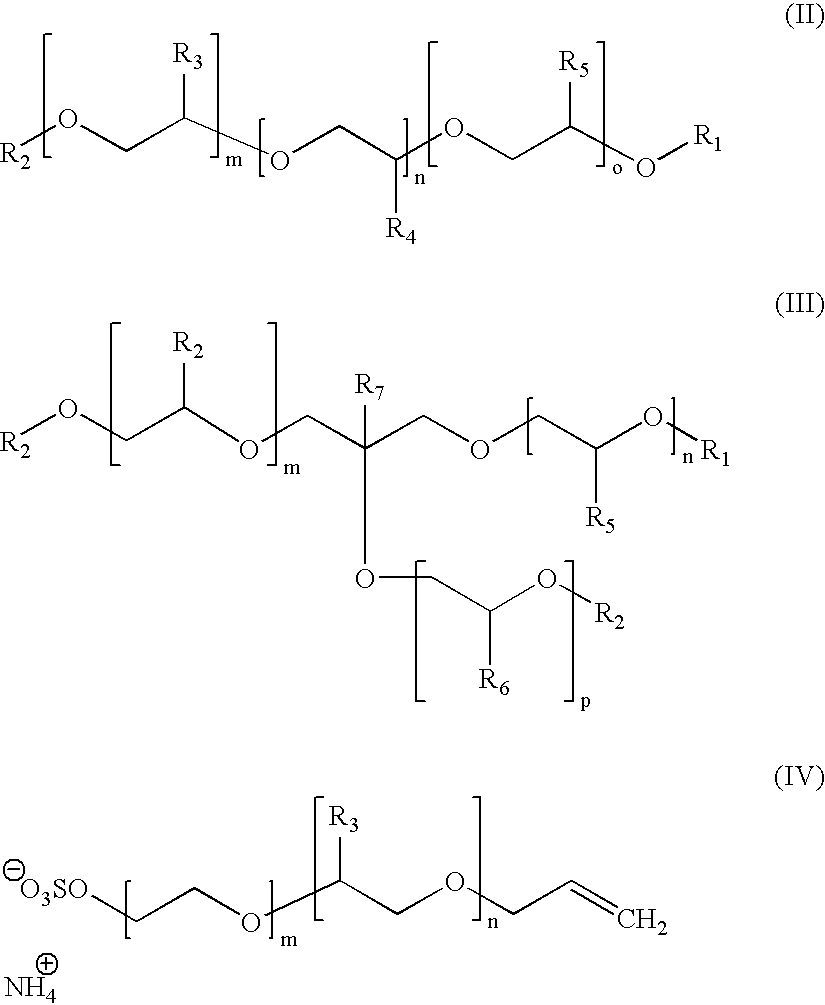

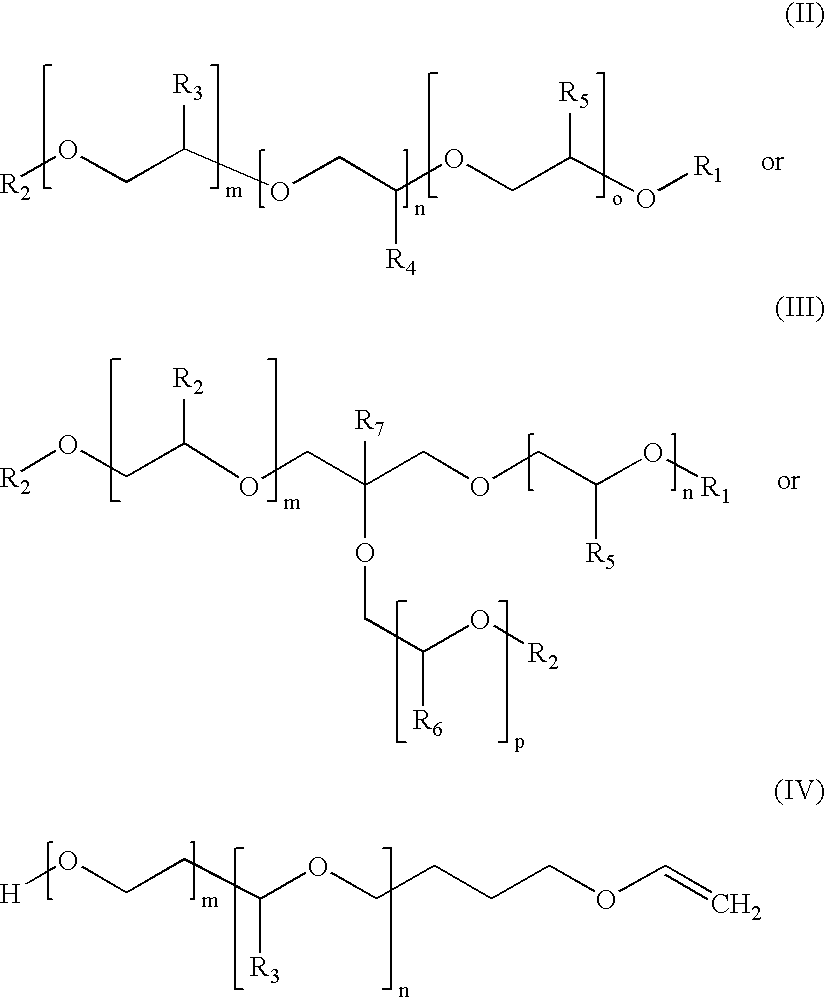

Curing agent component for an at least two-component mortar composition, method of preparing it and its use

ActiveUS20030232909A1High strengthIncrease the load valueOther chemical processesSpecial tyresSolubilityHydrogen

A curing agent component is described for an at least two-component mortar composition for the chemical fastening technique, containing at least one free radical-forming agent as curing agent for an organic resin component, water and at least one water-soluble, ethylenically unsaturated polyethylene glycol derivative, which can be copolymerized with the organic resin component and has a solubility in water at 25° C. of at least 10 g in 100 gram of water and has the structure given by the general formula I:R2-A-O-R1 (I)in which R1 represents a group having the formula CH2=CH-CH2-, CH2=CH-CO-O- or CH2=C(CH3)-CO-O-, R2 represents hydrogen, an alkyl group with 1 to 6 carbon atoms, a sulfonate group or a group having the formula CH2=CH-CH2-, CH2=CH-CO-O- or CH2=C(CH3)-CO-O-, and A represents a linear or branched, homopolymeric or copolymeric, optionally substituted polyoxyalkylene group. Furthermore, methods are described for producing and using the curing agent component in a two-component or multi-component mortar composition for fastening construction elements in a solid substrate.

Owner:HILTI AG

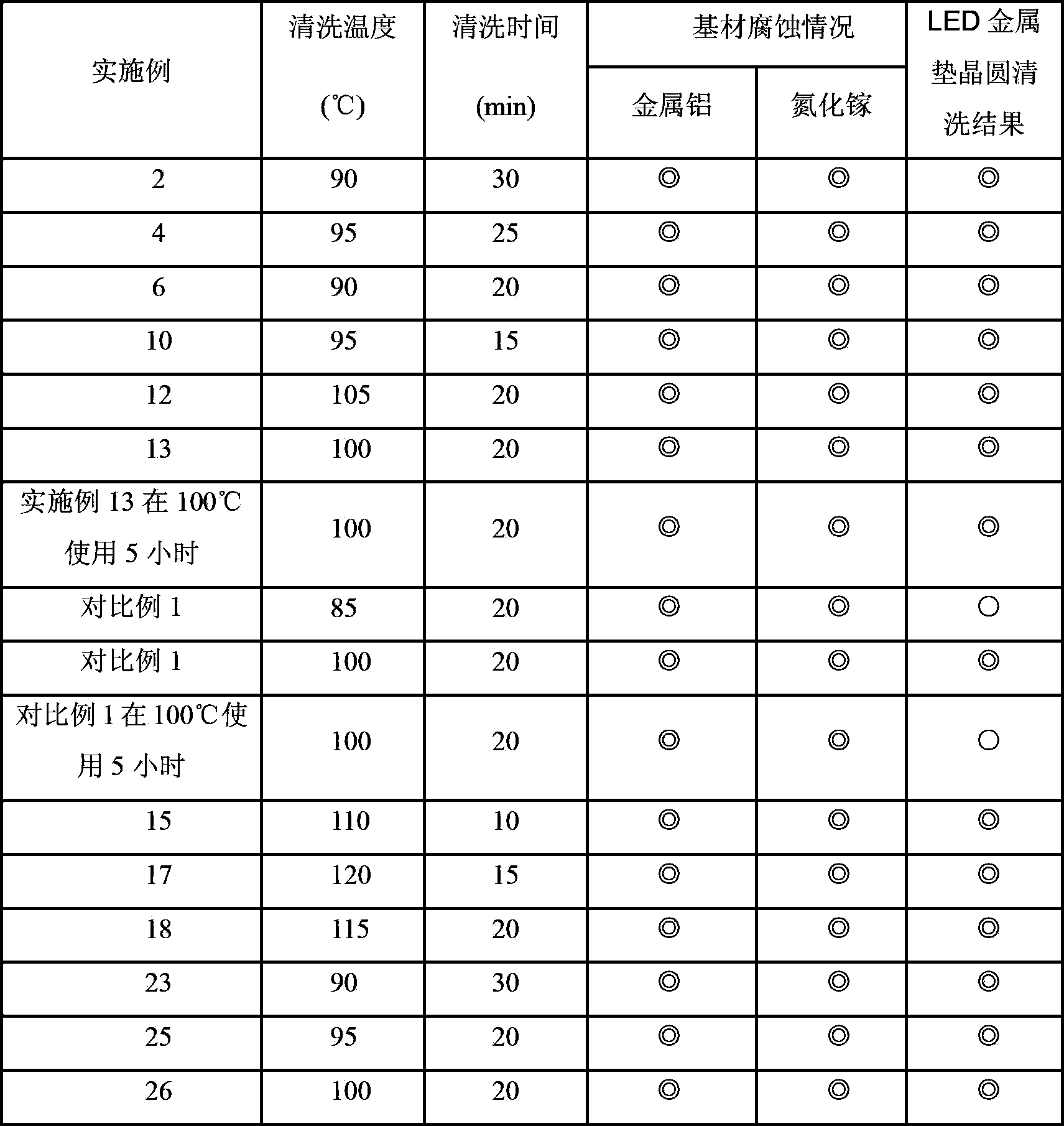

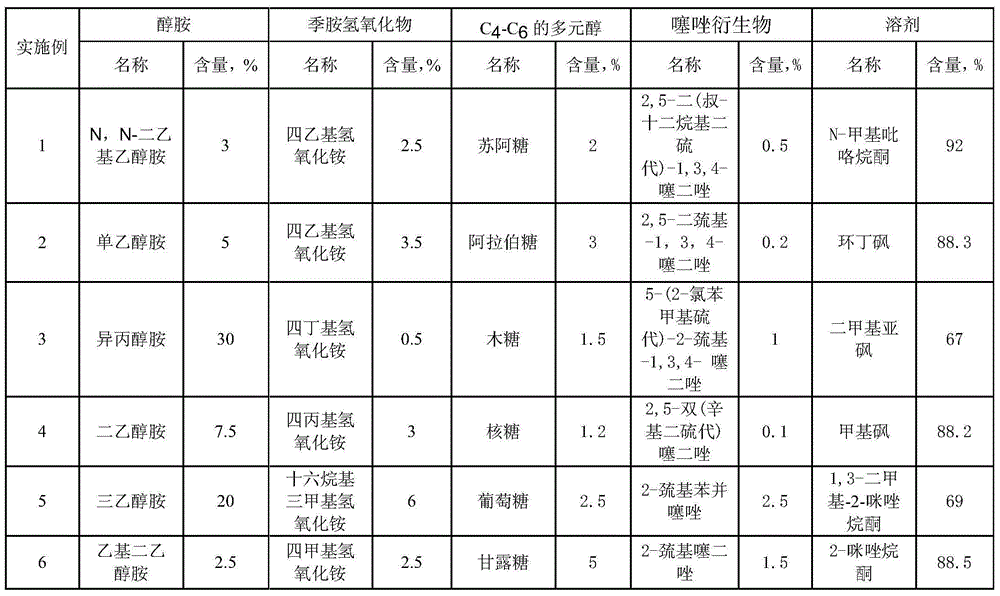

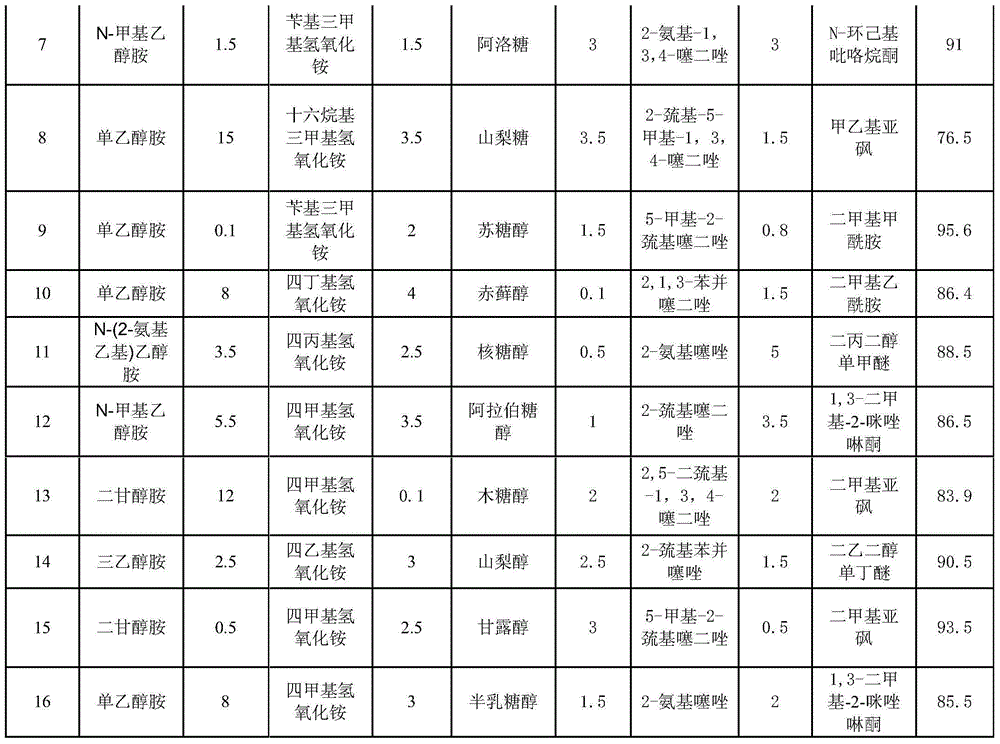

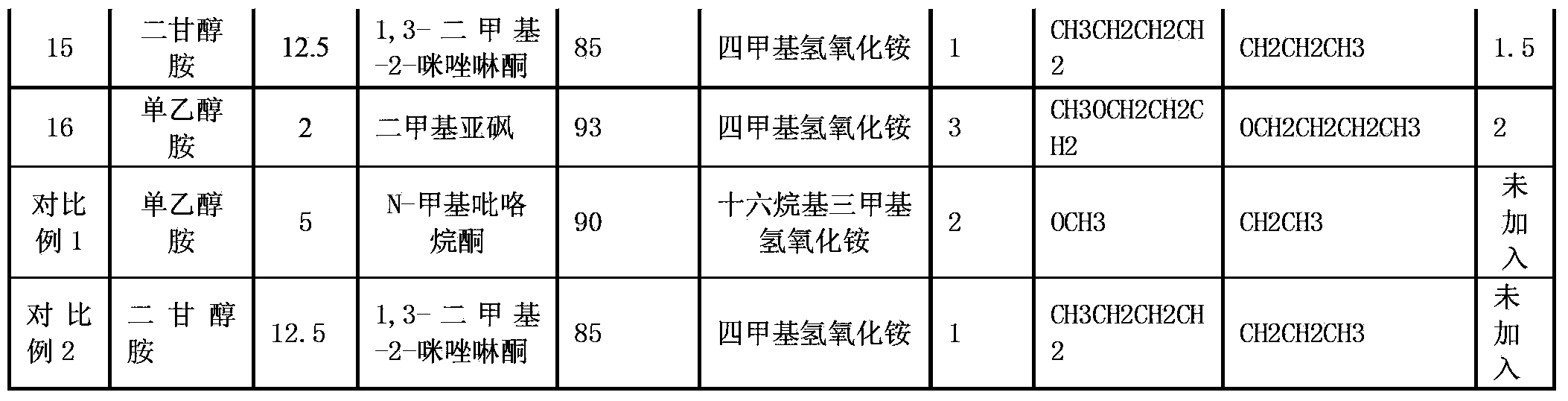

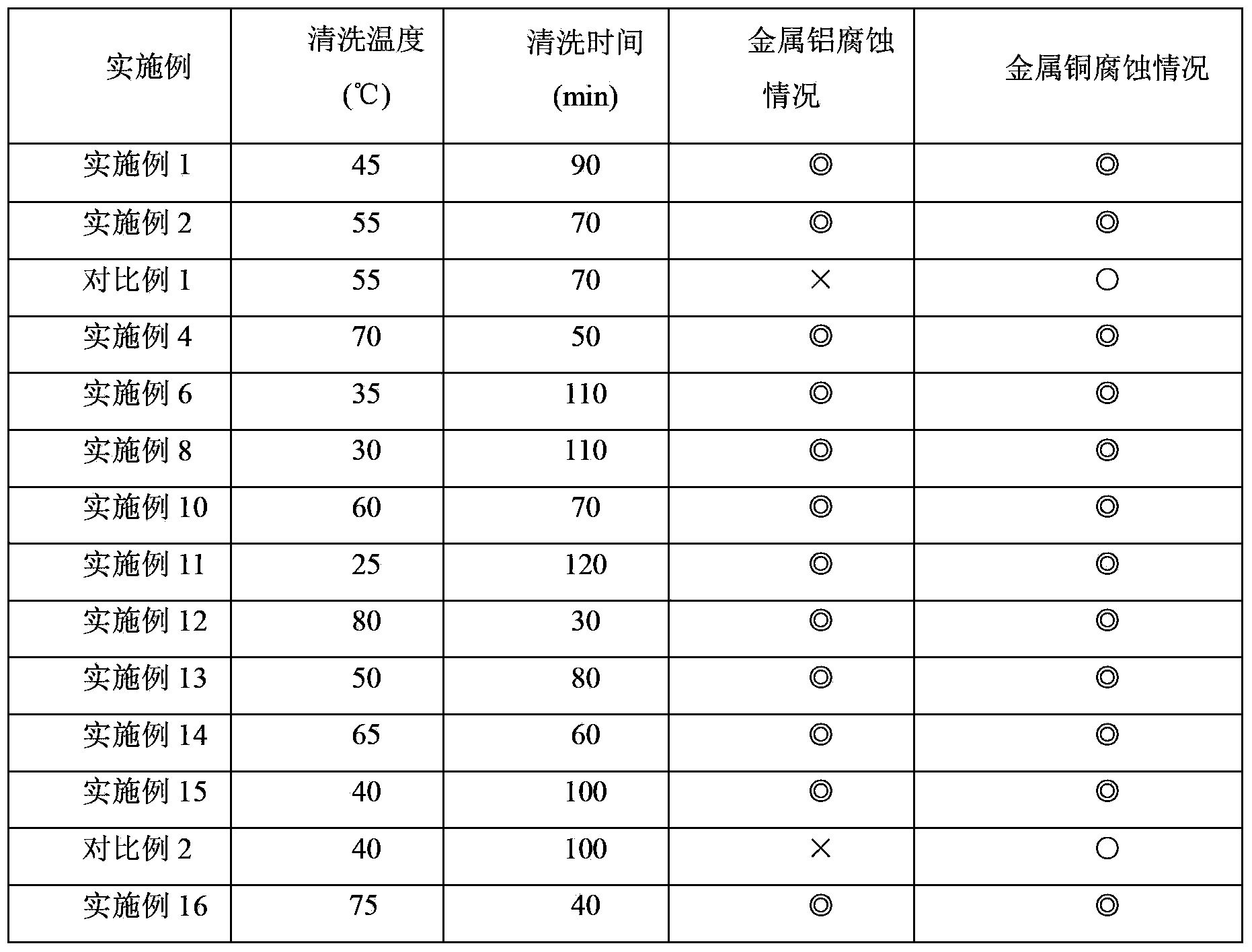

Cleaning liquid for removing photoresist residues

Owner:宁波安集微电子科技有限公司

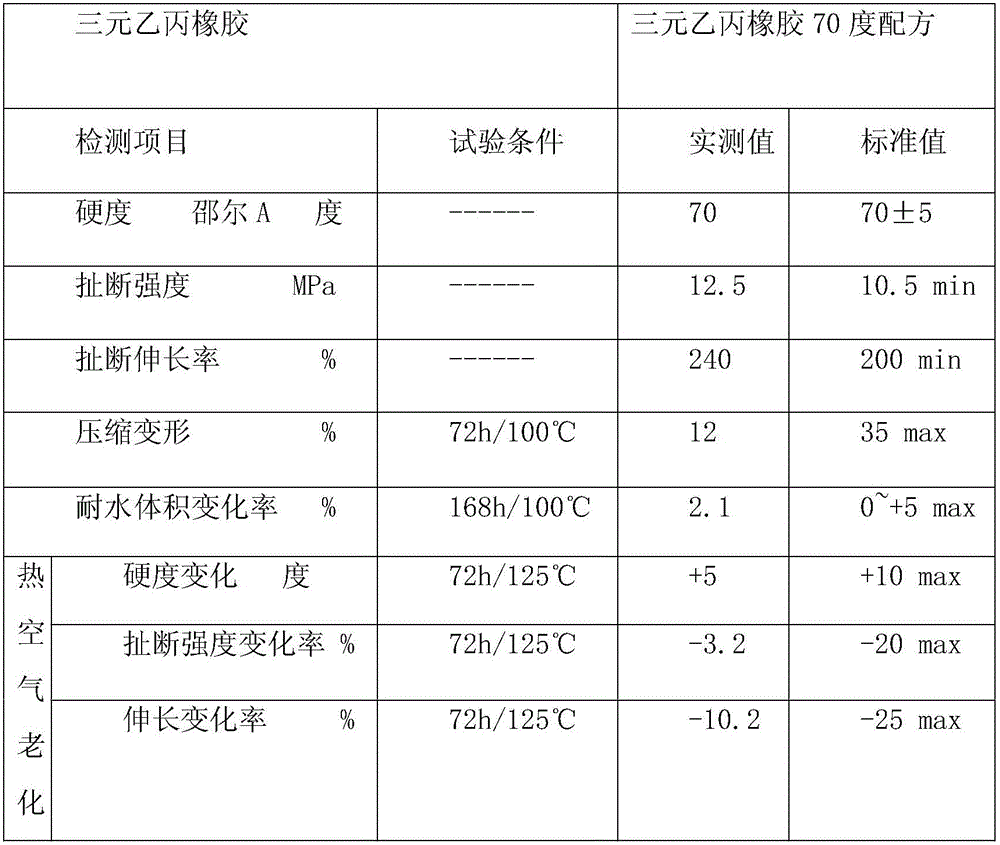

EPDM (Ethylene-Propylene-Diene Monomer) for sealing ring and vulcanization method thereof

The invention relates to EPDM (Ethylene-Propylene-Diene Monomer) for a sealing ring and a vulcanization method thereof. The EPDM for the sealing ring comprises the following components: non-oil-filled raw ethylene-propylene rubber, oil-filled raw ethylene-propylene rubber, ZnO, an anti-aging agent, general purpose black, sulfur, flavorless DCP and a cross-linking agent TAIC. In the cross-linking process, both C-C bonds and S cross-linking bonds are contained, the compression deformation rate is low, and the tear resistance is improved; the oil-filled raw ethylene-propylene rubber and the non-oil-filled raw ethylene-propylene rubber can be combined, so that the compression deformation performance is guaranteed, usage of plasticizer oil in the formula is reduced, and the rubber is easily and uniformly mixed and is high in liquidity, thin in rubber edge and easy to tear; and moreover, the product has the advantage that peroxide vulcanizedethylene-propylene rubber is low in permanent compression deformation rate, and the problem that peroxide vulcanizedEPDM products are difficult to tear is solved, so that the performance and production efficiency of the product are improved.

Owner:QINGDAO TKS SEALING IND

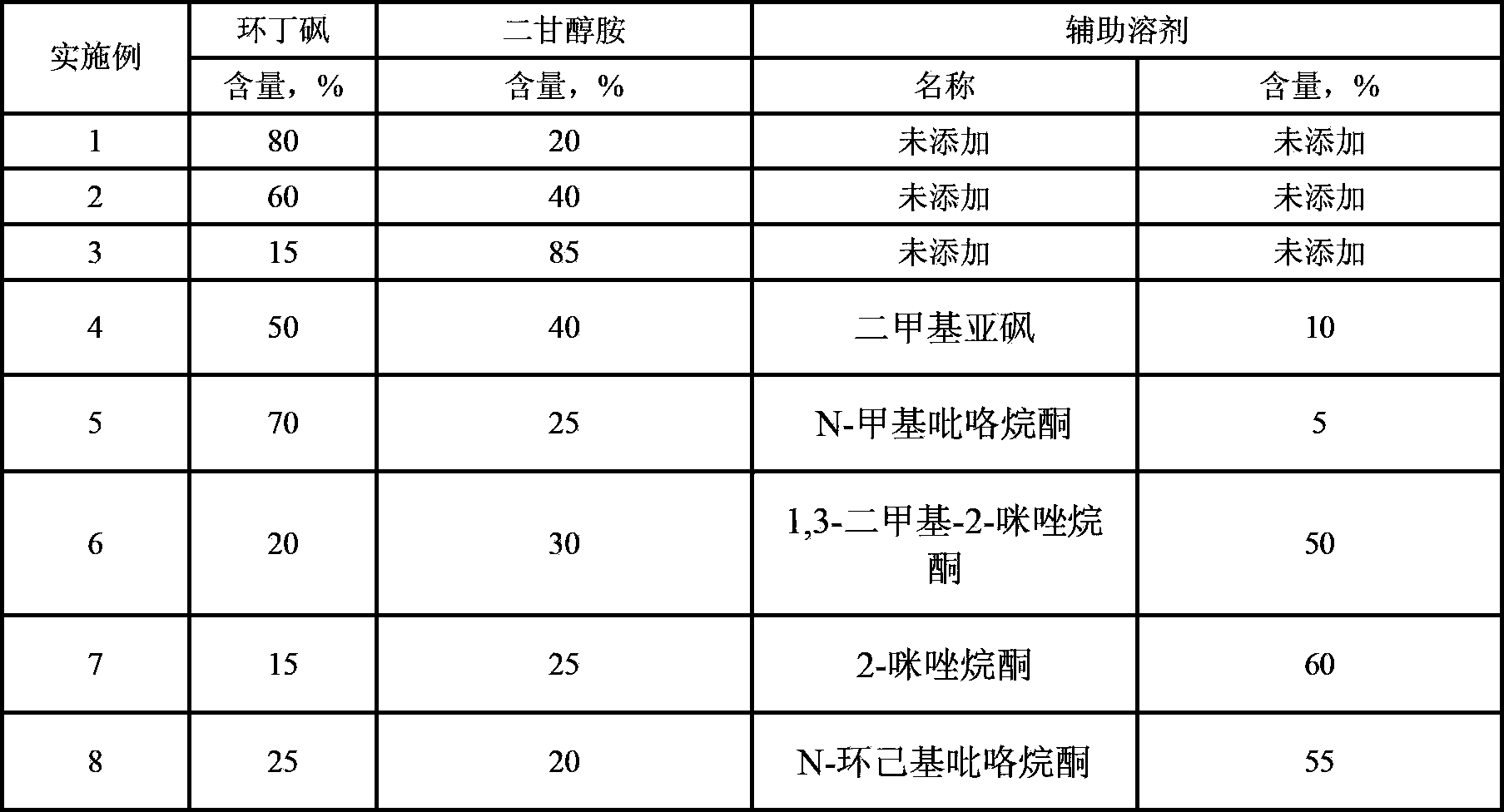

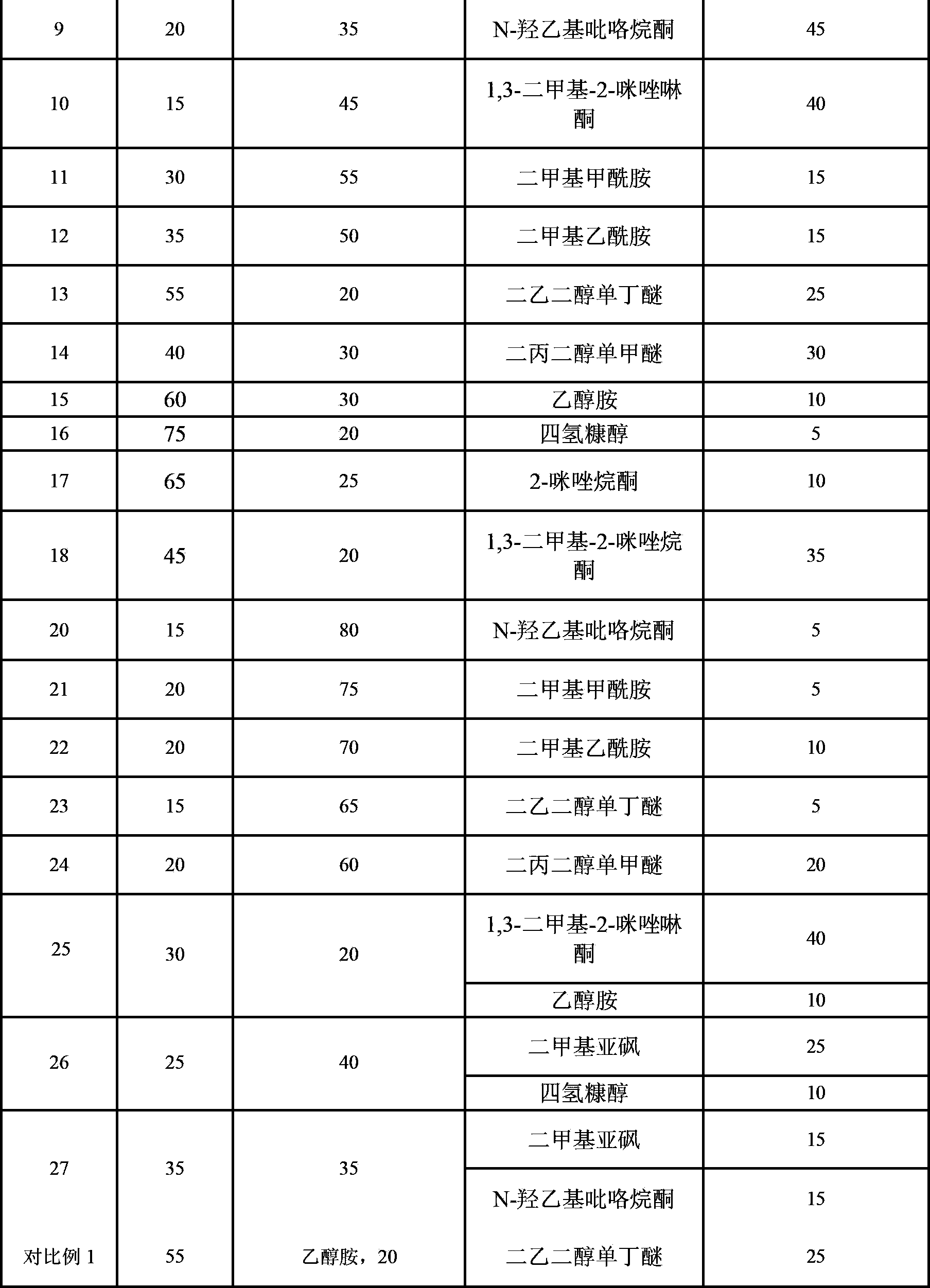

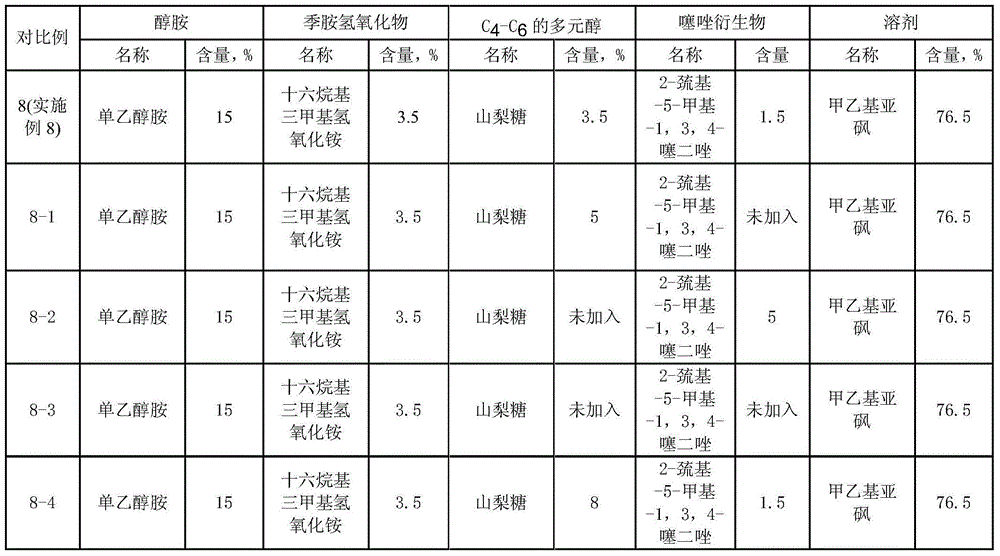

Photoresist cleaning liquid with extremely-low corrosion to metals

InactiveCN104678719AEfficient removalEasy to mix evenlyPhotosensitive material processingAlcoholSemiconductor chip

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

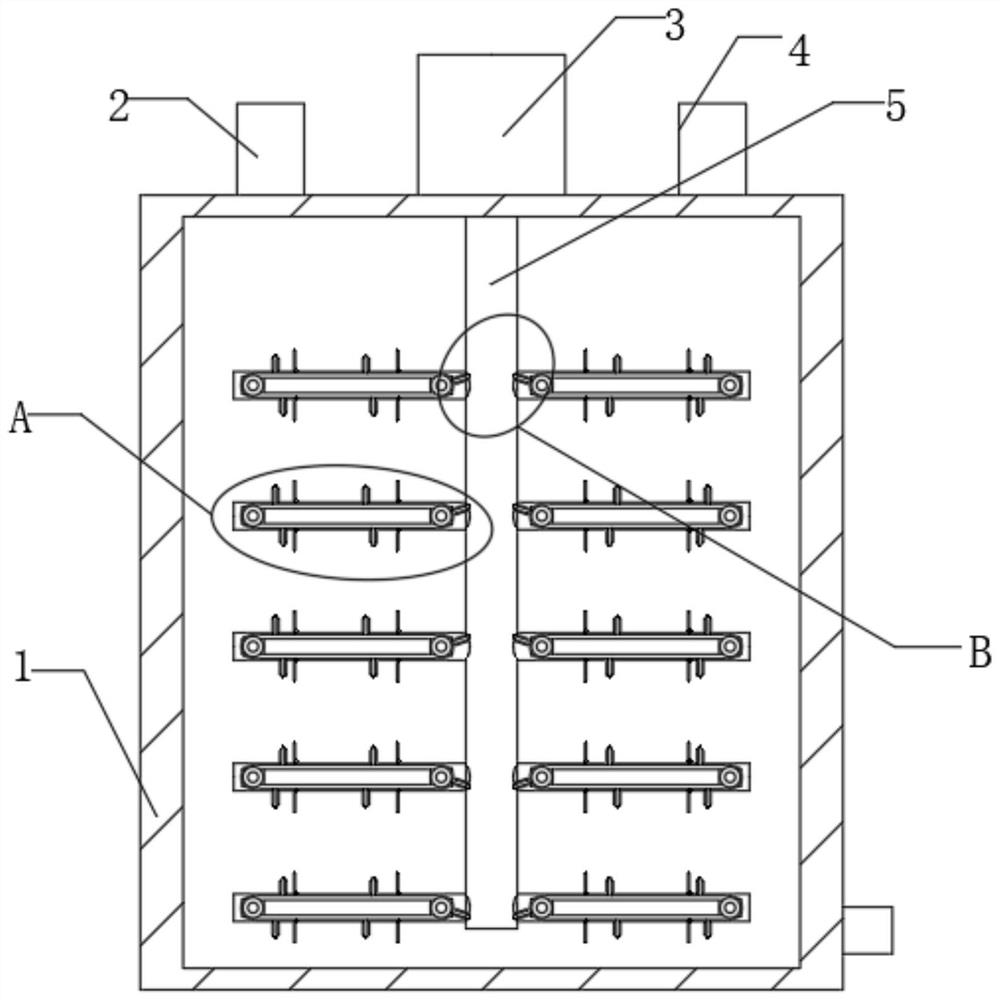

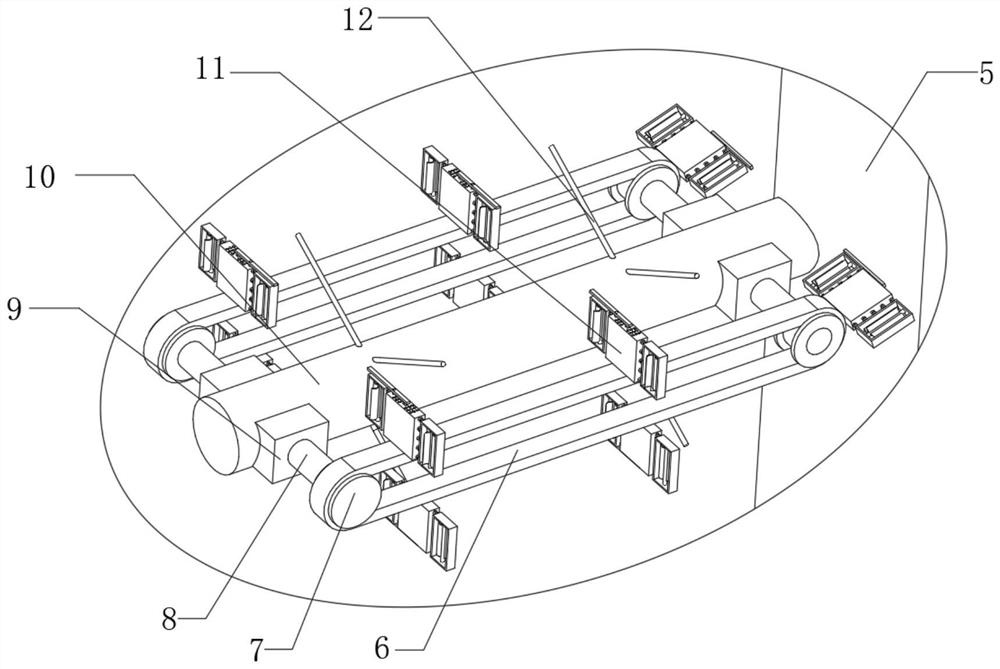

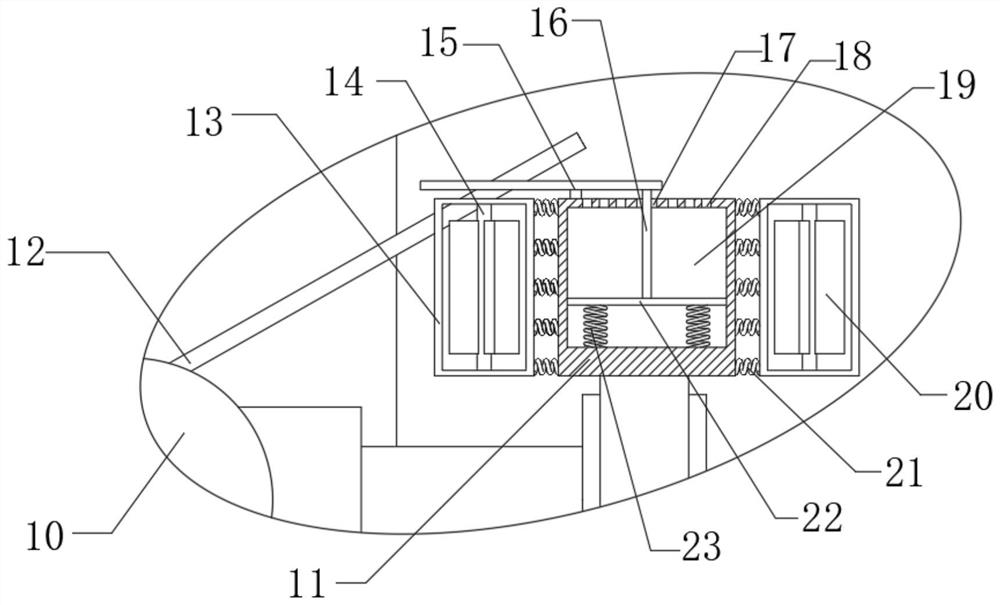

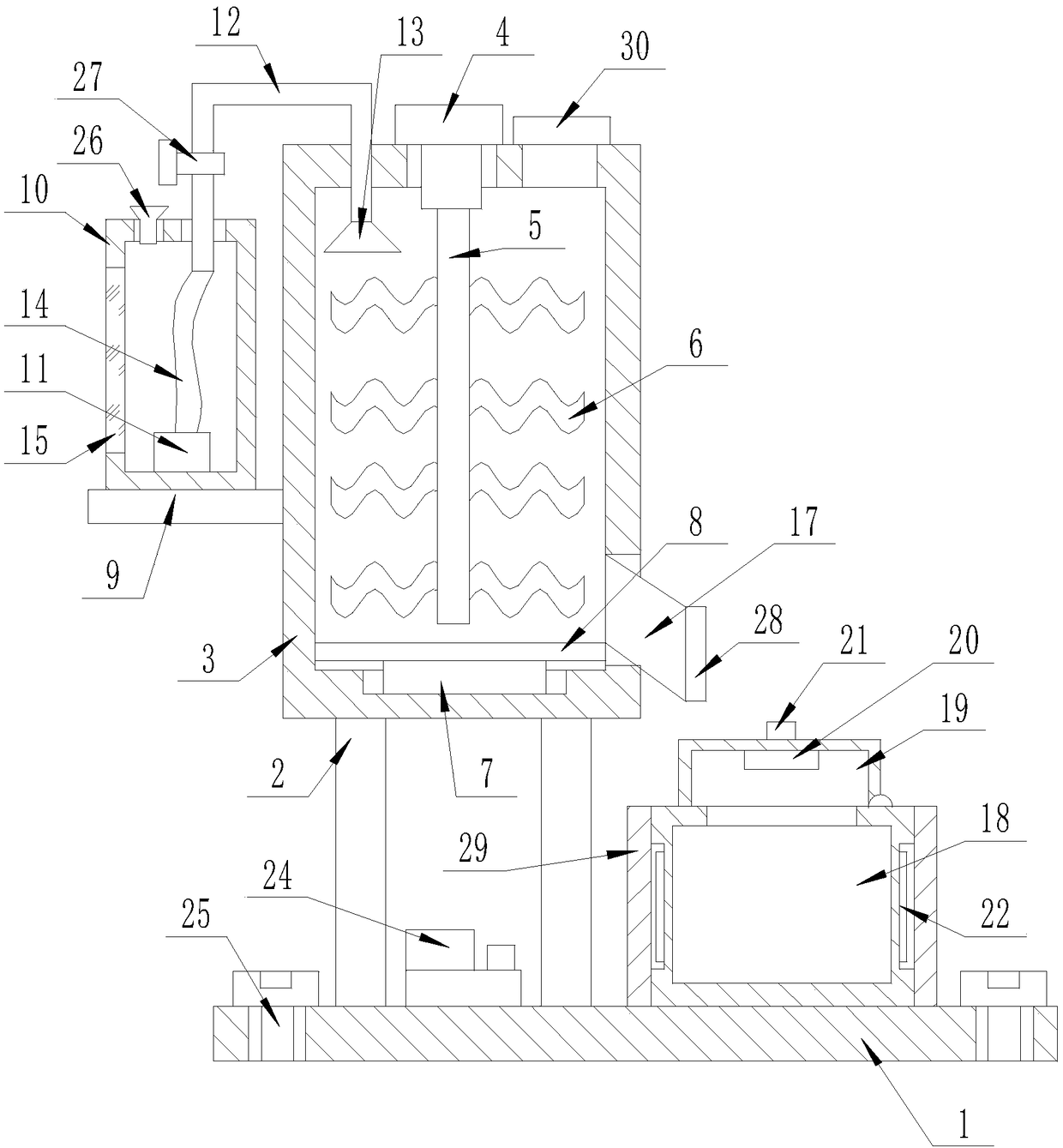

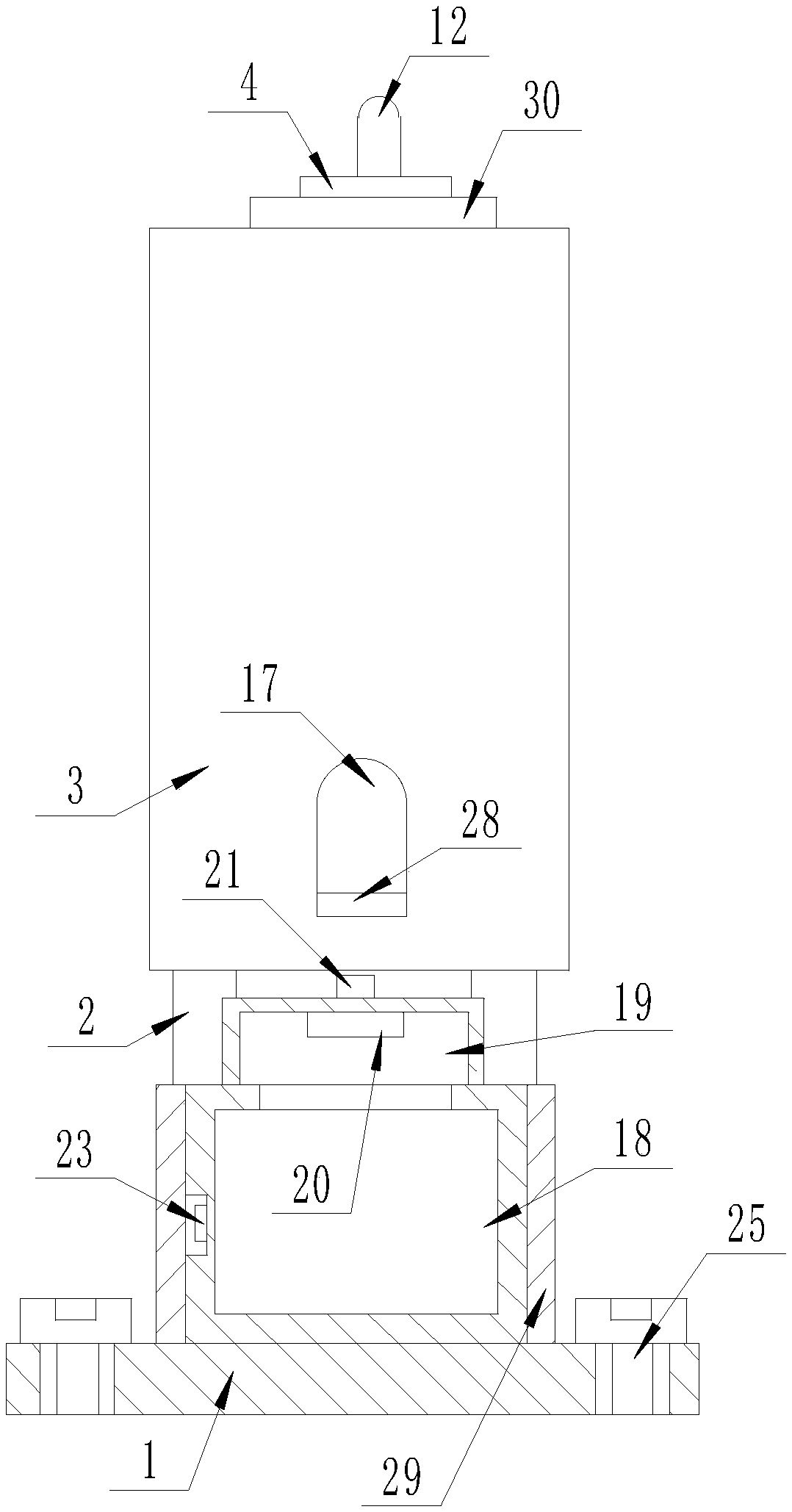

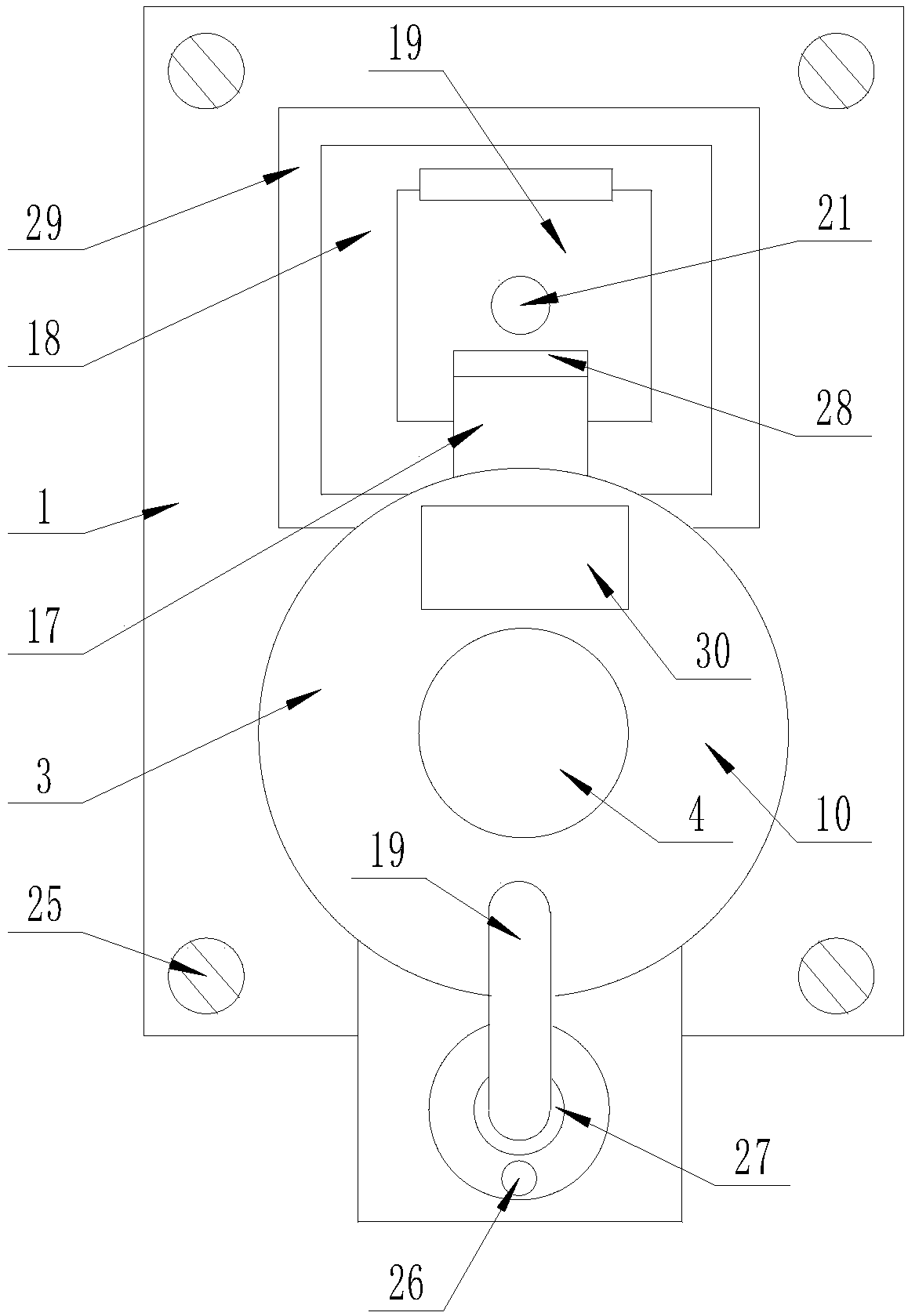

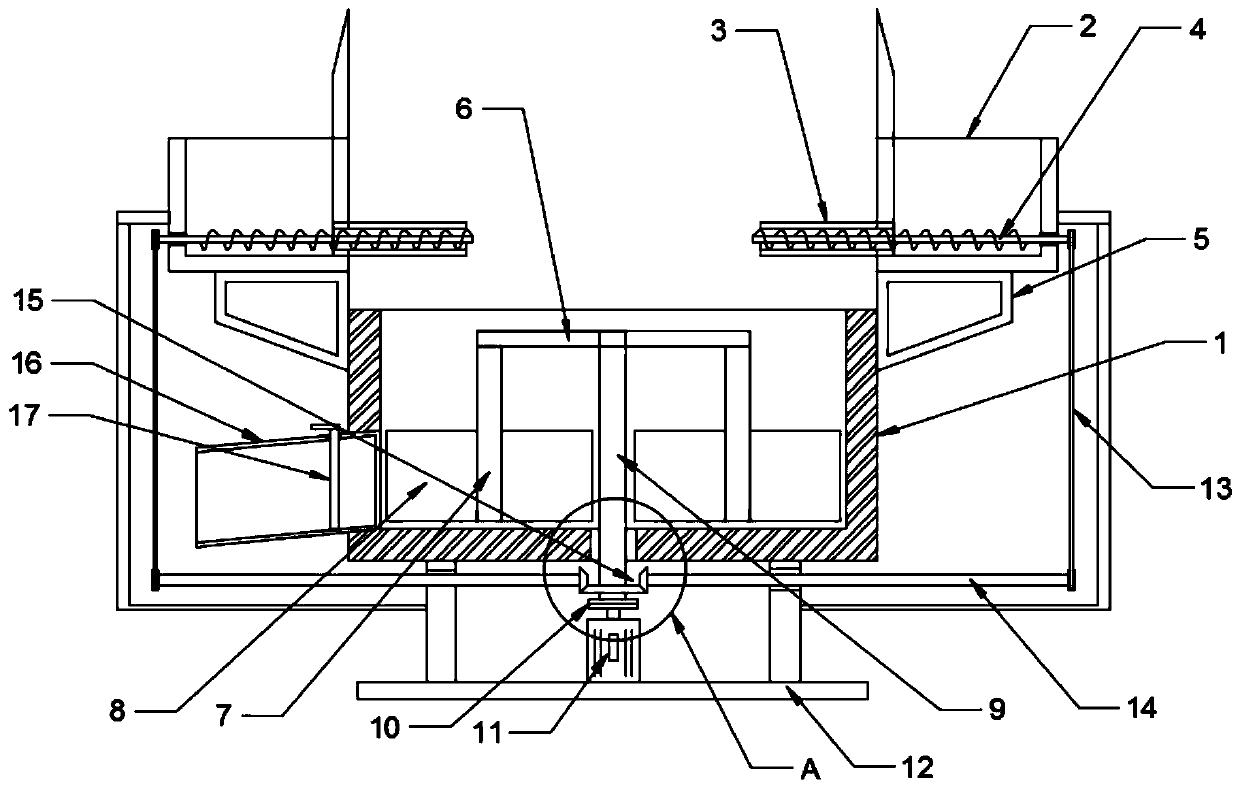

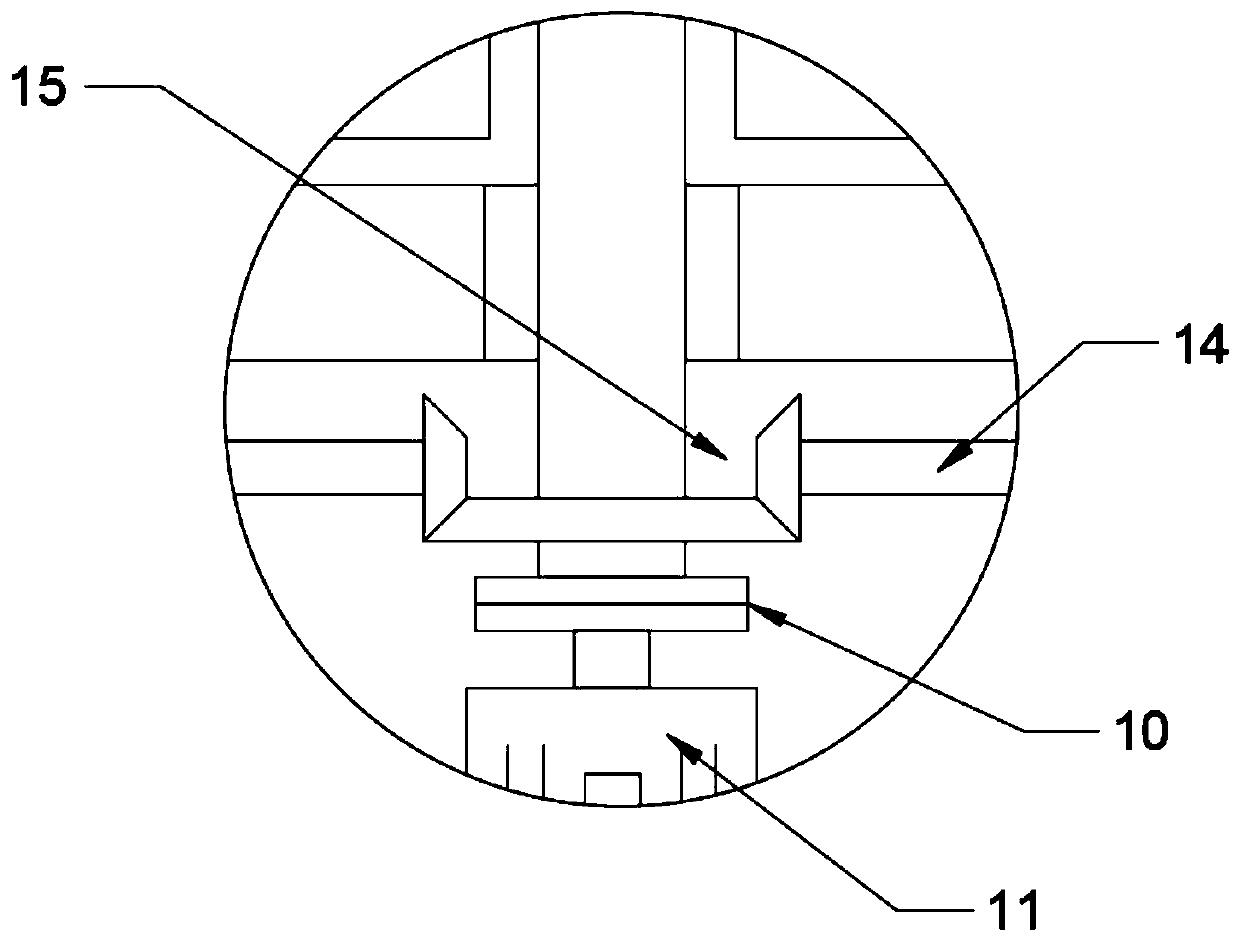

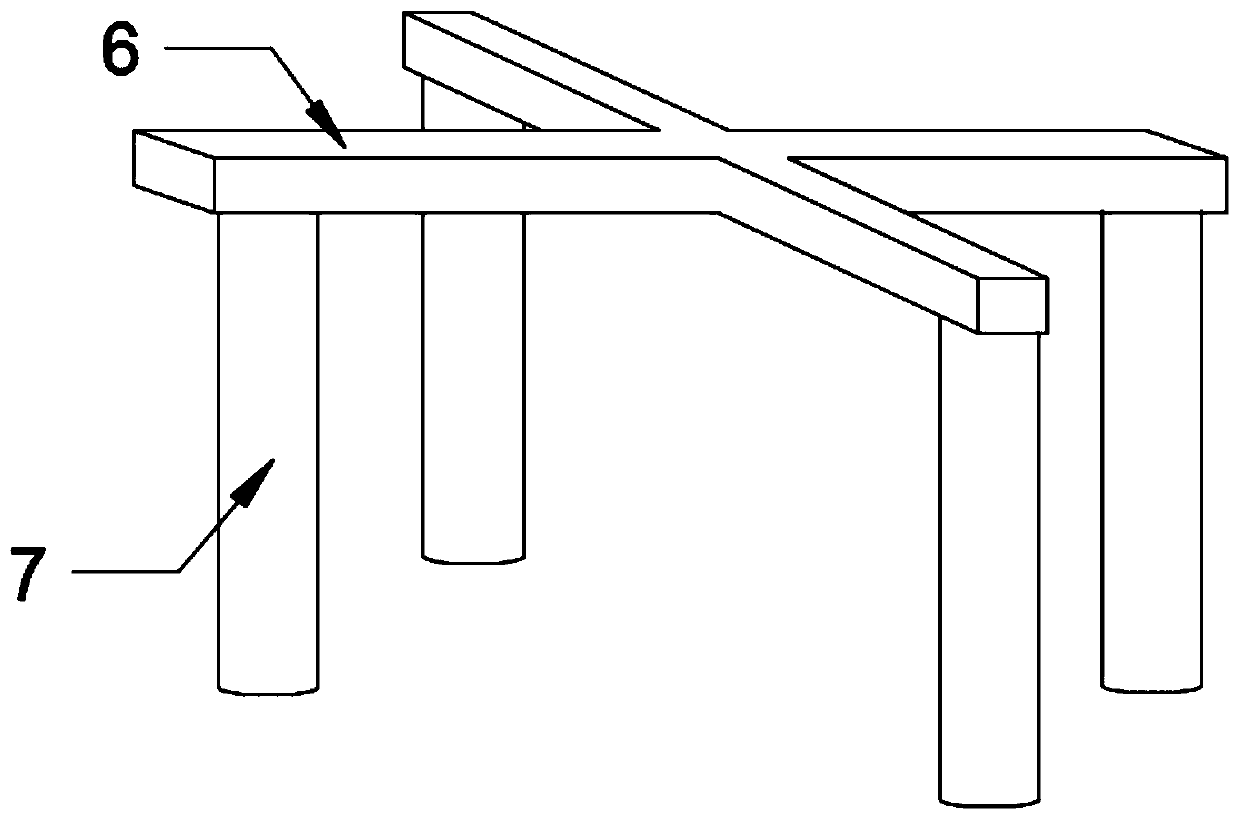

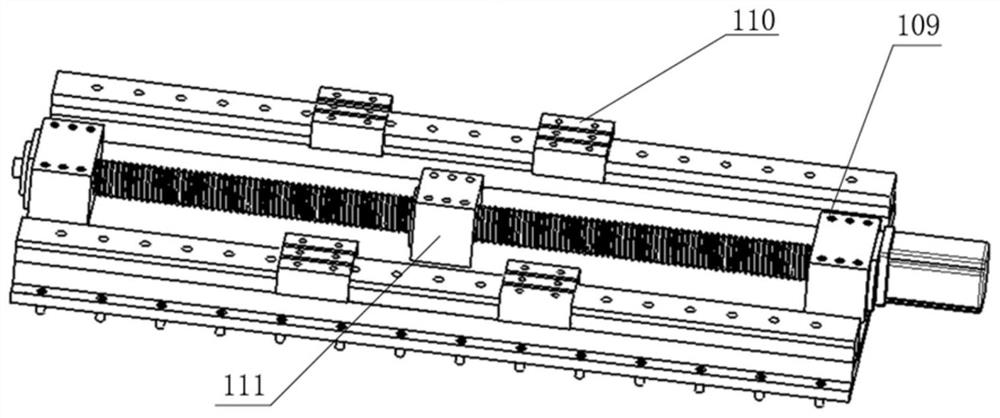

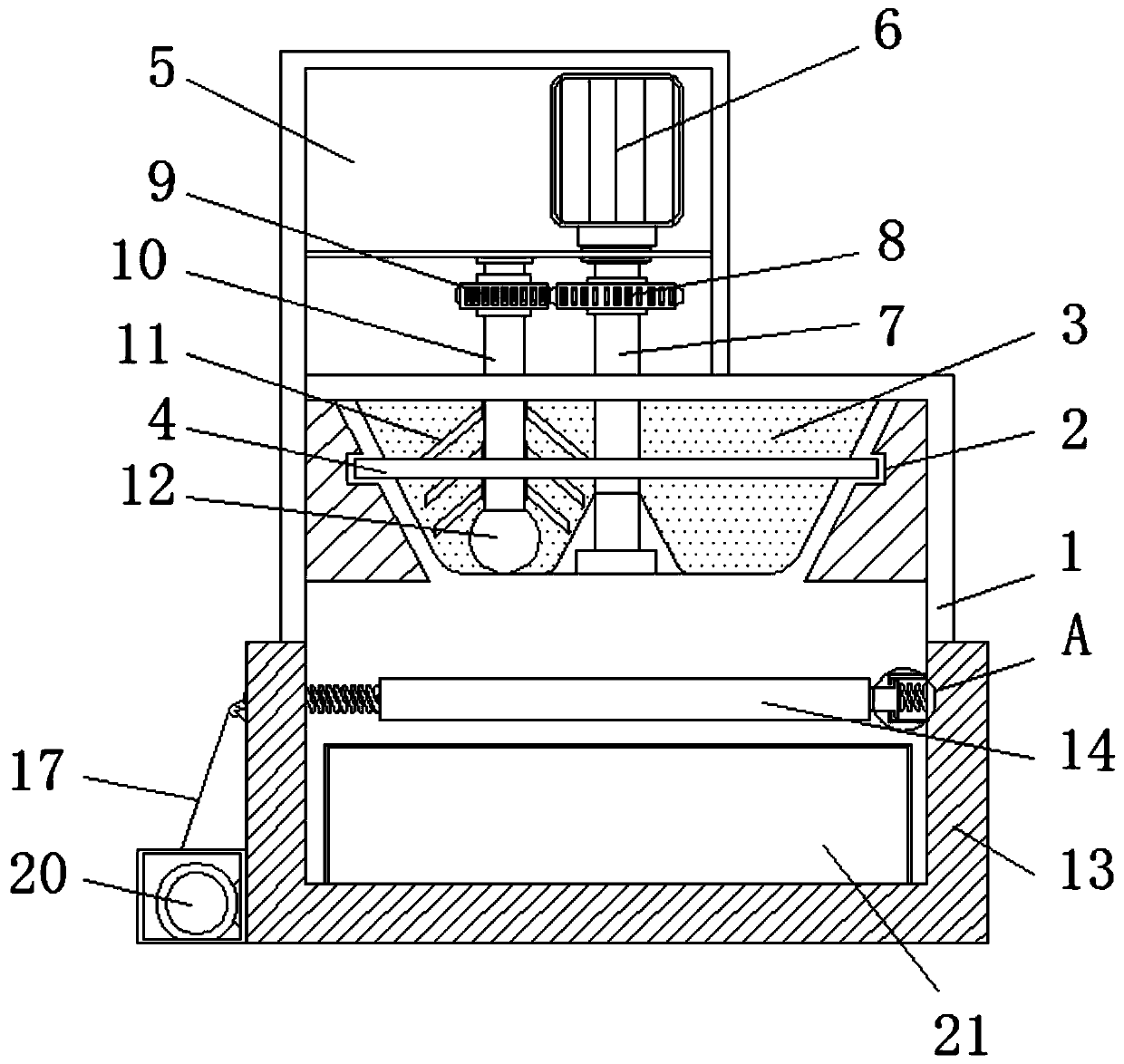

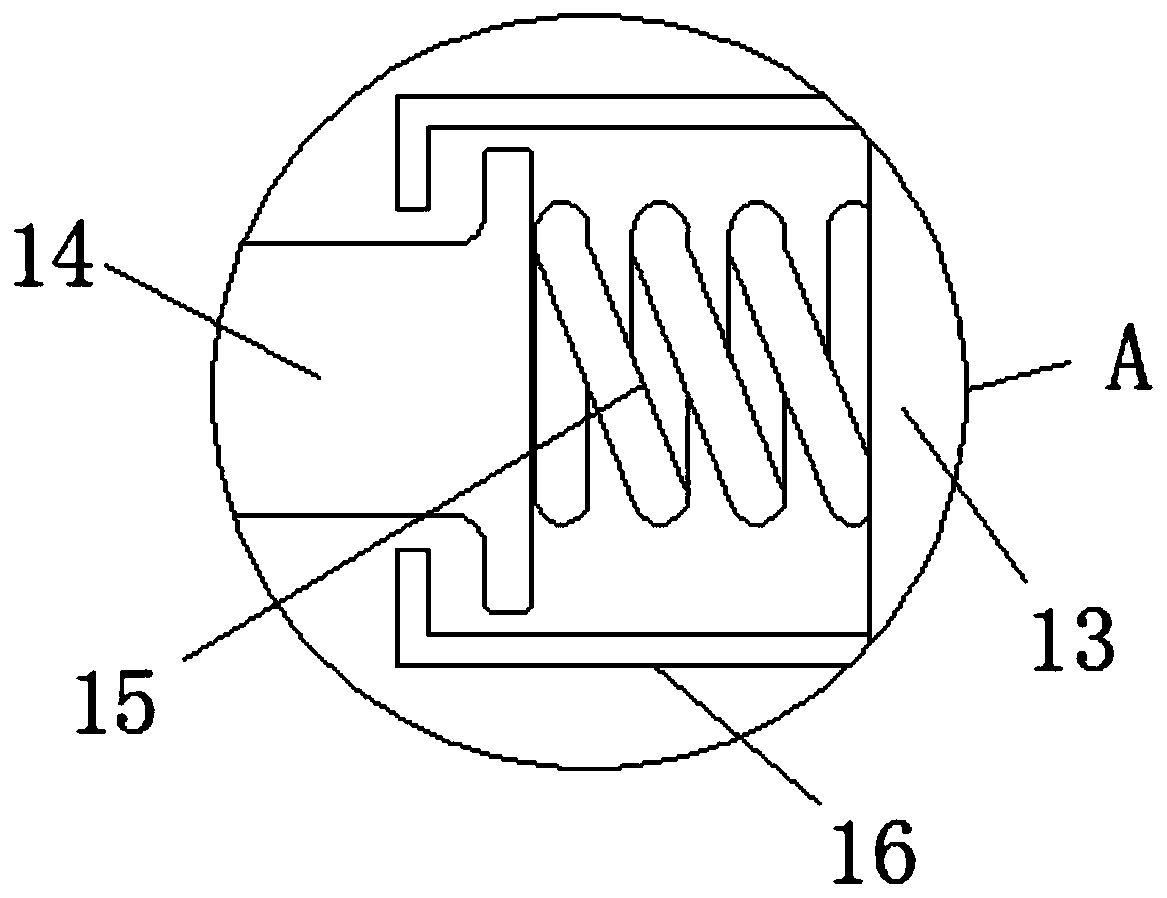

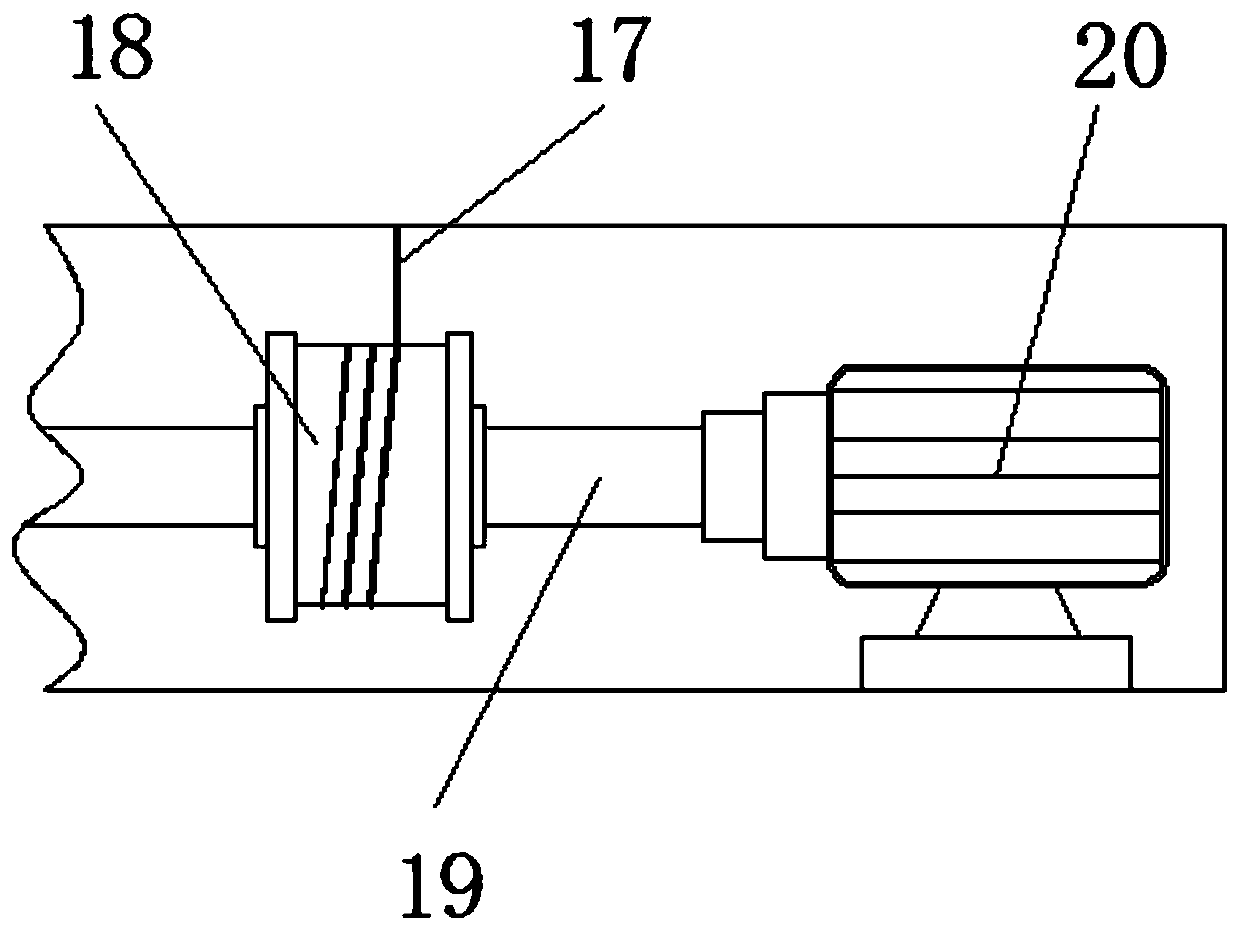

Carrier chemical modification treatment equipment for producing catalyst based on impregnation method

ActiveCN114768624AStir fully and evenlyThe stirring motor drives multiple stirring shafts through the rotating shaft to mix fully and evenlyShaking/oscillating/vibrating mixersTransportation and packagingRotational axisPtru catalyst

The carrier chemical modification treatment equipment comprises a mixing box, a rotating shaft is rotationally connected to the top of the mixing box, a stirring motor is arranged on the outer wall of the top of the rotating shaft, a liquid inlet and a feeding port are formed in the two sides of the stirring motor, and a plurality of stirring shafts are fixedly connected to the outer wall of the rotating shaft; a mounting plate is fixedly connected to the interior of the rotating shaft, a main shaft is rotatably connected to the outer wall of the mounting plate, a rotating motor is arranged on the outer wall of the top of the main shaft, a plurality of first bevel gears are fixedly connected to the outer wall of the main shaft, and the outer walls of the first bevel gears are engaged with a plurality of second bevel gears; the second bevel gears are fixedly connected to the outer wall of one side of the auxiliary shaft. When the moving belt moves, the plurality of stirring plates on the moving belt move from bottom to top, so that a compound moving towards the center can be stirred to the outer ring, and the compound and liquid can be fully and uniformly mixed.

Owner:上海蕙黔新材料科技有限公司

Low-metal-etching photoresist stripping liquid and application thereof

ActiveCN104570628AEfficient removalLarge operating windowPhotosensitive material processingMetallic aluminumAlcohol

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

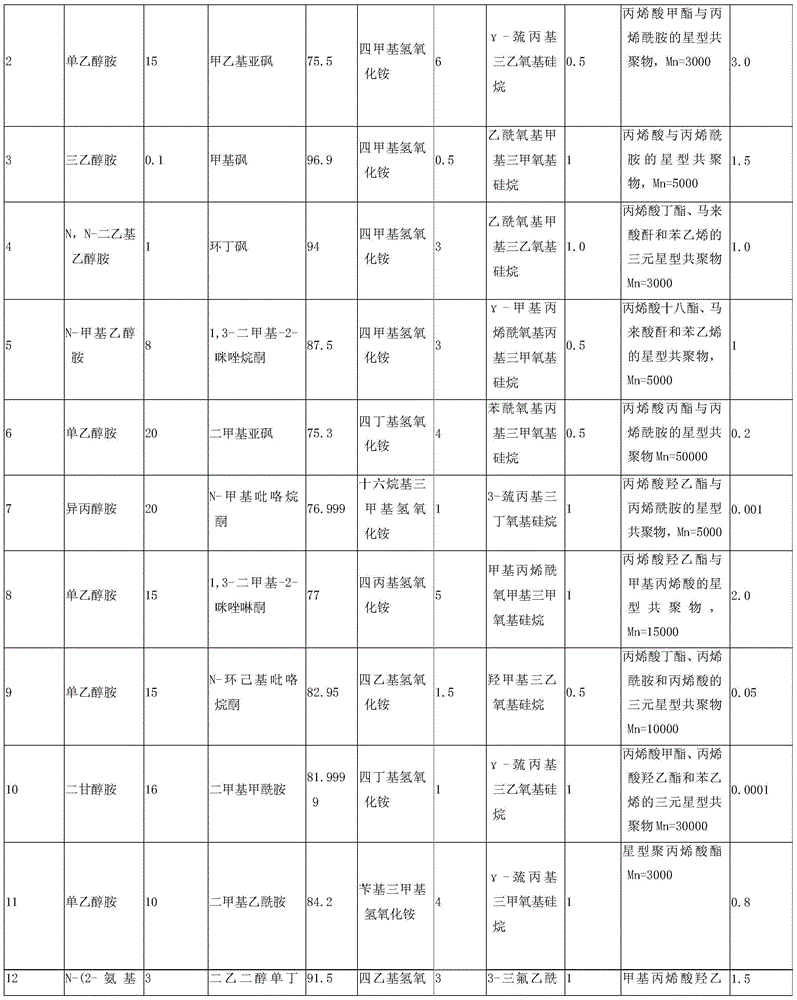

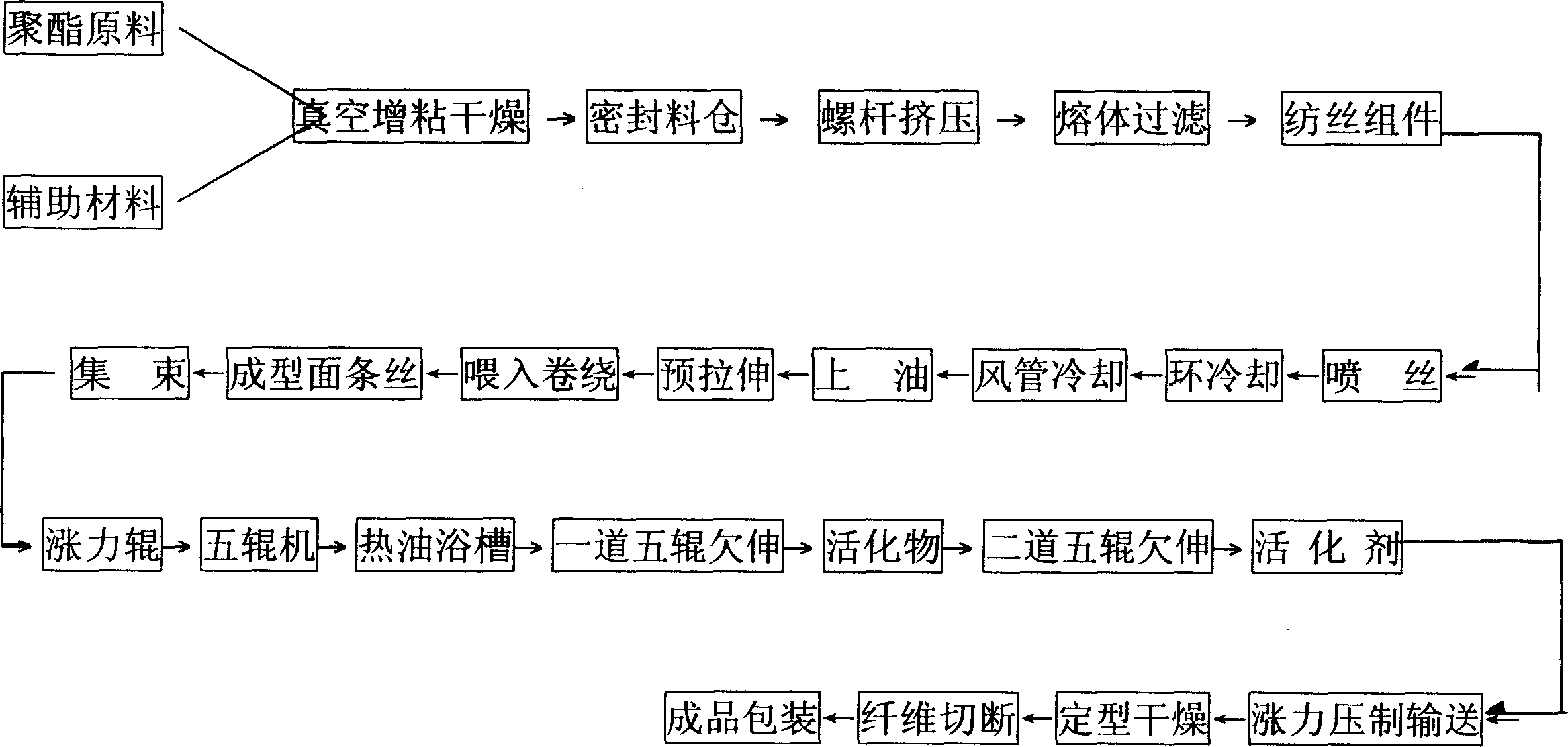

Production process of engineering fibre for polyester road

InactiveCN1467315ATangledExtend your lifeBuilding insulationsMonocomponent polyesters artificial filamentPolyesterFiber

A process for preparing the polyester fibres used for road engineering includes such steps as pretreating the polyester as raw material, fusing and extruding by screw extruder, jet spinning, cooling, prestretching, winding, collecting to 6-7 hundred thousands dens, tension mixing, stretching in oil bath, stretching, adding hot activator, stretching, adding hot activator, overheat stretching, extension, compression, drying and cutting short.

Owner:陈成泗 +2

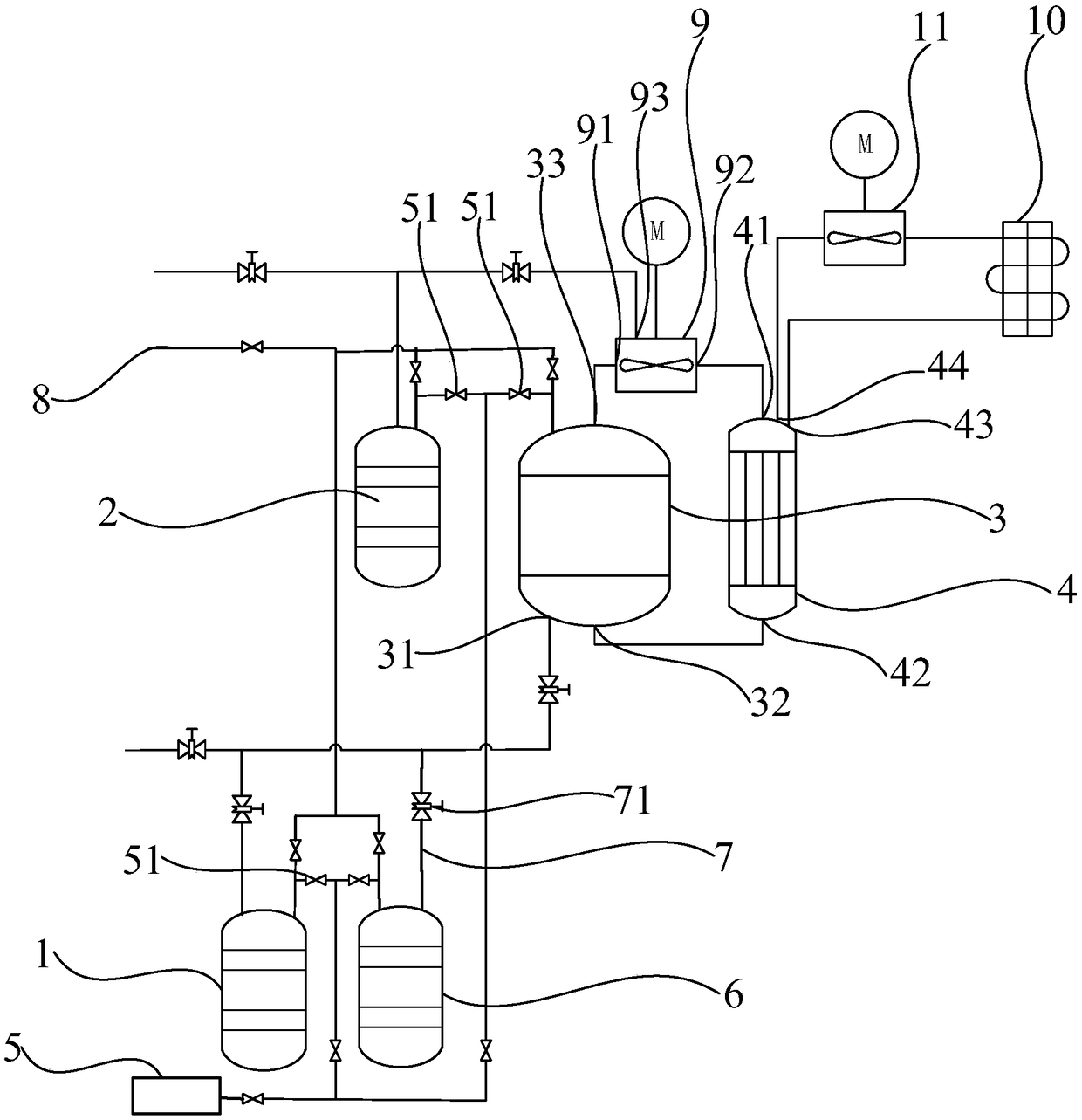

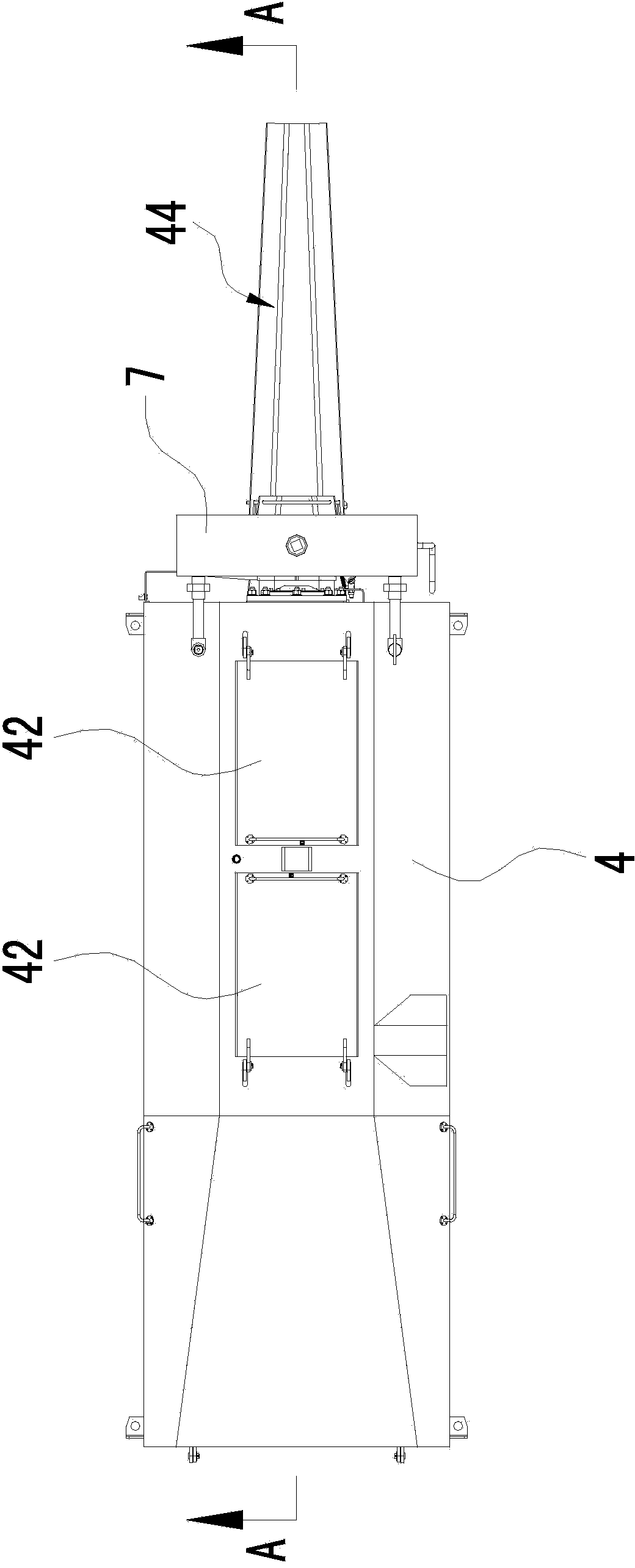

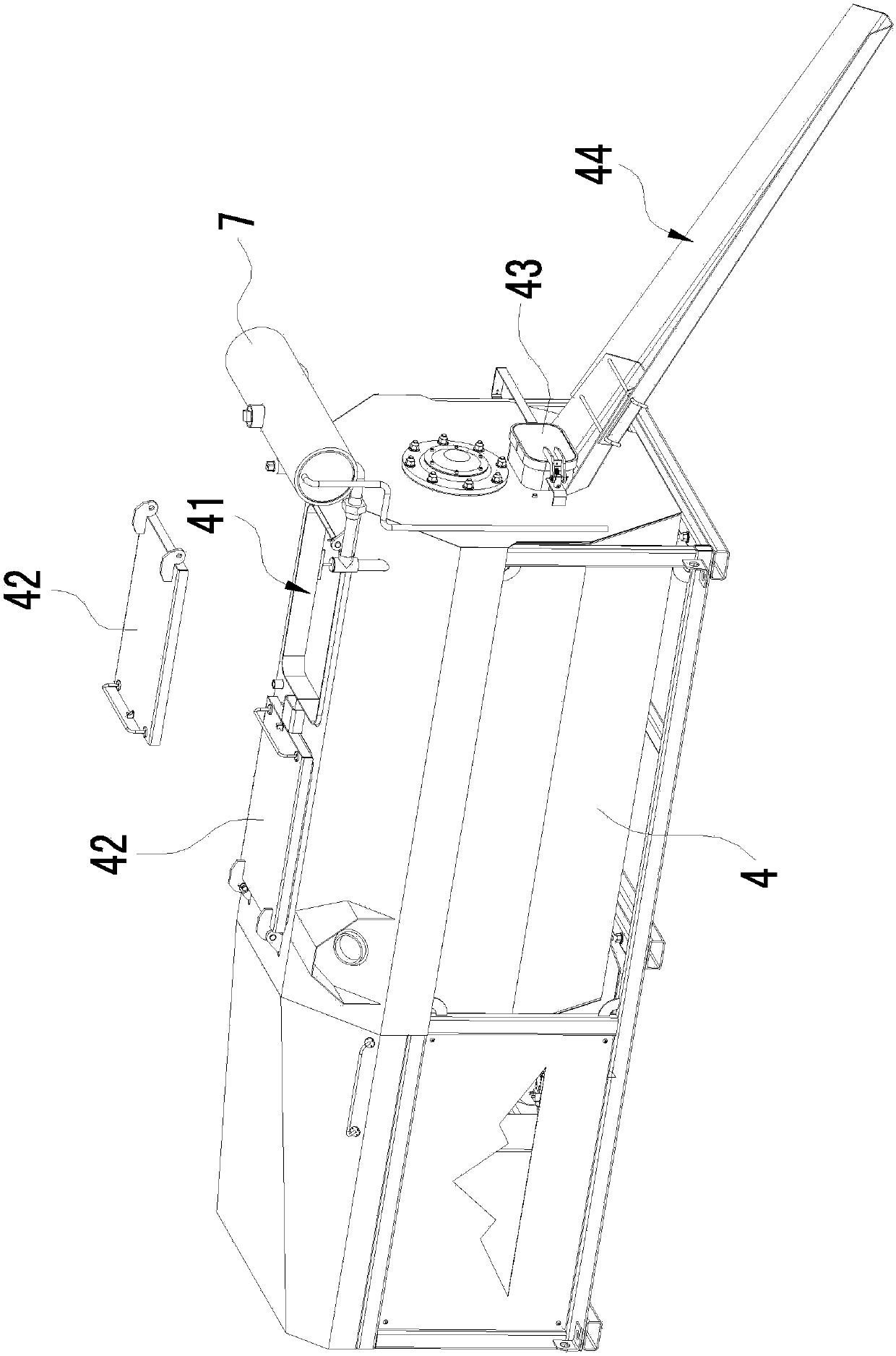

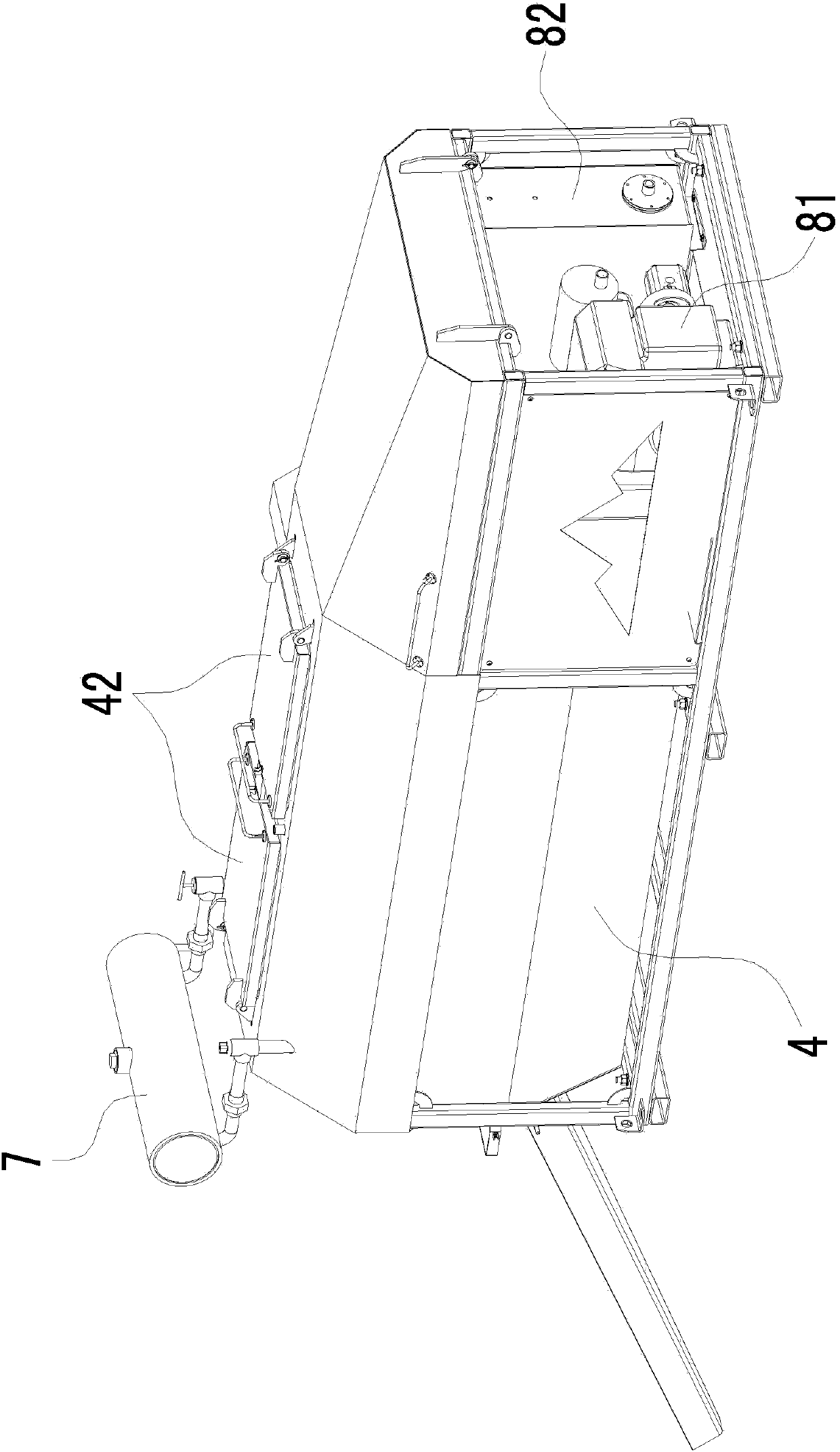

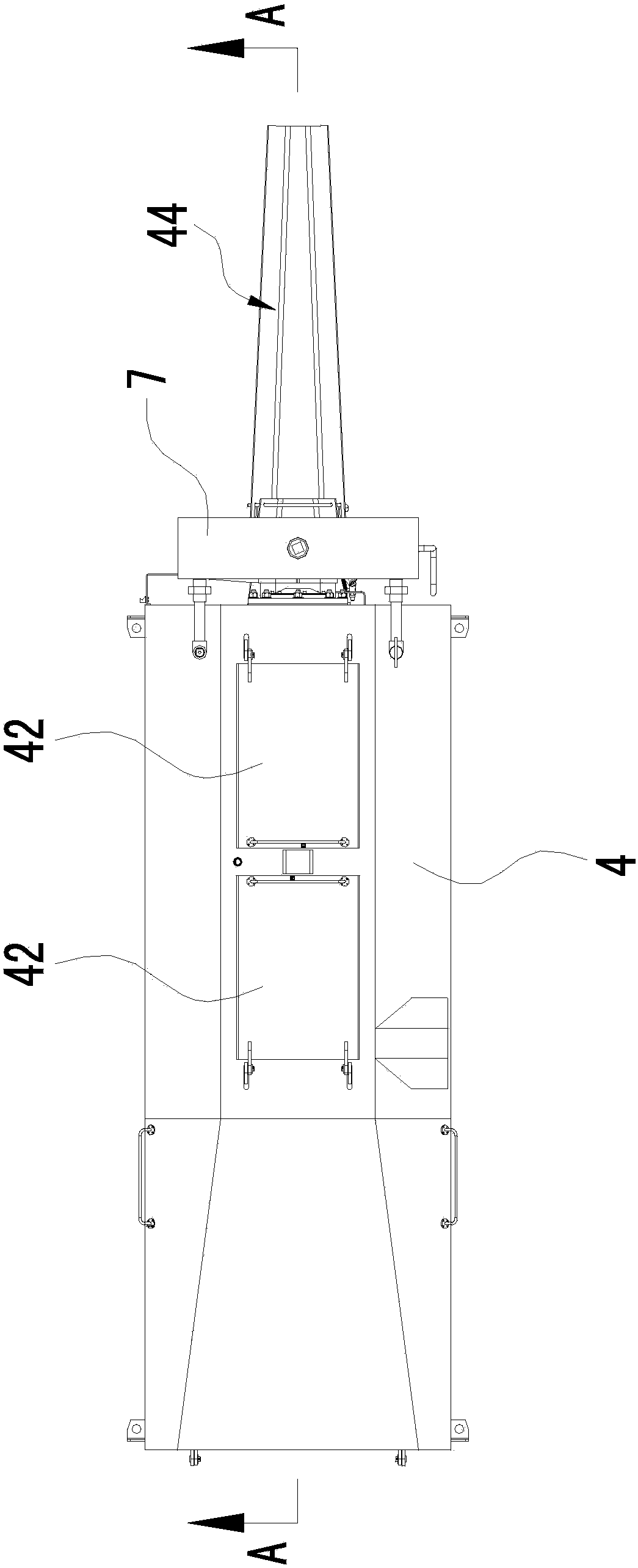

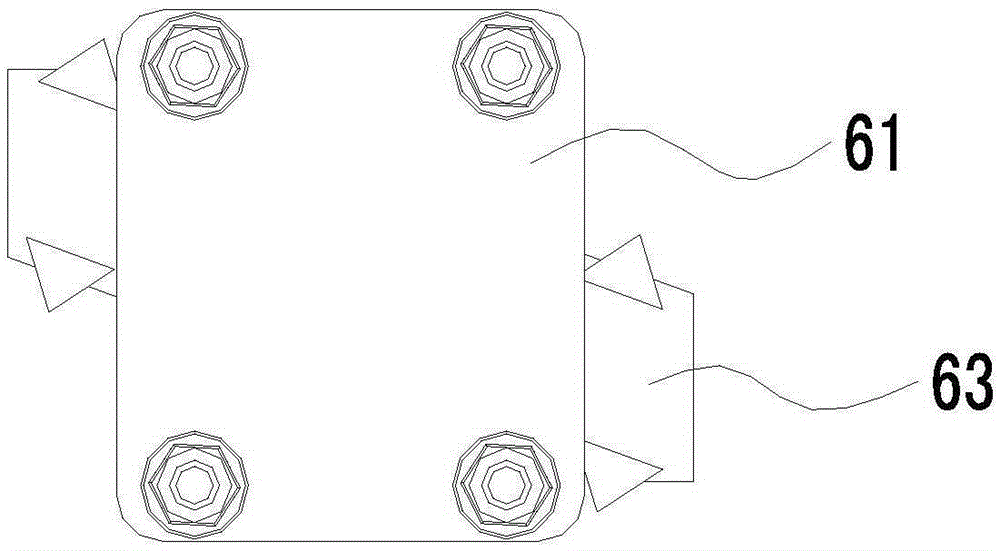

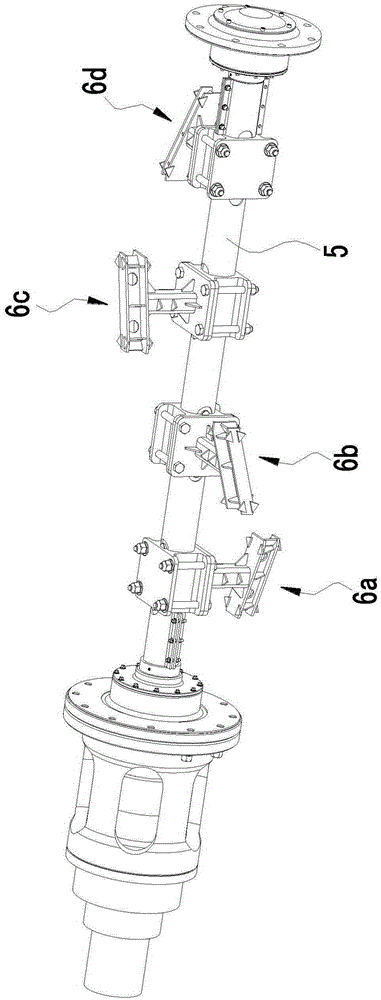

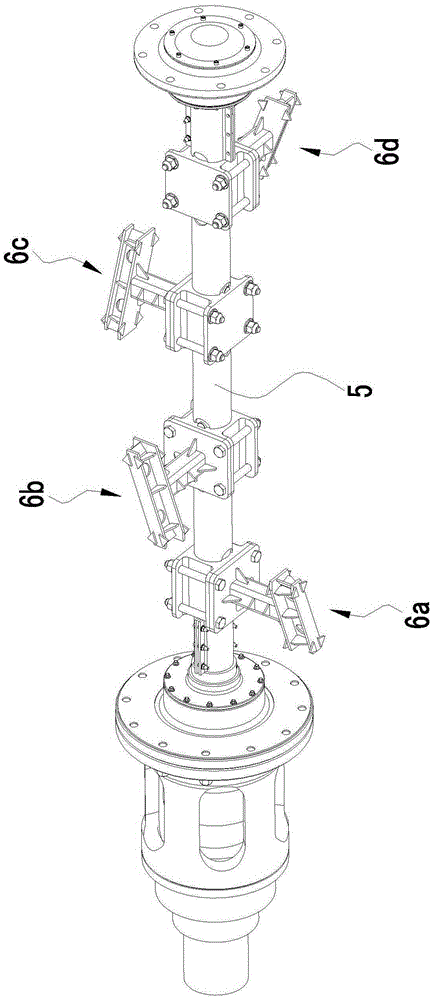

Molten salt reactor loading and unloading system

ActiveCN108511089AEasy to operate and controlEasy to mix evenlyNuclear energy generationReactor fuel susbtancesMolten salt reactorNuclear engineering

The invention discloses a molten salt reactor loading and unloading system, comprising at least one base salt tank, at least one feed salt tank, a reactor tank and a first heat exchanger, wherein theouter wall face of the reactor tank is provided with a base salt inlet, a fuel salt inlet and a fuel salt outlet; the base salt tank is connected with the base salt inlet and is communicated with thereactor tank; the feed salt tank is connected with the reactor tank and is communicated with the reactor tank; the fuel salt outlet and the fuel salt inlet are respectively connected with an inlet andan outlet of the first heat exchanger; a fuel salt loop is formed by the reactor tank and the first heat exchanger. According to the molten salt reactor loading and unloading system, the base salt tank and the feed salt tank can be used for respectively adding base salt and feed salt into the reactor tank, and the base salt and the feed salt in the fuel salt loop can be evenly mixed by means of the operation of the fuel salt loop; the uniform mixing is rapid and convenient, the operation is simple, and the cost is low.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

A feed fermentation device

InactiveCN108949538AQuality improvementEasy to mix evenlyBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlEngineering

A feed fermentation device is disclosed. The device includes a mounting base. The left end of the upper surface of the mounting base is fixedly connected to two pairs of round vertical columns. The upper surface of the round vertical columns are fixedly connected to a round feed stirring bin the upper surface of which is provided with a motor mounting hole. A stirring motor the rotating end of which faces downward is embedded in the motor mounting hole. The rotating end of the stirring motor is fixedly connected to a stirring shaft. The lower surface of the stirring shaft is fixedly connectedto a plurality of spiral stirring bars. The upper surface of the round feed stirring bin is provided with a material feeding port at the right side of the motor mounting hole. The inner lower surfaceof the round feed stirring bin is provided with a rectangular groove the lower inner surface of which is provided with a pressure sensor. Beneficial effects of the device are that feed raw materials can be stirred uniformly, water addition according to a ratio is facilitated, feed quality is improved, prompting after fermentation is facilitated, temperature control is convenient and the device hasa novel structure and high utilization value.

Owner:胡小丽

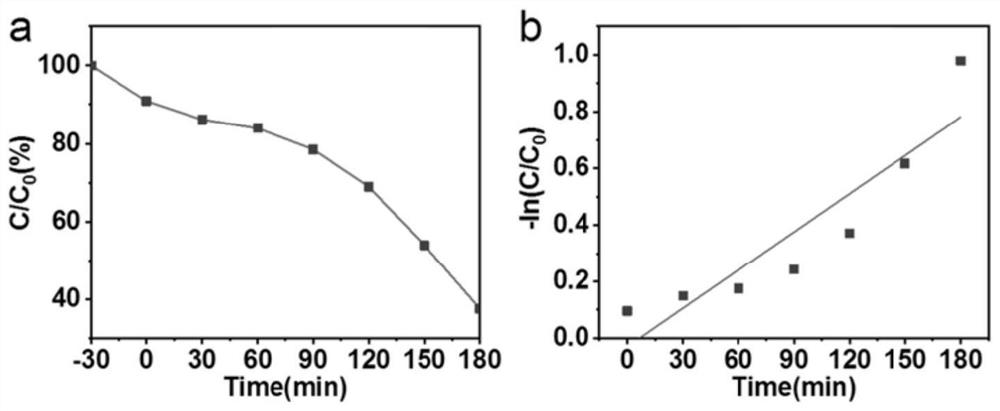

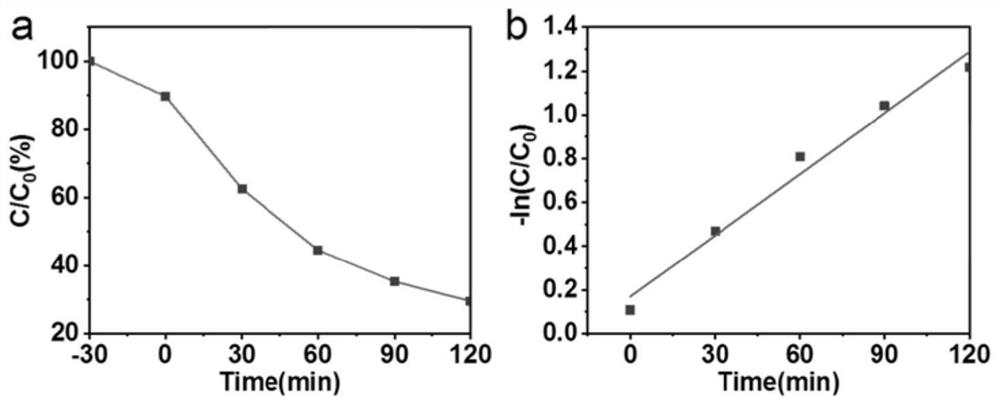

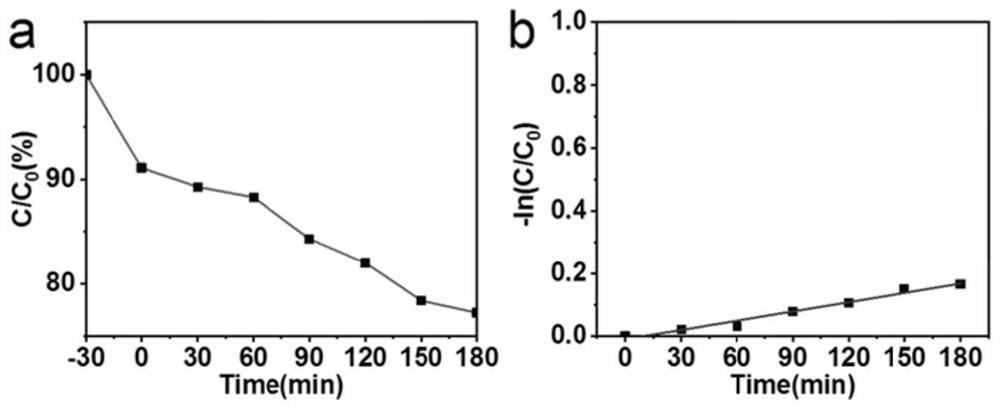

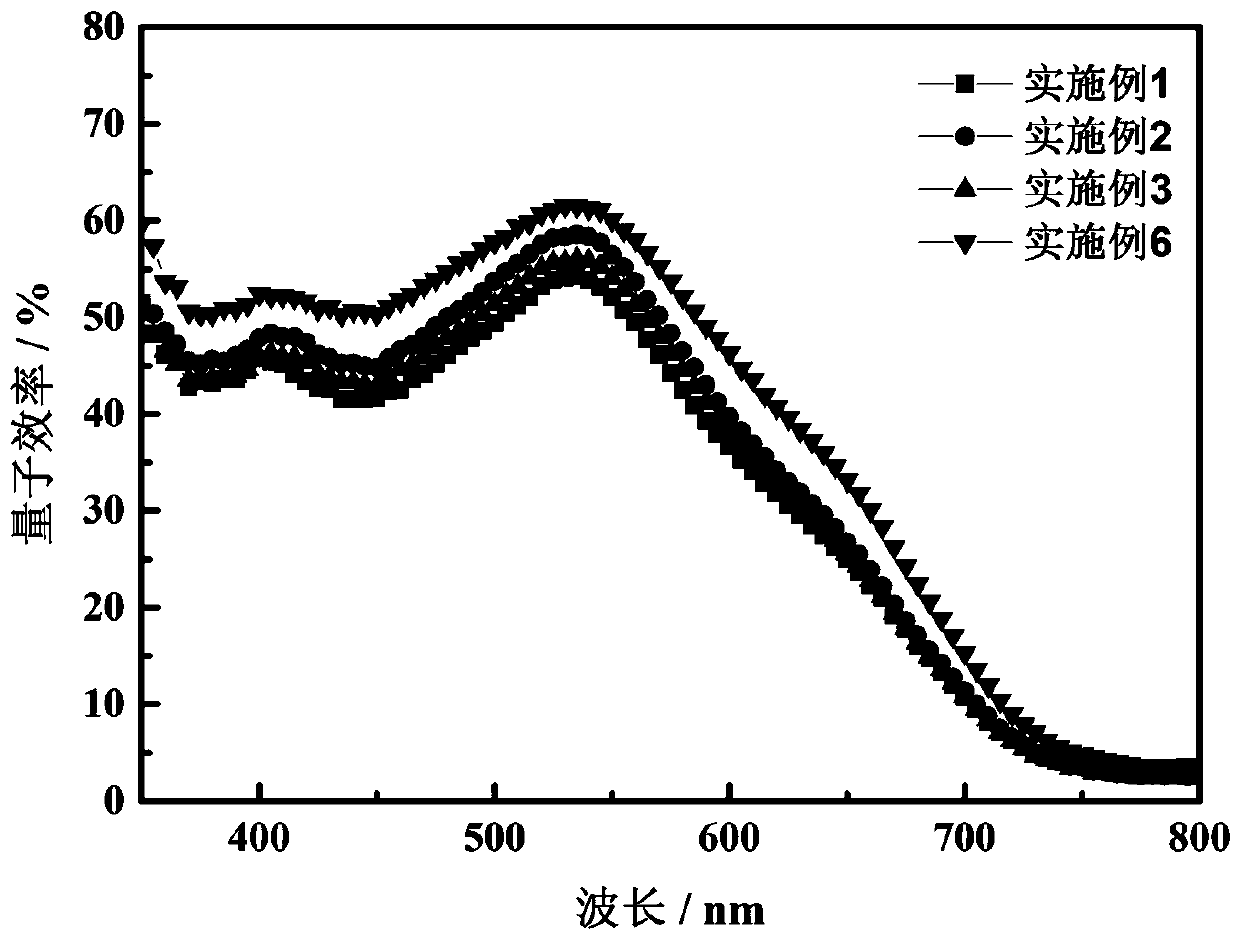

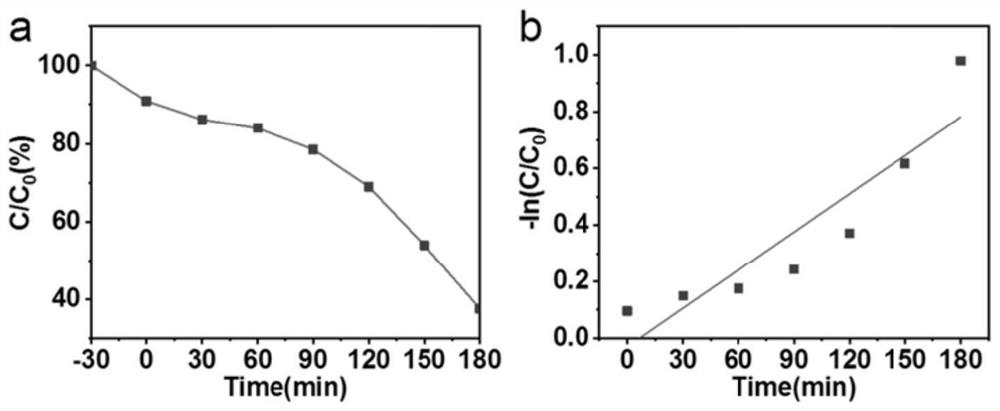

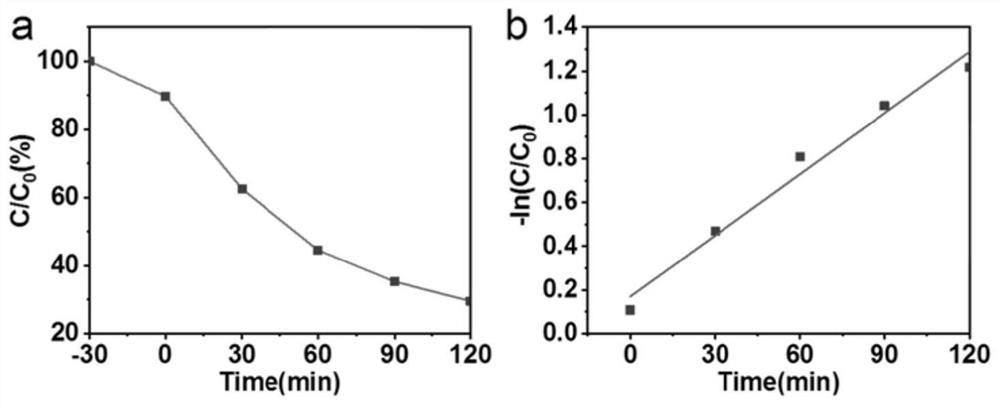

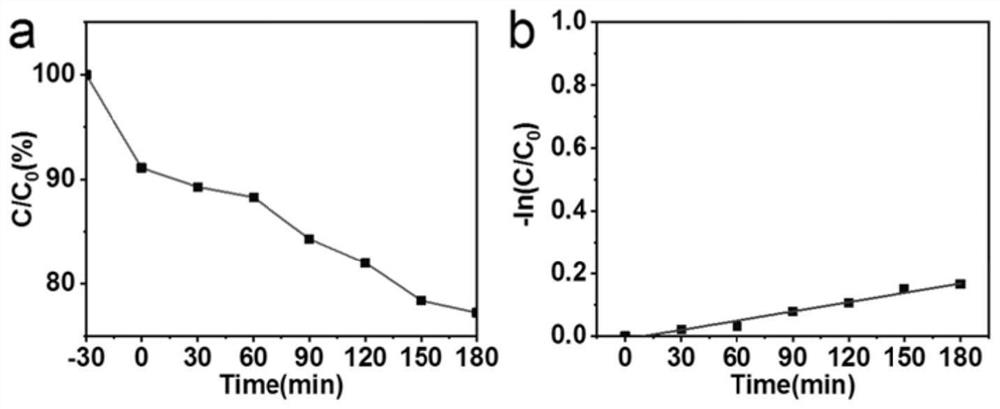

Compound near-infrared light photocatalyst as well as preparation method and application thereof

ActiveCN113413907AEasy to prepareEasy to mix evenlyWater/sewage treatment by irradiationWater treatment compoundsPtru catalystPhotochemistry

The invention discloses a compound near-infrared light photocatalyst and a preparation method and application thereof. CeF3-O serving as a main catalyst and silver nitrate serving as a cocatalyst are compounded according to a certain proportion, Ag nano-particles are deposited on the surface of CeF3-O under near-infrared light illumination, carrier separation is promoted through the surface plasma resonance effect, and meanwhile, tetracycline hydrochloride is efficiently degraded. The CeF3-O serves as a main catalyst, has a unique intermediate energy level structure, can directly absorb near-infrared light to generate photo-induced electron-hole pairs, and is essentially different from a composite catalyst which performs near-infrared catalysis through hot electron injection by utilizing the surface plasma resonance effect of Ag nanoparticles. In addition, the CeF3-O is used as a main catalyst, ethylene diamine tetraacetic acid is used as a cocatalyst, and the near-infrared light catalyst compounded according to a certain proportion can also efficiently degrade tetracycline hydrochloride. The process is simple, the compound photocatalyst is good in near-infrared light response, and the tetracycline hydrochloride degradation efficiency is effectively improved.

Owner:浙江省科创新材料研究院

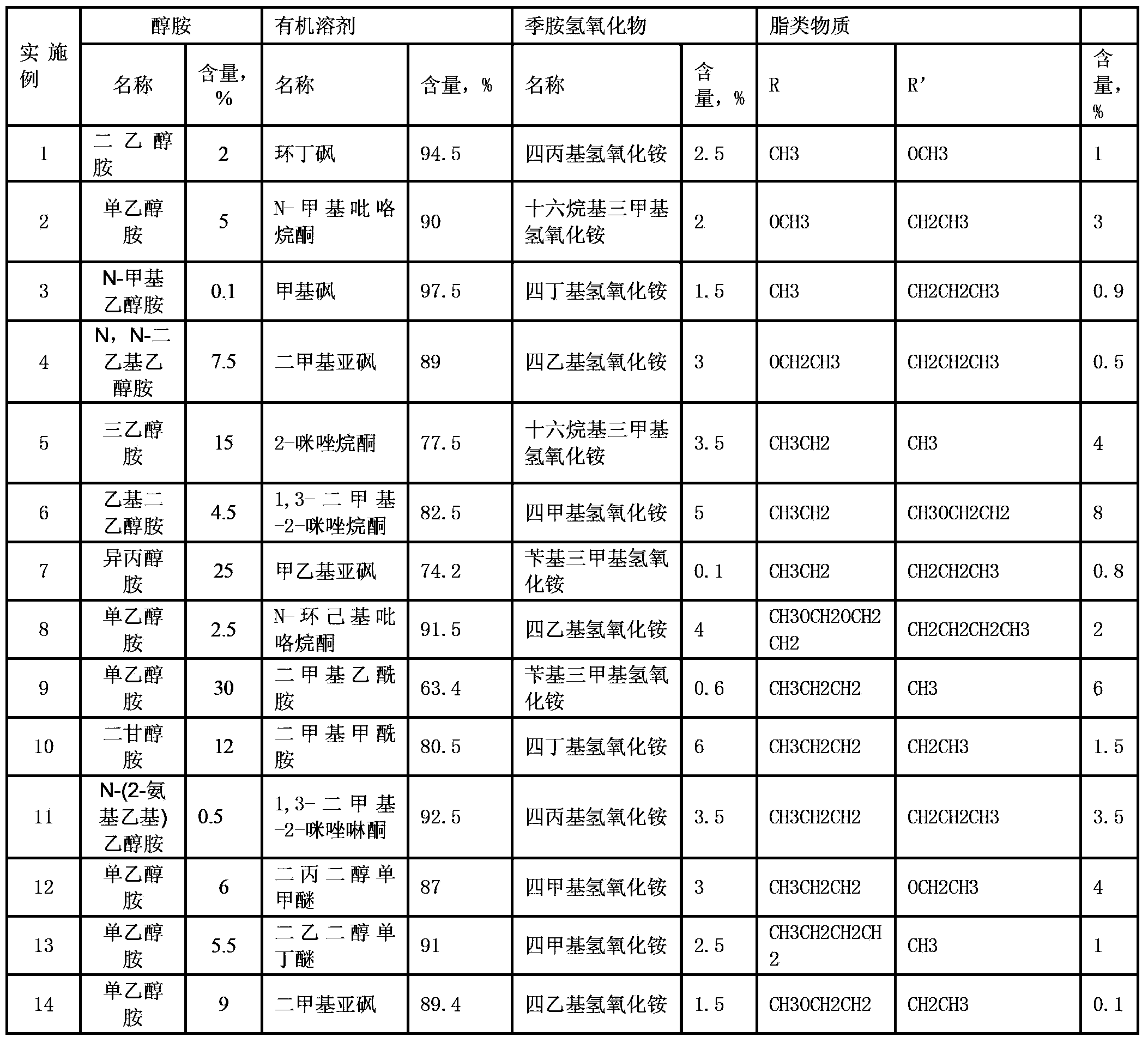

Cleaning solution for removing light resistance residue

InactiveCN104345582AEfficient removalEasy to mix evenlyPhotosensitive material processingSolventQuaternary amine

The present invention discloses a cleaning solution for removing a light resistance residue. The cleaning solution comprises a quaternary amine hydroxide, an alcohol amine and a solvent, and further comprises a lipid material, wherein the lipid material has the general formula of R-COCH2COOCH2R', and the number of the carbon molecules in the group R or R' is less than or equal to 4.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

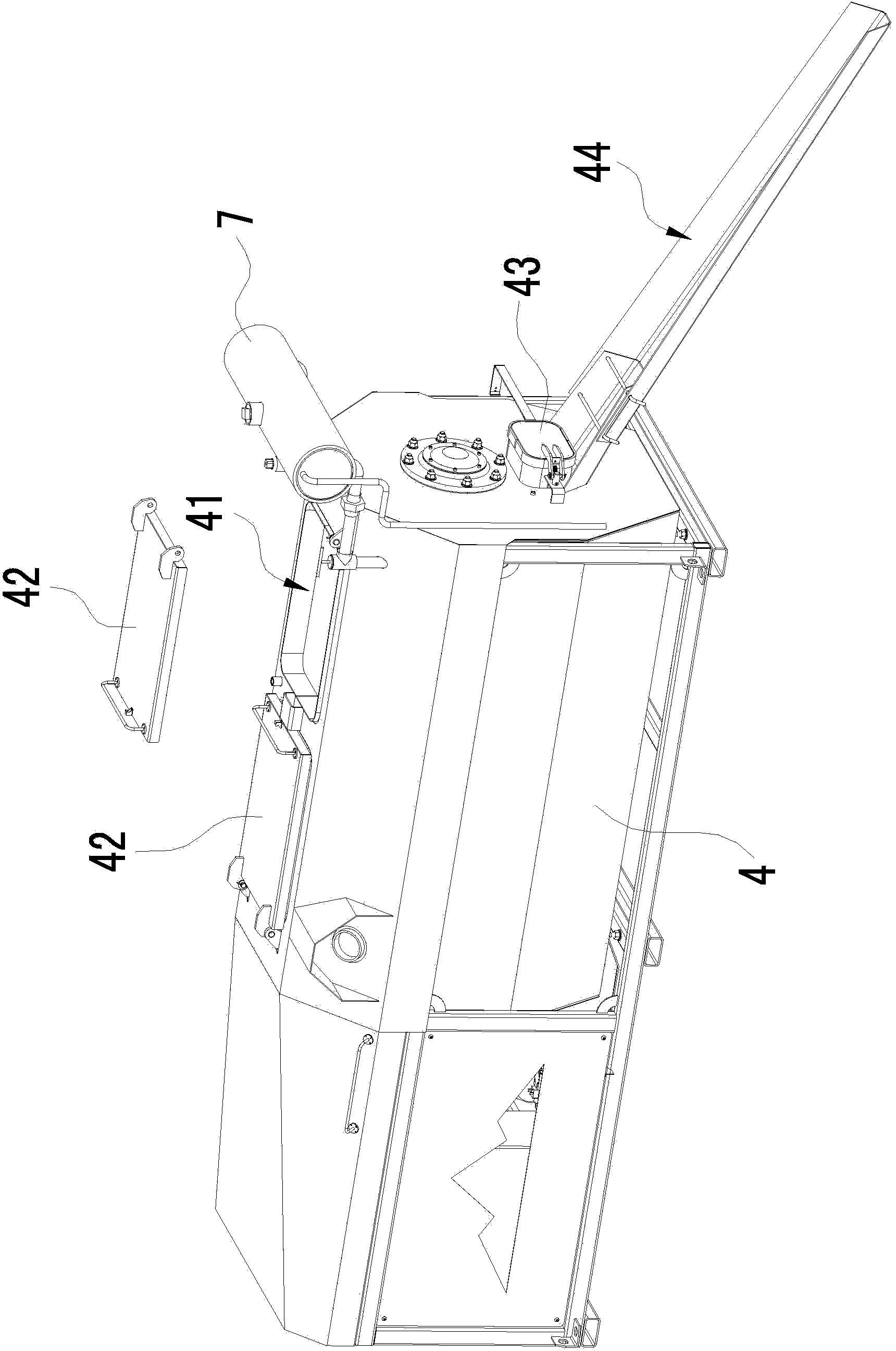

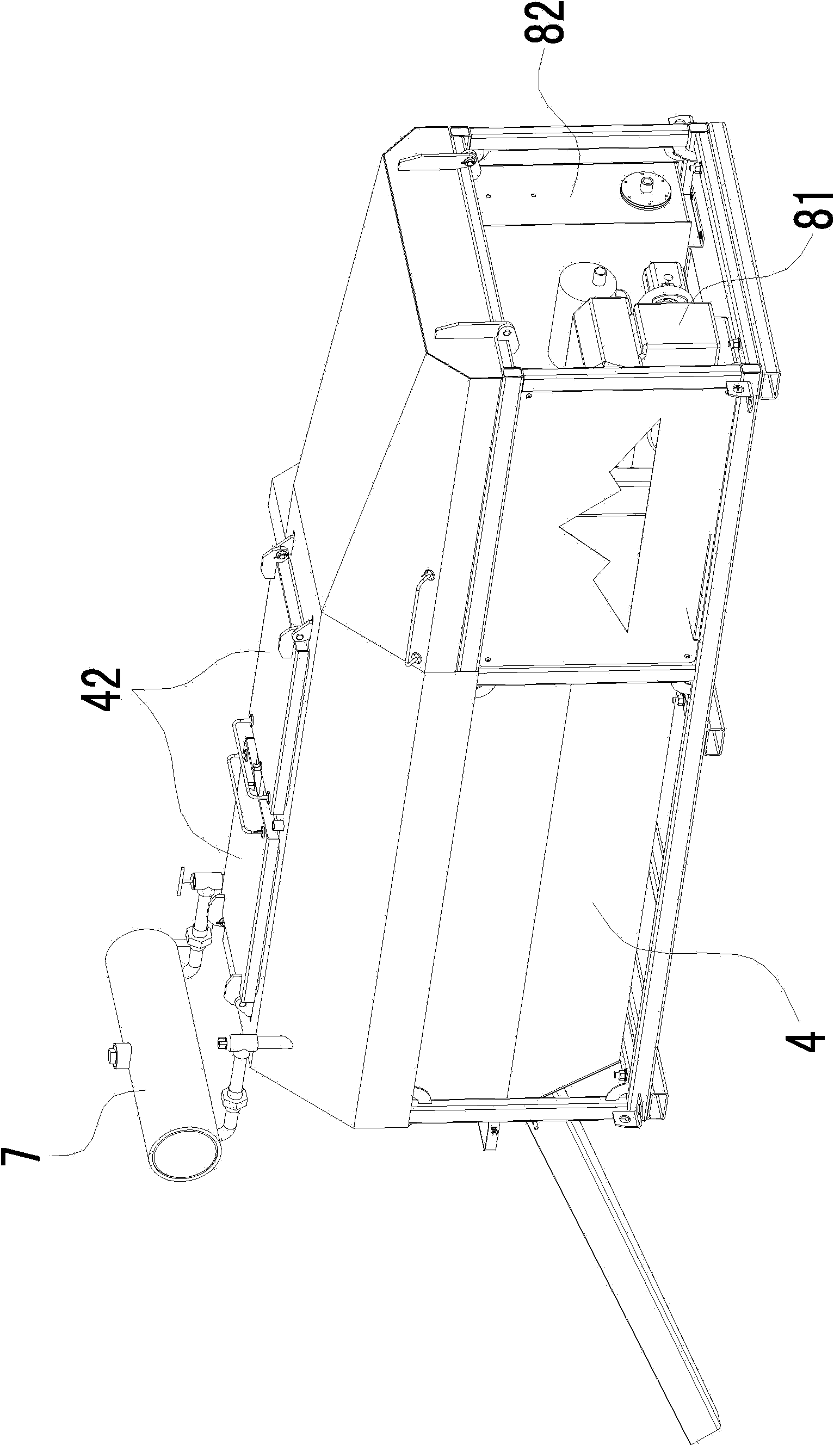

Asphalt stone mixing stirring heating kettle

The invention relates to an asphalt stone mixing stirring heating kettle. The asphalt stone mixing stirring heating kettle comprises a housing; a stirring chamber, wherein the top of the housing is provided with a feed inlet communicated with the stirring chamber; a heating chamber; a heat supplying chamber; a conduction oil circulating system comprising an oil storage tank and a conduction oil pipeline, wherein the conduction oil pipeline and the oil storage tank are communicated; a feed outlet which is arranged at the tail end of the housing, is communicated with the stirring chamber, and is provided with a door cover device; a stirring mechanism comprising a rotatable stirring shaft and a plurality of stirring blades arranged on the stirring shaft; a mechanical chamber, wherein a power device used for driving the stirring shaft to rotate is arranged in the mechanical chamber; and a heating device which is arranged between the mechanical chamber and the heat supplying chamber, and is used for providing heat for the heat supplying chamber. The asphalt stone mixing stirring heating kettle is capable of simplifying traditional preparation technology of asphalt concrete, and heating asphalt concrete, frying stone to be hot, and mixing and stirring at the same time so as to mix materials uniformly; mixing proportion is accurate; quality of obtained mixed material is high; labor consumption is reduced; production efficiency is increased, and production cost is reduced.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

A kind of asphalt stone mixing and stirring heating kettle

InactiveCN103669174BQuality improvementReduce consumptionRoads maintainenceProcess engineeringMixed materials

The invention relates to an asphalt stone mixing stirring heating kettle. The asphalt stone mixing stirring heating kettle comprises a housing; a stirring chamber, wherein the top of the housing is provided with a feed inlet communicated with the stirring chamber; a heating chamber; a heat supplying chamber; a conduction oil circulating system comprising an oil storage tank and a conduction oil pipeline, wherein the conduction oil pipeline and the oil storage tank are communicated; a feed outlet which is arranged at the tail end of the housing, is communicated with the stirring chamber, and is provided with a door cover device; a stirring mechanism comprising a rotatable stirring shaft and a plurality of stirring blades arranged on the stirring shaft; a mechanical chamber, wherein a power device used for driving the stirring shaft to rotate is arranged in the mechanical chamber; and a heating device which is arranged between the mechanical chamber and the heat supplying chamber, and is used for providing heat for the heat supplying chamber. The asphalt stone mixing stirring heating kettle is capable of simplifying traditional preparation technology of asphalt concrete, and heating asphalt concrete, frying stone to be hot, and mixing and stirring at the same time so as to mix materials uniformly; mixing proportion is accurate; quality of obtained mixed material is high; labor consumption is reduced; production efficiency is increased, and production cost is reduced.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

Concrete processing equipment

InactiveCN110802735AEasy to mix evenlyImprove mixing effectMixing operation control apparatusIngredients storageEngineeringStructural engineering

The invention discloses concrete processing equipment which comprises a stirring tank, a stirring plate and a stirring mechanism. A plurality of raw material boxes distributed in circumference are arranged above the stirring tank, feeding tubes communicate to the inner sides of the raw material boxes, and spiral feeding rollers are arranged in the feeding tubes. By arranging the raw material boxesdistributed in circumference and communicating to the feeding tubes, raw materials are quantatively and synchronously fed, so that the raw materials are uniformly stirred subsequently, the stirring effect is improved and the stirring time is shortened. By arranging the stirring plate connected to a suspension shaft through a rotating rack, the stirring range of the stirring plate is ensured. By arranging the spiral feeding rollers connected to the stirring shaft through a transmission mechanism, feeding and stirring are synchronized, so that a driving structure and a control node are simplified.

Owner:衡东盛世商品混凝土有限公司

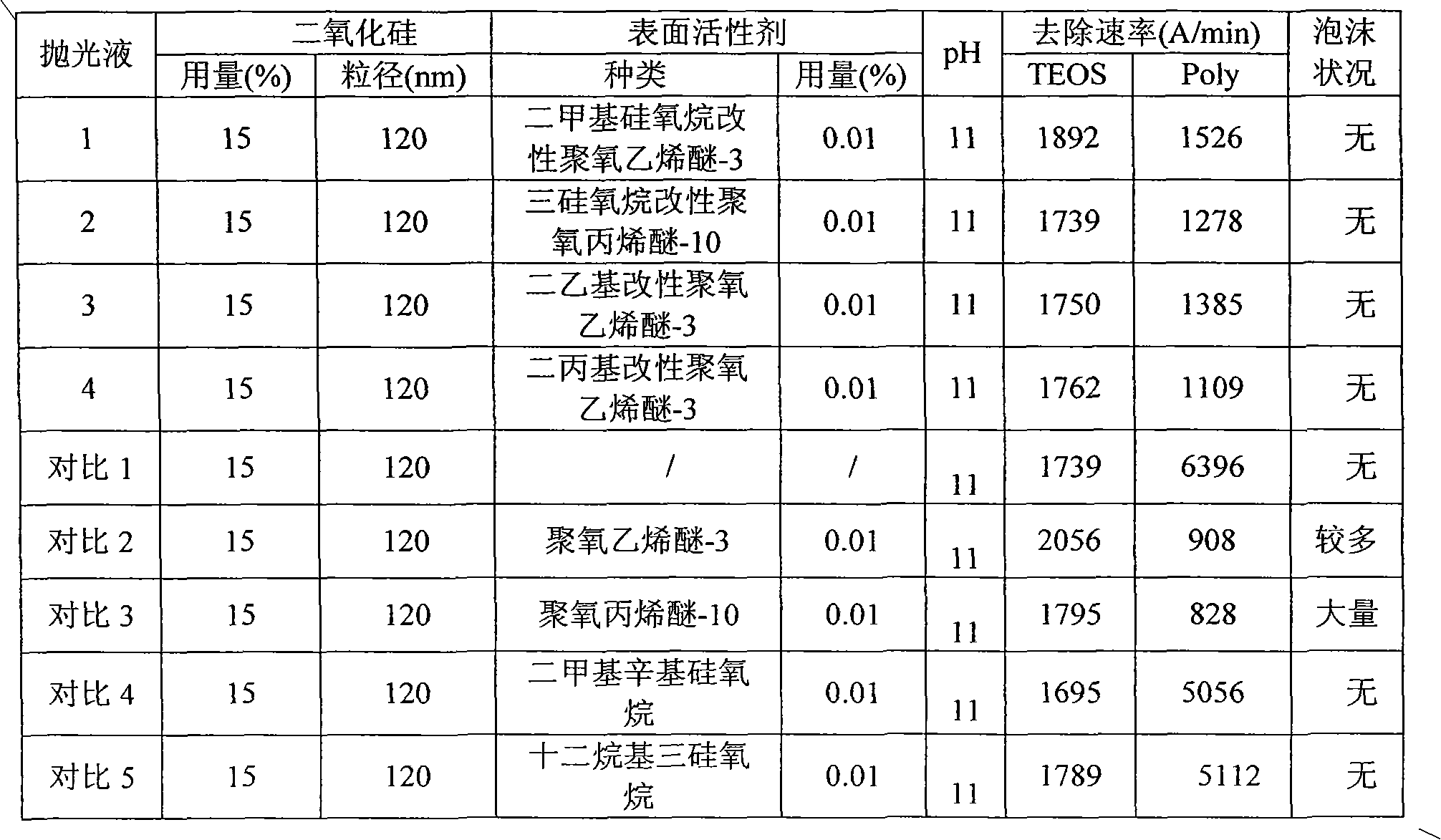

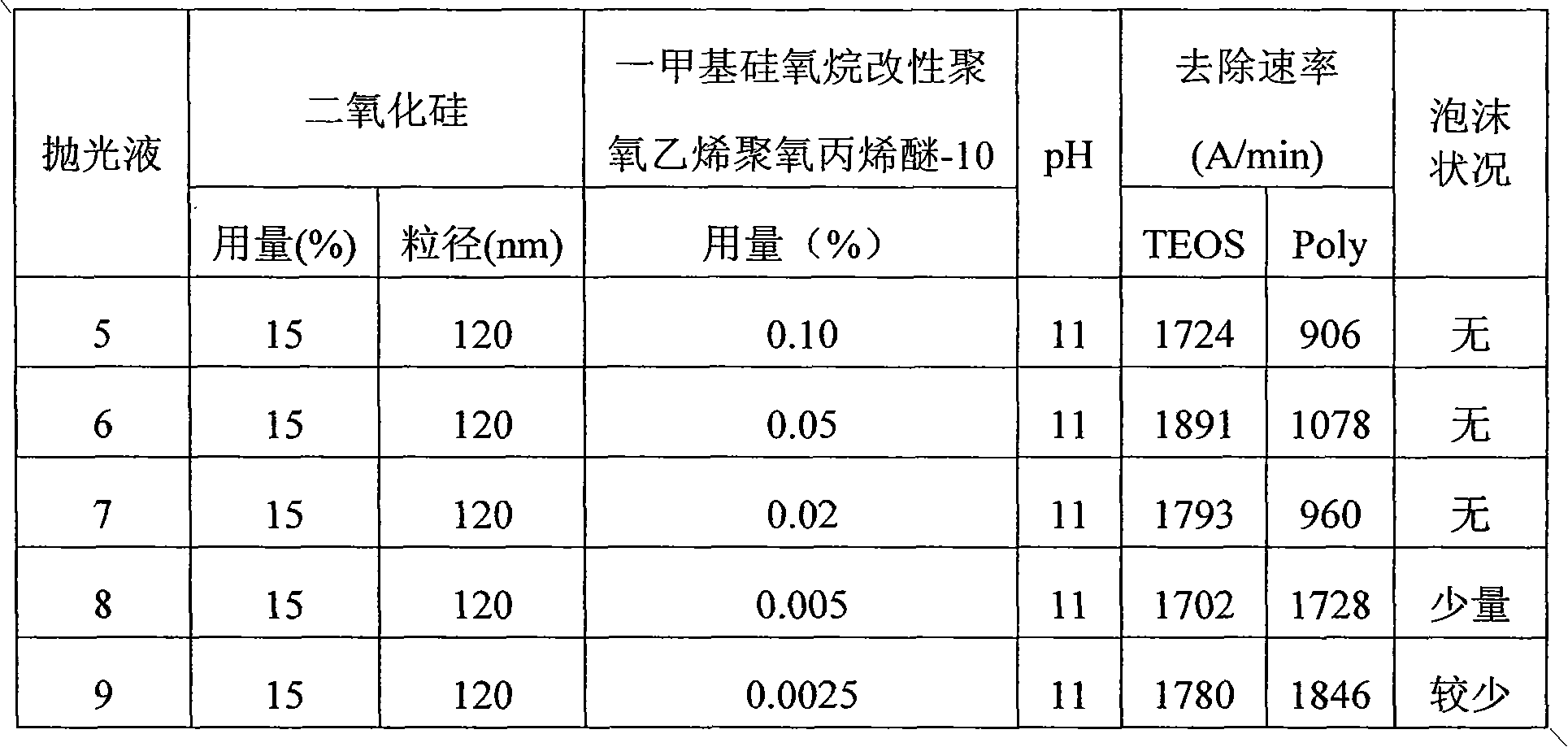

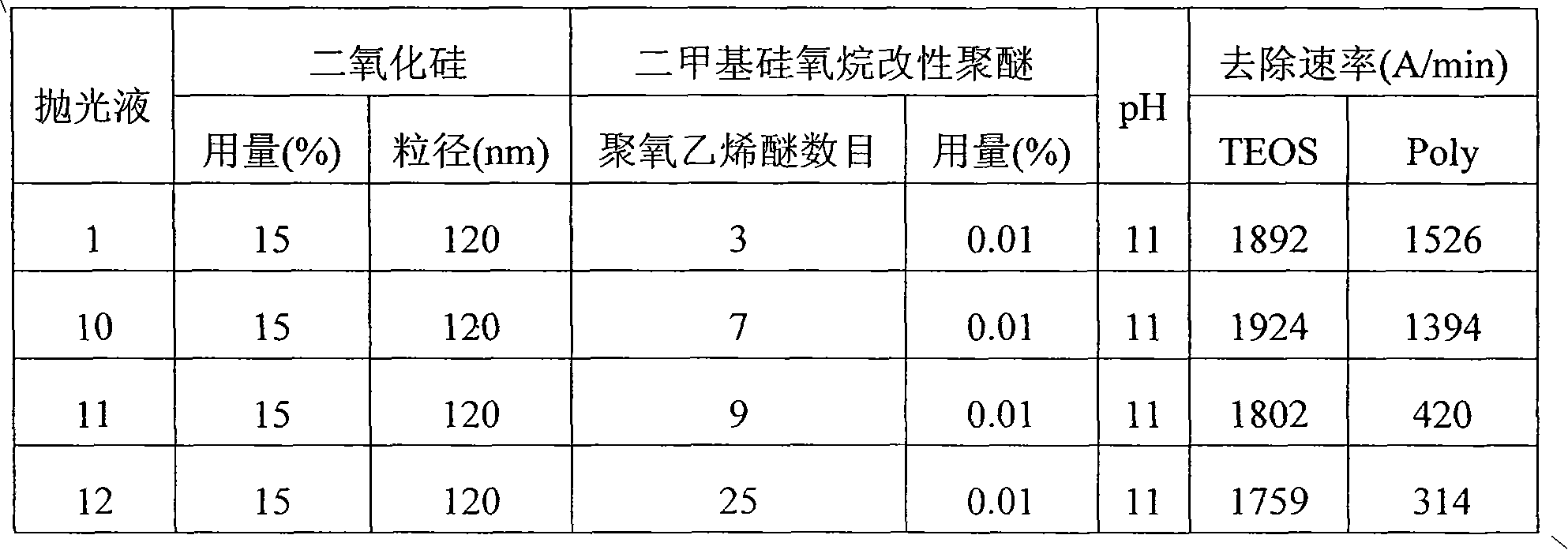

Chemically mechanical polishing solution

InactiveCN101928524AWon't happenDoes not affect polishing ratePolishing compositionsDielectricSilicon dioxide

The invention discloses a chemically mechanical polishing solution, which is characterized by comprising silica, alkylation siloxane end-capped poly-alkoxy and water. The polishing solution of the invention overcomes the defects that the existing chemically mechanical polishing solution used for polishing oxide dielectrics adopts polyether to restrain the polishing rate of polycrystalline silicon, a large amount of foam is generated in the polishing process, and the polishing rate is influenced and the environment is polluted. In the invention, modified polyether is used, a large amount of foam can not be generated even under severely stirring, the removal rate of the polycrystalline silicon is controlled, and the polishing rate of the oxide is not influenced, thus being benefit for transporting.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Semi-solid slurry preparation and feeding device for surface repair integrated equipment

ActiveCN112705714BEasy to mix evenlySimple structureAdditive manufacturing apparatusTransportation and packagingGear wheelSemi solid

The invention provides a semi-solid slurry preparation and feeding device for surface repair integrated equipment, which includes a hollow shaft feeding device, a semi-solid preparation cylinder, a transmission device, a material stop device and a segmented induction heating device. The output end of the shaft feeding device is connected to the input end of the semi-solid preparation cylinder. The transmission device and the semi-solid preparation cylinder are fixedly connected by bolts. On the steel plate workpiece, the gear pair split shaft transmission device and the multi-functional semi-solid slurry preparation cylinder pass through the three-nut bolt body and then tighten the first nut to fix it. The segmented induction heating device is connected to the servo motor base support seat, and the material stop device is placed on the Repair steel plate workpiece. It can realize the multifunctional integration of metal powder feeding, semi-solid slurry stirring, semi-solid slurry accelerated feeding and semi-solid slurry discharging, so as to achieve uniform and sufficient stirring.

Owner:西安永成混凝土搅拌工程有限公司

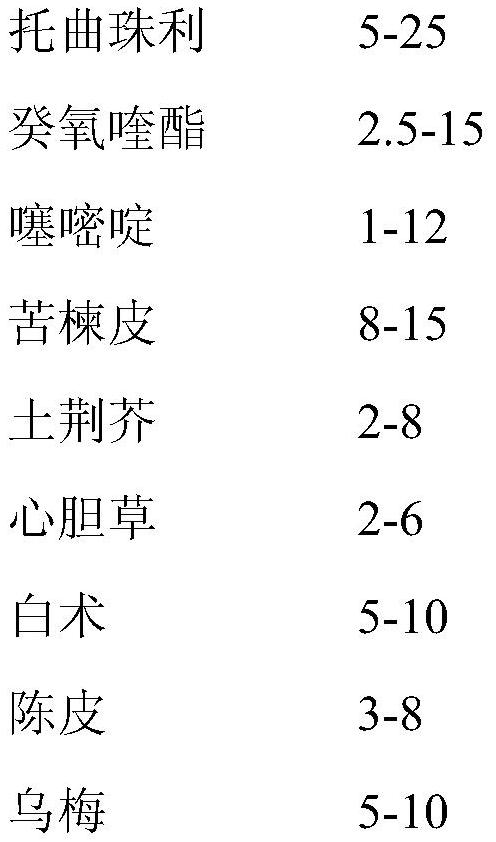

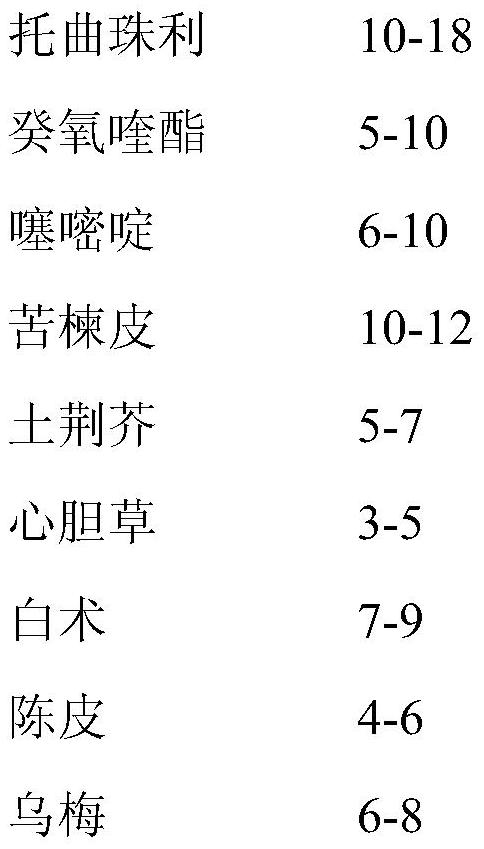

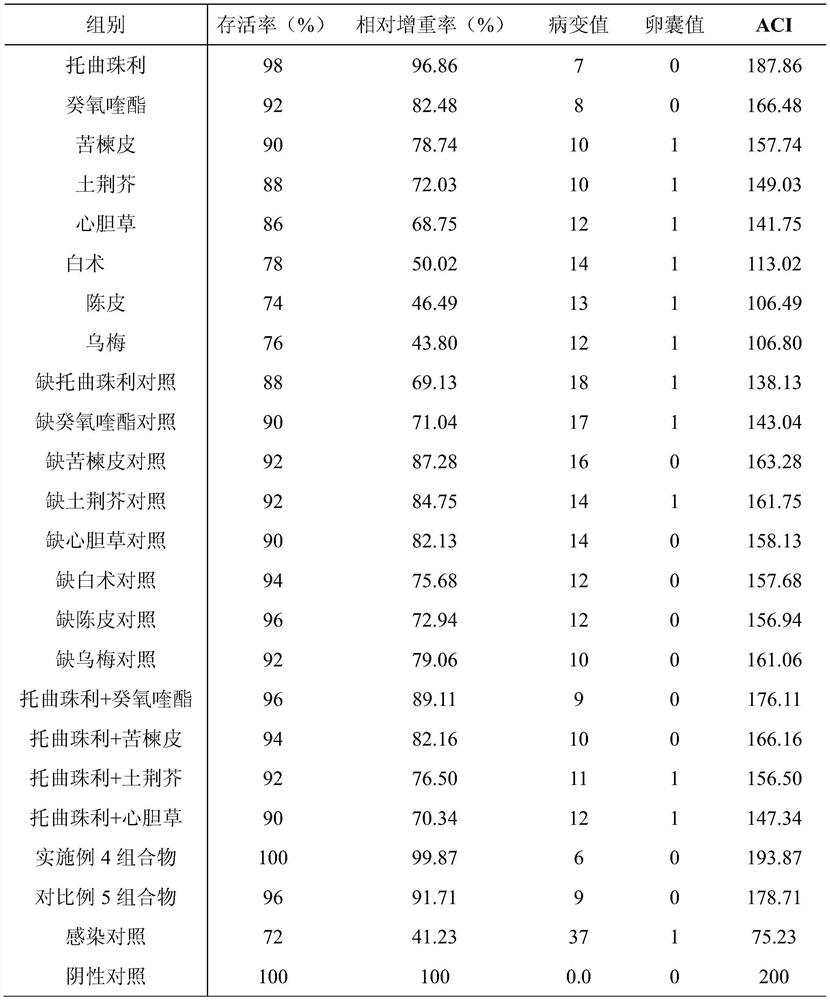

A kind of veterinary drug composition and its preparation method and application

ActiveCN108175793BReduce dosageSmall toxicityAntiparasitic agentsHeterocyclic compound active ingredientsBiotechnologySide effect

The invention provides a veterinary drug composition. The veterinary drug composition comprises, by mass, 5-25 parts of toltrazuril, 2.5-15 parts of decoquinate, 1-12 parts of pyrantel, 8-15 parts ofCortex Meliae, 2-8 parts of Chenopodium ambrosioides, 2-6 parts of Herb of Longseed Willowweed, 5-10 parts of Rhizoma Atractylodis Macrocephalae, 3-8 parts of dried orange peel and 5-10 parts of darkplum. The invention also provides a preparation method and an application of the veterinary drug composition. The veterinary drug composition has the advantages of reasonable compatibility, quick effect, minimal toxic and side effects, effective reduction of the drug resistance and drug residues, very clear therapeutic effect on intestinal injuries, reduced appetite and lean bodies of animals, caused by coccidiosis, low cost, and easiness in use. The invention further provides the application of the composition in the treatment of histomoniasis.

Owner:JIANGSU LINGYUN PHARMA

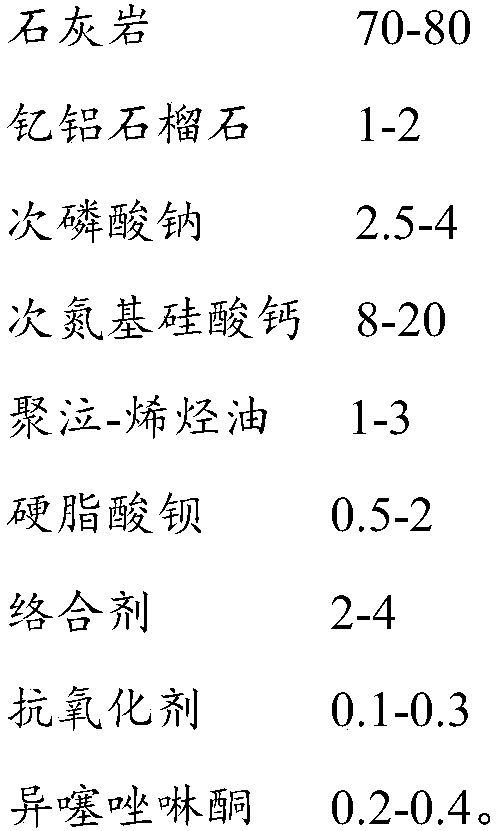

PPM environmentally friendly material and preparation method thereof

The invention discloses a PPM environmentally friendly material which is prepared from the following raw materials in parts by mass: 70-80 parts of limestone, 1-2 parts of yttrium aluminium garnet, 2.5-4 parts of sodium hypophosphite, 8-20 parts of nitrilo-calcium silicate, 1-3 parts of poly-olefin oil, 0.5-2 parts of barium stearate, 2-4 parts of a complexing agent, 0.1-0.3 part of an antioxidantand 0.2-0.4 part of isothiazolinone. At a temperature of -18 DEG C or below, the PPM environmentally friendly material has high flexibility and does not get crisp easily and can bear certain externalforce. A preparation method of the PPM environmentally friendly material comprises the following steps: (a) uniformly mixing the limestone, the sodium hypophosphite, the nitrilo-calcium silicate, theyttrium aluminum garnet and the barium stearate to obtain a mixture A; (b) adding the poly-olefin oil into the mixture A, and stirring uniformly to obtain a mixture B; (c) sequentially adding the complexing agent, the antioxidant and the isothiazolinone into the mixture B, and stirring uniformly in a water bath at 50-60 DEG C to obtain the PPM environmentally friendly material.

Owner:河南东贵电子科技有限公司

Fertilizer slow-release long-acting agent and preparation process thereof

InactiveCN109988050AEasy to fixReduce volatilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateTrace element

The invention discloses a fertilizer slow-release long-acting agent which is low in cost, high in benefit and wide in application and has a urease inhibitor and a nitrification inhibitor, and naturalzeolite containing various trace elements used as a carrier to be matched with monoammonium phosphate, and a preparation process thereof. The synergist can be matched with any form of nitrogen fertilizer according to a weight ratio of 3-5:100 to form a long-acting nitrogen fertilizer or various compound special fertilizers. Compared with the same amount of fertilizer, the yield of crops can be increased by 10-15%. Fertilizer can be saved by 15-15% under same yield level condition, and the fertilizer slow-release long-acting agent is used as a base fertilizer to be deeply applied, so that the labor and the time can be saved. And the fertilizer slow-release long-acting agent is a product most suitable for small chemical fertilizer enterprise production and rural popularization and application.

Owner:青岛华夏沃土生物科技有限公司

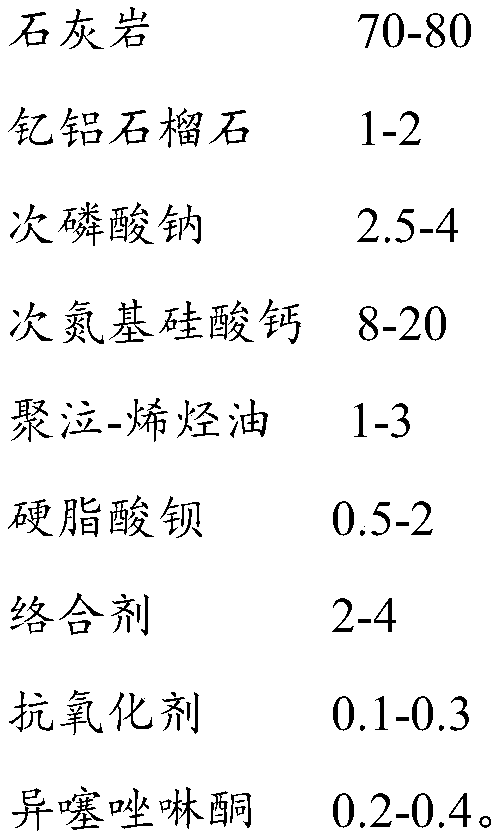

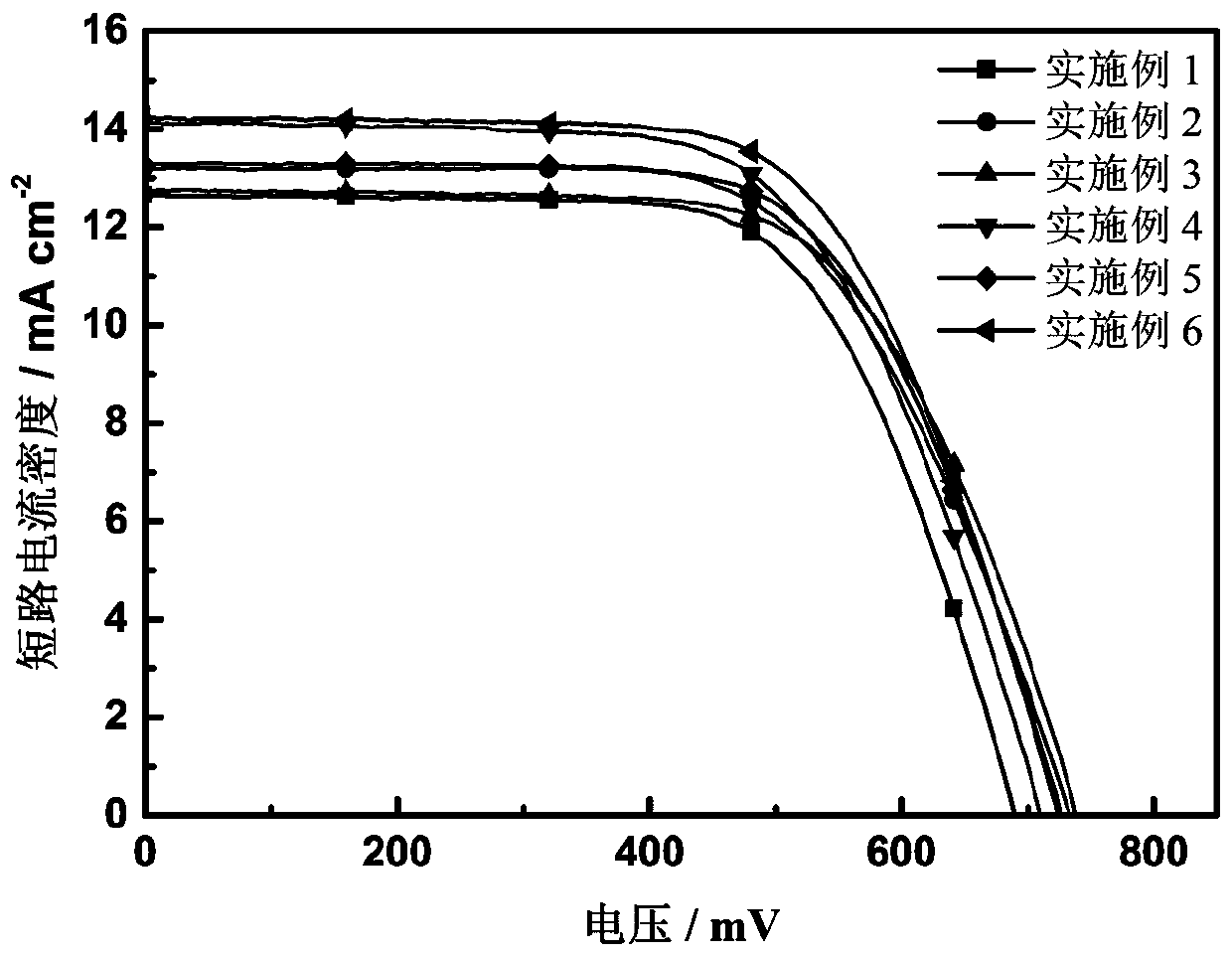

Method for preparing nitrogen and iodine co-doped titanium dioxide barrier layer

InactiveCN109545559AHigh impedanceInhibitory complexLight-sensitive devicesPhotovoltaic energy generationMuffle furnaceSolvent

The invention provides a nitrogen and iodine co-doped titanium dioxide barrier layer and a method for preparing same. The method comprises: under an ice bath condition, mixing and stirring tetrabutyllipid titanate and absolute ethanol, and diethanolamine for 1 hour and then using as a precursor liquid A; then, using deionized water and absolute ethanol as reaction solvents, and adding certain amount of urea and iodine, uniformly stirring to prepare a B solution, and adding the B solution to the precursor A liquid dropwise, rapidly stirring for 24 hours to obtain a colloidal solution C liquid;dropping the C liquid on a cleaned FTO conductive surface, using a spin coater to prepare a titanium dioxide film by spin coating, and sintering at 500 DEG C for 30 minutes in a muffle furnace to obtain a high-efficiency nitrogen and iodine co-doped titanium dioxide barrier layer. The barrier layer can effectively reduce recombination of electron hole pairs and improve light quantum conversion efficiency (IPCE) of a battery. The barrier layer can obviously open circuit voltage and short circuit current of a solar cell when the barrier layer is used for a quasi-solid-state dye-sensitized solarcell, and photoelectric conversion efficiency of the battery can reach 6.65%.

Owner:CHINA THREE GORGES UNIV

Stirring mechanism of asphalt stone mixing and stirring heating tank

InactiveCN103726431BStir wellImprove the mixing effectRoads maintainenceBituminous materialsEngineering

The invention relates to a stirring mechanism for mixing, stirring and heating kettle of bituminous materials and aggregates. The stirring mechanism includes a stirring shaft and a plurality of stirring blades mounted on the stirring shaft, wherein the rotary stirring shaft drives the stirring blades to rotate; the stirring blades are arrayed at intervals in the axial direction of the stirring shaft; each stirring blade includes a base, a stirring arm and a blade part; one end of the stirring arm is connected with the base, the other end of the stirring arm is connected with the blade part, and the base is mounted on the stirring shaft; the projection of the two adjacent stirring blades on the plane vertical to the axis of the stirring shaft is V-shaped; the blade parts of all the stirring blades are arrayed to be spiral in space. The stirring mechanism is uniform in stirring operation and better in stirring effect and improves the stirring efficiency, through the arrangement manner of all the blade parts, the mixture of mixed bituminous materials and aggregates can be conveyed during the rotation of the blade parts, so as to give assistance to discharge, as a result, the stirring mechanism can be used for conveying the mixture, and when the mixture is stirred, the stirring blades can be used for pushing and squeezing the mixture, and all the stirring blades can be used for cutting and smashing the mixture.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

Plasma etching residue cleaning solution

ActiveCN101666984BAvoid corrosionEasy to mix evenlyDetergent mixture composition preparationSemiconductor/solid-state device manufacturingFluorideSolvent

The invention discloses plasma etching residue cleaning solution, which comprises a solvent, water, fluoride, and a star polymer containing pigment affinity groups. The plasma etching residue cleaning solution can effectively remove photoresist residues after plasma etching, can simultaneously inhibit corrosion of metal (in particular aluminum) and non-metals in high efficiency, and has larger operating windows for cleaning and rinsing.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

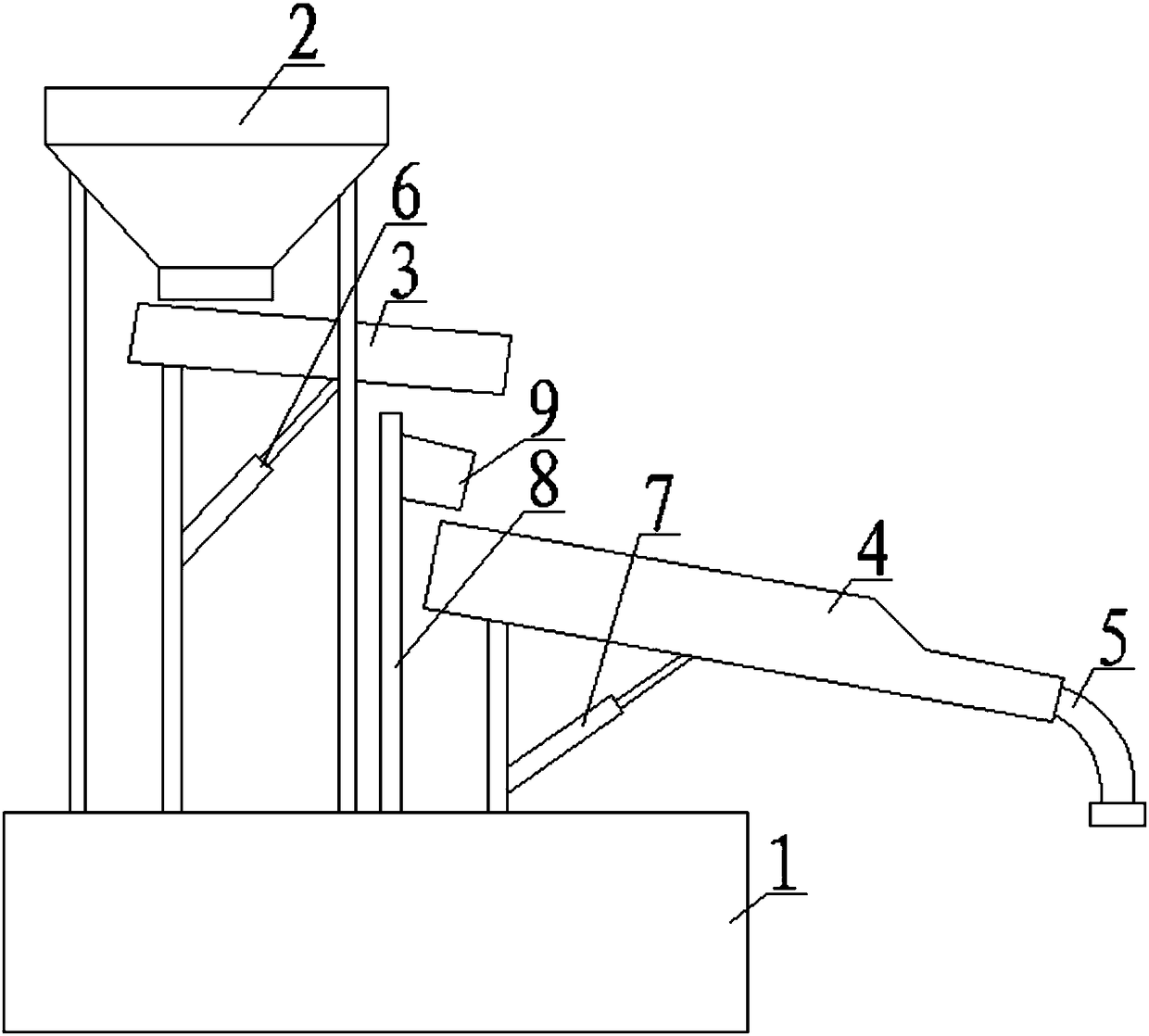

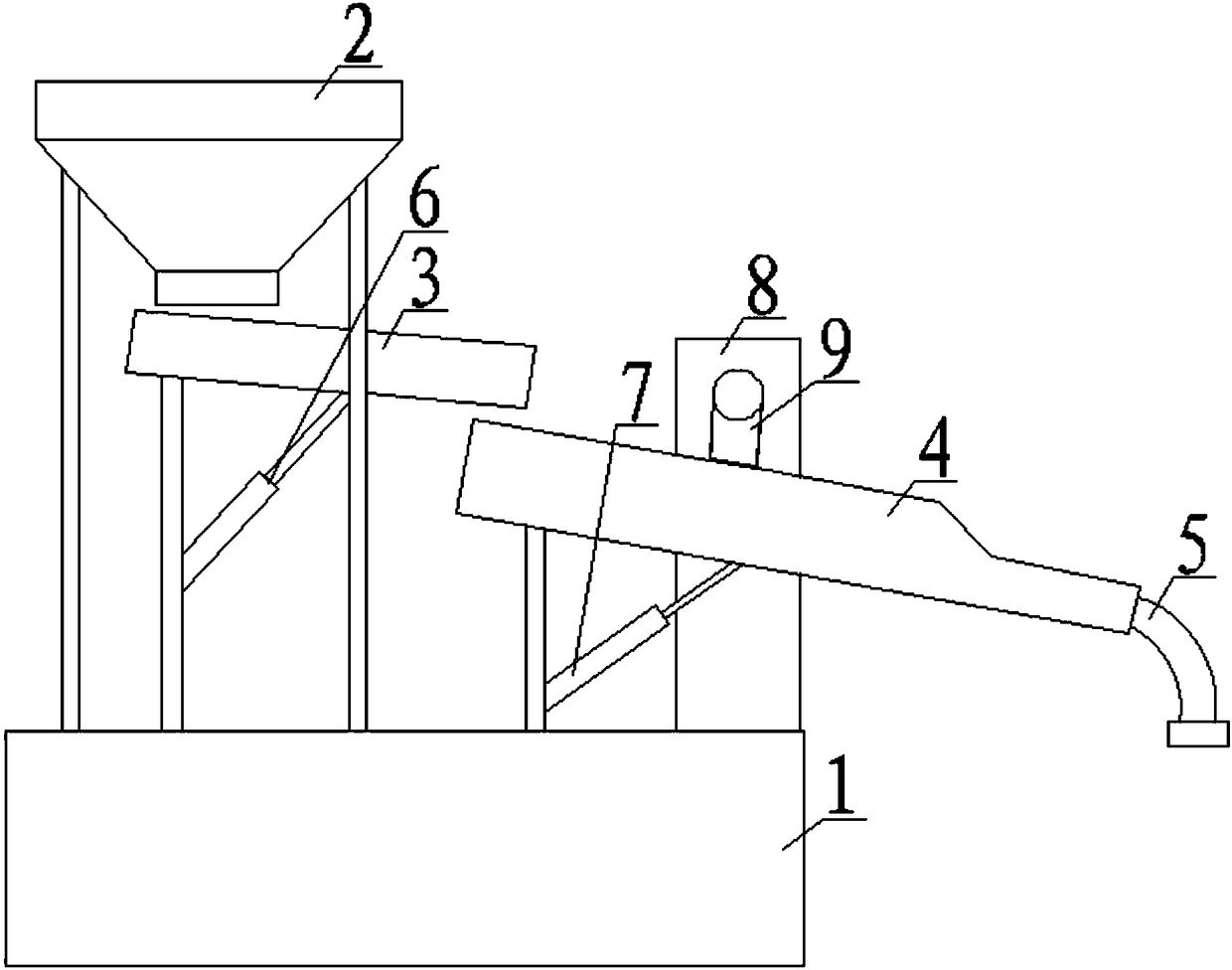

Paint conveyor with controllable conveying efficiency

InactiveCN109420459AEasy to mix evenlySimple structureTransportation and packagingMixer accessoriesArchitectural engineering

The invention discloses a paint conveyor with controllable conveying efficiency. The paint conveyor comprises a conical feeding groove, a first opening groove, a second opening groove, a first telescopic support, a second telescopic support, a mounting column and an aerator, wherein the first opening groove and the second opening groove are both obliquely arranged with a higher left part and a lower right part; the right end of the first opening groove is open; the left end and the right end of the second opening groove are both open; the left end of the first opening groove is arranged belowa conical feeding groove; and the left end of the second opening groove is arranged below the first opening groove. The first telescopic support and the second telescopic support both comprise a supporting column, a positioning cylinder, a supporting rod and an elastic piece, wherein the upper end of the supporting column of the first telescopic support and the right end of the supporting rod of the first telescopic support are both fixed at the bottom of the first opening groove; and the upper end of the supporting column of the second telescopic support and the right end of the supporting rod of the second telescopic support are both fixed at the bottom of the second opening groove. The mounting column is fixed on a supporting platform, the aerator is fixed on the mounting column, and anair outlet of the aerator right faces to the left end opening of the second opening groove. The paint conveyor is used for transition of oil paint during oil paint mixing, and oil paint mixing efficiency can be improved.

Owner:刘荣伟

Paint feeder

InactiveCN109420454AEasy to mix evenlySimple structureTransportation and packagingMixer accessoriesArchitectural engineering

The present invention discloses a paint feeder, comprising a tapered feeding trough, a first open trough, a second open trough, a first telescopic bracket, a second telescopic bracket, a supporting bracket and a scraping broom, wherein the first open trough and the second open trough are both obliquely disposed in a left high and right low way and each have an open right end; the left end of the first open trough is disposed below the tapered feed trough, and the left end of the second open trough is disposed below the first open trough; the first telescopic bracket and the second telescopic bracket each include a support column, a positioning cylinder, a support rod and an elastic member; the upper end of the support column of the first telescopic bracket and the right end of the supportrod of the first telescopic bracket are both fixed at the bottom of the first open trough; the upper end of the support column of the second telescopic bracket and the right end of the support rod ofthe second telescopic bracket are both fixed to the bottom of the second open trough; and the supporting bracket is fixed on a supporting platform, the scraping broom is fixed on the supporting bracket, and the hair end of the scraping broom is disposed in the second open trough. The paint feeder of the invention is used for transition of paint when the paint is mixed, and can improve the mixing efficiency of the paint.

Owner:刘荣伟

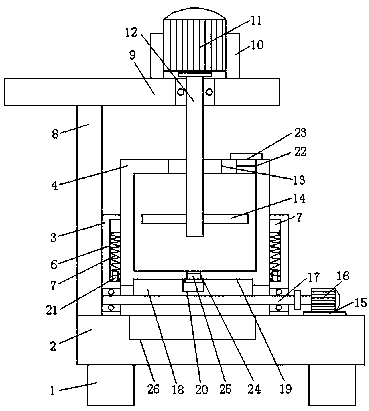

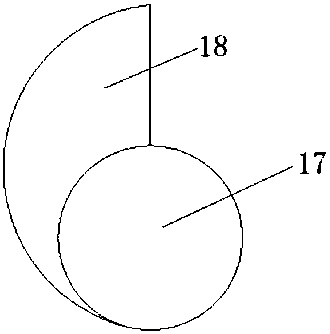

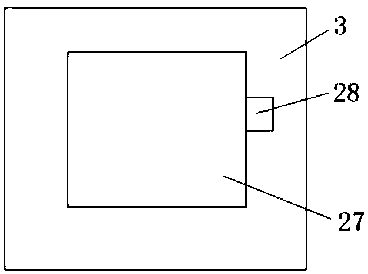

Stirring device convenient for uniform stirring for organic silica gel production

InactiveCN107930494AEasy to mix evenlyShaking/oscillating/vibrating mixersTransportation and packagingEngineeringSilica gel

The invention discloses a stirring device convenient for uniform stirring for organic silica gel production. The stirring device comprises a supporting leg, wherein the surface of the supporting leg is fixedly connected to a supporting table; the surface of the supporting table is fixedly connected to a ring body; the surface of the ring body is slidably connected to a stirring box; a shock absorbing tank is formed in the inner wall of the ring body; the inner wall of the shock absorbing tank is fixedly connected to a spring; one end of the spring is fixedly connected to a limiting block; thesurface of the limiting block is fixedly connected to the surface of the stirring box; the surface of the supporting table is fixedly connected to a supporting plate; and the surface of the supportingplate is fixedly connected to a top plate. According to the stirring device convenient for uniformly stirring for organic silica gel production, by arranging the ring body, the spring and the limiting block, the stirring box is kept in a steady state in sinking and ascending processes to achieve the effect of uniformly and steadily stirring, so that the problem that a common organic silica gel stirring device is inconvenient for uniform stirring, consumes a relatively long time in stirring processing, and affects the work efficiency is solved.

Owner:WUXI HITXINCHENG POLYMER TECH

Brucite granular fertilizer and its preparation method

InactiveCN100358843CReduce pollutionNo wasteMagnesium fertilisersFertiliser formsSoil scienceBrucite

The present invention relates to a brucite granule fertilizer and its preparation method. Said preparation method includes the following steps: mixing brucite, natural magnesium sulfate and light calcined magnesium, using water or 5% (mass) of citric acid solution as binding agent, mixing all the materials, granulating drying and packaging so as to obtain spherical granules whose diameter is 2-4mm, in which water content is less than or equal to 1%, hardness is 1.5-4kg / sq.cm, disintegration rate is greater than or equal to 90%, citric-soluble MgO mass content is 53-62% and water-soluble MgO mass content is 3-5%.

Owner:大连爱思凯矿产有限公司

Coal mine exploitation screening device for facilitating uniform stirring

InactiveCN109999987AEasy to mix evenlyReduce processing costsSievingScreeningArchitectural engineeringCoal

The invention discloses a coal mine exploitation screening device for facilitating uniform stirring. The coal mine exploitation screening device comprises a main shell, a servo motor, a positive and negative motor and a collecting trough; the main shell is internally provided with a sliding slot, the main shell is internally provided with a crushing barrel, a convex ring is fixedly connected to the middle portion of the outer side of the crushing barrel, an upper end cover is fixed to the left side of the main shell, the servo motor is fixedly mounted in the upper end cover, the lower end of amain shaft is fixedly mounted at the bottom of the crushing barrel, springs are arranged on the left and right sides of a screening plate, the right side of the screening plate is arranged in a sleeve, a steel rope is connected to the left side of the screening plate, the steel rope is arranged inside the springs, the other end of the steel rope penetrates through a left-side base to be connectedto a rotary disc, a fixing shaft is connected to the positive and negative motor, and the collecting trough is arranged at the bottom of the base. By means of the coal mine exploitation screening device for facilitating uniform stirring, the screening device moves left and right to enable coal mine on the screening plate to be separated faster, and the work efficiency is improved.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com