Concrete processing equipment

A technology for processing equipment and concrete, which is applied in the direction of clay preparation device, mixing operation control, mixing operation control device, etc. It can solve the problems of poor mixing uniformity, lower production efficiency and production benefits, and long mixing time, so as to achieve uniform mixing, The effect of improving the stirring effect and reducing the stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

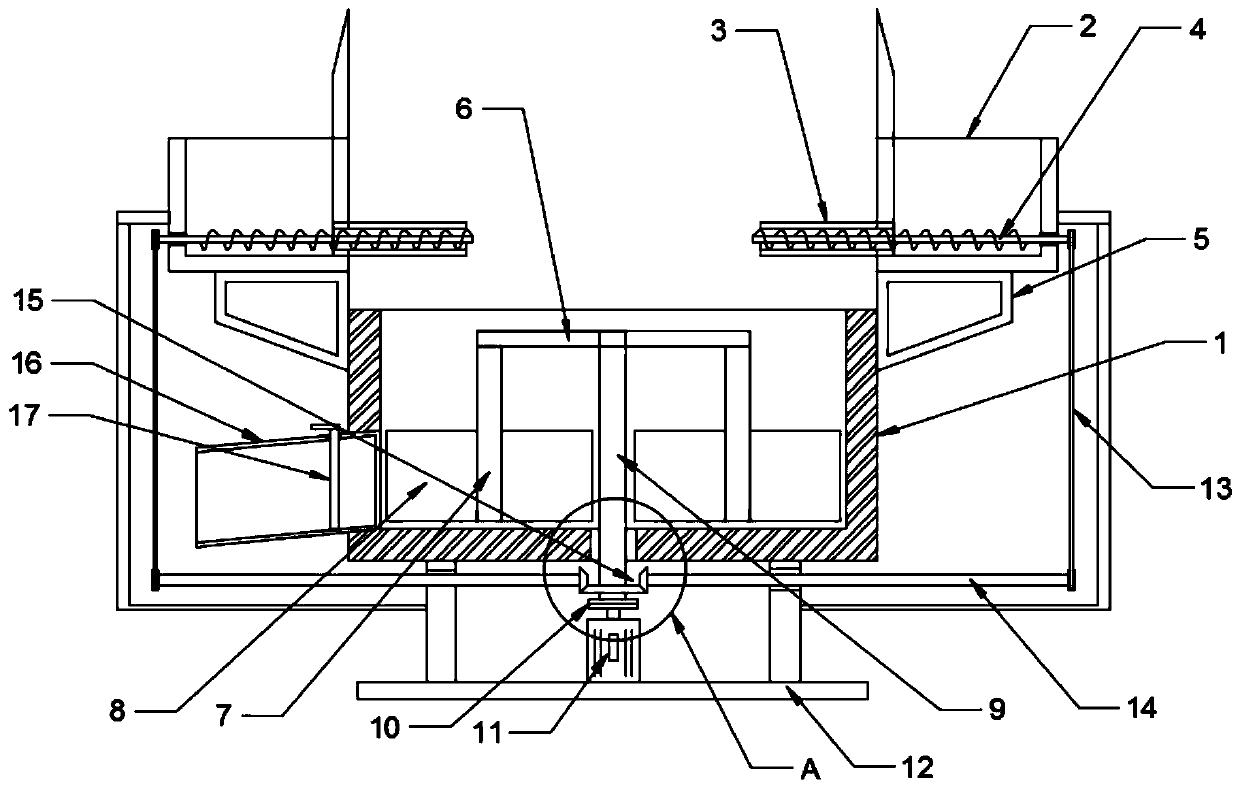

[0022] see Figure 1-4 , in an embodiment of the present invention, a concrete processing equipment includes a mixing tank 1 and a mixing plate 8; A plurality of raw material boxes 2 distributed in a circle, the raw material boxes 2 are detachably connected with the upper edge of the mixing tank 1 through the mounting frame 5, which is convenient for increasing and decreasing the quantity of the raw material boxes 2, and the inner side of the raw material box 2 is connected with the feeding pipe 3, the feeding pipe 3 Extending to the top of the mixing tank 1, the feeding pipe 3 is provided with a screw feed roller 4, and the screw feed roller 4 extends into the raw material box 4; specifically, each raw material of the concrete is placed in the circular distribution according to the required amount. In the raw material box 2, the screw feed roller 3 feeds each raw material at a constant speed and quantitatively, and the stirring structure performs agitation and processing of e...

Embodiment 2

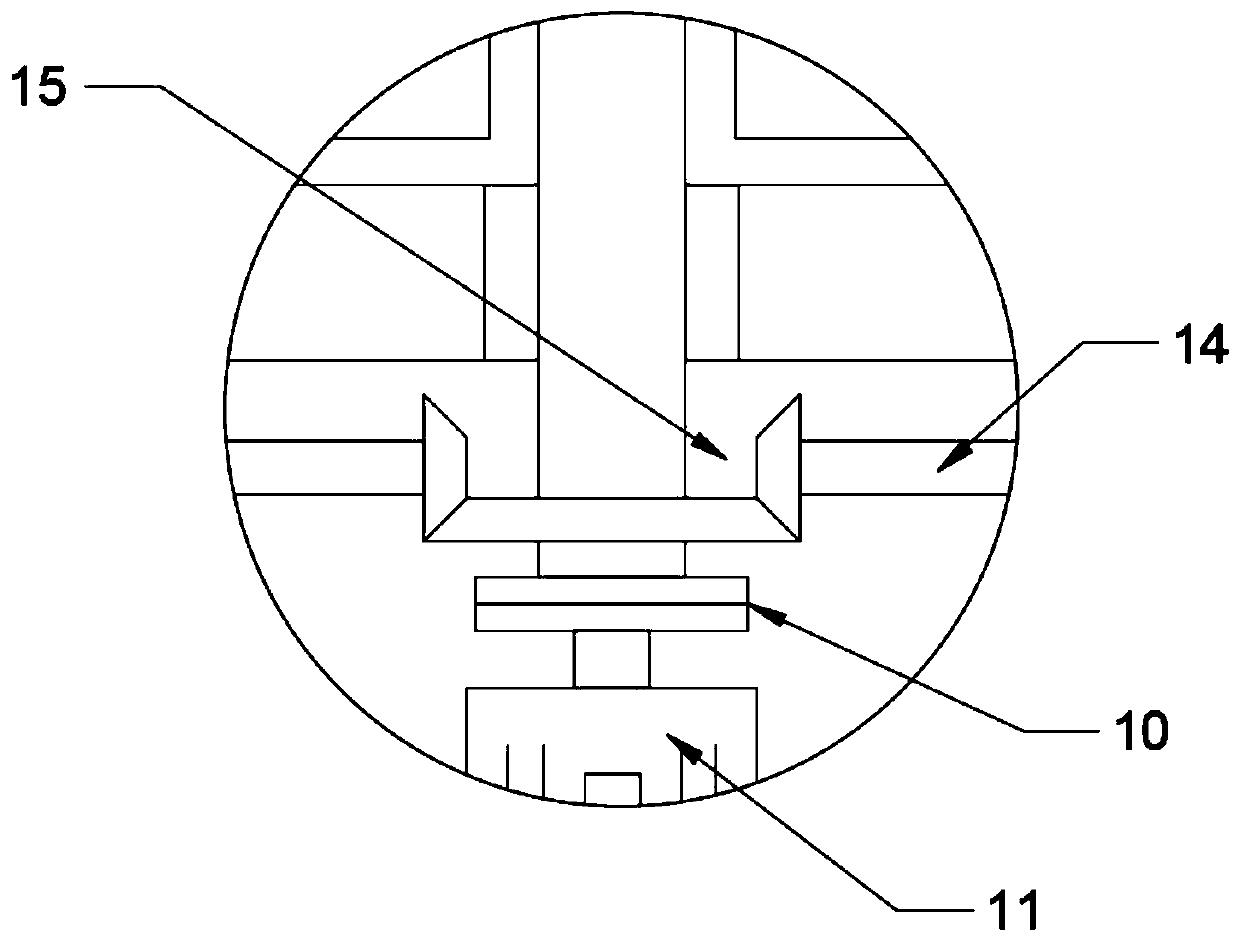

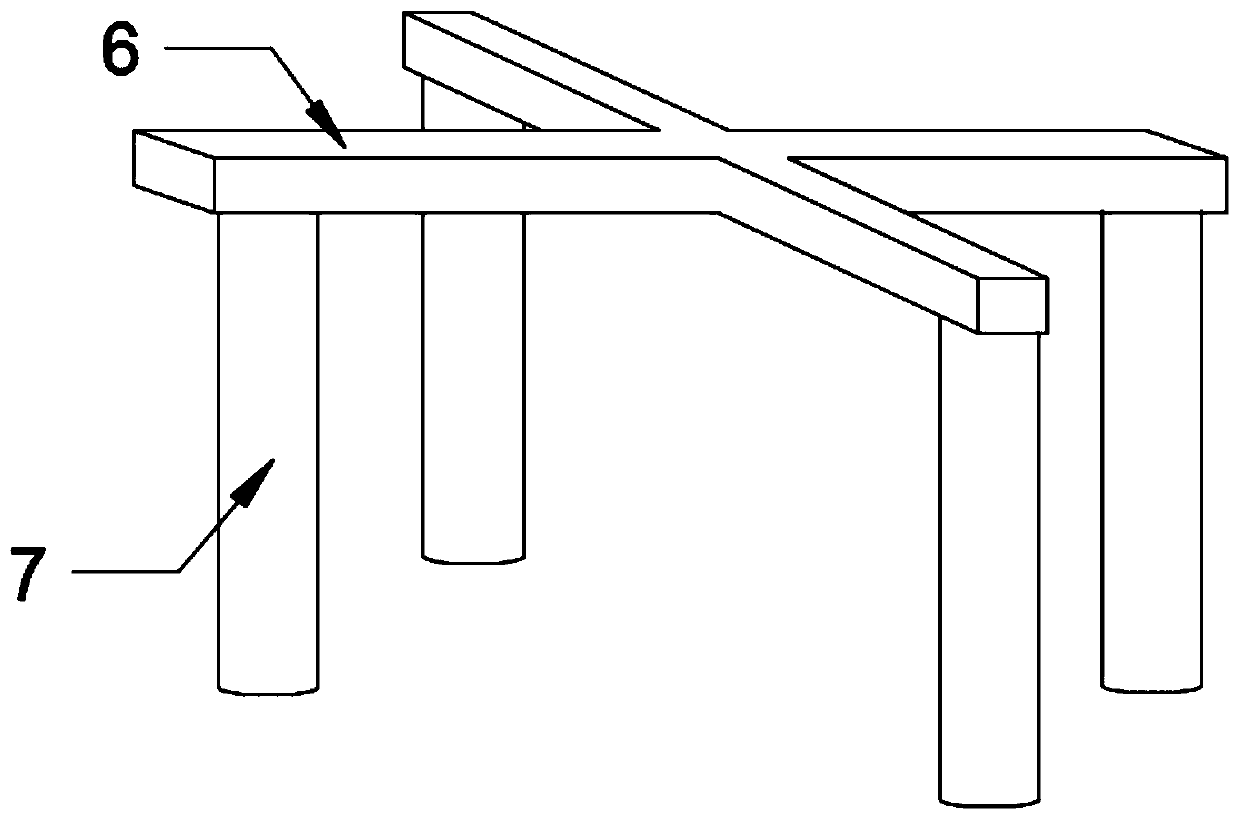

[0024] The difference between this embodiment and Embodiment 1 is that the stirring mechanism includes a turret 6, the turret 6 is cross-shaped, the outer end of the turret 6 is fixedly connected with a suspension shaft 7, and the suspension shaft 7 is fixedly connected with a stirring plate 8, The stirring range is covered comprehensively, and the stirring effect is ensured; the central position of the turret 6 is fixedly connected with the stirring shaft 9, and the stirring shaft 9 extends to the bottom of the stirring tank 1 and is connected with the output shaft of the stirring motor 11 through the coupling 10, thereby driving The stirring plate 8 rotates to realize stirring.

[0025] In order to realize the rotary feeding of the screw feed roller 3, the end of the screw feed roller 3 is connected with a transmission shaft 14 through a transmission belt 13, and the transmission shaft 14 is connected with a stirring shaft through a transmission gear set 15, and the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com