Paint feeder

A feeder and paint technology, which is applied in the field of furniture production, can solve the problems of affecting construction efficiency, increasing mixing time, and paint accumulation, and achieves the effects of easy paint circulation, easy mixing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

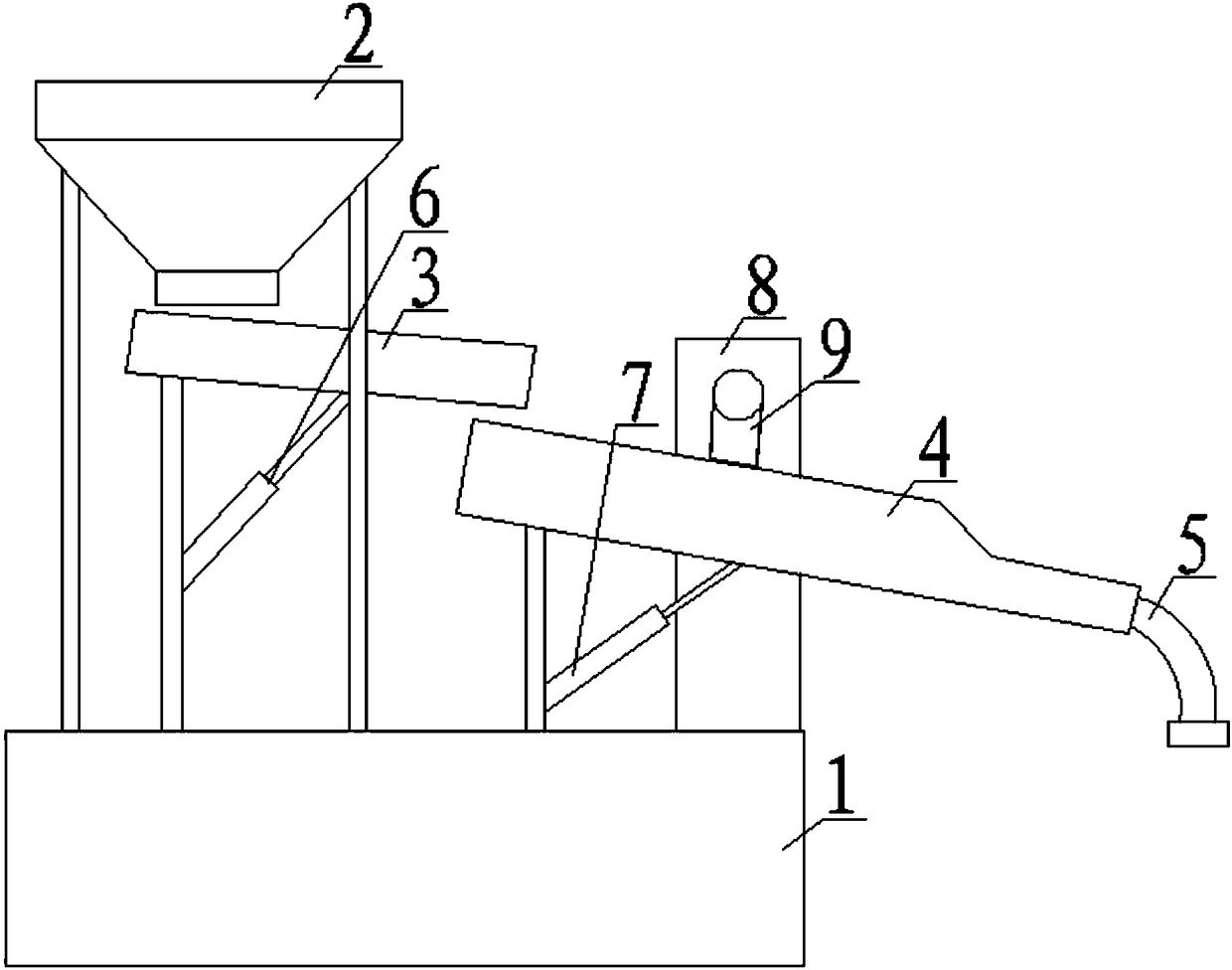

[0016] Such as figure 1 As shown, the paint feeder includes a support platform 1, a tapered feed trough 2, a first open trough 3, a second open trough 4, a first telescopic support 6, a second telescopic support 7, a support frame 8 and a scraper Broom 9, wherein, the support platform 1 is provided with a plurality of uprights supporting the conical feeding trough 2. The first open groove 3 and the second open groove 4 are all left high and right low and inclined to set and the right ends of both are all open. The lower end of the center is facing the first opening groove 3 groove body. The left end of the second open slot 4 is located below the first open slot 3 , and the right end of the first open slot 3 is located directly above the body of the second open slot 4 . The first telescopic bracket 6 and the second telescopic bracket 7 all include a support column, a positioning cylinder, a support rod and an elastic member. The support column is vertically arranged and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com