A compound type near-infrared light photocatalyst and its preparation method and application

A near-infrared light and photocatalyst technology is applied in the field of photocatalytic degradation of pollutants, which can solve the problems of low efficiency of organic pollutants, and achieve the effects of simple preparation method, promotion of carrier separation, and improvement of efficiency and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 20mg CeF 3 -O and 0.85 mg AgNO 3 Mix evenly to obtain a compound near-infrared photocatalyst, and store it away from light for future use.

[0033] Dissolve the prepared compound near-infrared photocatalyst in 50ml of tetracycline hydrochloride (20mg / L) solution by ultrasonic dispersion, react in dark for 30min, and then illuminate under 300w xenon lamp (filter: λ>680nm) , Sampling and testing every 30 minutes.

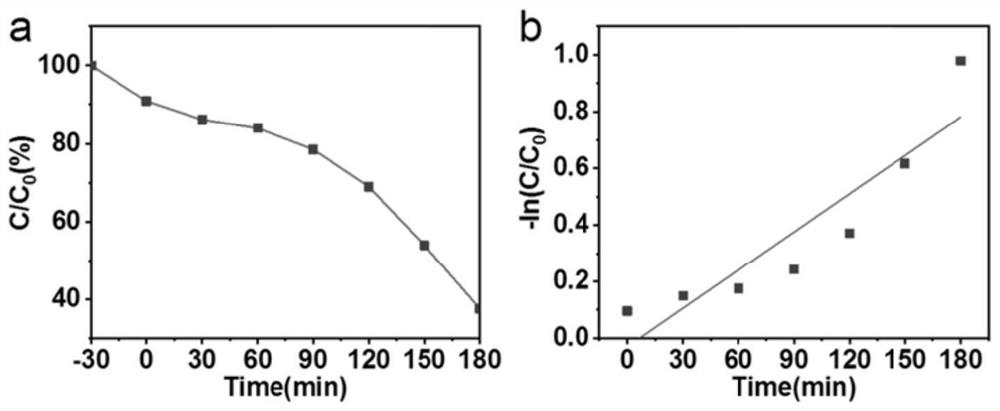

[0034] It was found that, if figure 1 Shown are the degradation efficiency (a) and rate (b) curves of the composite near-infrared photocatalyst under near-infrared light for the degradation of tetracycline hydrochloride. It can be seen from the figure that the compound near-infrared photocatalyst has a degradation efficiency of 73.1% for tetracycline hydrochloride within 180 min, and the kinetic reaction rate k of the first order reaction is 4.5×10 -3 min -1 .

Embodiment 2

[0036] 20mg CeF 3 -O and 0.5mg EDTA-2Na are evenly mixed to obtain a compound near-infrared photocatalyst, which can be stored in the dark for future use.

[0037] Dissolve the prepared compound near-infrared photocatalyst in 50ml of tetracycline hydrochloride (20mg / L) solution by ultrasonic dispersion, react in dark for 30min, and then illuminate under 300w xenon lamp (filter: λ>680nm) , Sampling and testing every 30 minutes.

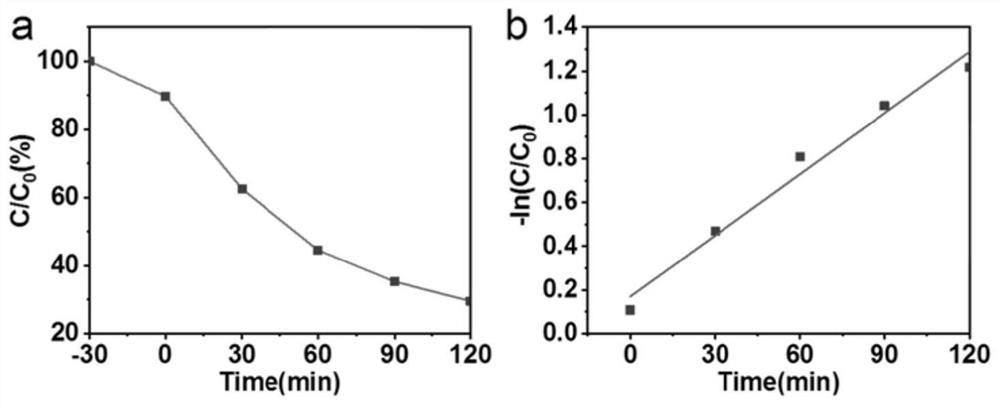

[0038] It was found that, if figure 2 Shown are the degradation efficiency (a) and rate (b) curves of the composite near-infrared photocatalyst under near-infrared light for the degradation of tetracycline hydrochloride. It can be seen from the figure that the compound near-infrared light photocatalyst has a degradation efficiency of 70.4% for tetracycline hydrochloride within 120 min, and the kinetic reaction rate k of the first order reaction is 9.3×10 -3 min -1 .

Embodiment 3

[0040] 20mg CeF 3 -O and 1.02mg AgNO3 Mix evenly to obtain a compound near-infrared photocatalyst, and store it away from light for future use.

[0041] Dissolve the prepared compound near-infrared photocatalyst in 50ml of tetracycline hydrochloride (20mg / L) solution by ultrasonic dispersion, react in dark for 30min, and then illuminate under 300w xenon lamp (filter: λ>680nm) , Sampling and testing every 30 minutes.

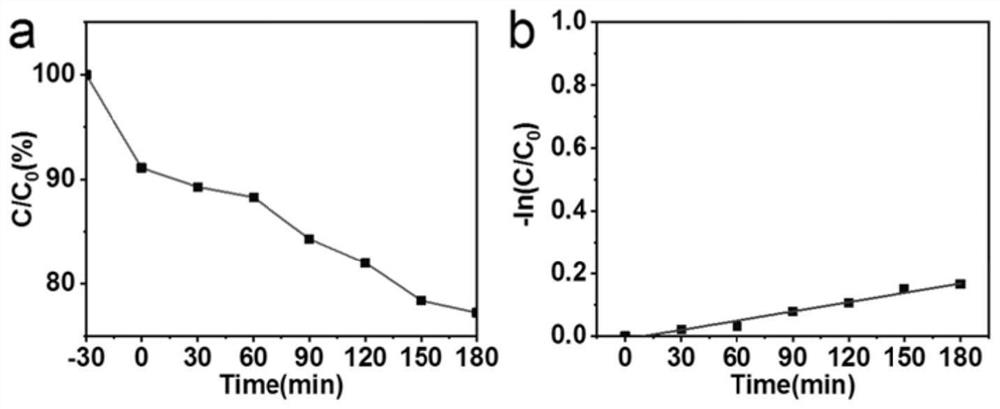

[0042] It was found that the degradation efficiency of the compound near-infrared photocatalyst to tetracycline hydrochloride was 72.8% within 180 min, and the reaction rate k of the first-order reaction kinetics was 4.5×10 -3 min -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com