EPDM (Ethylene-Propylene-Diene Monomer) for sealing ring and vulcanization method thereof

A technology of EPDM rubber and sealing ring, applied in the rubber field, can solve the problems such as troublesome trimming of sealing ring products, poor production process, product appearance defects, etc., to ensure compression deformation performance, low compression set Difficulty tearing the edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

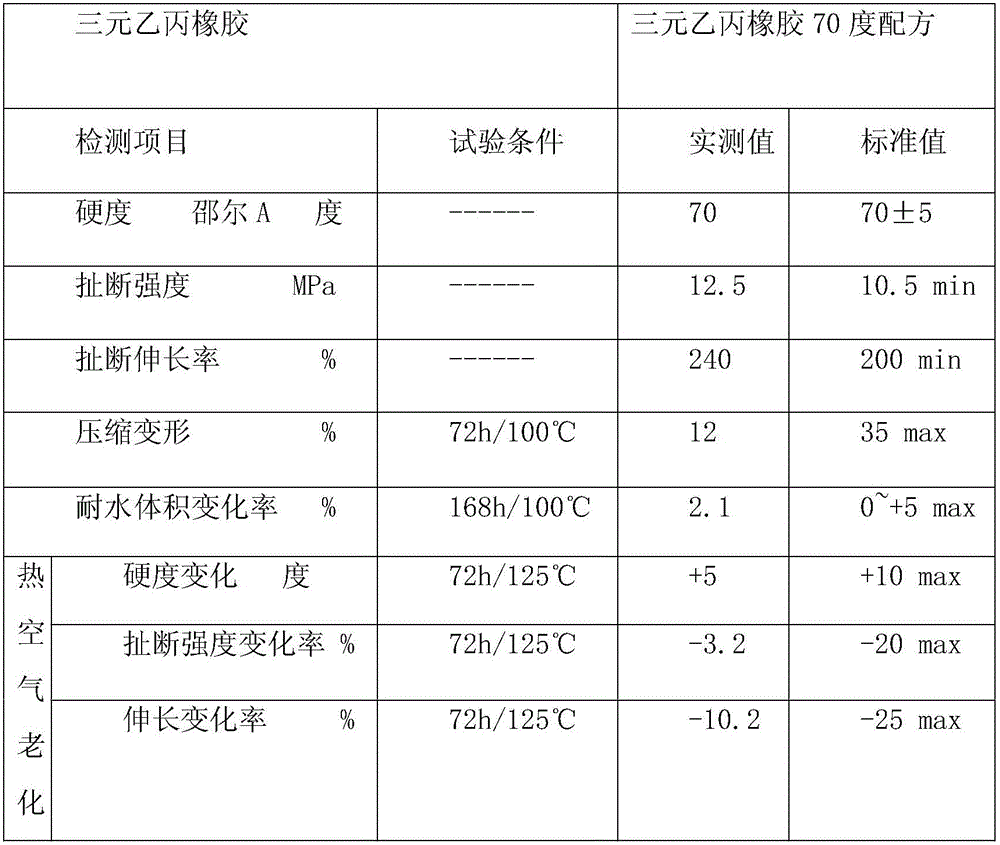

Image

Examples

Embodiment 1

[0017] An EPDM rubber for sealing rings, comprising the following components: non-oil-extended ethylene-propylene rubber, oil-extended ethylene-propylene rubber, ZnO, anti-aging agent, general-purpose carbon black, sulfur, odorless DCP, and crosslinking agent TAIC. Sulfur and peroxides are used in conjunction with a vulcanization system. The peroxide vulcanizing agent adopts dicumyl peroxide. The sealing ring is made of EPDM rubber by mixing method. The compression deformation rate of the rubber is less than 15%. The parts by weight of each component are: 50 parts of non-oil-extended ethylene-propylene rubber raw rubber; 50 parts of oil-extended ethylene-propylene rubber raw rubber (according to the oil-extending amount); 5 parts of ZnO; 1 part of anti-aging agent; 60 parts of general-purpose carbon black ( According to hardness); 0.5 parts of sulfur, 2.5 parts of odorless DCP; 0.5 parts of crosslinking agent TAIC.

Embodiment 2

[0019] A kind of EPDM rubber for sealing ring, similar to Example 1, the difference is that the parts by weight of each component are: 60 parts of non-oil-extended ethylene-propylene rubber raw rubber; 80 parts of oil-extended ethylene-propylene rubber raw rubber 5 parts of ZnO; 2 parts of anti-aging agent; 80 parts of universal carbon black (according to hardness); 1.5 parts of sulfur, 3.5 parts of odorless DCP; 1 part of crosslinking agent TAIC.

[0020] Example 2:

[0021] A kind of EPDM rubber for sealing ring, similar to Example 1, the difference is that the parts by weight of each component are: 55 parts of non-oil-extended ethylene-propylene rubber raw rubber; 65 parts of oil-extended ethylene-propylene rubber raw rubber 5 parts of ZnO; 1.5 parts of anti-aging agent; 70 parts of universal carbon black (according to hardness); 1 part of sulfur, 3 parts of odorless DCP; 0.8 parts of crosslinking agent TAIC.

Embodiment 4

[0023] A vulcanization method of EPDM rubber for sealing rings, comprising the following steps: the first step, cleaning the mold, placing the rubber blank, and closing the mold; the second step, entering the vulcanization equipment after the mold is closed, and the vulcanization equipment enters the mold, The time before pressing up is set between 5s; the third step is to press up when the mold is about to bear pressure after rising, and rise to the pressure peak within 2s; the fourth step is to unload the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com