Carrier chemical modification treatment equipment for producing catalyst based on impregnation method

A technology for chemical modification and processing equipment, applied in chemical/physical processes, chemical instruments and methods, mixers, etc., can solve problems such as the impact of chemical modification, insufficient mixing of compounds and liquids, etc., and achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

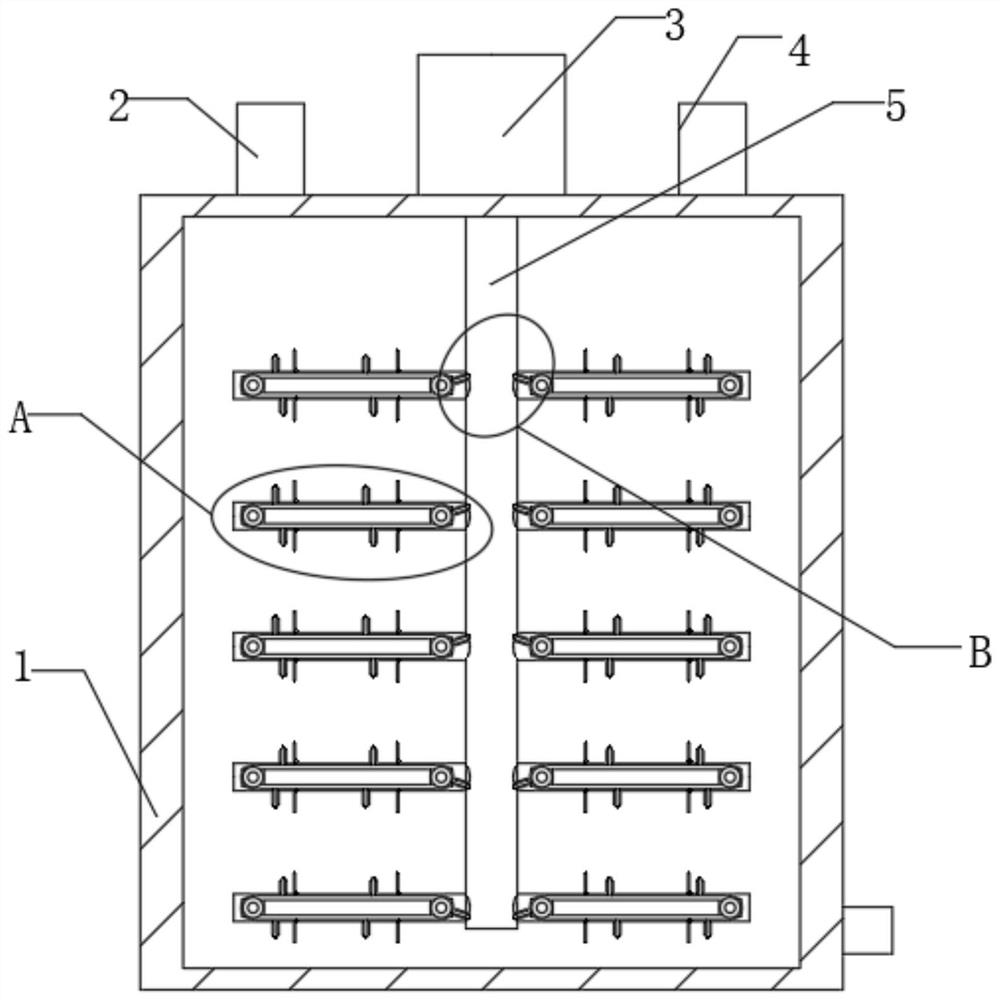

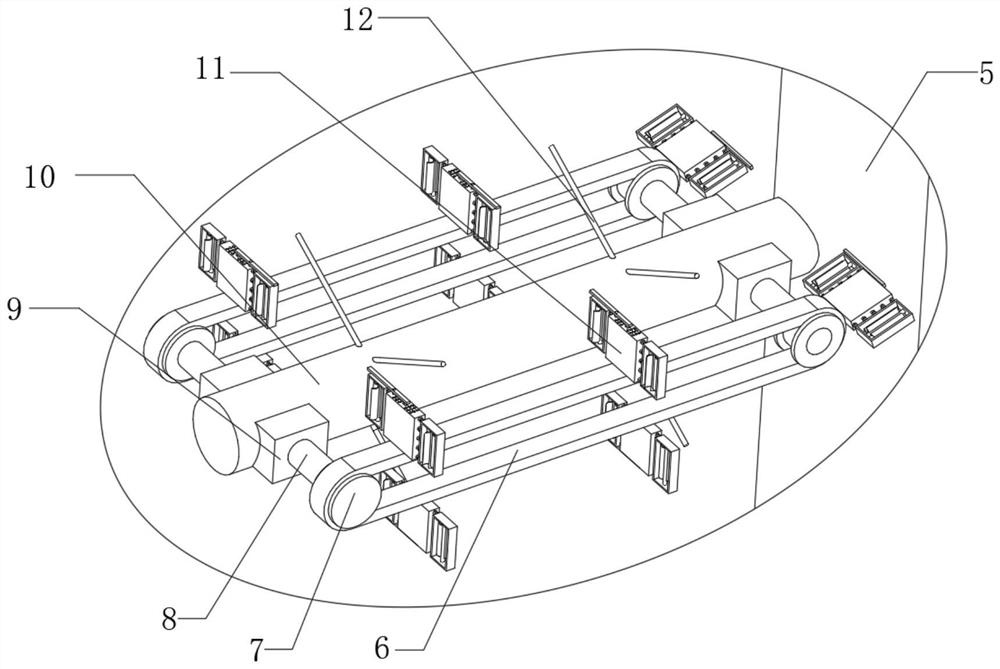

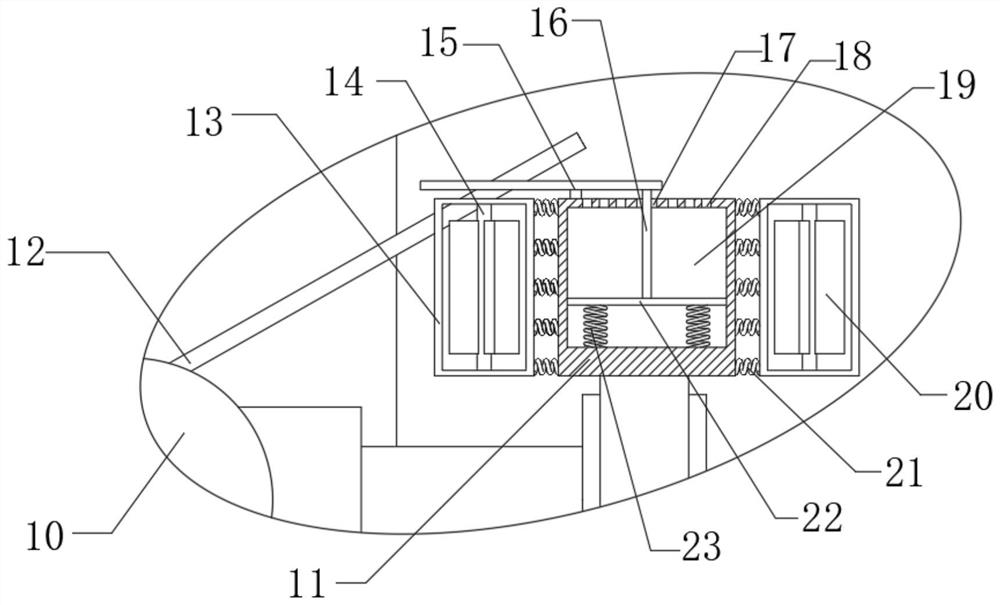

[0031] refer to Figure 1-Figure 5, a kind of carrier chemical modification treatment equipment based on the impregnation method to produce catalyst, including mixing box 1, the top of the mixing box 1 is rotatably connected with a rotating shaft 5, and the outer wall of the top of the rotating shaft 5 is provided with a stirring motor 3, and the two sides of the stirring motor 3 are provided with There are a liquid inlet 2 and a feeding port 4, a plurality of stirring shafts 10 are fixedly connected to the outer wall of the rotating shaft 5, and a secondary shaft 24 is rotatably connected at the connection between the stirring shaft 10 and the rotating shaft 5, and a mounting plate is fixedly connected inside the rotating shaft 5 26, and the outer wall of the mounting plate 26 is rotatably connected with the main shaft 29, the top outer wall of the main shaft 29 is provided with a rotating motor 25, and the outer wall of the main shaft 29 is fixedly connected with a plurality ...

Embodiment 2

[0037] refer to Figure 1-Figure 7 , a kind of carrier chemical modification treatment equipment based on the impregnation method to produce catalyst, including mixing box 1, the top of the mixing box 1 is rotatably connected with a rotating shaft 5, and the outer wall of the top of the rotating shaft 5 is provided with a stirring motor 3, and the two sides of the stirring motor 3 are provided with There are a liquid inlet 2 and a feeding port 4, a plurality of stirring shafts 10 are fixedly connected to the outer wall of the rotating shaft 5, and a secondary shaft 24 is rotatably connected at the connection between the stirring shaft 10 and the rotating shaft 5, and a mounting plate is fixedly connected inside the rotating shaft 5 26, and the outer wall of the mounting plate 26 is rotatably connected with the main shaft 29, the top outer wall of the main shaft 29 is provided with a rotating motor 25, and the outer wall of the main shaft 29 is fixedly connected with a plurality...

Embodiment 3

[0045] refer to Figure 1-Figure 9 , a kind of carrier chemical modification treatment equipment based on the impregnation method to produce catalyst, including mixing box 1, the top of the mixing box 1 is rotatably connected with a rotating shaft 5, and the outer wall of the top of the rotating shaft 5 is provided with a stirring motor 3, and the two sides of the stirring motor 3 are provided with There are a liquid inlet 2 and a feeding port 4, a plurality of stirring shafts 10 are fixedly connected to the outer wall of the rotating shaft 5, and a secondary shaft 24 is rotatably connected at the connection between the stirring shaft 10 and the rotating shaft 5, and a mounting plate is fixedly connected inside the rotating shaft 5 26, and the outer wall of the mounting plate 26 is rotatably connected with the main shaft 29, the top outer wall of the main shaft 29 is provided with a rotating motor 25, and the outer wall of the main shaft 29 is fixedly connected with a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com