Gypsum raw material mixing apparatus used for medical orthopaedics

A technology of mixing equipment and gypsum, which is applied in the direction of mixers, mixing methods, and pretreatment of mixed materials, etc. It can solve the problems of slow speed, uneven and sufficient mixing, and inability to screen the size of gypsum raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

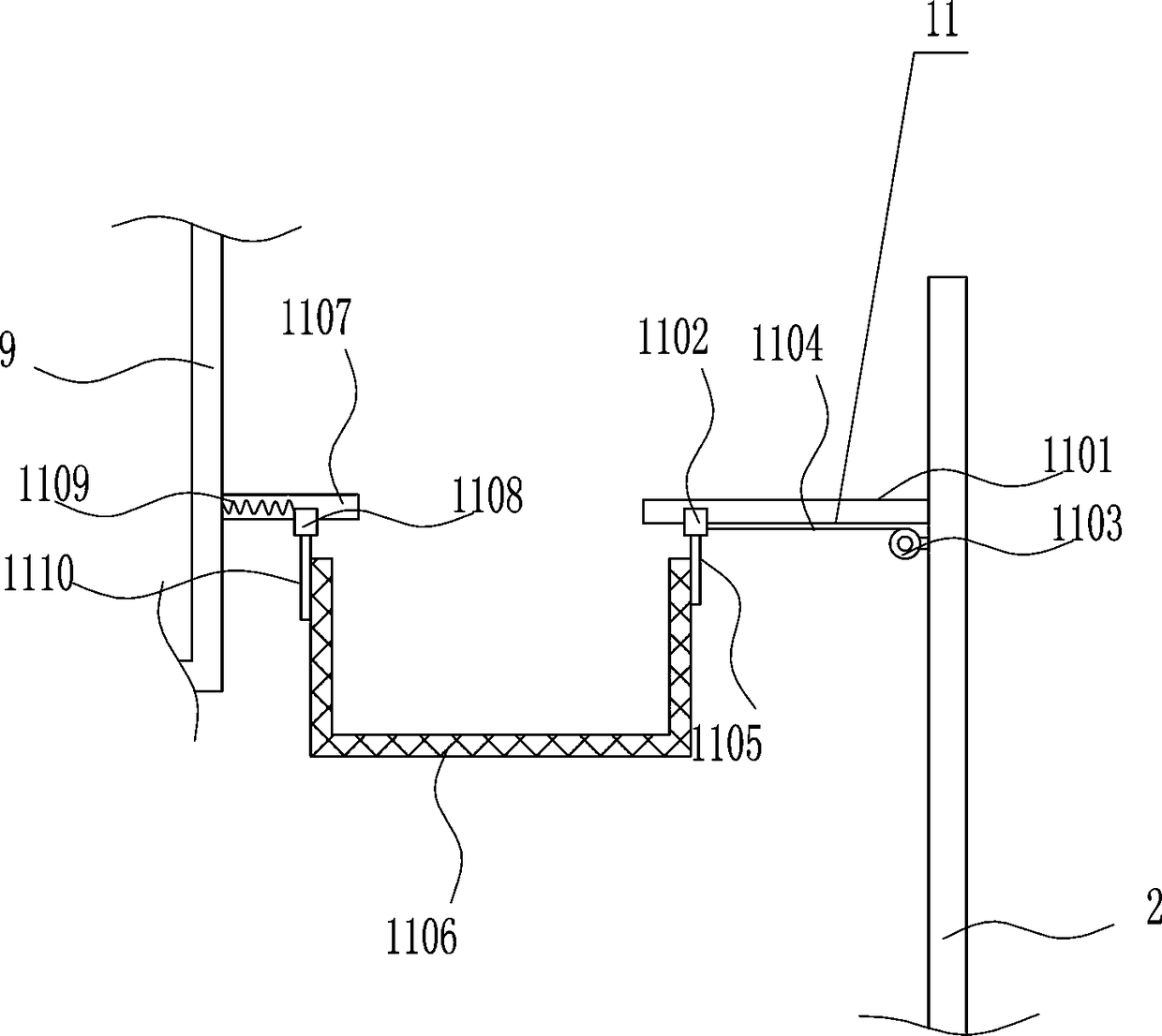

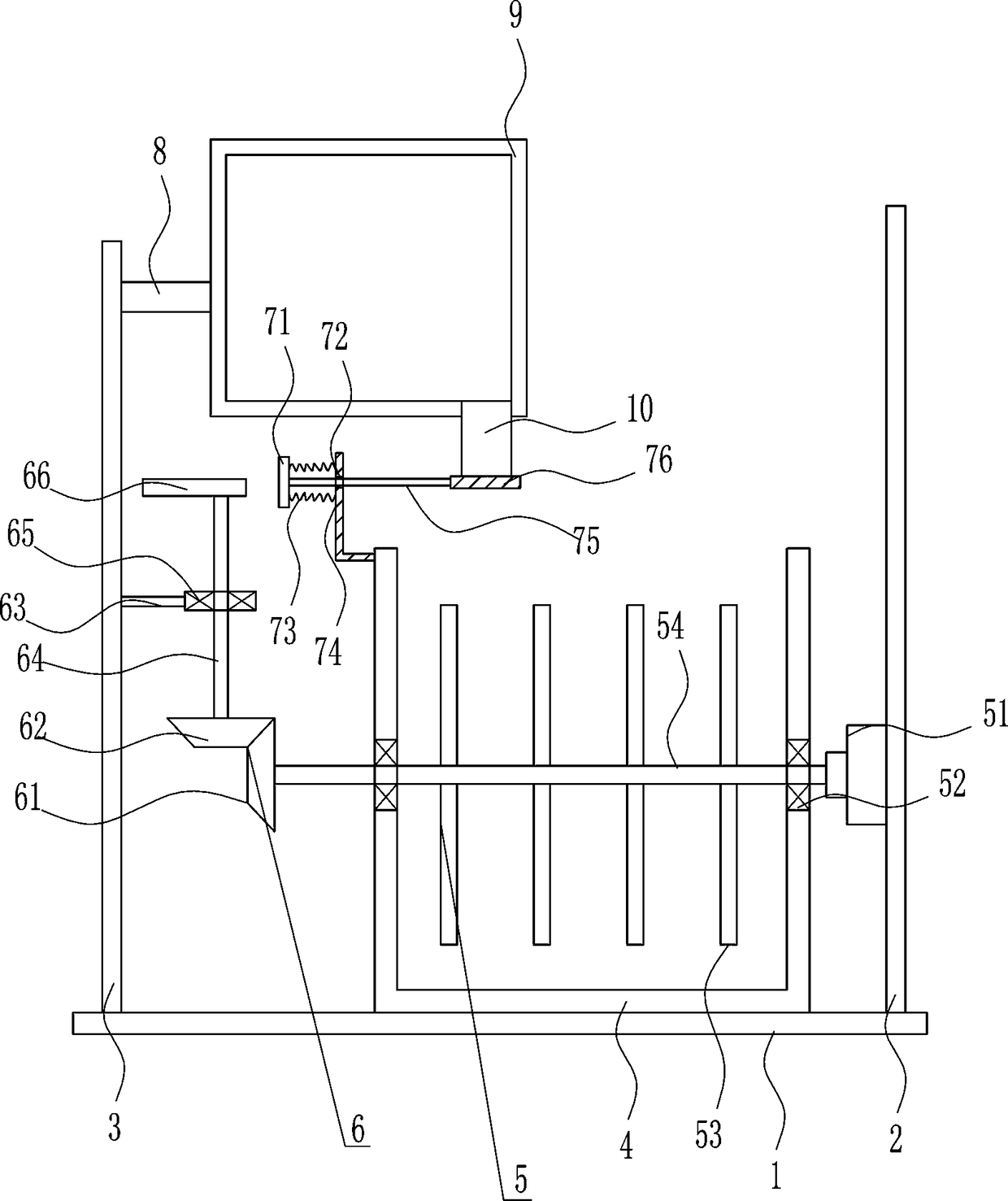

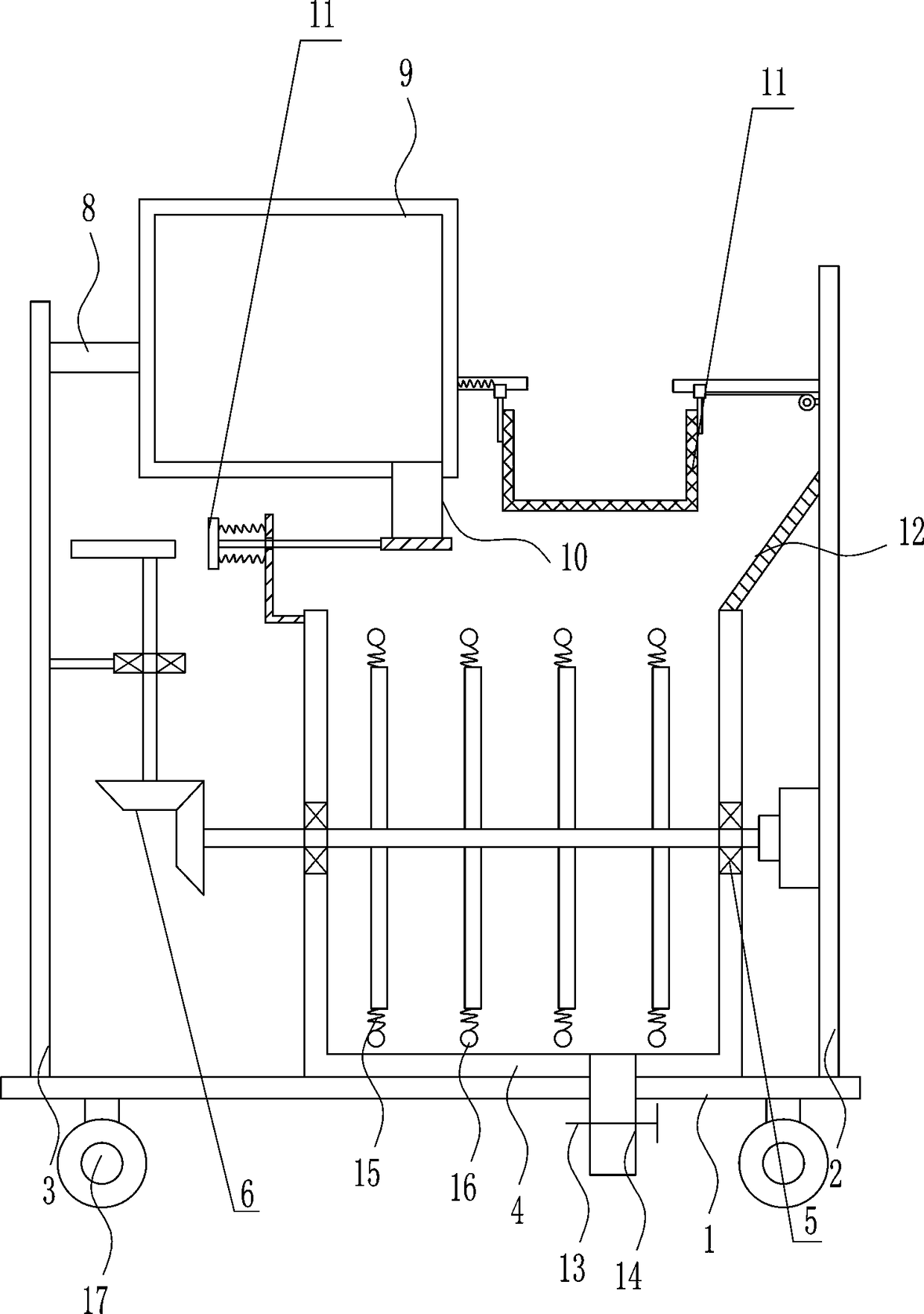

[0034] A kind of gypsum raw material mixing equipment for medical orthopedics, such as Figure 1-3 As shown, it includes a bottom plate 1, a right support plate 2, a left support plate 3, a stirring box 4, a stirring mechanism 5, a transmission mechanism 6, a feeding mechanism 7, a second pole 8 and a water tank 9, and the left side of the top of the bottom plate 1 A left support plate 3 is provided, a right support plate 2 is provided on the right side of the top of the bottom plate 1, a stirring box 4 is provided in the middle of the top of the bottom plate 1, a stirring mechanism 5 is provided on the left side of the right support plate 2, and a left support plate 3 A transmission mechanism 6 is provided on the right side of the left support plate 3, a second pole 8 is provided above the right side of the left support plate 3, a water tank 9 is provided at the right end of the second pole 8, and a first outlet is provided at the bottom of the water tank 9. Feeding pipe 10, ...

Embodiment 2

[0036] A kind of gypsum raw material mixing equipment for medical orthopedics, such as Figure 1-3 As shown, it includes a bottom plate 1, a right support plate 2, a left support plate 3, a stirring box 4, a stirring mechanism 5, a transmission mechanism 6, a feeding mechanism 7, a second pole 8 and a water tank 9, and the left side of the top of the bottom plate 1 A left support plate 3 is provided, a right support plate 2 is provided on the right side of the top of the bottom plate 1, a stirring box 4 is provided in the middle of the top of the bottom plate 1, a stirring mechanism 5 is provided on the left side of the right support plate 2, and a left support plate 3 A transmission mechanism 6 is provided on the right side of the left support plate 3, a second pole 8 is provided above the right side of the left support plate 3, a water tank 9 is provided at the right end of the second pole 8, and a first outlet is provided at the bottom of the water tank 9. Feeding pipe 10, ...

Embodiment 3

[0039] A kind of gypsum raw material mixing equipment for medical orthopedics, such as Figure 1-3 As shown, it includes a bottom plate 1, a right support plate 2, a left support plate 3, a stirring box 4, a stirring mechanism 5, a transmission mechanism 6, a feeding mechanism 7, a second pole 8 and a water tank 9, and the left side of the top of the bottom plate 1 A left support plate 3 is provided, a right support plate 2 is provided on the right side of the top of the bottom plate 1, a stirring box 4 is provided in the middle of the top of the bottom plate 1, a stirring mechanism 5 is provided on the left side of the right support plate 2, and a left support plate 3 A transmission mechanism 6 is provided on the right side of the left support plate 3, a second pole 8 is provided above the right side of the left support plate 3, a water tank 9 is provided at the right end of the second pole 8, and a first outlet is provided at the bottom of the water tank 9. Feeding pipe 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com