Patents

Literature

122results about How to "Not easy to knot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromagnetic automatic line throwing appliance for recycling underwater robot

ActiveCN105644739AStrong and stable suctionEasy to operateVessel salvagingControl systemMarine engineering

The invention relates to the field of underwater robots, in particular to an electromagnetic automatic line throwing appliance for recycling an underwater robot. The electromagnetic automatic line throwing appliance for recycling the underwater robot comprises an electromagnet, a spring clamping ring, a cable, an end cover, a buoyancy block, a launching tube, a bottom steel plate, a spring and a base, wherein the base is fixedly mounted on an underwater robot main body; the launching tube is fixedly mounted on a flange of the base; the electromagnet is arranged in the launching tube and controlled by a control system of the underwater robot main body to be powered on and off; the electromagnet is filled with oil to balance external pressure; the bottom steel plate is arranged in the launching tube and adsorbed by the electromagnet; the spring sleeves the electromagnet; the spring pushes the bottom steel plate and each part above the bottom steel plate out of the launching tube through the spring clamping ring; the cable and the buoyancy block are arranged in the launching tube, within a space between the end cover and the bottom steel plate; one end of the cable is fixedly connected with the bottom steel plate; and the other end of the cable is connected with the underwater robot main body after being led out from the launching tube. The electromagnetic automatic line throwing appliance has the advantages of convenient operation, small size and low cost and can bear deep sea water pressure for a long time.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

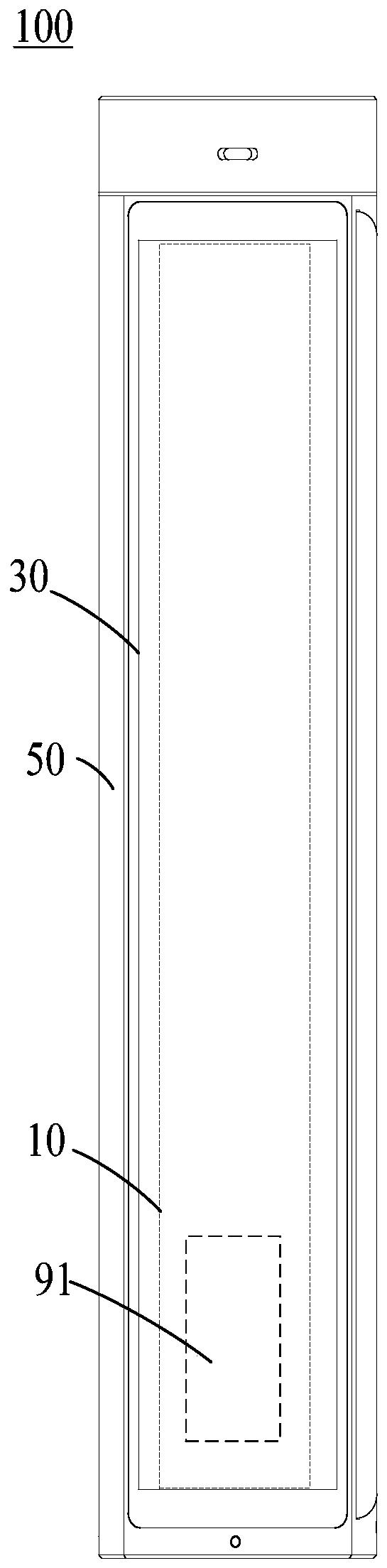

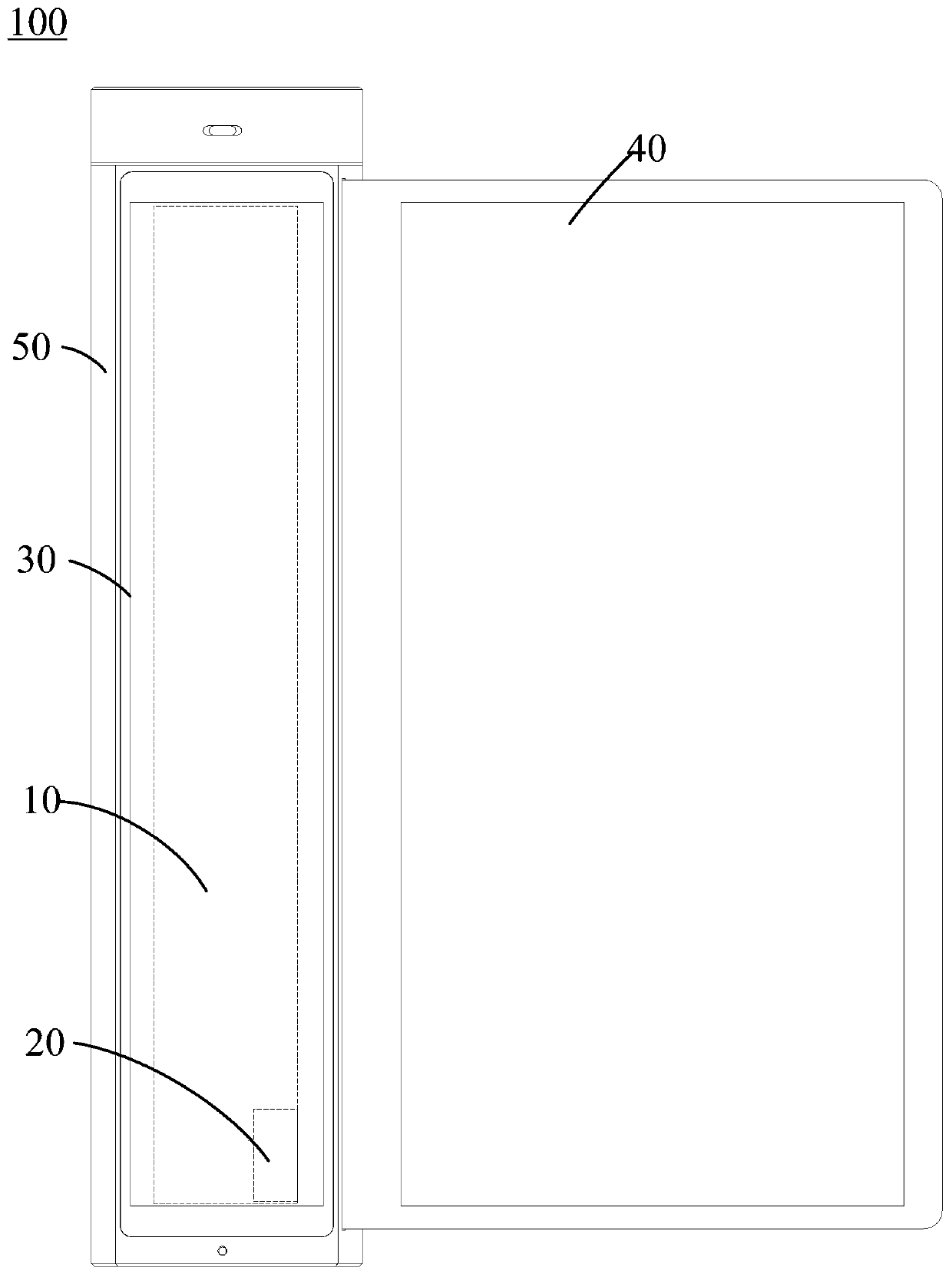

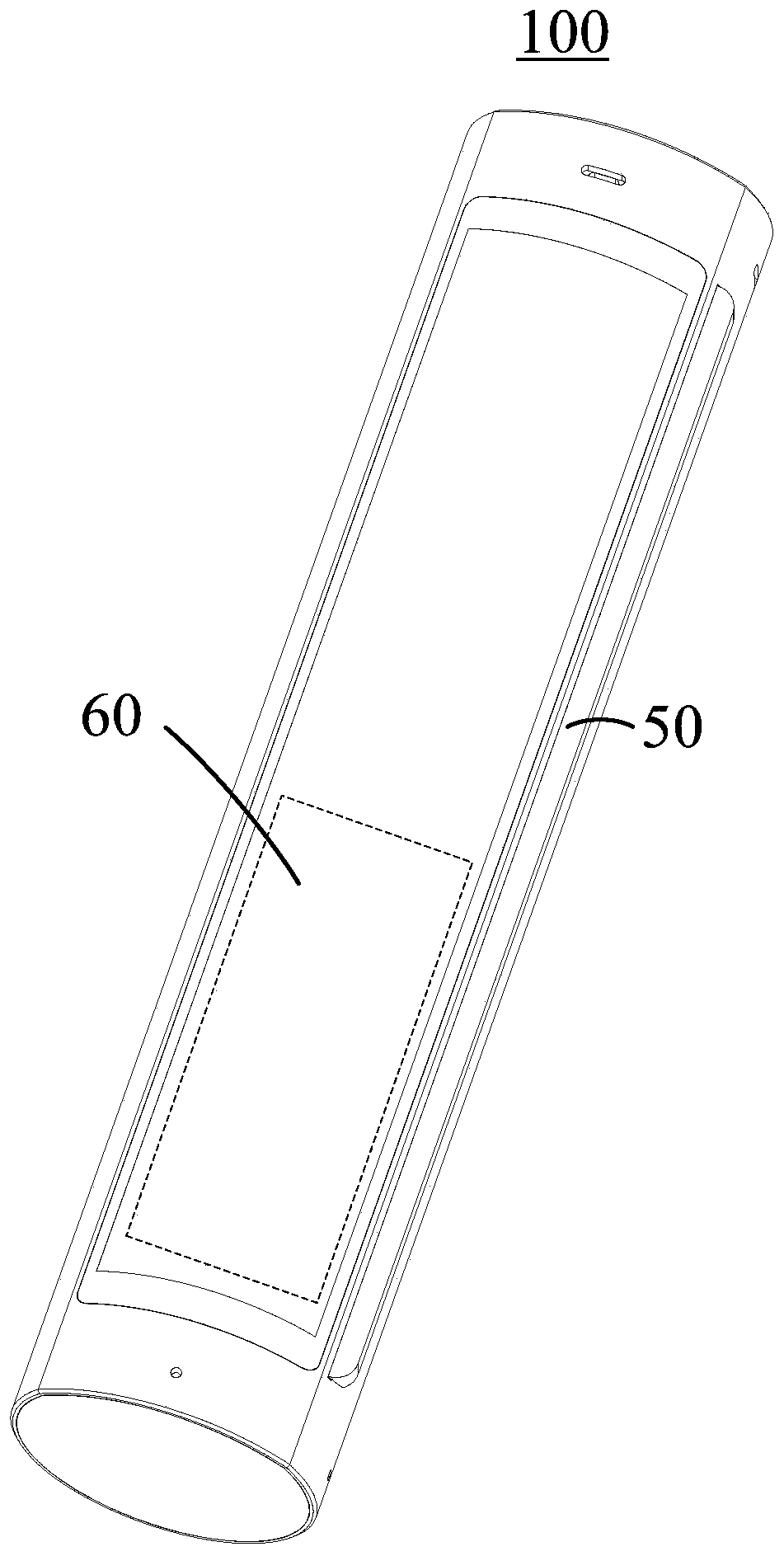

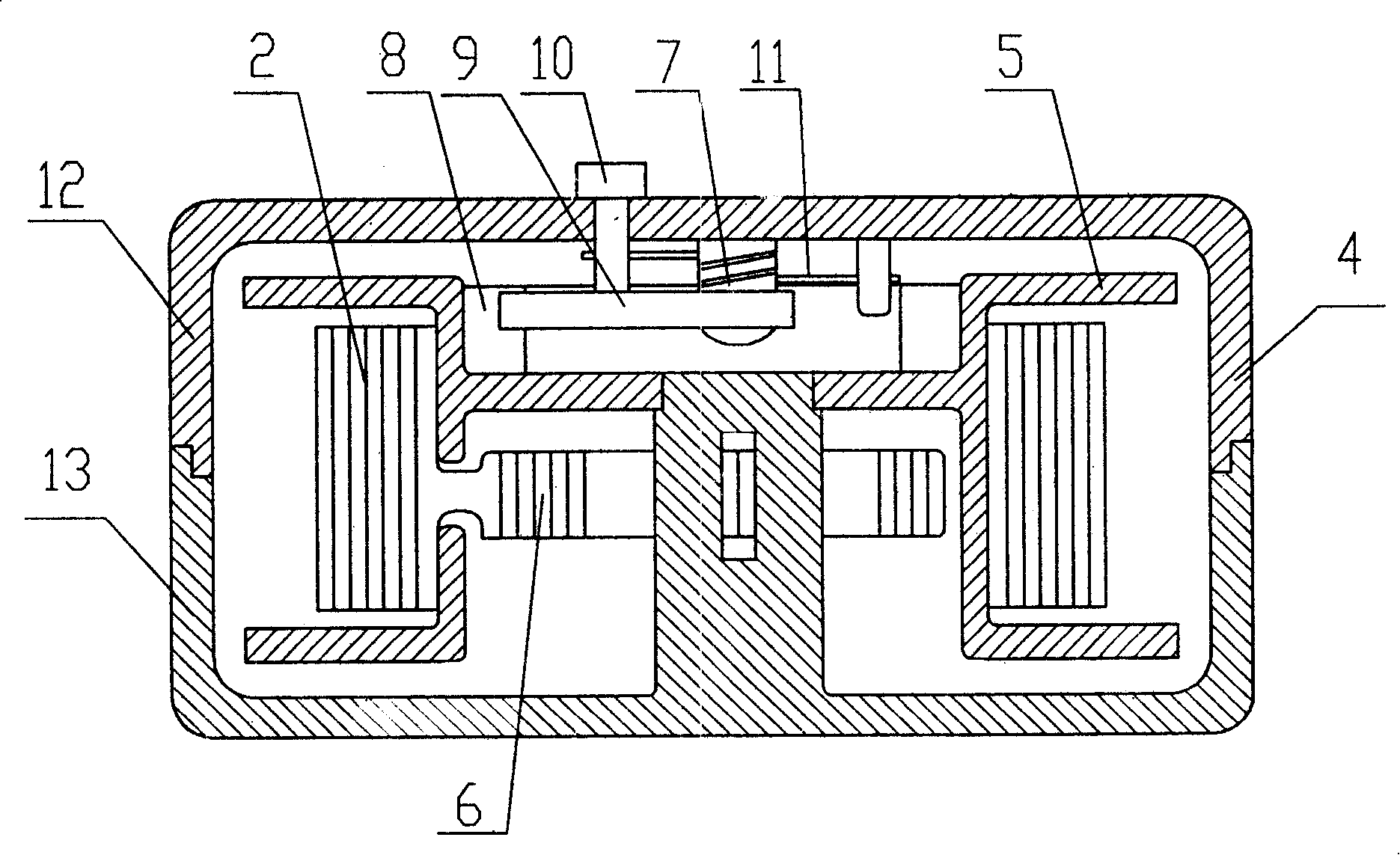

Electronic equipment

ActiveCN111385393AIncrease diversityNot easy to knotDigital data processing detailsTelephone set constructionsFlexible circuitsEngineering

The embodiment of the invention provides electronic equipment. The electronic equipment comprises a main body, a gear set, a flexible display screen and a flexible circuit board, wherein the main bodyis columnar; a groove is formed in the outer periphery of the main body; a rotating part is arranged on the outer side of the main body in a sleeving manner; one side of the flexible display screen is connected with the rotating part; the rotating part can drive the flexible display screen to be wound or unfolded relative to the rotating par; the flexible circuit board is connected with the flexible display screen; when the flexible display screen is unfolded, the flexible circuit board is unfolded along with the flexible display screen, and when the flexible display screen is wound, the flexible circuit board is wound into the groove along with the flexible display screen. According to the electronic equipment, the display area of the flexible display screen can be changed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

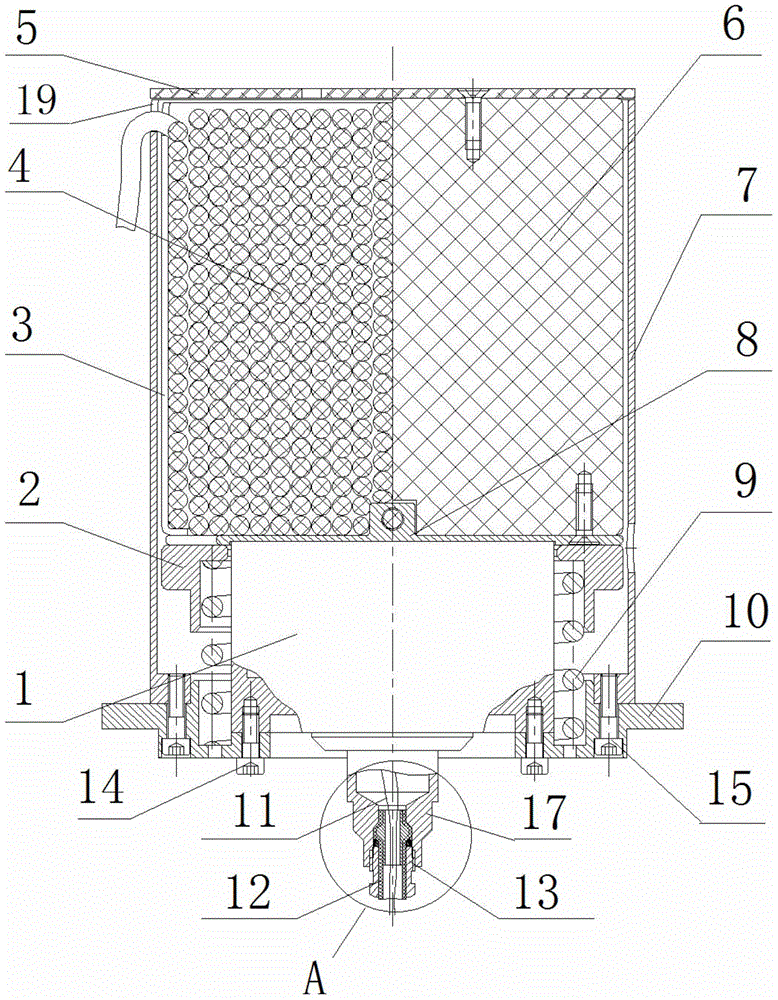

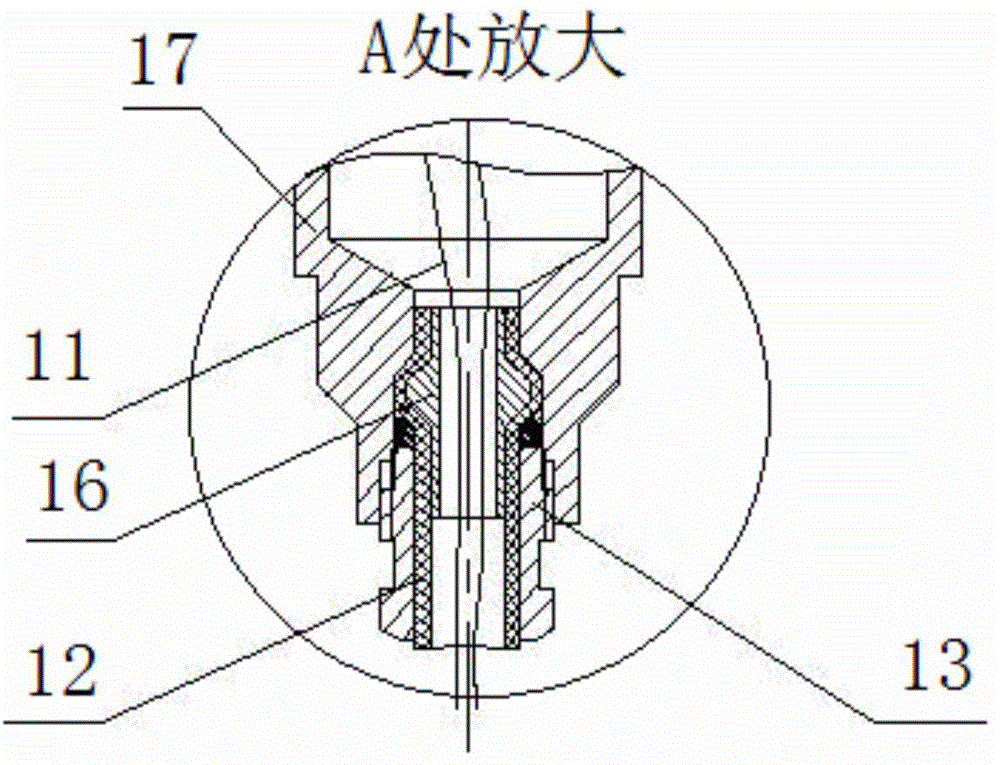

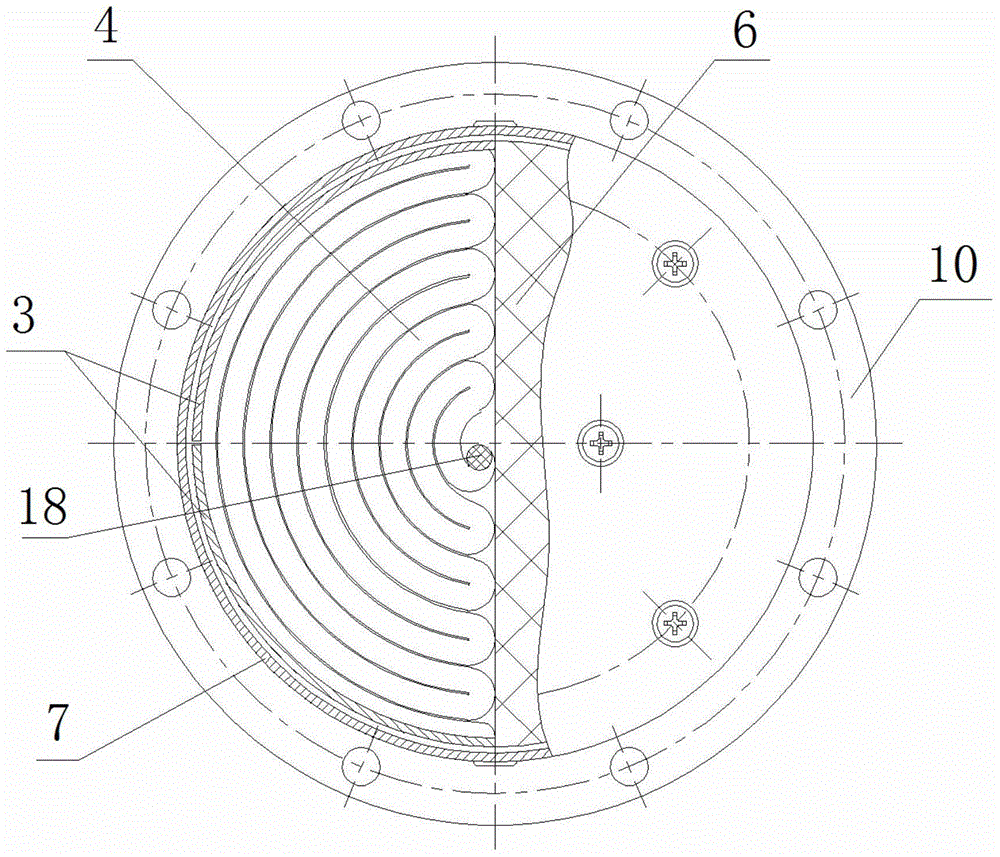

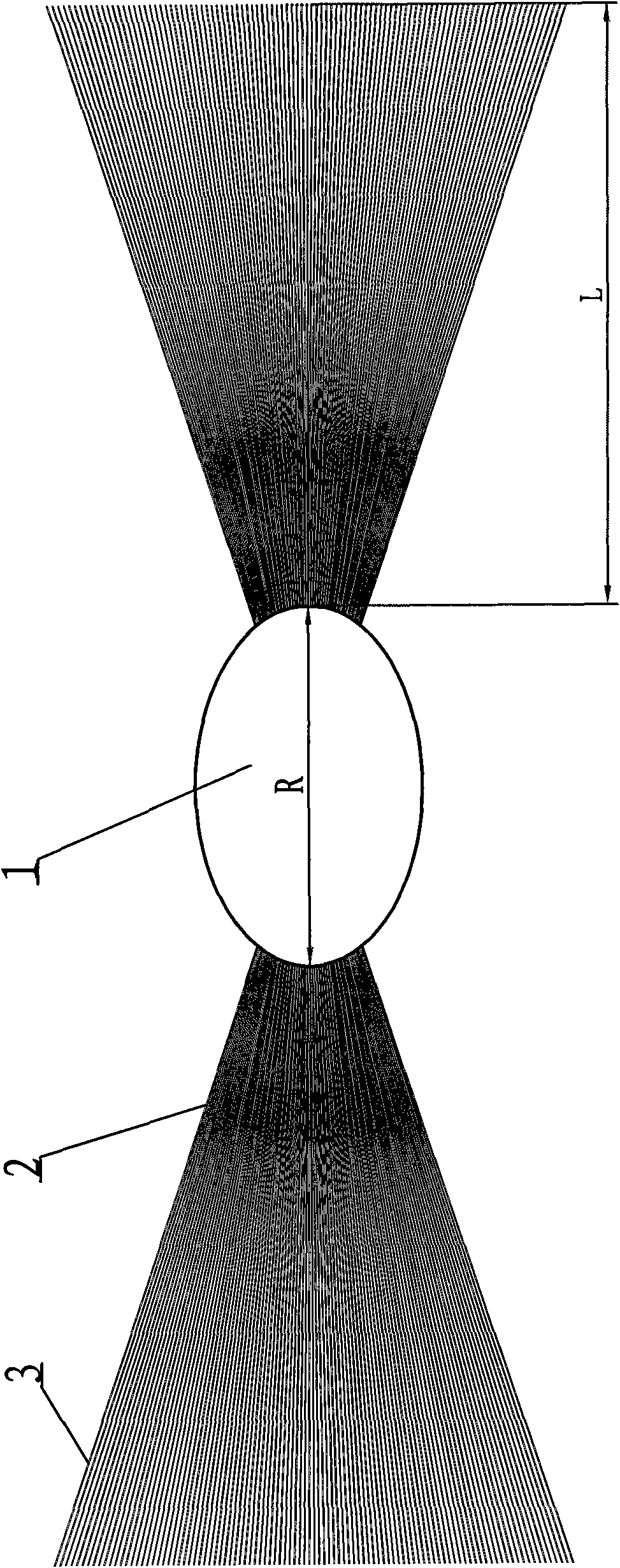

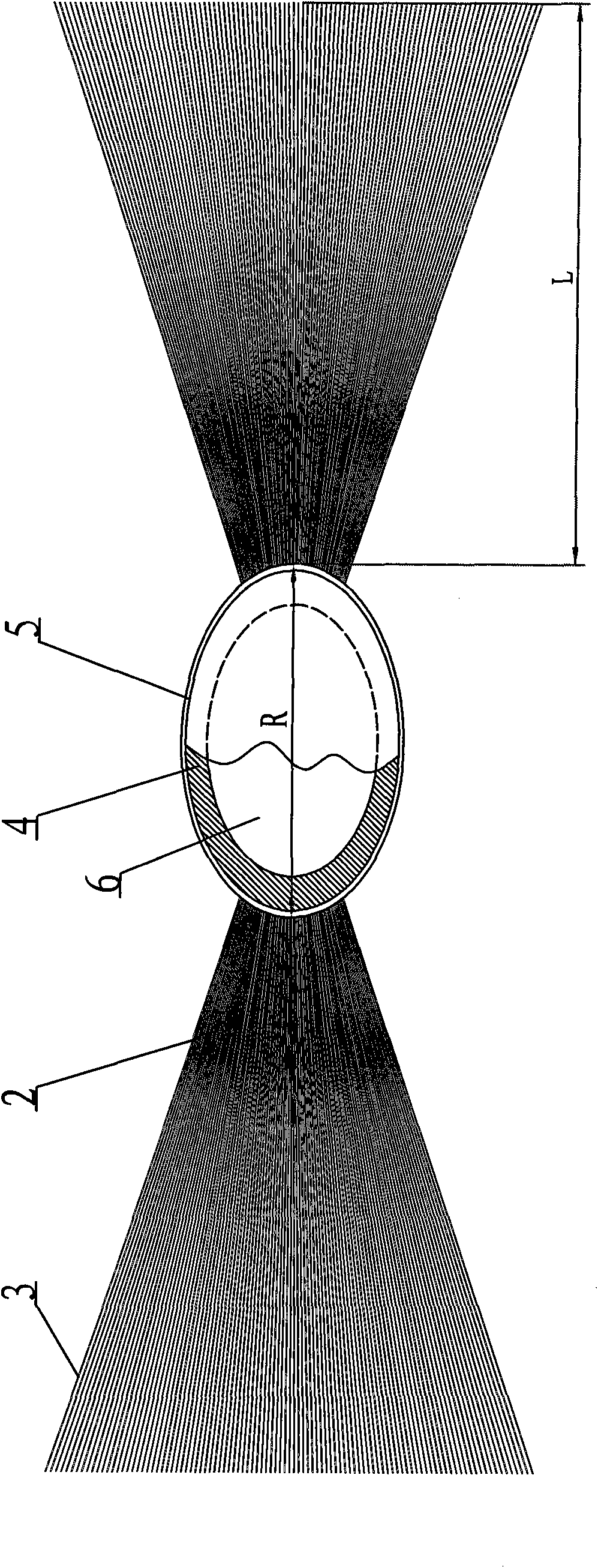

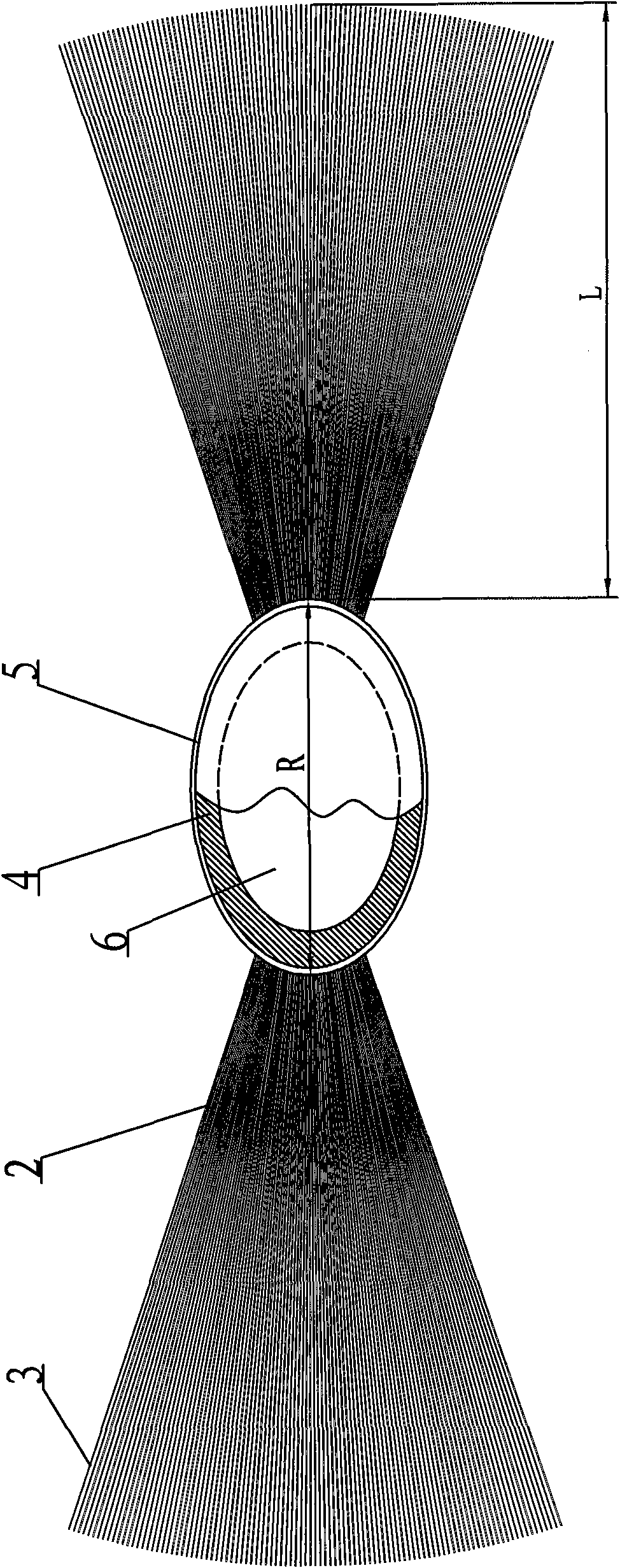

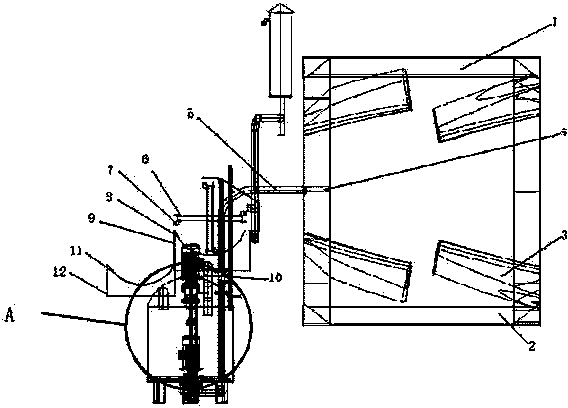

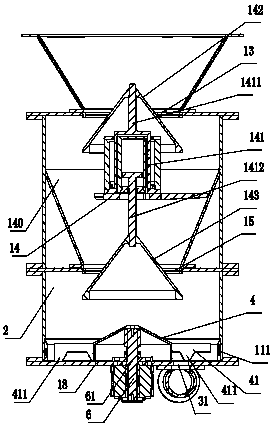

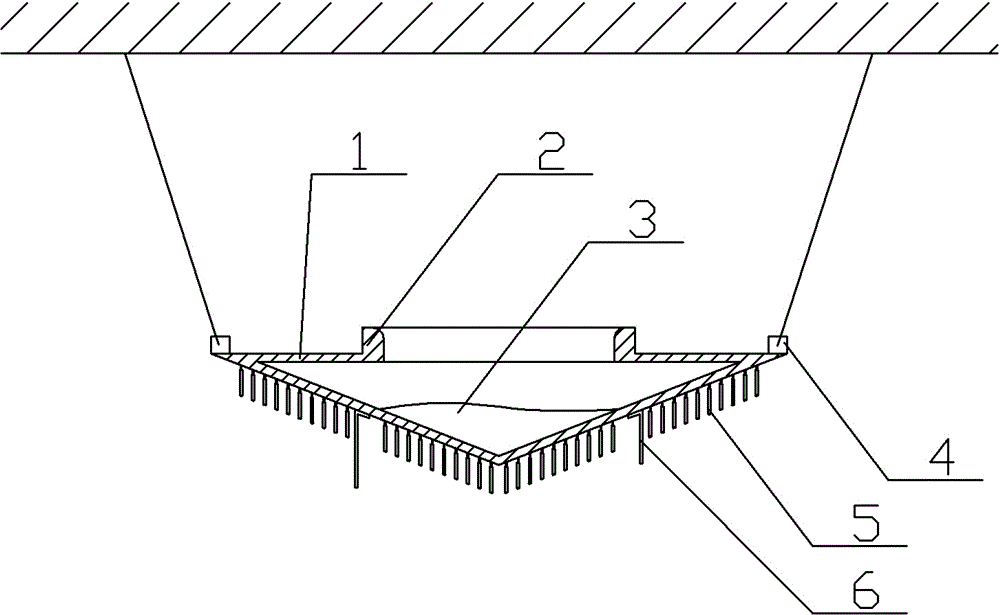

Butterfly high-efficiency self-adaptive plastic-fiber mixed filter material filter

ActiveCN101884860AHigh interception capacityHigh filtration precisionFiltration separationCorrosion resistantSmall footprint

The invention discloses a butterfly high-efficiency self-adaptive plastic-fiber mixed filter material filter. The filter consists of filter material monomers, wherein each filter material monomer is formed by connecting a weight-balancing core body and paired corrosion-resistant balancing filtering wing bodies in a matching way; the surface of the weight-balancing core body is made of plastic; the weight-balancing core body is ellipsoidal; the threshold of the average density p0 of the weight-balancing core body is between 1.30 and 1.50 g / cm<3>; the two ends of a long axis of the ellipsoidal weight-balancing core body are provided with balancing wing bodies respectively; each balancing wing body is made from fiber bundles consisting of artificial fiber yarns; and the inner ends of the artificial fiber yarns constituting each fiber bundle are fixedly connected to each end of the long axis of the weight-balancing core body and the other ends of the artificial fiber yarns are in a diffused state so as to form a whisker form. The filter has the technical advantages of high porosity, high filtering speed, high filtering accuracy, low resistance, high filth holding capacity, small backwashing water using amount, high periodic water yield, low operating cost, small floor area and high anti-load impact capacity.

Owner:新疆德安环保科技股份有限公司

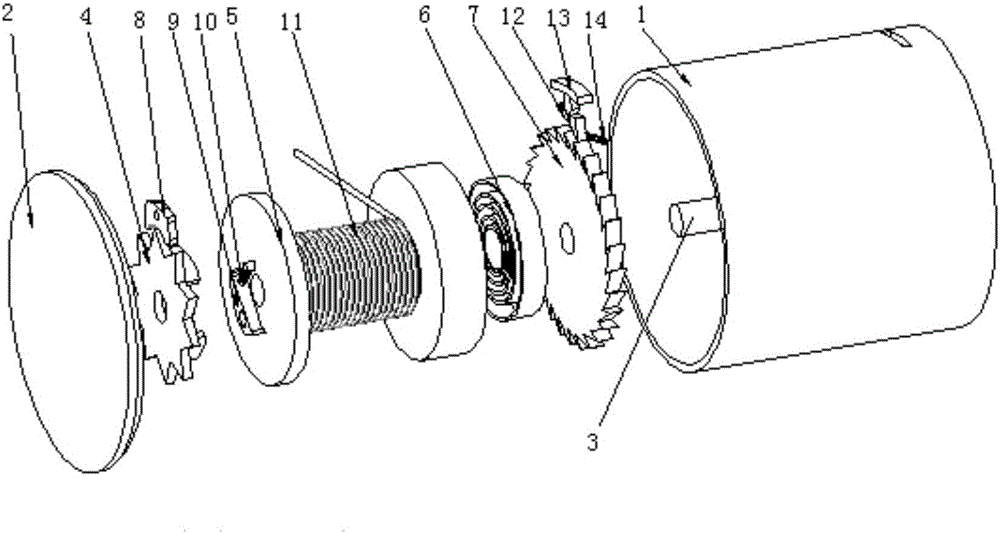

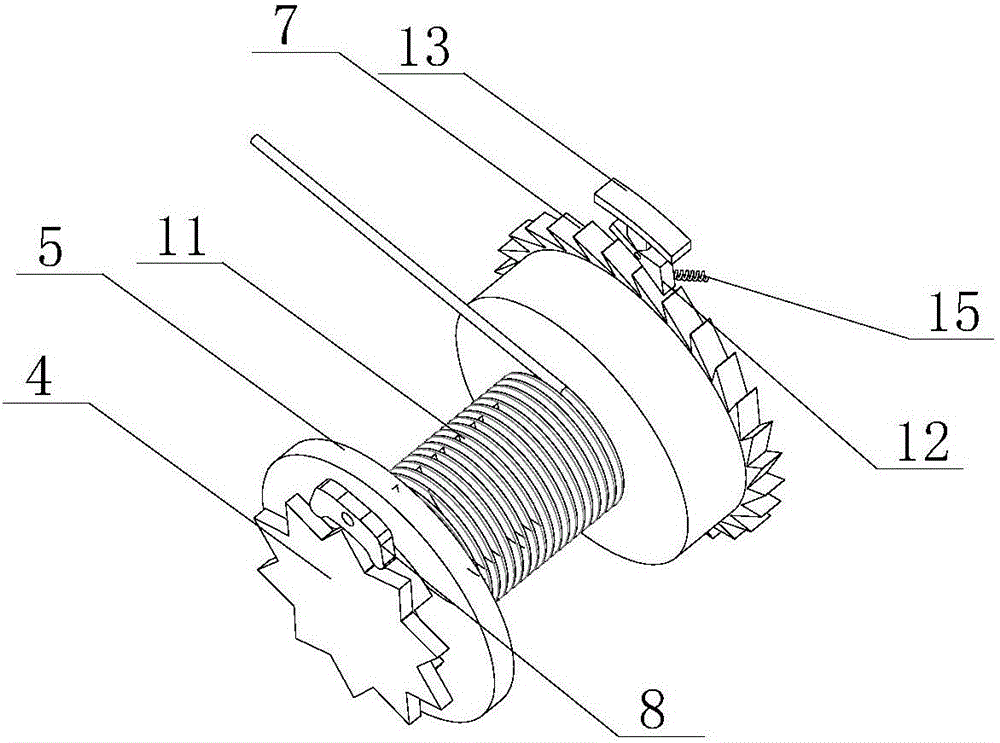

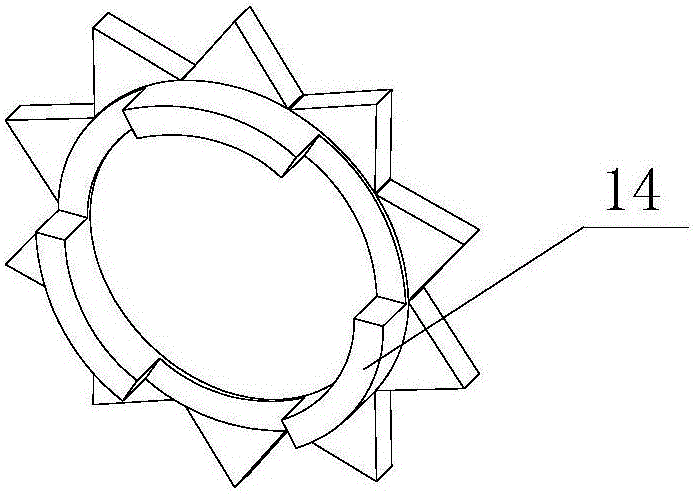

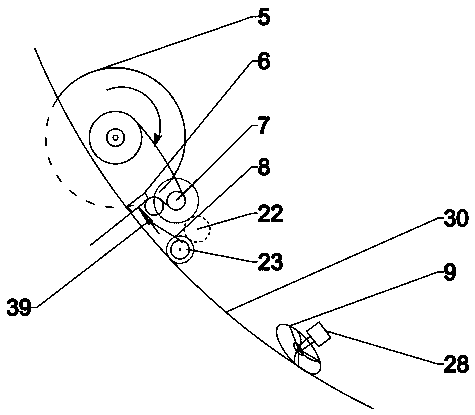

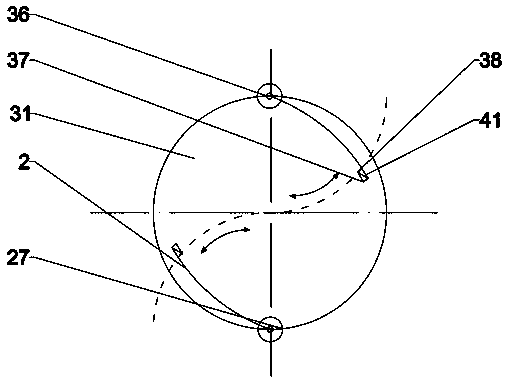

Multifunctional firefighter lifesaving device

The invention discloses a multifunctional firefighter lifesaving device, belonging to the field of firefighting equipment. The multifunctional firefighter lifesaving device comprises a shell with an opening at one end and an end cover which covers the opening of the shell, wherein a main shaft is fixedly arranged in the shell; the main shaft is sequentially sleeved with a pallet wheel, a rope reeling wheel, a coil spring and a ratchet wheel; a pallet fork is arranged on a position, corresponding to the pallet wheel, in the shell; the end surface of one side, close to the pallet wheel, of the rope reeling wheel is provided with an centrifugal fling block and a fling block spring which are connected; the end surface of the other side of the rope reeling wheel is provided with a dented concave table; the coil spring is embedded in the concave table; the rope reeling wheel is wound with a rope; one end of the rope is fixed on the rope reeling wheel, and the other end extends out of the shell; a pallet is arranged on a position, corresponding to the ratchet wheel, in the shell; the pallet is connected with a pallet spring in the shell; and the pallet is further provided with a multifunctional button which extends out of the shell. By using the multifunctional firefighter lifesaving device, self-saving and escaping of a firefighter can be realized during a task.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY +1

Double-layer clean-type warping machine

ActiveCN106283323AReasonable transmissionAvoid wastingWarping machinesOther manufacturing equipments/toolsYarnEngineering

The invention discloses a double-layer clean-type warping machine. The double-layer clean-type warping machine comprises a frame, a partition plate is arranged in the middle of the frame horizontally and partitions the frame into an upper layer and a lower layer, and a passage is formed on one side of the partition plate. A bottom plate is arranged at the bottom of the lower layer, a yarn unwinding component is arranged on the upper layer, a first rotating roller is arranged on one side of the yarn unwinding component, a yarn collecting beam is arranged on one side of the first rotating roller, and a tensioning component is arranged on one side of the yarn collecting beam and in the passage. A first dividing frame is arranged on the lower layer and disposed below the tensioning component, a second dividing frame, a yarn guide component and a third dividing frame are arranged on one side of the first dividing frame, a warping component is arranged on one side of the third dividing frame, the bottom plate is provided with a plurality of rectangular grooves in which negative pressure blowers are disposed, and a plurality of square pipes correspondingly connected with the rectangular grooves are arranged at the bottom of the bottom plate in the frame and are disposed in a collecting box arranged at the bottom of the frame.

Owner:吴江市晓月昱喷织厂

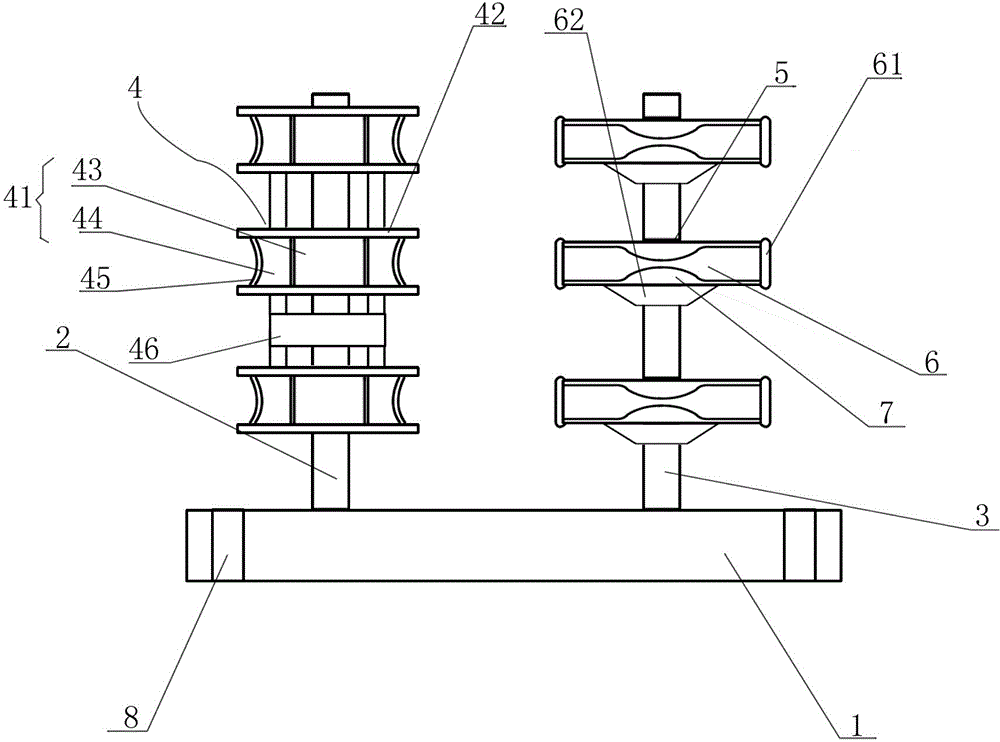

Efficient winder device for spinning

The invention discloses an efficient winder device for spinning; the efficient winder device for spinning comprises a pedestal; the pedestal is respectively provided with a first upright column and a second upright column which are used for installing winders for winding yarns and yarn carding tubes; the winders are used for winding yarns; the yarn carding tubes are used for carding the yarns; the first upright column is sleeved with at least three winders in order to conveniently wind three pieces of yarns at the same time, thus increasing the efficiency; through holes are arranged at the same heights on the second upright columns with respect to the winders; the yarn carding tubes are arranged inside the through holes; the inner walls of the yarn carding tubes are provided with arc-shaped inner layers whose middle portions protrude inwardly, thus yarns are unlikely to be tied in knots while passing through the yarn carding tubes; and the inner layers made of ceramic or plastic materials reduce the friction to the yarns; the first upright column is provided with a motor for driving the winders to rotate. The efficient winder device for spinning has the advantages of simple in structure, convenient in use, efficient, and the like.

Owner:SONGLING BRANCH WUJIANG MINGMIN GARMENTS

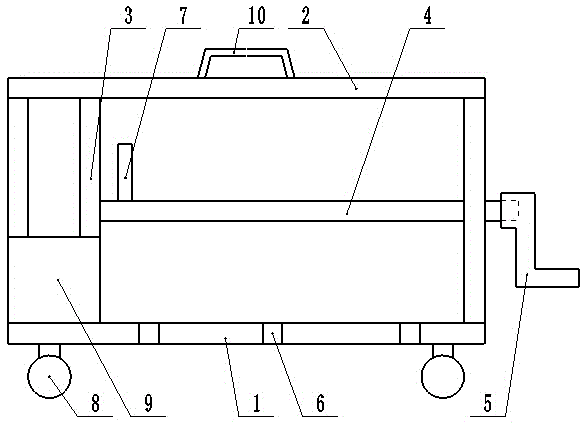

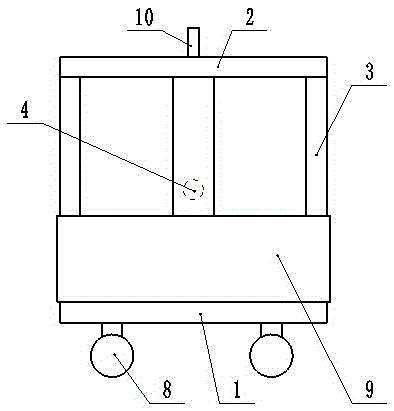

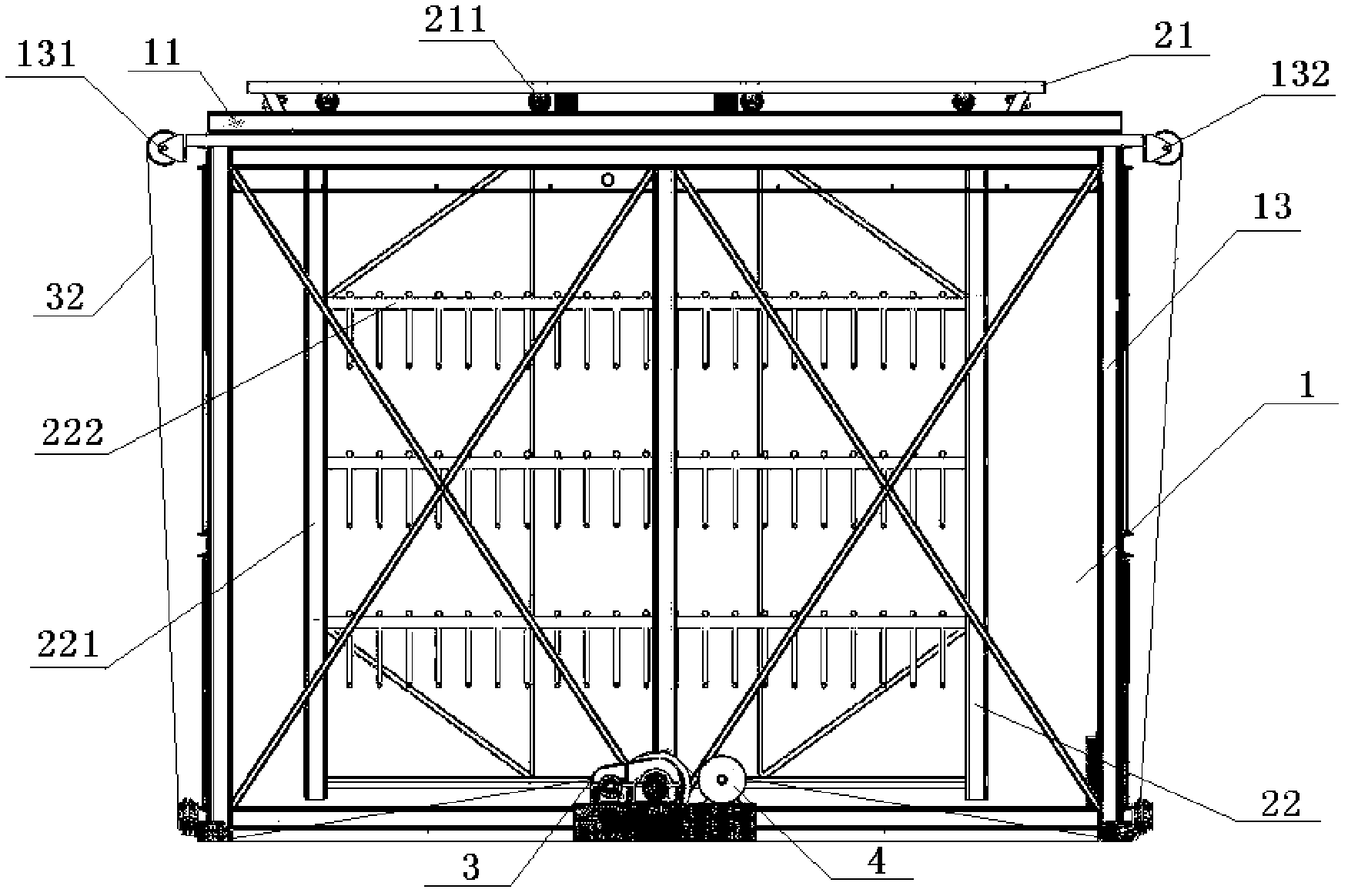

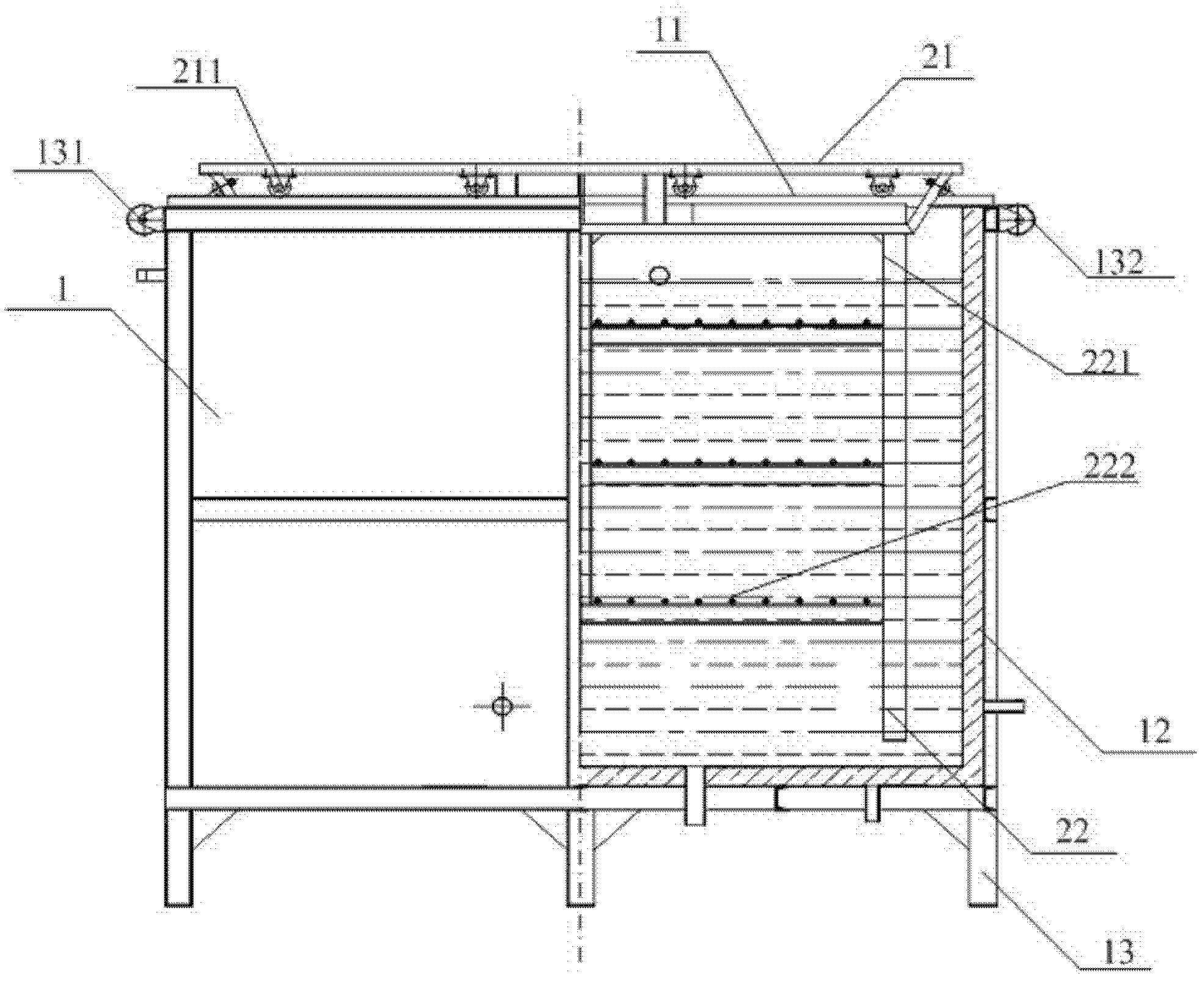

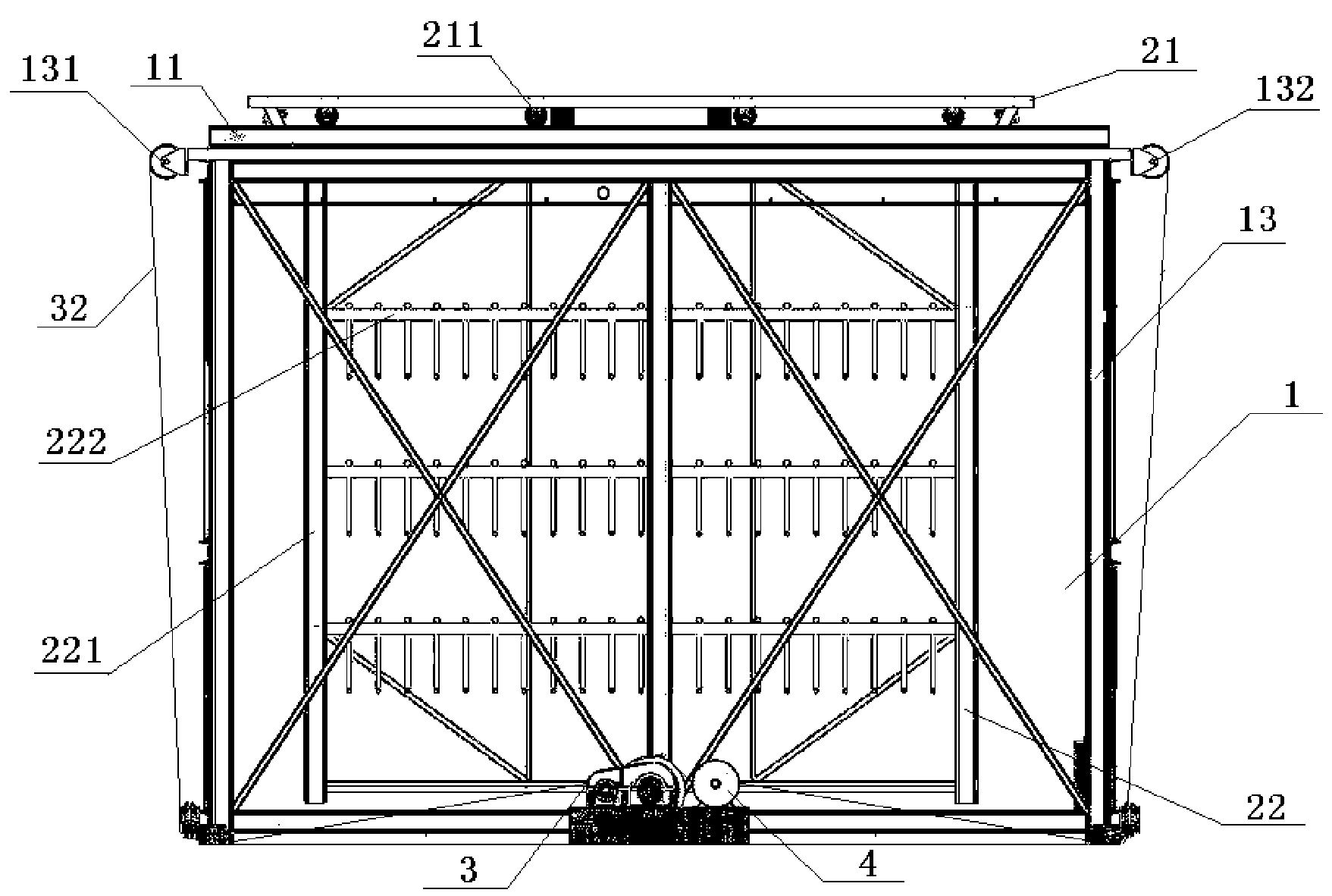

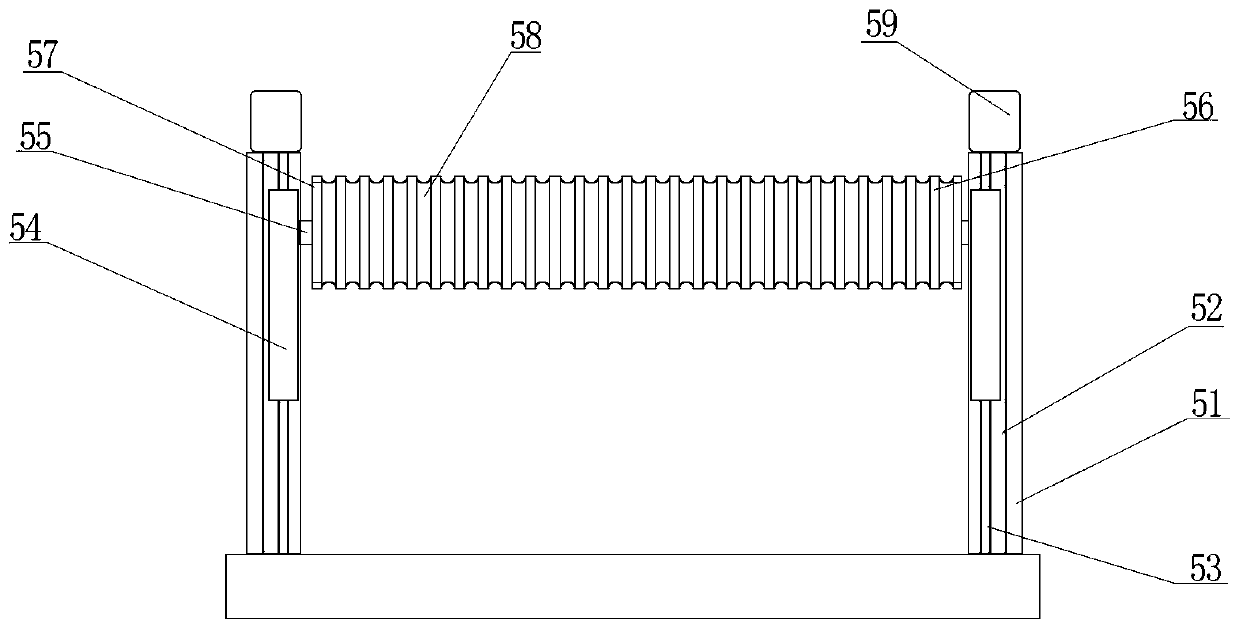

Ground wire storage frame

The invention provides a ground wire storage frame and belongs to the technical field of tools used for putting away, spreading and storing ground wires during circuit and power transformation construction and maintenance. According to the technical problem to be solved, the ground wire storage frame provided by the invention is capable of making the ground wires be used and stored on site conveniently, knotting is not liable to occur, using is convenient and clean, and a protection function on the ground wires is achieved. According to the adopted technical scheme, the ground wire storage frame comprises a bottom plate, a top plate, vertical support rods, a rotary shaft and a crank. The bottom plate and the top plate are fixedly connected to form a frame through the multiple vertical support rods. Through a bearing, the rotary shaft is horizontally installed in the frame composed of the bottom plate, the top plate and the vertical support rods, and one end of the rotary shaft extends out of the frame to be connected with the crank through a quadrangular end. According to the ground wire storage frame, the crank controls the rotary shaft to rotate to achieve twining storage of the ground wires on the rotary shaft. During usage, wire taking can be easily achieved by directly pulling the ground wires, the ground wires are not liable to be knotted, work is clean, and the labor intensity of workers is relieved.

Owner:YUNCHENG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +1

Sulfonic acid type water-based polyurethane pressure-sensitive adhesive and preparation method thereof

InactiveCN109401712AImprove hydrophilicityWell mixedNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedPolymer science

The invention discloses a sulfonic acid type water-based polyurethane pressure-sensitive adhesive and a preparation method thereof. The sulfonic acid type water-based polyurethane pressure-sensitive adhesive takes a polymer composed of isocyanate, polymer diatomic alcohol, small molecular polyhydric alcohol and a chain extender as a main body of the pressure-sensitive adhesive, takes deionized water as a solvent, is free of toluene and other organic solvents, and is nontoxic, pollution-free and environment-friendly; the chain extender, a stabilizer, a regulator and a blocking agent are also added; a mixture of 8-naphthylamine-1,6-disulfonate sodium, 1,4-bis(butyryloxy)-2-butene and sodium N-tris(hydroxymethyl)methyl-3-aminopropane sulfonate is selected as the chain extender; under combinedaction of the three substances, a good chain extending effect is achieved, the length of a polymer is extended, the structure of the polymer is adjusted, and the chain extender has a synergistic effect with the polymer main body; and meanwhile, the prepared pressure-sensitive adhesive has certain temperature tolerance, the finally prepared pressure-sensitive adhesive has high initial viscosity and strong holding power, and the application range of the water-based polyurethane pressure-sensitive adhesive is greatly extended.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

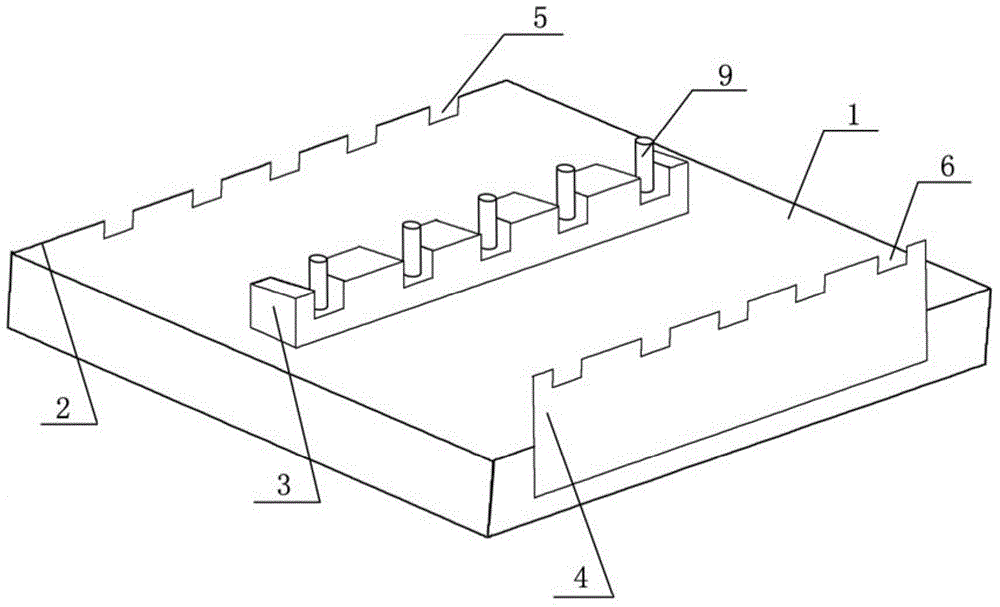

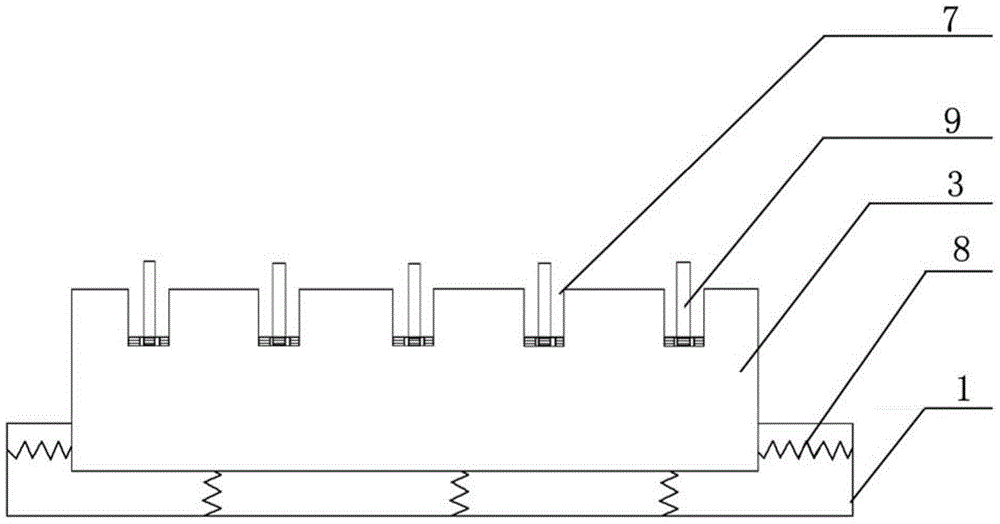

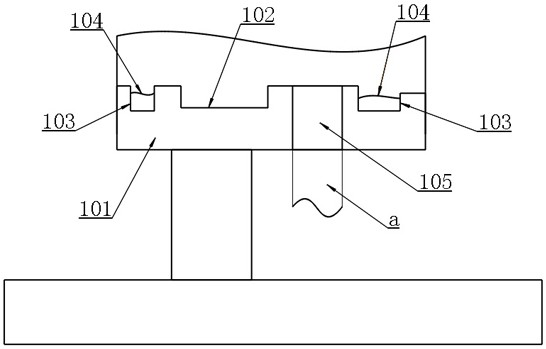

Spinning yarn positioning jig

The invention relates to the technical field of spinning equipment, in particular to a spinning yarn positioning jig. The spinning yarn positioning jig comprises a guiding platform. The guiding platform is provided with a yarn inlet end, a yarn guiding device and a yarn outlet plate. A plurality of notches are formed in the yarn inlet end. A plurality of slots are formed in the yarn outlet plate. The yarn guiding device is provided with a plurality of breaking openings. Spinning yarn passes through the breaking openings of the yarn guiding device through the notches and then is led out of the slots, and accurate guiding on the spinning yarn is achieved. The notches, the breaking openings and the slots are correspondingly arranged in pairs, and the bottom faces of the notches, the breaking openings and the slots pass the same plane, wherein a certain upward inclination angle is formed between the plane and the horizontal plane. The spinning yarn walks in the manner of being closely attached to the bottom faces of the notches, the breaking openings and the slots in the walking process, and the moving range of the spinning yarn is limited through friction. Meanwhile, positioning columns are in threaded connection with the bottom faces of the breaking openings, the possible moving tendency of various kinds of spinning yarn in the left and right direction can be further limited through the positioning columns, and the swinging amplitude of the various kinds of spinning yarn in the walking process is better reduced. An elastic body is arranged at the lower portion of the yarn guiding device, and the walking process of the spinning yarn is more smooth and gentler.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

Fur niter-dyeing machine

ActiveCN104388607AIncrease heightReduce strong mechanical actionLeather/skins/hides/pelt chemical treatment apparatusTemperature controlScrub brushes

The invention discloses a fur niter-dyeing machine. The fur niter-dyeing machine comprises a rotary drum structure, a filtering device and a stirring device. The rotary drum structure comprises a flat and straight baffle plate arranged at the inner surface of the drum body along an axis direction, an inclined baffle plate structure and inlet and outlet water pipes. The filtering device comprises a liquid inlet pipe, a primary filtering device and a secondary filtering device. The opening of a liquid outlet pipe is arranged above the primary filtering device. The primary filtering device comprises a rubber scrubbing brush, a hairbrush and a primary filtering screen. The rubber scrubbing brush is located in front of the hairbrush. The secondary filtering device comprises a secondary filtering screen and a secondary liquid outlet pipe. The stirring device comprises a temperature control device, a steam heating device and an inclined stirring device arranged in the cylindrical shell of the stirring device. A water outlet of the rotary drum structure is connected to the liquid inlet pipe of the stirring device. The primary liquid outlet pipe and the secondary liquid outlet pipe of the filtering device are respectively connected to the primary liquid inlet pipe and the secondary liquid inlet pipe of the stirring device. The fur niter-dyeing machine can be used in fur niter-dyeing and guarantees finished fur quality.

Owner:桐乡市鑫诺皮草有限公司

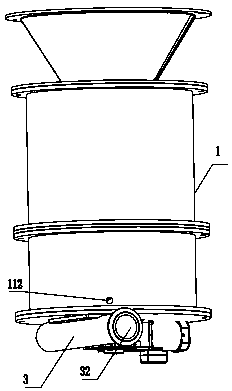

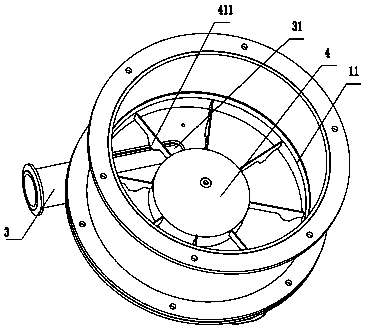

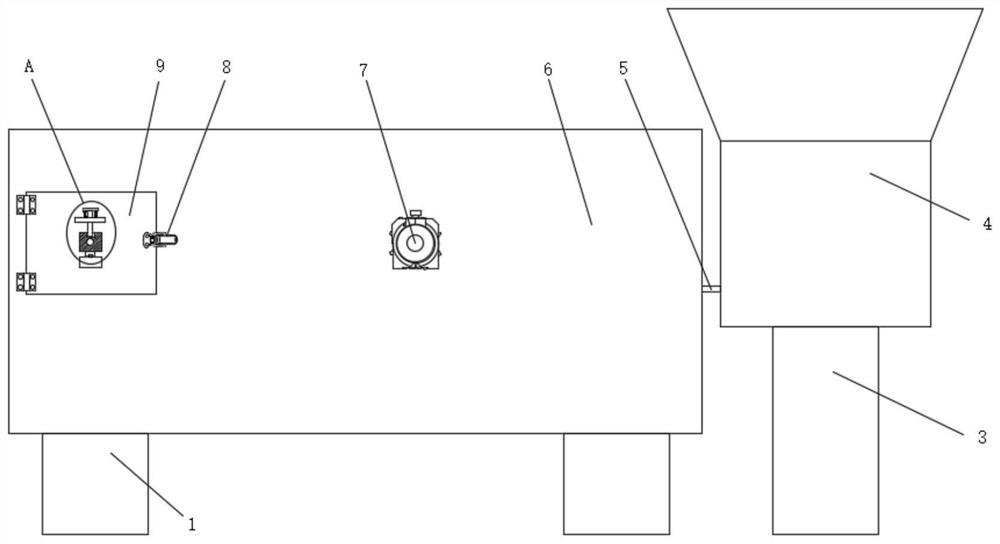

Slurry spraying machine

PendingCN111101711AUniform dischargeNot easy to knotUnderground chambersFoundation engineeringProcess engineeringSlurry

The invention discloses a slurry spraying machine which mainly solves the problems that a slurry spraying machine on the market at present is likely to accumulate materials and uneven in discharge. The slurry spraying machine is characterized by further comprising a discharge pipe (3) connected with a first gas source, the bottom of a shell is provided with a feed inlet (31) which communicates with the discharge pipe, the discharge pipe is further provided with a discharge port (32) which communicates with the feed inlet, a discharge cavity is internally provided with a rotor (4) connected with a first power source and capable of rotating along the self axis, a push plate (41) is arranged on the outer wall of the rotor, and the push plate is used for pushing slurry to the discharge port. According to the slurry spraying machine, when the rotor is rotated, slurry is evenly conveyed to the feed inlet through the push plate, caking is not likely to occur, and discharge is uniform.

Owner:温州燧人智能科技有限公司

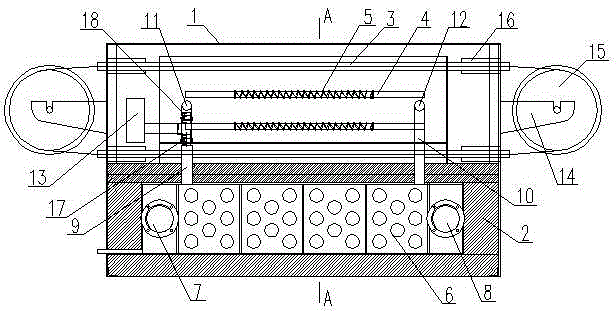

High-efficiency online oven for steel wires

ActiveCN105241197ANot easy to knotHeating evenlyDrying gas arrangementsDrying machines with progressive movementsHot air ovenHeating time

The invention relates to a high-efficiency online oven for steel wires. The high-efficiency online oven for the steel wires comprises an electric heating oven body and a hot air oven body. The electric heating oven body is mounted on the hot air oven body. Two rows of horizontally-arranged heat transfer pipes are arranged at the upper end and the lower end of the interior of the electric heating oven body respectively, and two rows of electric heating pipes are arranged in the middle of the electric heating oven body and sleeved with electric heating wires. A heat exchanger is arranged in the hot air oven body. A hot air inlet and a hot air outlet are formed in the front end face of the hot air oven body. A heat exchange inlet and a heat exchange outlet are formed in the upper end of the heat exchanger. An air blowing opening and a heat inlet are formed in the front end face of the electric heating oven body. A fan is arranged at the front end of the electric heating oven body. The fan is connected with the air blowing opening and the heat inlet through pipelines. The heat exchange outlet is connected with the heat inlet. The high-efficiency online oven for the steel wires is simple in structure, convenient to operate, high in drying efficiency, short in heating time, capable of reducing energy consumption and low in production cost.

Owner:YANGZHOU JINCHEN STAINLESS STEEL MFR

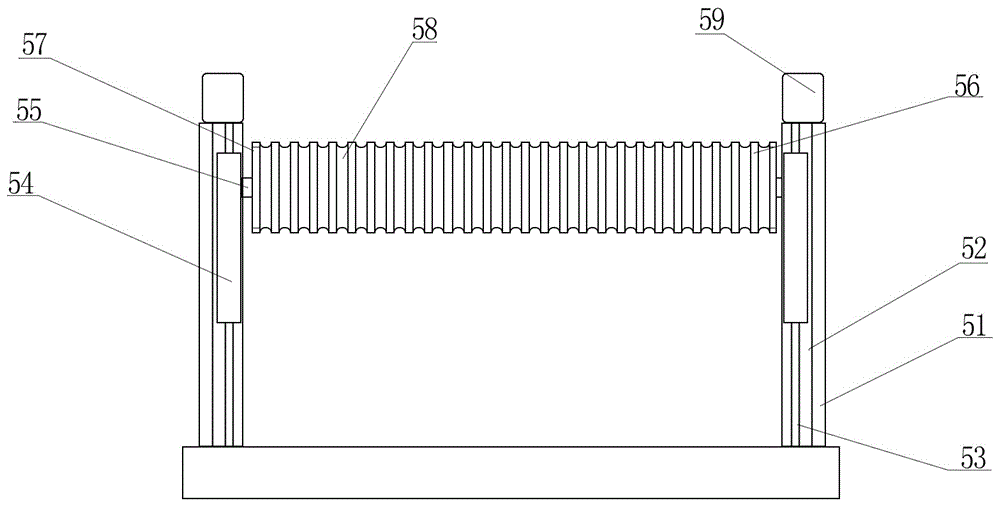

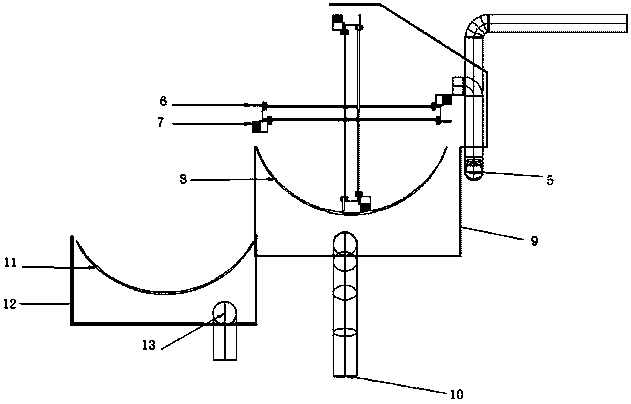

Vibration fermentation apparatus for biological degumming of phloem fiber

InactiveCN102304771ANot easy to knotDegumming completelyBiochemistry apparatusDe-gumming silkEngineeringFiber

The present invention provides a vibration fermentation apparatus for biological degumming of phloem fiber. The apparatus comprises: a fixed water tank; a load device, wherein the load device can move reciprocatly in the fixed water tank, the load device comprises a bracket and a material load rack, the bracket is arranged on the top of the fixed water tank and can move reciprocatly the material load rack is connected with the bracket, moves reciprocatly through the bracket driving, and is arranged inside the fixed water tank; a transimisson apparatus provided for driving the load device to move reciprocatly; a driving apparatus provided for driving the transimisson apparatus to move. According to the present invention, when the vibration fermentation apparatus is used for biological degumming of the phloem fiber, the phloem fiber is placed on the material load rack; after the amplification-culture degummed bacteria is inoculated, the driving apparatus is started; the transimisson apparatus drives the bracket to move reciprocatly; the bracket drives the material load rack to move reciprocatly in the fixed water tank, such that the phloem fiber on the material load rack completely contacts with the bacteria so as to realize the vibration fermentation.

Owner:杨政

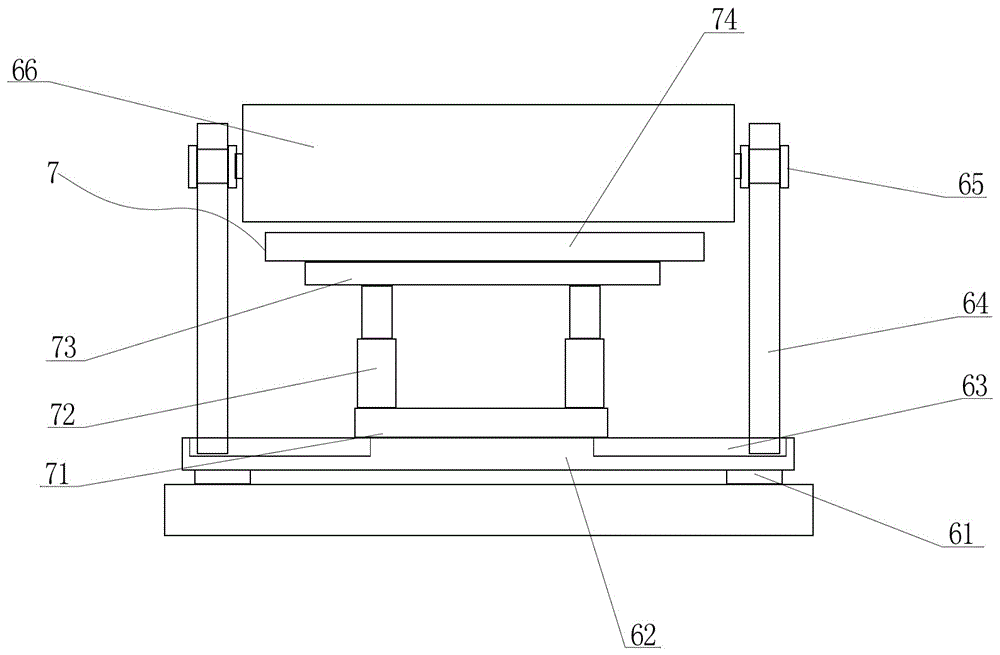

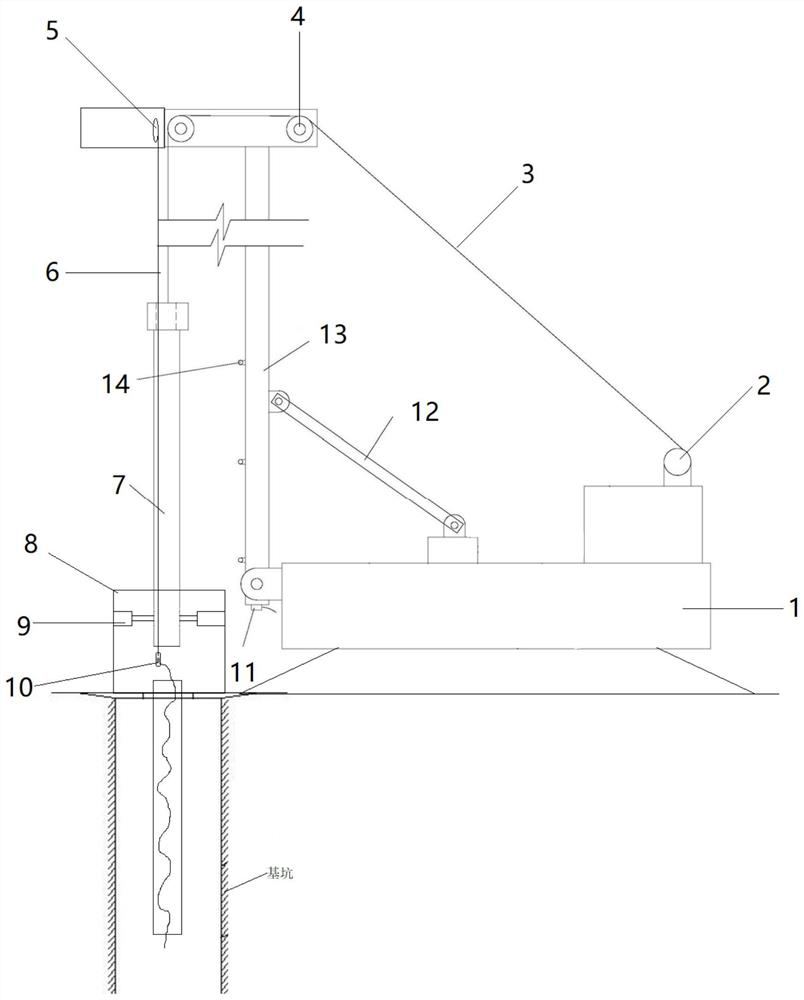

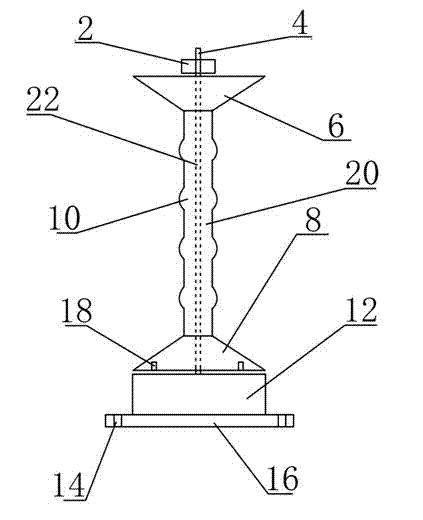

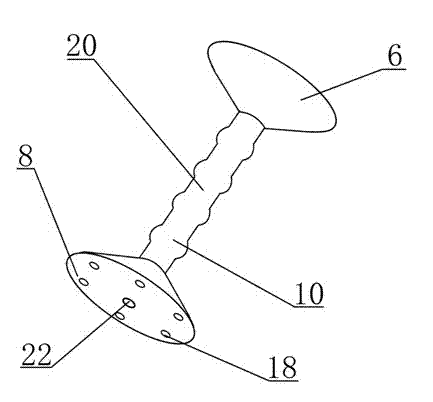

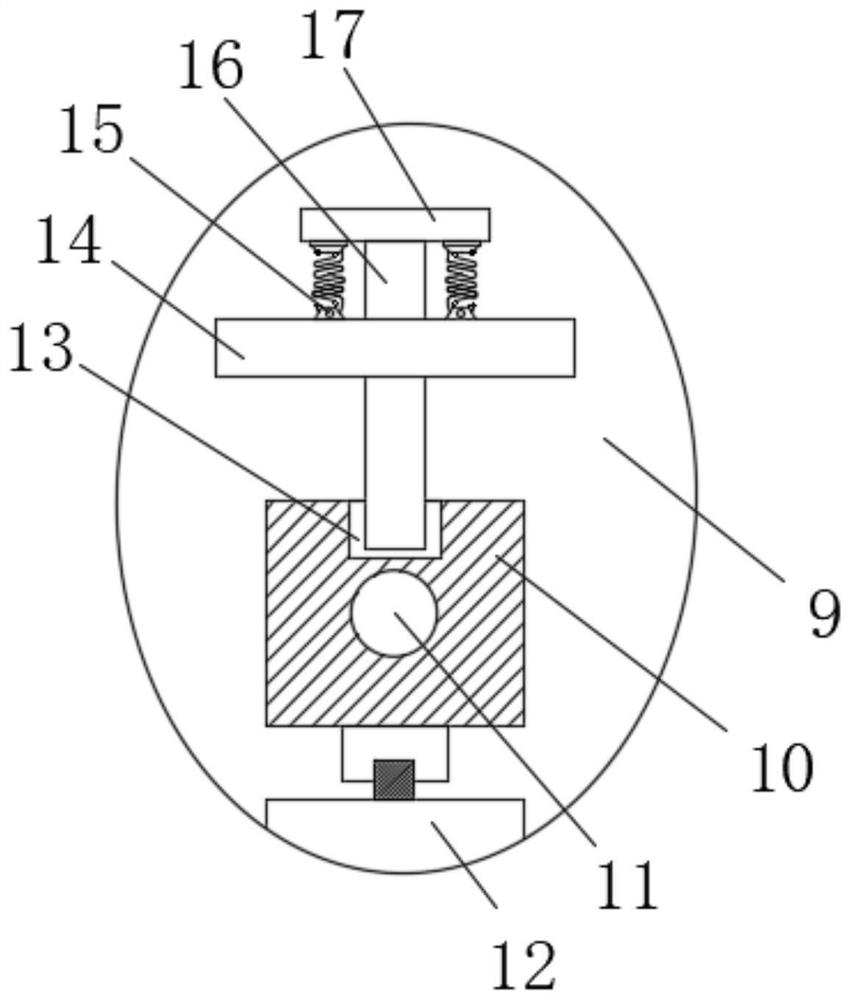

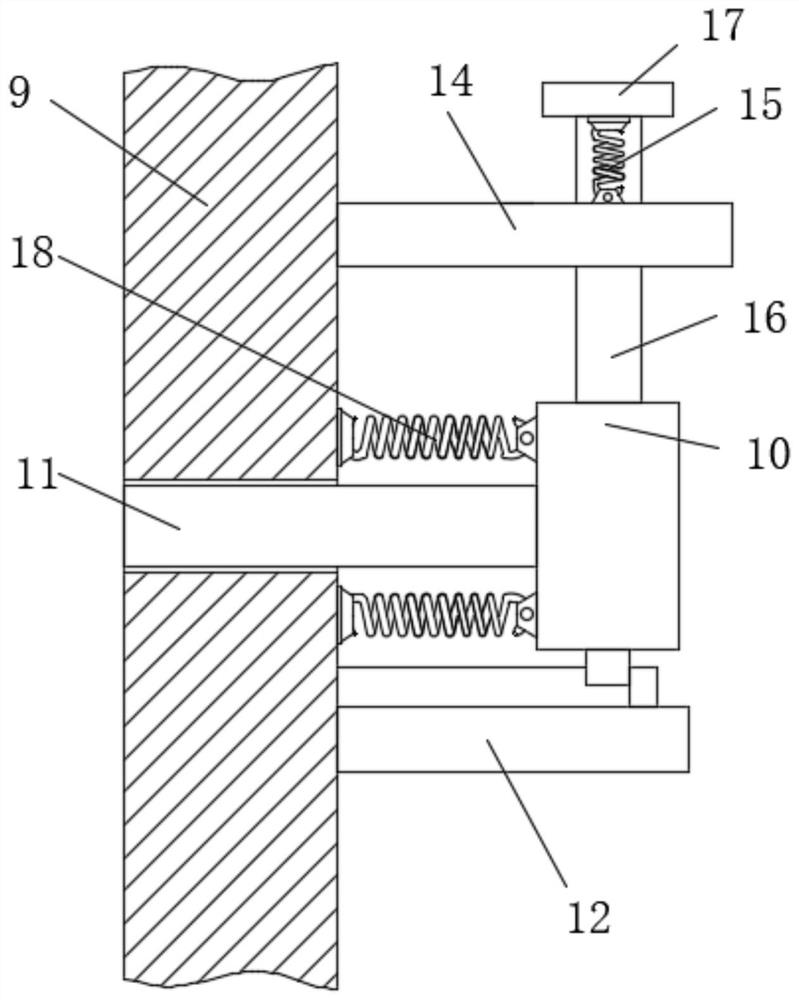

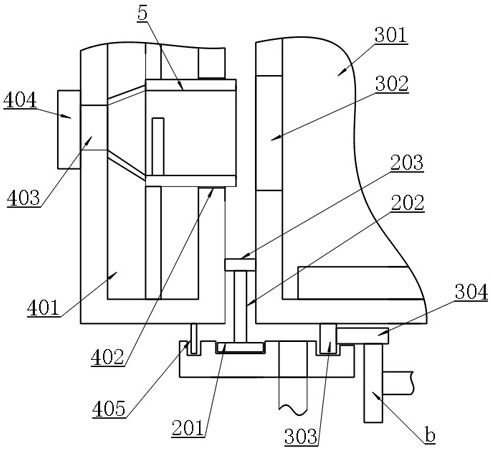

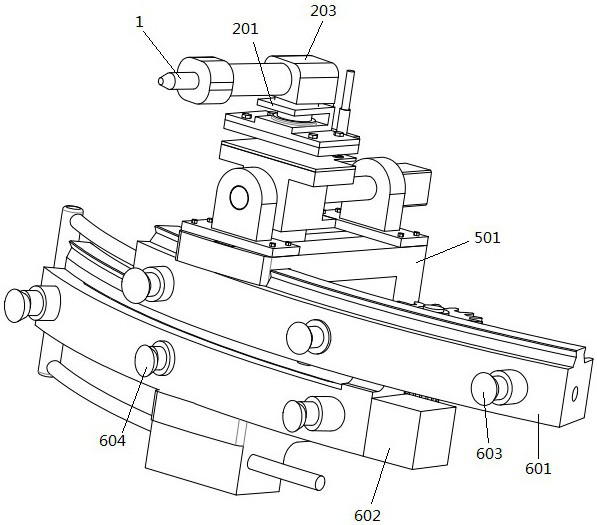

Self-balancing static drill rooted pile hoisting and threading device and construction method thereof

PendingCN112265919ASolve the difficult problem of passing through the pile hole of the upper sectionSpeed up the construction processCranesLoad-engaging elementsBlock and tackleDrill

The invention relates to a self-balancing static drill rooted pile hoisting and threading device which comprises a self-balancing hoisting device and a lifting rope hook mechanism. The self-balancinghoisting device comprises a base and a supporting column, a hoisting bracket is arranged at the upper end of the supporting column, a hoisting pulley block is arranged on the hoisting bracket, a hoisting inhaul cable is wound on the hoisting pulley block, and a first driving mechanism used for winding the hoisting inhaul cable is arranged on the base; the supporting column is provided with a plurality of sensors used for detecting whether a tubular pile is parallel to the supporting column or not; the lifting rope hook mechanism is installed on the lifting bracket and comprises a lifting ropepulley, a hanging rope arranged on the lifting rope pulley and a pendant connected to the lowermost end of the hanging rope, and the lifting rope pulley is connected with the second driving mechanismand can be wound around the lifting rope pulley under the action of the second driving mechanism to ascend or descend; and the pendant penetrates through a middle hole channel of the hoisted tubular pile. Compared with the prior art, the self-balancing static drill rooted pile hoisting and threading device can solve the problem that a wire in a pile hole of the lower pile section is difficult to penetrate through a pile hole of the upper pile section, and meanwhile the perpendicularity of pile planting can be kept.

Owner:SHANGHAI GUANGDA FOUND ENG

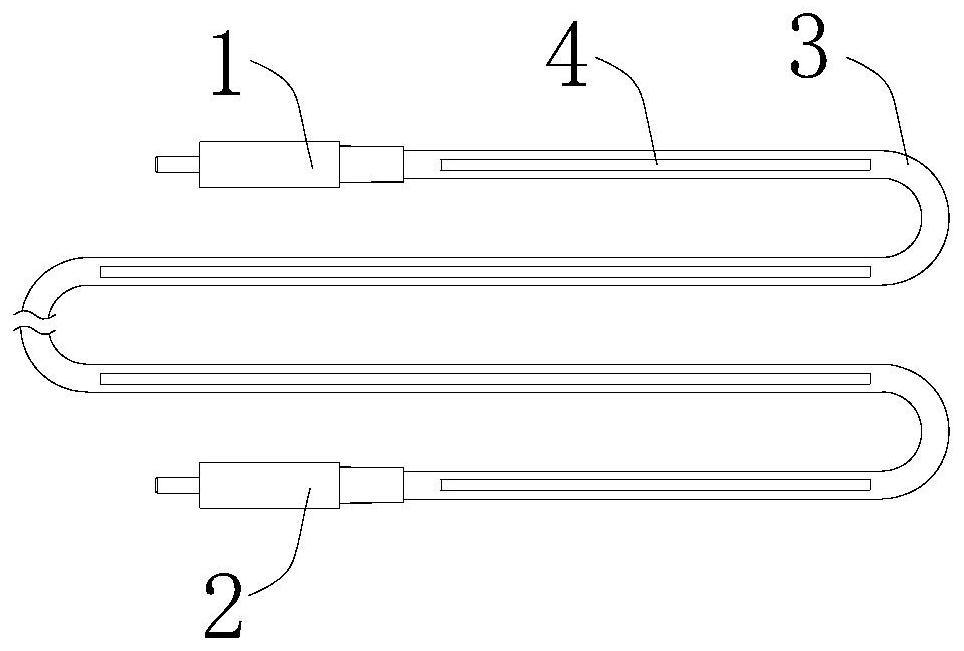

Data line convenient to store

PendingCN112885511AGather quicklyNot easy to knotCoupling device connectionsFlexible cablesComputer hardwareDatabase

Owner:FSP POWERLAND TECH

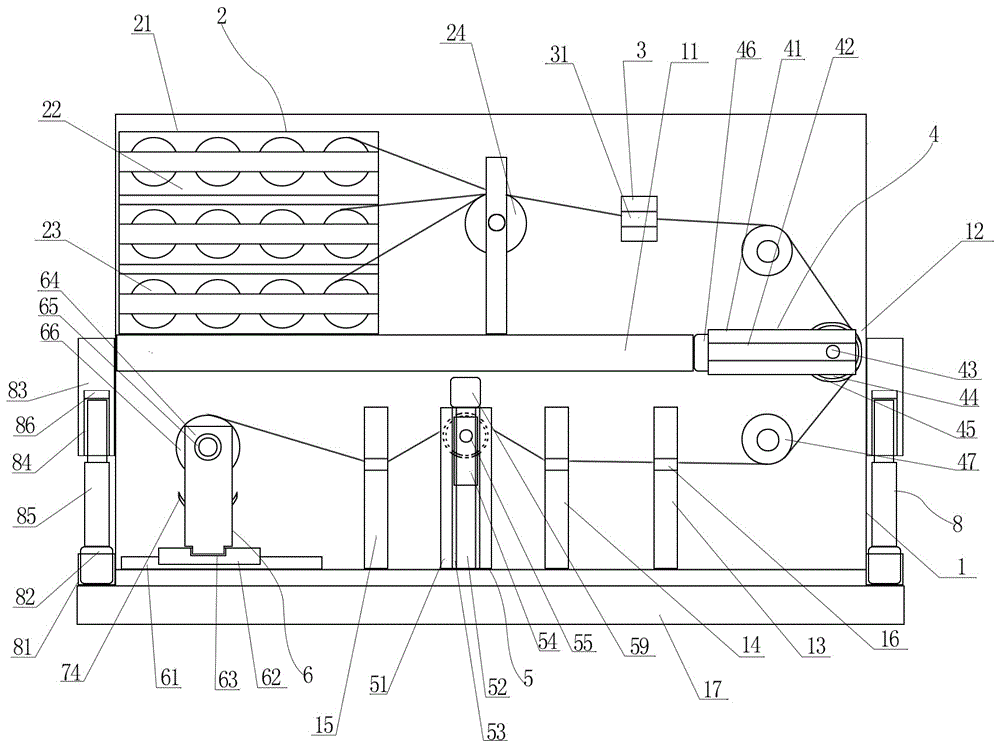

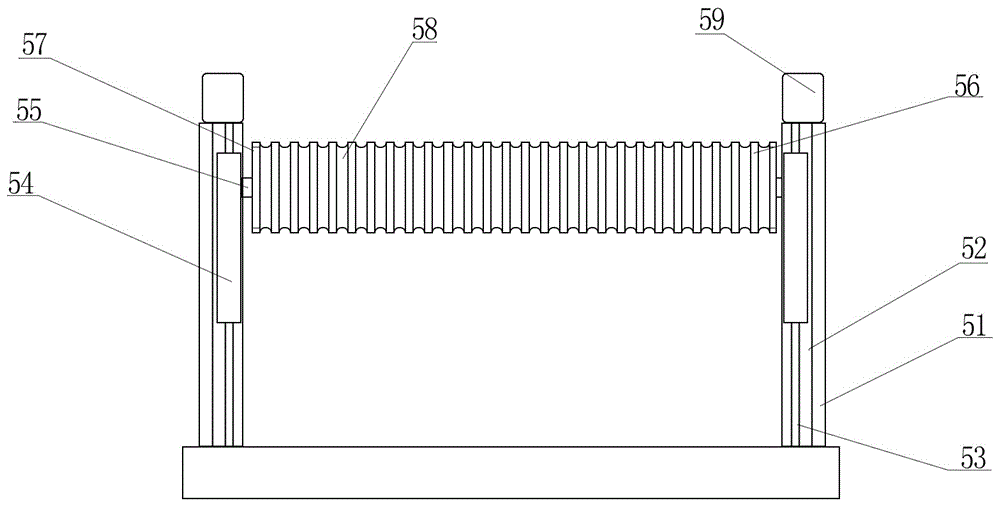

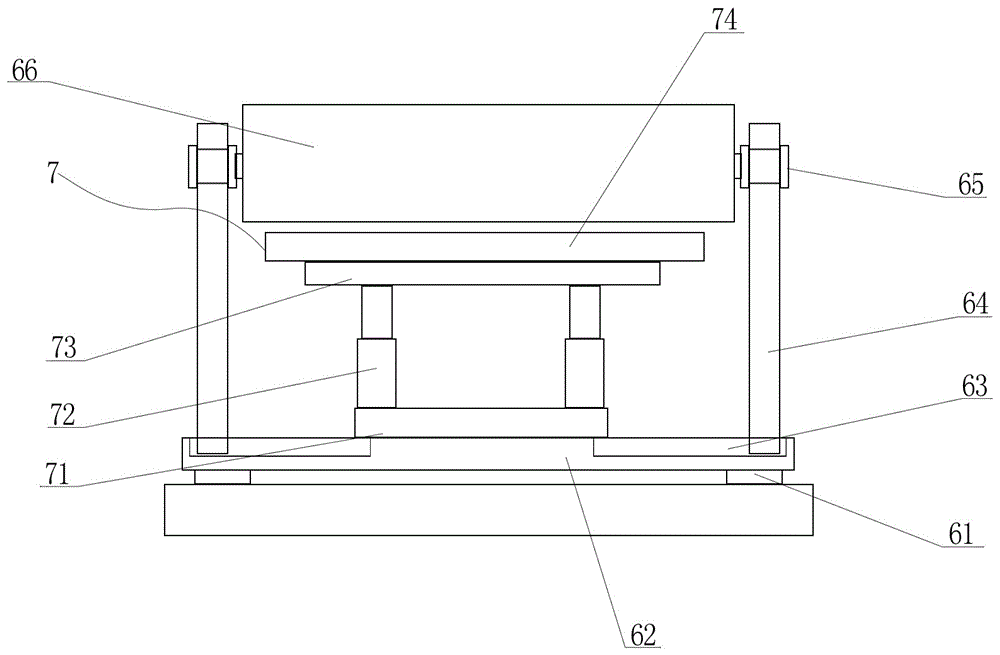

Double-layer lifting warping machine

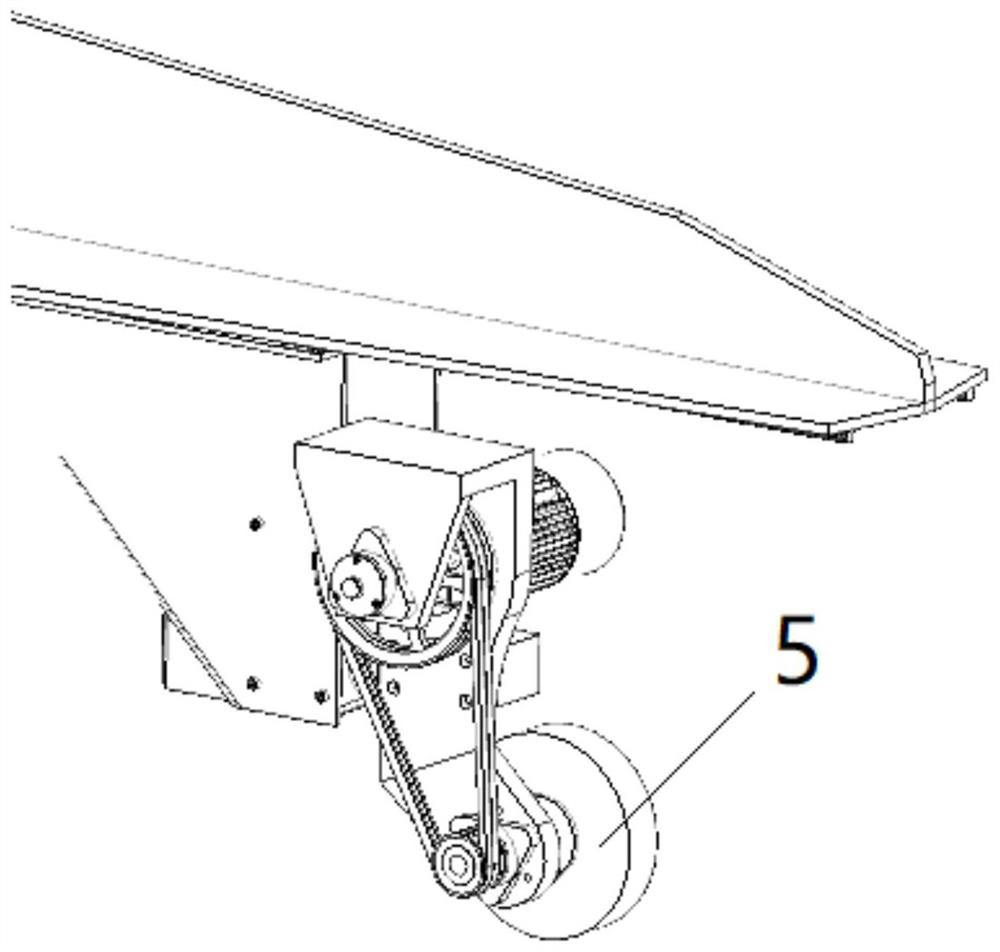

ActiveCN106283320AReasonable transmissionAvoid wastingWarping machinesOther manufacturing equipments/toolsYarnEngineering

The invention discloses a double-layer lifting warping machine. The double-layer lifting warping machine comprises a base, a frame is arranged at the top of the base, a partition plate is arranged in the middle of the frame horizontally and partitions the frame into an upper layer and a lower layer, and a passage is arranged on one side of the partition plate. A yarn unwinding component is arranged on the upper layer, a first rotating roller is arranged on one side of the yarn unwinding component, a yarn collecting beam is arranged on one side of the first rotating roller, and a tensioning component is arranged on one side of the yarn collecting beam and in the passage. A first dividing frame is arranged on the lower layer and disposed below the tensioning component, a second dividing frame, a yarn guide component and a third dividing frame are arranged on one side of the first dividing frame, a warping component is arranged on one side of the third dividing frame, and lifting components are arranged on two side faces of the base and the frame. The double-layer lifting warping machine has the advantages of space saving, reasonable conveyance, less proneness to knotting, clear layering, high yarn guide precision, good warping quality and the like.

Owner:WUJIANG XIAOYU JET WEAVING

Yarn winding device

The invention discloses a yarn winding device. The yarn winding device comprises a body and a base which is arranged below the body, wherein the body comprises a tip cone, a vertical rod and a bottom cone. The yarn winding device is characterized in that a plurality of circles of protrusions are arranged on the vertical rod, the tip cone is an inverted cone which is big-end-up, and the bottom cone is a cone which is big-end-down. According to the yarn winding device, the structure of the body is improved, yarn can not be disengaged or knotted easily due to the arrangement of the tip cone and the bottom cone, friction and resistance are increased when the device works due to the fact that the circles of protrusions are additionally arranged on the vertical rod, and slipping and disengaging of the yarn can not occur easily. The yarn winding device has the advantages of being simple in structure, convenient and fast to use, low in cost and the like.

Owner:WUJIANG QIANQIANHE TEXTILE

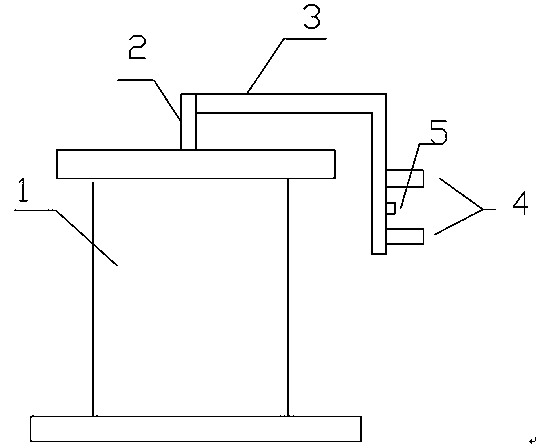

Pay-off spool for steel wire rope

InactiveCN103588019ANot easy to knotEasy to installFilament handlingEngineeringUltimate tensile strength

The invention discloses a pay-off spool for a steel wire rope. The pay-off spool comprises a pay off spool body (1), wherein a rotating shaft is arranged by penetrating through the top end of the pay-off spool body (1), an L-type support (3) is welded to the rotating shaft (2), and two sliding grooves (4) are welded to the outer side of the L-type support (3) from top to bottom. Due to the L-type support which rotates under the driving of the rotating shaft and is arranged on the pay-off spool for the steel wire rope and the two sliding grooves formed in the support, the steel wire rope can be paid off directly through the two sliding grooves, and therefore the pay-off process is safe and simple, meanwhile, the rope is not prone to tying a knot, labor intensity is relieved, and work efficiency is improved.

Owner:CHONGQING HENGTAI CABLE GRP

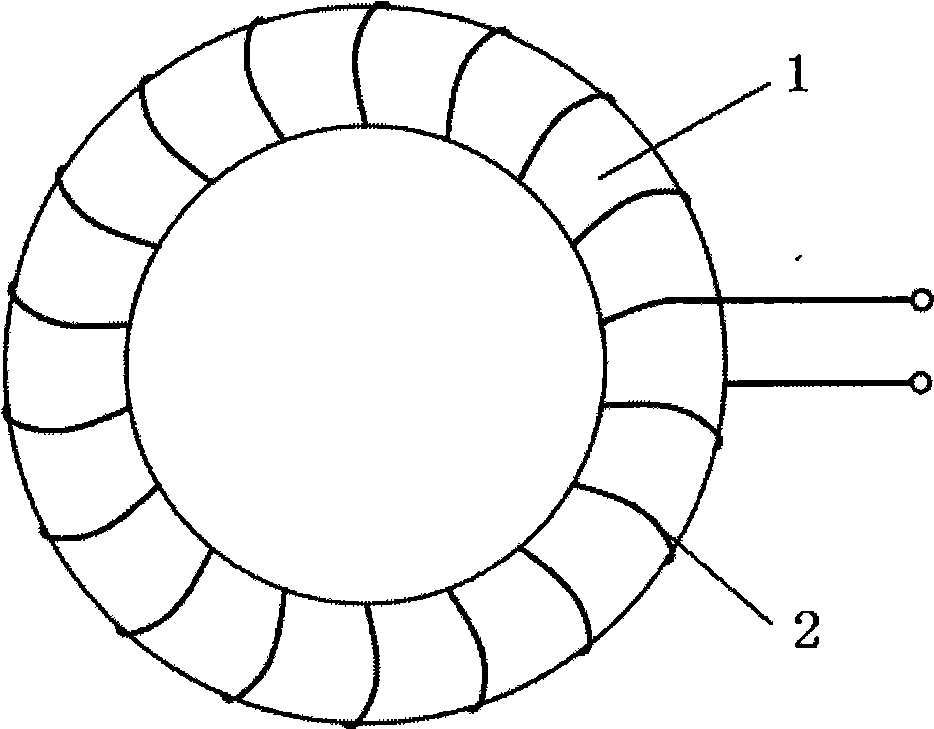

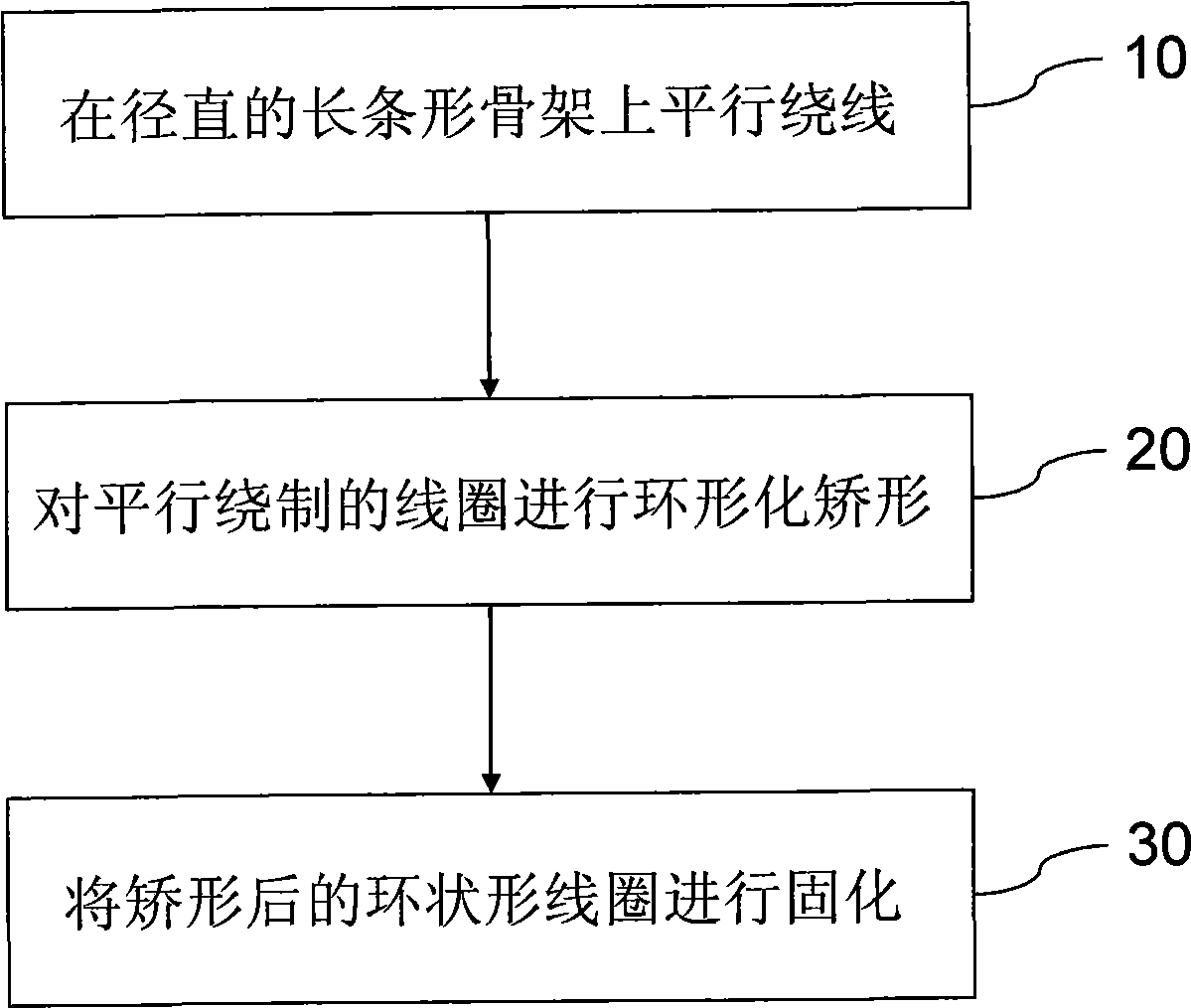

Coiling method for ring-shaped framework coil

InactiveCN101499366AArranged tightly and evenlyImprove winding efficiencyTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringKnot tying

The invention discloses a method for winding a circular frame coil; the method mainly comprises the steps as follows: cutting off and straightening a circular frame, and paralleling a winding to a straight long strip shape frame; carrying out circular shape righting to the parallel winded coil; and curing the shape-righting circular coil. The method has simple process and high production efficiency, and is not easy to generate common adverse issues which appear in circular winding methods such as line broken, knot tied, and the like; and the winded coils are arranged closely and uniformly, therefore, the method is especially suitable for industrial mass production.

Owner:SOUTH CHINA UNIV OF TECH

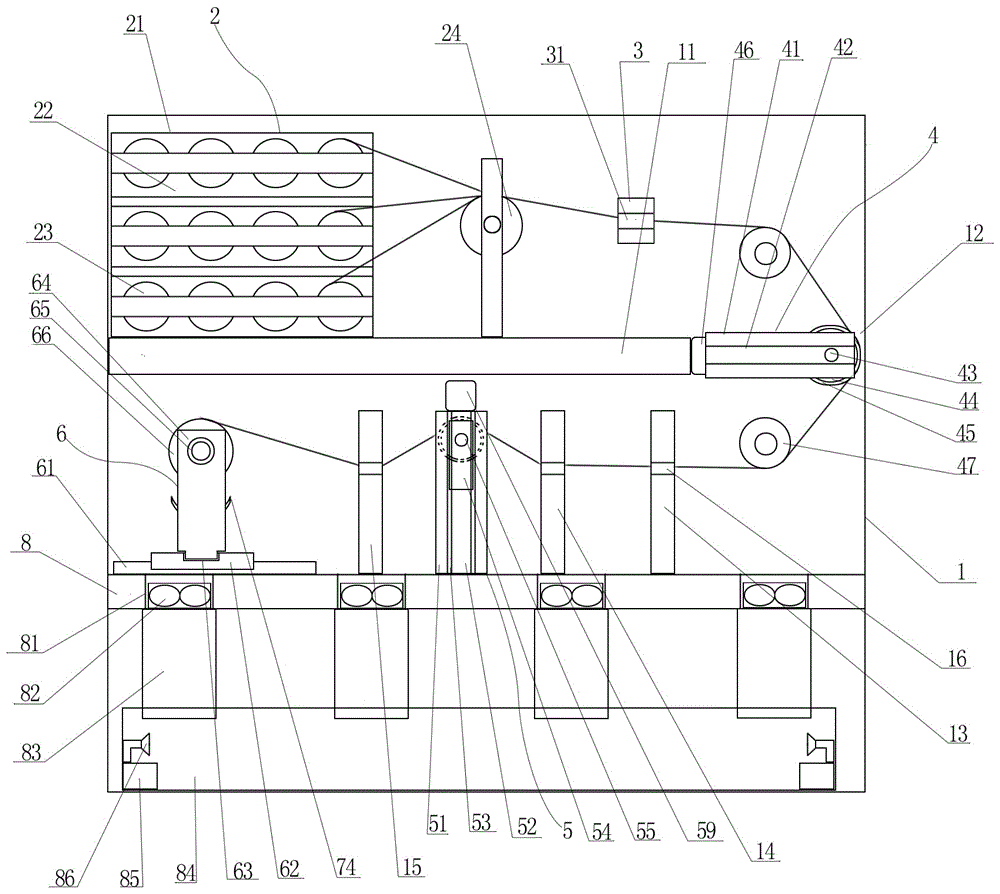

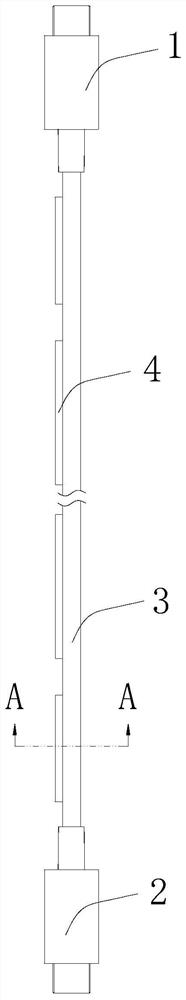

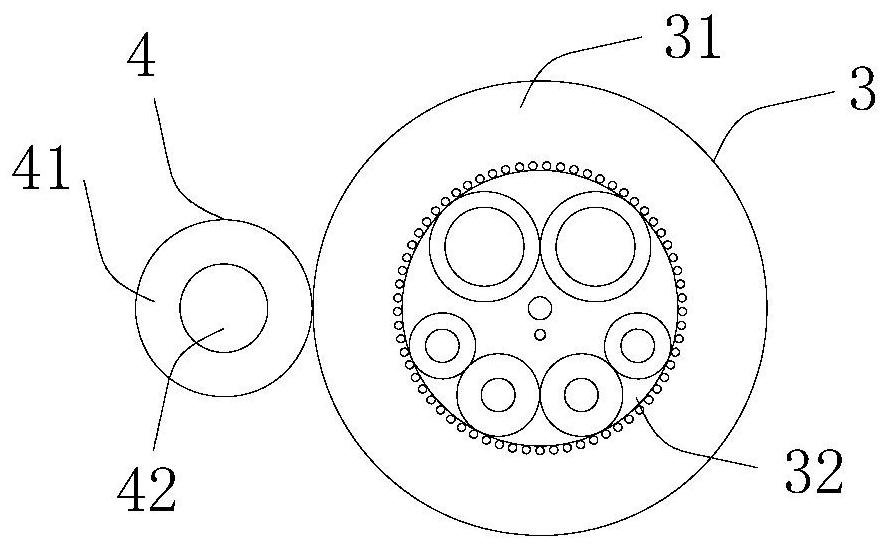

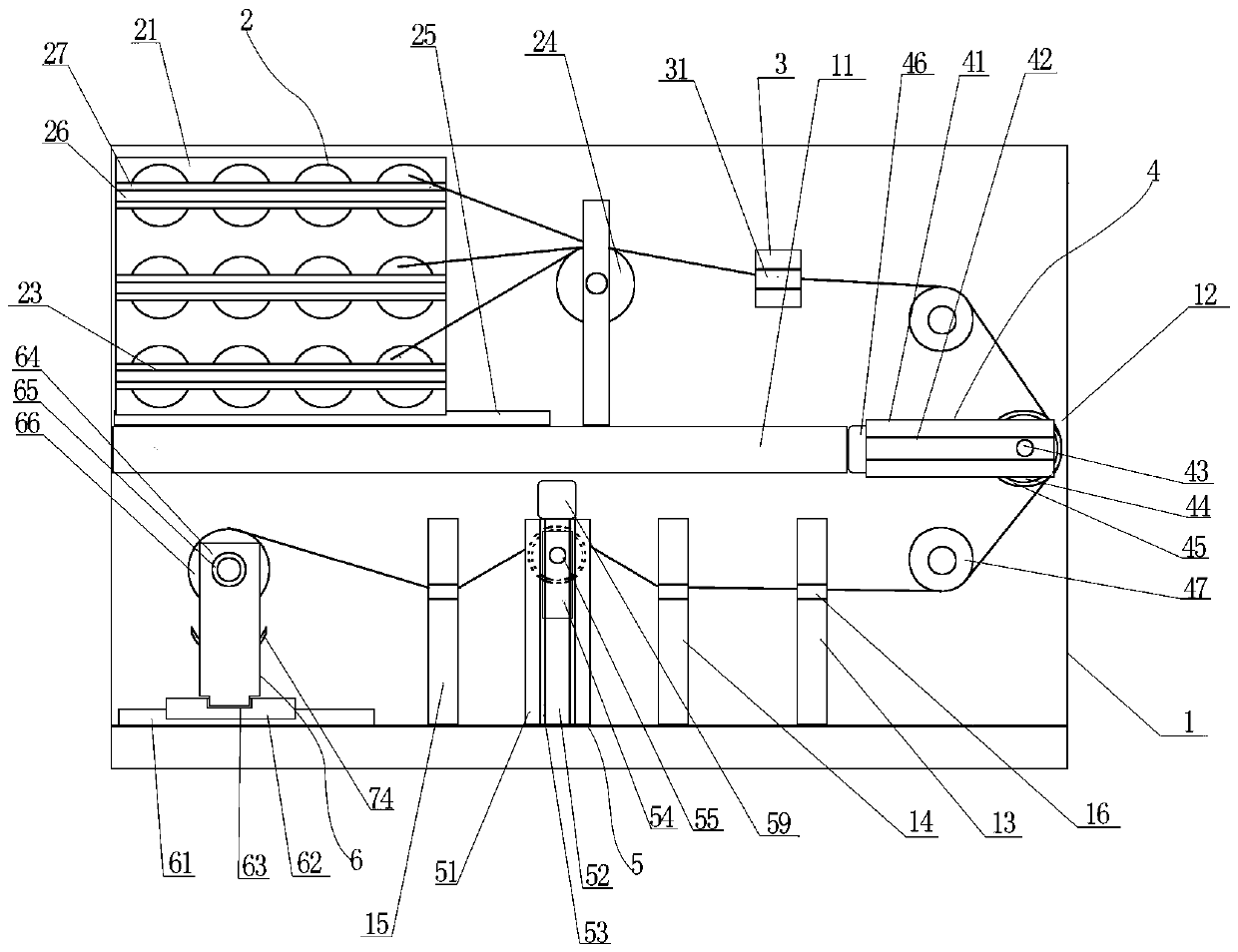

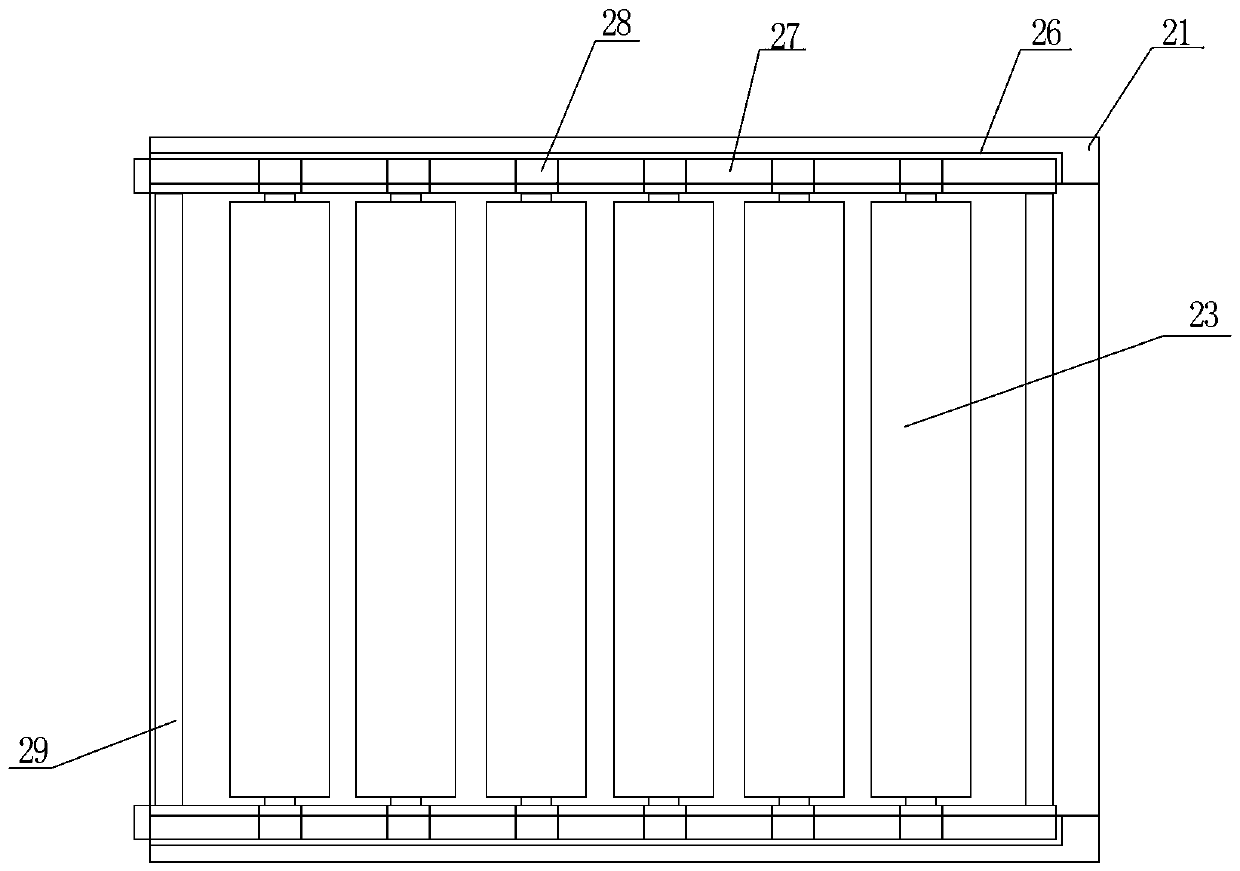

A kind of double-layer warping equipment

ActiveCN106283322BReasonable transmissionAvoid wastingWarping machinesOther manufacturing equipments/toolsYarnEngineering

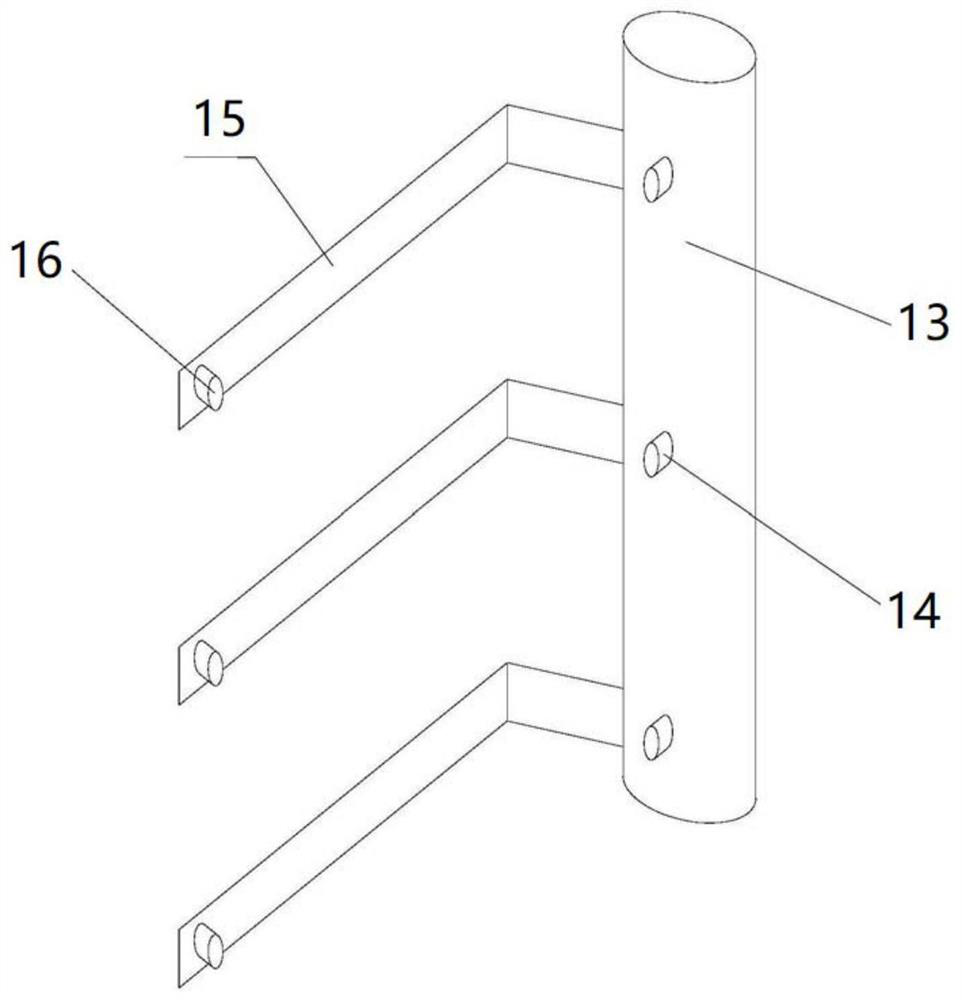

A warping device of a double-layer type, comprising a rack (1) which is horizontally provided at the middle portion of the rack with a partition plate (11), a passage (12) being provided at one side of the partition plate (11), the partition plate (11) separating the rack (1) into an upper layer and a lower layer, the upper layer being provided with a yarn unwinding component (2), a first rotary roller (24) and a yarn collecting beam (3), a tensioning component (4), which is provided between the passages (12), being provided at one side of the yarn collecting beam (3); the lower layer being provided with a first yarn separating frame (13), a second yarn separating frame (14), a yarn guiding component (5), a third yarn separating frame (15) and a warping component (6). The yarn unwinding component can move into or move out of the rack under the effect of a chute, facilitating a worker to change a yarn package to be processed, improving work efficiency.

Owner:WUJIANG XIAOYU JET WEAVING

Automatic stretching, cutting and filamentation device for packaging bag processing

ActiveCN113308749AAchieve stretchEasy to stretchArtificial filament heat treatmentStretch-spinning methodsEngineeringMechanical engineering

The invention belongs to the field of packaging bag processing, particularly relates to an automatic stretching, cutting and filamentation device for packaging bag processing, and aims to solve the problems that an existing stretching, cutting and filamentation device is poor in stretching effect, needs braided lines for natural shaping, is low in efficiency and speed, needs manual collection, consumes time and labor and is poor in collection effect, braided lines are prone to knotting and breakage and using and selling are affected. According to the scheme, the device comprises a processing box, an extruder and the braided lines, wherein the extruder is located on one side of the processing box, and first bases are fixedly connected to the four corners of the bottom of the processing box correspondingly. According to the invention, while the braided lines are tightly pressed through a pressing assembly, a stretching assembly is used for stretching the braided lines, discontinuous stretching is carried out, the function that the braided lines can be well stretched without being snapped can be achieved, the braided lines can be shaped more quickly through a shaping assembly, and the braided lines can be collected and taken out conveniently through a collecting assembly.

Owner:WENZHOU POLYTECHNIC

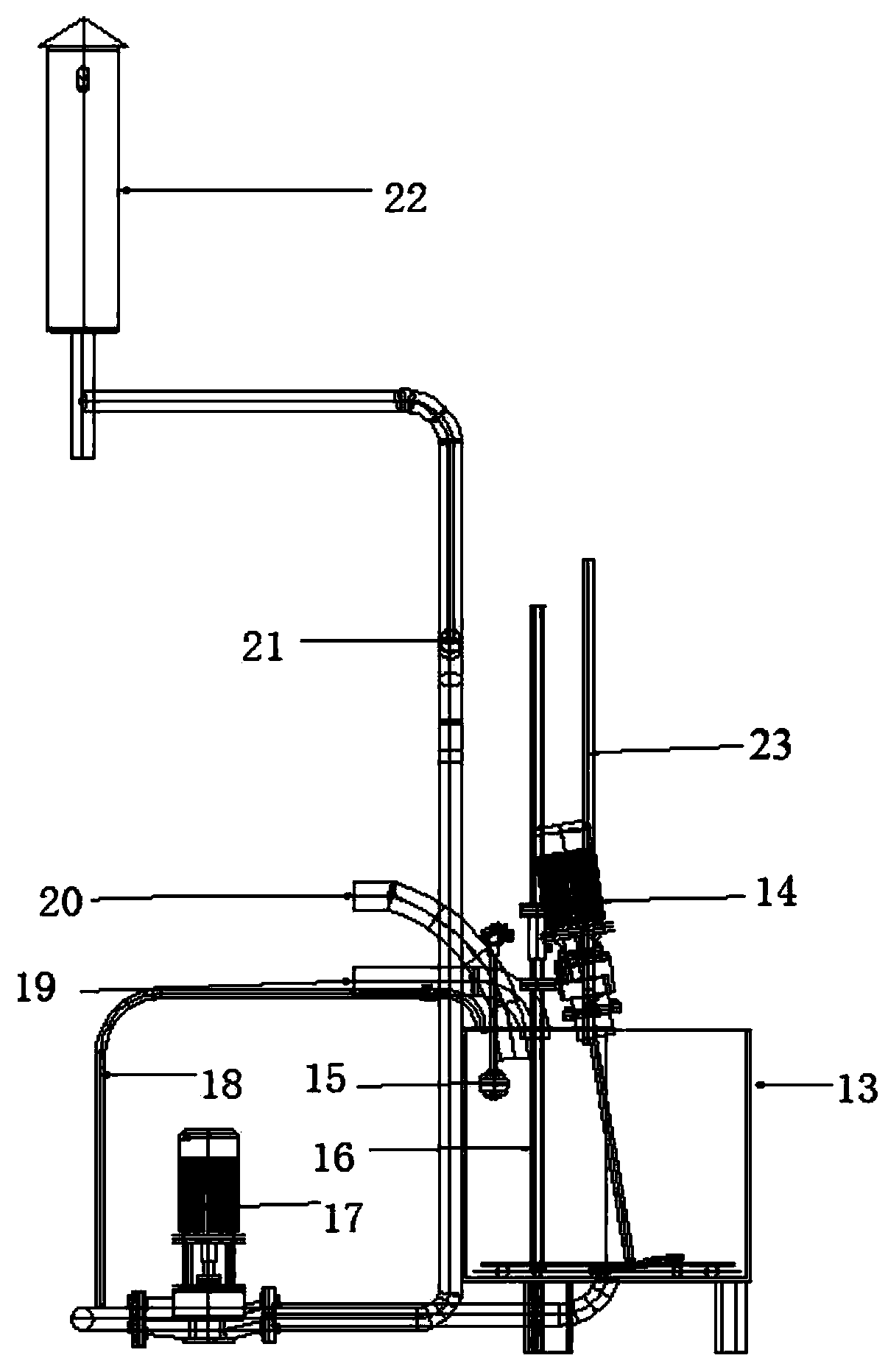

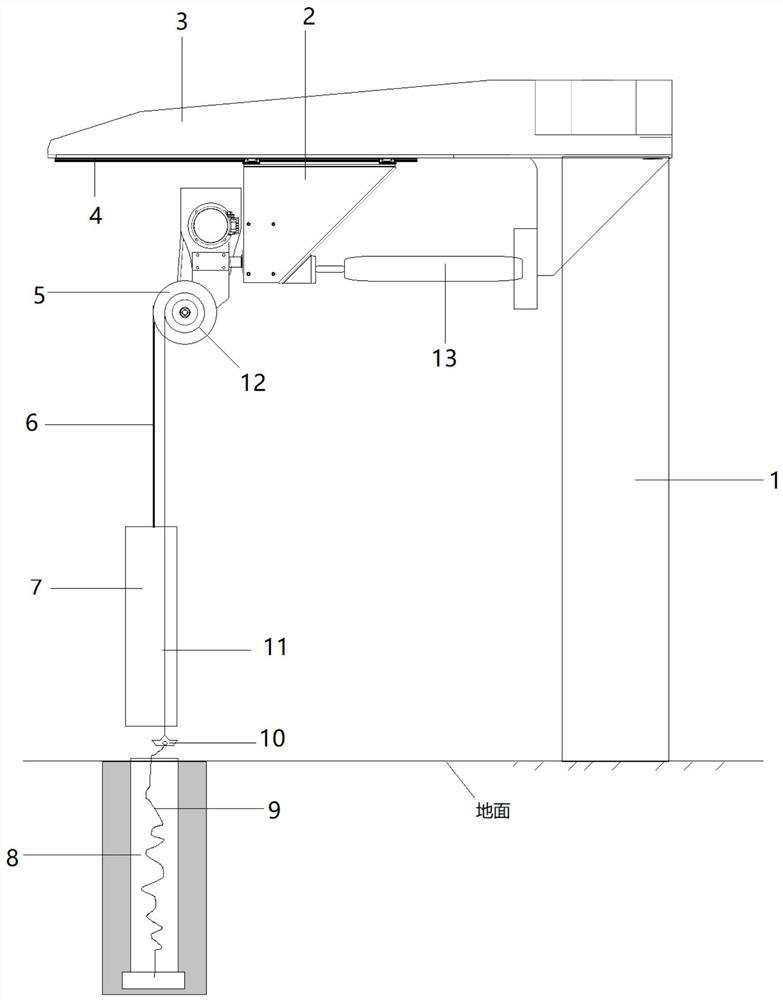

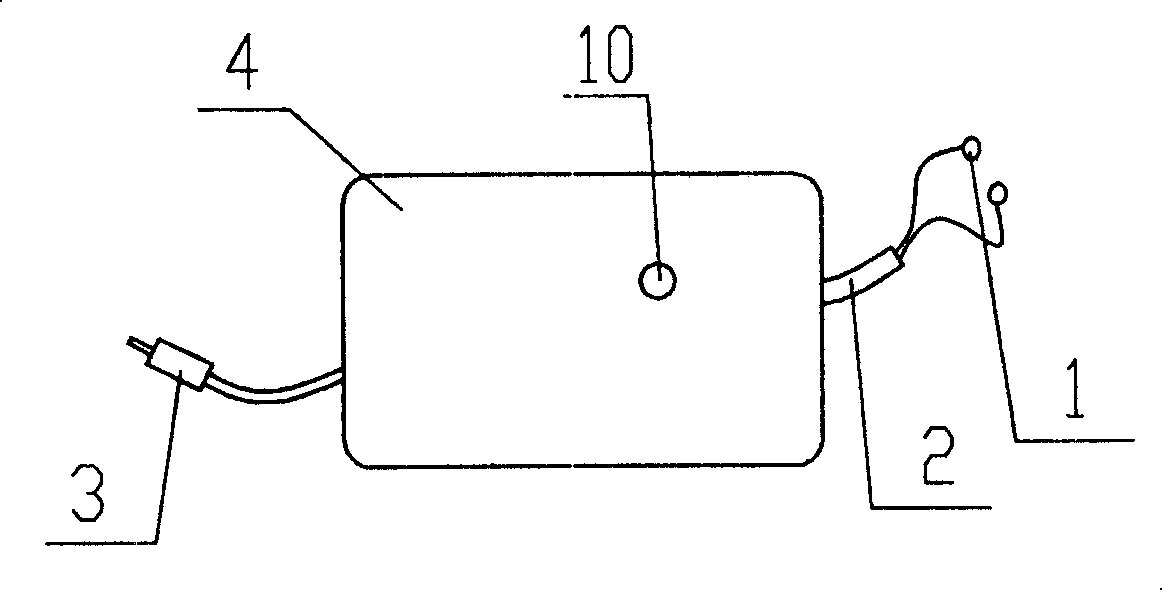

Umbilical cord capstan with life support system

ActiveCN103754787ANot easy to knotProtection securityWinding mechanismsUmbilical cordReal-time communication

The invention discloses an umbilical cord capstan with a life support system. The umbilical cord capstan with the life support system comprises a base seat, a rotation disk, a hydraulic drive device, a manual brake device and the like, wherein the hydraulic drive device drives the rotation disk to rotate forward or backward so as to draw back or stretch out a diving umbilical cord in real time, communication signals are firstly transmitted to a rotation junction box through a fixing junction box and then transmitted to the diving umbilical cord through a slip ring during the diving process, and real-time communication during the diving process is achieved. When a diver dives, the diver can timely control the diving umbilical cord through the manual brake device if an emergency or danger happens, and therefore diving safety of the diver is guaranteed.

Owner:上海打捞局芜湖潜水装备厂有限公司

Superfine steel slag powder based on 3D printing technology and preparation method thereof

ActiveCN114249552ASufficient and appropriate particle sizeSpecific surface area parameters are sufficient and appropriateAdditive manufacturing apparatusSolid waste managementSlagPipe

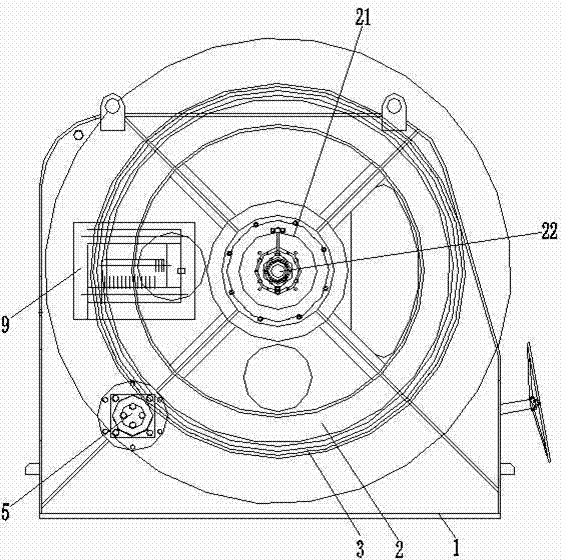

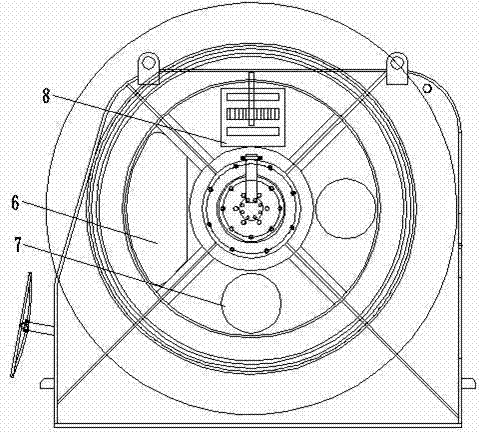

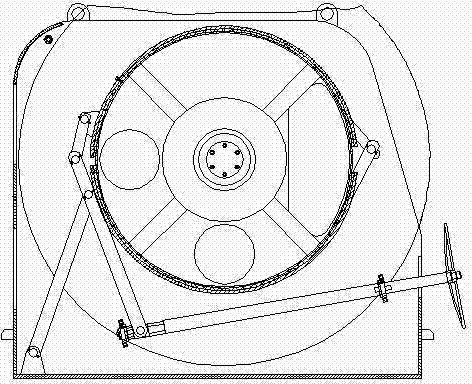

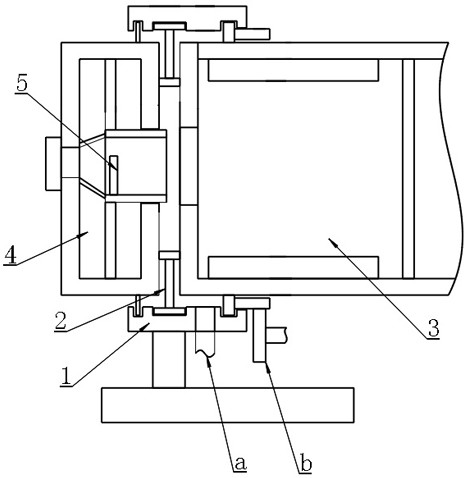

The invention belongs to the technical field of concrete, and particularly relates to superfine steel slag powder based on a 3D printing technology and a preparation method of the superfine steel slag powder. According to the invention, the coarse steel slag powder raw material is ground until the particle size is less than or equal to 6.5 mu m and the specific surface area is 720-750m < 2 > / kg, so that the steel slag powder meets the superfine requirement and can be quickly combined and cured with cement in concrete. In addition, the invention further provides an annular blowing type ball mill which structurally comprises a supporting ring unit, a middle rotating ring unit, a grinding cylinder unit, a feeding cylinder unit and a sliding pipe unit and has the effects of being sufficient in grinding strength and high in grinding efficiency.

Owner:福建源鑫环保科技有限公司

Static drill rooted pile lifting and threading device and construction method thereof

PendingCN112265920ASolve the difficult problem of passing through the pile hole of the upper sectionSpeed up the construction processCranesLoad-engaging elementsPre stressArchitectural engineering

The invention relates to a static drill rooted pile lifting and threading device. The device comprises a self-balancing lifting tool for lifting a pipe pile and a lifting rope hook assembly; the lifting rope hook assembly is mounted on the self-balancing lifting tool and comprises a first pulley, a hanging rope arranged on the first pulley and a pendant connected to the lowermost end of the hanging rope; the first pulley is connected with a first driving mechanism and can be wound around the first pulley under the action of the first driving mechanism to ascend or descend; and the pendant penetrates through a middle hole channel of a lifted tubular pile. When the device is used, an upper pile section is lifted, the pendant penetrates through the middle hole channel of the upper pile section and the bottom of the upper pile section, then the pendant is connected with a prestressed wire at the top of a lower pile section buried underground, and the first pulley performs winding to drivethe prestressed wire at the lower part to move upwards and penetrate through a hole of the upper pile section. Compared with the prior art, the device can solve the problem that a wire in a pile holeof the lower pile section can hardly penetrate through a hole of the upper pile section, and the construction process is greatly accelerated.

Owner:SHANGHAI GUANGDA FOUND ENG

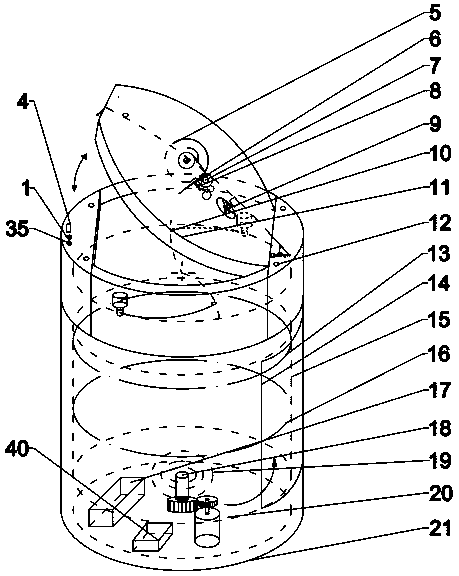

Garbage can with intelligent packaging and bagging functions

The invention discloses a garbage can with intelligent packaging and bagging functions. The garbage can comprises an automatic bagging device (30), an automatic packaging device (32), a cover openingdevice (3), a human body infrared monitoring sensor (1) and a control system (40); the automatic bagging device (30) and the automatic packaging device (32) are respectively arranged on a garbage cancover (11) and at the bottom of a garage can inner barrel (15); the automatic bagging device (30), together with two bag pulling shafts (7) located on the garbage can cover (11), is used for carryingout bagging on the garbage can through a pulling-down pawl I (10) and a pulling-down pawl II (37) located on the inner wall of an outer barrel (21) right above the top of the inner barrel (15); the automatic packaging device (32) is used for monitoring the amount of garbage through a pressure sensor (18) at the bottom, a pressure monitoring ring (13) at the upper end of the inner wall, a pressuremonitoring ring (16) at the middle end of the inner wall and four ultrasonic sensors (12) inside the top end of the garbage can cover (11), and garbage bags are packaged by a rotating mechanism (33) at the bottom and the pulling-down pawl I (10) and the pulling-down pawl II (37) right above the top of the inner barrel (15); and the human body infrared monitoring sensor (1) can monitor a human bodyand control opening and closing of the garbage can cover (11) through the cover opening device (3). According to the garbage can with the intelligent packaging and bagging functions, the problems ofgarbage bag breakage, sewage flowing and the like when the garbage is being bagged and packaged can be effectively solved, the transmission of infectious diseases through the garbage is greatly blocked, the stability of the garbage bags is increased, and thus the quality of life is improved.

Owner:SICHUAN AGRI UNIV

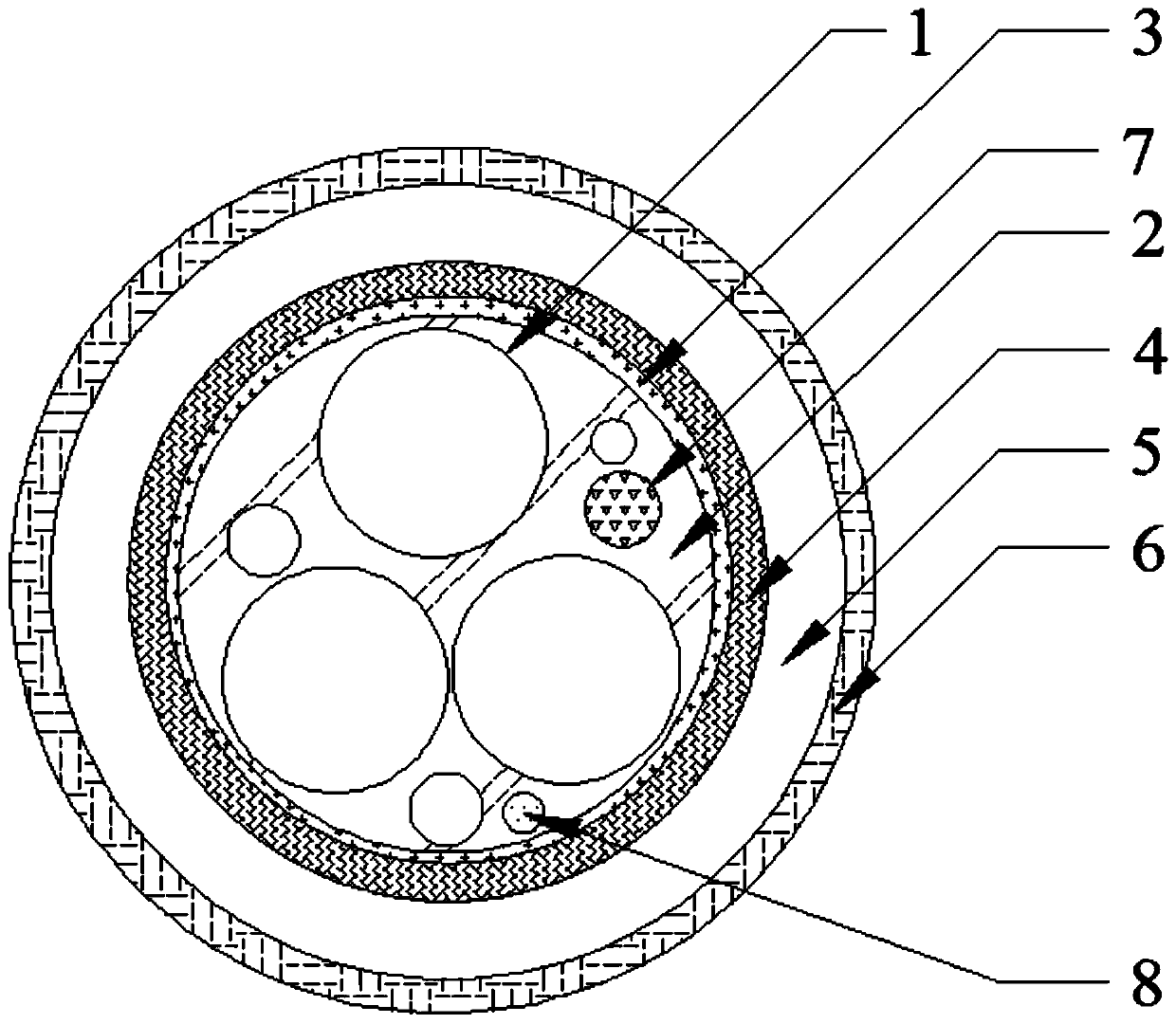

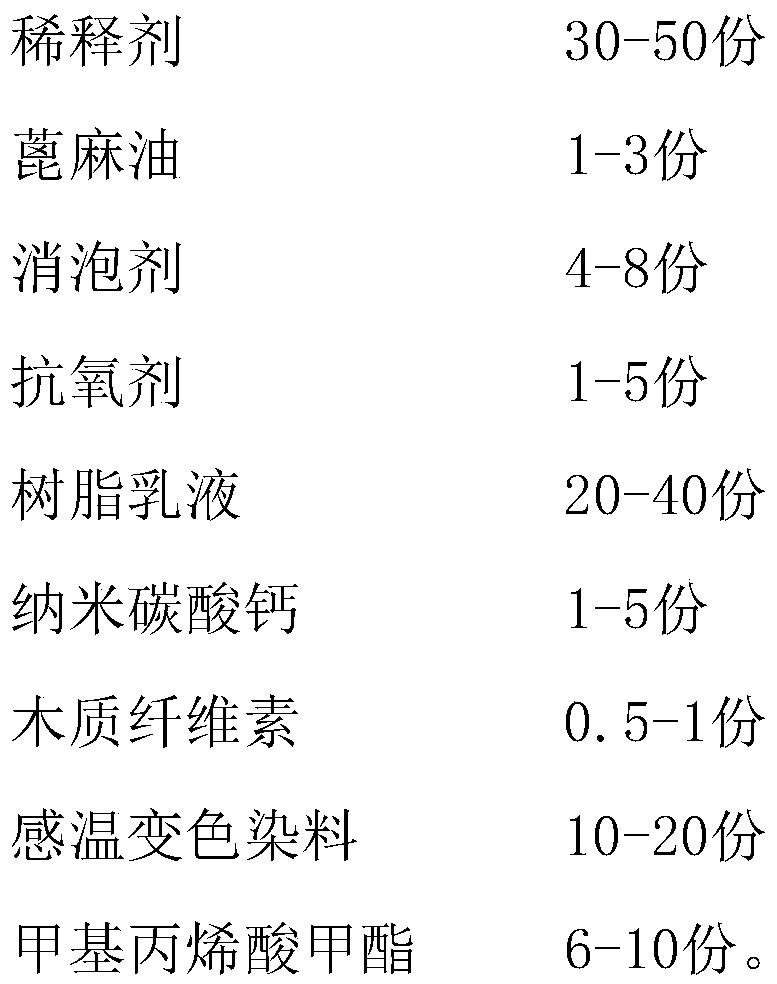

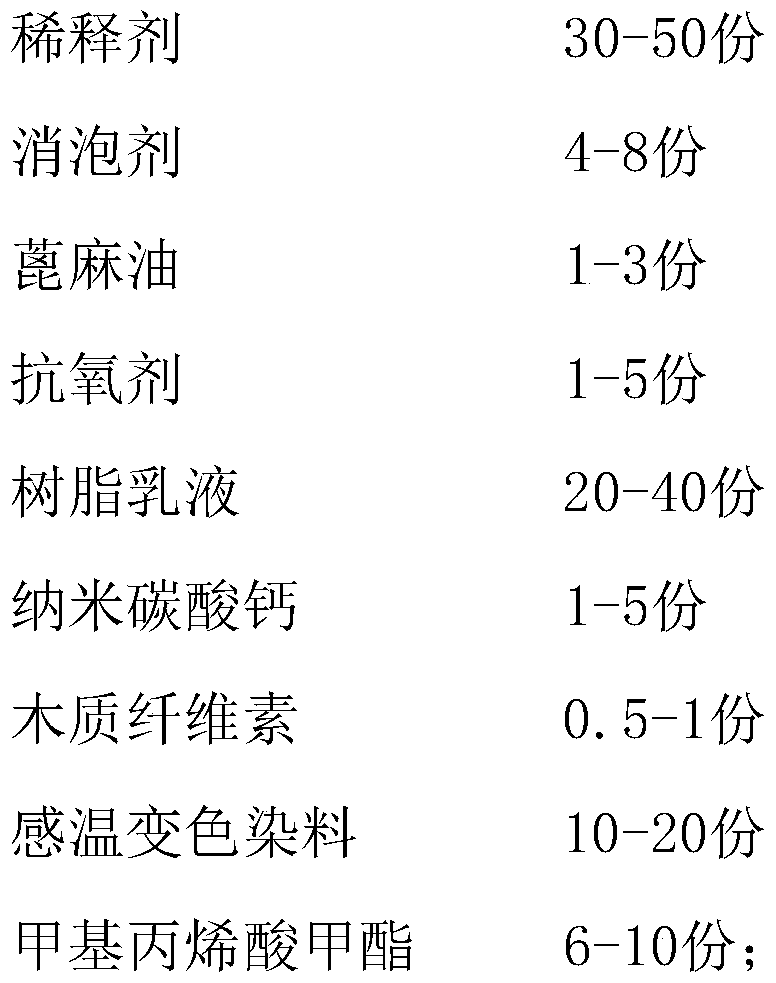

Thermochromic cable and application thereof

The invention relates to the technical field of thermosensitive color-changing cables, in particular to a thermochromic cable, which comprises a plurality of conductive cables with FEP layers, and further comprises a flame-retardant layer, an aluminum foil sleeve layer, a PU winding layer, an insulating layer, a leather layer, a plurality of ground wires and nylon wires, wherein the conductive cables, the ground wires and the nylon wires are mutually twisted and are arranged in the aluminum foil sleeve layer; the aluminum foil sleeve layer is filled with the flame-retardant layer; the outer surface of the aluminum foil sleeve layer is coated with the PU winding layer; the outer surface of the PU winding layer is coated with the insulating layer; the outer surface of the insulating layer iscoated with the leather layer; and the surface of the leather layer is coated with temperature sensing ink. The thermochromic cable prepared by the invention has excellent discoloration, conductivity, wear resistance and aging resistance, and the thermochromic data line prepared from the thermochromic cable has freshness and fashion sense, and in addition, the data line also has the characteristics of smooth surface, difficulty in knotting, firmness and durability.

Owner:DONGGUAN YINGTONG WIRE

Telescopic earphone

InactiveCN101193455ANot easy to knotNot easy to be pulledEarpiece/earphone attachmentsEngineeringHeadphones

Owner:王磊

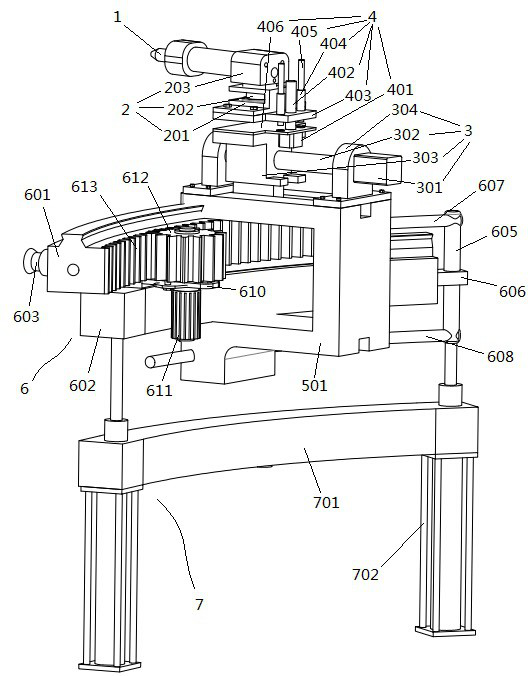

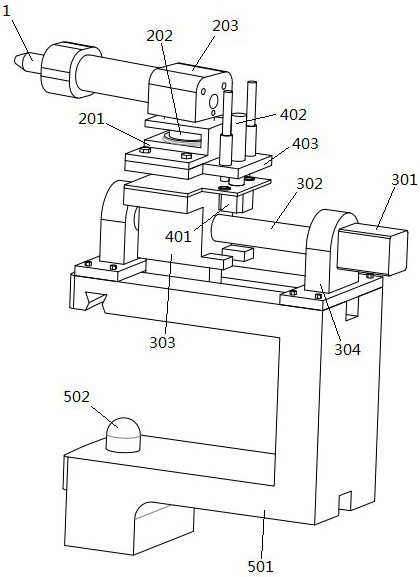

Self-crawling type automatic welding device for large pipelines and containers

ActiveCN114227089AGuaranteed accuracyQuality assuranceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention discloses a self-crawling type automatic welding device for large pipelines and containers. The self-crawling type automatic welding device comprises a welding gun, a welding gun moving mechanism, an annular rotating mechanism and a climbing mechanism. The welding gun movement mechanism comprises a rotating assembly, a feeding assembly, a lifting assembly and a moving assembly. The welding gun is connected to the rotating assembly, the rotating assembly is connected to the feeding assembly, the feeding assembly is connected to the lifting assembly, and the lifting assembly is connected to the moving assembly. The annular rotating mechanism comprises an upper sliding block and a lower sliding block; the upper sliding block and the lower sliding block are both in an arc shape, the upper sliding block is connected to the lower sliding block in a sliding mode, a telescopic magnetic piece a is connected to the outer arc face of the upper sliding block, a telescopic magnetic piece b is connected to the outer arc face of the lower sliding block, and the moving assembly is connected to the top end of the upper sliding block in a sliding mode. Automatic welding of the inner wall of a pipeline or a metal container can be completed, and time and labor are greatly saved; and during welding work, the whole device is stable and reliable, the accuracy of a welding seam is guaranteed, and then the welding quality is guaranteed.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Squeezing preparation method for high-purity mountain tea-seed oil and prepared tea-seed oil capsules

InactiveCN109852468ARetain natural flavorImprove qualityFatty-oils/fats refiningFatty-oils/fats productionFlavorCamellia oleifera

The invention relates to a squeezing preparation method for high-purity mountain tea-seed oil and prepared tea-seed oil capsules. The preparation method comprises the steps: carrying out seed selecting and stack retting till natural cracking; stripping oil tea seeds, and carrying out kernel-shell separation; crushing tea seed kernels into granules, and carrying out low-temperature freezing and vacuum drying; carrying out primary squeezing, so as to squeeze out 30% to 40% of crude oil and prepare tea seed cakes; carrying out secondary squeezing, so as to squeeze out remaining crude oil; carrying out standing oil clarifying, so as to settle impurities in the crude oil and achieve oil-water separation; and carrying out filtering, selecting crude oil of a middle-upper section of an oil clarifying tank, carrying out centrifugal filtering-standing cycling for 2 to 3 times, and carrying out refining, thereby preparing the high-purity mountain tea-seed oil. According to the method, the retention rate of effective ingredients is high, the oil extraction rate is high, the oil quality is high, and the tea-seed oil and the tea-seed oil capsules, which are suitable for being directly eaten, canbe prepared without decolorization and deodorization; and an entire process is free of any chemical assistant, pure physical methods are adopted, and thus, natural flavors and fruity flavors of mountain tea-seed oil are effectively reserved.

Owner:五华县琴江园农业发展有限公司

Shoelace placement device

The invention relates to the technical field of processing of shoes, in particular to a shoelace placement device. The shoelace placement device comprises a conical metal container with a downward head, a round opening is formed in the center of the top of the metal container, and the metal container contains talcum powder. The shoelace placement device is characterized in that the top surface of the metal container is horizontally placed, connecting buckles are evenly arranged on the top edge of the metal container in the peripheral direction and are hung through ropes inclining outwards, a magnet layer is arranged on the inner side of the bottom of the metal container, and a metal end socket for absorbing a shoelace is arranged on the outer side of the bottom of the metal container. By means of the technical scheme, the shoelace is prevented form abrading the hands of workers easily, is not prone to being knotted and can penetrate through a shoe buckle more easily.

Owner:CHONGQING SHUAIMEI SHOES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com