Coiling method for ring-shaped framework coil

A skeleton coil and winding method technology, applied in coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve problems such as disconnection, knotting, and poor coil consistency, and achieve simple procedures, high production efficiency, Effect of improving winding efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings:

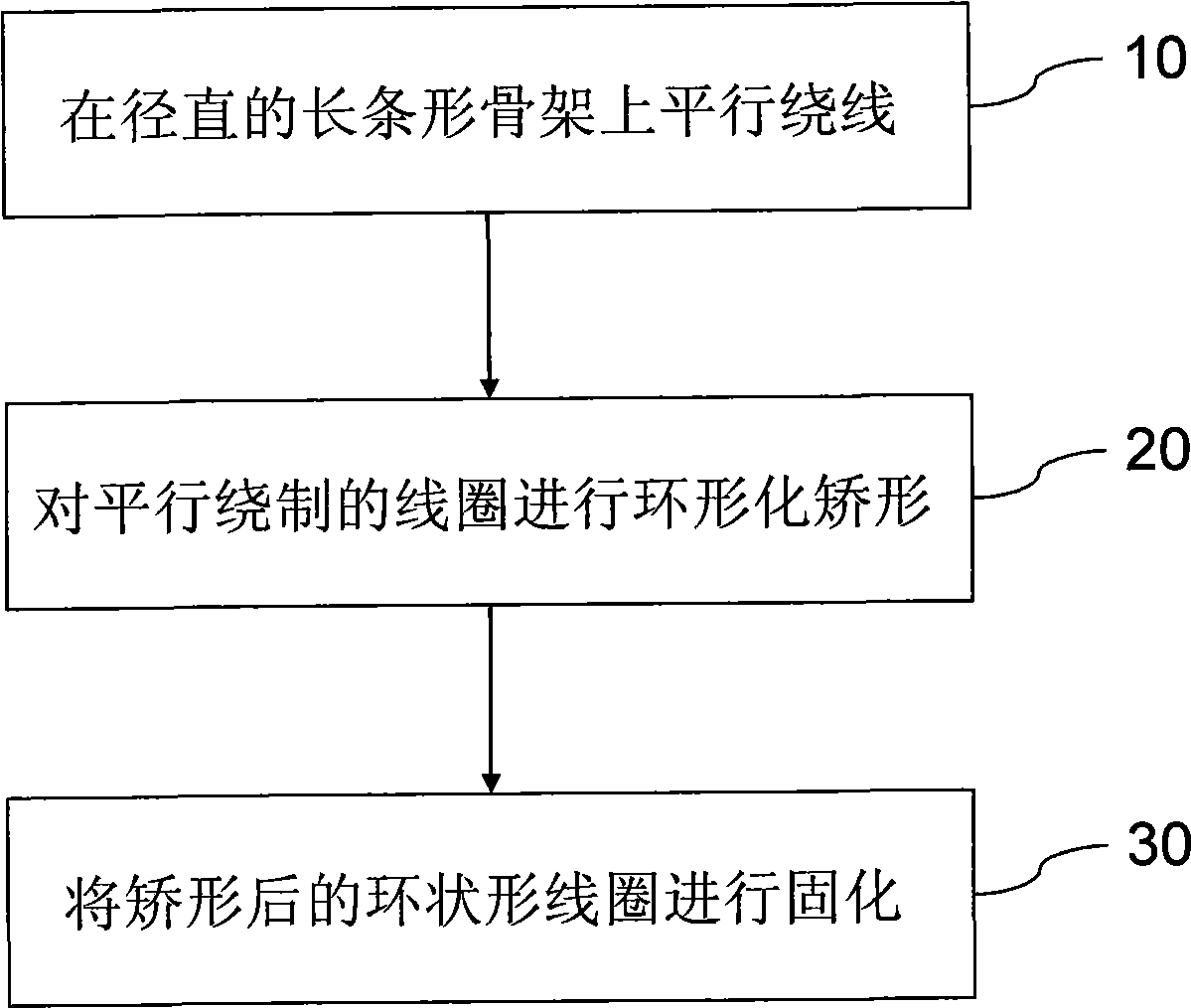

[0021] This embodiment provides a winding method of a ring-shaped bobbin coil, such as image 3 As shown, the method mainly includes:

[0022] Step 10: Parallel winding on the straight strip-shaped skeleton;

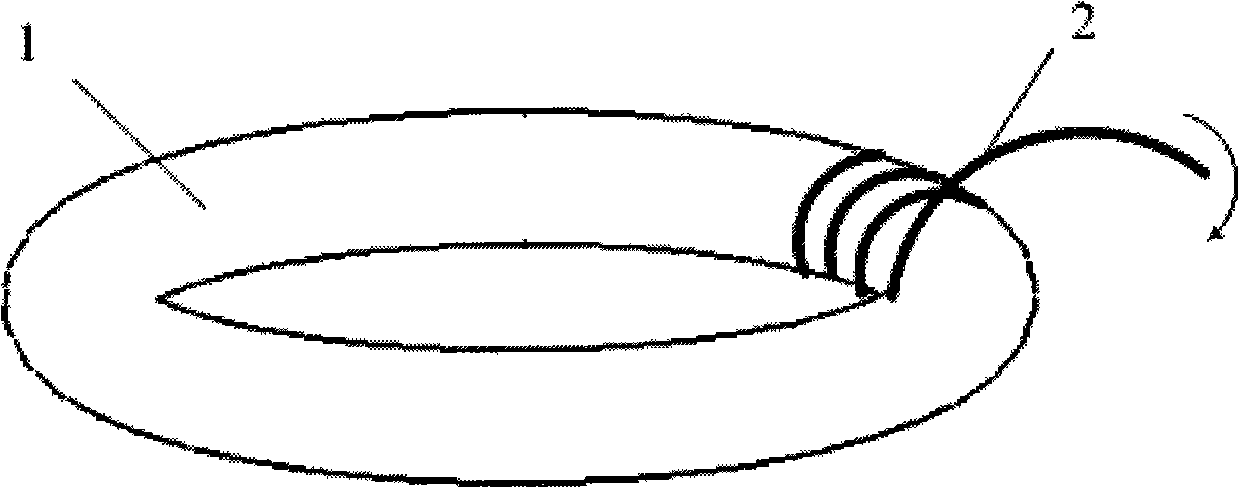

[0023] Step 20 performs ring-shaped correction on the coils wound in parallel;

[0024] Step 30 cures the shaped toroidal coil.

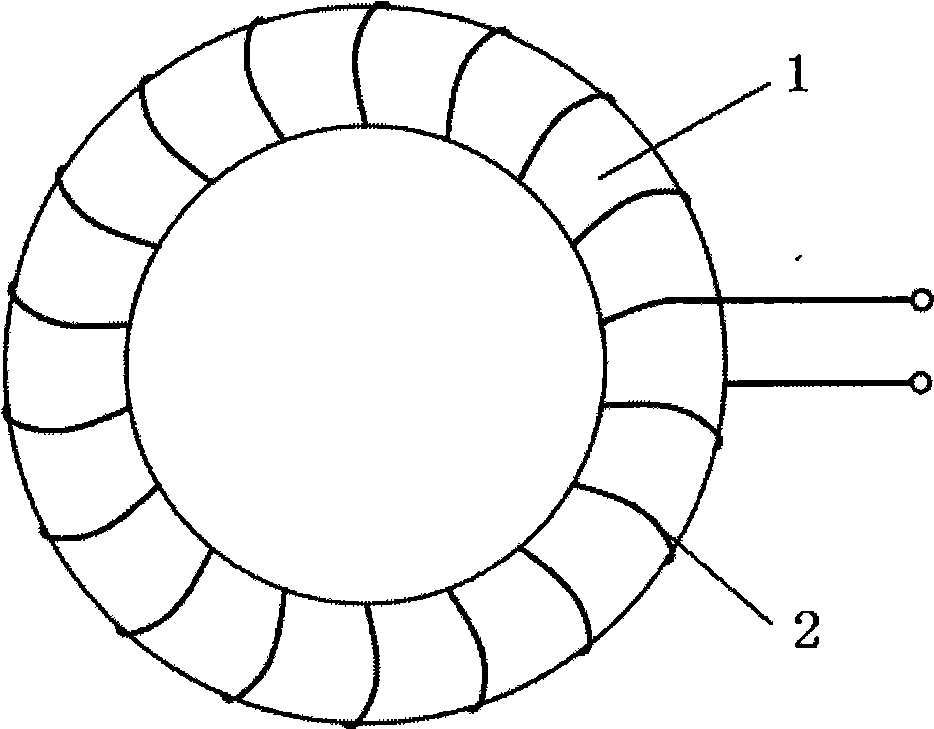

[0025] Described also includes a step before carrying out step 10, skeleton blanking step: as Figure 4 As shown, according to the design requirements, the length l and cross-sectional area s of the skeleton 1 are calculated, and appropriate materials are selected, and a certain margin Δl is reserved on the basis of the calculated length l, and the skeleton 1 is l'=l+Δl The length of blanking.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com