Bead planting method of glass beads of reflective materials

A technology of glass microbeads and reflective materials, applied in optics, optical components, devices for coating liquid on surfaces, etc. Improve product appearance defects, uneven reflective brightness, uniform depth, and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

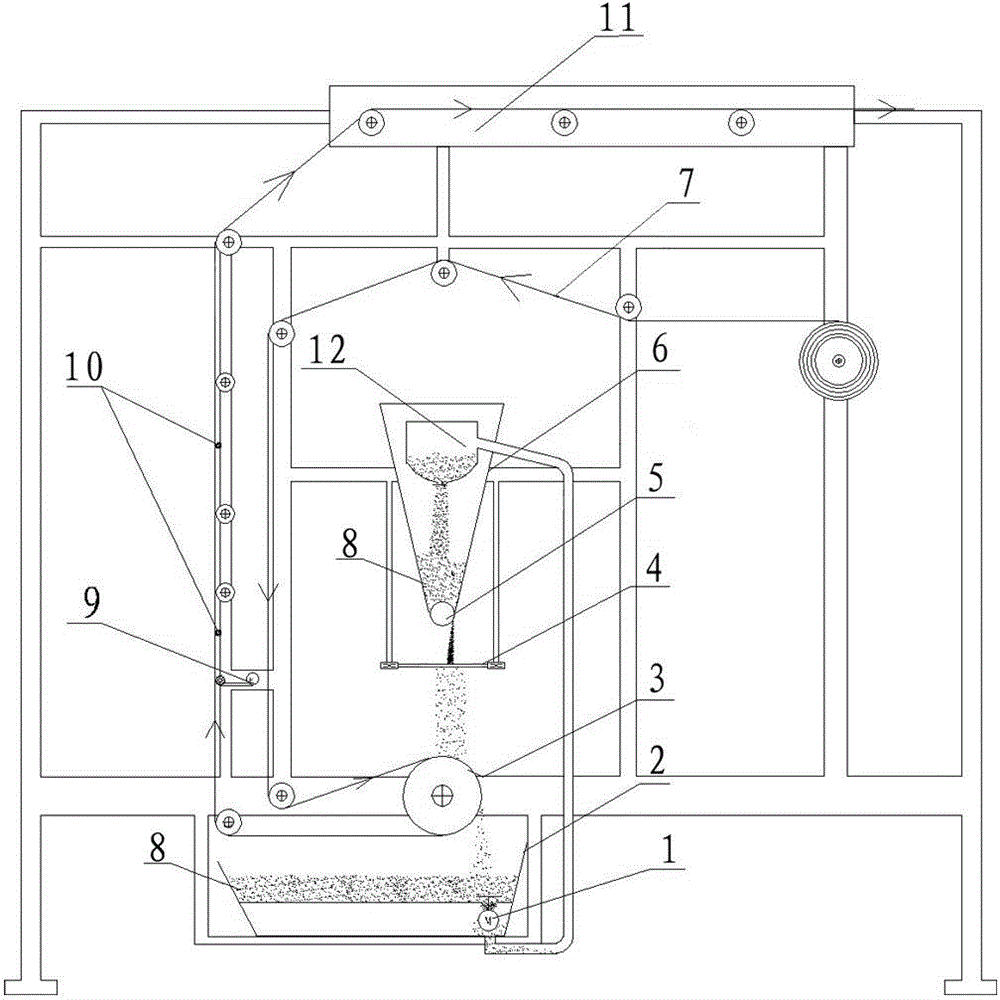

[0041] The method for planting beads of reflective material glass beads comprises the following steps:

[0042] a. Place the glass beads 8 in the trough 6, and heat the heating roller 3 to 50°C;

[0043] b. PET composite film 7 is heated by heating roller 3;

[0044] c. The glass beads 8 in the material trough 6 are evenly spread to the viscous film surface of the heated PET composite film 7 by the feeding roller 5, so as to obtain a PET composite film with evenly distributed glass beads.

[0045] Preferably, the adhesive film layer of the PET composite film 7 is a hot-melt resin film layer. Such as: polyester resin, elastic polyurethane resin, polyvinyl alcohol resin.

Embodiment 2

[0047] In the bead planting method of reflective material glass beads, in step a, the heating roller 3 is heated to 80° C., and preferably, the adhesive film layer of the PET composite film 7 is a thermoplastic resin film layer. Such as: polyethylene vinyl acetate resin, polyethylene resin.

[0048] All the other implementation steps and modes are the same as in Example 1.

Embodiment 3

[0050] In the bead planting method of reflective material glass beads, in step a, the heating roller 3 is heated to 160° C., and preferably, the adhesive film layer of the PET composite film 7 is a thermoplastic resin film layer. Such as: polyethylene vinyl acetate resin, polyethylene resin.

[0051] All the other implementation steps and modes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com