Continuous strip forming manufacturing method of flexible circuit boards, and device

The technology of a flexible circuit board and its manufacturing method is applied in the directions of printed circuit manufacturing, lighting and heating equipment, structural connection of printed circuit, etc. It can solve the problems of limited original film length and unfavorable light strip, etc., and achieves simple method, easy operation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention relates to a method for continuously forming flexible circuit boards into strips. The flexible circuit boards with several strip-shaped units arranged side by side face each other end-to-end and are connected with one strip-shaped unit apart, and then the strip-shaped units are separated from each other and wound into a strip.

[0026] In the present invention, the flexible circuit boards with several strip-shaped units arranged side by side face each other end-to-end and connect with one strip-shaped unit, and then the strip-shaped units are separated from each other and wound into a strip. The length of the strip-shaped flexible circuit board obtained by winding is not Several times the length of the flexible circuit board at the end connection, the method is simple, easy to operate, no intertwining phenomenon will occur after the dislocation connection is completed, it can be quickly rewound, the efficiency of production and processing is improved, and it...

Embodiment 2

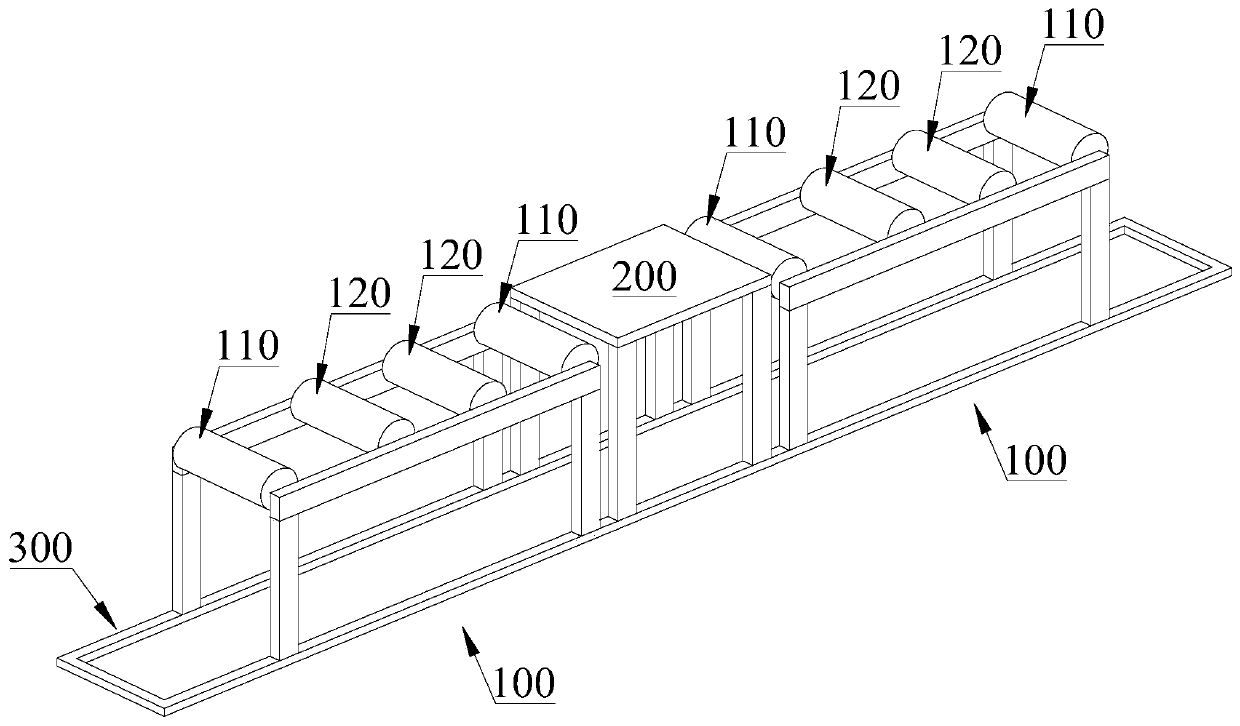

[0034] Such as figure 1 As shown, a kind of equipment that applies the above-mentioned flexible circuit board continuous strip manufacturing method includes two end brackets 100 arranged apart from each other and a docking platform 200 arranged between the two end brackets 100 apart from each other, and has several side-by-side strip-shaped The first and last ends of the flexible circuit board of the unit go around the two end brackets 100 and then stagger a belt-shaped unit on the docking platform 200 to join. The docking platform 200 provides a stable support operation platform for the head-to-tail misalignment connection, where workers can perform connection operations; the docking platform 200 is arranged between the two end brackets 100, and the head and tail ends of the flexible circuit board are respectively bypassed by two The end brackets 100 finally converge on the docking platform 200, which can avoid winding when they are divided into strips after connection, and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com