Yarn winding device

A winding device and yarn technology, applied in the field of textile machinery, can solve problems such as difficult winding, easy yarn falling off, inconvenient production and processing of textile machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below.

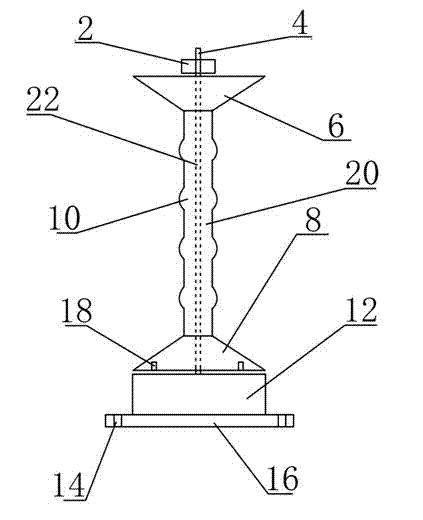

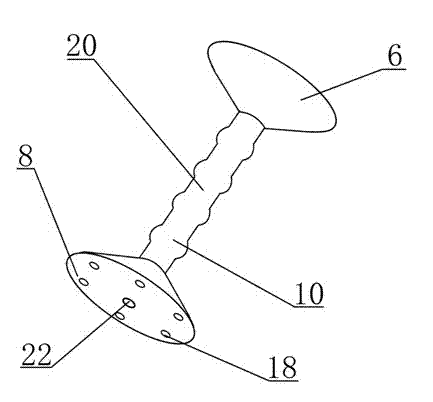

[0017] Such as figure 1 with figure 2 As shown, a yarn winding device of the present invention includes a device main body 20 and a base 12 arranged below the main body. The device main body 20 includes a top cone 6, a vertical rod 10 and a bottom cone 8. There are several circles of protrusions on the vertical rod 10. , the top cone 6 is an inverted cone with a large top and a small bottom, and the bottom cone 8 is a positive cone with a small top and a large bottom; the number of protrusions on the vertical rod 10 is 4; the diameter of the upper and lower vertebral bodies is 5 times the diameter of the vertical rod The center of the main body 20 of the yarn winding device is a through passage 22, which is used to connect to the base 12; the bottom surface of the bottom cone 8 is a circle of fixing holes 18; On the bottom plate 16 below the base, the column 4 is used to connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com