High-efficiency online oven for steel wires

A technology of oven and steel wire, which is applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of low work efficiency, easy to produce staggered knots, uneven oven temperature, etc., and achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

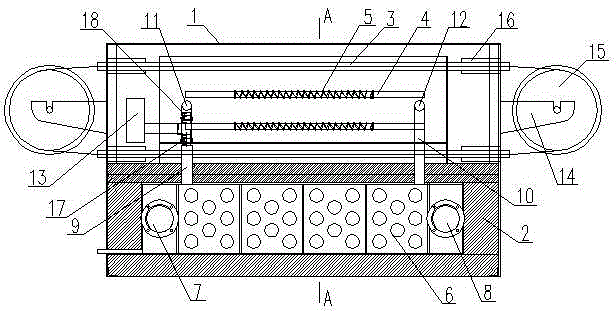

[0018] A high-efficiency steel wire online oven, comprising an electric heating oven 1 and a hot air oven 2, the electric heating oven 1 is installed above the hot air oven 2, a row of horizontally arranged heat transfer tubes 3 are respectively arranged at the upper and lower ends of the electric heating oven 1, and the electric heating There are two rows of electric heating tubes 4 in the middle of the oven 1, the electric heating tubes 4 are covered with electric heating wires 5, the hot air oven 2 is provided with a heat exchanger 6, and the front end of the hot air oven 2 is provided with a hot air inlet 7 and a hot air outlet 8, the upper end of the heat exchanger 6 is provided with a heat exchange inlet 9 and a heat exchange outlet 10, the front end of the electric heating oven 1 is provided with a blowing port 11 and a heat inlet 12, and the front end of the electric heating oven 1 is provided with a fan 13. The blower 13 is respectively connected to the air outlet 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com