Patents

Literature

65results about How to "Good filtration accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gradient-pore silicon nitride and silicon carbide combined film tube and preparation method therefor

ActiveCN105727755AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareChemical industryPorous ceramics

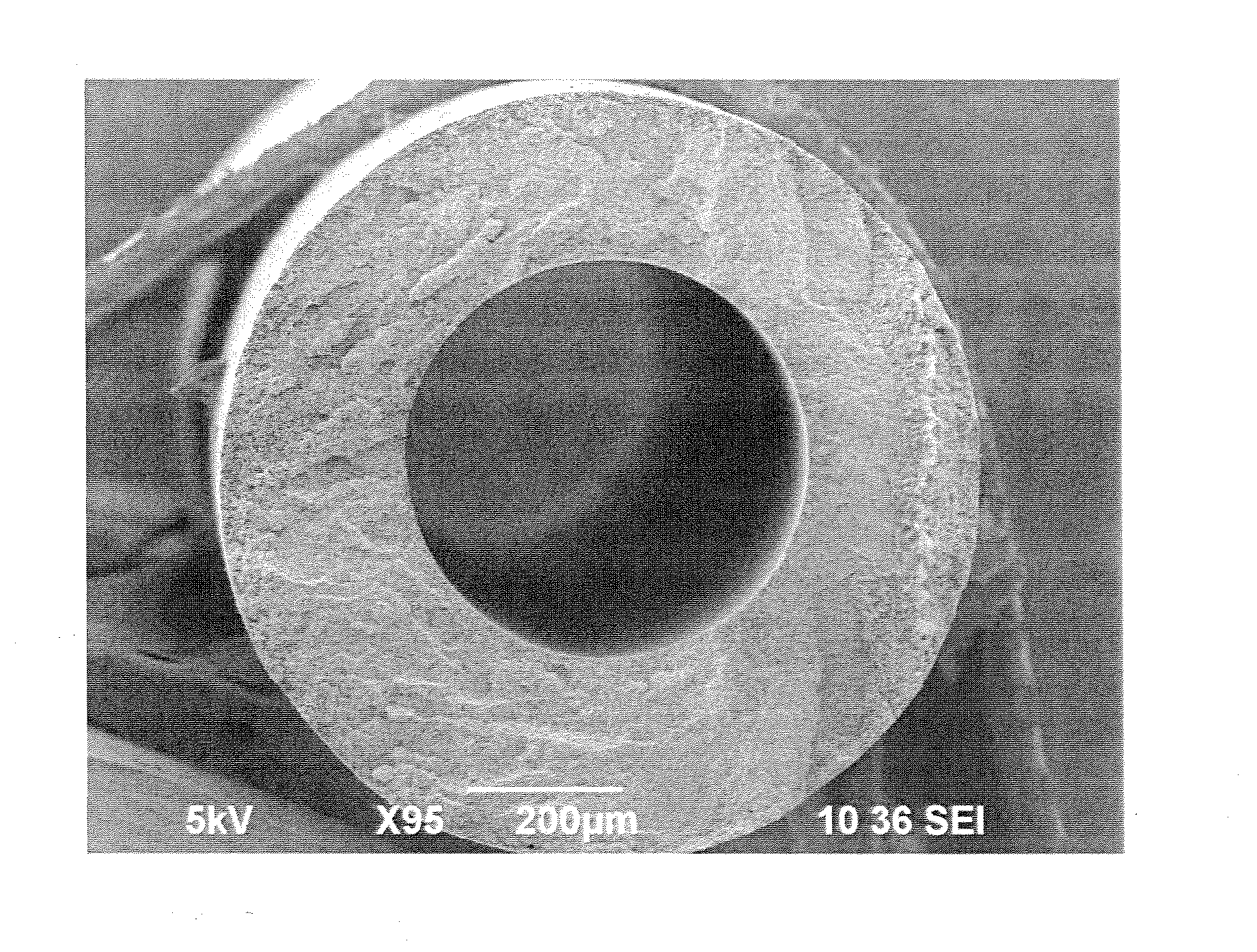

The invention belongs to the field of porous ceramic materials and particularly relates to a gradient-pore silicon nitride and silicon carbide combined film tube and a preparation method therefor. The film tube material is prepared from silicon nitride and silicon carbide, and a gradient filtering structure is formed by a supporting body layer and a surface film layer; a supporting body is formed through combining silicon nitride produced from a reaction with coarse silicon carbide grains and has the average pore size of 10 to 80 microns, the surface film layer is formed through combining the silicon nitride produced from the reaction with fine silicon carbide grains and has the average pore size of 0.1 to 20 microns, and the overall porosity of the film tube is 35% to 50%. The preparation method sequentially comprises the steps of carrying out batching, forming the supporting body, preparing the film layer and carrying out firing, wherein the forming is carried out by adopting isostatic pressing, the forming pressure is controlled to 40MPa to 150MPa, the firing temperature is controlled to 1,400 DEG C to 1,650 DEG C, and the heat preserving time is 3 to 5 hours. The film tube can be used in an oxidative atmosphere, can also be used in a reducing atmosphere, is high in acid-alkali corrosion resistance and can be applied to the filtering and purifying of various high- and low-temperature fluids of coal gasification chemical industry, IGCC and PFBC coal-gasified power generation, high-temperature flue gas, automobile exhaust gas, water purification and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

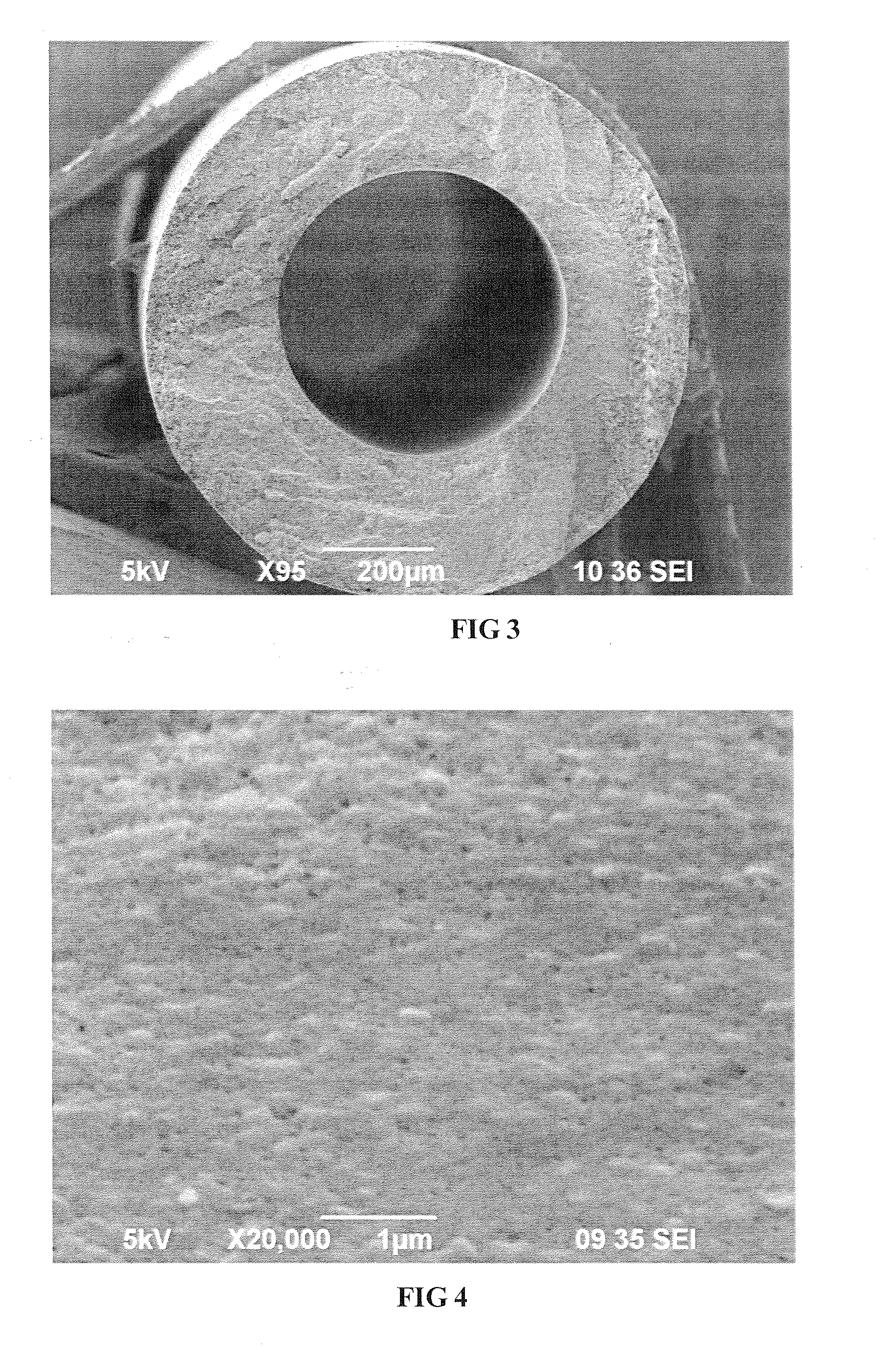

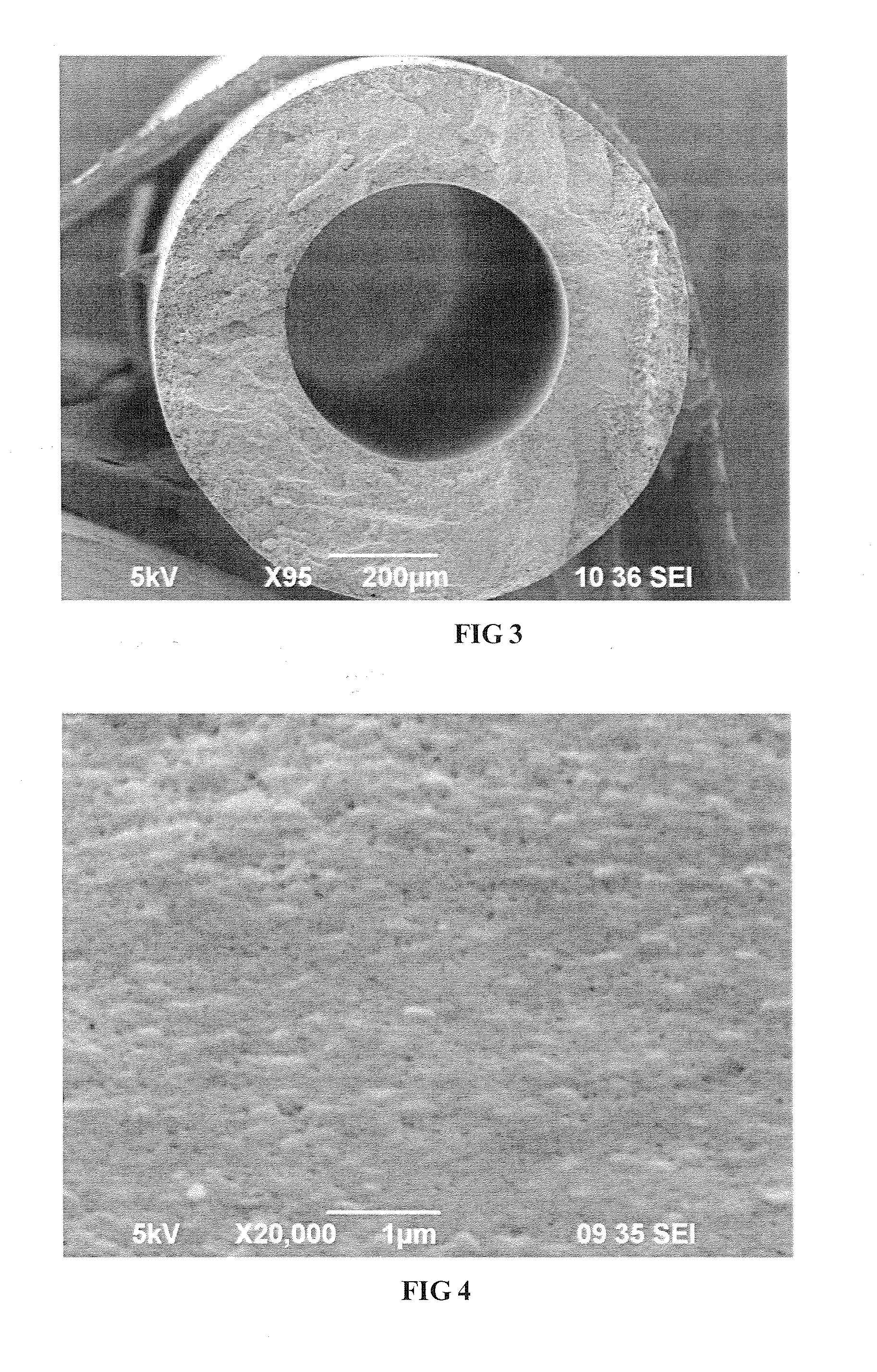

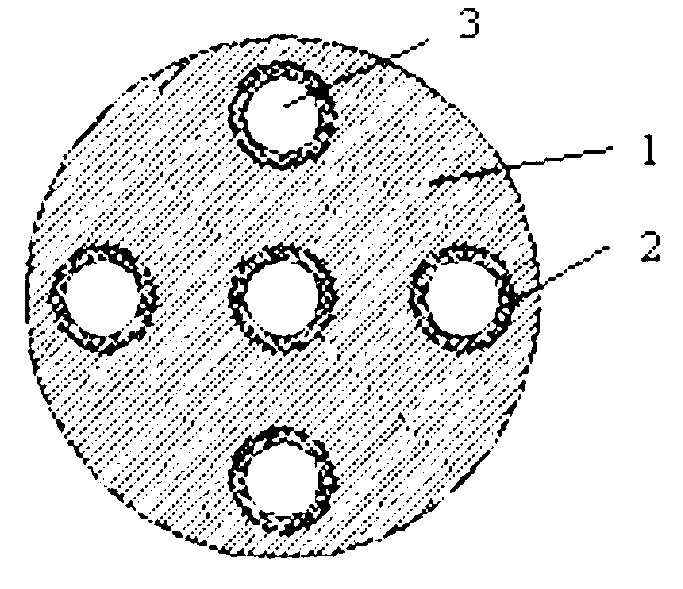

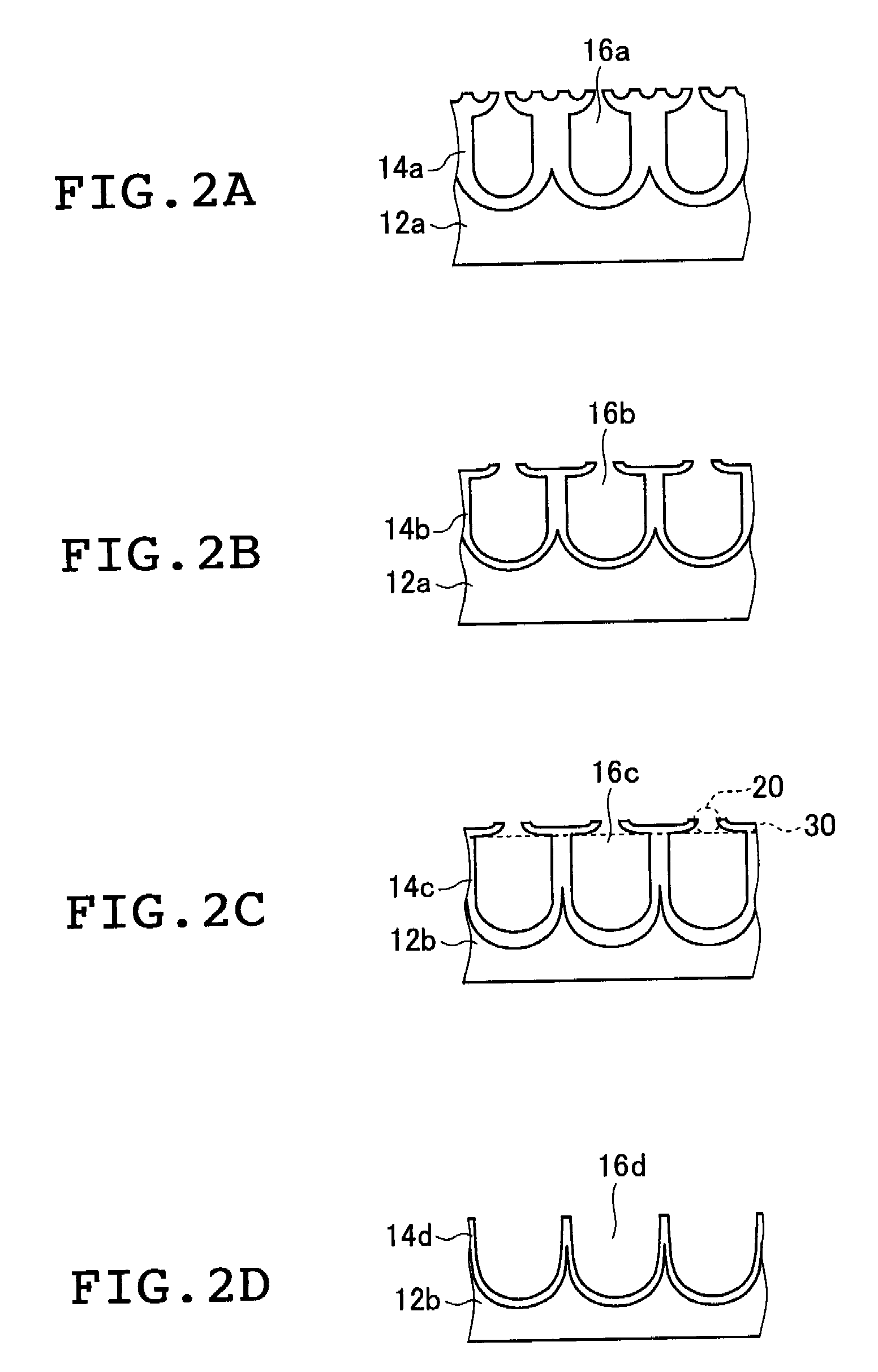

Method for preparing double layered porous hollow membrane and device and product thereof

InactiveUS20150136691A1Easily and quickly abstractedLow mechanical strengthSemi-permeable membranesMembranesFiberFiltration

A method for preparing a double layered porous hollow fiber membrane and the device and product thereof. The method comprises preparing uncured porous hollow fiber with larger pore diameters as the inner robust supporter of the membrane from thermoplastic polymeric resins by thermal induced phase separation (TIPS) method and then binding an ultra thin coating layer with hydrophilic microfiltration or ultrafiltration function and fine pore diameters prepared on the outer surface of the robust hollow fibers from a solution of the thermoplastic polymeric resins by a coating process using non-solvent induced phase separation (NIPS) method. The double layered porous hollow fiber membranes have such excellent mechanical strength and high water permeation as the membranes prepared by thermal induced phase separation (TIPS) method, such high accurate filtration effect, high hydrophilic effect and high fouling resistance as the membranes prepared by non-solvent induced phase separation (NIPS) method, and high binding force of the membranes between the layers by the above method.

Owner:MEMSTAR (GUANGZHOU) CO LTD

Method for preparing composite multilayer porous hollow membrane and device and product thereof

ActiveUS20120085698A1Easily and quickly abstractedLow mechanical strengthSemi-permeable membranesLiquid surface applicatorsFiberPolymer science

A method for preparing a composite multilayer porous hollow fiber membrane and the device and product thereof. The method comprises preparing uncured porous hollow fibers with larger pore diameters as the inner supporter of the membrane from thermoplastic macromolecule polymer resins by thermal induced phase separation method and then bonding a superthin coating layer with microfiltration or nanofiltration function and small pore diameter prepared on the outer surface of the hollow fibers from a solution of the thermoplastic macromolecule polymer resins by a coating process using non-solvent induced phase separation method. The composite multilayer porous hollow fiber membrane has such excellent mechanical strength and high water flux as the membranes prepared by thermal induced phase separation method, such high precision filter effect and high contamination resistance as the membranes prepared by non-solvent induced phase separation method, and high binding force of the membrane prepared by the above method.

Owner:JIANGSU MEMSTAR MEMBRANE MATERIAL TECH CO LTD

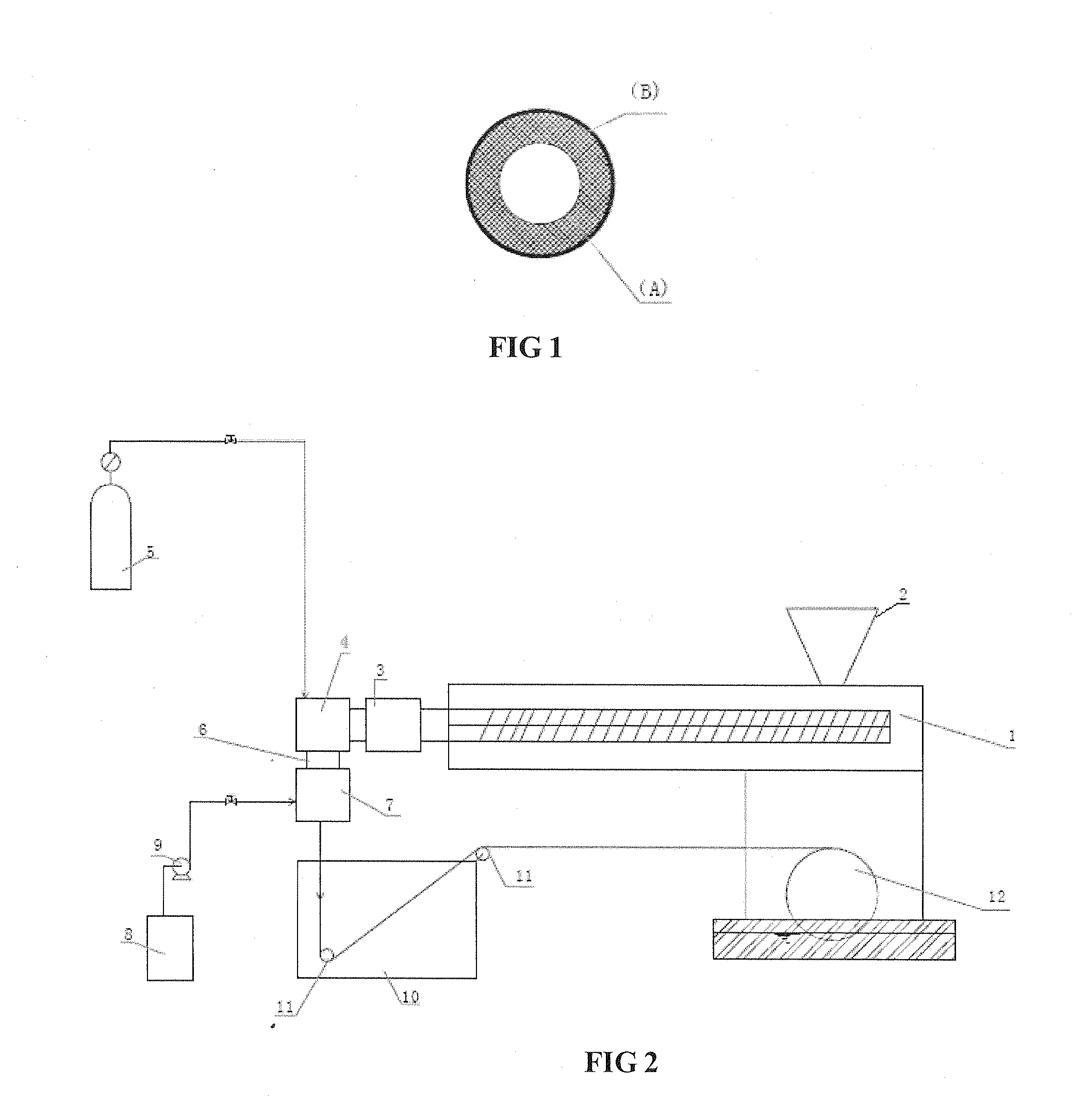

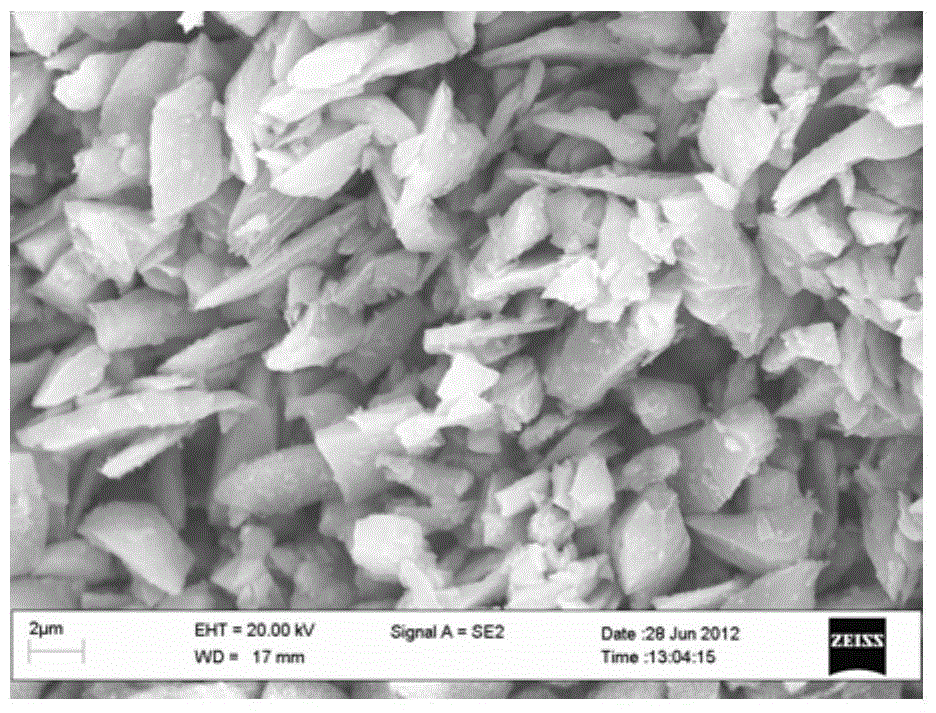

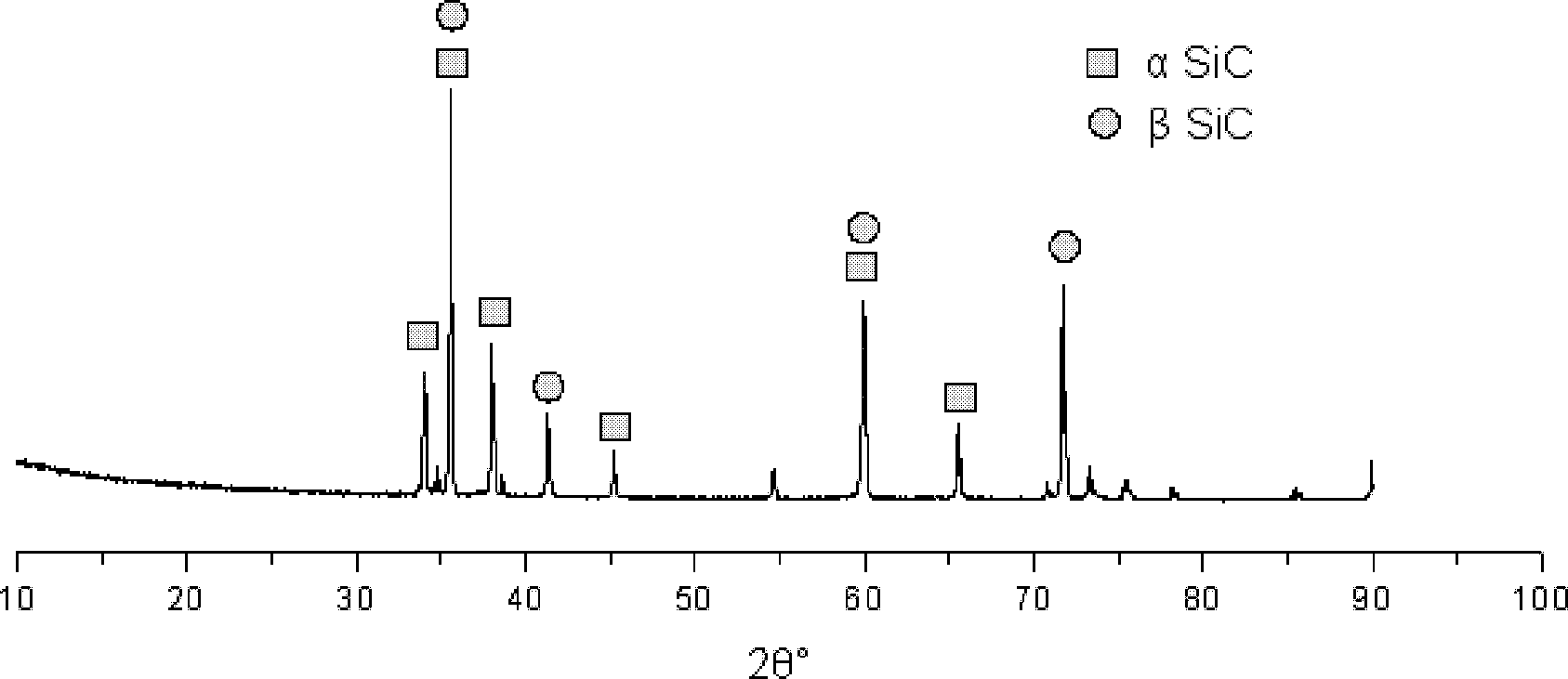

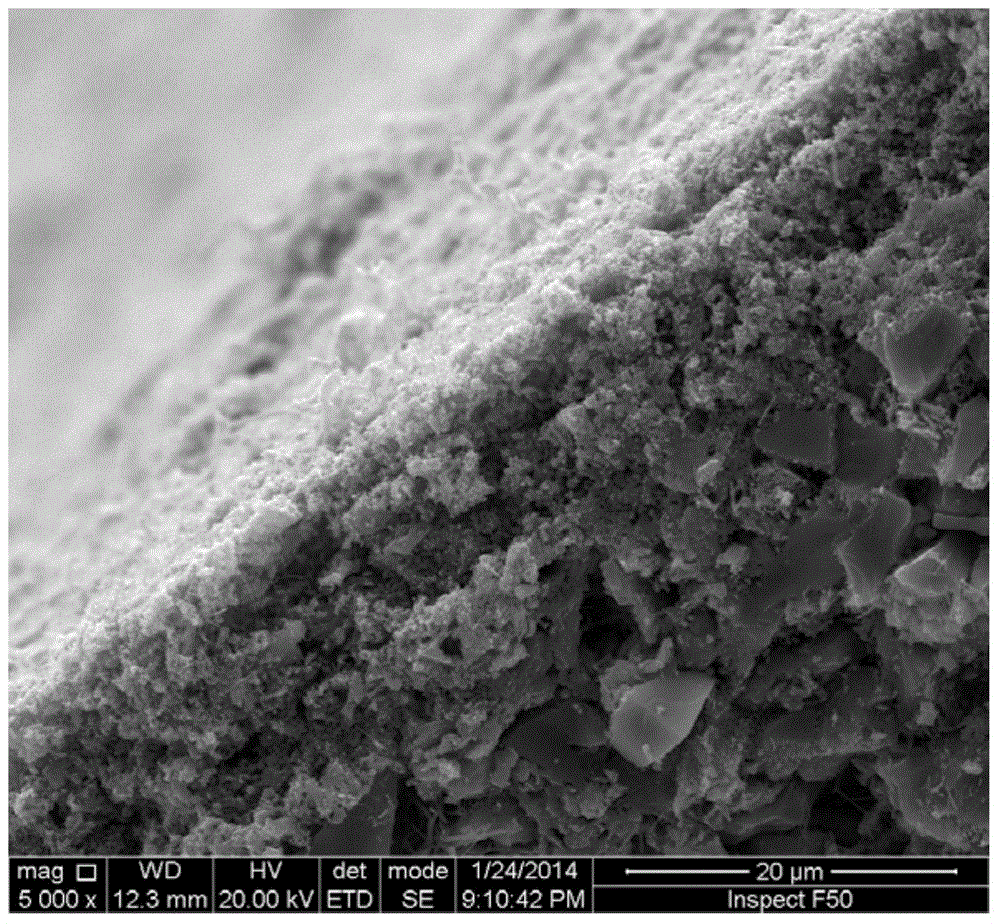

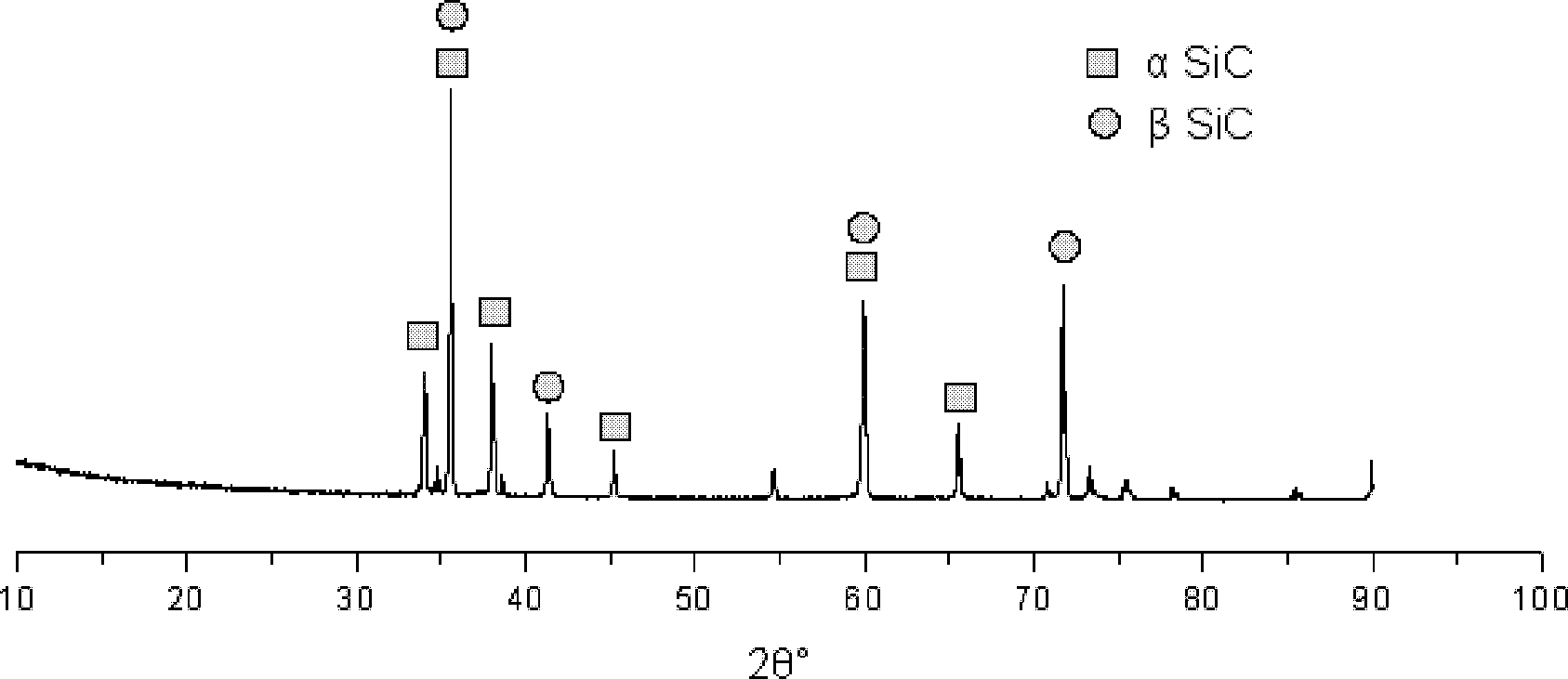

Silicon carbide filtering film and low temperature preparation method thereof

ActiveCN105693276AGood stabilityExtended service lifeSemi-permeable membranesCeramicwareStrong acidsMicrometer

The invention belongs to the field of porous ceramic materials and discloses a silicon carbide filtering film and a low temperature preparation method thereof. The silicon carbide filtering film comprises pure SiC, a surface film layer is prepared from fine grain silicon carbide through accumulation, has the pore diameter of 20 nanometers to 20 micrometers and film layer porosity of 40-50% and has high through porosity, low pressure drop, high strength, good thermal shock resistance and a high usage temperature. Film slurry is prepared from fine silicon carbide particles, an organosilicon precursor and a pore forming agent additive, the surface is spray-coated with the film slurry so that a film layer is formed, and the film layer is dried and sintered so that a pure silicon carbide film is obtained. The organosilicon precursor is cracked to produce a coupling phase, a sintering temperature is low, an aperture structure can be controlled easily, and the film layer can be used in an oxidation atmosphere and in a reduction atmosphere, has strong acid and base resistance and can be used for various high and low temperature fluid filtering purification such as coal gasification chemical engineering, IGCC and PFBC coal gasification generating, and high temperature flue gas, automobile exhaust and water purification.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Supported hydrophilic polyvinylidene fluoride microporous membrane and preparation method thereof

ActiveCN104667763AThorough extractionUniform pore size distributionSemi-permeable membranesPolyvinylidene difluorideSolvent

The invention relates to a supported hydrophilic polyvinylidene fluoride microporous membrane and a preparation method thereof. The pore size of the microporous membrane is 0.1-20 mu m, and the thickness of the microporous membrane is 90-200 mu m. The method comprises the following steps: 1)the preparation of a casting membrane solution, dissolving a polyvinylidene fluoride resin in a solvent firstly, adding hydrophilic components and an additive, and at temperature of 30-80 DEG C, fully stirring the obtained mixture so as to form the uniform and stable casting membrane solution; and 2) membrane formation by phase inversion: casting the casting membrane solution on a support layer, carrying out membrane wiping on the support layer saturating in the casting membrane solution by using a scraper under the condition that a gap between the scraper and the support layer is 15-40 mu m, standing for 10-400 seconds in the air, and after a membrane sequentially passes through a first coagulation bath, a second coagulation bath and a third coagulation bath, taking out the membrane, and drying the membrane,,and then the hydrophilic microporous membrane is obtained. Compared with the prior art, the membrane disclosed by the invention has the advantages of thorough extraction, uniform pore size distribution, better filtering accuracy and filtering efficiency, capability of being applied to continuous mass production, stable product performances, and the like.

Owner:上海一鸣过滤技术有限公司

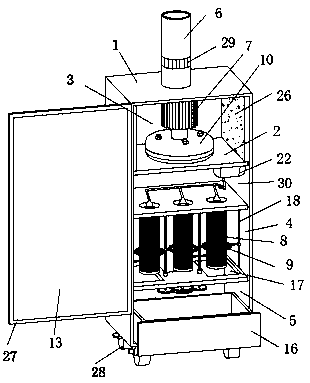

Movable dust removal equipment for industrial factory building

InactiveCN111346449AExtended service lifeFast cleaningDispersed particle filtrationTransportation and packagingActivated carbon filtrationDust control

The invention relates to the technical field of industrial factory building dust removal, and in particular, relates to movable dust removal equipment for an industrial factory building, wherein the movable dust removal equipment comprises a machine box body, the interior of the machine box body is sequentially divided into a power cavity, a reverse blowing cavity, a filtering cavity and a collecting cavity from top to bottom through two transverse partition plates, an air outlet pipe is arranged at the top of the power cavity, and an activated carbon filter is arranged on the air outlet pipe;a centrifugal fan communicated with the air outlet pipe is arranged in the power cavity, and the bottom end of the centrifugal fan is communicated with an air collecting disc; a filter cartridge typefilter and an ash removal device are arranged in the filter cavity, the left outer wall and the right outer wall of the filter cavity are communicated with air inlets, and electronic air valves are arranged in the air inlets; an ash collecting drawer is slidably mounted in the collecting cavity, and an ash falling hole is formed in the transverse partition plate between the collecting cavity andthe filtering cavity; walking wheels are fixedly mounted at four corners of the lower end surface of the bottom end of the machine box body; dust on the surface of the filter element can be cleaned while the filter element filters gas, and meanwhile, the filter element can be matched with the reverse blowing system to accelerate the cleaning speed of industrial dust.

Owner:界首尚嘉工业设计有限公司

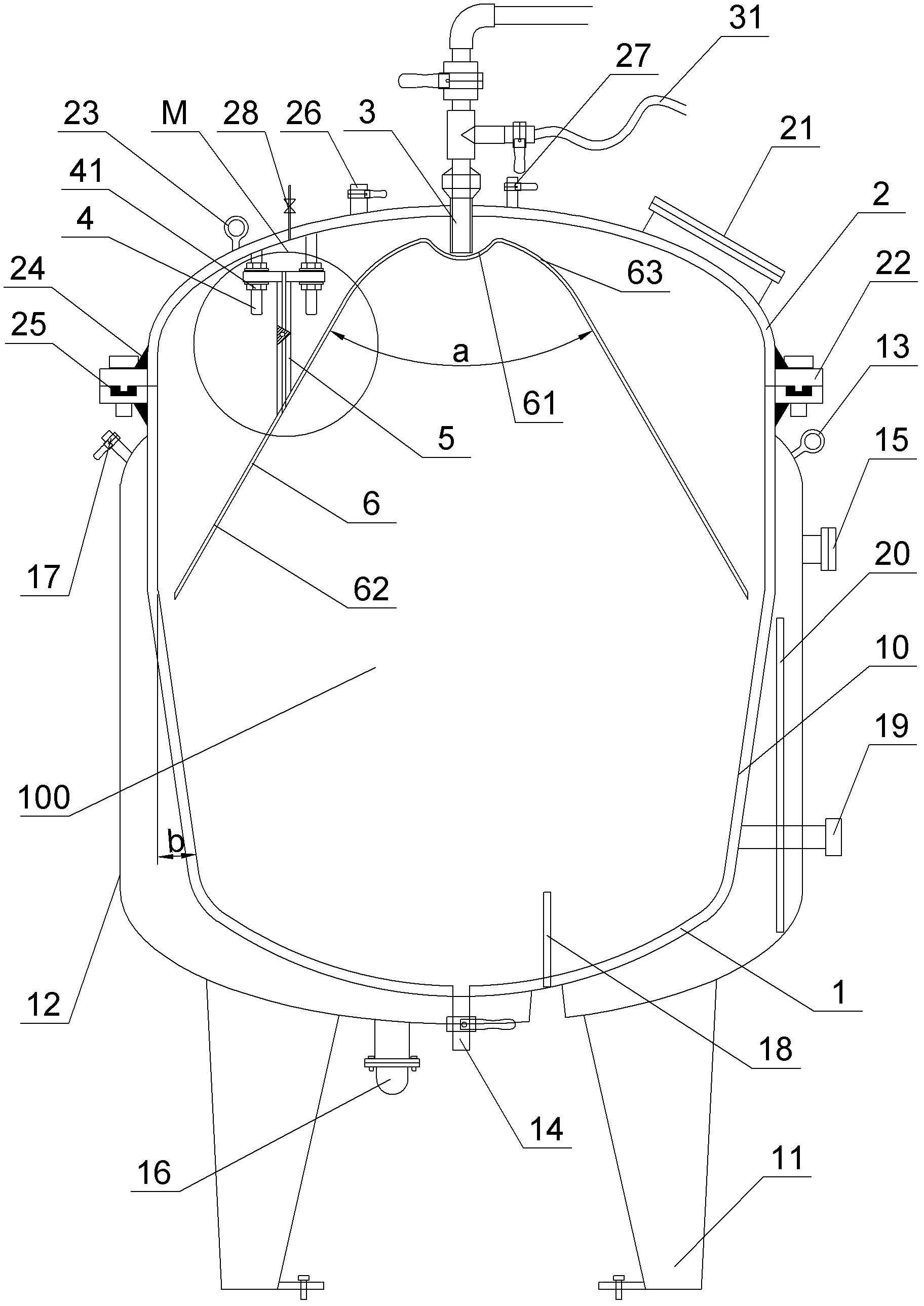

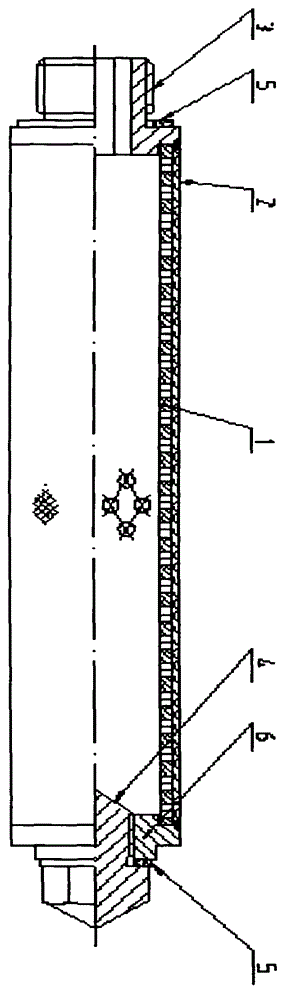

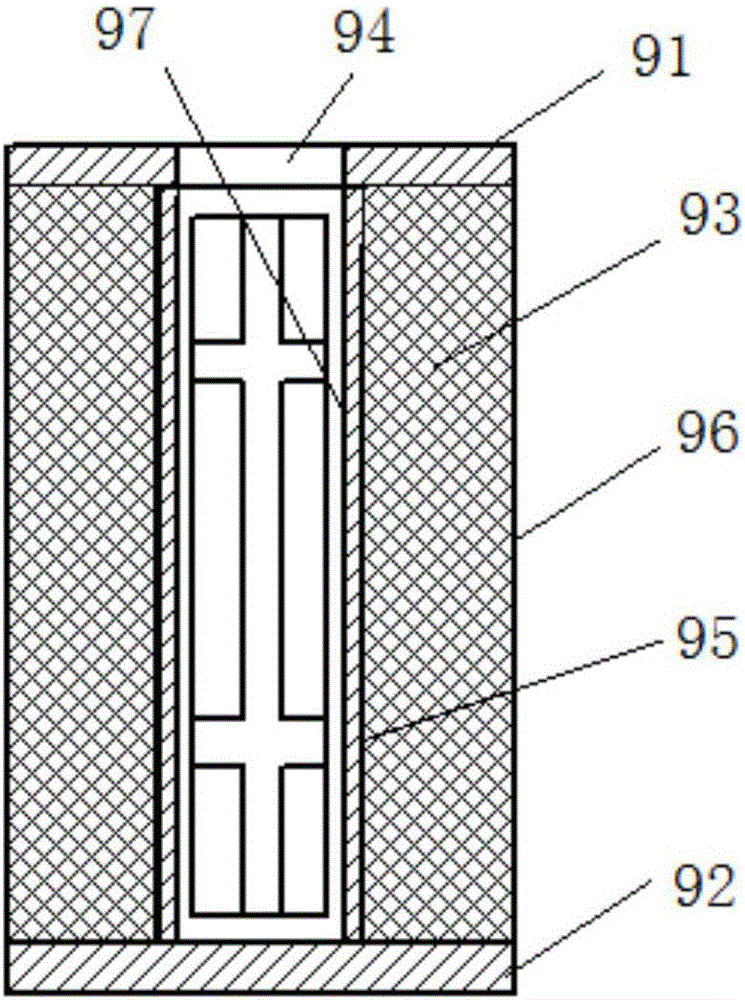

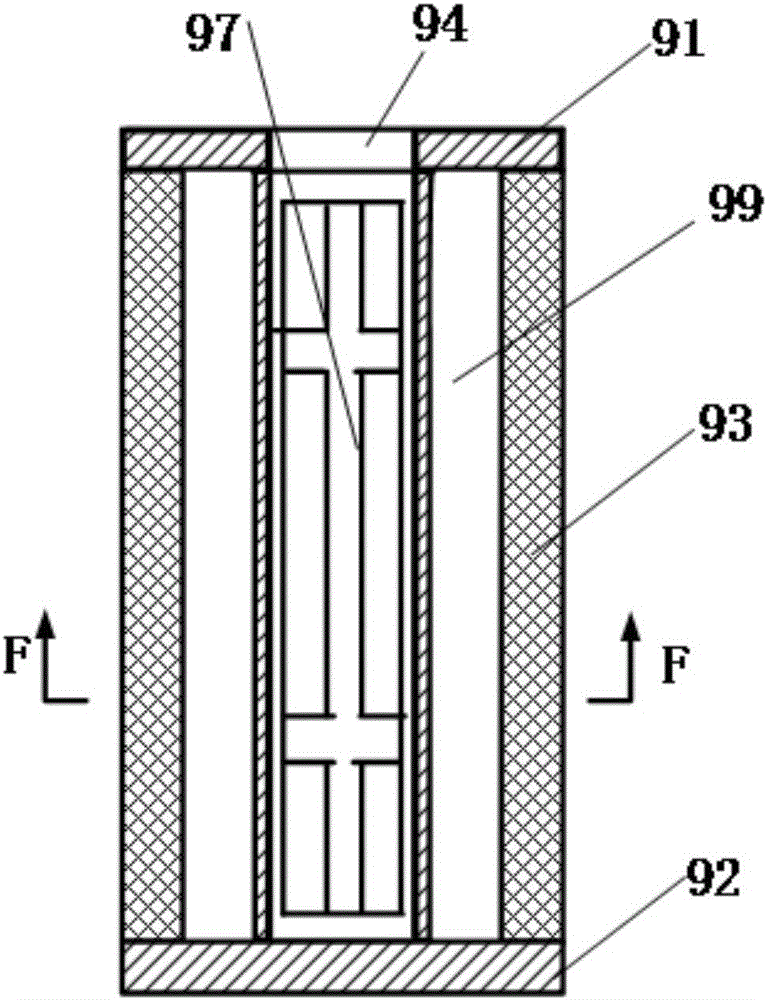

Ultrafiltration membrane deaerating unit

ActiveCN102657958ASolve the accuracy problemGood filtration accuracyLiquid degasificationUltrafiltrationUltrafiltrationDeaerator

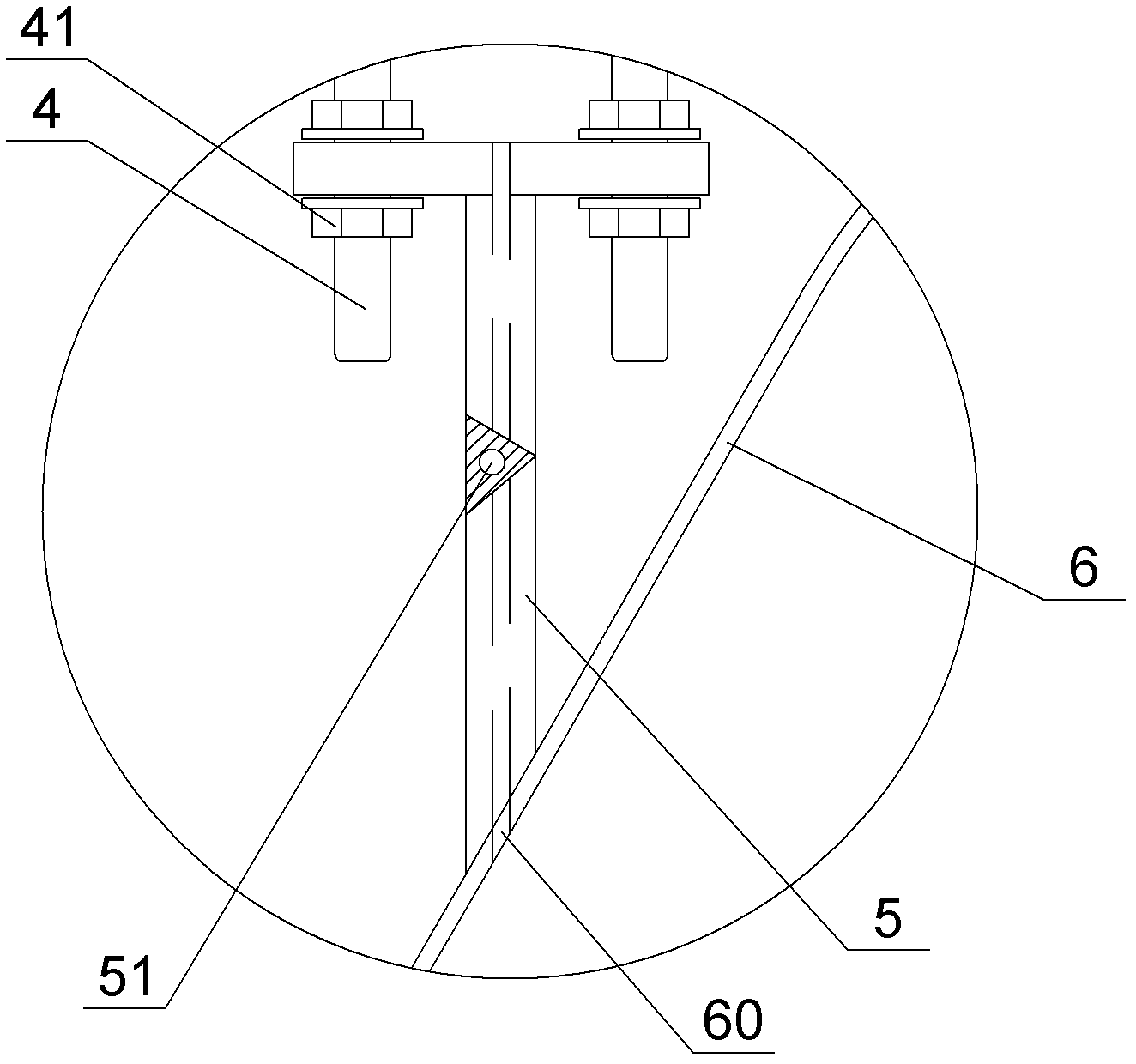

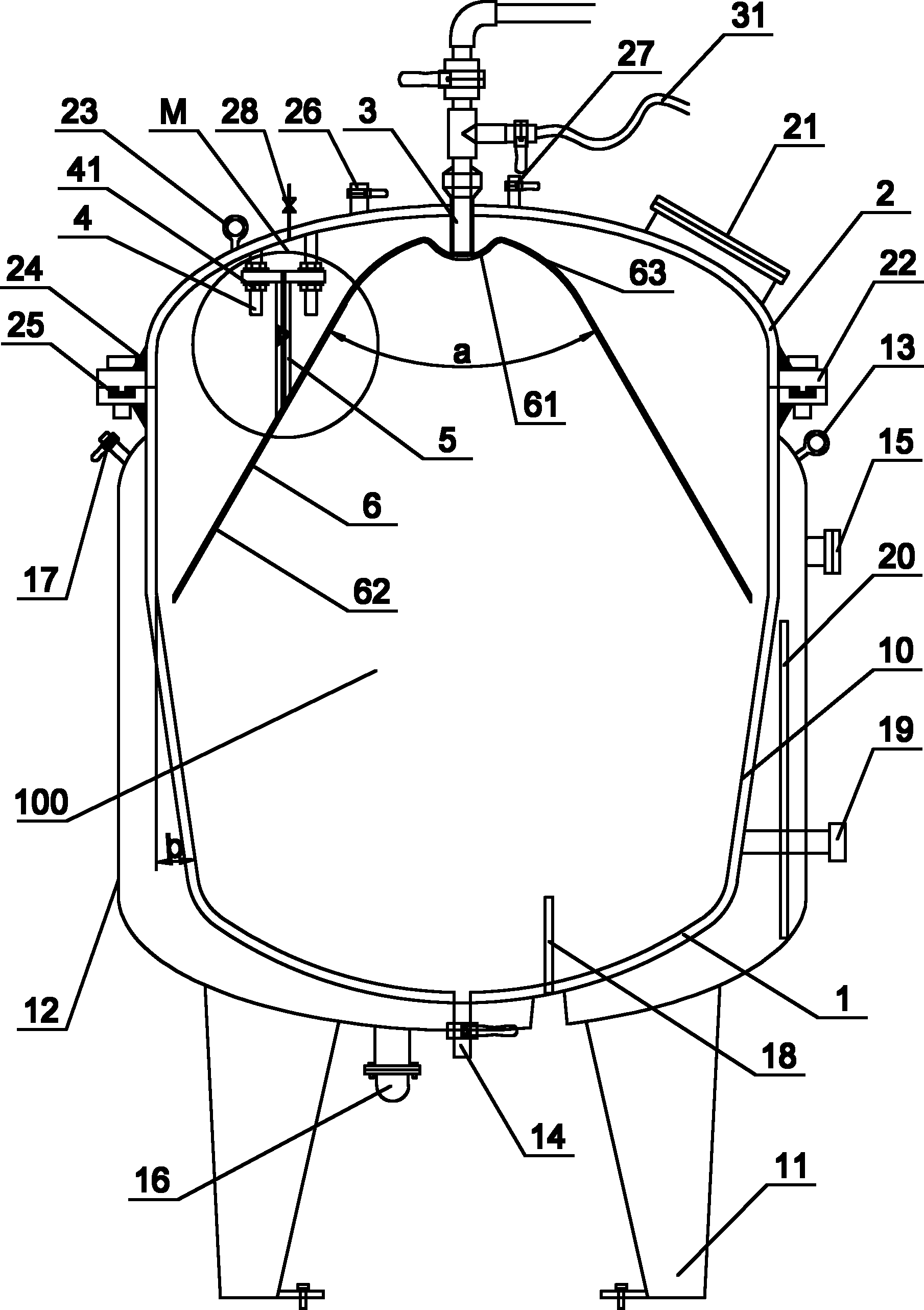

The invention discloses an ultrafiltration membrane deaerating unit which is high in deaerating efficiency and effective in deaerating and enables ultrafiltration membrane filtrating precision to be improved and blow holes in spinning to be avoided. The ultrafiltration membrane deaerating unit is capable of removing bubbles once and is widely applicable to feed liquid in wide viscosity range. The ultrafiltration membrane deaerating unit comprises a tank (1) and an upper cover (2). The tank (1) and the upper cover (2) are connected to form a closed space (100). A feed pipe component (3) is connected to the center of the top of the upper cover (2). A liquid outlet (14) is reserved at the center of the bottom of the tank (1). An umbrella-shaped deaerator (6) is arranged on the inner upper portion of the closed space (100) and comprises an overflow groove (61) at the center of the top and a deaeration leveling umbrella-shaped face (62) around the overflow groove (61), and the overflow groove (61) corresponds to a feed inlet of the feed pipe component (3). A slanting deaeration membrane-drawing slope is reserved on the lower middle of the inner wall of the tank (1). The ultrafiltration membrane deaerating unit is widely applicable to the field of ultrafiltration membrane preparation.

Owner:怀集汇清环保设备工程有限公司

High density fibrous filter plate and manufacturing method

InactiveCN1562442AHigh filtration precisionFiltration accuracy is higher than or excellentFibreboardStationary filtering element filtersPorosityEpoxy

A high-density filtering fibreboard is prepared from sepiolite wool, paper pulp fibre, adhesive (polyvinyl alcohol or epoxy resin), wet strengthening agent (polyvinylimine, polyamide epoxy resin, or cyanuramide), and dry strengthening agent (carboxymethyl cellulose or polyacrylamide) through preparing pulp, mixing shaping, baking, and shearing by needed sizes. It has high porosity and filtering throughput.

Owner:HEBEI UNIV OF TECH

Antibacterial type air filter paper and production process thereof

InactiveCN106283828AReduce air permeabilityImprove filtration efficiencySurfactants additionPaper/cardboardAir filtrationFiber

The invention discloses antibacterial type air filter paper and a production process thereof. The antibacterial type air filter paper is prepared from the following components in parts by weight: 40 to 60 parts of plant fiber, 10 to 15 parts of a fiber binding agent, 25 to 40 parts of active carbon, 8 to 15 parts of a surfactant, 1 to 2 parts of a glyoxal modified polyacrylamide wet strength agent and 15 to 25 parts of latex. By adding the surfactant into the production process, the surface tension of the filter paper can be effectively reduced; the powdery active carbon is added into paper pulp at a certain ratio and a mixture is subjected to papermaking to obtain the antibacterial type air filter paper; the strength problem of paper sheets is solved by adopting the latex through a surface treatment manner; good parameters including air permeability, adsorptivity and filtering precision of the active carbon filter paper are guaranteed.

Owner:JIANGSU HAINA AIR CONDITIONER PURIFICATION EQUIP

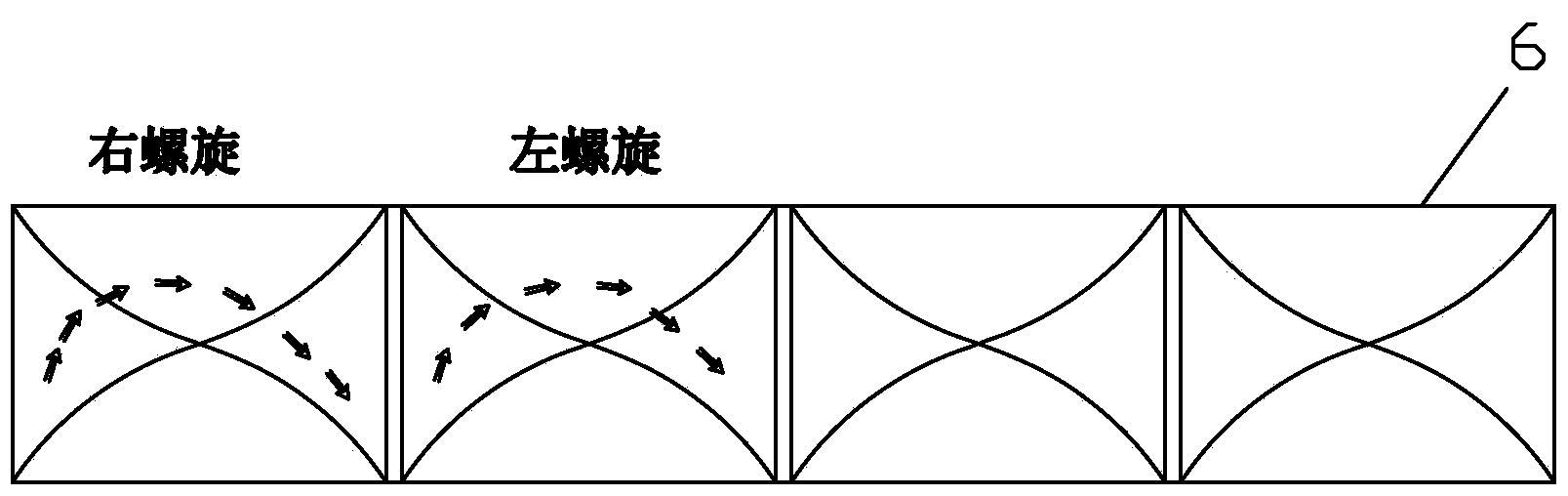

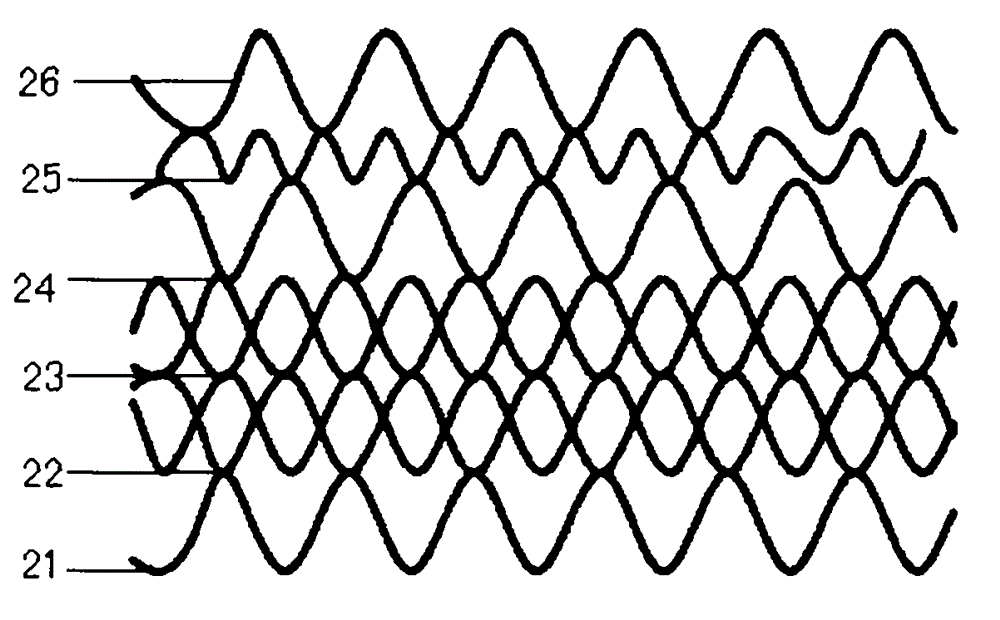

Efficient low-resistance spunbonded nonwoven filter material, production equipment and manufacturing method thereof

ActiveCN103638746AImprove filtration efficiencyImprove breathabilityFiltration separationPolymer scienceEngineering

The invention relates to an efficient low-resistance spunbonded nonwoven filter material which comprises at least four rows of silks, including first to fourth rows of silks, sequentially arranged from top to bottom, wherein the first row of silks has a rough filtration function, and the fineness is 2.5-3.5dtex; the second row of silks has a fine filtration function, and the fineness is 0.5-1.5dtex; the third row of silks has the effect of a framework and a stiffening function, and the fineness is 10-15dtex; the fourth row of silks has a ventilating function and a good adhesive effect, and the fineness is 5-7dtex. The finenesses of all rows of silks in the non-woven fabric are agilely adjusted, so that the filter material is high in air permeability, small in filter resistance and long in filter period while achieving high filter efficiency. Compared with conventional spunbonded nonwoven filter materials, the efficient low-resistance spunbonded nonwoven filter material has the advantages that the finenesses of the layers of the product are different, so that the filter material has a good gradient filter effect. The filter material is excellent in air permeability, small in filter resistance and long in filter period while achieving good filter efficiency.

Owner:FOSHAN S L P SPECIAL MATERIALS

Inorganic-organic composite film and preparation method thereof

The invention discloses an inorganic-organic composite film. A support is made of inorganic porous materials and comprises organic materials and cross-linking agents which sequentially coat the support, the thickness of the inorganic porous materials is 1mm-3mm, the thickness of the organic materials is 10-50 micrometers, and the pore diameter of the inorganic-organic composite film is 0.001-1 micrometer. The inorganic-organic composite film has high-strength, impact-resistant, high-precision and high-selectivity filtration performances, and is excellent in renewability. According to a preparation method of the inorganic-organic composite film, after prepared organic material casting solution and the cross-linking agents are poured into a tank, the surfaces of the inorganic porous materials are sequentially coated with the organic material and the cross-linking agents in a spin coating mode, film preparation procedures are finished, operation is simple and convenient, controllability is strong, and stability is high.

Owner:WESTERN BAODE TECH CO LTD

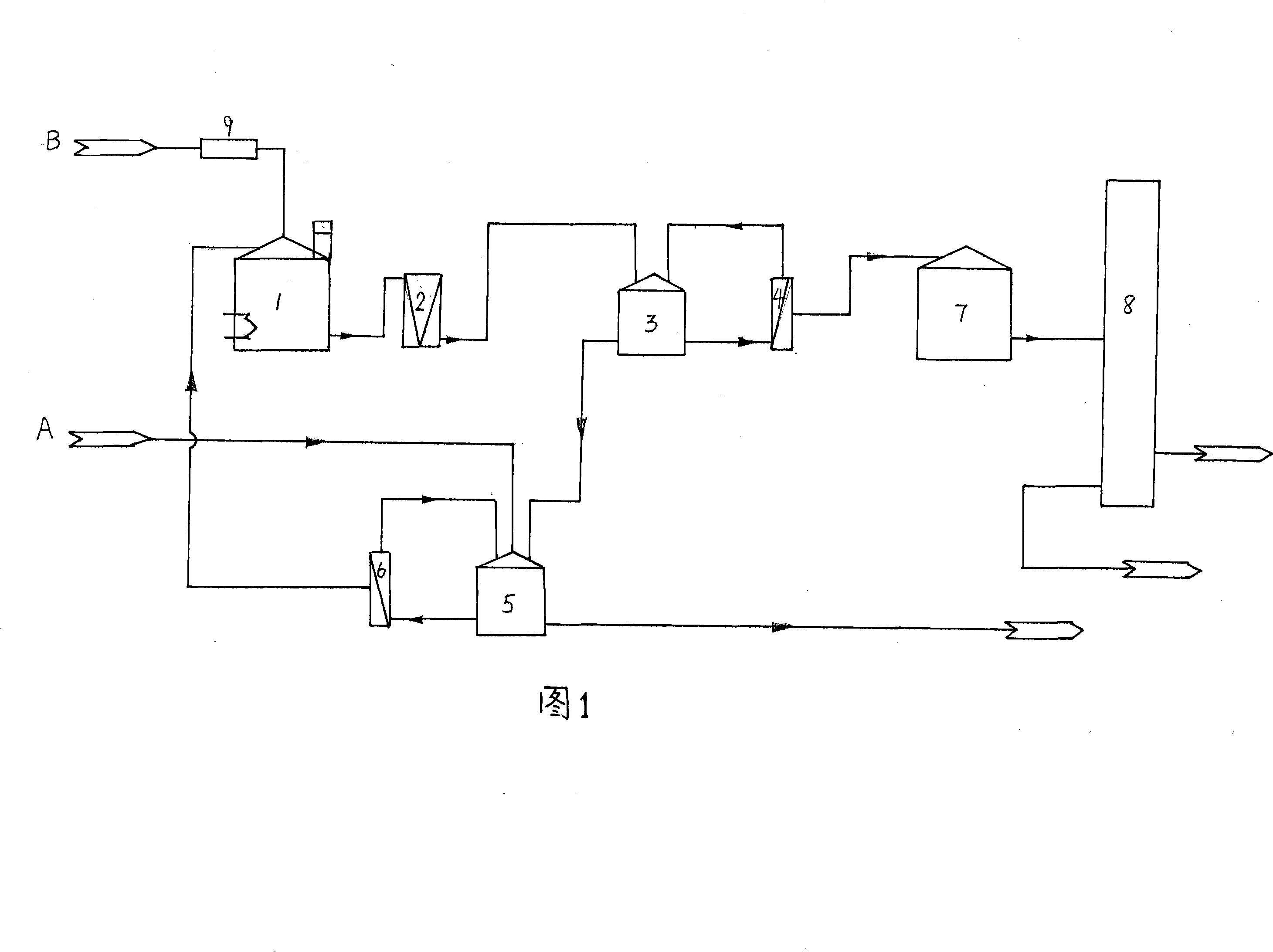

Process and device for zero discharge treatment of coal chemical wastewater

ActiveCN107311374AEfficient accumulationEfficient accumulation and removalTreatment involving filtrationMultistage water/sewage treatmentSludgeFiltration

The invention relates to a process and device for zero discharge treatment of coal chemical wastewater and belongs to the technical field of water treatment. The process comprises the steps of adding a bio-surfactant into coal wastewater, and then causing the bio-surfactant to undergo electric flocculation treatment; causing electric flocculation sludge to undergo dehydration and incineration treatment; sending water generated by the electric flocculation into an iron carbon microelectrolysis tower for oxidation treatment; adding NaOH and Na2CO3 into the water generated by iron carbon microelectrolysis, and causing calcium and magnesium in salt-containing wastewater to precipitate; sending the obtained wastewater into a ceramic ultrafiltration membrane to be filtered, and sending a concentrated solution of a nanofiltration membrane into a first evaporator for evaporation and crystallization, and obtaining recycled Na2SO4; sending water generated by the nanofiltration membrane into a reverse osmosis membrane for filtration, sending a concentrated solution of the reverse osmosis membrane for evaporation and crystallization, and obtaining recycled NaCl.

Owner:SUZHOU XINER ENVIRONMENTAL TECH CO LTD

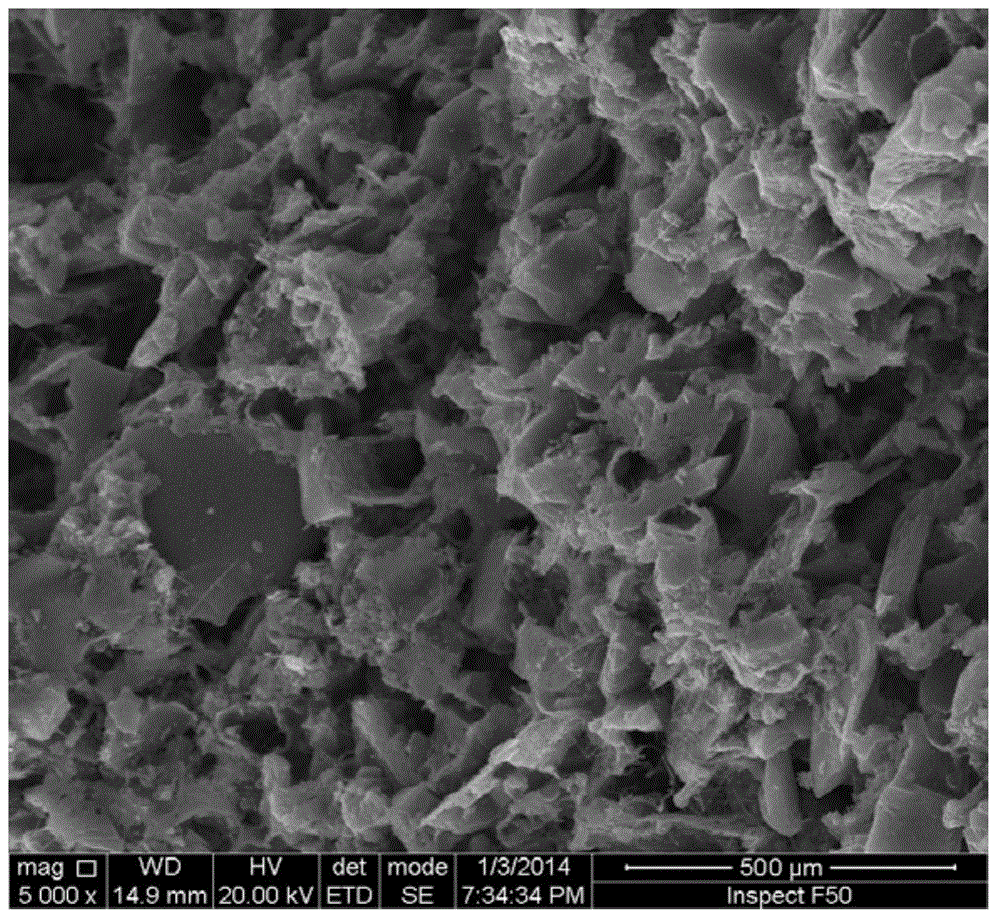

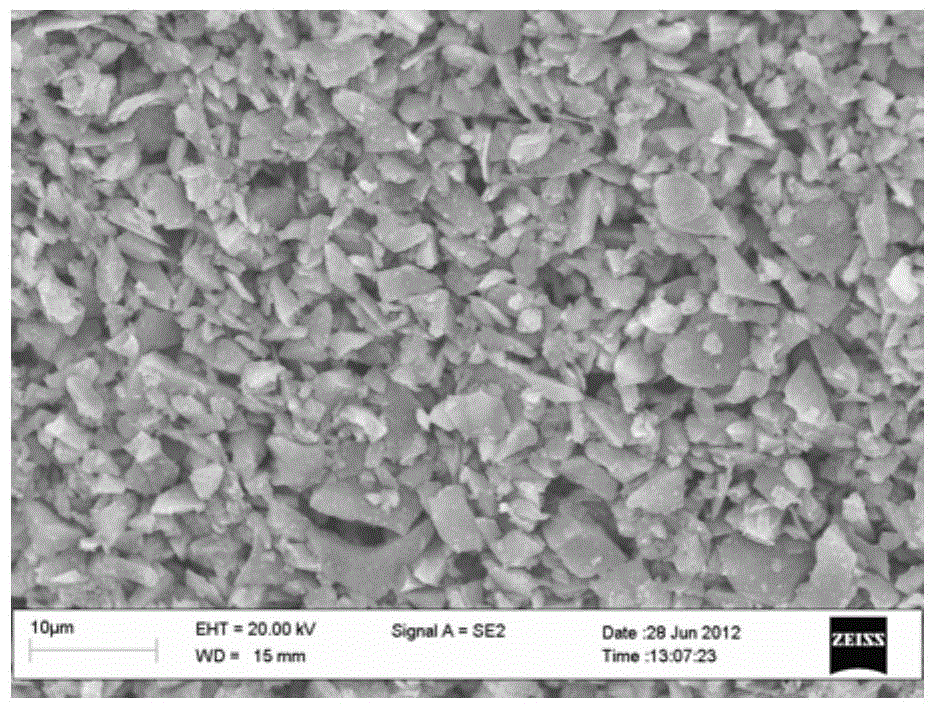

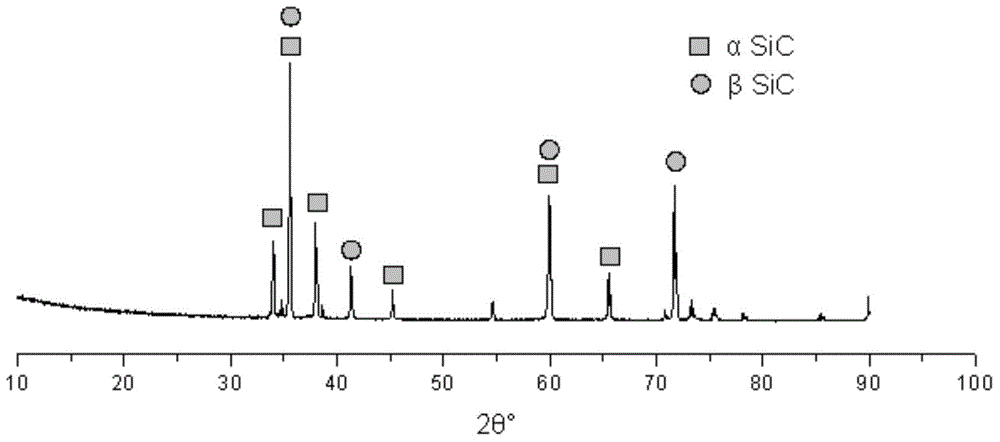

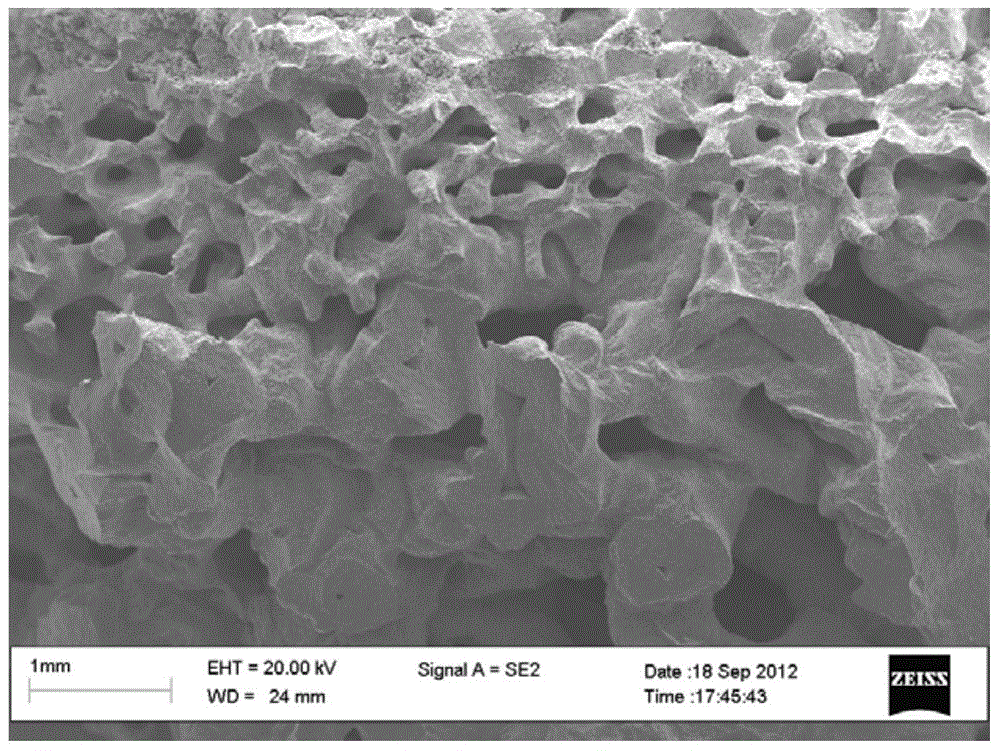

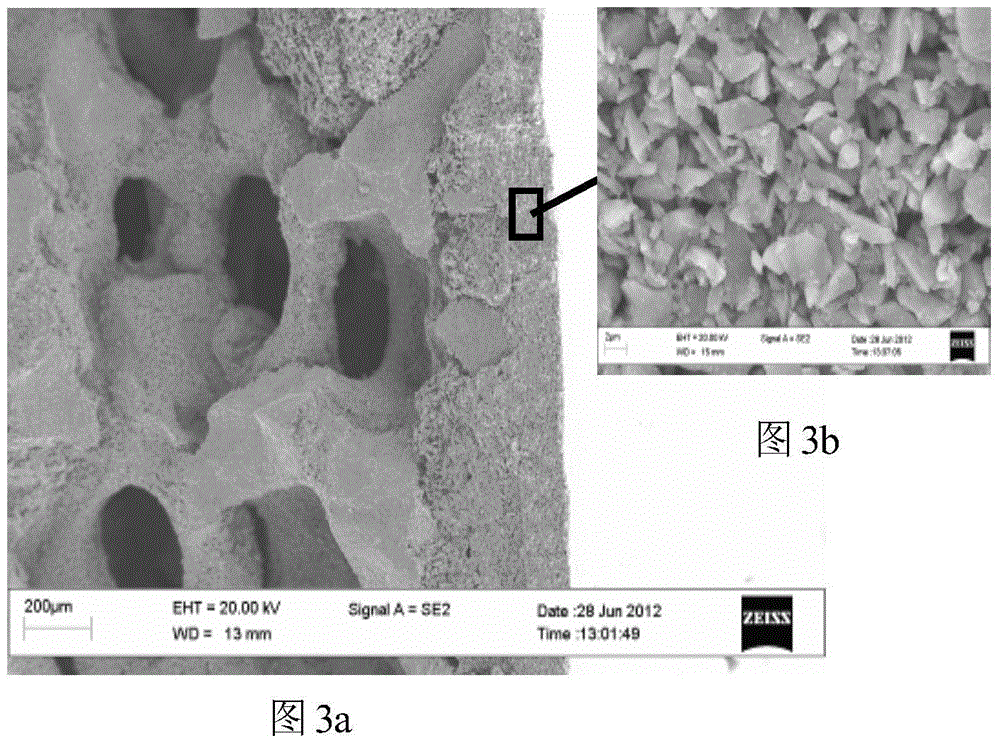

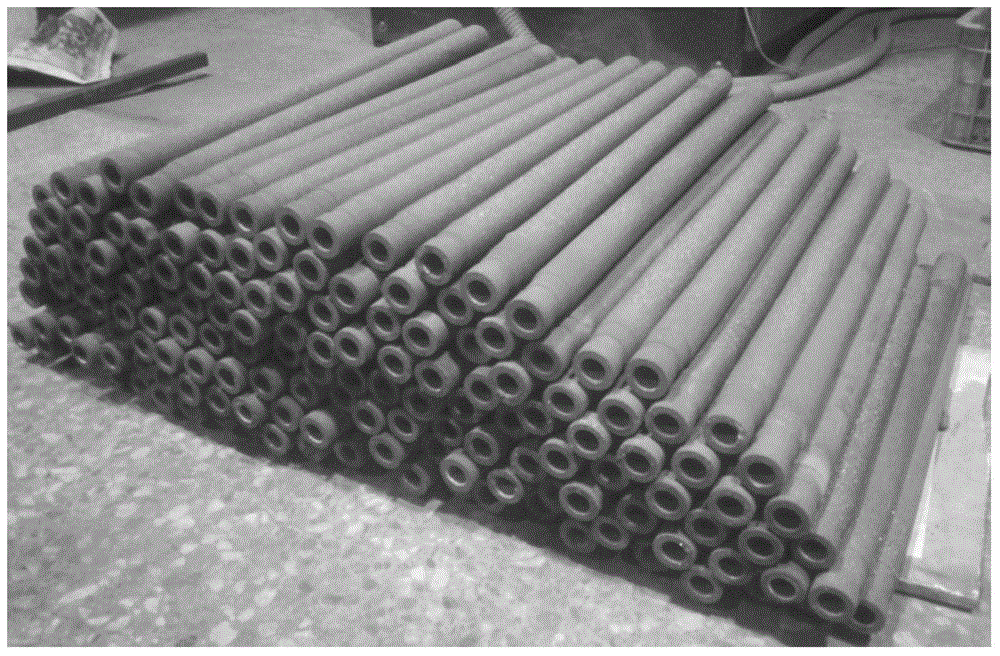

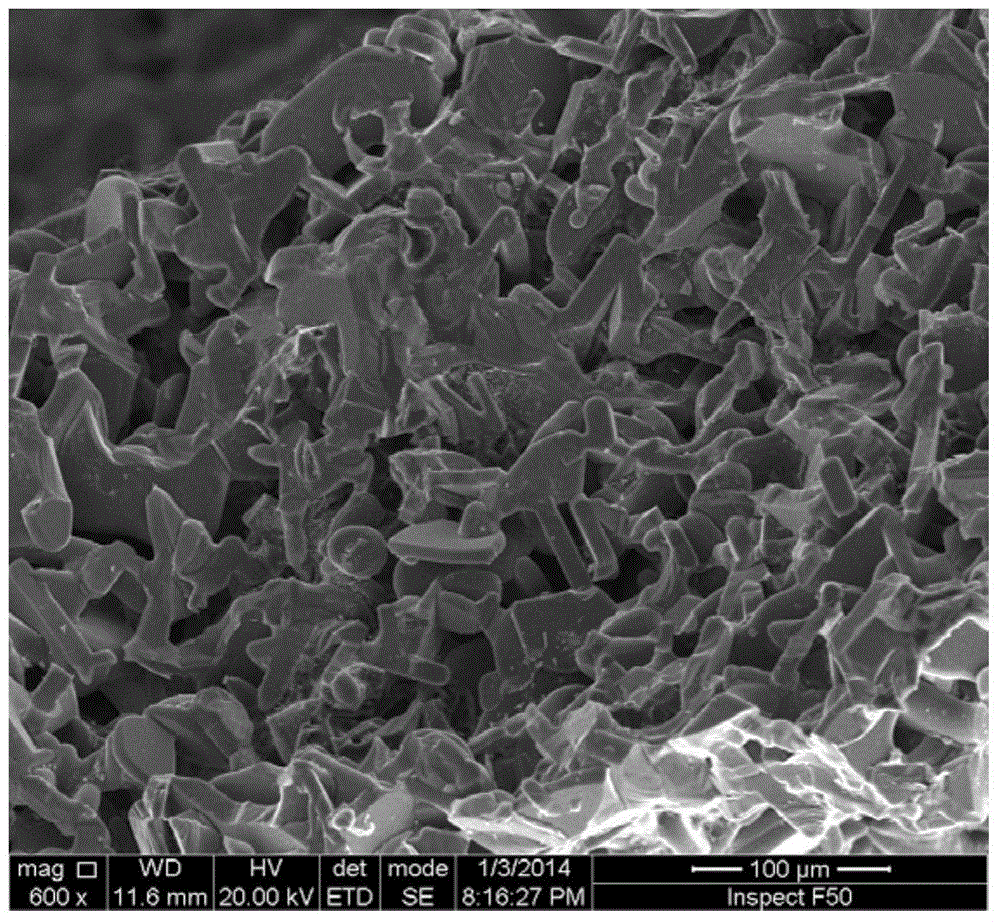

Pure foam silicon carbide support membrane tube with three-gradient pore structure and preparation method

ActiveCN105688684AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesStrong acidsPorous ceramics

Belonging to the field of porous ceramic materials, the invention in particular relates to a pure foam silicon carbide support membrane tube with a three-gradient pore structure and a preparation method thereof. According to the foam silicon carbide support membrane tube, a dual-gradient pore structure pure foam silicon carbide support and a surface film layer form a three-gradient filtration structure, the support is composed of a dual-gradient pore structure pure foam silicon carbide support, the average pore size of the outer layer is 300-500micrometers, the average pore size of the inner layer is 1-3mm, and the support porosity is 35-65%; the surface film layer is formed by combination of silicon carbide powder, the pore size is 50nm-20micrometers, and the film layer porosity is 35%-50%. The preparation method comprises the following steps in order: burdening, foam support molding, support sintering, film layer preparation and firing. The pure foam silicon carbide support membrane tube provided by the invention can be used in oxidizing atmosphere and reducing atmosphere, has strong acid and alkali corrosion resistance, and can be used for coal gasification chemical engineering and IGCC, PFBC coal gasification power generation, high temperature flue gas, automobile exhaust, water purification and other high and low temperature fluid filtration purification.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

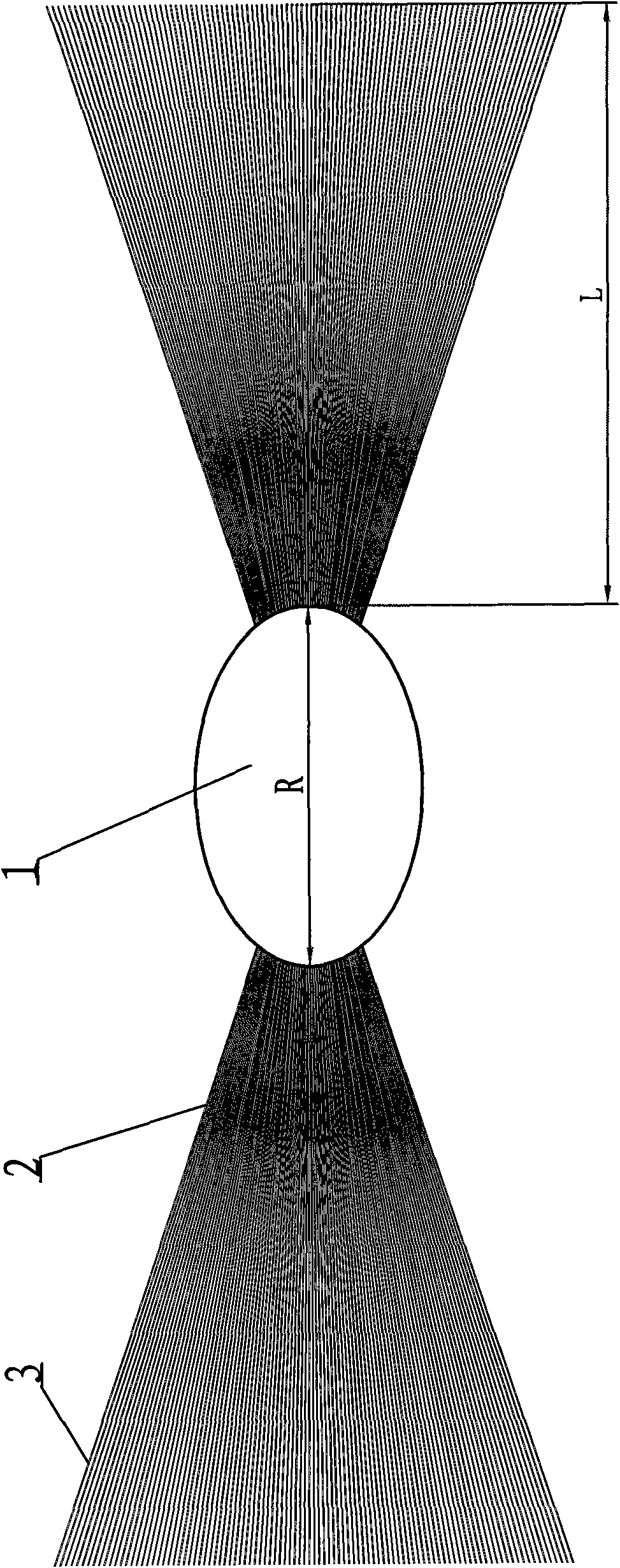

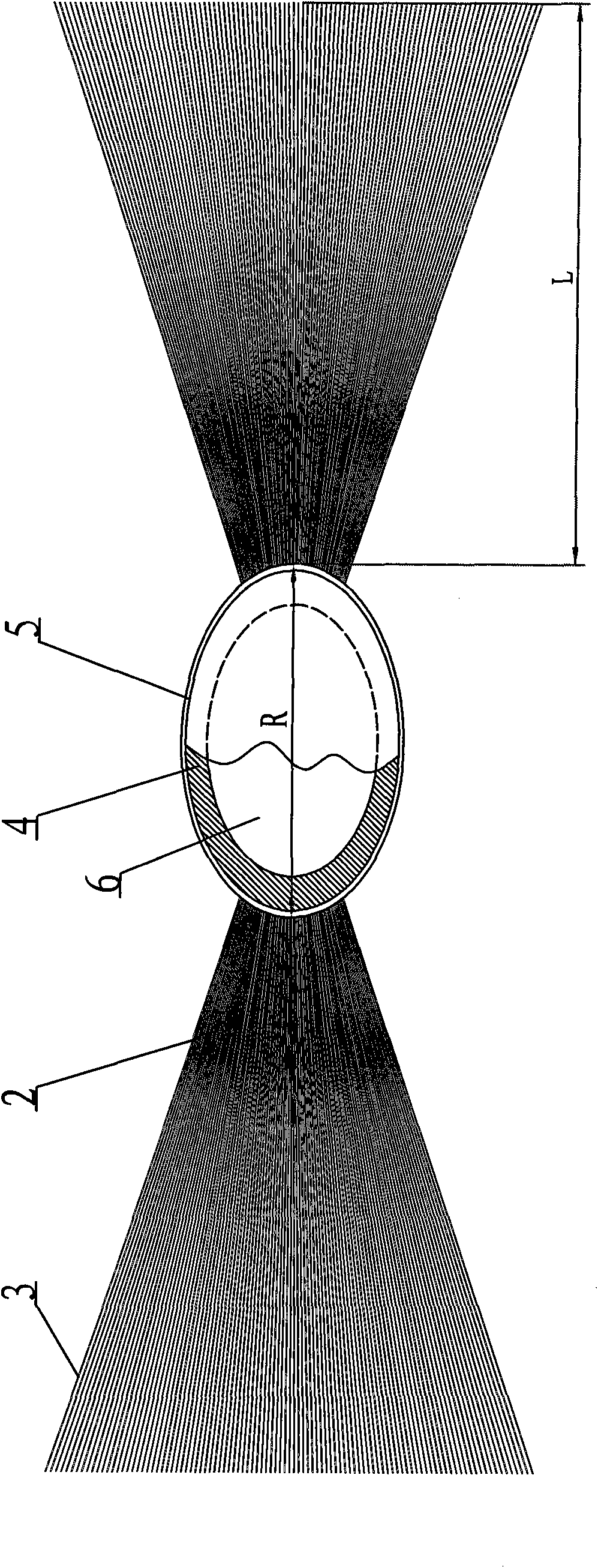

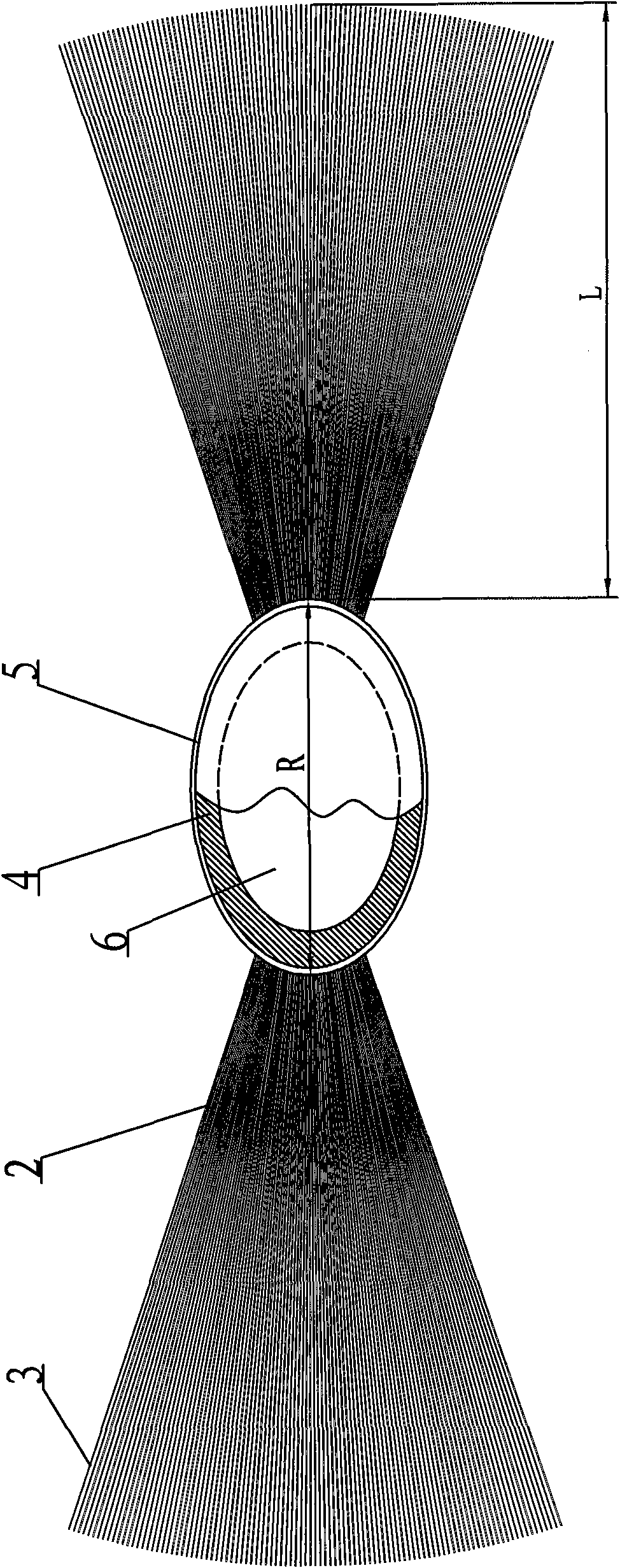

Butterfly high-efficiency self-adaptive plastic-fiber mixed filter material filter

ActiveCN101884860AHigh interception capacityHigh filtration precisionFiltration separationCorrosion resistantSmall footprint

The invention discloses a butterfly high-efficiency self-adaptive plastic-fiber mixed filter material filter. The filter consists of filter material monomers, wherein each filter material monomer is formed by connecting a weight-balancing core body and paired corrosion-resistant balancing filtering wing bodies in a matching way; the surface of the weight-balancing core body is made of plastic; the weight-balancing core body is ellipsoidal; the threshold of the average density p0 of the weight-balancing core body is between 1.30 and 1.50 g / cm<3>; the two ends of a long axis of the ellipsoidal weight-balancing core body are provided with balancing wing bodies respectively; each balancing wing body is made from fiber bundles consisting of artificial fiber yarns; and the inner ends of the artificial fiber yarns constituting each fiber bundle are fixedly connected to each end of the long axis of the weight-balancing core body and the other ends of the artificial fiber yarns are in a diffused state so as to form a whisker form. The filter has the technical advantages of high porosity, high filtering speed, high filtering accuracy, low resistance, high filth holding capacity, small backwashing water using amount, high periodic water yield, low operating cost, small floor area and high anti-load impact capacity.

Owner:新疆德安环保科技股份有限公司

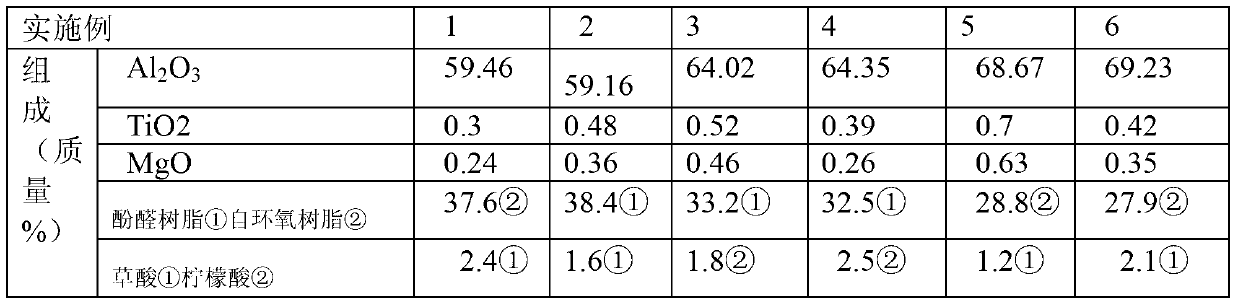

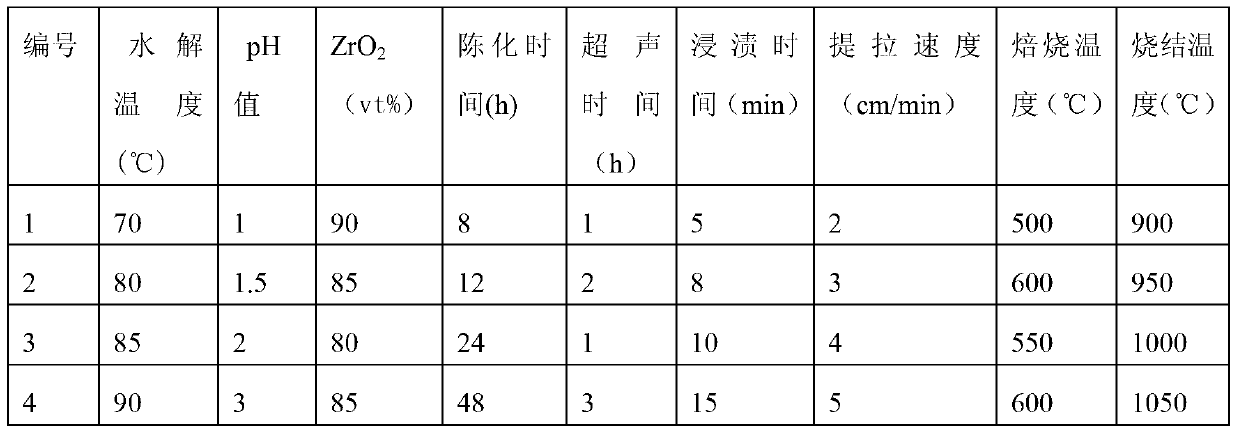

Preparation method of nanocomposite Al2O3 ceramic filter element

The invention discloses a preparation method of a nanocomposite Al2O3 ceramic filter element with high strength. The preparation method is characterized by comprising the following steps of: firstly, preparing an Al2O3 porous matrix with macroscopic straight pores; and secondly, preparing a porous nannocomposite coating on the walls of the macroscopic straight pores of the Al2O3 porous matrix, wherein the second step comprises the following concrete steps of: (1) dissolving aluminum isopropoxide into distilled water with the temperature of 70-90 DEG C, stirring the solution, and adding nitric acid to control the pH value, wherein the aluminum isopropoxide is hydrolyzed to form a sol; (2) carrying out ultrasonic treatment at the temperature of 40 DEG C under one atmospheric pressure, and ageing the sol; (3) completely immersing the sintered Al2O3 porous matrix with the macroscopic straight pores into the aged sol, impregnating, lifting, and then carrying out freeze drying so that the sol becomes a gel; (4) carrying out thermal treatment on the gel at the temperature of 500-600 DEG C, and then, cooling along with a furnace; and (5) finally, sintering the gel at the temperature of 900-1100 DEG C to obtain the nanocomposite Al2O3 ceramic filter element.

Owner:XI AN JIAOTONG UNIV

Purification recovering method for sodium thiocyanate solution of acrylic fiber production

A method for purifying and recovering sodium thiocyanate aqueous solution in acrylic production relates to a sewage treatment method, in particular to a method for purifying and recovering sodium thiocyanate aqueous solution in the acrylic production process. Including buffer storage, filtration, primary nanofiltration, secondary nanofiltration, evaporation and concentration process. After the purification and recovery of the present invention, the quality of sodium thiocyanate in the waste liquid accounts for no more than 5% of the total mass of sodium thiocyanate in the raw feed solution, and the recovery of sodium thiocyanate can reach more than 98%, and the production process does not need to add Chemical raw materials such as caustic soda, sulfuric acid, diatomaceous earth, etc., compared with the usual traditional purification and recovery methods, one evaporation and concentration process is reduced, the amount of desalted water is reduced by more than 80%, the amount of evaporation and concentration water is also greatly reduced, and the amount of sewage discharge is also greatly reduced.

Owner:JIANGDU COUNTY ENVIRONMNT PROTECTION EQUIPS FACTORY +1

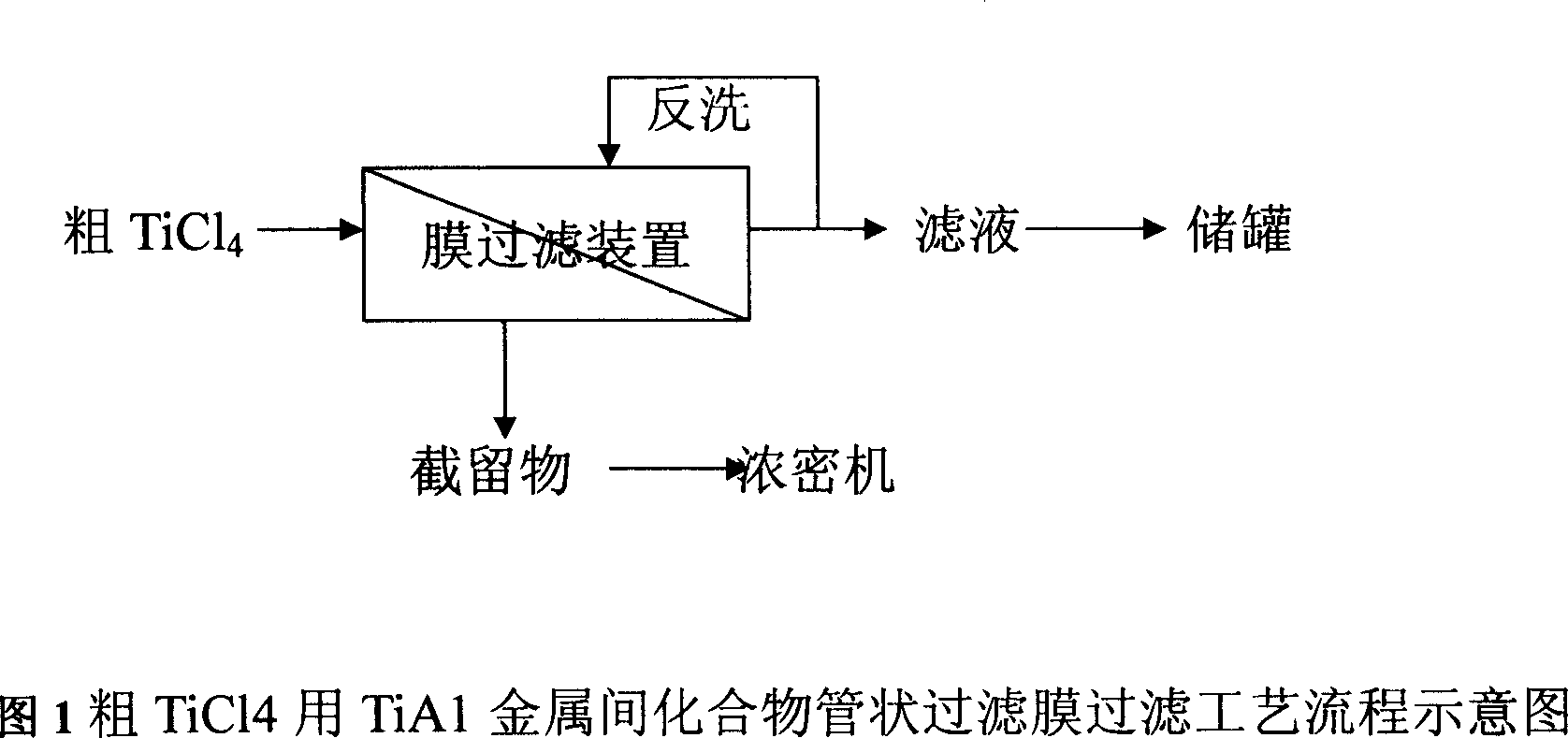

Coarse TiCl4 filtering method

The invention provides a course TiCl4 filtering method, using TiAl intermetalic compound tubular filter membrane as filtering component, and the filtering course mainly comprises two steps of course TiCl4 filtering and regularly stripping, controlling the pressure range of course TiCl4 filtering at 0.10-0.20MPa, filtering course TiCl4 liquid flow through a filtering device with the TiAl intermetalic compound filter membrane so as to obtain high-grade filtrate, , stopping filtering after 30-90 min, stripping with stripping agent to remove suspended solid accumulated on the membrane, discharging the obtained entrapped matters into a densifier for settlement separation and after the stripping ends, resuming filtering, where the stripping pressure is higher than the filtering pressure and the stripping time is 5-30 s, the stripping can use TiCl4 filtrate as stripping agent, dry air, nitrogen gas, or argon gas as stripping agent, and the gas-liquid mixture of TiCl4 filtrate and dry air (nitrogen gas, or argon gas) as stripping agent.

Owner:ZUNYI TITANIUM +1

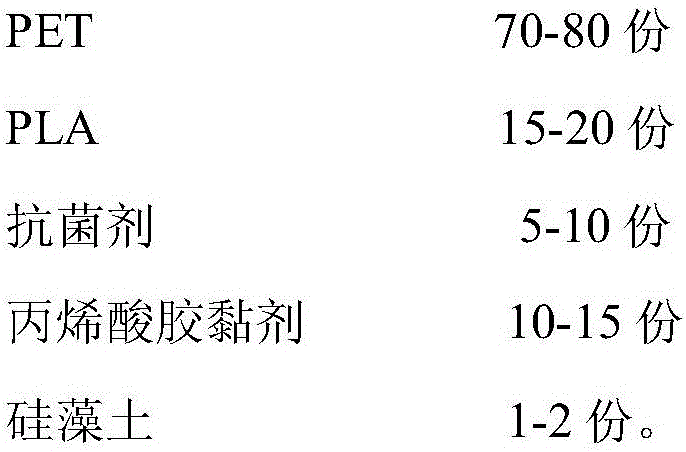

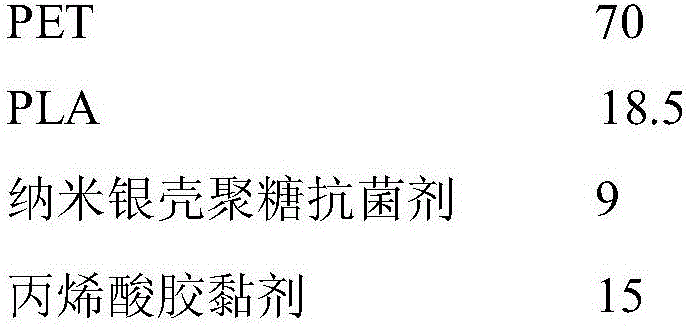

Nonwoven fabric and production process and application thereof

ActiveCN106048894AAvoid breedingGuaranteed service lifeStain/soil resistant fibresBiochemical fibre treatmentMicroorganismPolyethylene terephthalate glycol

The invention discloses a nonwoven fabric, made with the following materials according to parts by weight: 70-80 parts of PET (polyethylene terephthalate), 15-20 parts of PLA (polylactic acid), 5-10 parts of an antibacterial agent, 10-15 parts of acrylic adhesive, and 1-2 parts of diatomaceous earth; diatomaceous earth particles are fine and porous and can improve filtering precision of the nonwoven fabric, microorganisms such as Escherichia coli are filtered, direct filtration under non-uniform fiber pore size of the nonwoven fabric is avoided, filtering effect of the nonwoven fabric is guaranteed, the antibacterial agent can inhibit reproduction of the microorganisms such as bacteria, antibacterial capacity of the nonwoven fabric is improved, and therefore the produced nonwoven fabric has good antibacterial performance and high filtering precision. The invention also discloses a production process and application of the nonwoven fabric.

Owner:温州新宇无纺布有限公司

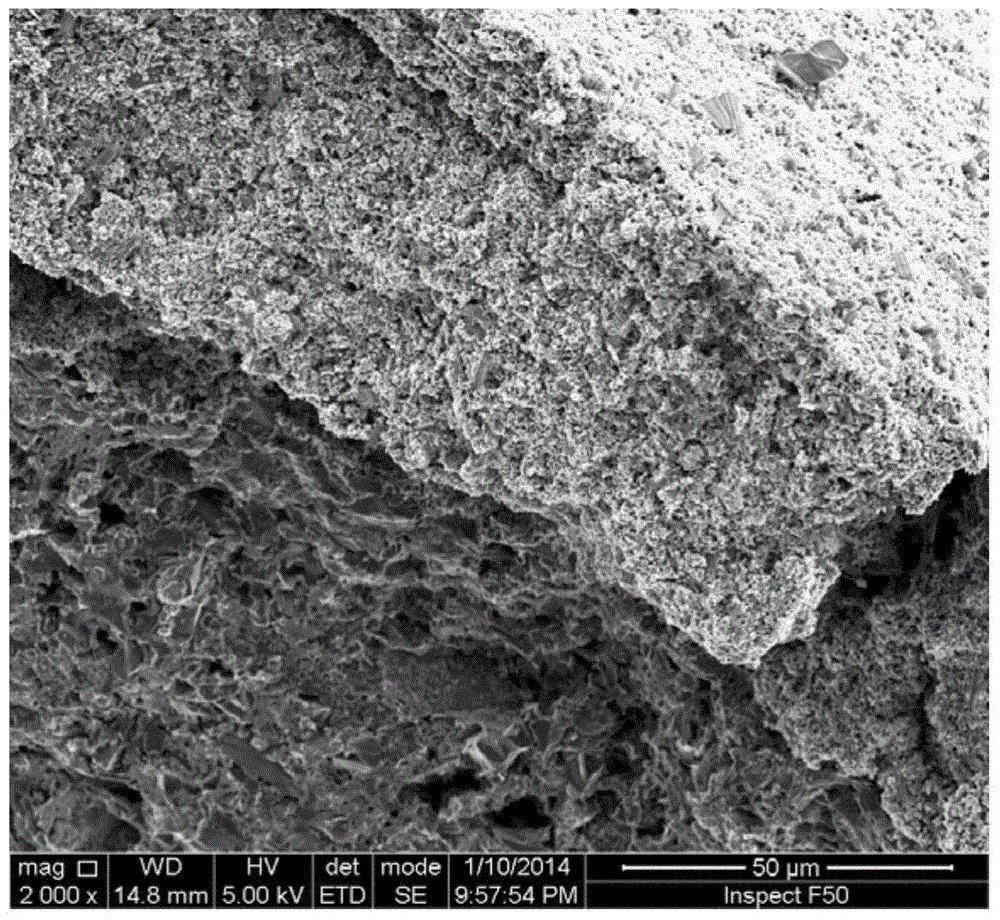

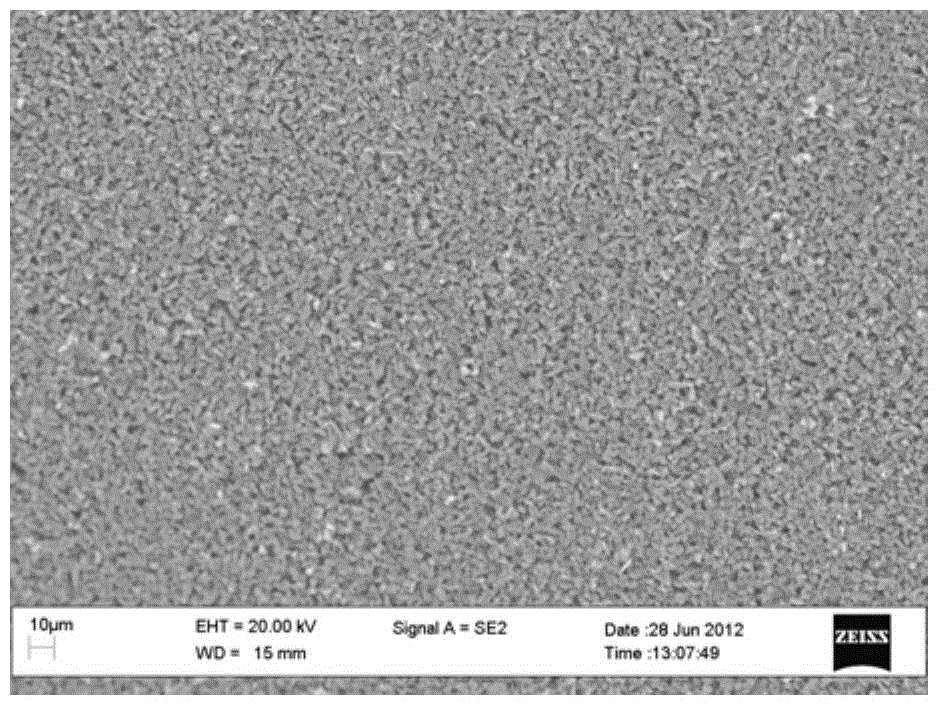

Pure silicon carbide filtering membrane

ActiveCN102659447BGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareStrong acidsThermal shock

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

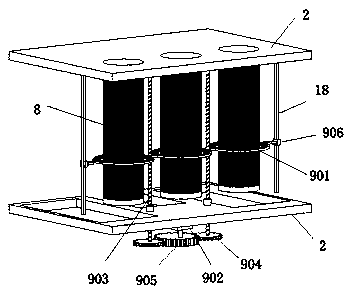

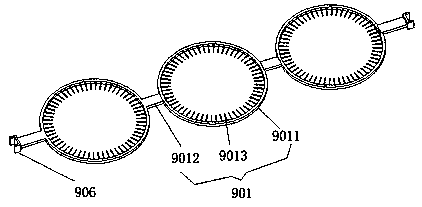

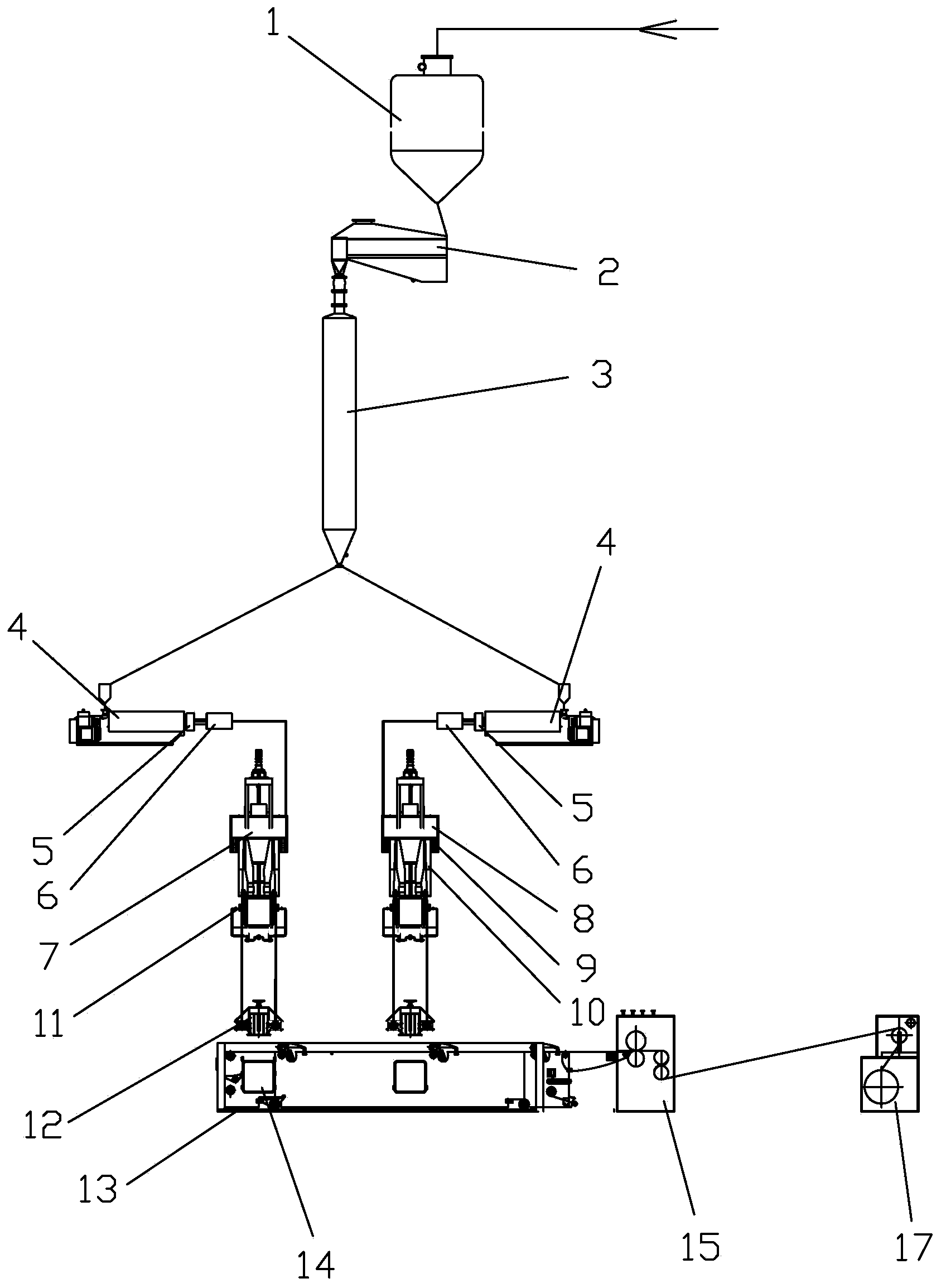

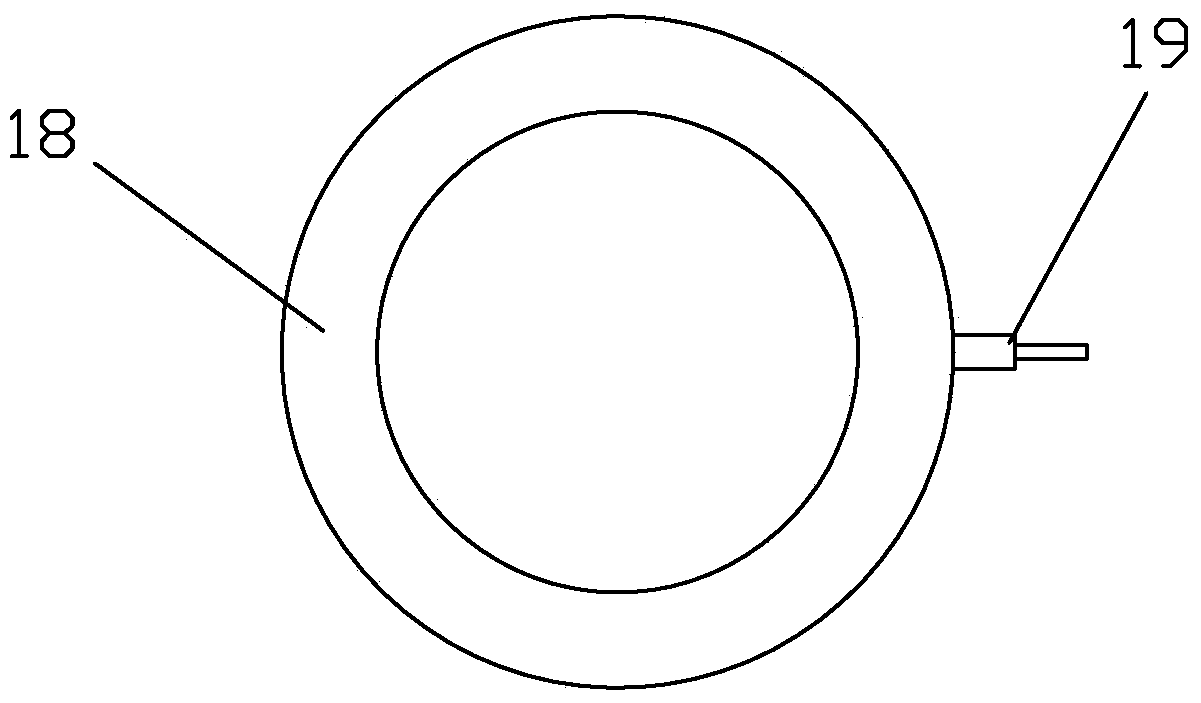

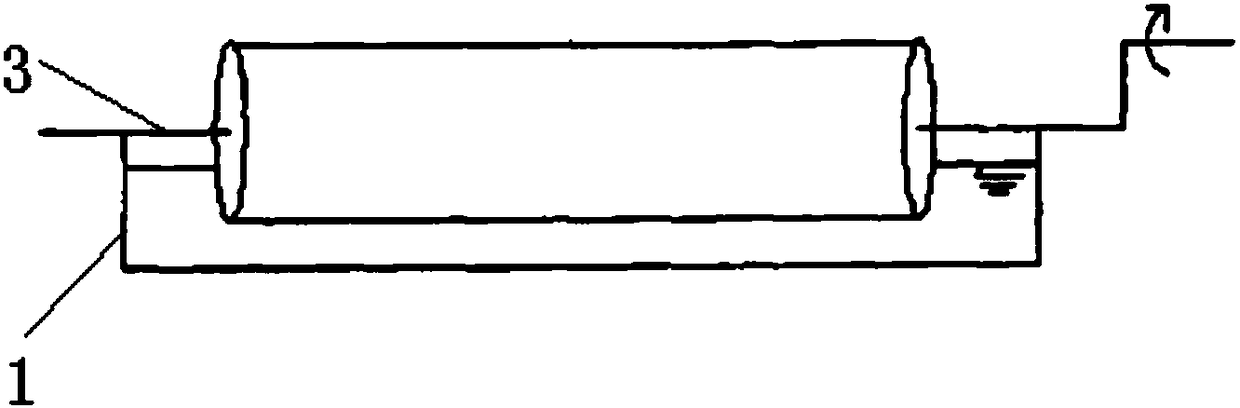

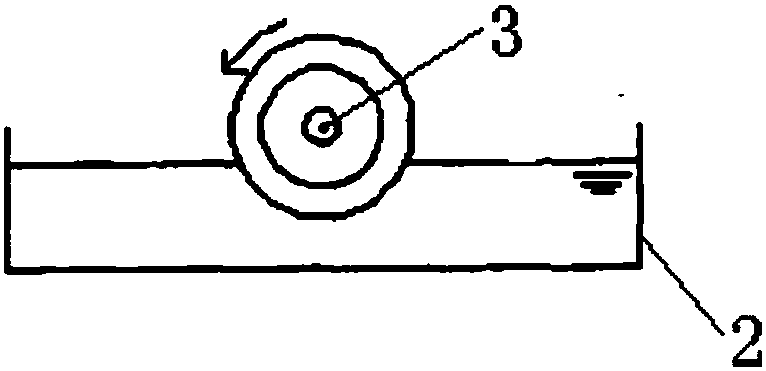

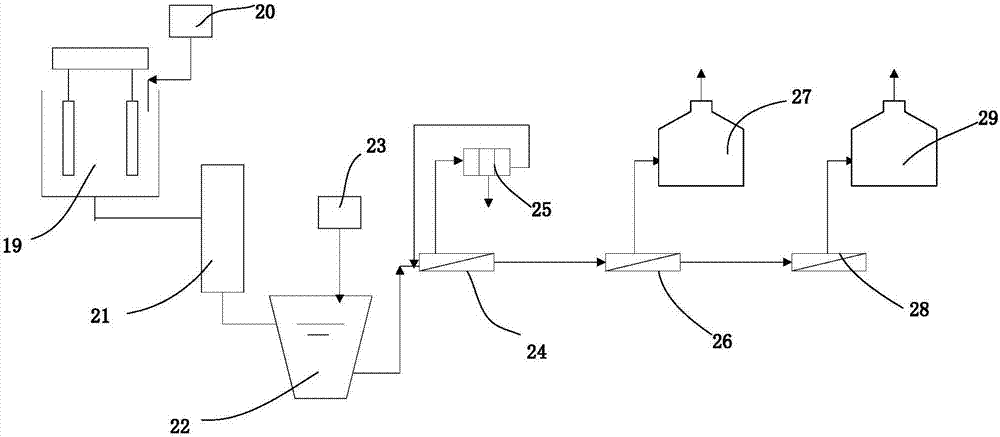

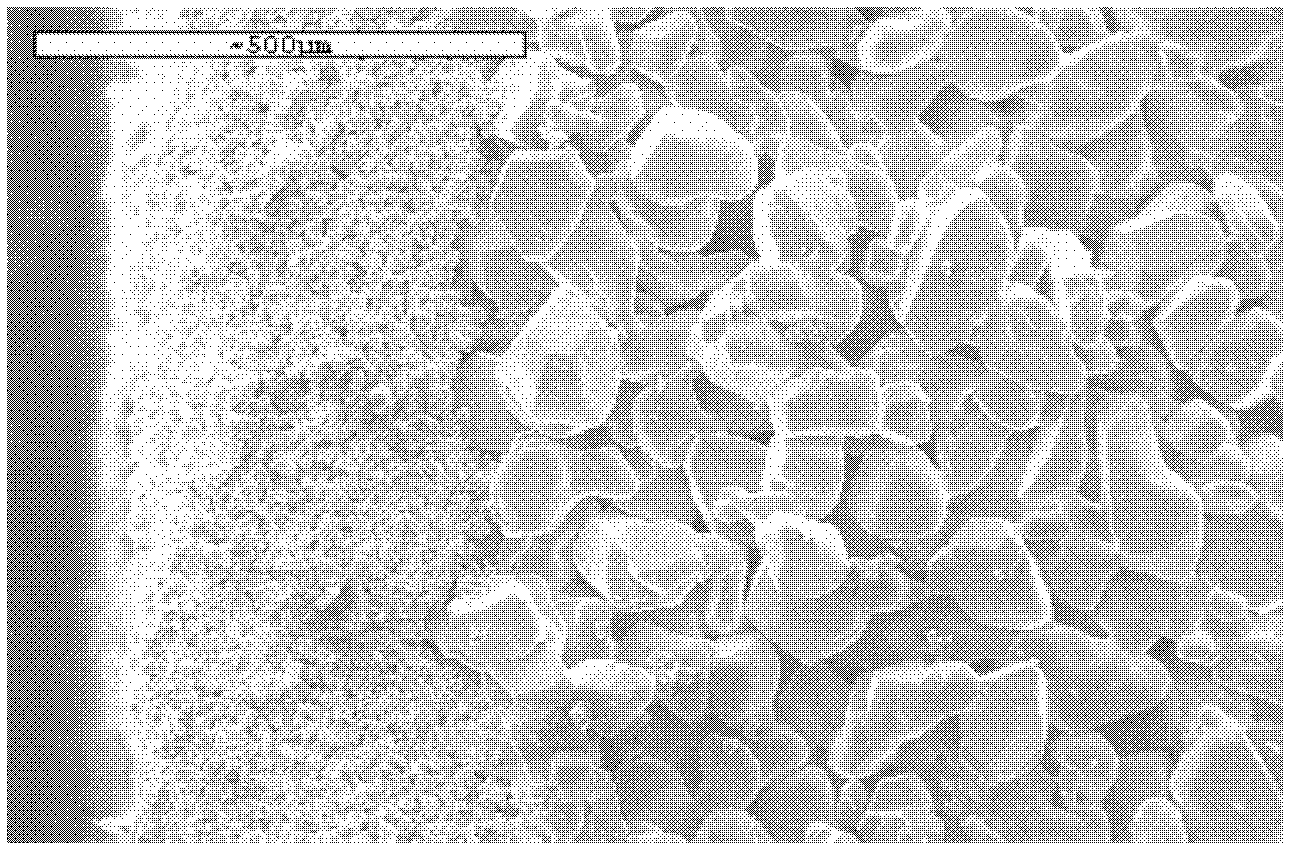

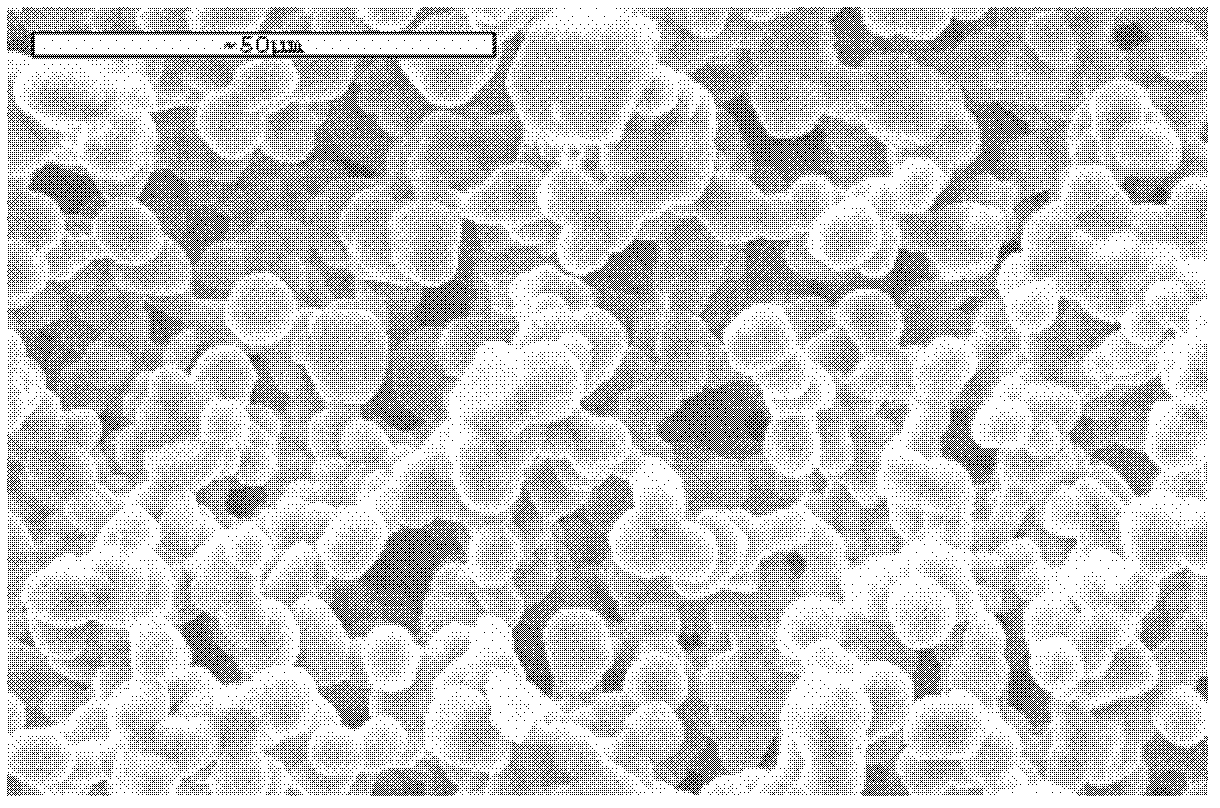

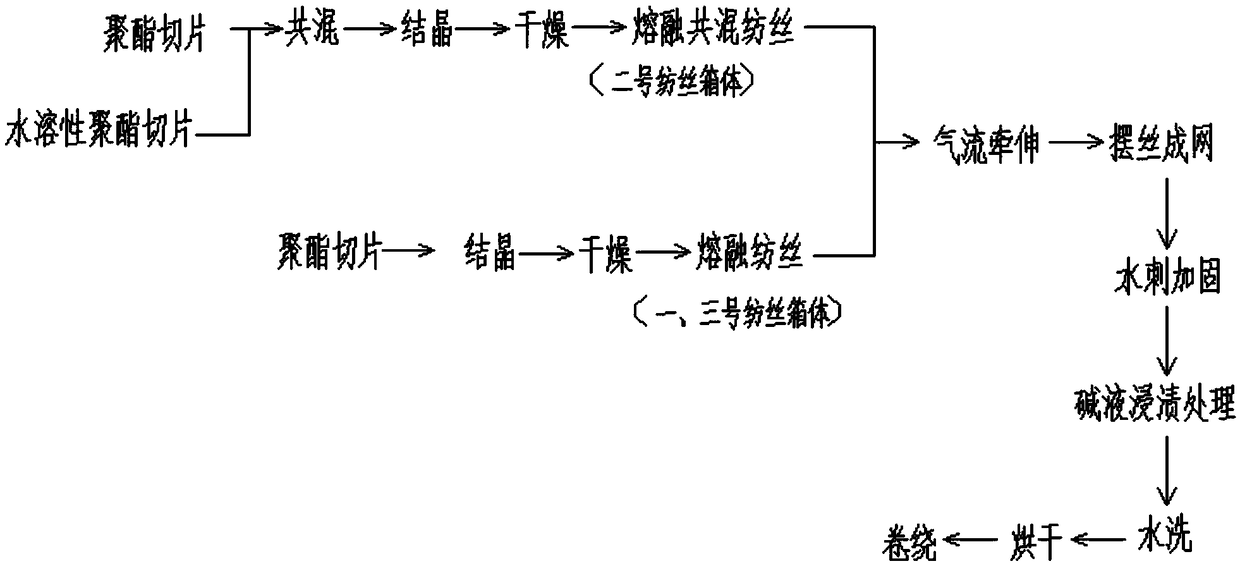

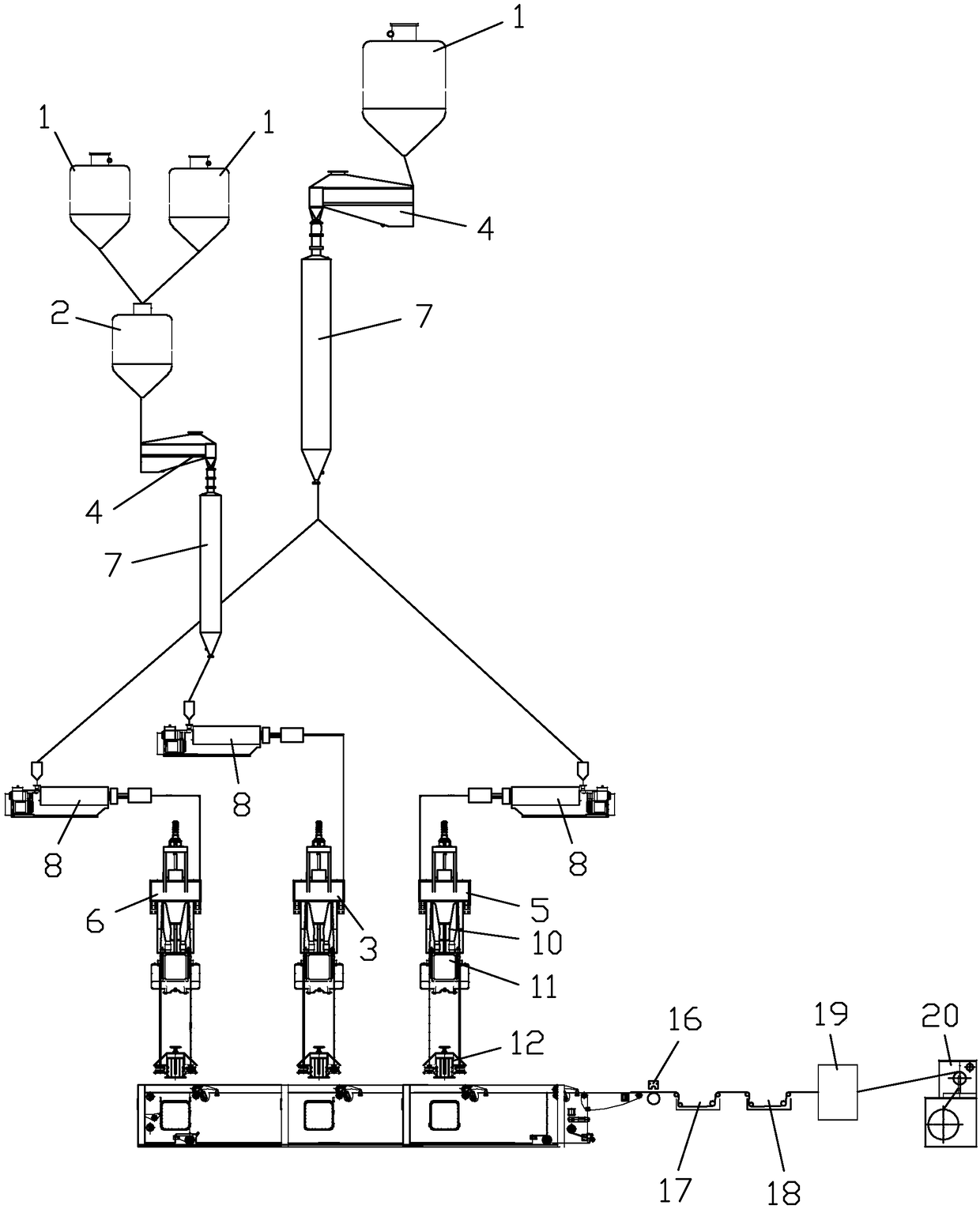

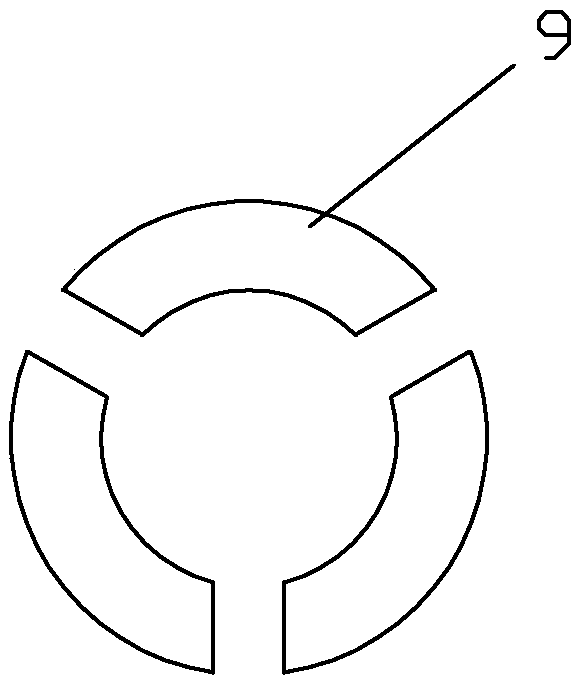

Manufacturing equipment of polyester spunbonded non-woven fabric with high filtering precision and method of equipment

ActiveCN109056196AImprove mechanical propertiesGood filtration accuracyNon-woven fabricsPolyesterWater soluble

The invention discloses manufacturing equipment of polyester spunbonded non-woven fabric with high filtering precision and a method of the equipment. The equipment comprises a mixing tank, a crystallizer, a drying tower, a screw extruder, a first spinning box, a second spinning box and a third spinning box; water-soluble polyester slices and partial polyester slices pass through the mixing tank, the crystallizer, the drying tower, the screw extruder and the second spinning box in sequence, and spinneret orifices of a spinneret plate of the second spinning box are of an annular structure; another part of polyester slices pass through the crystallizer, the drying tower, the screw extruder, the first spinning box and the third spinning box in sequence; the second spinning box, the first spinning box and the third spinning box are all connected with a drafting nozzle, and the drafting nozzle is connected with a web forming device, a spunlace reinforcing device, an alkaline liquor immersiontreatment device, a washing device and a drying device in sequence. Through a multi-box spinning technology, the upper and lower face layers of the non-woven fabric have good mechanical performance,and the middle layer has good filtering precision.

Owner:FOSHAN S L P SPECIAL MATERIALS

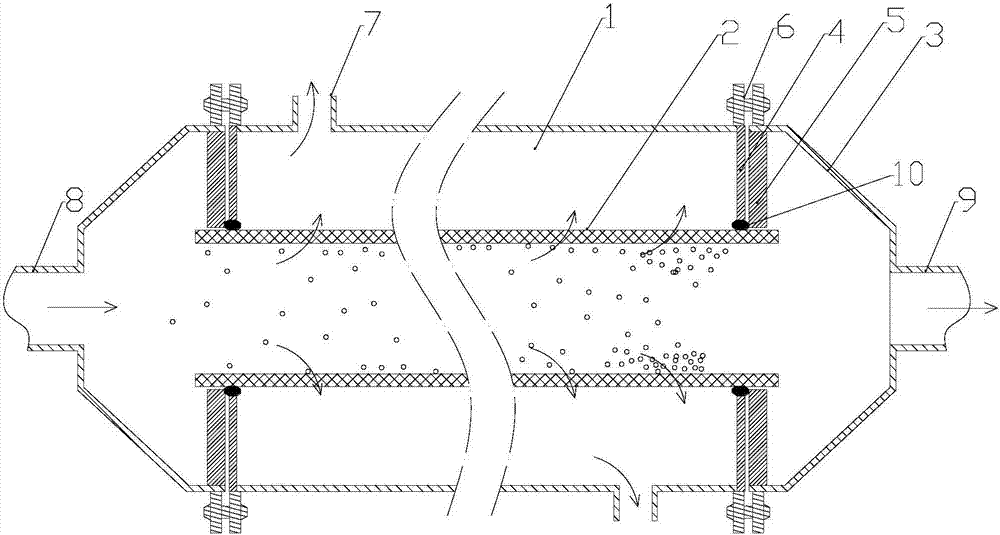

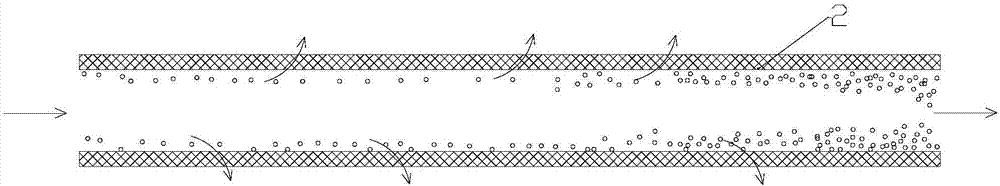

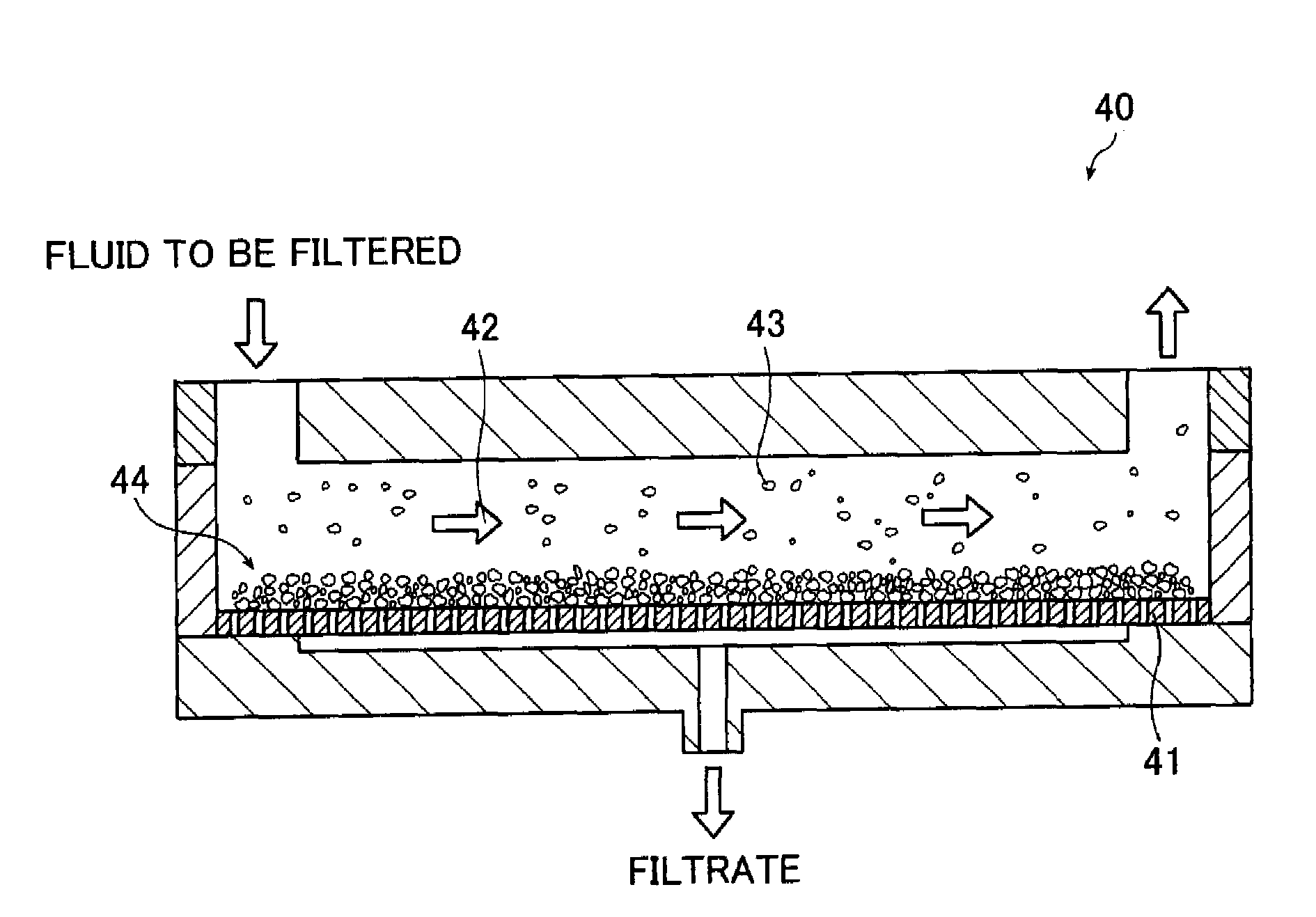

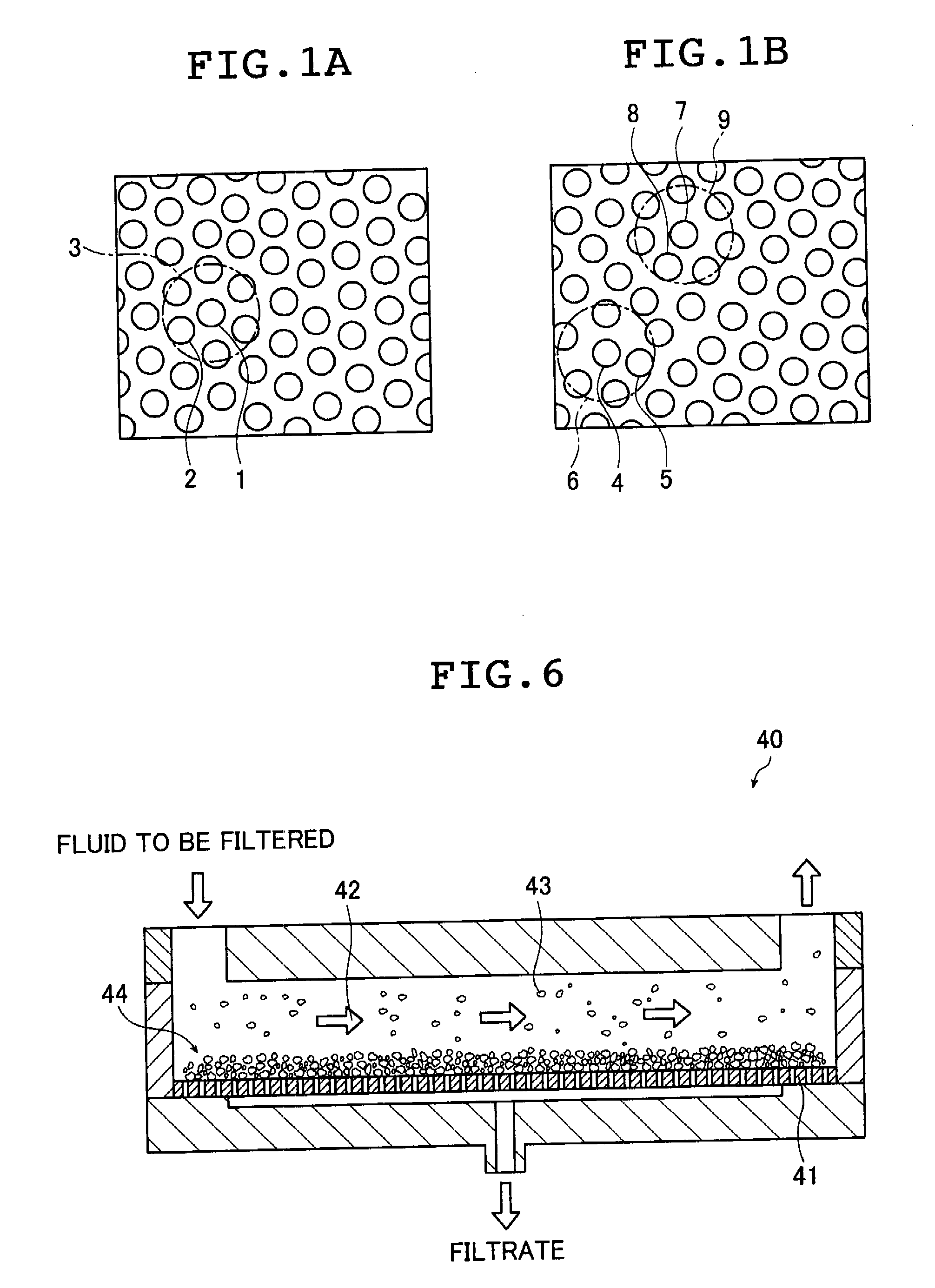

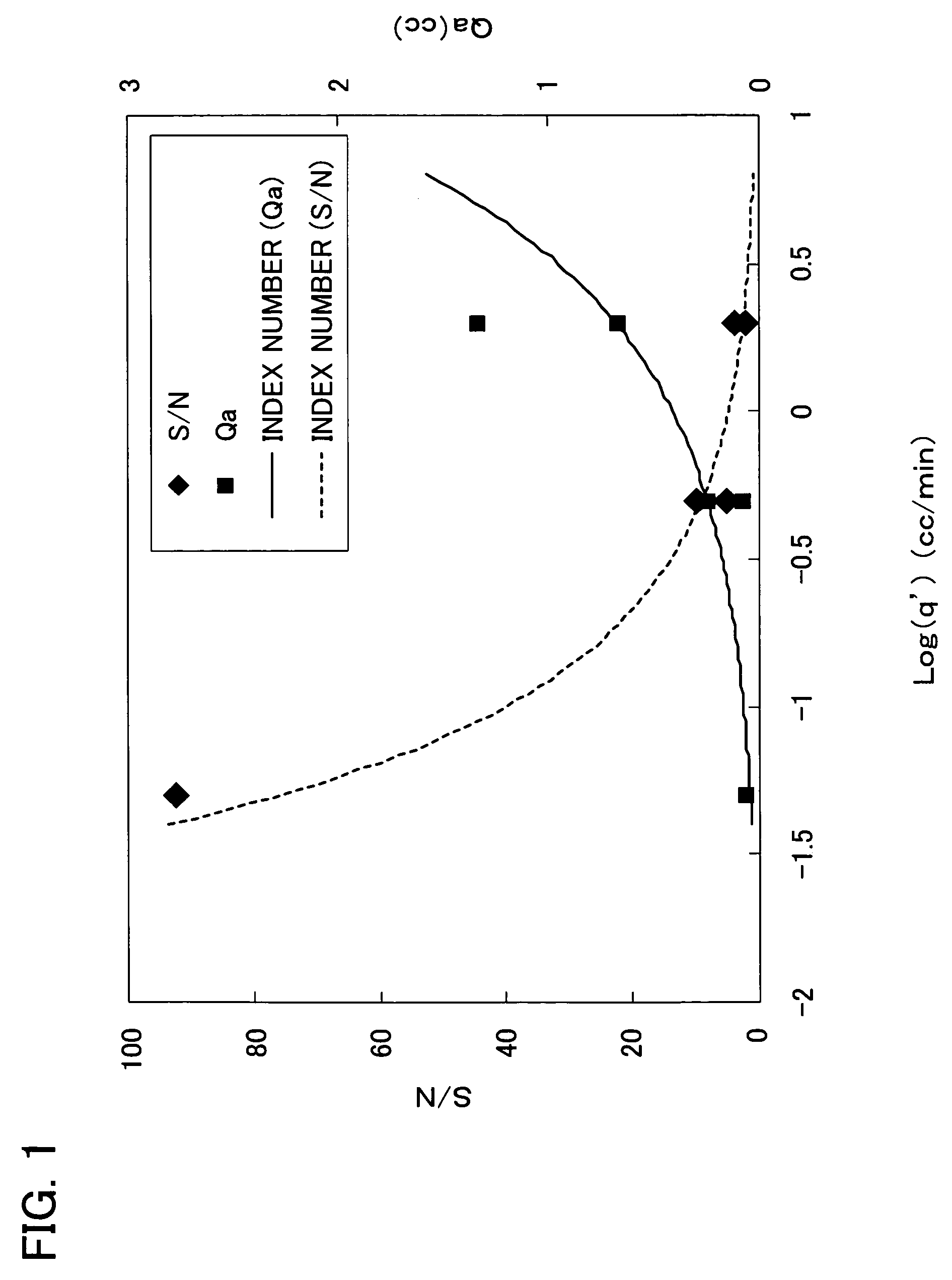

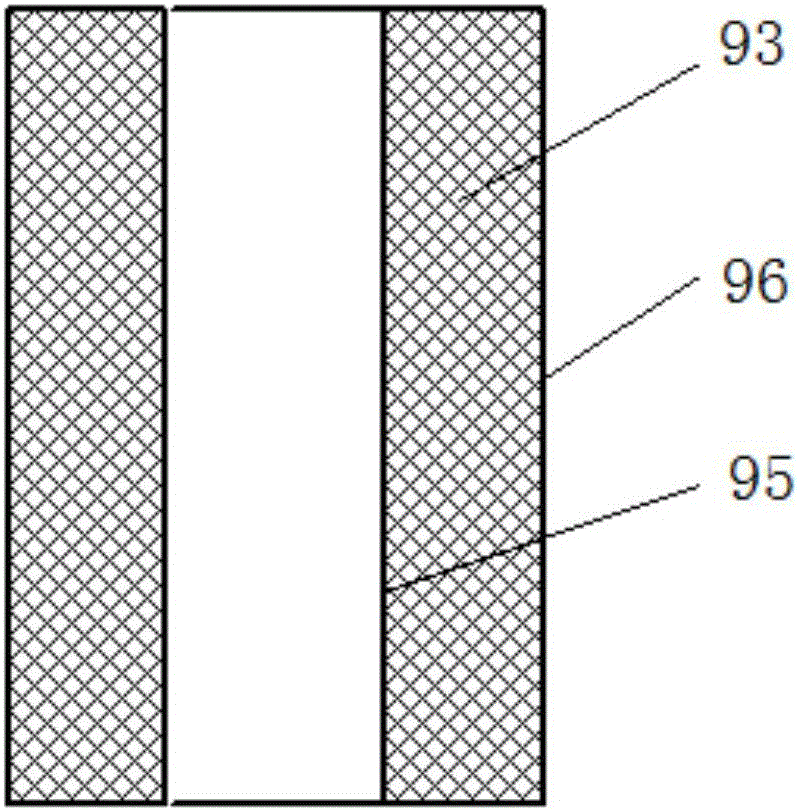

Cross-flow filtration method and cross-flow filtration device

InactiveUS20090050564A1Good filtration accuracyIncrease volumeAnodisationMembranesChemistryCross-flow filtration

A method of cross-flow filtration using a membrane filter has a feeding a fluid to be filtered across a membrane surface of a porous alumina membrane filter serving as the membrane filter so that the fluid flows parallel to the membrane surface to separate material to be filtered with the porous alumina membrane filter. The porous alumina membrane filter is made of an aluminum anodized film and includes micropores having a degree of ordering as defined by formula (1):Degree of ordering (%)=B / A×100 (1)of at least 50%, a porosity as defined by formula (2):Porosity (%)=C / D×100 (2)of at least 40%, and a percentage of a pore size standard deviation to an average pore size of up to 10%.

Owner:FUJIFILM CORP

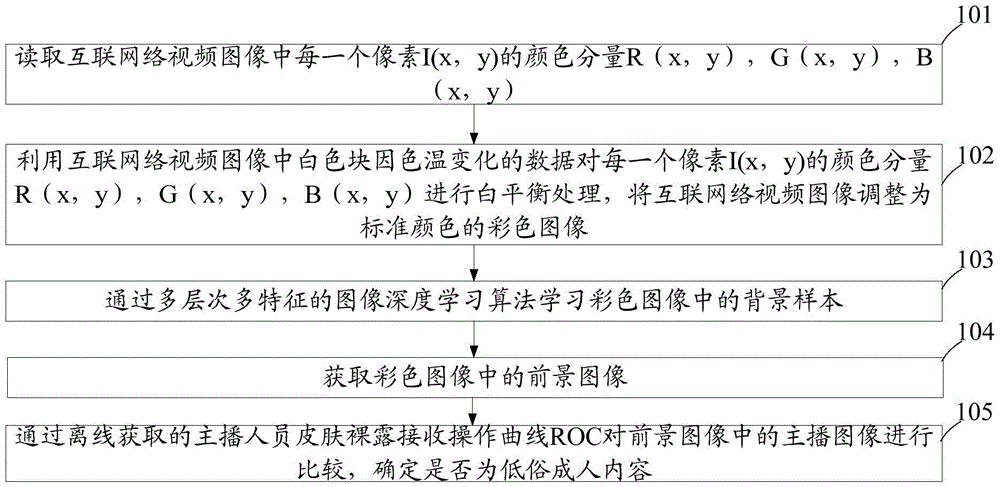

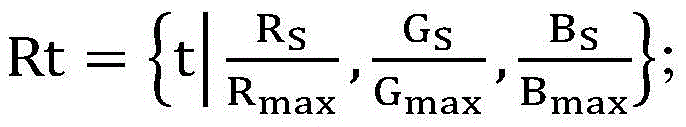

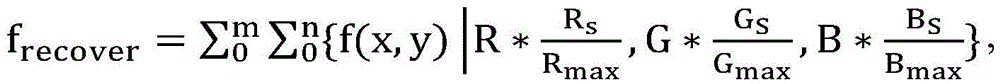

Detection method for vulgar adult content of Internet video image

InactiveCN105654059ASolve the low detection efficiencyIntelligent detectionCharacter and pattern recognitionPattern recognitionVideo processing

The invention relates to the technical field of image and video processing and particularly relates to a detection method for vulgar adult content of an Internet video image. The detection method comprises the following steps: reading color components R, G and B of each pixel in the Internet video image; carrying out white balance processing on the color components R, G and B of each pixel by utilizing data of changes of white blocks due to temperatures in the Internet video image, and adjusting the Internet video image into a standard-color colorful image; learning a background sample in the colorful image through a multi-level and multi-characteristic image deep learning algorithm so as to obtain a foreground image in the colorful image; and comparing an anchor image in the foreground image through an offline-acquired anchor skin nakedness receiving operation curve ROC, and determining whether the content is the vulgar adult content or not. The detection method provided by the invention has a relatively rapid detection and filtering speed, and has relatively good filtering precision and relatively low system expenditures; and the working amount of manual judgment can be extremely reduced so that the detection of the vulgar adult content of the Internet video image is efficient and intelligent.

Owner:WUHAN HONGRUIDA INFORMATION TECH CO LTD

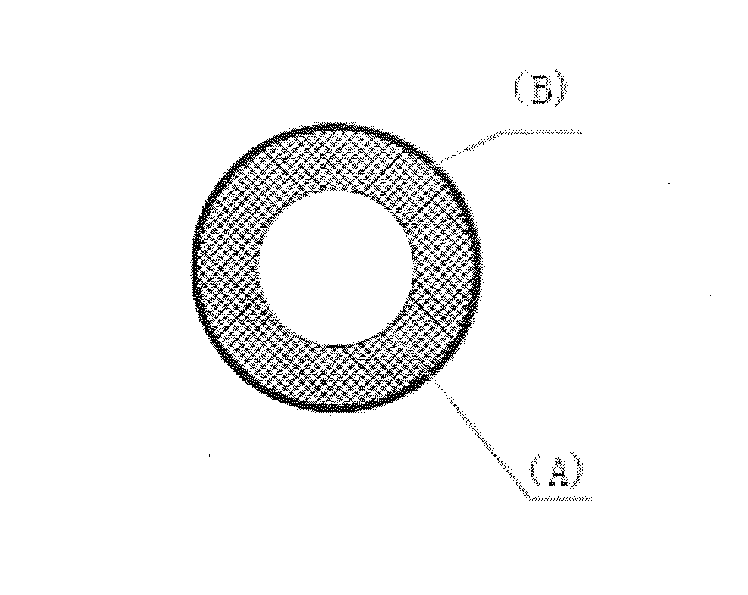

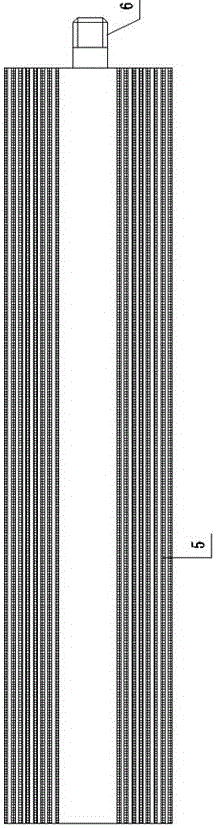

Dual-gradient pore-structure sialon and silicon carbide combined membrane tube and preparation method thereof

ActiveCN105727756AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareMaterials preparationFiltration

The invention relates to the field of porous ceramic materials, and specifically relates to a dual-gradient pore-structure sialon and silicon carbide combined membrane tube and a preparation method thereof. The membrane tube material is composed of sialon and silicon carbide. The membrane tube has a dual-gradient filtering structure composed of a support body layer and a surface membrane layer. The support body layer is composed of a combination of sialon produced through a reaction and coarse silicon carbide grains, and has an average pore size of 10-50mum. The surface membrane layer is composed of a combination of sialon produced through a reaction and fine-particle silicon carbide grains, and has an average pore size of 0.1-5mum. An overall porosity of the membrane tube is within a range of 40-50%. The preparation method of the membrane tube sequentially comprises the steps of material preparation, support forming, membrane layer preparation and firing. Isostatic pressing is adopted in the forming step, wherein a forming pressure is controlled at 100-150MPa. The firing temperature is controlled at 1650-1850 DEG C, and a temperature maintaining time is 3-5h. The method is easy to realize. With the method, product performance can be ensured. The membrane tube provided by the invention has the advantages of high application temperature, high acid corrosion resistance and high alkali corrosion resistance. The membrane tube can be used in filtration purification of various fluids with high temperature or low temperature, such as high-temperature high-press gas filtration dedusting, water purification and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

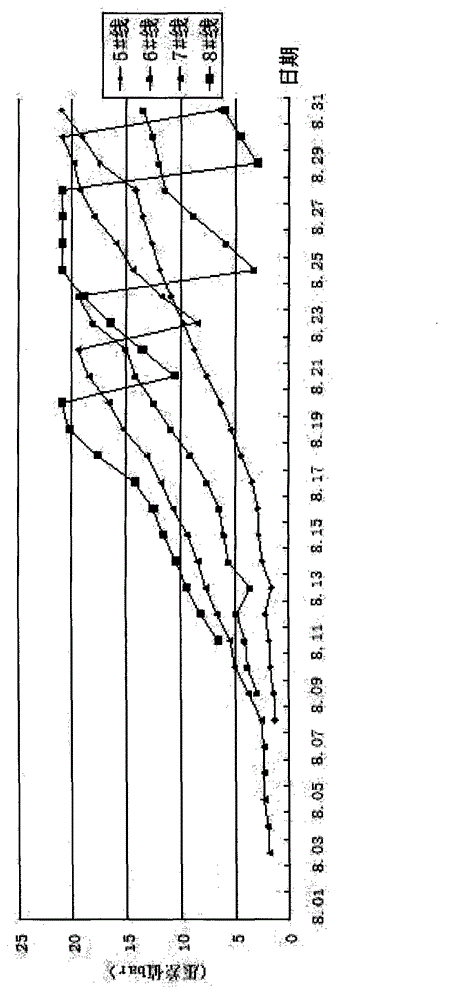

Melt filter element for spandex production

ActiveCN102943310AHigh strengthImprove permeabilityFilament-forming treatmentControl layerPressure difference

The invention relates to a melt filter element for spandex production. The melt filter element comprises a support frame and a filter element cartridge, wherein the filter element cartridge is sleeved on the support frame, is integrally welded with the support frame and is a hollow cylinder formed by welding a stainless steel sintered mesh. The stainless steel sintered mesh sequentially comprises a protection layer, a control layer, a diffusion layer, a first framework layer and a second framework layer from outside to inside. The melt filter element for spandex production is simple in structure, low in initial pressure difference, slow in pressure drop and rise, fine in filtering effect and low in cost, and has excellent social and economic values.

Owner:新乡市中邦科技有限公司

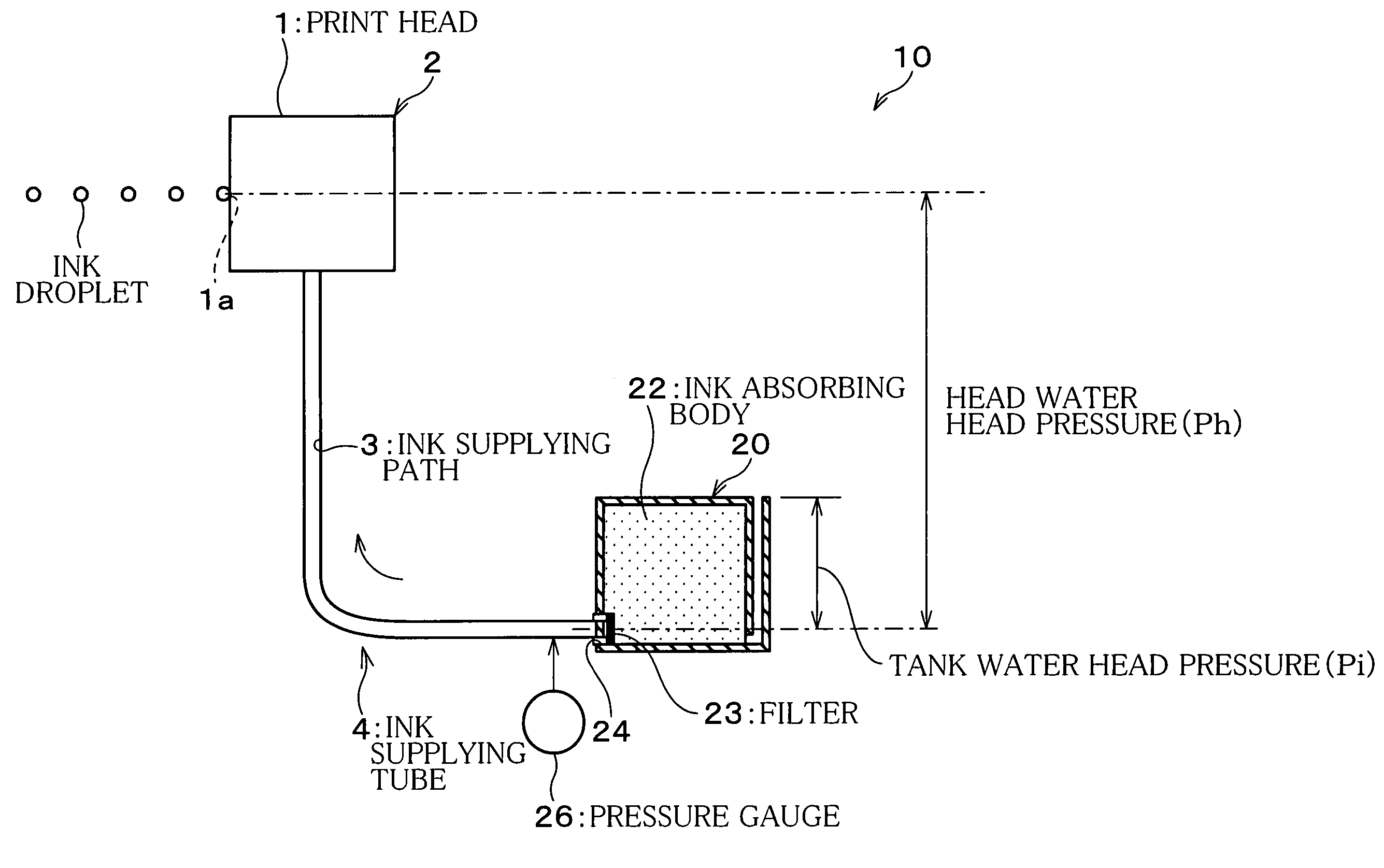

Image forming apparatus

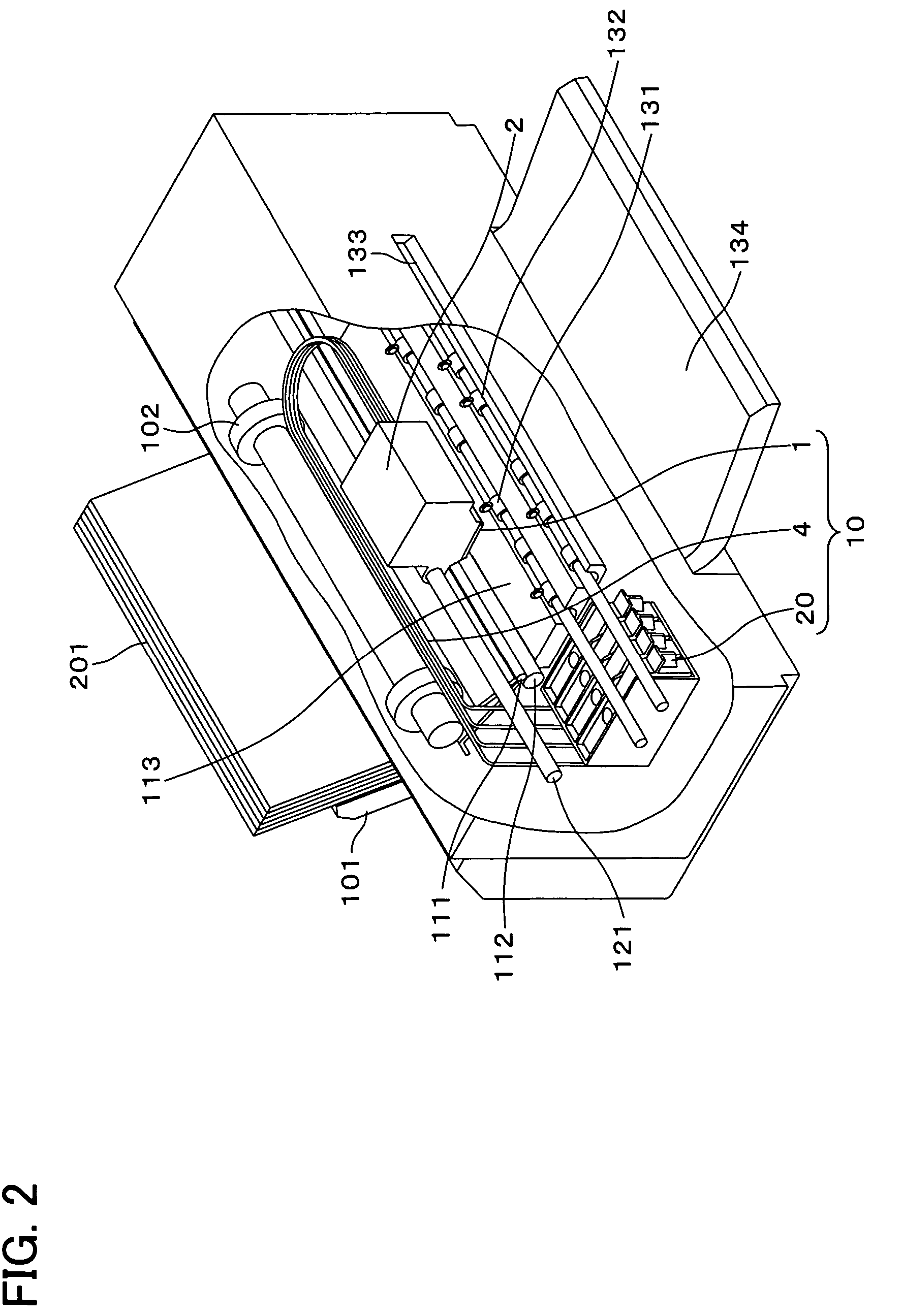

ActiveUS7226152B2Improve accuracyPrevent the S/N ratio of the detecting electrode from being loweredPrintingImage formationMechanical engineering

An image forming apparatus in which ink depletion detection accuracy will not be deteriorated even if an air bubble is created in an ink supplying path. The image forming apparatus is provided with (a) an ink storage section for storing ink therein, (b) an ink supplying path for supplying, to a print head, the ink stored in the ink storage section, and (c) an electrode for detecting whether the ink is present or absent in the ink supplying path, an amount of the ink supplied into the ink supplying path being 1.0 cc or less per minute.

Owner:SHARP KK

Polyamide filter element obtained through sweat soldering and manufacturing method thereof

InactiveCN105797485AHigh and oil-water separation abilityOil-resistant and alcohol-resistantMachines/enginesMembrane filtersPolyamideHollow cylinder

The invention discloses a polyamide filter element obtained through sweat soldering and a manufacturing method thereof. The polyamide filter element comprises an end cover, a lower end cover and a polyamide filter material. The polyamide filter material is of a hollow cylinder structure formed by processing polyamide materials through a melt-blowing technology, and bonding and twining blown-out superfine cellosilk. The filter material is of a loose structure and is provided with filter holes of different hole diameters. The hole diameter of the filter holes is gradually decreased from the outer layer to the inner layer of the cylinder structure. The upper end cover and the lower end cover are welded to the two ends of the filter material through a hot-melt technology. The at least one of the upper end cover and the lower end cover is provided with an oil outlet hole. The filter element has the good filter precision, pollutant carrying capacity and flow resistance parameters on the premise of ensuring that the material has the oil resistance and alcohol corrosion resistance, non-glue connection is achieved by adopting the sweat soldering scheme, and the filter requirements of oil products, chemical waste liquid and chemical waste gas are met.

Owner:XIAN TIANHOU FILTRATION TECH

Novel metal film filter material and preparation method and application thereof

ActiveCN105999851AHigh strengthImprove rigidityMembrane filtersFiltration separationFiltrationWater quality

The invention relates to a water filtration filter material, in particular to a novel metal film filter material and a preparation method and application thereof. The novel metal film filter material is made of stainless steel wire meshes, the wire meshes are subjected to multilayer overlaying and vacuum sintering, mesh holes of all layers of a metal film mesh overlay structure sintered mesh are mutually staggered, and the metal film filter material with the uniform structure is formed. According to the novel metal film filter material and the preparation method and application thereof, the problems that a traditional sewage filtration filter material cannot conduct effective filtering separation on low molecular weight organic matter, tiny suspended solids and objects with small particle sizes, and water subjected to conventional treatment cannot meet the water quality index requirement of state stratum reinjection water, inland exterior drainage and drinking water of residents are solved. The metal film filter material is widely applied to fine filtering equipment, high in grain boundary corrosion resistance requirement, of wild outdoor machines in chemical, coal and petroleum industries or heat-resistant parts of building materials and parts difficult in heat treatment and fine filtering equipment of the drinking water of the residents.

Owner:河北银达环保科技有限公司

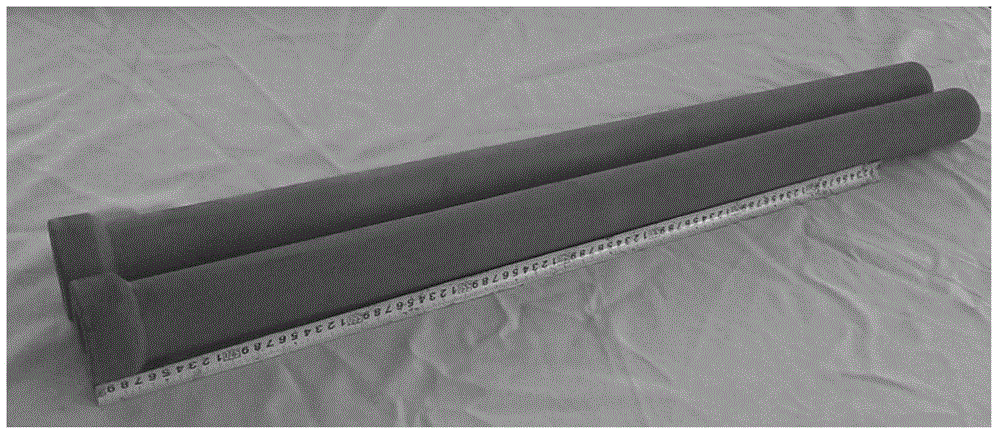

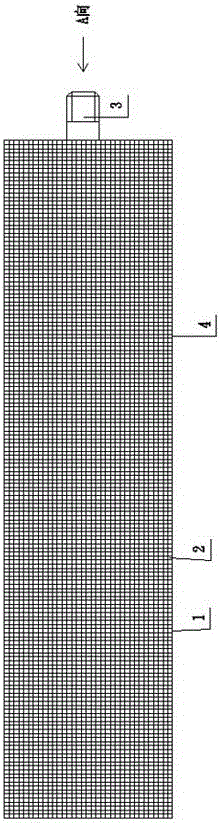

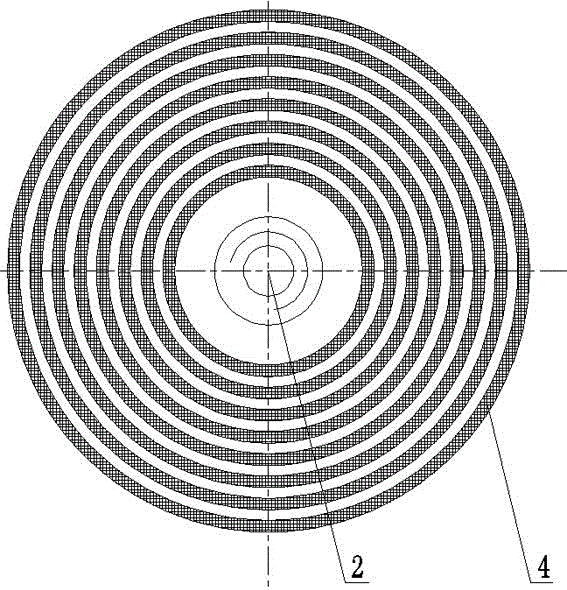

Gradient-porosity pure silicon carbide membrane tube

ActiveCN102633531BGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareIntegrated gasification combined cycleSurface membrane

The invention belongs to the technical field of multipore ceramic materials and preparation thereof, and particularly relates to a gradient-porosity pure silicon carbide membrane tube and a preparation method thereof. The gradient-porosity pure silicon carbide membrane tube consists of pure SiC; a gradient filter structure consists of a supporting body layer and a surface membrane layer, wherein the supporting body is formed by stacking and combining roughly granular SiC, and the average aperture is 5-120 mu m; the surface membrane layer is formed by stacking and combining finely granular SiC, and the aperture is 0.1-20 mu m; and the whole porosity of the membrane tube is 25-50%. The preparation method comprises burdening, forming the supporting body, preparing the membrane layer and sintering, wherein forming is performed under equal static pressure; the forming pressure is controlled between 40 and 150MPa; the sintering temperature is controlled between 1,500 and 2,400 DEG C; and heat is preserved for 0.5-5 hours. The method is easy to implement, and the performance of a product can be guaranteed. The gradient-porosity pure silicon carbide membrane tube can be used under an oxidization atmosphere and a reduction atmosphere, is high in acid and alkaline corrosion resistance and can be applied to gas chemical engineering and integrated gasification combined cycle (IGCC) and pressurized fluidized bed combustion (PFBC) power generation and used for filtering and purifying various types of high- and low- temperature fluid, such as high-temperature flue, automobile tail gas, water and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

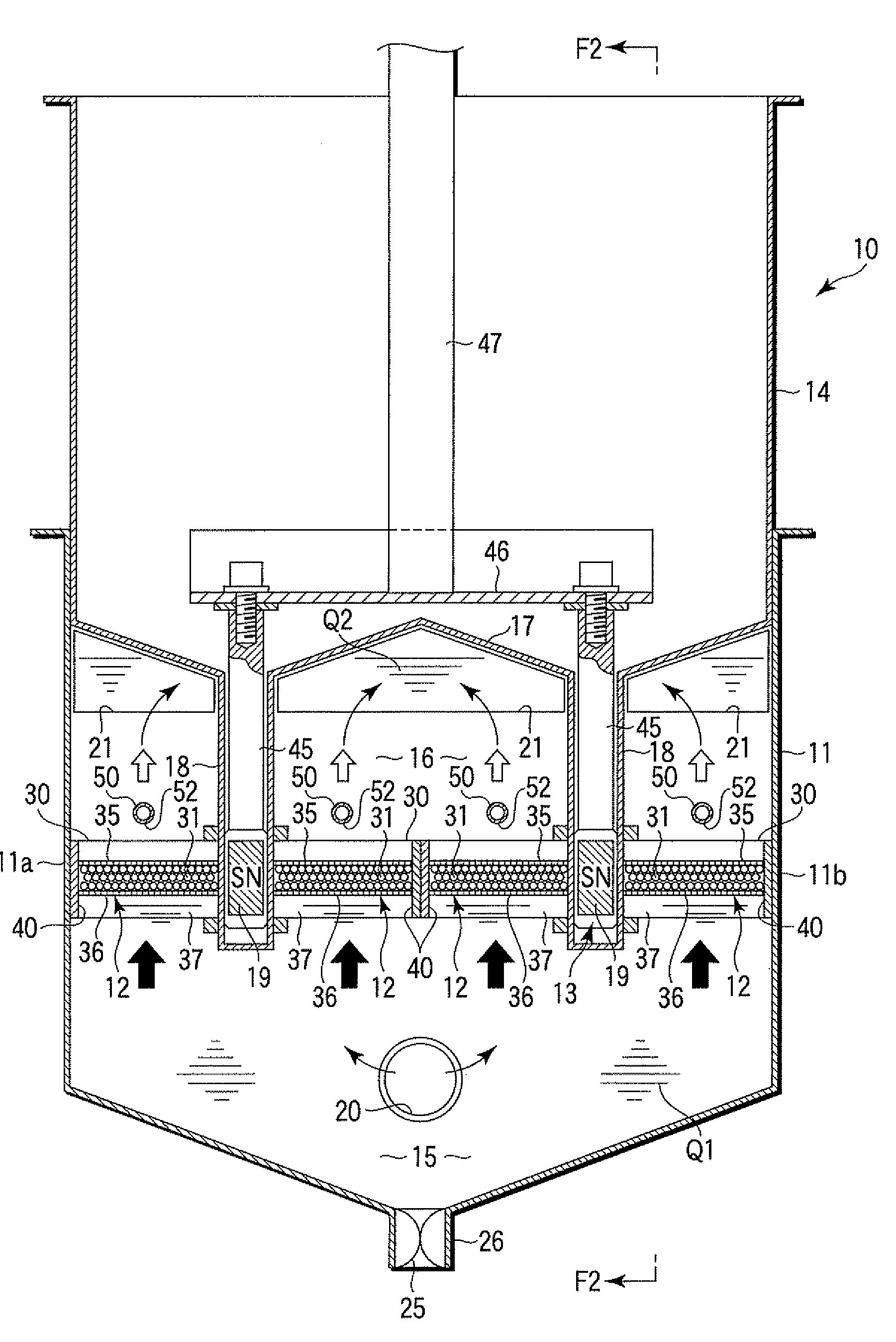

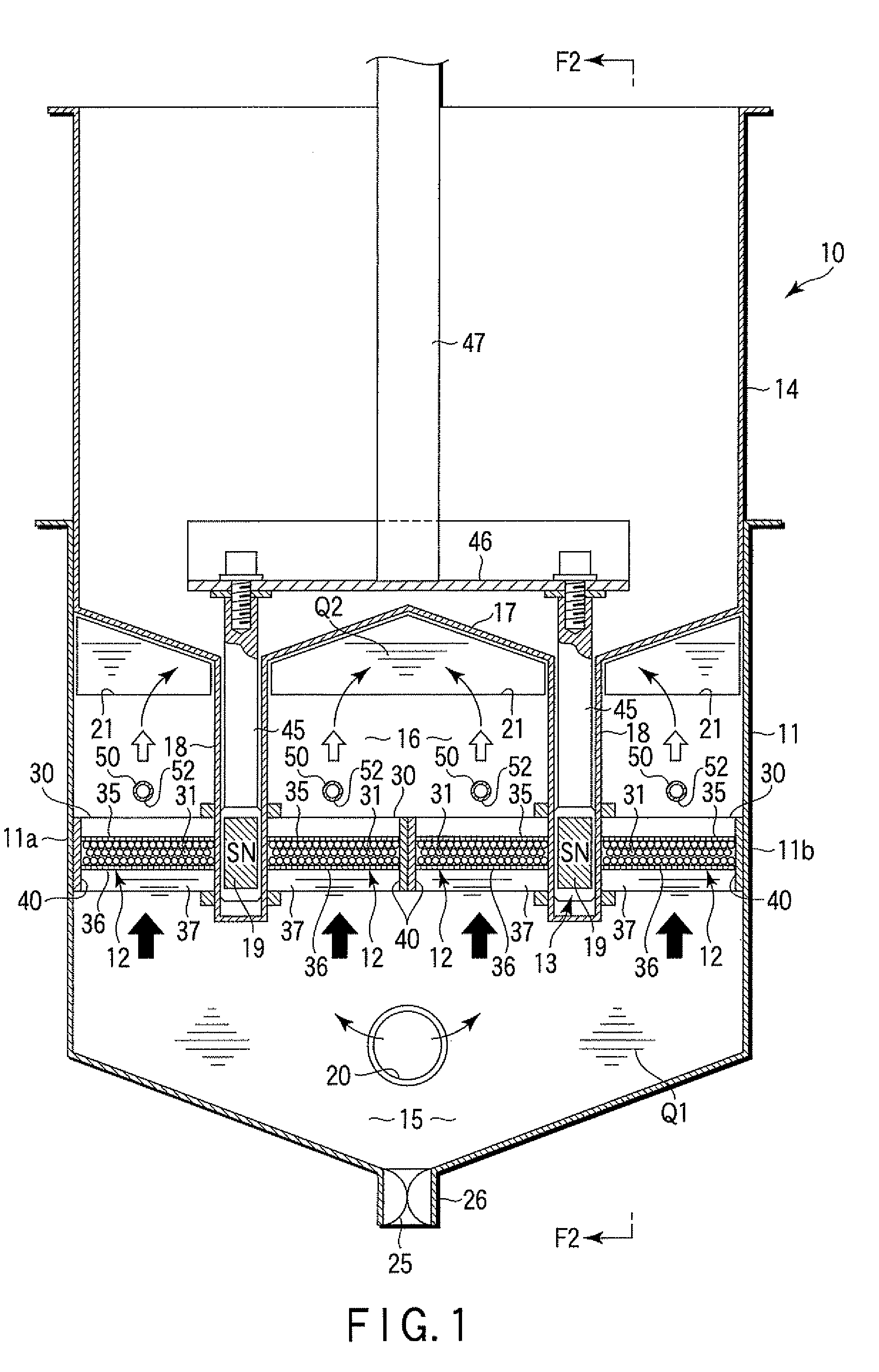

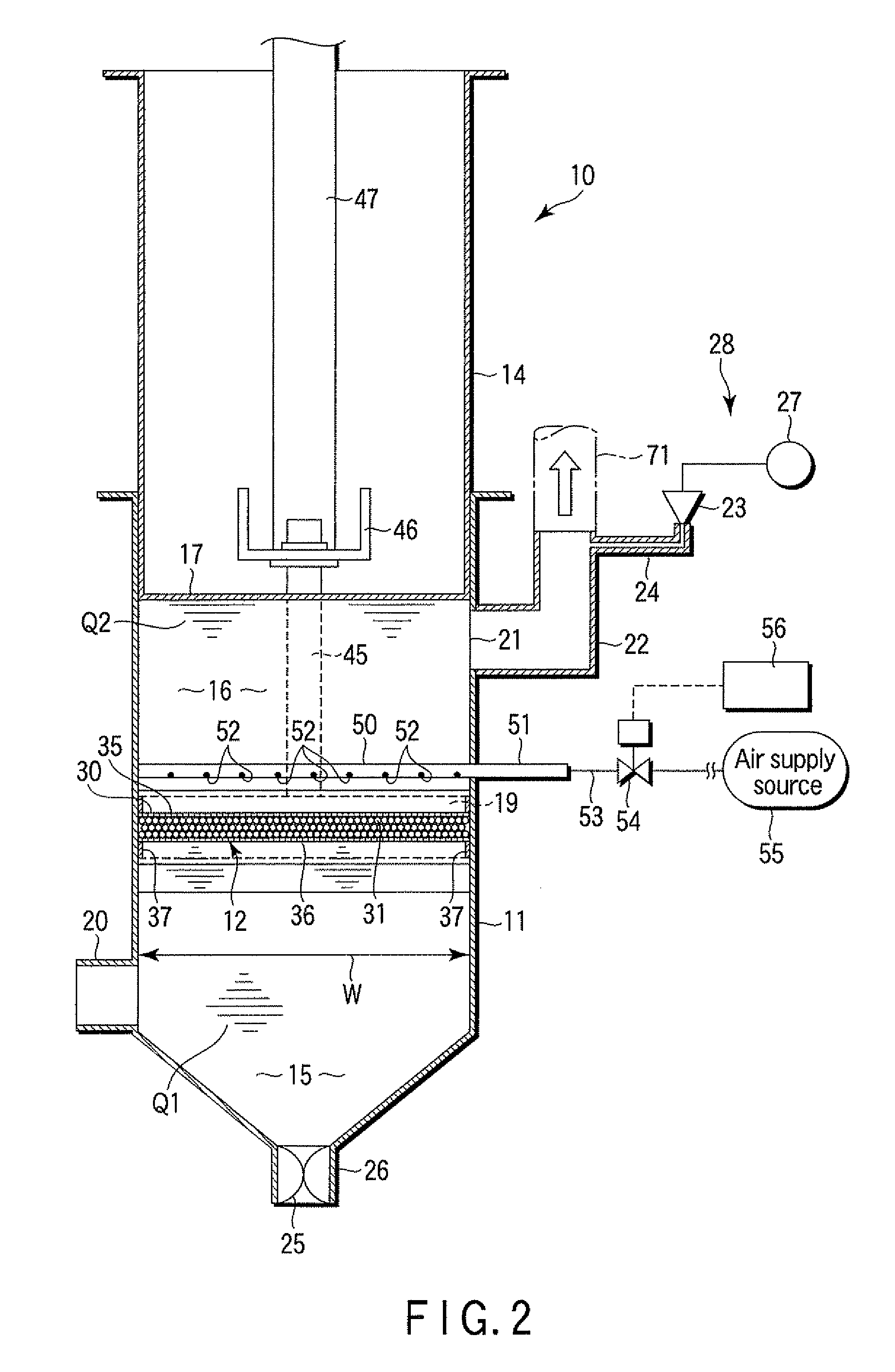

Filtration device

InactiveUS20110062064A1Process cleaningEffectively and thoroughly cleanedMagnetic separationMaintainance and safety accessoriesFilter mediaAir bubble

A filtration device is provided with a filter tank, filter medium unit, magnet, and submerged air discharging mechanism. The filter medium unit includes a large number of magnetic filter medium granules formed of metal balls. When the magnet is in a first position, the magnetic filter medium granules magnetically attract one another. When the magnet is moved to a second position, the magnetic filter medium granules are released from the mutual magnetic attraction. In cleaning the magnetic filter medium granules, a clean fluid located above the magnetic filter medium granules is poured between the magnetic filter medium granules. In cleaning the magnetic filter medium granules, the submerged air discharging mechanism ejects air into the clean fluid above the magnetic filter medium granules and toward the magnetic filter medium granules. Air bubbles are introduced into the clean fluid by the ejected air.

Owner:BUNRI

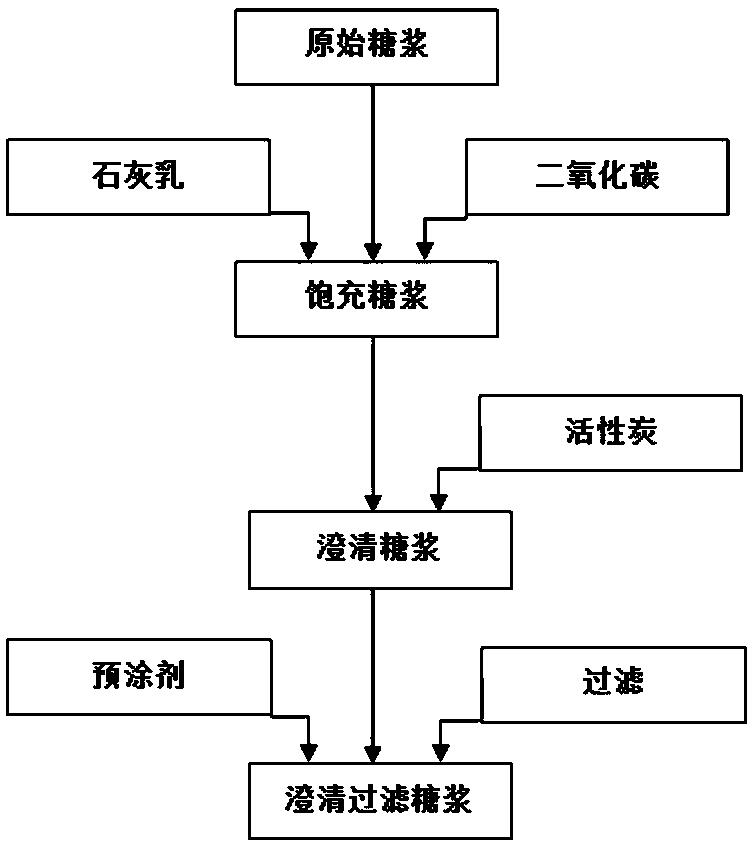

Syrup clarification method using combination of active carbon and carbonic acid method

InactiveCN110358870AImprove the effect of decolorization and clarificationImprove filtration efficiencyPurification using adsorption agentsPurification using chemicalsActivated carbonFiltration

The invention relates to the technical field of sugar manufacturing and discloses a syrup clarification method using a combination of active carbon and a carbonic acid method. The syrup clarificationmethod using the combination of active carbon and the carbonic acid method comprises the following steps: step I, adding lime milk and carbon dioxide into original syrup for saturation by the carbonicacid method to form saturated syrup, step II, adding 0.03-0.05% of active carbon into the saturated syrup for a clarification reaction to form clarified syrup, and step III, performing filtration onthe clarified syrup to form clarified and filtered syrup. The method integrates active carbon and the carbonic acid method to exert a synergistic effect; a decoloration and clarification effect of thesyrup is improved; synchronous separation of active carbon and filtrated mud is achieved through original pressure filtration due to a filtration aiding effect of calcium carbonate in the saturated syrup on active carbon; additional filtration equipment is not required; the equipment investment cost is lowered; pressure filtration equipment is additionally coated with a precoating agent, so thatcarbon leakage is effectively avoided; the filtration efficiency and filtration precision are improved; a clarification effect is good; and the method is short in technical process and high in safety.

Owner:中粮崇左糖业有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com