Novel metal film filter material and preparation method and application thereof

A metal membrane and filter material technology, applied in the field of new metal membrane filter material and its preparation, can solve problems such as the inability to meet the national stratum reinjection water, inland and outdoor drainage residents' drinking water quality index requirements, etc., and maintain high flow and low pressure drop. characteristics, good rigidity, high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

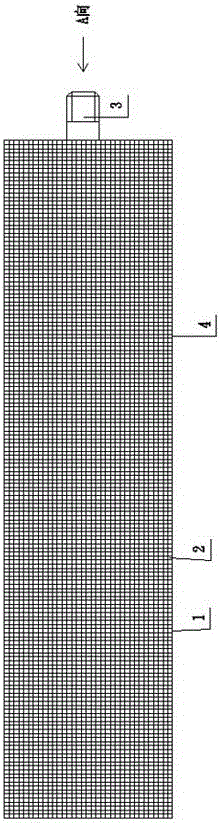

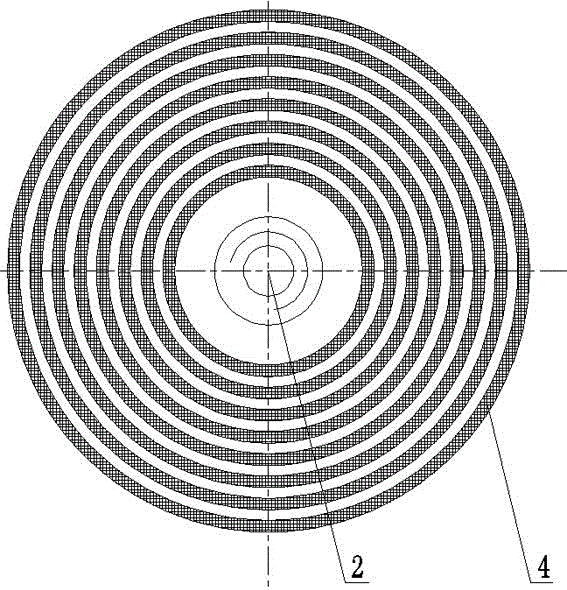

[0044] Combine below Figures 1 to 3 The given examples further illustrate the present invention, but the examples do not constitute any limitation to the present invention.

[0045] A kind of novel metal film filter material described in this embodiment, see Figures 1 to 3 , with 321 stainless steel wire mesh 1 as the material, the metal mesh is superimposed by 8 layers, vacuum sintered, and the meshes of each layer of the sintered mesh of the metal film mesh superimposed structure are interlaced to form a uniform structure of the metal film filter material.

[0046] The pre-filtration water inlet channel 2 of the metal film filter material is placed at the lower end of the metal film filter material, and the filtered water outlet channel 3 is located on the right side of the metal film filter material.

[0047] The metal film protective net 4 is placed on the periphery of the metal film filter material.

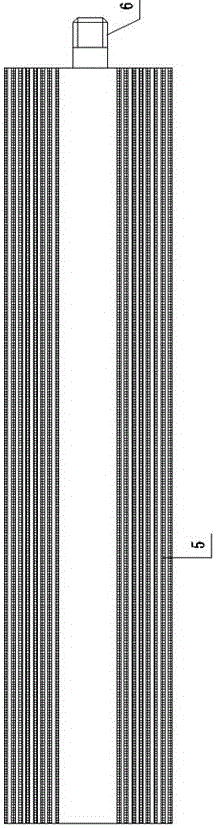

[0048] The metal film layer 5 is fixed by the metal film fixing end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com