Process and device for zero discharge treatment of coal chemical wastewater

A coal chemical wastewater and treatment process technology, applied in the field of water treatment, can solve the problems of calcium and magnesium reverse osmosis, scaling of evaporation devices, low utilization of solid waste, etc., and achieve the effects of reducing pollution, avoiding scaling, and improving floating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

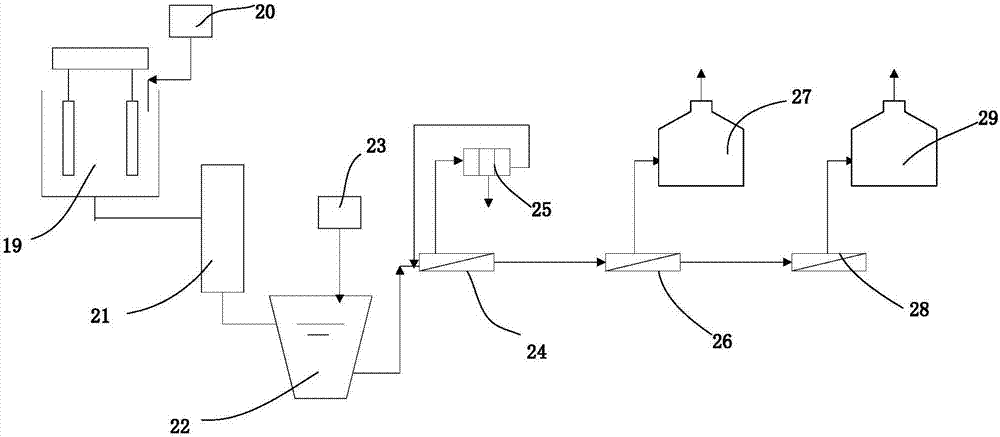

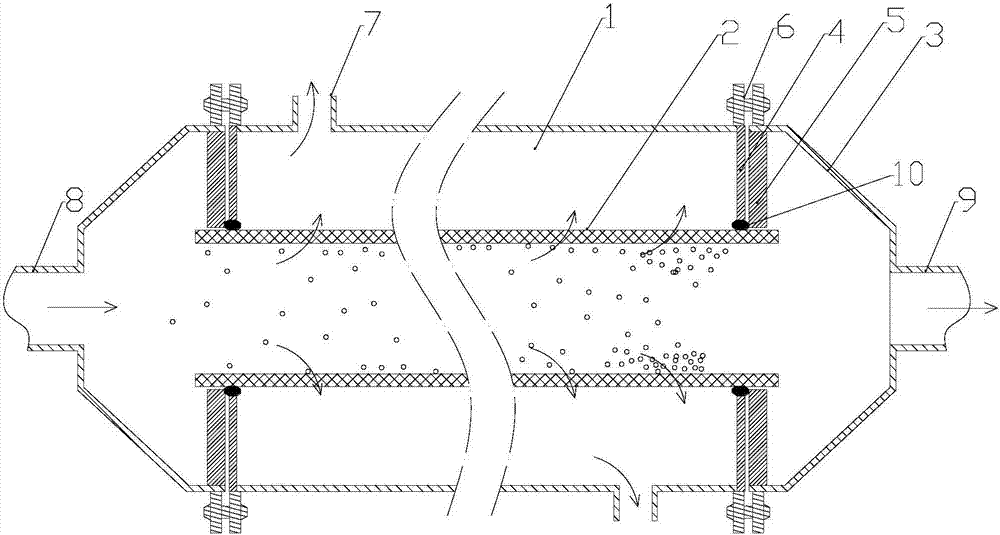

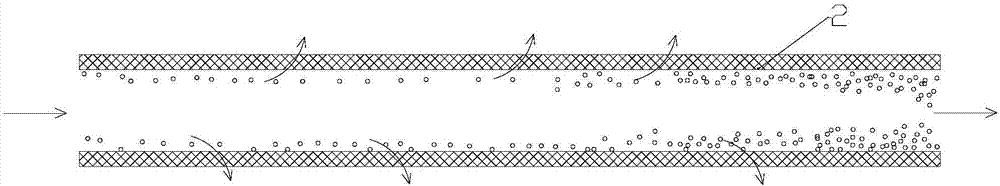

Method used

Image

Examples

Embodiment 1

[0089] In the first step, 0.05wt% rhamnolipid is added to the high-salt wastewater of the coal chemical industry, and then sent to electrocoagulation treatment. The electrodes in the electrocoagulation process are pure aluminum electrodes, the distance between the plates is 0.8cm, and the current density is 3.5A / m 2 , carry out the electrocoagulation reaction, the electrolysis time is 200s; the electrocoagulation sludge is sent to dehydration and incineration;

[0090] Step 2: Pre-adding acid to control the pH value of the water produced by electricity regulation flocculation is 4-6, and through aeration to make the dissolved oxygen of the wastewater 2mg / L, send it to the iron-carbon micro-electrolysis tower for oxidation treatment, and the iron-carbon The hydraulic retention time of wastewater in the micro-electrolysis tower is 1h; the iron-carbon micro-electrolysis filler is composed of iron filings and powdered activated carbon, and the weight ratio of iron filings to powder...

Embodiment 2

[0096] In the first step, 0.2wt% rhamnolipid is added to the high-salt wastewater of the coal chemical industry, and then sent to electrocoagulation treatment. The electrodes in the electrocoagulation process are pure aluminum electrodes, the distance between the plates is 1.2cm, and the current density is 5.5A / m 2 , carry out the electrocoagulation reaction, the electrolysis time is 350s; the electrocoagulation sludge is sent to dehydration and incineration;

[0097] Step 2: Pre-adding acid to control the pH value of the water produced by electric regulation and flocculation is 4 to 6, and through aeration to make the dissolved oxygen of the wastewater 3mg / L, and send it to the iron-carbon micro-electrolysis tower for oxidation treatment, and the iron-carbon The hydraulic retention time of wastewater in the micro-electrolysis tower is 2.5h; the iron-carbon micro-electrolysis filler is composed of iron filings and powdered activated carbon, and the weight ratio of iron filing...

Embodiment 3

[0103] In the first step, 0.1wt% rhamnolipid is added to the high-salt wastewater of the coal chemical industry, and then sent to electrocoagulation treatment. The electrodes in the electrocoagulation process are pure aluminum electrodes, the distance between the plates is 1.0m, and the current density is 4.0A / m 2 , carry out the electrocoagulation reaction, the electrolysis time is 200-350s; the electrocoagulation sludge is sent to dehydration and incineration;

[0104] Step 2: Pre-adding acid to control the pH value of the water produced by electricity regulation flocculation is 4-6, and through aeration to make the dissolved oxygen of the wastewater 2mg / L, send it to the iron-carbon micro-electrolysis tower for oxidation treatment, and the iron-carbon The hydraulic retention time of wastewater in the micro-electrolysis tower is 2 hours; the iron-carbon micro-electrolysis filler is composed of iron filings and powdered activated carbon, and the weight ratio of iron filings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com