Ultrafiltration membrane deaerating unit

An ultrafiltration membrane and defoaming technology, which is applied in ultrafiltration, liquid degassing, chemical instruments and methods, etc., can solve the problem of difficult to complete the defoaming of material and liquid, and achieves improved defoaming efficiency, high defoaming efficiency, and avoidance of Hole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

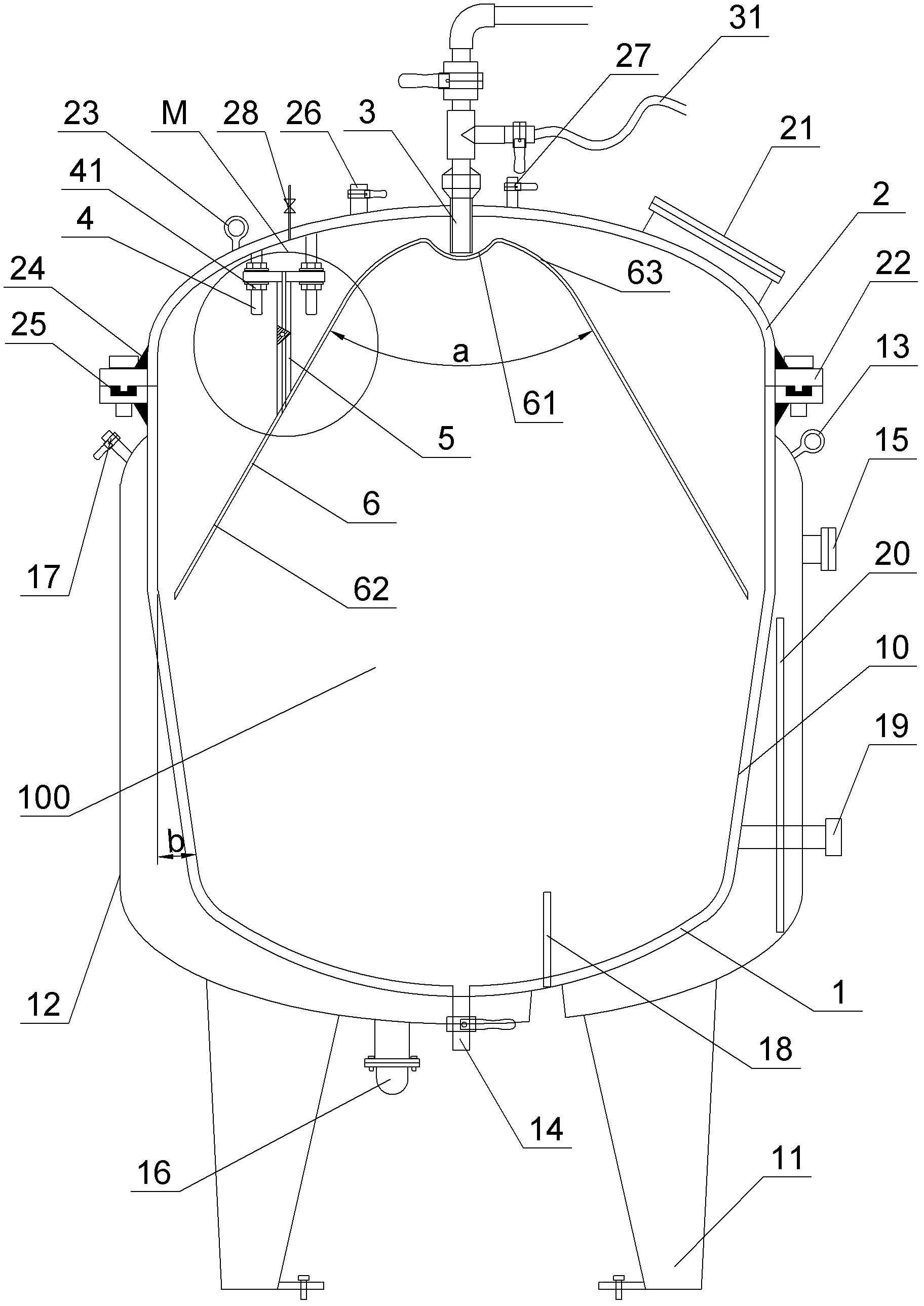

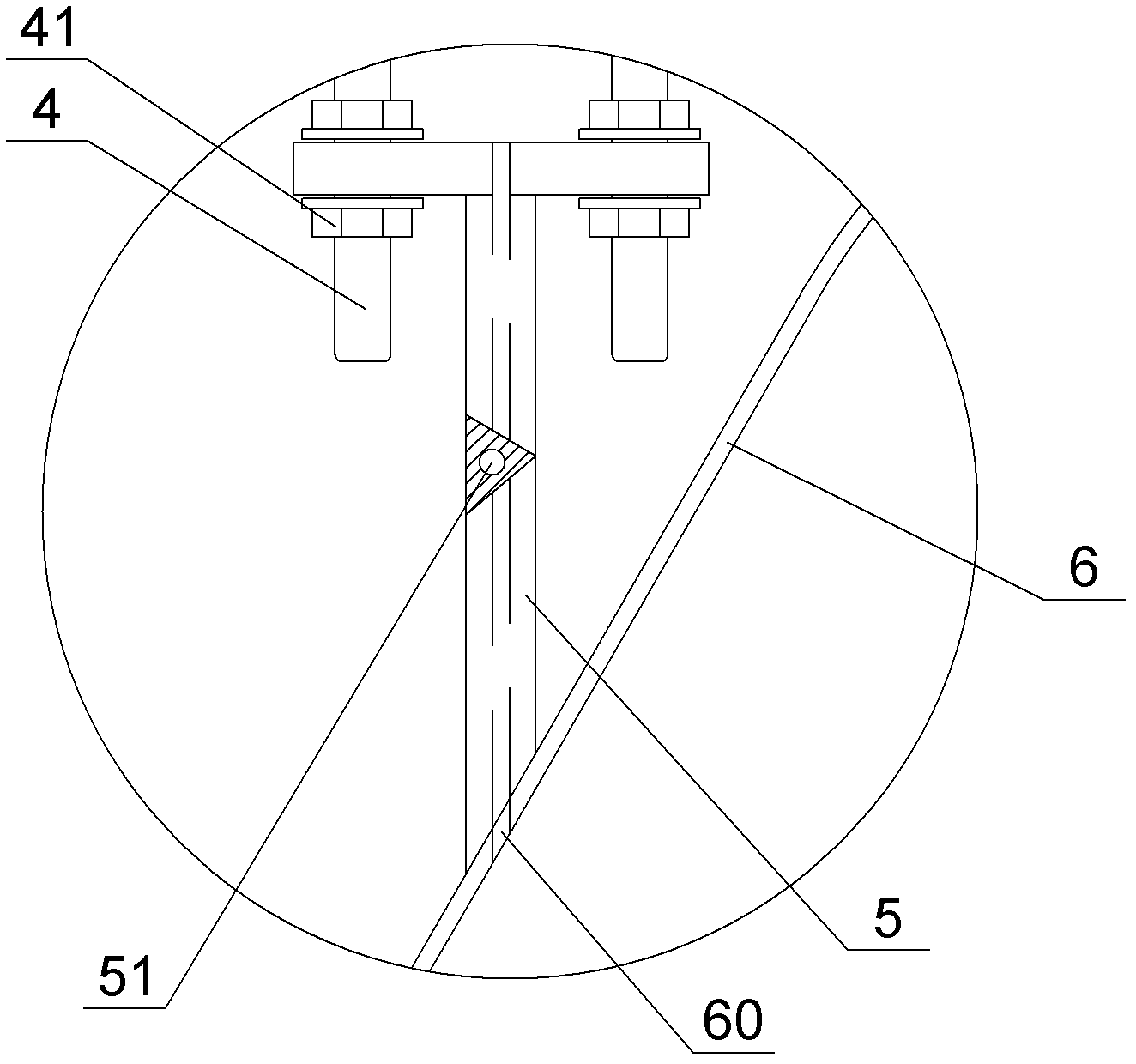

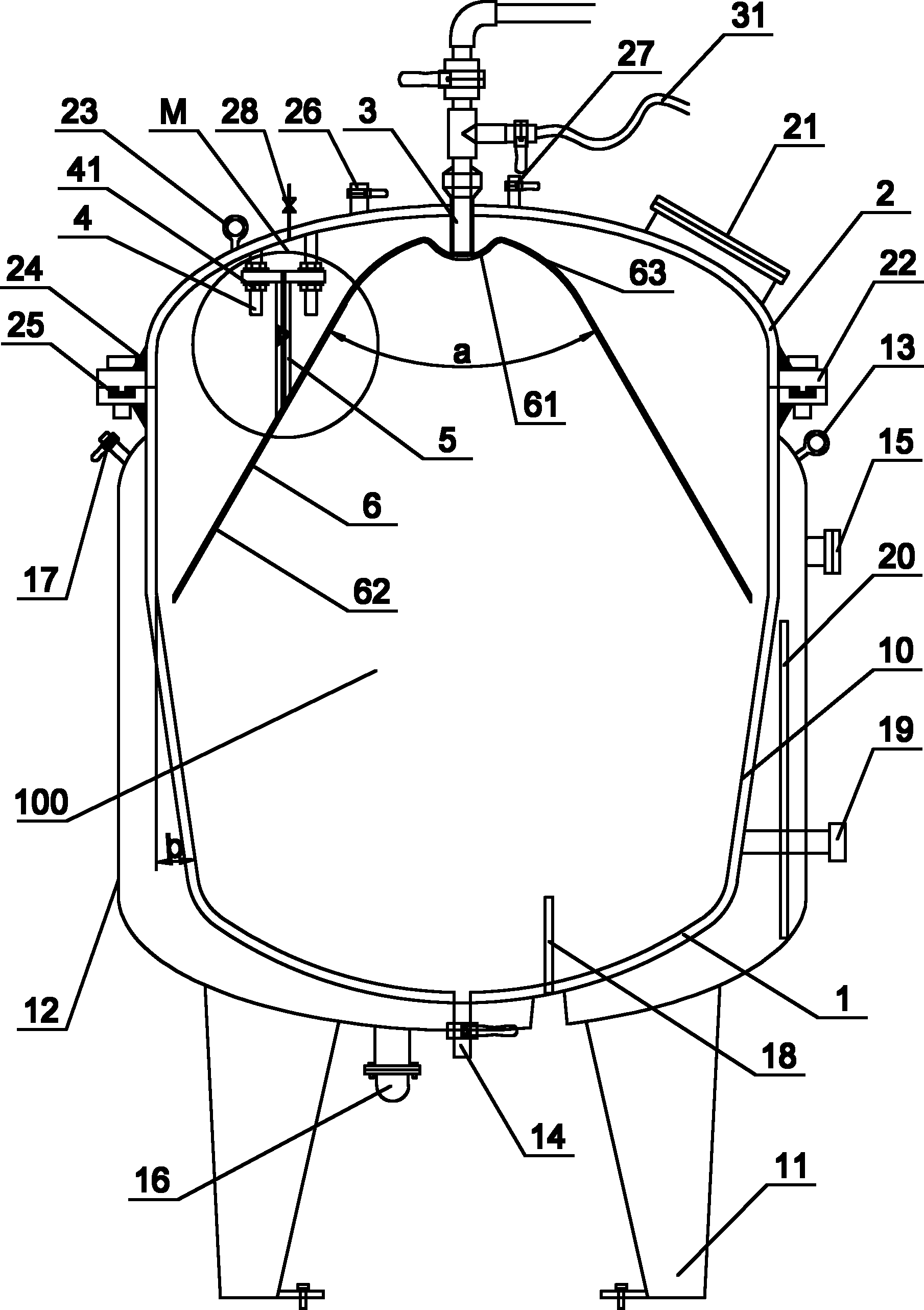

[0018] Such as figure 1 , figure 2 As shown, the ultrafiltration membrane degassing device of the present embodiment includes a tank body 1 and an upper cover 2, and the tank body 1 is connected with the upper cover 2 to form a closed space area 100, and the upper cover 2 and the upper cover 2 The tank bodies 1 are connected by flange components 22 and sealed by asbestos packing 25 to avoid friction and dust. The upper cover 2 and the tank body 1 are respectively provided with Reinforcing rib 24, to avoid deformation of the flange assembly 22, the surface polishing treatment of the upper cover 2 and the inner wall of the tank body 1, the top center of the upper cover 2 is connected with the feed pipe assembly 3, so The upper cover 2 is also connected with a vacuum pump pipe joint 26, the feed pipe assembly 3 is connected with an air blowing pipe 31, and the bottom center of the tank body 1 is provided with a feed liquid outlet 14 to ensure that the feed liquid can be dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com