Preparation method of nanocomposite Al2O3 ceramic filter element

A ceramic filter element and al2o3 technology, applied in the field of preparation of Al2O3 ceramic products, can solve the problems of decreased ceramic strength, low air permeability, uneven distribution of ceramic pores, etc., and achieve improved air permeability and strength, high filtration accuracy, and good air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

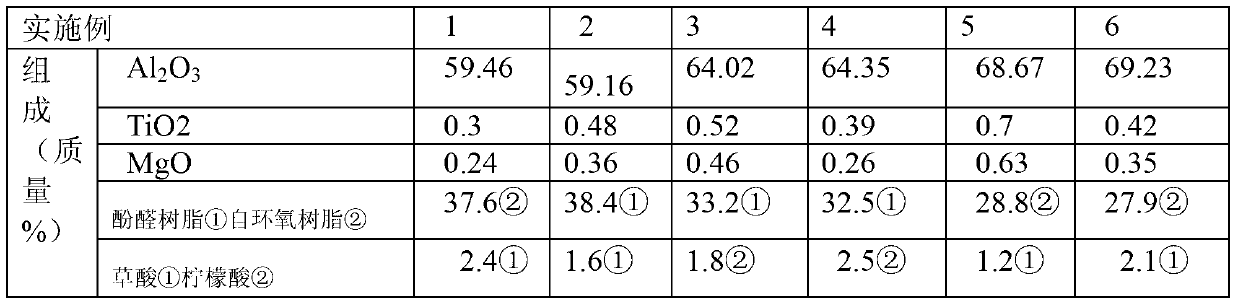

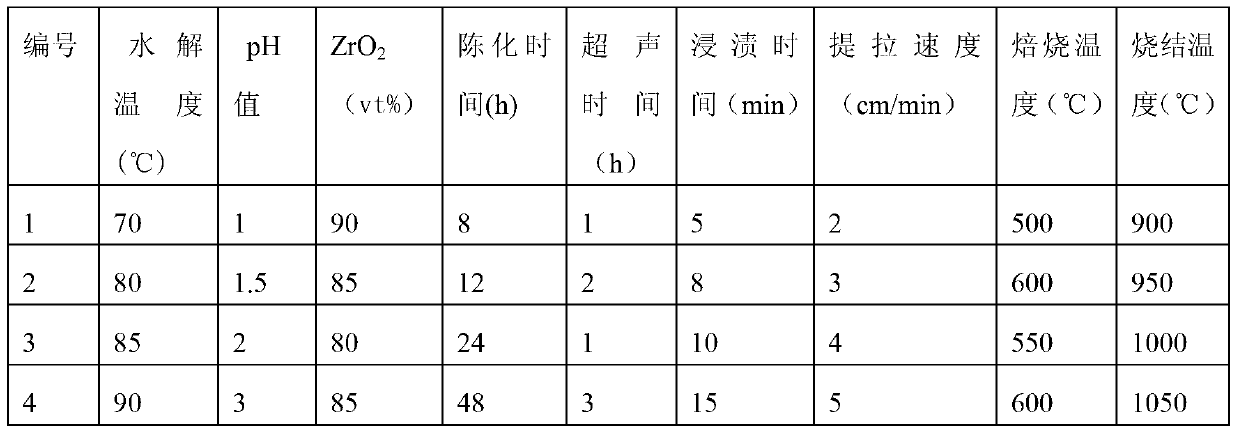

Examples

Embodiment Construction

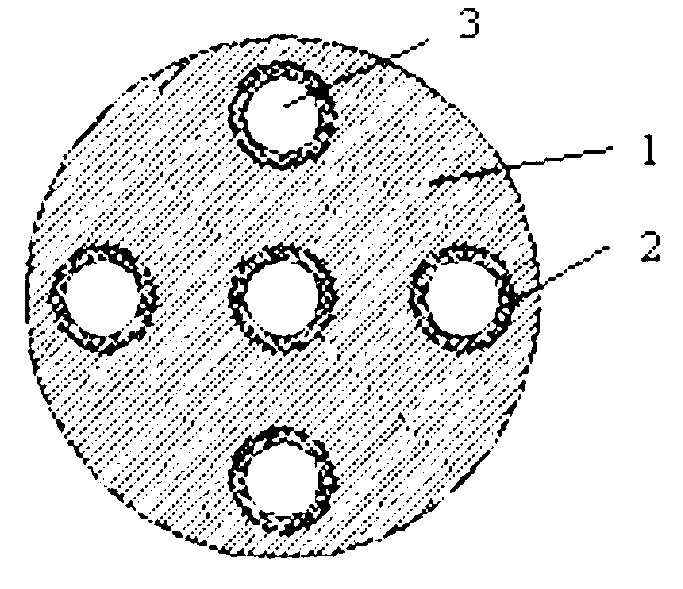

[0024] see figure 1 , the invention's high-strength, nanocomposite Al 2 o 3 Ceramic filter elements (filter tubes) including micron-sized spherical alumina (Al 2 o 3 ) powder extrusion molding and sintering containing macroscopic straight pores porous matrix 1, the nanocomposite phase of macroscopic straight pores (Al 2 o 3 —ZrO 2 ) Coat 2. The filter element (filter tube) should be in direct contact with the filtrate, so the entire filter element is required to have the characteristics of high temperature resistance, corrosion resistance, thermal shock resistance, and good air permeability.

[0025] Micron Al 2 o 3 The sintered porous material of the matrix has a relatively large pore size and good air permeability, and is used as a supporting material. In order to improve the filtration accuracy, a nano-scale composite ceramic coating is attached to the wall of the straight hole to perform high-precision filtration, so that the filtration accuracy can reach the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com