Nonwoven fabric and production process and application thereof

A production process and technology of non-woven fabrics, applied in textiles and papermaking, non-woven fabrics, biochemical fiber treatment, etc., can solve the problems of poor antibacterial performance of non-woven fabrics, unguaranteed filtration accuracy, and reduced service life, so as to achieve guaranteed use Long service life, good filtration accuracy, and the effect of improving the regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

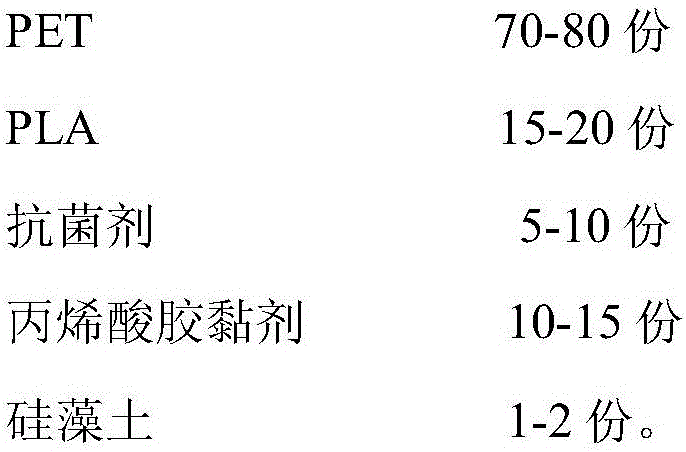

[0043] A non-woven fabric, including the following weight substances: (kg)

[0044]

[0045]

[0046] The preparation method of nano-silver chitosan antibacterial agent comprises the steps:

[0047] SP1, adding the silver nitrate solution with a concentration of 0.003mol / L into the dialdehyde chitosan oxidation degree is 40% aqueous solution, the molar ratio of silver nitrate and dialdehyde chitosan is 1: 2, to obtain the reaction solution;

[0048] SP2, using nitric acid to adjust the pH value of the reaction solution to 2.1;

[0049] SP3, making the reaction solution react at a constant temperature at 52°C for 8 hours, the reaction is completed, and a semi-finished product solution is obtained;

[0050] SP4, heating the semi-finished product solution obtained after the reaction to 90 degrees centigrade and distilling for 30 minutes to obtain the nano-silver chitosan antibacterial agent.

[0051] The production process of this non-woven fabric comprises the following ...

Embodiment 2

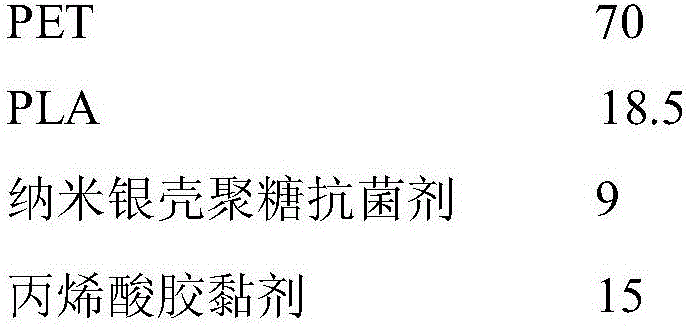

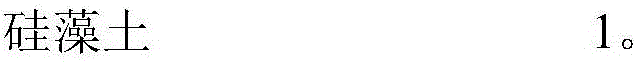

[0056] A non-woven fabric, including the following weight substances: (kg)

[0057]

[0058] The preparation method of nano-silver chitosan antibacterial agent comprises the steps:

[0059] SP1, adding a silver nitrate solution with a concentration of 0.001mol / L to the 35% aqueous solution of dialdehyde chitosan, the molar ratio of silver nitrate to dialdehyde chitosan is 1: 2.8, to obtain a reaction solution;

[0060] SP2, using nitric acid to adjust the pH value of the reaction solution to 2;

[0061] SP3, making the reaction solution react at a constant temperature of 60°C for 8 hours, the reaction is completed, and a semi-finished product solution is obtained;

[0062] SP4, heating the semi-finished product solution obtained after the reaction to 90 degrees centigrade and distilling for 30 minutes to obtain the nano-silver chitosan antibacterial agent.

[0063] The production process of this non-woven fabric comprises the following steps:

[0064] Step 1, performing op...

Embodiment 3

[0068] Embodiment three: a kind of non-woven fabric, comprises following weight material: (kg)

[0069]

[0070] The preparation method of nano-silver chitosan antibacterial agent comprises the steps:

[0071] SP1, the silver nitrate solution that concentration is 0.01mol / L is added in dialdehyde chitosan oxidation degree is 39% aqueous solution, the molar ratio of silver nitrate and dialdehyde chitosan is 1: 2.6, obtains reaction solution;

[0072] SP2, using nitric acid to adjust the pH value of the reaction solution to 2.7;

[0073] SP3, making the reaction solution react at a constant temperature of 55°C for 8 hours, the reaction is completed, and a semi-finished product solution is obtained;

[0074] SP4, heating the semi-finished product solution obtained after the reaction to 90 degrees centigrade and distilling for 30 minutes to obtain the nano-silver chitosan antibacterial agent.

[0075] The production process of this non-woven fabric comprises the following ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com