Syrup clarification method using combination of active carbon and carbonic acid method

A technology of activated carbon and carbonic acid method, applied in the direction of purification, application, and sucrose production using physical methods, can solve the problems of single syrup clarification method, poor decolorization and clarification effect, and easy addition of activated carbon, achieving good clarification effect and reducing equipment investment. High cost and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

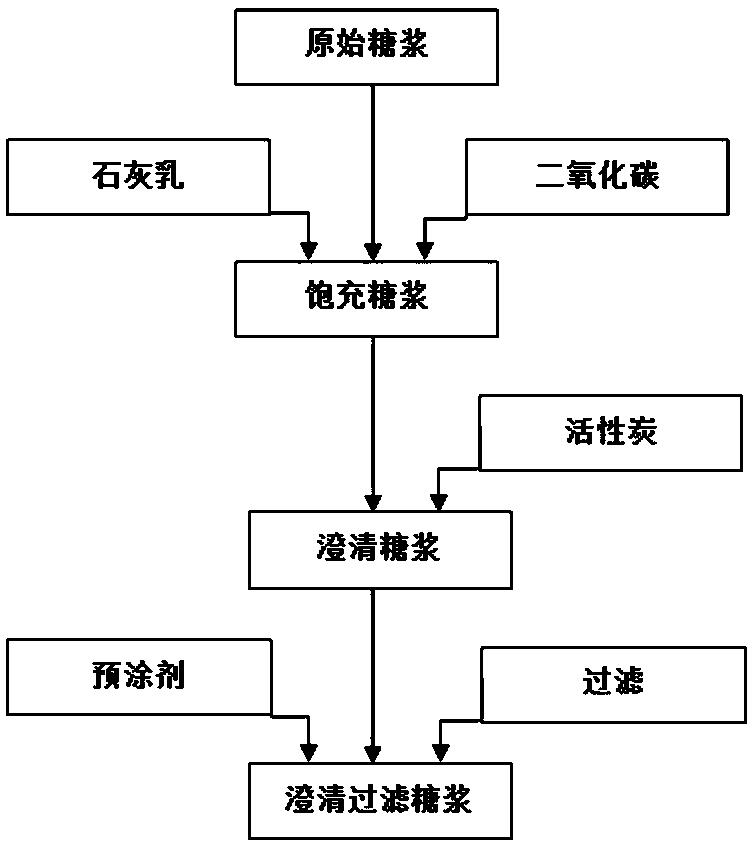

[0020] Embodiment 1: The syrup clarification method that this active carbon and carbonic acid method are combined use is carried out according to the following method: the first step, adopts carbonic acid method to add milk of lime and carbon dioxide to the original syrup and carry out filling, obtain full filling syrup; , adding 0.3‰ to 5‰ activated carbon to the saturated syrup for clarification reaction to obtain clarified syrup; in the third step, the clarified syrup is filtered to obtain clarified filtered syrup.

[0021] In the present invention, milk of lime is existing known calcium hydroxide, and calcium hydroxide reacts with carbon dioxide to generate calcium carbonate.

[0022] In the present invention, powdered activated carbon is added to the saturated syrup filled by the carbonation method, and the combination of activated carbon and carbonation method two clarification technologies can not only realize protein, colloid, organic acid, melanoidin, caramel pigment, ...

Embodiment 2

[0023] Example 2: As an optimization of the above example, 0.3‰ to 3‰ of activated carbon was added to the saturated syrup for clarification reaction.

Embodiment 3

[0024] Example 3: As an optimization of the above examples, the particle size of activated carbon is 0.5 μm to 200 μm, and the specific surface area is 1000 m 2 / g to 2000 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com