Manufacturing equipment of polyester spunbonded non-woven fabric with high filtering precision and method of equipment

A technology of filtration precision and non-woven fabrics, which is applied in the direction of non-woven fabrics, textiles, and papermaking. It can solve the problems of no product, low single-fiber filtration efficiency, and inability to produce polyester melt-blown non-woven fabrics, so as to improve filtration efficiency. , the effect of good filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

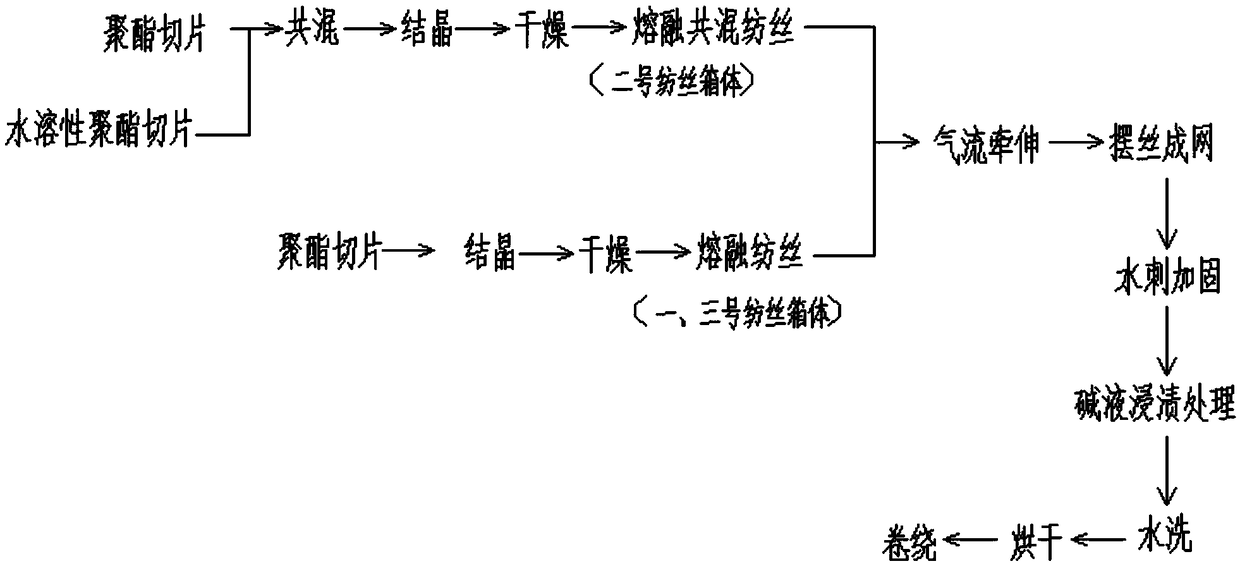

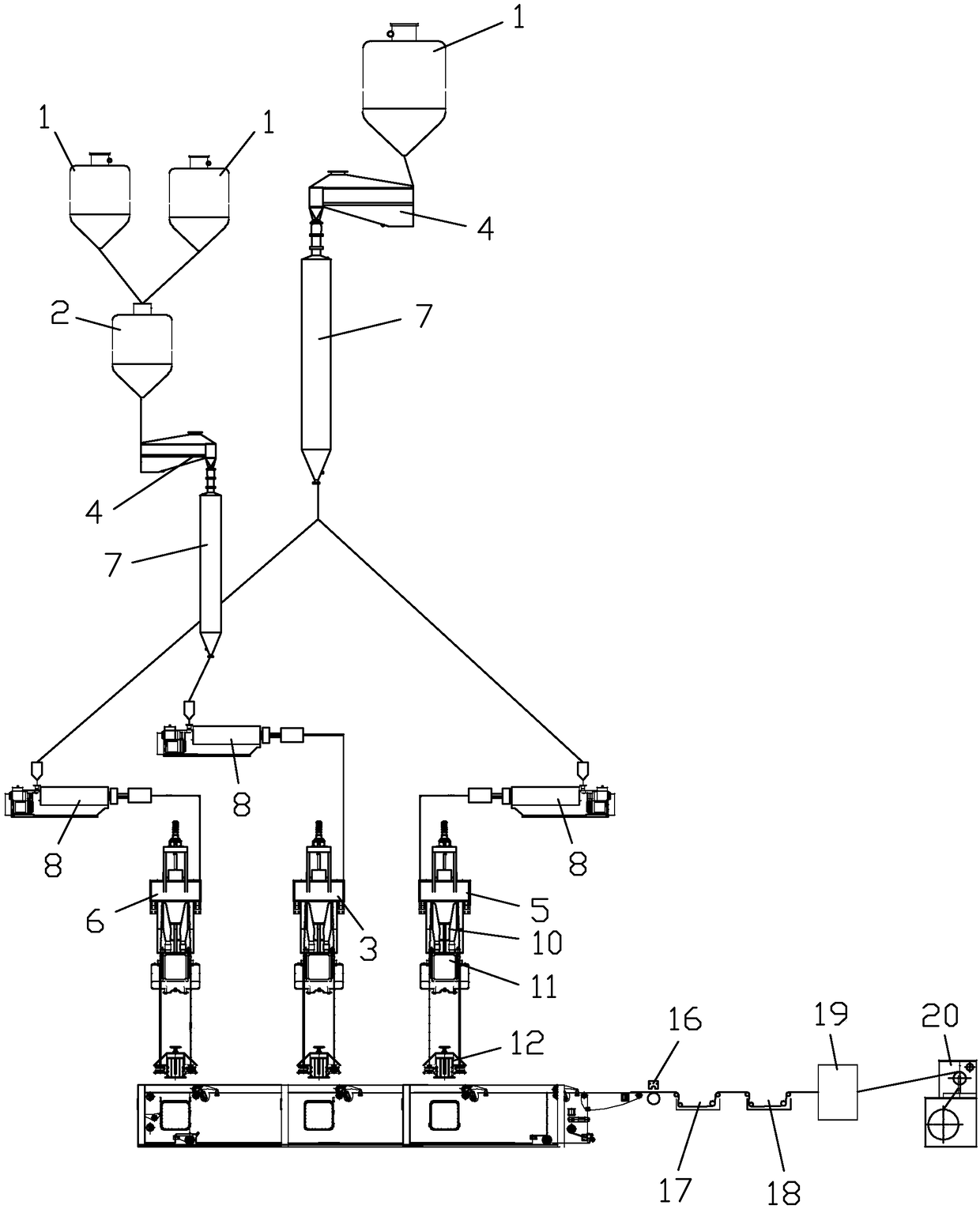

[0044] like figure 1 and figure 2 As shown, the polyester chips and water-soluble polyester chips are put into their respective barrels, and after the impurities are screened out by the vibrating screen, the pulsed airflow generated by the Roots blower is transported to the respective large bins 1 on the roof, where Part of the polyester chips and water-soluble polyester chips are conveyed into the mixing tank 2 through the rotary valve, stirred and mixed evenly by the agitator, and then conveyed through the rotary valve, and then fall into the corresponding crystallizer of the second spinning box 3 4 miles. The mixing ratio of polyester chips and water-soluble p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com