Butterfly high-efficiency self-adaptive plastic-fiber mixed filter material filter

A filter body and filter material technology, which is applied to a butterfly-type high-efficiency self-adjusting plastic fiber mixed filter material filter body. It can solve the problems of filtration efficiency, pollution interception rate, and cleaning rate reduction, and achieve the effect of good filtration cycle, increased surface free energy, and small loss of filter material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

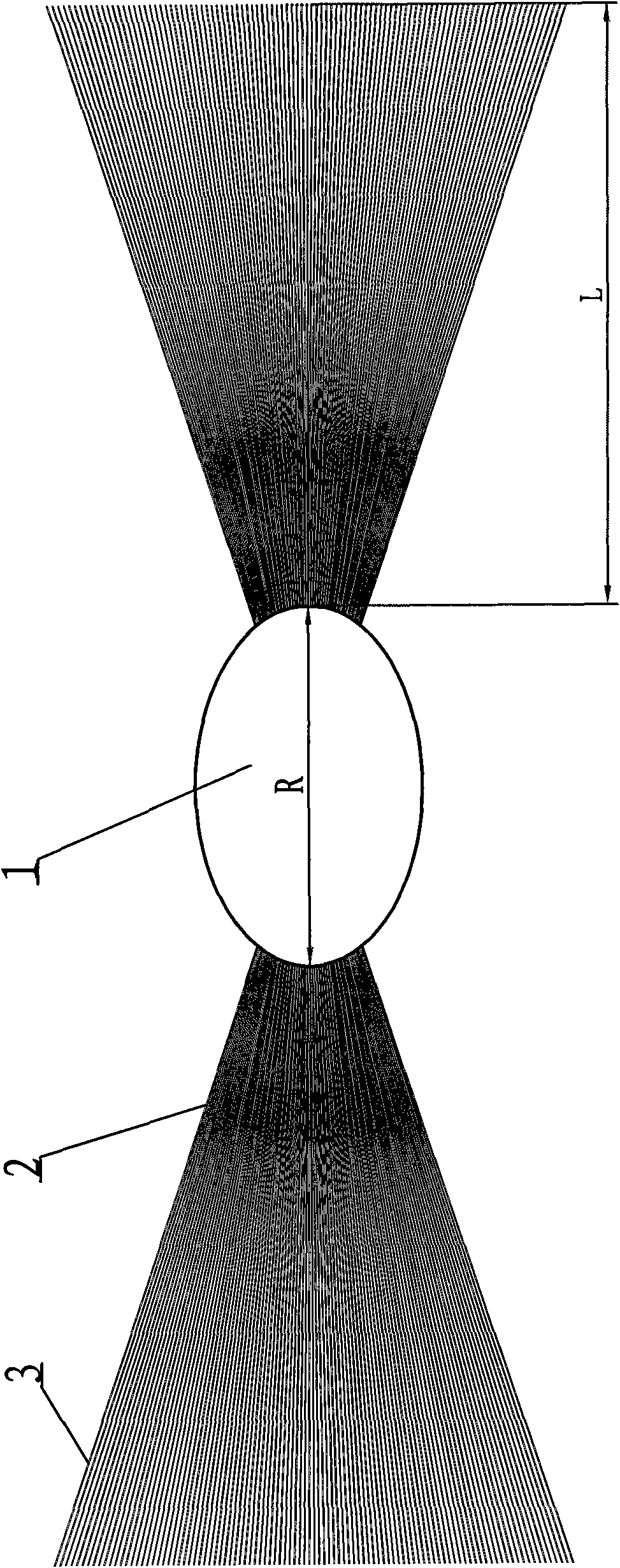

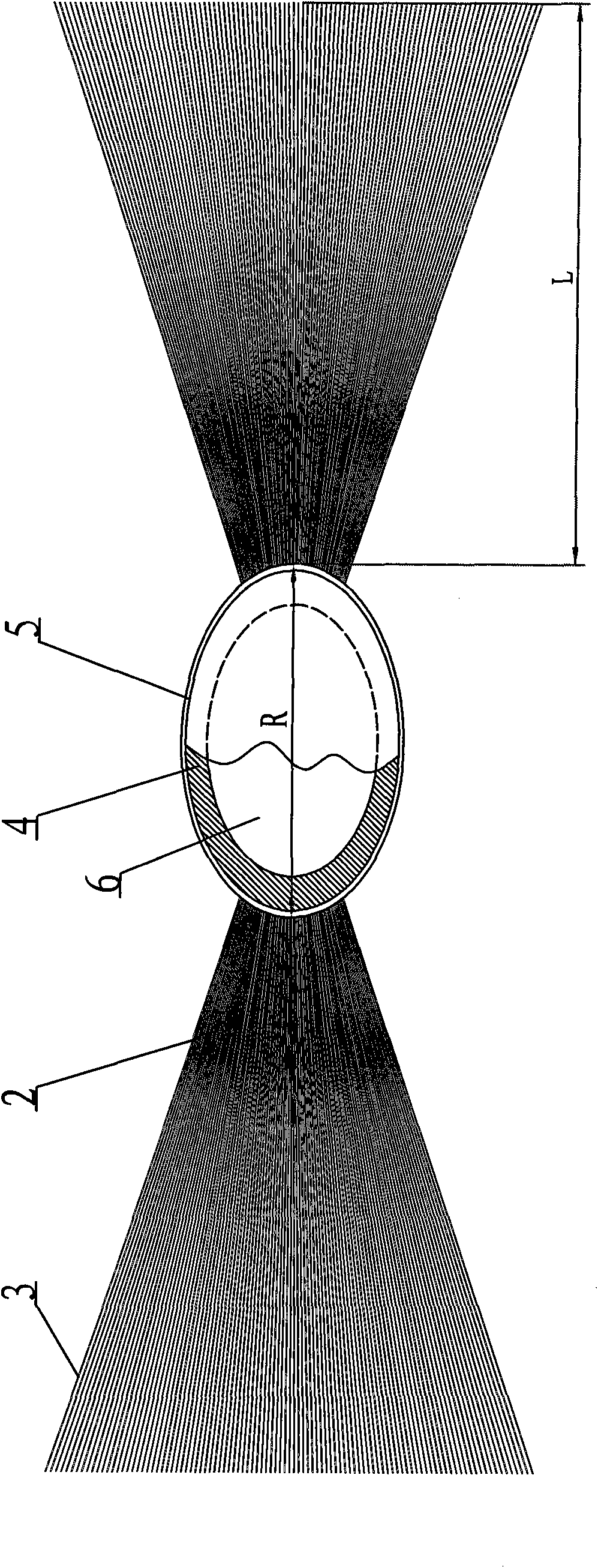

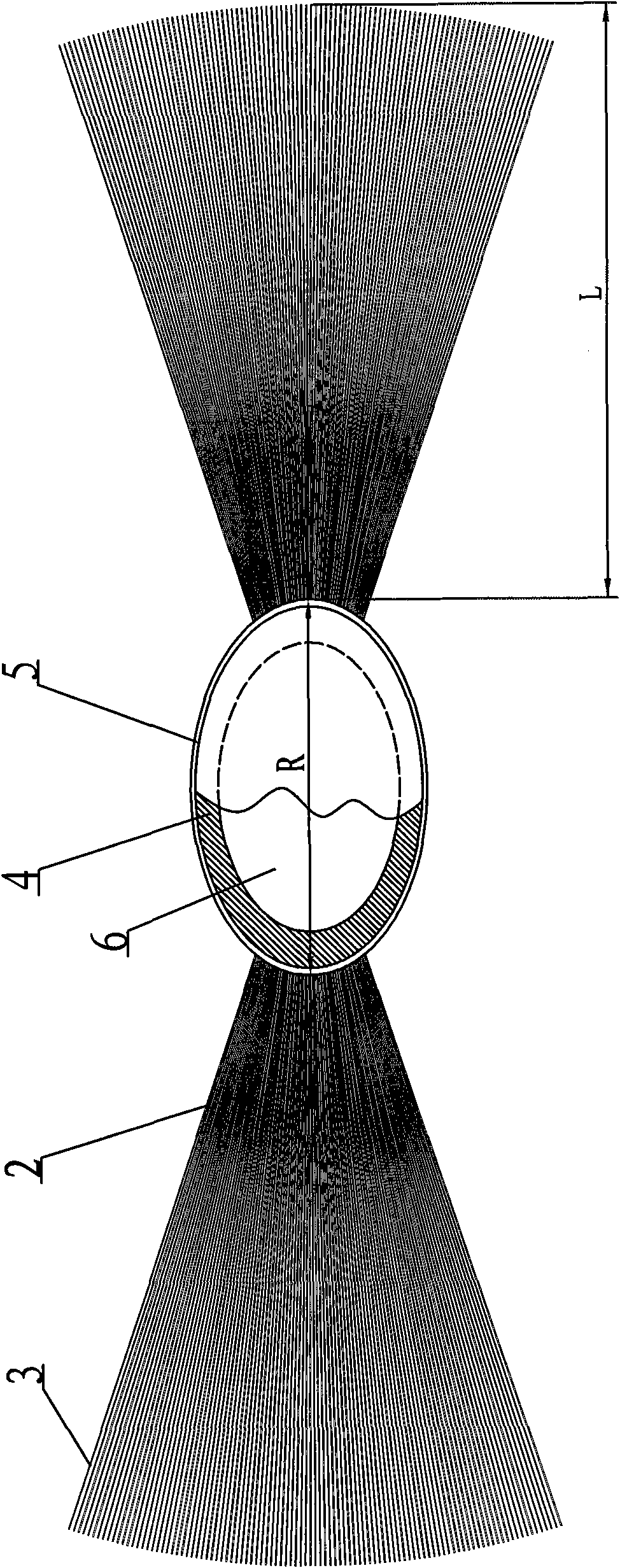

[0039] A butterfly-shaped high-efficiency self-adjusting plastic fiber mixed filter material filter body, such as Figure 1 to Figure 4 As shown, it is composed of filter material monomers. Each filter material monomer is composed of a counterweight core and a pair of corrosion-resistant balanced filter wings 2. The surface of the counterweight core is plastic and ellipsoidal. Density ρ O The threshold range is 1.30g / cm 3 -1.50g / cm 3 , the two ends of the long axis of the ellipsoidal weight core are respectively provided with balance wing bodies 2, each balance wing body 2 is a fiber bundle composed of artificial fiber filaments 3, and the inner end of the artificial fiber filament 3 forming each fiber bundle It is fixed at each end of the long axis of the counterweight core, and the other end is in a diffuse state, forming a tentacle shape.

[0040] The threshold range of the sum (R+2L) of the length R of the major axis of the ellipsoidal weight core 1 and the length L of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

| Major axis length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com