Asymmetric fiber filter

A fiber filter, asymmetrical technology, applied in gravity filter, loose filter material filter, filter separation, etc., can solve the problems of high cost of use of filter devices, reduced ability of filter material to intercept dirt, and inability to clean thoroughly , to achieve the effect of easy backwashing, fast filtration speed and COD reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

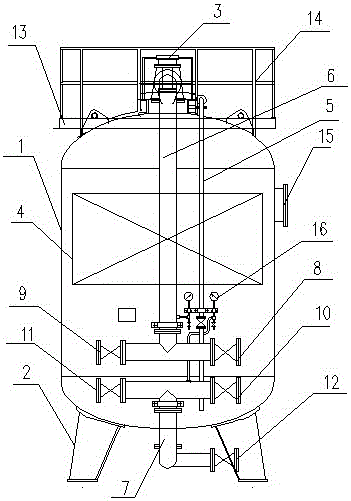

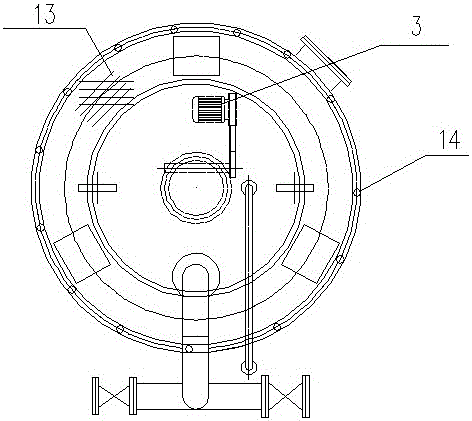

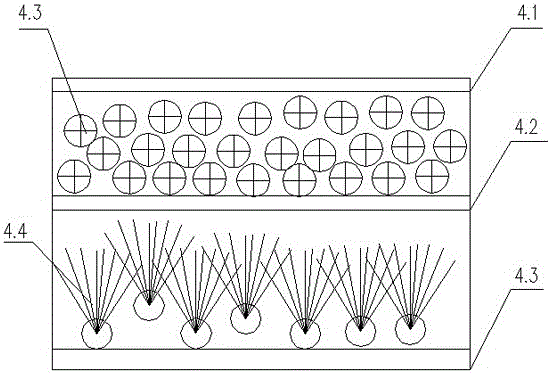

[0016] An asymmetric fiber filter mainly includes a tank body 1, a support 2, a motor 3, a filter unit 4, an exhaust pipe 5, a water inlet pipe 6 and a water outlet pipe 7, the tank body 1 is cylindrical, and the tank body The body 1 is fixed on the support 2, the top of the tank body 1 is a motor 3, the exhaust pipe 5 is fixed on the side wall of the tank body 1, the water inlet pipe 6 goes deep into the tank body 1, and is connected with the water inlet valve 9 and the reverse valve respectively. The flushing drain valve 8 is connected, the outlet pipe 7 is located at the bottom of the tank body 1, and is respectively connected with the outlet valve 10, the backwash inlet valve 11 and the vent port 12, and the filter unit 4 is composed of a filler, a first partition 4.1, The second partition 4.2 and the third partition 4.3 are composed, the filler is an asymmetric fiber filament 4.5 and a fiber ball 4.4, and the asymmetric fiber filament 4.5 is a fiber whose one end remains l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com