Patents

Literature

68results about How to "Backwashing is easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of concave convex stick ceramic grain filter

InactiveCN100423808CGood film-hanging performanceImprove stabilityFiltration separationClaywaresRough surfaceWater quality

The invention discloses a produce method for concavo-convex bar ceramsite filtering material. Wherein, the said filter material comprises concavo-convex bar clay, coal gangue and volcanic ash, and is produced by burdening, milling, granulating, baking, screening and packaging. The filter material has rough surface, well bonding film property, small flow resistance, and well stability and adsorption properties. This invention needs low cost and baking temperature, can save much energy, has no secondary pollution and fit to water purification treatment.

Owner:许盛英

Production method of concave convex stick ceramic grain filter

InactiveCN1762540ASave fuelReduce waste of resourcesFiltration separationClaywaresVolcanic ashCoal gangue

The invention discloses a produce method for concavo-convex bar ceramsite filtering material. Wherein, the said filter material comprises concavo-convex bar clay, coal gangue and volcanic ash, and is produced by burdening, milling, granulating, baking, screening and packaging. The filter material has rough surface, well bonding film property, small flow resistance, and well stability and adsorption properties. This invention needs low cost and baking temperature, can save much energy, has no secondary pollution and fit to water purification treatment.

Owner:许盛英

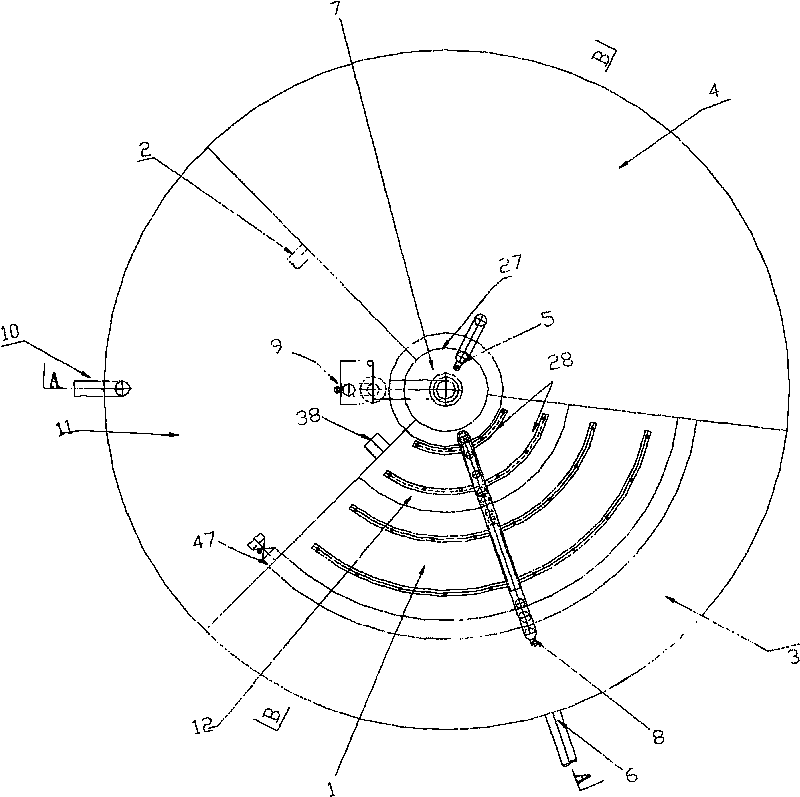

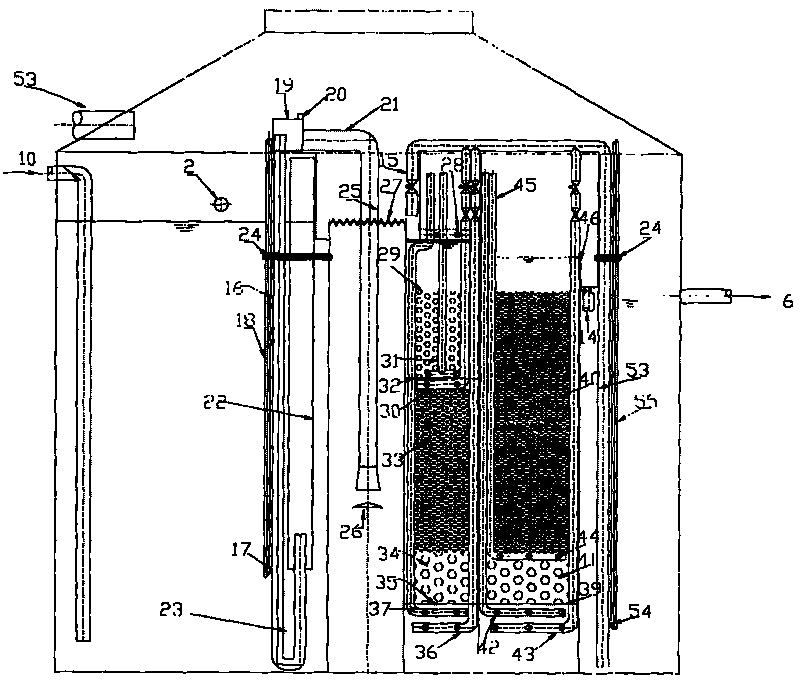

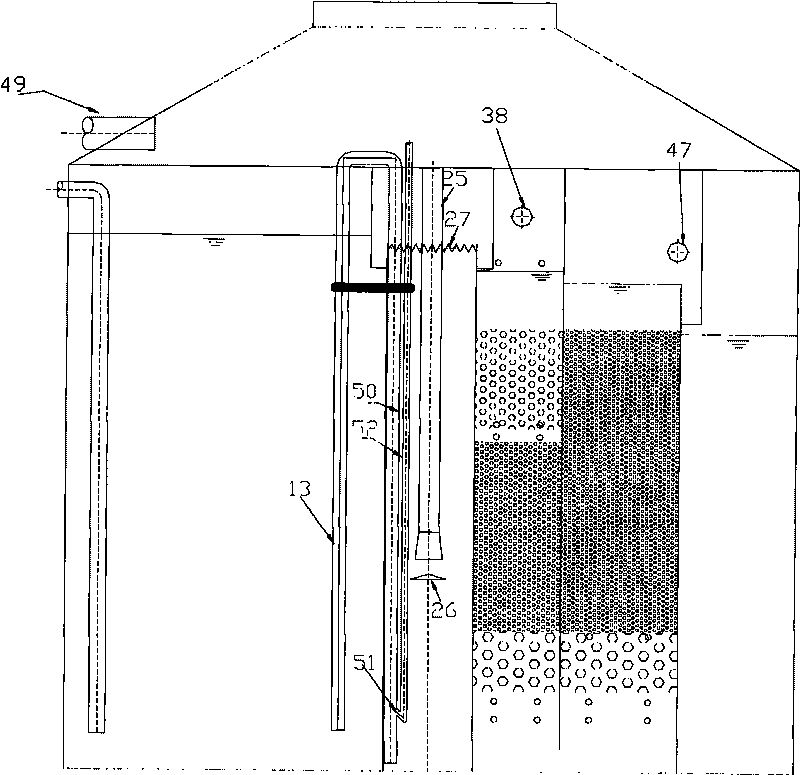

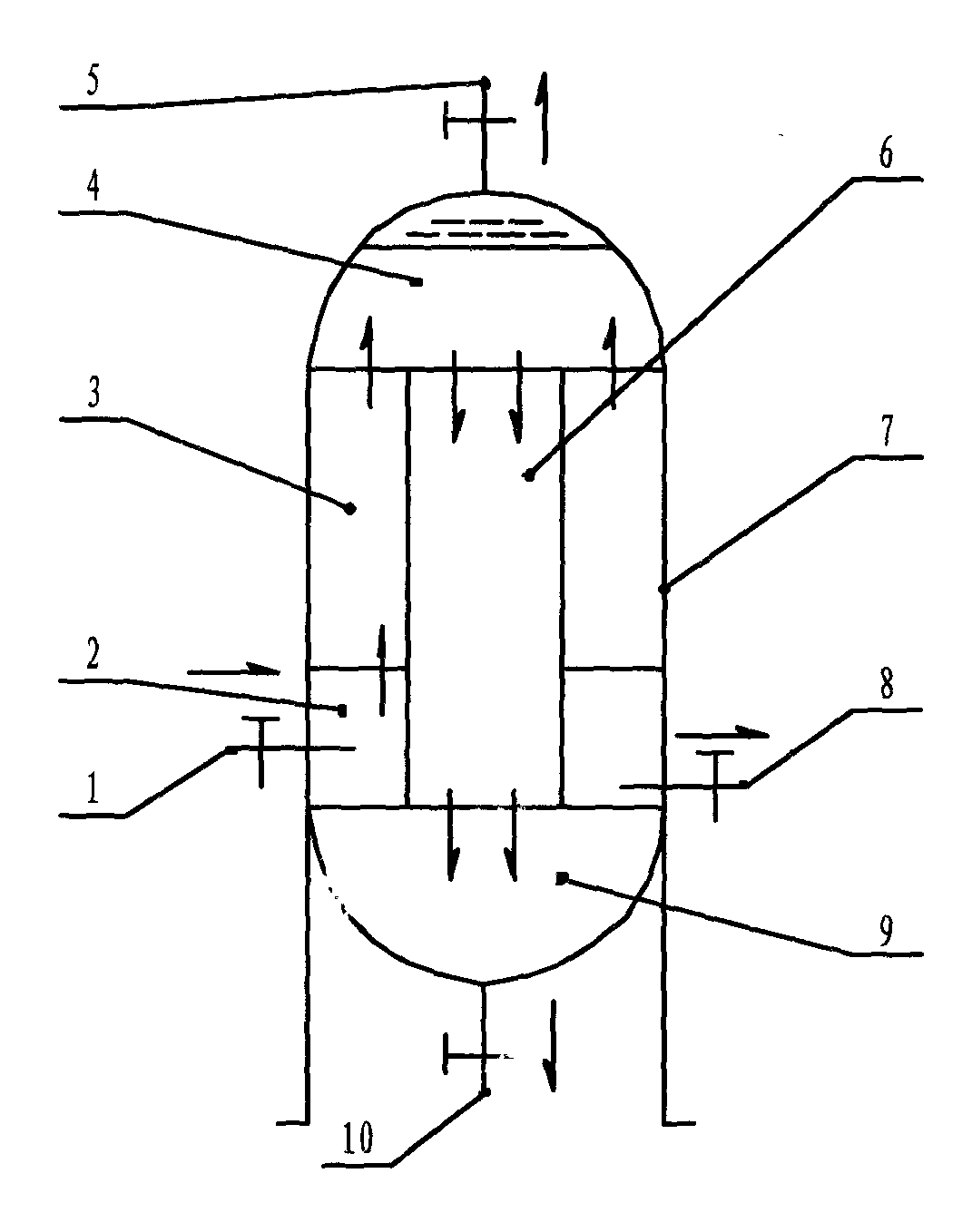

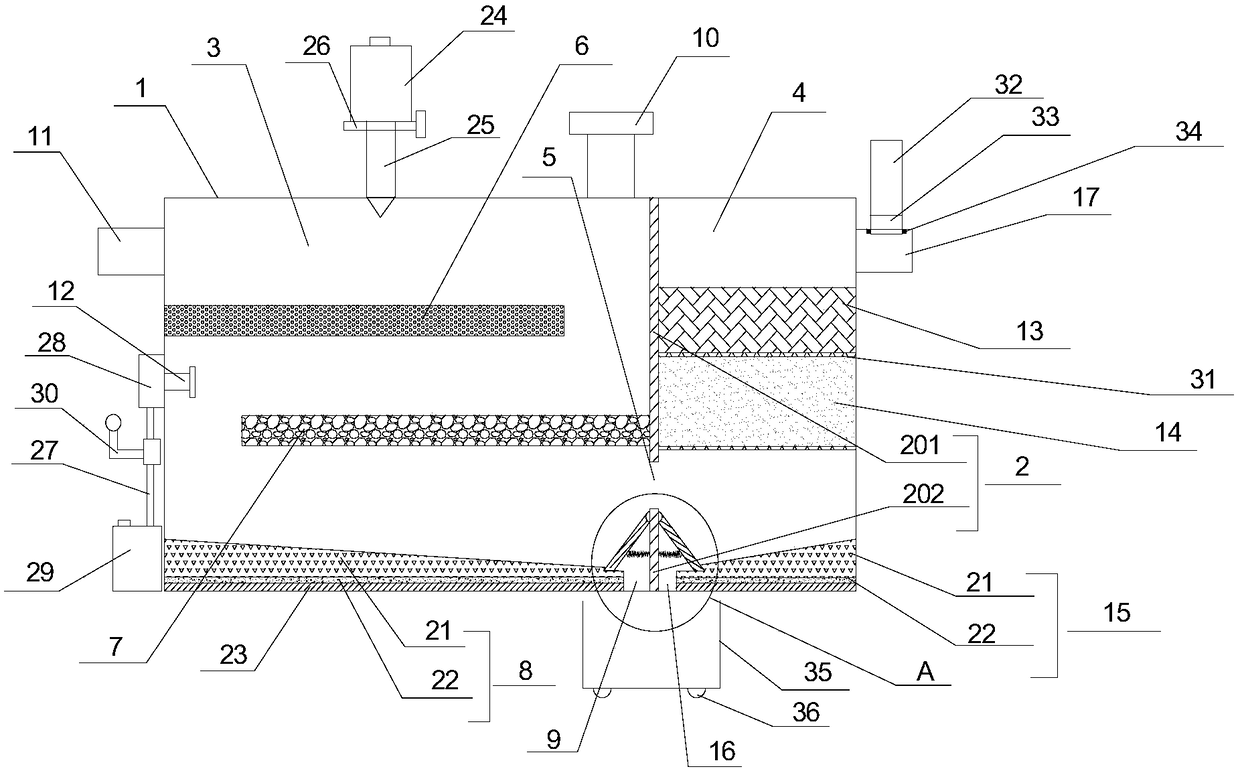

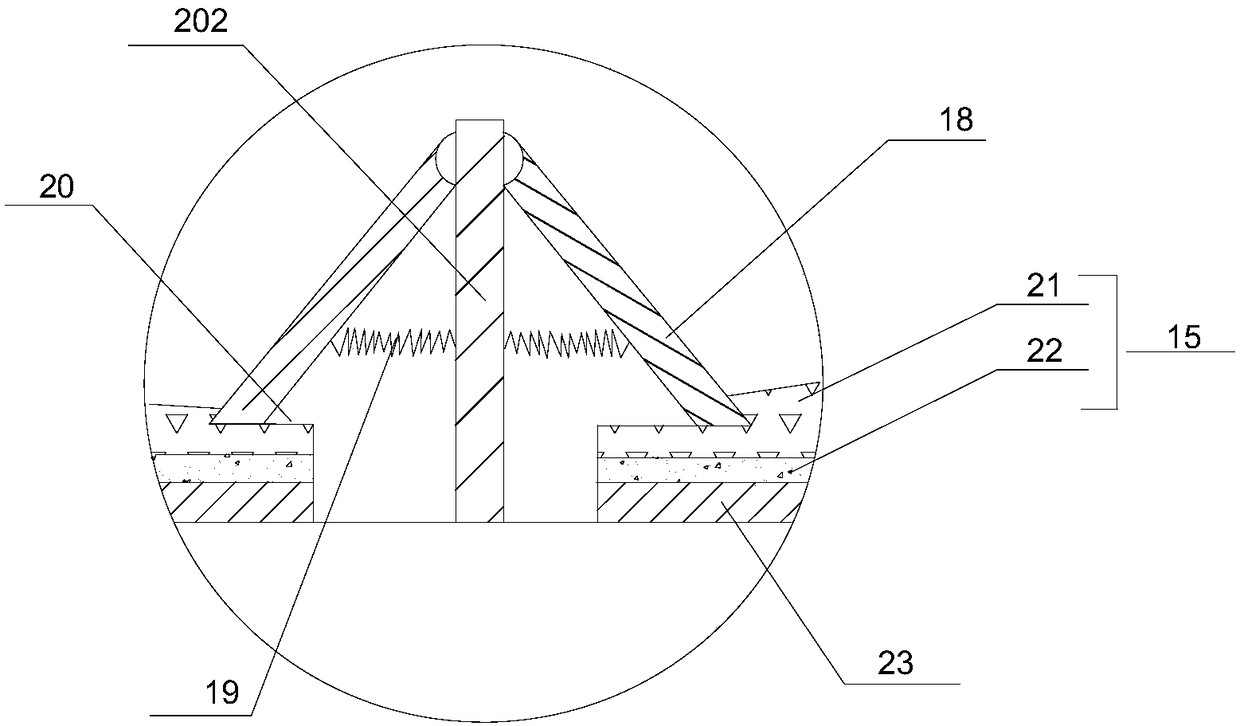

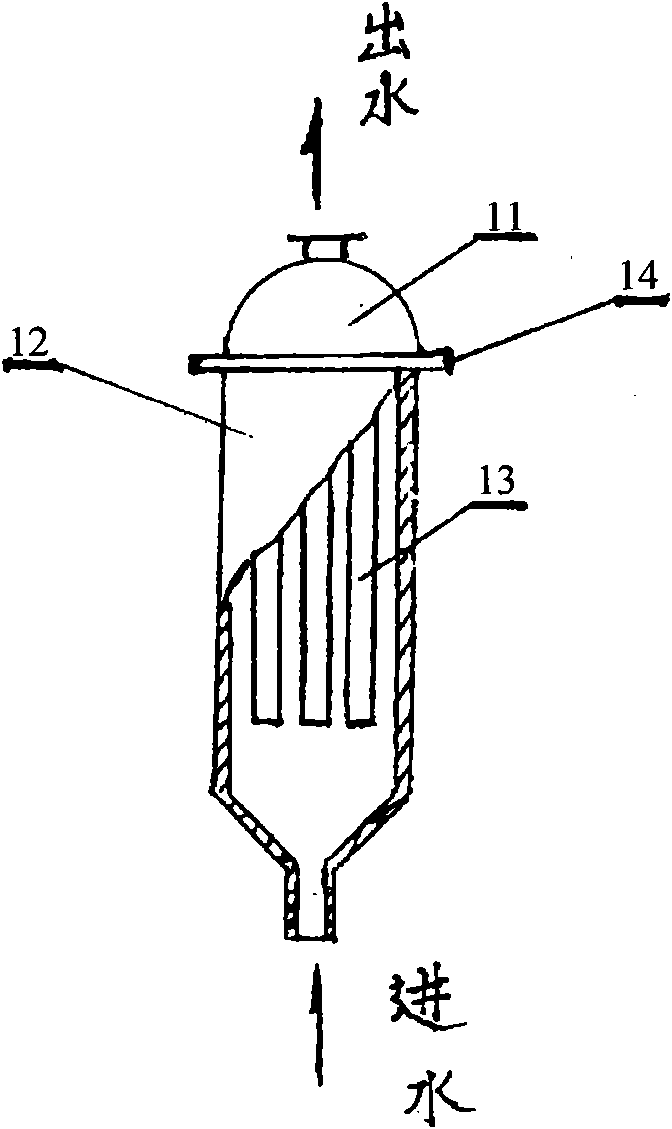

Integrated A/O bacteria filter device for treating dispersed wastewater

ActiveCN101723560ARealize integrationCompact structureTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeWastewater

The invention relates to an integrated A / O bacteria filter device for treating dispersed wastewater, which has a cylindrical structure in shape. The center of the integrated A / O bacteria filter device is provided with a cylindrical erect flow primary settling tank, a baffle wall is arranged between an inner cylinder body and an outer cylinder body, and a space is divided into an adjusting tank, a hypoxia bacteria filter, an aerobe filter, a clear water tank and a mud storage tank. The aerobe filter and the clear water tank are in a concentric circle arc structure. Wastewater in the adjusting tank is lifted into the primary settling tank through an air lifter, the settled wastewater and recycled nitrification liquor are together distributed into the hypoxia bacteria filter for denitrification, the bottom and the middle part of the hypoxia bacteria filter are provided with backwashing pipelines which can realize subsection washing; the hypoxia bacteria filter is communicated with the bottom of the aerobe filter, the denitrified wastewater overflows from the surface into the clear water tank for outputting after organic matters are removed and nitrification is carried out in the aerobe filter. The backwashing wastewater of the device flows into the adjusting tank per se, and mud in the primary settling tank is lifted into the mud storage tank through the air lifter. The invention has the advantages of less investment, little operation cost, longer mud discharge period and convenient management, thereby being suitable for treating the dispersed wastewater in countryside.

Owner:TONGJI UNIV

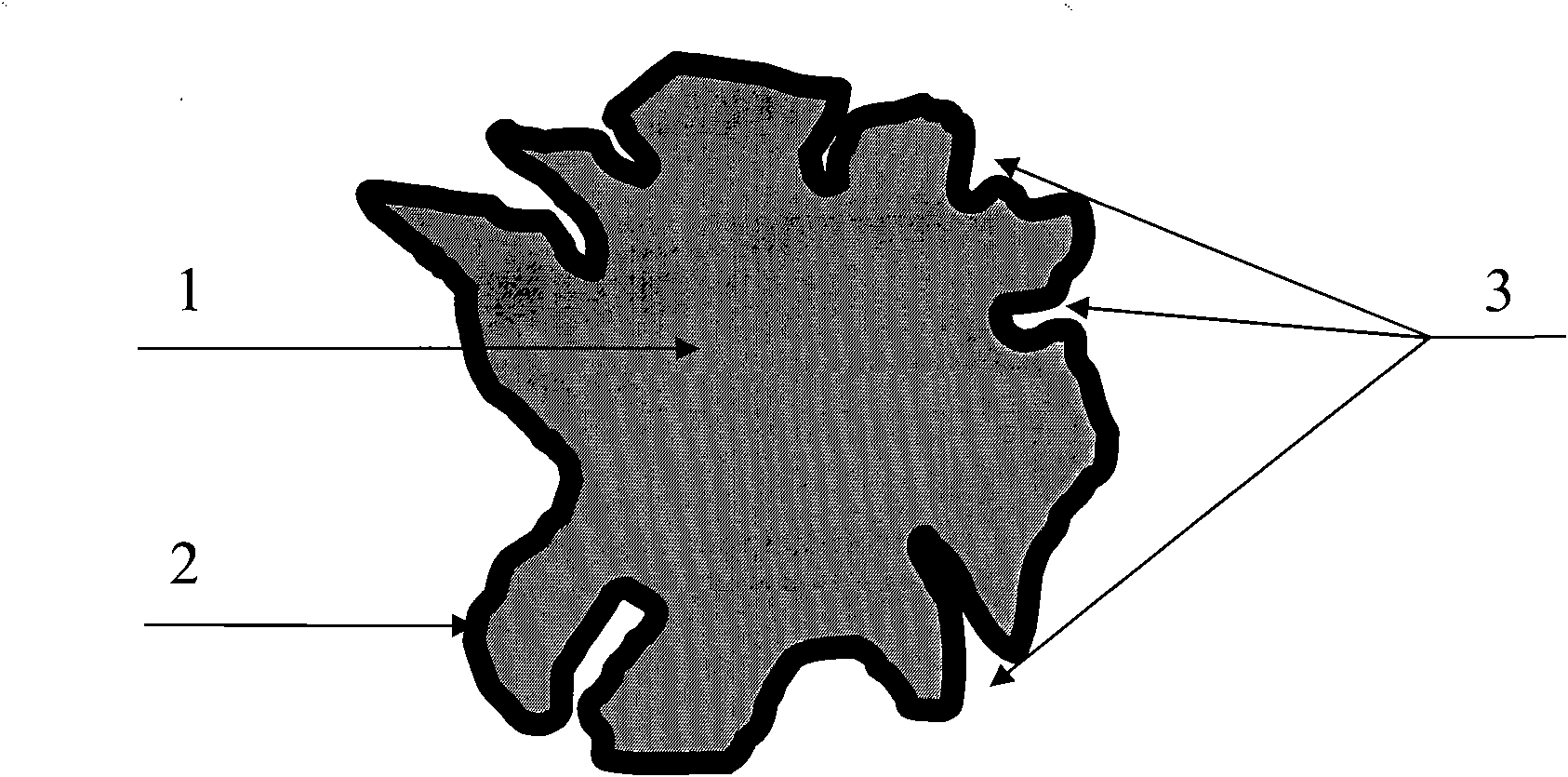

Lightweight highly effective filtering material for biology and its preparation method

InactiveCN1876579AImprove performanceLarge specific surface areaTreatment using aerobic processesSustainable biological treatmentRough surfaceVoid ratio

The invention relates the method of producing filtering material used in bio-aeration filter tank. The lightweight and highly effective biology filtering material comprises 65wt%-80wt% red earth ore, 10wt%-30wt% coal ash and 5wt%-15wt% pore-forming agent. The method comprises the following steps: breaking the 65wt%-80wt% red earth ore, drying at 130Deg.C-170Deg.C; fetching 10wt%-30wt% coal ash; fetching 5wt%-15wt% pore-forming agent, water content being below 3%, mixing them, adding water to form ball, drying, calcining, at 1050Deg.C-1250Deg.C, cooling, breaking, barreling and screening until the grain size being 3-8mm. The invention has the advantages of macroporous structure, rough surface, proper void ratio and large specific surface area. Every property is satisfied for the request of bio-aeration filter tank filtering material.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

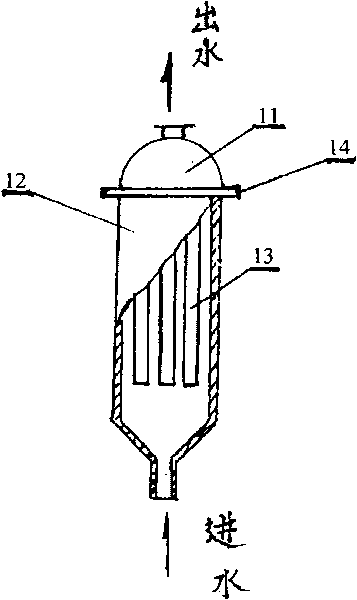

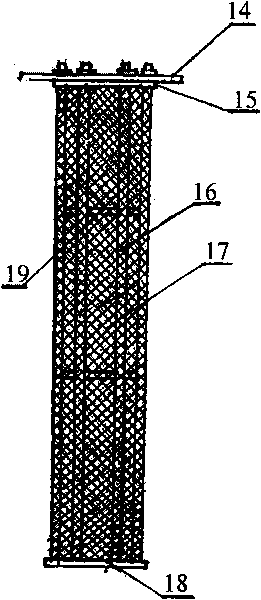

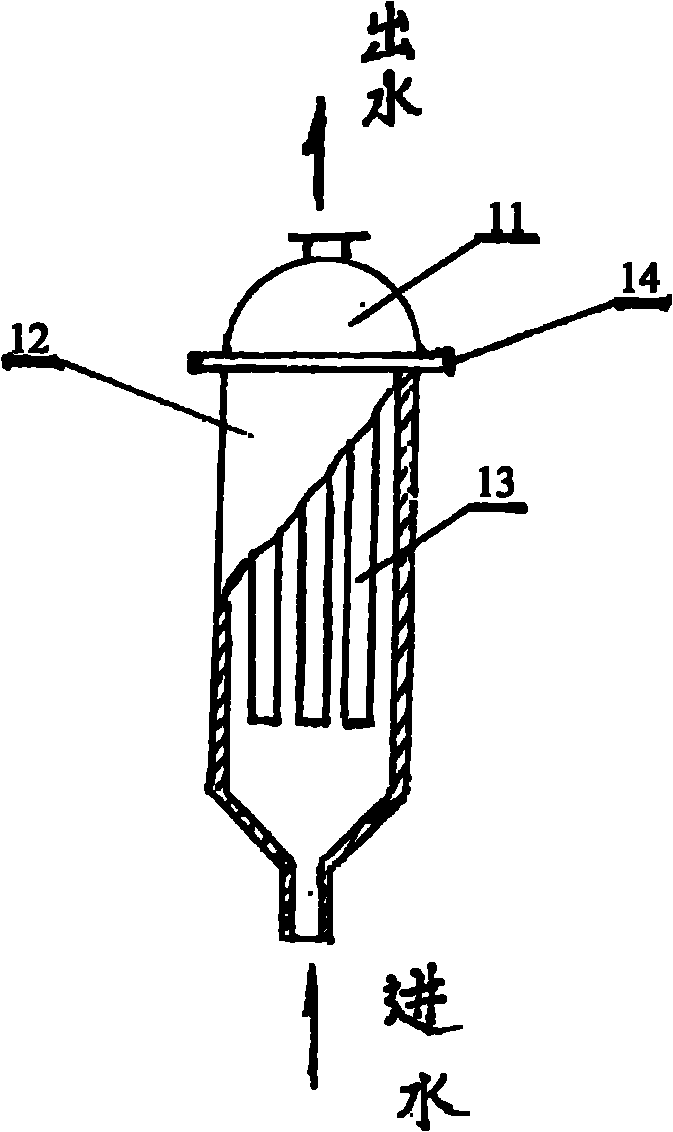

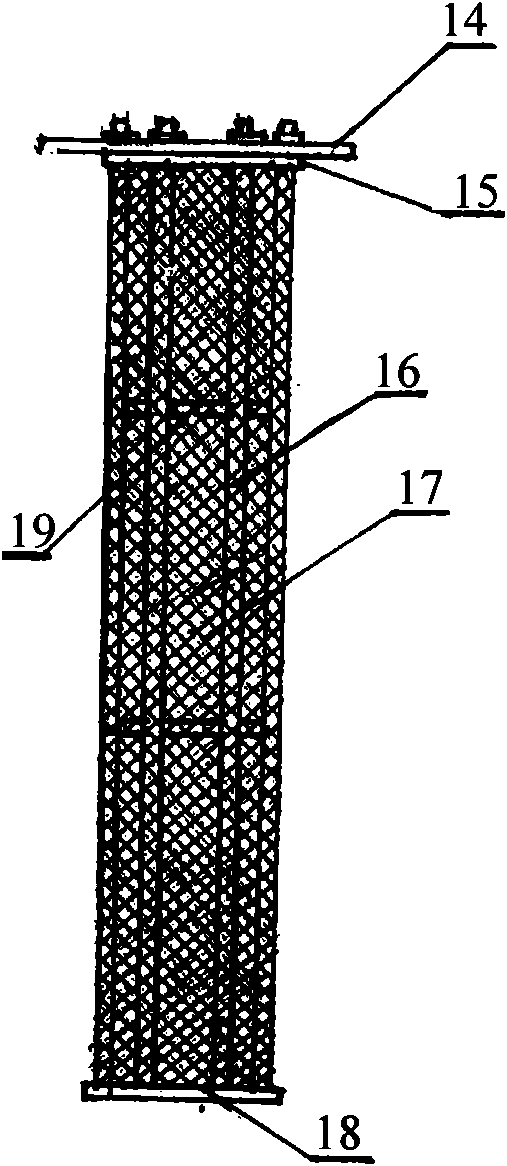

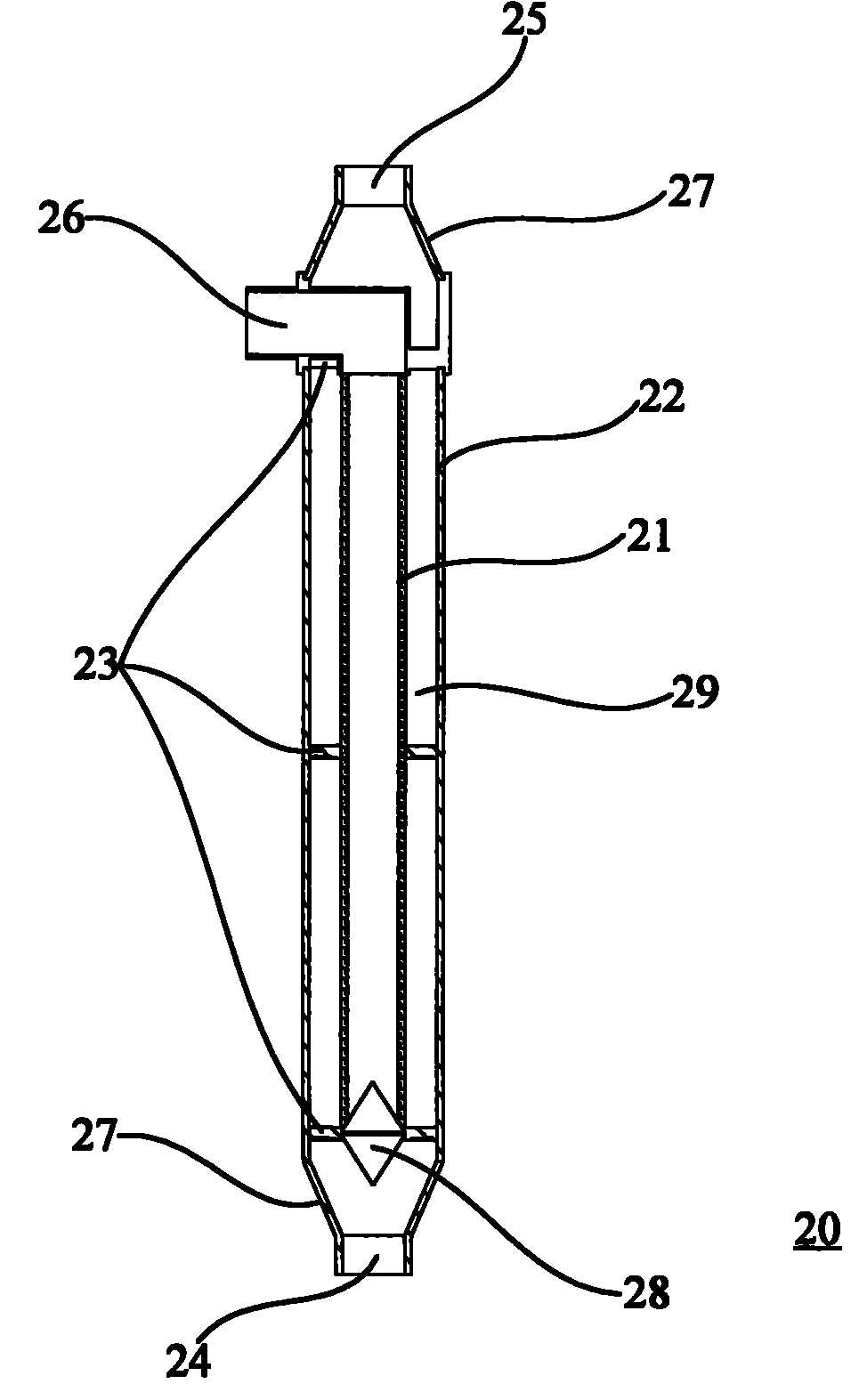

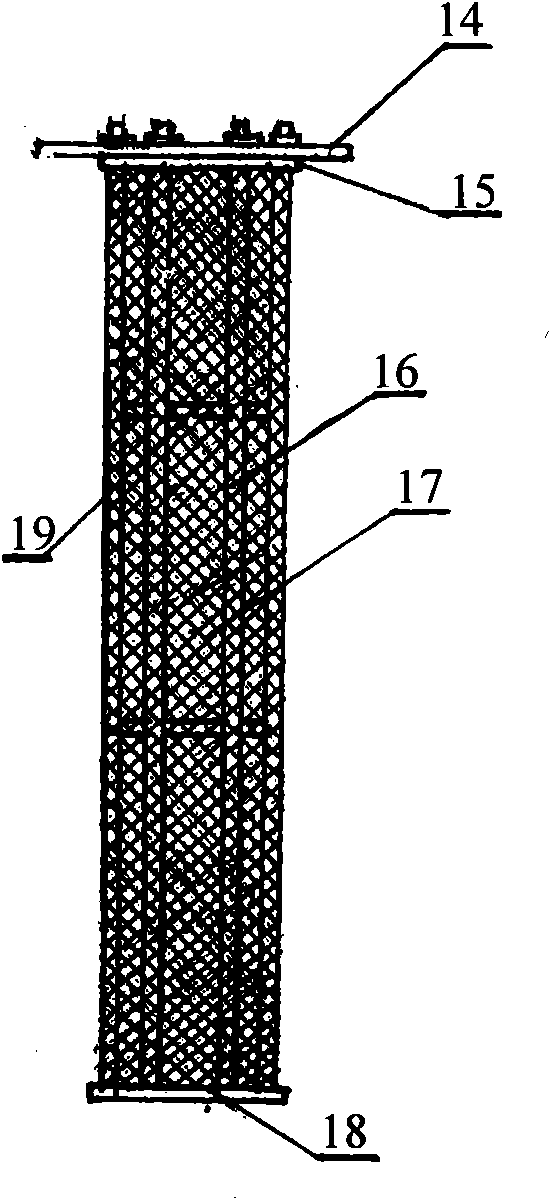

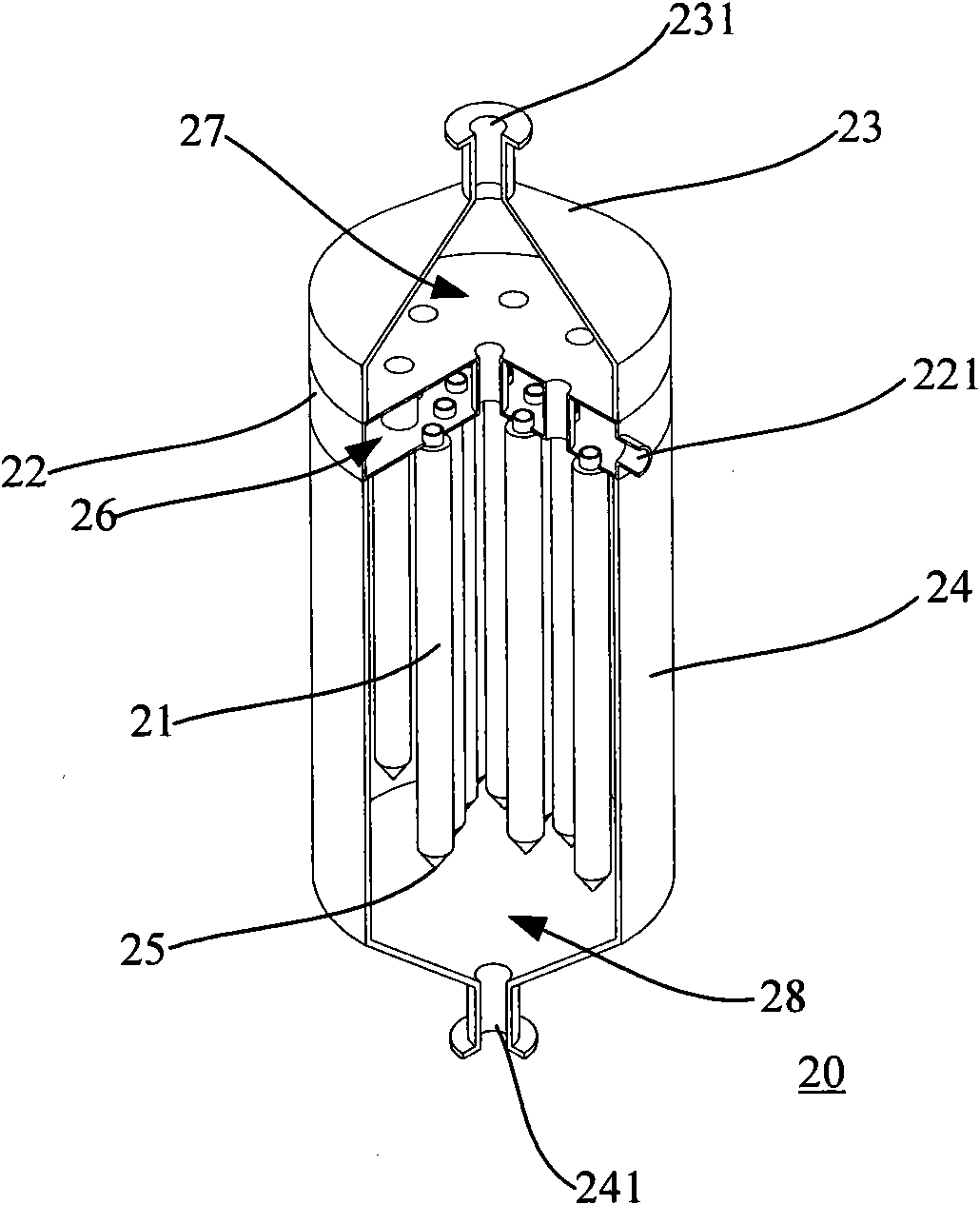

Multi-pipe internal pressure mechanical circulation forced cross current solid-liquid separation dynamic membrane system and device thereof

InactiveCN101757854AIncrease water pressureUniform thicknessSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisVena contracta diameterWork period

The invention relates to a multi-pipe internal pressure mechanical circulation forced cross current solid-liquid separation dynamic membrane system and a device thereof; wherein the dynamic membrane comprises a tubular shape internal pressure supporting body with plural number of large aperture nets, an upper orifice plate and a lower orifice plate, a shell, an upper cover and a lower cover; the upper orifice plate and the lower orifice plate are respectively provided with plural number of jack sockets, the tubular shape internal pressure supporting body is connected with the jack sockets; the shell is connected with the upper orifice plate and the lower orifice plate to form a water purification chamber; the upper cover and the upper orifice plate are connected to form a cross current backflow chamber, and the upper cover is provided with an water outlet for the cross current backflow water; the lower cover and the lower orifice plate are connected to form a water inlet chamber and the lower cover is provided with a raw water inlet thereupon. The dynamic membrane device of the invention has the advantages of no water power dead angle, short pre-coating time, convenient back wash, continuous work, improved dynamic membrane flux, stable water yield and long work period.

Owner:上海臻泓环境科技工程有限公司

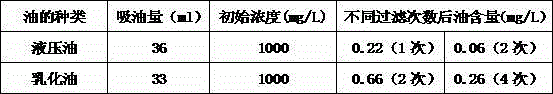

Process for preparing porous functional ceramic material

The invention relates to a process for preparing a porous functional ceramic material. The process comprises the following steps: 1) activating treatment of the porous ceramic material, namely soaking the porous ceramic material into a mixed solution of a dilute acid and hydrogen peroxide, of which the concentration is 0.1-15%, placing for 0.1-2 hours under the condition at 20-90 DEG C, and then drying for 10-120 minutes under the condition at 100-200 DEG C; 2) preparation of mother liquor, namely taking 1-50ml of silane coupling agent to 100ml of absolute ethyl alcohol, and then adding 1-10% of water and 0.1-2ml of acetic acid (HAC), placing for 0.1-3 hours at 20-80 DEG C; and 3) surface modification reaction. The porous functional ceramic material disclosed by the invention is simple in preparation technology, and the raw materials are subjected to modification treatment, so that the original hydrophily of the material is converted into strong hydrophobicity (lipophilicity), the water contact angle exceeds 120 degrees, the material has an ultra-strong adsorbing effect on oil, and has the characteristics of being easy for backwash after the oil is absorbed, and the prepared porous functional ceramic material can be widely applied to fine filtration treatment of an oily wastewater generated in the industries such as petrifaction, smelting and medicines.

Owner:格丰科技材料有限公司

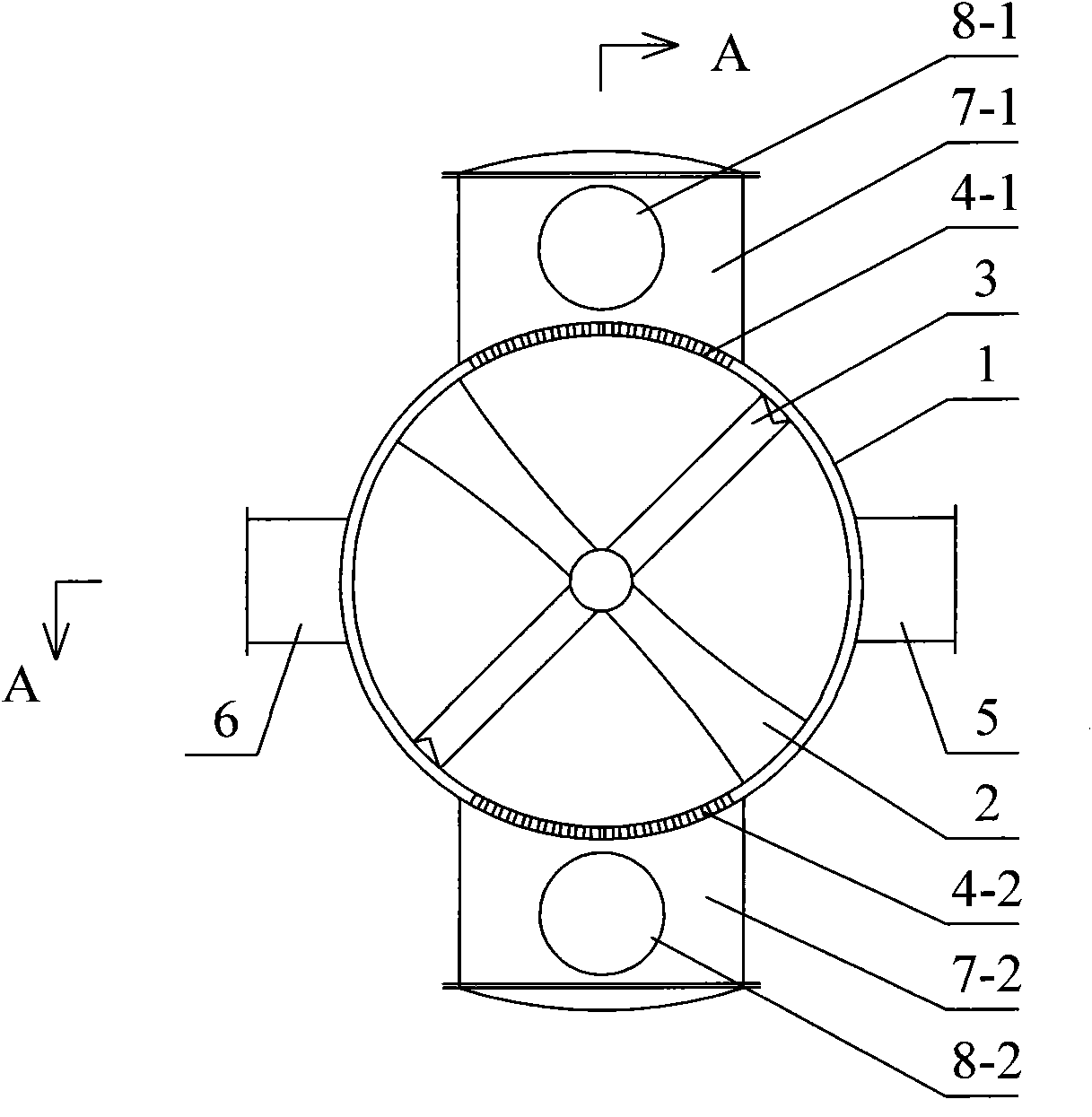

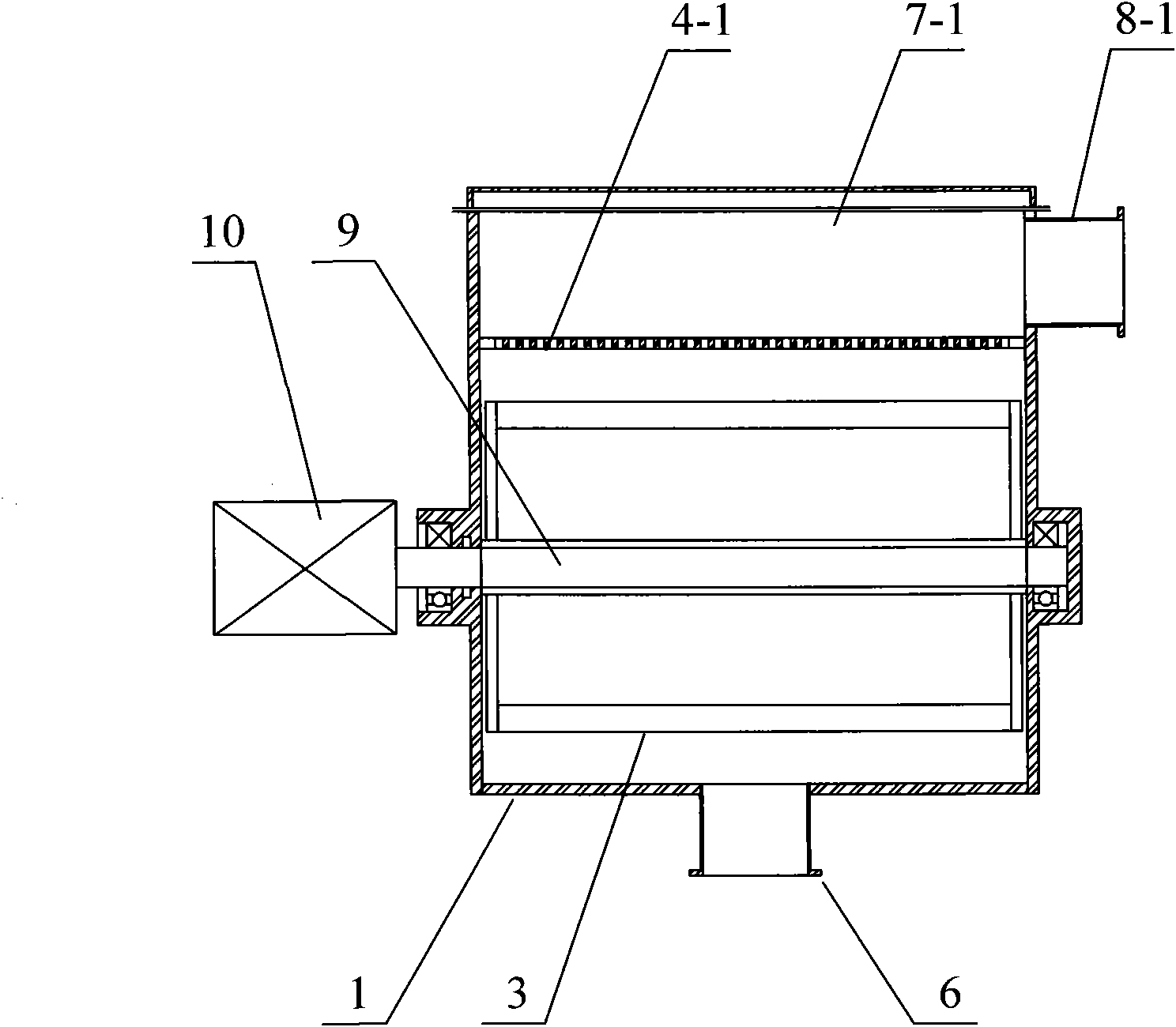

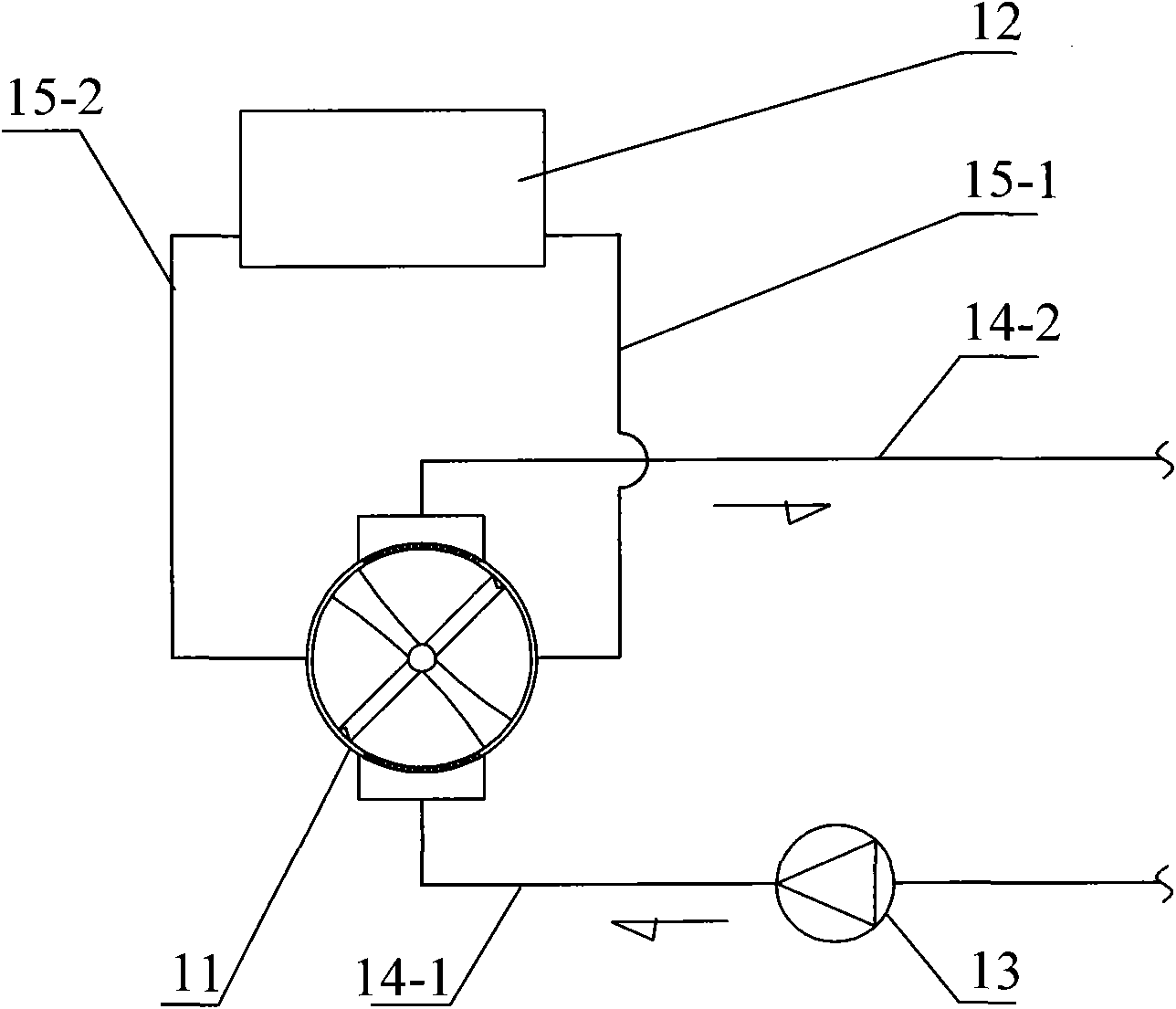

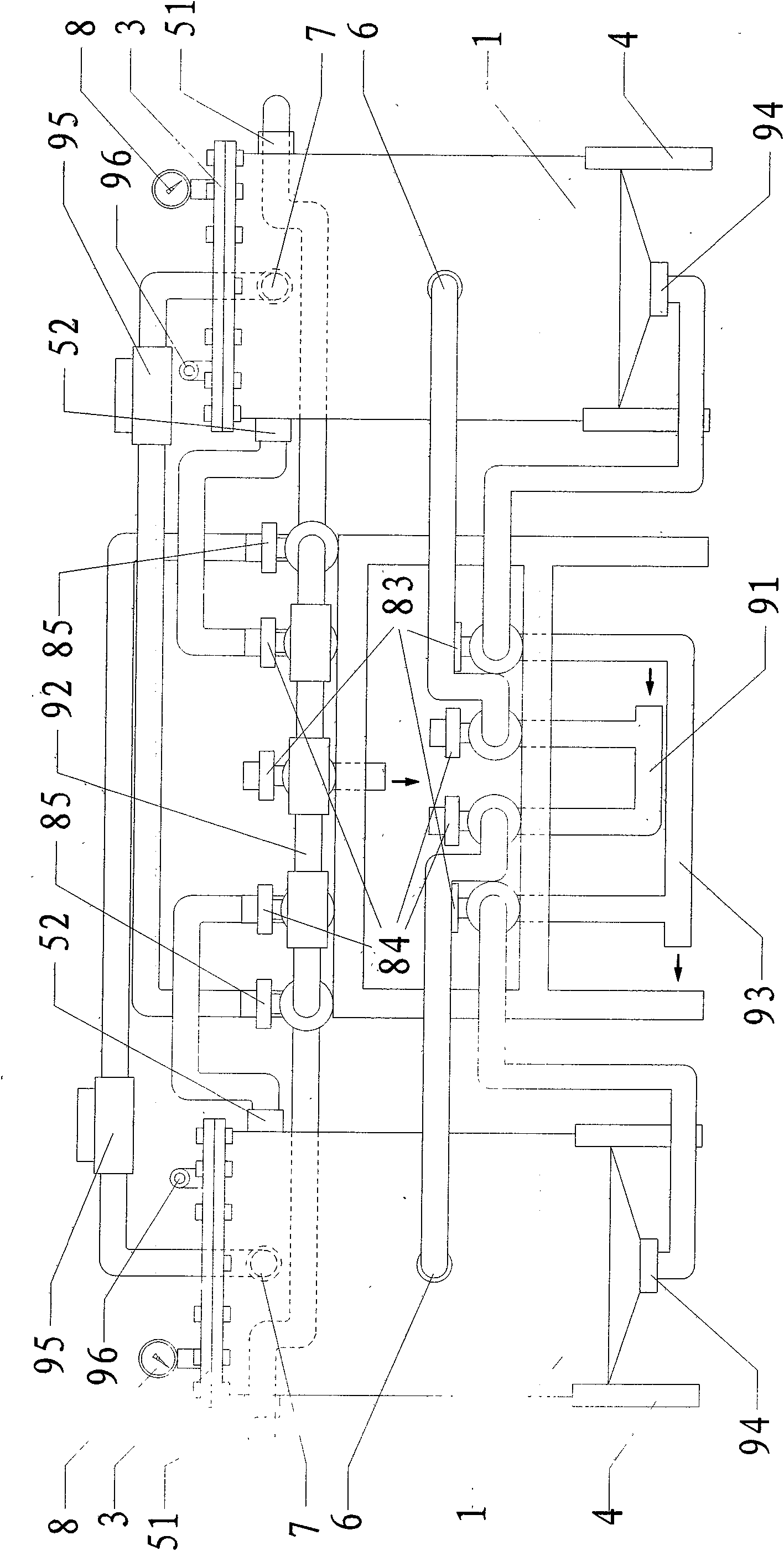

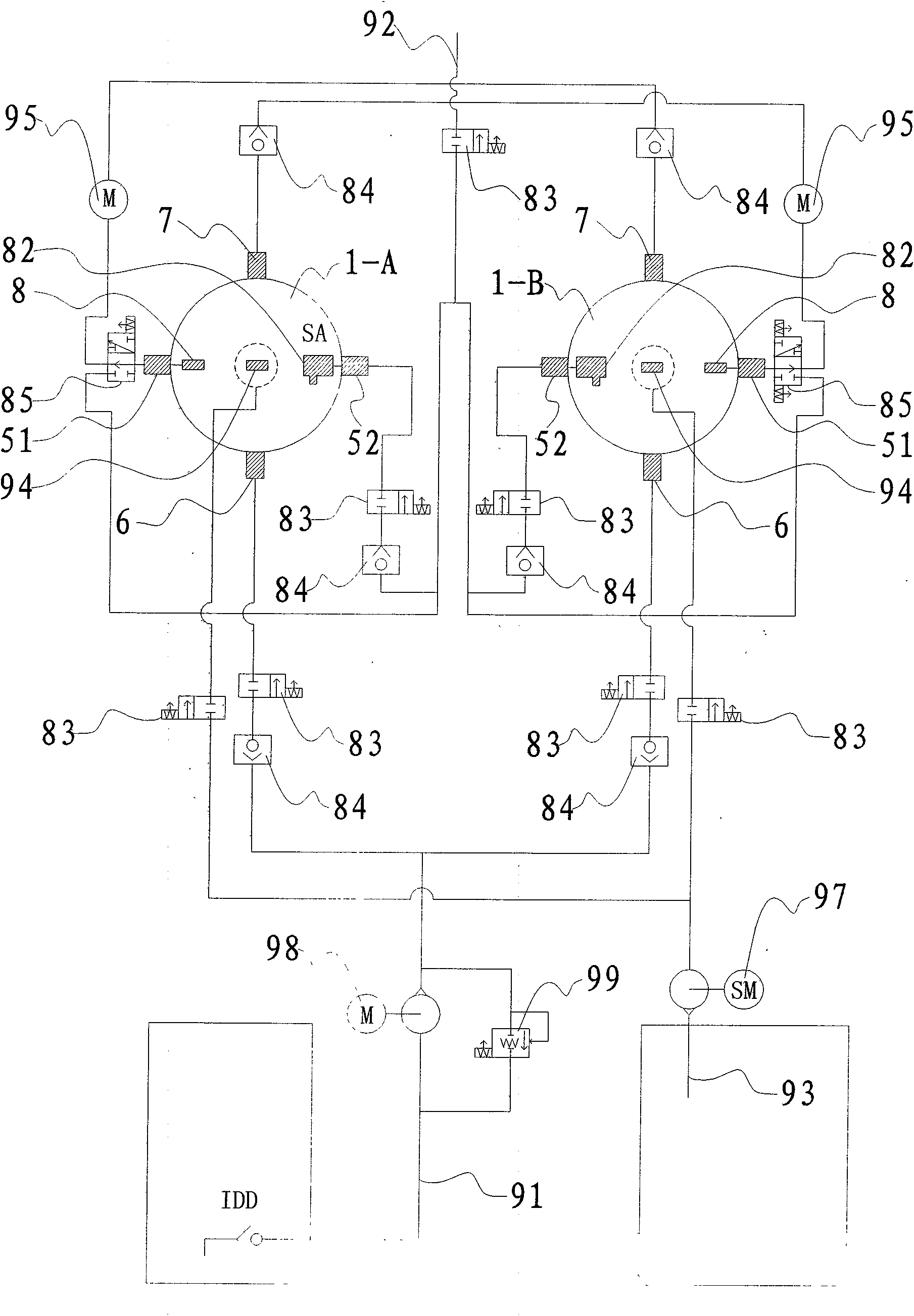

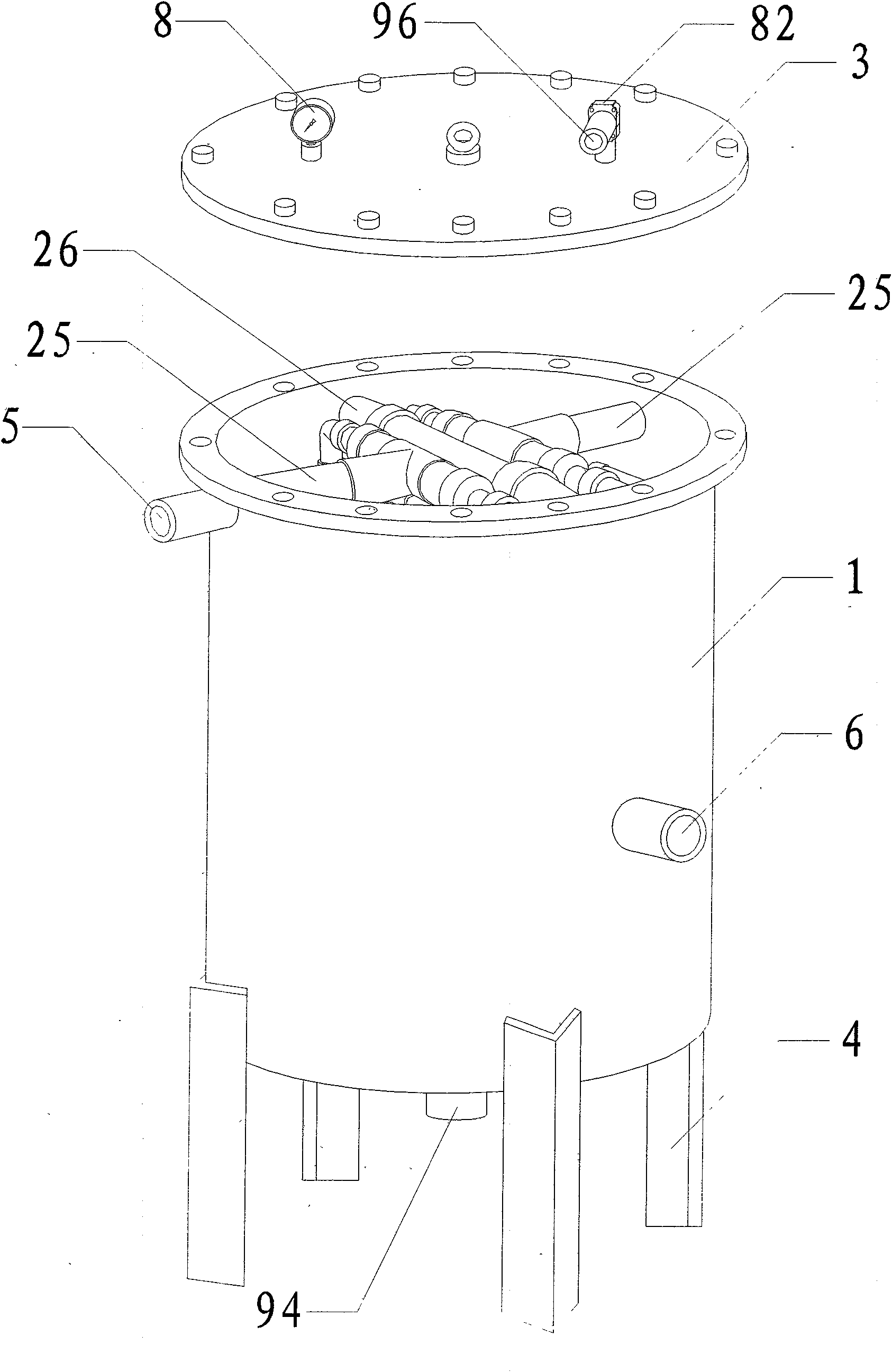

Cold and heat source revolution type dual-prevention device for sewage or surface water and system thereof

InactiveCN101935112AThe principle is simpleThe system process is not complicatedMultistage water/sewage treatmentProcess engineeringSewage

The invention discloses a cold and heat source revolution type dual-prevention device for sewage or surface water and a system thereof and relates to a device for preventing blocking and scaling while extracting cold and heat in sewage or surface water by utilizing a heat pump technology and a system thereof, belonging to the technical field of energy and aiming to effectively solve the problem of heat exchange equipment blockage by impurities in the sewage or the surface water and on how to reduce the growth thickness of dirt in the heat exchange equipment. The device comprises a shell, a valve body, a scraper, a filter piece 1, a filter piece 2, a water inlet, a water outlet, two connecting ports, a rotating component, and the like. The system comprises a heat pump set, the device, a connecting pipeline, and the like. When one filter piece works, the other filter piece is used for back washing, the rotating component intermittently changes the direction of the valve body to ensure that the two filter pieces are used for alternately filtering and back washing, and filtered sewage or surface water enters the heat pump set or the heat exchange device again to carry out cold and heat exchange. The invention is suitable for a cold and heat source system of the sewage or the surface water.

Owner:青岛科创蓝新能源股份有限公司

Preparation method of polytetra fluorethylene hydrophilic micro filtering membrane

InactiveCN1785490ANo initial filtration periodHigh filtration precisionSemi-permeable membranesPolyvinyl alcoholTeflon membrane

A hydrophilic microfiltering teflon membrane is prepared from teflon resin (95-100 mass%) and PVA (0-5) through mixing, bidirectional stretching to become membrane, fixing its shape at 270-500 deg.C and activiating. It has high hydrophilicity and water permeability.

Owner:LISHUI UNIV

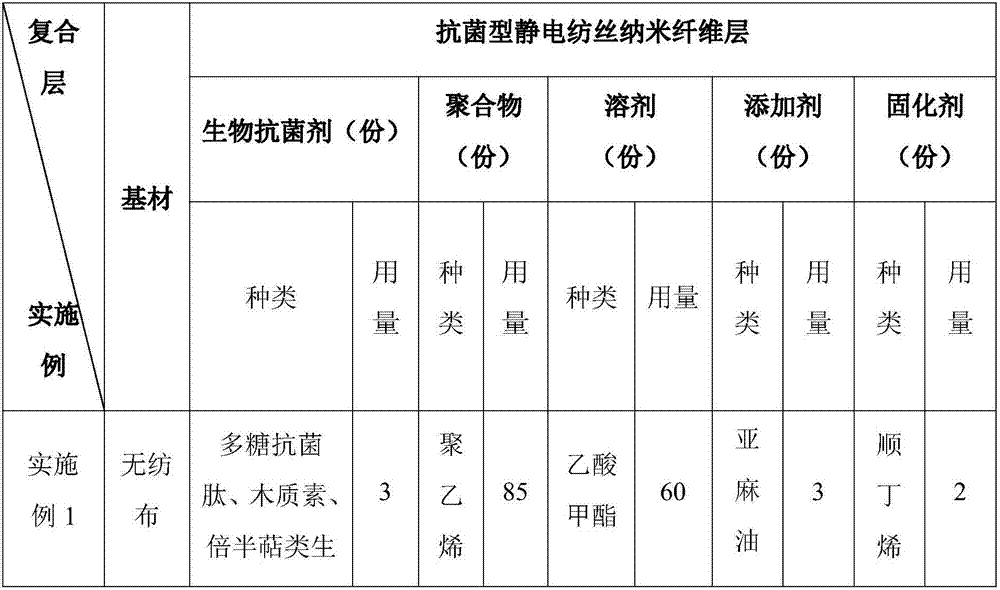

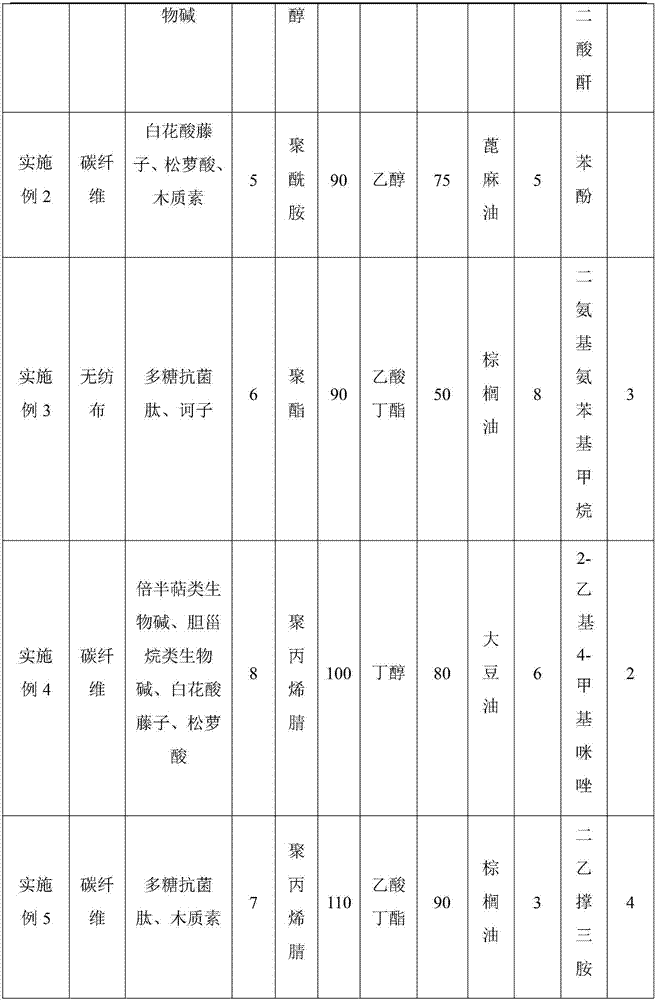

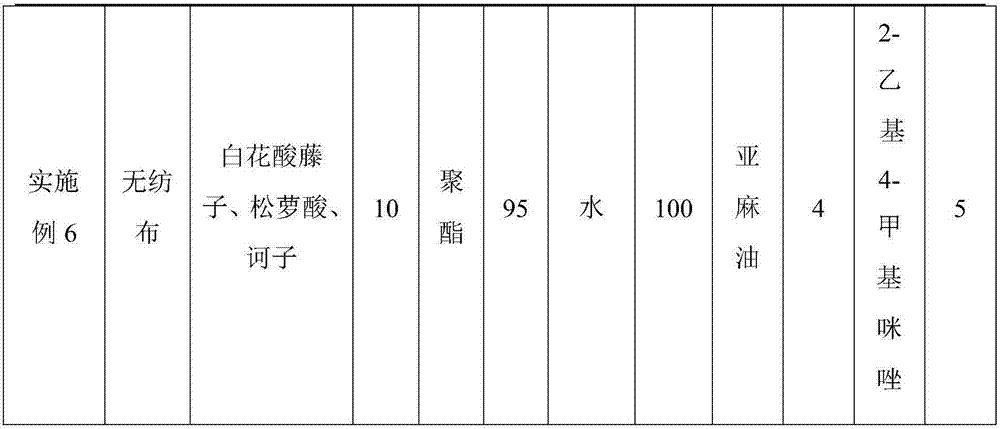

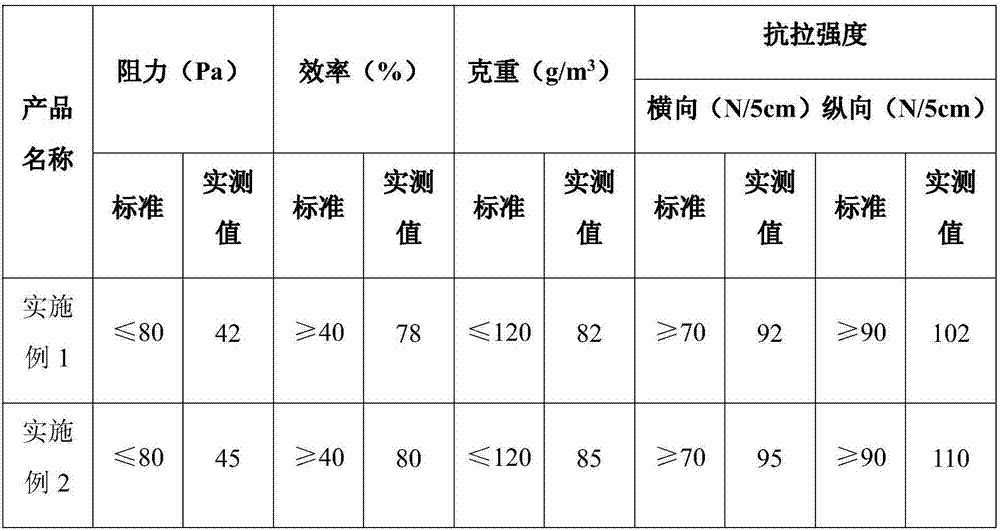

Functional air filtering material

InactiveCN107261865AGood flexibilitySmall fiber diameterSemi-permeable membranesDispersed particle filtrationCompound aElectrospinning

The invention provides a functional air filtering material. The functional air filtering material is formed by compounding a base material and an antibacterial electrostatic spinning nanofiber layer, wherein an antibacterial agent in the antibacterial electrostatic spinning nanofiber layer is a biological bactericide. According to the functional air filtering material provided by the invention, a spinning solution added with the biological bactericide is spun on the base material by adopting an electrostatic spinning preparation process. The air filtering material provided by the invention has the advantages of high flexibility, small fiber diameter, high porosity, uniform distribution of pore diameter, light weight, high permeability, high environment-friendly property and remarkable filtering effect.

Owner:长沙善道新材料科技有限公司

Method for preparing liquid ferrous chloride for water treatment by taking waste hydrochloric acid as raw material

ActiveCN104229902AReduce qualityEasy to buyWater/sewage treatmentIron halidesIron(II) chlorideEnergy consumption

The invention discloses a method of preparing liquid ferrous chloride for water treatment by taking waste hydrochloric acid as a raw material. The method comprises the following steps: firstly, controlling content of ferrous chloride to be not lower than 20wt% in the waste hydrochloric acid and controlling the content of free aid to be not greater than 5wt%; secondly, exhausting the waste hydrochloric acid into an acid storage tank, standing and precipitating for 24-48 hours; extracting the waste hydrochloric acid at the upper layer of the acid storage tank again and conveying the extracted waste hydrochloric acid to a filter tank to filter; and finally, detecting content of acid non-soluble substances in filtered waste hydrochloric acid, and collecting the obtained waste hydrochloric acid, namely qualified liquid ferrous chloride product for water treatment when the content of the acid non-soluble substances in the waste hydrochloric acid is not greater than 0.5wt%. The method is low in energy consumption for treating the waste hydrochloric acid, low in cost, high in efficiency, convenient to operate, good in applicability, capable of utilizing products produced by waste hydrochloric acid treatment secondarily and high in economic value.

Owner:杭州富阳立利冷轧有限公司

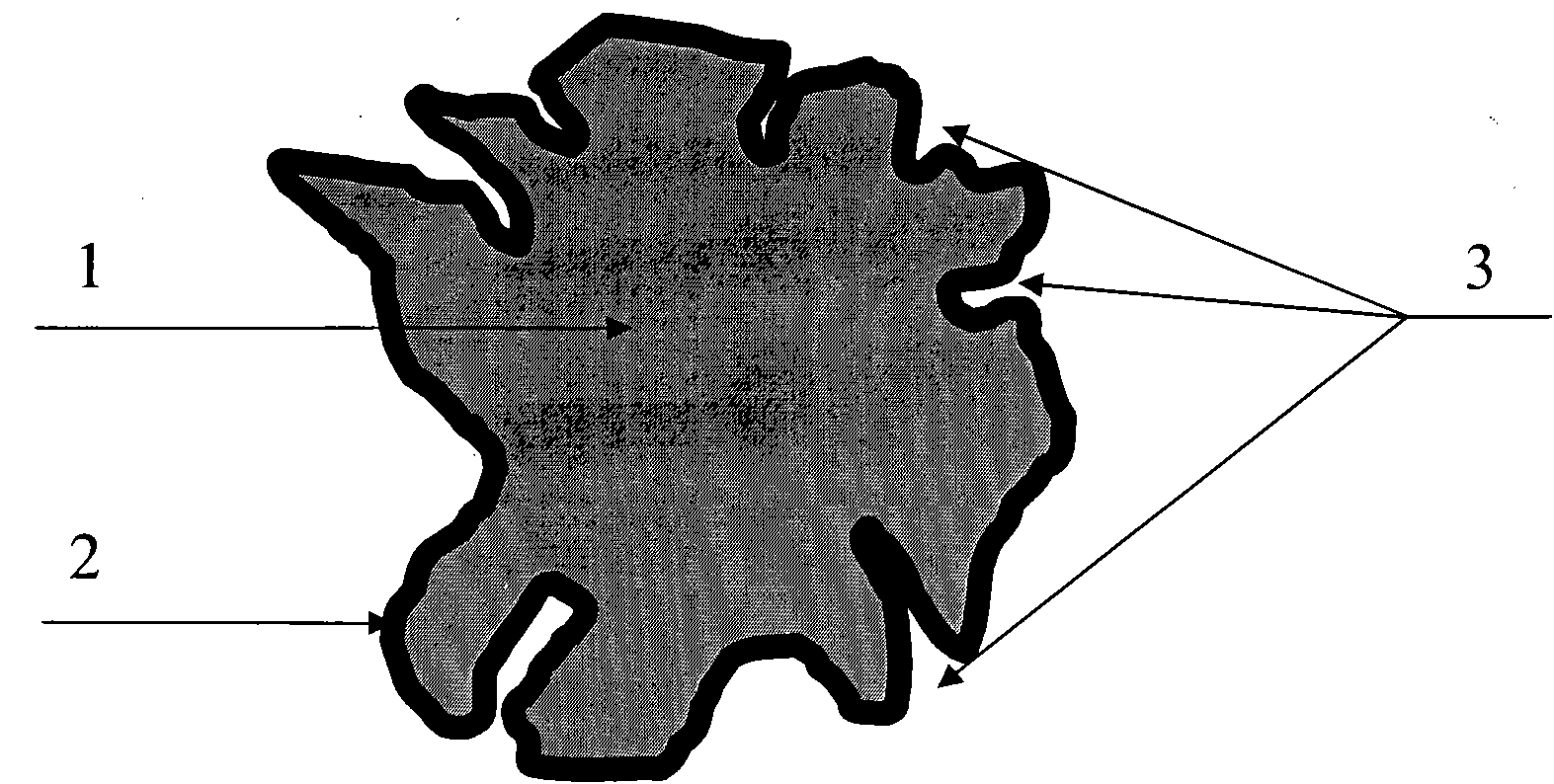

Highly effective filtering material for biology and its preparation method

ActiveCN1876580AImprove performanceLarge specific surface areaTreatment using aerobic processesSustainable biological treatmentRough surfaceVoid ratio

The invention relates the method of producing filtering material used in bio-aeration filter tank. The highly effective biology filtering material comprises 70wt%-90wt% red earth ore and 10wt%-30wt% coal ash. The filtering material is out-of-shape, and the grain diameter is between 3mm and 8mm. The method comprises the following steps: breaking the 70wt%-90wt% red earth ore, drying at 130Deg.C-170Deg.C; fetching 10wt%-30wt% coal ash; fetching 5wt%-15wt% pore-forming agent, water content being below 3%, mixing them, adding water to form ball, drying, calcining, at 1050Deg.C-1250Deg.C, cooling, breaking, barreling and screening until the grain size being 3-8mm. The invention has the advantages of macroporous structure, rough surface, proper void ratio and large specific surface area. Every property is satisfied for the request of bio-aeration filter tank filtering material.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

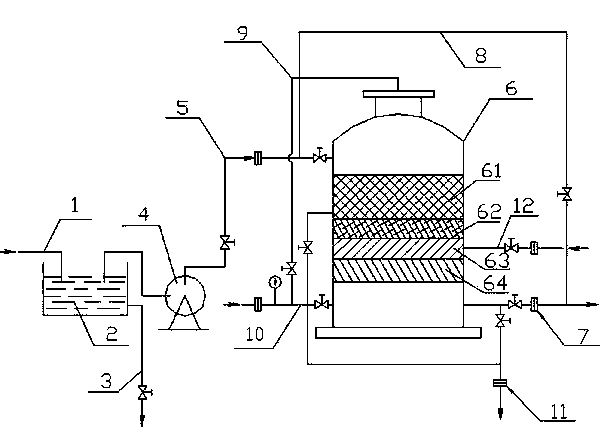

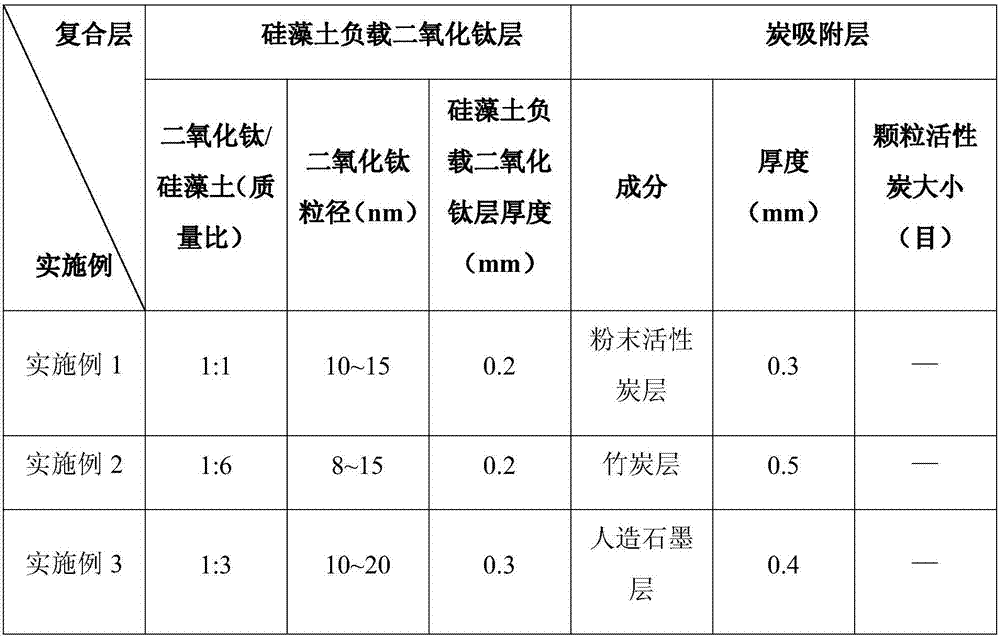

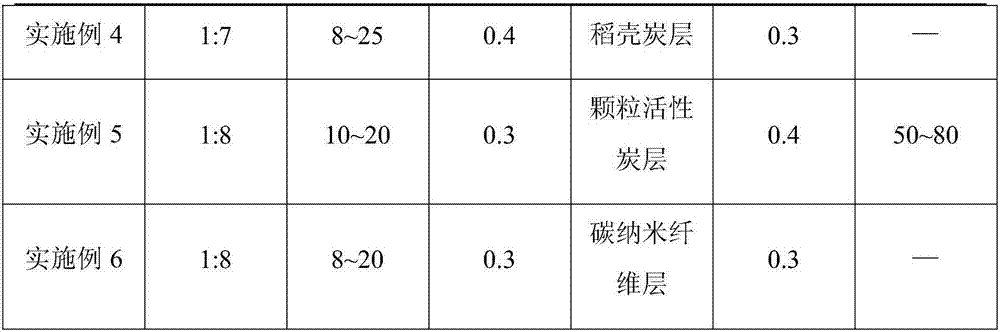

Air filtering material

InactiveCN107198906AEffective combinationImprove adsorption capacityBiocideDispersed particle filtrationFiberAir filtration

The invention provides an air filtering material, which comprises a base material and a compound layer, wherein the base material consists of an upper layer of carbon fiber reticular filtering cloth and a lower layer of carbon fiber reticular filtering cloth; the compound layer is positioned between the upper layer of carbon fiber reticular filtering cloth and the lower layer of carbon fiber reticular filtering cloth and comprises a kieselguhr loaded titanium dioxide layer and a carbon material adsorption layer from top to bottom in sequence. In the air filtering material, the kieselguhr loaded titanium dioxide layer and the carbon material adsorption layer are taken as main adsorption layers so as to effectively combine physical adsorption with chemical adsorption. While small particles are filtered, volatile organic compounds can be degraded into poisonless and harmless CO2 and H2O as well as corresponding inorganic ions, and therefore, the air filtering material has the advantages of no secondary pollution, high adsorption function, obvious filtering effect and wide popularization function.

Owner:长沙善道新材料科技有限公司

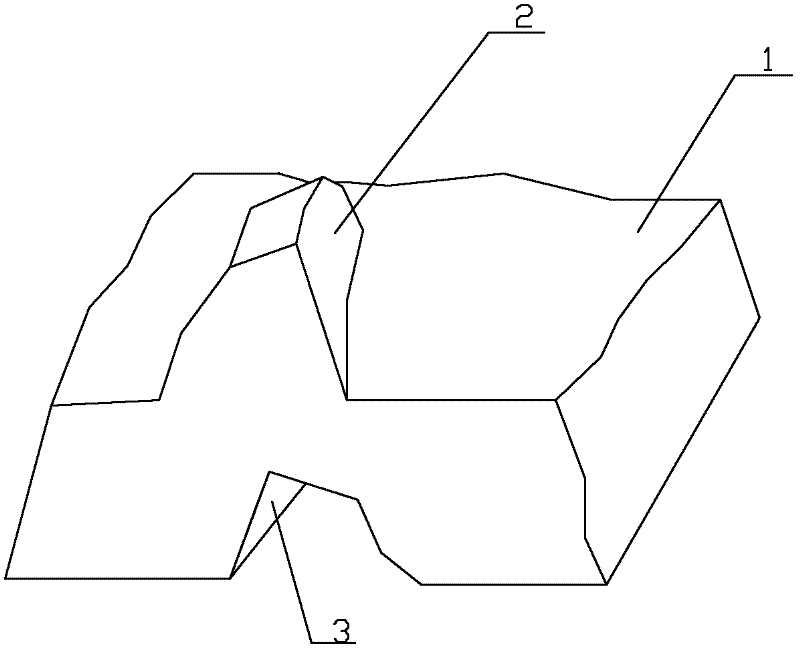

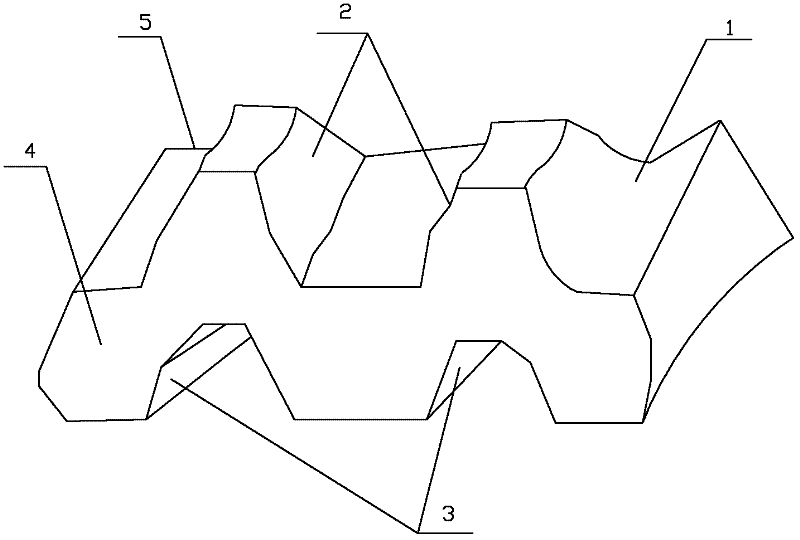

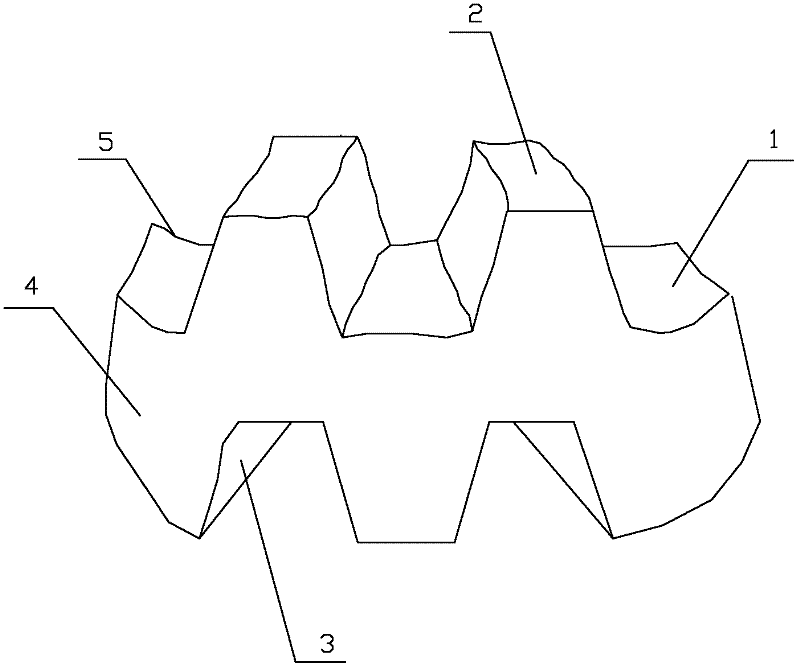

Irregular micro electrolysis iron carbon filling material

ActiveCN102336456AEasy to handleIncrease contact reaction areaWater/sewage treatmentElectrolysisFilling materials

The invention relates to an irregular micro electrolysis iron carbon filling material, which is in a blocky shape. At least one irregular bulge and at least one irregular groove are respectively distributed and arranged on the two opposite end surfaces of the filling material, the irregular bulge and the irregular groove are correspondingly distributed and arranged at top and bottom on the two opposite end surfaces of the filling material, the irregular bulge and the irregular groove are approximately in a gear shape, and the whole of the filling material is inclined and / or has the radian. The technology solves the technical problems of the traditional filling material that the production cost is high, the contact reaction area is small, the reverse flushing is not easy, in addition, the effect is poor, the service life is short, and the like. The irregular micro electrolysis iron carbon filling material has the advantages that the large contact reaction area is realized, the sewage treatment effect is good, the reverse flushing is easy, in addition, the effect is good, the labor operation quantity is reduced, and the production cost and the use cost are reduced.

Owner:常州海龙环保设备厂

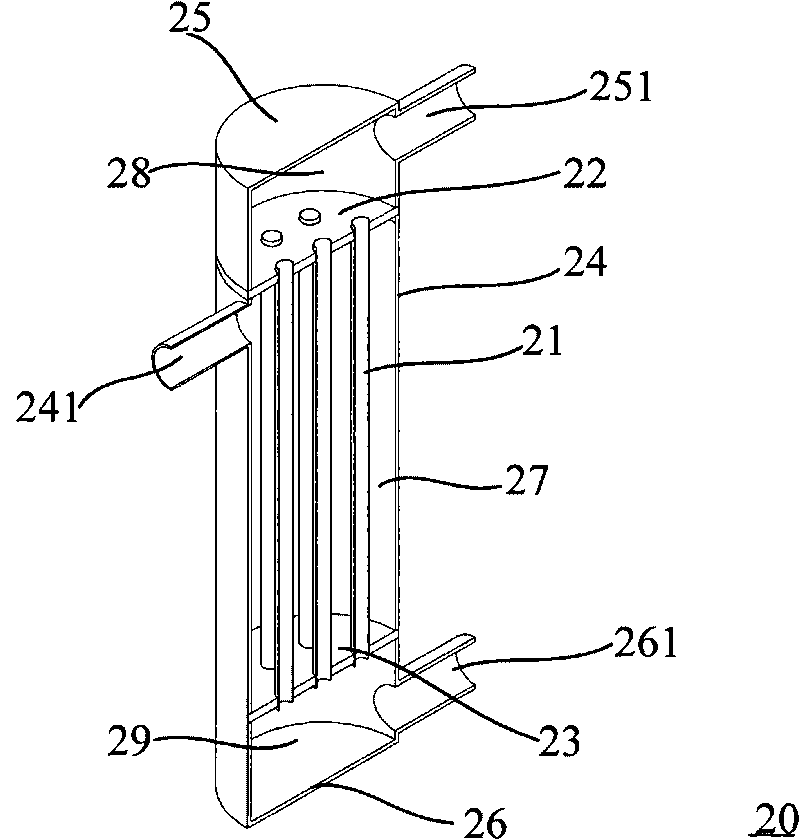

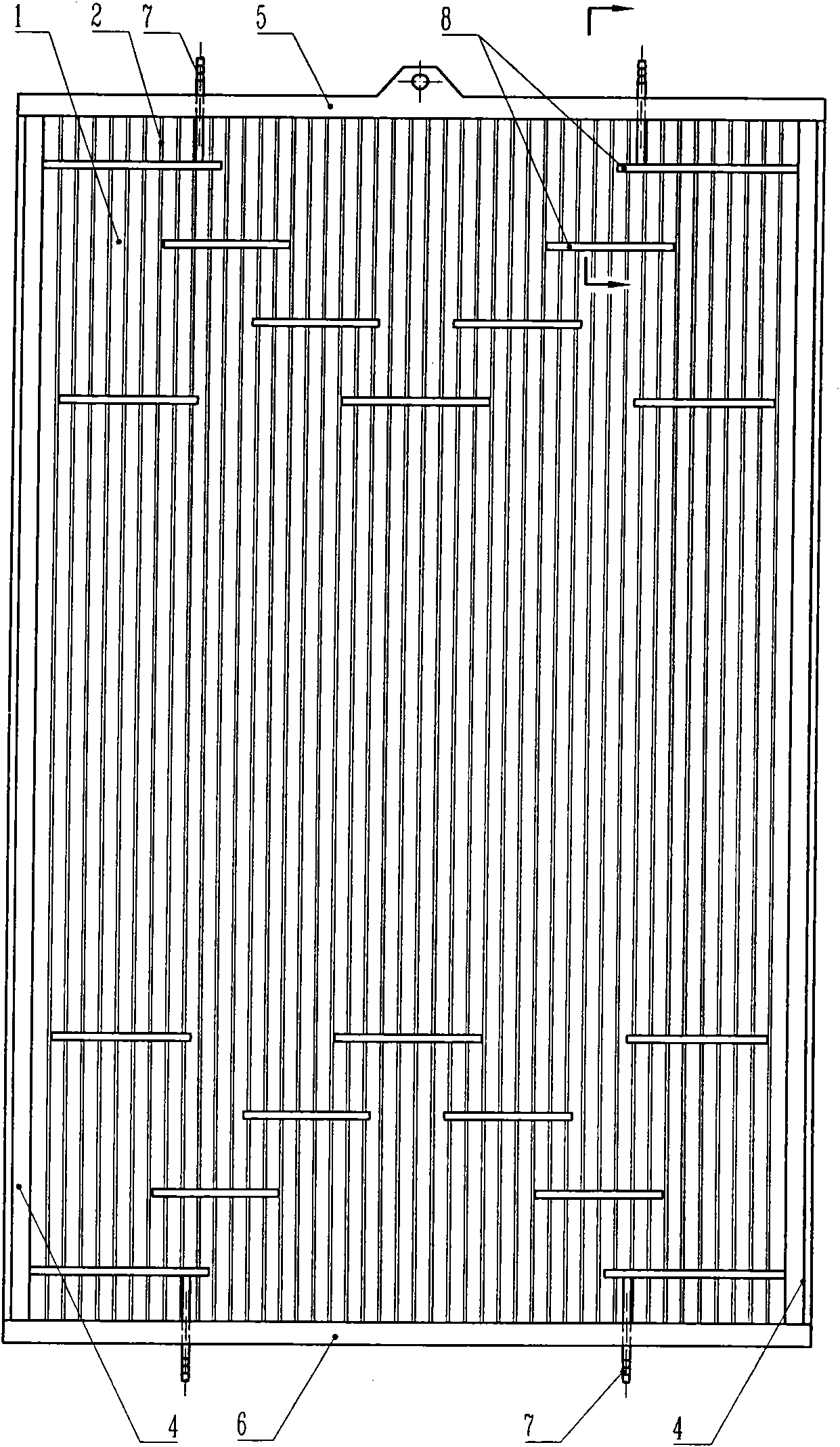

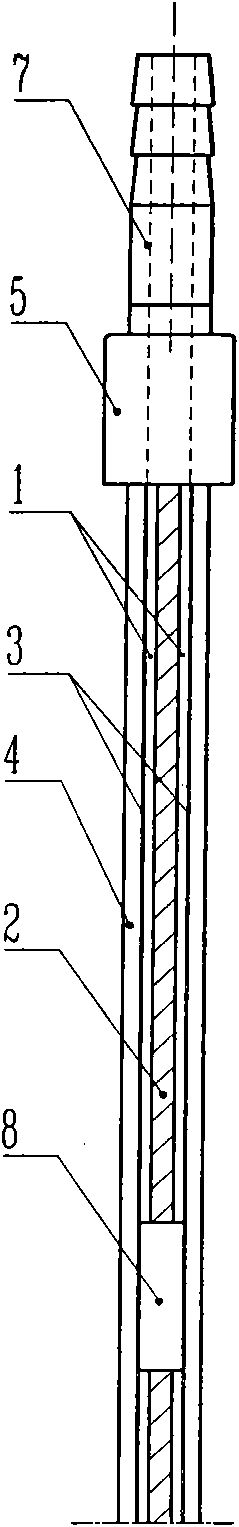

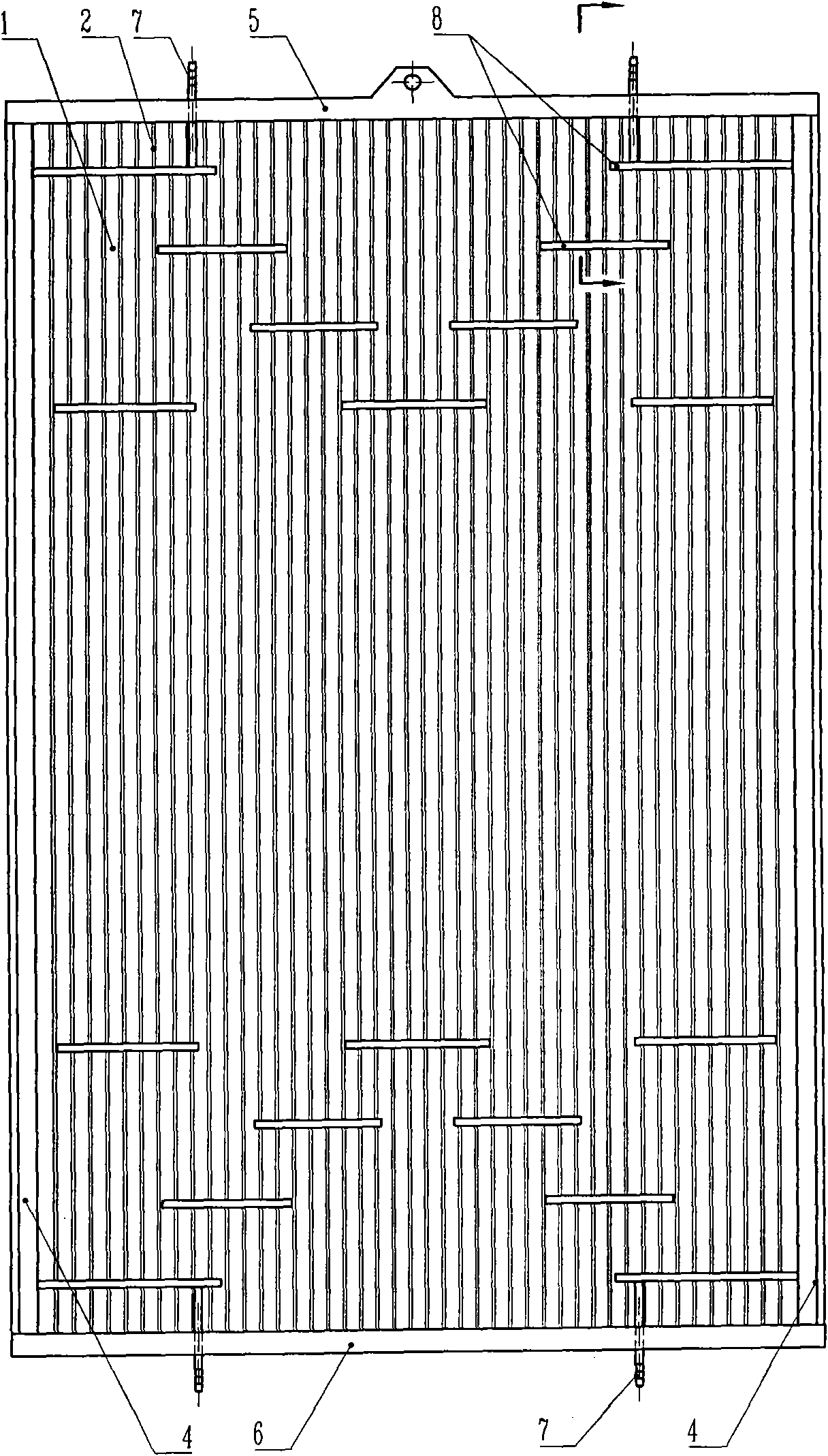

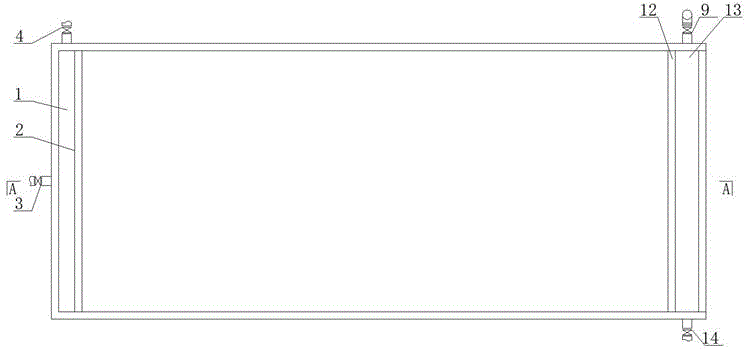

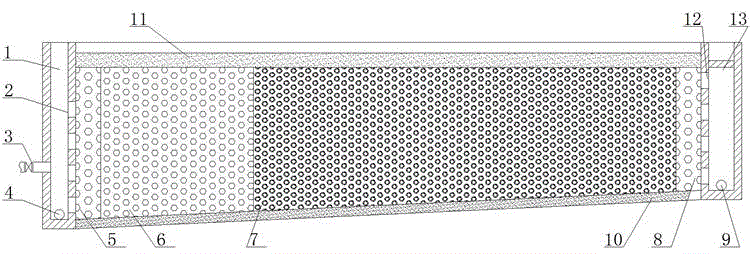

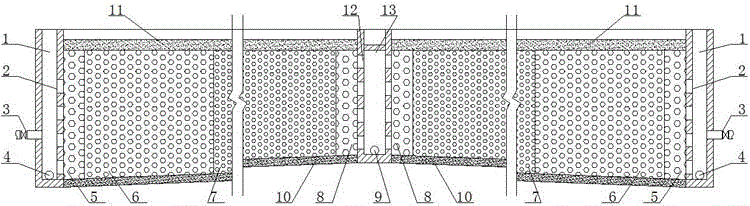

Novel submerged flat membrane element

ActiveCN101857302AEasy to backwashBackwashing is easySustainable biological treatmentBiological water/sewage treatmentBiochemical engineeringSewage treatment

The invention relates to a novel submerged flat membrane element, which comprises a middle support plate (2), wherein the two plate surfaces of the same plate are provided with a plurality of vertical guide channels (1); and the membranes (3) are arranged on the two surfaces of the middle support plate (2). The novel submerged flat membrane element is characterized in that: side compression bars (4) are arranged on the left and right sides of the middle support plate (2), and an upper end part (5) and a lower end part (6) are arranged on the upper and lower ends of the middle support plate (2) respectively; the upper end part (5) and the lower end part (6) are provided with two suction pipes (7) respectively; a plurality of water gathering channels (8) are formed on the middle support plate (2); and the membranes (3) are covered the outside of the water gathering channels (7). In the invention, four suction pipes adopted are favorable for the backwash of the membranes when the membranes are used for a period of time; the novel submerged flat membrane element has the characteristics of easy water outflow, large effective processing area, large flow and the like, improves the effective efficiency of aeration, reduces washing time and saves energy; the membranes can reach 2.5 meters at most; and the occupied area is smaller on the premise of identical sewage treatment amount.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

Composite-method oil removing apparatus

ActiveCN103285655ABackwashing is easyHigh efficiency of removing impuritiesLiquid separationFiltration circuitsFiltrationOil water

The invention provides a composite-method oil removing apparatus which employs composite principles of aggregation and oleophobicity, belonging to the technical field of oil-water separation and filtration. The apparatus comprises a water inlet, a water inflow chamber, an oil collecting chamber, a floating oil chamber, an oil outlet, an oleophobic chamber, a shell, a drain outlet, a clear water chamber and a water outlet, wherein raw water enters into the water inflow chamber from the water inlet, impurities in the water deposit on the bottom of the water inflow chamber and are discharged from the drain outlet, then the water enters into the oil collecting chamber, an oleophylic and oil-accumulating material is disposed in the oil collecting chamber, dispersed oil in the water is aggregated to form large-grained oil droplets which enter into the floating oil chamber, the water in the lower part of the floating oil chamber enters into the oleophobic chamber, an oleophylic and oil-separating material is disposed in the oleophobic chamber to further obstruct residual oil in the water, obtained clear water enters into the clear water chamber and is discharged from the water outlet, and floating oil is discharged from the oil outlet. The composite-method oil removing apparatus provided by the invention can realize backwashing, removes impurities and oil without addition of additives and guarantees that the properties of original liquid maintain invariable; and usage of a plurality of the oil removing apparatuses in series connection enables oil to be thoroughly removed, so the oil removing apparatus has wide market prospects.

Owner:浙江安博特环保科技有限公司

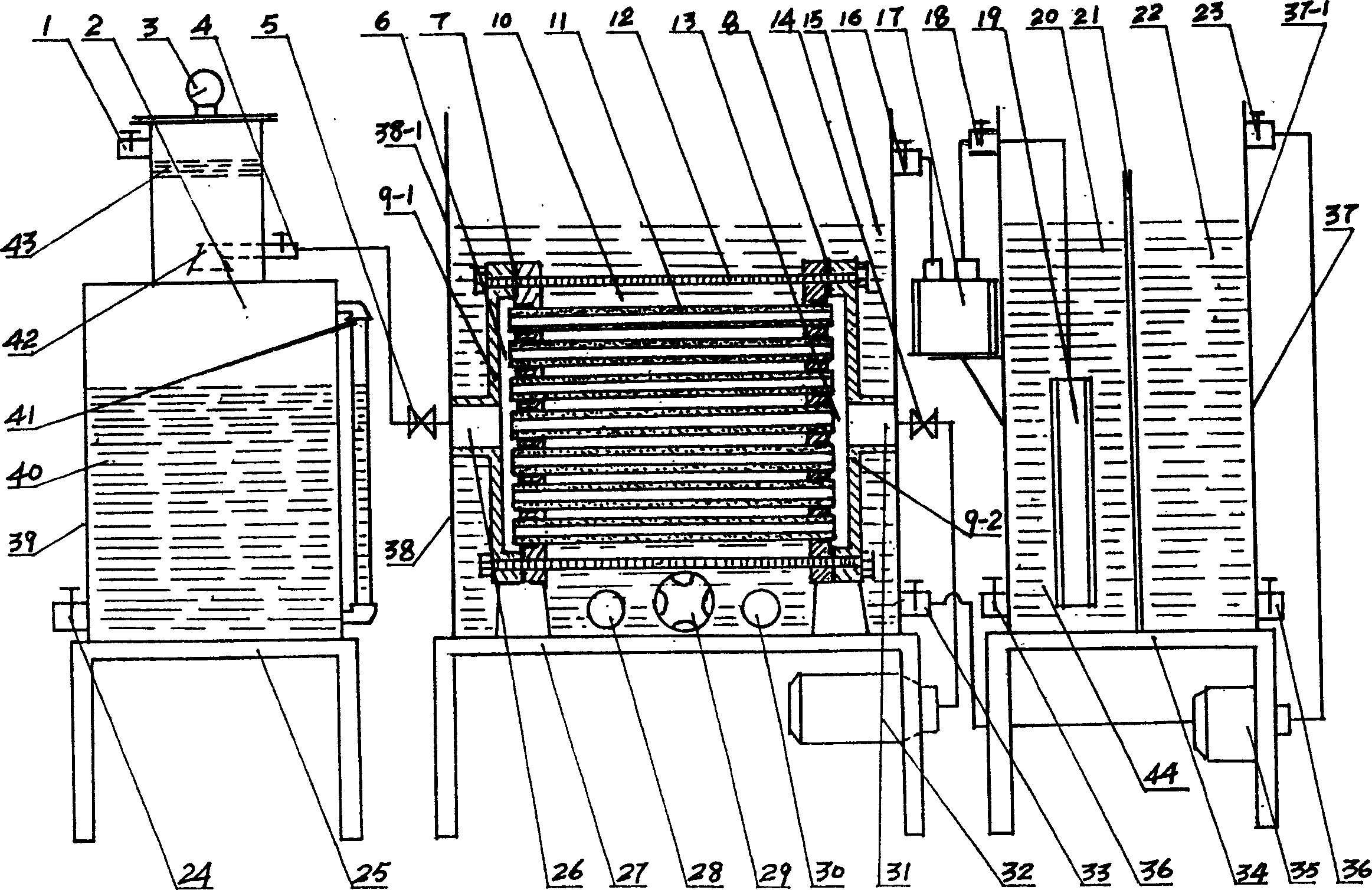

Water filter unit and filter method thereof

InactiveCN101670241ABackwashing is simpleImprove filtration efficiencySemi-permeable membranesWater/sewage treatmentSewageFilter element

The invention discloses a water filter unit and a filter method thereof, the water filter unit comprises a first filter tank and a second filter tank, wherein a first water discharging hole of the first filter tank is connected with a three-way valve and then respectively communicated with a washing hole and a water discharging pipe of the second filter tank, a first water discharging hole of thesecond filter tank is connected with the three-way valve and then respectively communicated with a washing hole and a water discharging pipe of the first filter tank, second water discharging holes oftwo filter tanks are communicated with the water discharging pipes, water feeding holes of two filter tanks are communicated with each other and then communicated with a water feeding pipeline, and sewage draining exits of two filter tanks are communicated with each other and then communicated with a sewage draining pipeline; two filter tanks of the water filter unit can complete the filter independently and can also backwash the filter element of the other at the same time of filter, and the backwashing is simple and the filter efficiency is greatly enhanced.

Owner:罗鹏

Method and apparatus for efficiently extracting or separating nano-grade matter in solution

The present invention discloses a method for high-effectively extracting and separating nano-grade substance from solution and its equipment, belonging to the field of substance extraction and separation technology. Said equipment includes coarse filtration system, fine filtration system, ultrafiltration system, negative pressure suction system, back-flushing system and whole system program controller.

Owner:何锡伶 +1

High-efficiency loaded bio-membrane purification device

PendingCN108689549ABiodegradablePlay the role of mixingTreatment involving filtrationMultistage water/sewage treatmentFiltrationBiochemical engineering

The invention provides a high-efficiency loaded bio-membrane purification device. The device comprises a reaction tank, the internal of the reaction tank is divided into a first reaction chamber and asecond reaction chamber by a separation plate, the separation plate is provided with a through hole, the through hole divides the separation plate into an upper separation plate and a lower separation plate, a coal gangue ceramsite layer, a biological sludge ceramsite layer and a first double-layer filtration layer are sequentially arranged in the first reaction chamber from top to bottom, the coal gangue ceramsite layer and the biological sludge ceramsite layer are arranged in an interlaced manner, a nano-modified ceramic layer, a porous sponge layer and a second double-layer filter layer are sequentially arranged in the second reaction chamber from top to bottom, movable plates are hingedly connected to two sides of the lower separation plate, the movable plates and the lower separationplate are connected by compression springs, L-shaped limiting grooves are symmetrically arranged at one sides, close to the lower separation plate, of the first double-layer filter layer and the second double-layer filter layer, and the free ends of the movable plates are located in the L-shaped limiting grooves. The device has a biodegradation function and a good sewage treatment effect.

Owner:TIANJIN WATER RESOURCES RES INST

Bioactive filtering material for water treatment and baking technology thereof

InactiveCN1546398AHigh strengthHigh porositySustainable biological treatmentFiltration separationSulfonateFoaming agent

A biologically active filtering material for water treatment and its roasting process by using clay as the principal raw material for the biologically active filtering material, charging lignin sulfonate plasticizing agent and polyvinyl alcohol foaming agent, wherein the biological activity is achieved through roasting process and biological modification. The advantages of the invention are strong biological adhesion, high performance of film suspension, good current fluidized form, easy backwash and strong dirt-blocking capability.

Owner:SHANDONG UNIV +1

Single-pipe external-compression type mechanical-circulation forced-cross flow solid and liquid-separating dynamic membrane system and device

ActiveCN101805058AReduce hydraulic dead spaceReduce precoating timeTreatment with anaerobic digestion processesWater/sewage treatment bu osmosis/dialysisPurified waterWaste management

The invention relates to single-pipe external-compression type mechanical-circulation forced-cross flow solid and liquid-separating dynamic membrane system and device. The dynamic membrane device comprises a tubular external-compression type supporter with a large-hole diameter net, a shell arranged at the outer side of the tubular external-compression type supporter, a plurality of supports, a raw water inlet and a plurality of purified water outlet tubes, wherein the inner part of the shell and the outer part of the tubular external-compression type supporter form a water inlet chamber, and the supports are arranged between the tubular external-compression type supporter and the shell at intervals and are respectively sheathed with the tubular external-compression type supporter and the tubular external-compression type supporter; the raw water inlet is connected to the lower end of the shell and is communicated with the water inlet chamber; and the purified water outlet tubes penetrate through the shell and are communicated with the inner cavity of the tubular external-compression type supporter. The dynamic membrane device also comprises a cross-flow backflow water outlet which is connected to the upper end of the shell and is communicated with the water inlet chamber. The dynamic membrane device has the advantages of no waterpower blind angel, short precoating time, convenient back washing, continuous working, improved membrane flux, stable water yield and long working period.

Owner:临沂高新城乡发展有限公司

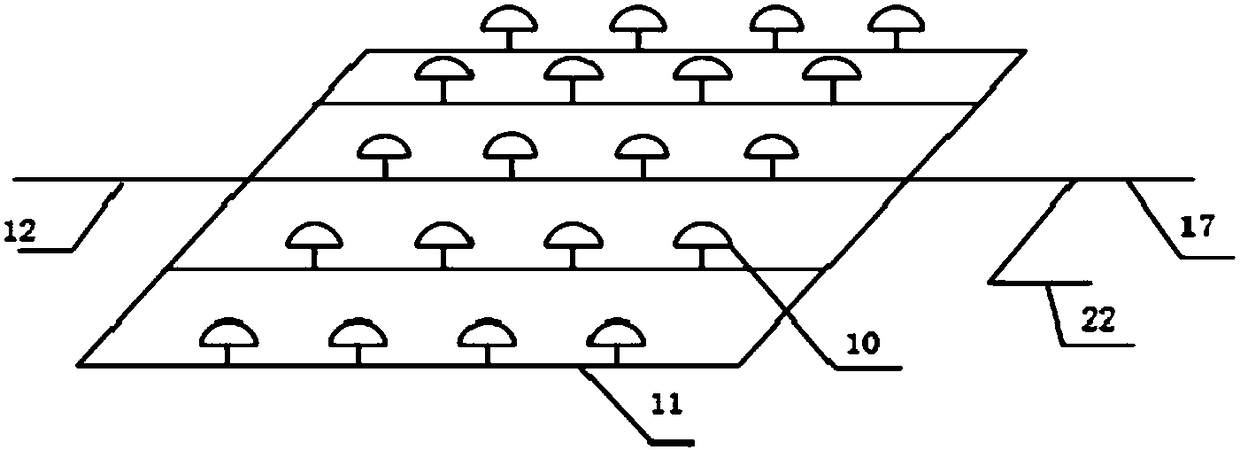

Backwashable horizontal underflow artificial wetland capable of retarding front section clogging reducing

InactiveCN105399207AReduce cloggingEasy to clogSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandEngineering

The invention relates to a backwashable horizontal underflow artificial wetland capable of retarding front section clogging. The backwashable horizontal underflow artificial wetland is characterized in that the top portion of a water outlet ditch is sealed, the particle size of the wetland front section (front 1 / 4-1 / 2) matrix is larger than the particle size of the rear section matrix, the bottom portion from the water inlet end to the water outlet end has rising slope, the water inflow and the water outflow use perforated walls, the length is less than the conventional artificial common length and is generally less than 15 m, the maximum length does not exceed 20 mm, the particle size of the front section matrix is 12-30 mm, the particle size of the rear section matrix is 4-12 mm, the rising slope from the water inlet end to the water outlet end is 0.5-2%, and the holes on the water inlet perforated wall and the water outlet perforated wall are uniformly arranged in the horizontal direction and in the vertical direction. According to the present invention, the particle size of the front end is larger than the particle size of the rear section so as to retard the wetland front end clogging and improve the hydraulic efficiency of the wetland, the sufficient pressure can be provided through the water outlet ditch sealing, and the wetland clogging is solved through the backwashing.

Owner:CHINA UNIV OF MINING & TECH

Filtering material for removing iron and manganese

InactiveCN101869791AHigh mechanical strengthGood chemical stabilityOther chemical processesFiltration separationFiltrationManganese

The invention relates to a filtering material for removing iron and manganese from water, and a manufacturing method thereof. The invention is characterized in that the filtering material is made by using irregular polyhedral filtration particles, which are obtained by crushing and screening building ceramic particles and of which the surfaces have pores, and by making an adhesive layer containing ferric oxide and manganese on the surfaces of the filtration particles by using a chemical or coating method. The filtering material has a large specific surface ratio, a small specific gravity and good physical and chemical properties and can be manufactured by a simple and convenient method. The water iron and manganese filtration effect of the filtering material is better than that of natural manganese sand, so the filtering material has a promising market application prospect.

Owner:YUNNAN NEWGOT

Sewage treatment biological filter material based on low-voltage electric porcelain waste and preparation method thereof

InactiveCN104058781ASimple preparation processRaw materials are cheapCeramicwareClaywaresPelletizingHeat conservation

The invention specifically relates to a sewage treatment biological filter material based on low-voltage electric porcelain waste and a preparation method of the sewage treatment biological filter material. According to the technical scheme, the method includes the first step of using 40.0-60.0 wt% of the low-voltage electric porcelain waste, 15.0-25.0 wt% of coal ash, 10.0-20.0 wt% of pyrophyllite and 5.0-15.0 wt% of clay as raw materials, adding 500-1000 L of pore-forming agents into per ton of the raw materials, conducting mixing, further adding 2.0-5.0 wt% of binding agents and 15.0-25.0 wt% of water, and then conducting pelleting forming, and the second step of conducting drying for 24-48 hours at the temperature ranging from 80 DEG C to 140 DEG C, conducting heat preservation for 2-12 hours at the temperature ranging from 800 DEG C to 1200 DEG C, and finally obtaining the sewage treatment biological filter material based on the low-voltage electric porcelain waste. The method has the advantages of being simple in process, capable of saving resources and friendly to the environment. Products manufactured through the method are large in specific surface area, high in mechanical strength, good in wear resistance and high in apparent porosity.

Owner:WUHAN UNIV OF SCI & TECH

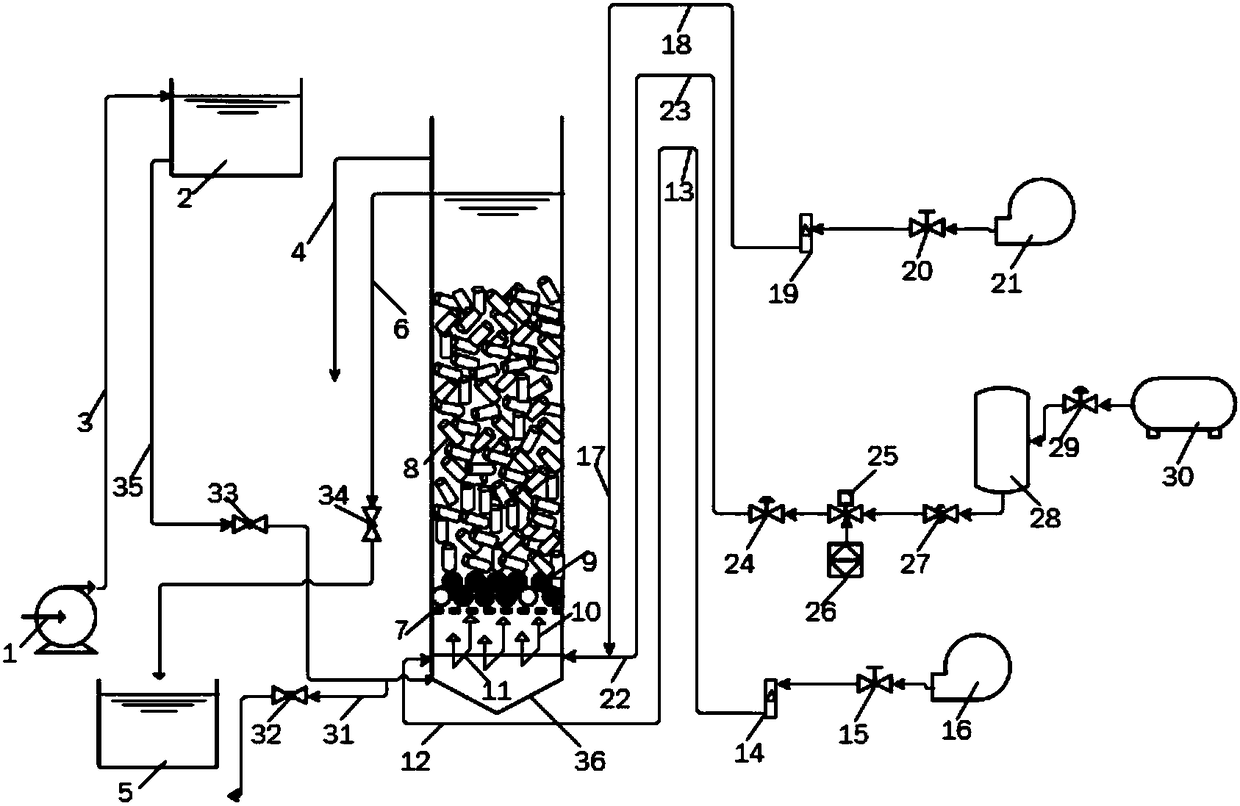

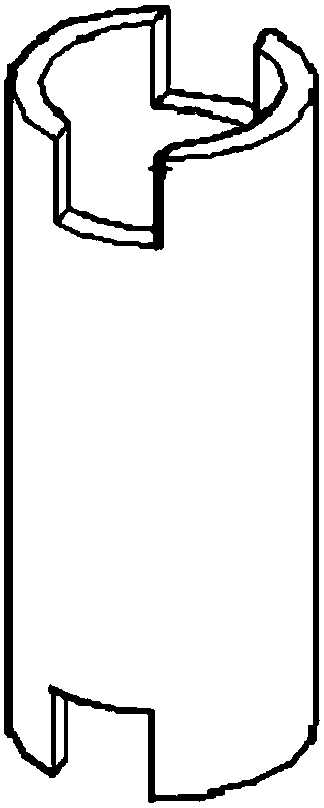

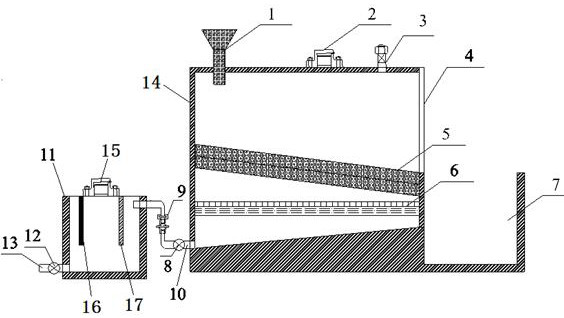

Water treatment device comprising circular pipe filling and use method

ActiveCN108059243ASimultaneous realization of nitrification and denitrification reactionsStable biological stateTreatment with aerobic and anaerobic processesWater qualityPolyvinyl chloride

The invention discloses a water treatment device comprising circular pipe filling and a use method and belongs to the technical field of water treatment. The water treatment device comprises a tank body reaction system, a gas distribution system and a water distribution system, wherein gas is supplied to a gas distribution pipe via adjustment and opening of an aeration pipe, the gas distribution pipe and a pulse pipe in a gas distribution area; the pulse pipe is connected with a gas storage tank from a high pressure fan via an adjustment valve; an outlet is connected with the pulse pipe via areducing valve, an electromagnetic valve and an adjustment valve; the circular pipe filling is 3-6mm in outer diameter D, 10-30mm in length L, 0.5-1mm in pipe wall thickness h and 1.05-1.2g / cm<3> in density rho; U-shaped notches are formed at the two ends of circular pipes; and the circular pipes are made from PVC (polyvinyl chloride). An operating state of the filling can be changed by adjustinga gas distribution valve according to influent quality. The device is used for biochemical sewage treatment and has a good synchronous treatment effect on C, N and P; the working state of the fillingcan be adjusted according to different C / N ratios; back flushing is easy and low in energy consumption; the possibility of blocking is low; the surface area per unit volume is large; and the device issimple to manufacture.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Highly effective filtering material for biology and its preparation method

ActiveCN100417605CImprove performanceLarge specific surface areaTreatment using aerobic processesSustainable biological treatmentRough surfaceVoid ratio

The invention relates the method of producing filtering material used in bio-aeration filter tank. The highly effective biology filtering material comprises 70wt%-90wt% red earth ore and 10wt%-30wt% coal ash. The filtering material is out-of-shape, and the grain diameter is between 3mm and 8mm. The method comprises the following steps: breaking the 70wt%-90wt% red earth ore, drying at 130Deg.C-170Deg.C; fetching 10wt%-30wt% coal ash; fetching 5wt%-15wt% pore-forming agent, water content being below 3%, mixing them, adding water to form ball, drying, calcining, at 1050Deg.C-1250Deg.C, cooling, breaking, barreling and screening until the grain size being 3-8mm. The invention has the advantages of macroporous structure, rough surface, proper void ratio and large specific surface area. Every property is satisfied for the request of bio-aeration filter tank filtering material.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

Multi-pipe external-compression type mechanical circulation forced cross flow solid-liquid separation dynamic membrane system and device

ActiveCN101780349AReduce hydraulic dead spaceReduce precoating timeStationary filtering element filtersWork cyclePurified water

The invention relates to multi-pipe external-compression type mechanical circulation forced cross flow solid-liquid separation dynamic membrane system and device. The dynamic membrane device comprises a plurality of large-aperture net tubular external-compression type supporting bodies, a water purification cavity, an upper cover and a shell, wherein the inner cavity of the water purification cavity forms a water purification chamber, a plurality of through holes and a plurality of purified water outlets are arranged on the water purification cavity, and a plurality of supporting body connecting holes are arranged on a lower end plate of the water purification cavity; all the tubular external-compression type supporting bodies are communicated with the water purification cavity through the supporting body connecting holes; the upper cover is connected to the upper part of the water purification cavity and forms a cross flow backflow chamber together with the water purification cavity, and a cross flow backflow water outlet is arranged on the upper cover; the shell is connected to the lower part of the water purification cavity and forms a water inlet chamber together with the water purification cavity; and a raw water inlet is arranged on the shell. The multi-pipe external-compression type mechanical circulation forced cross flow solid-liquid separation dynamic membrane device has the advantages of no hydraulic dead angle, short precoating time, convenient backwashing, capability of continuously working, membrane flux increase of the dynamic membrane, stable water yield and long work cycle.

Owner:NANTONG HISIN INFORMATION TECH CO LTD

Bioactive filtering material for water treatment and baking technology thereof

InactiveCN1220543CHigh strengthHigh porositySustainable biological treatmentFiltration separationSulfonateFoaming agent

A biologically active filtering material for water treatment and its roasting process by using clay as the principal raw material for the biologically active filtering material, charging lignin sulfonate plasticizing agent and polyvinyl alcohol foaming agent, wherein the biological activity is achieved through roasting process and biological modification. The advantages of the invention are strong biological adhesion, high performance of film suspension, good current fluidized form, easy backwash and strong dirt-blocking capability.

Owner:SHANDONG UNIV +1

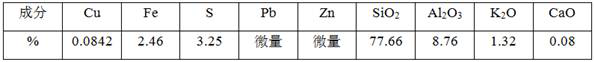

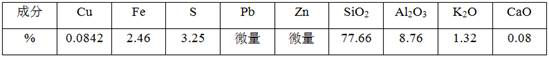

Method for preparing filtering material from copper tailings and application

InactiveCN111760381AHigh economic valueReduce pollutionCeramic materials productionCeramicwareFiberAdhesive

The invention discloses a method for preparing a filtering material from copper tailings. The method comprises the following steps of: mixing pretreated copper tailings, water, a modifier and an adhesive to prepare a raw material with the water content of 10-30%; and performing injection molding and roasting on the raw material so as to obtain the filtering material. The energy-saving and environment-friendly filter material is prepared on the premise of solving the problems of low comprehensive utilization rate of metal tailings and the like, and is applied to filtration and dehydration of mine concentrates and solid-liquid separation in the industries of coal, fine chemical engineering, papermaking, pharmacy, chemical fibers, foods, environmental protection and the like, so that the resource utilization of the tailings is efficiently realized.

Owner:KUNMING UNIV OF SCI & TECH

Sewage degreasing agent

InactiveCN113184943AFast flocculationNo stickinessWater treatment compoundsWater contaminantsSodium phosphatesPhenyl Ethers

The invention belongs to the technical field of sewage degreasing and relates to a sewage degreasing agent which comprises urea, carbon disulfide, a sodium hydroxide solution, triphosphoric acid, nonylphenol polyoxyethylene ether, fatty alcohol-polyoxyethylene ether, polyethylene glycol octylphenol ether, triethanolamine oleate, alkali liquor, an additive, sodium aluminate, a mixture of sodium tripolyphosphate and sodium gluconate, and water. The sewage degreasing agent is prepared from the following components by weight: 40 to 135 g of urea, 100 to 250 g of carbon disulfide, 250 to 300 g of sodium hydroxide solution, 6 to 10 g of triphosphoric acid, 30 to 50 g of nonylphenol polyoxyethylene ether, 50 to 100 g of fatty alcohol-polyoxyethylene ether, 10 to 30 g of polyethylene glycol octylphenol ether, 20 to 50 g of triethanolamine oleate, 80 to 400 g of alkali liquor, 5 to 65 g of additive, 60 to 80 g of the mixture of sodium tripolyphosphate and sodium gluconate and a proper amount of water. Theflocculation speed of thedegreasing agent is high, the degreasing agent can flocculate within several seconds, does not contain any metal ions such as aluminum and iron, does not contain PAM, has no viscosity, is easy to backwash, can improve the degreasing efficiency and effect, and can well protect equipment when used.

Owner:神美科技有限公司

Preparation method of modified magnetic bamboo fiber composite adsorbent

InactiveCN111545177AHigh selectivityEasy to eluteOther chemical processesAlkali metal oxides/hydroxidesFiberPyrrolidine

The invention discloses a preparation method of a modified magnetic bamboo fiber composite adsorbent, which is characterized by comprising the following steps: pretreating bamboo fiber powder by hydrochloric acid and sodium chloride to obtain pretreated bamboo fiber powder; adopting pretreated bamboo fiber powder, polyvinylidene fluoride and carboxylated ferroferric oxide magnetic nanoparticles toprepare magnetic bamboo fiber composite spheres; then, in a reactor, and respectively adding 83-87% of 1, 4-dioxane solvent and 8-12% of magnetic bamboo fiber composite spheres, soaking for 24 hours,stirring, adding 4-6% of 1-(2-aminoethyl) pyrrolidine, heating to 50 + / -2 DEG C, reacting at constant temperature for 4 hours, carrying out solid-liquid separation, soaking in a NaON solution, washing and drying to obtain the modified magnetic bamboo fiber composite adsorbent. The adsorbing material has selective adsorption on arsenazo III, chloroazo III and acid red 52, has good mechanical properties, has good chemical stability, is high in adsorption speed and easy to elute, and has regeneration capacity.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com