Backwashable horizontal underflow artificial wetland capable of retarding front section clogging reducing

A technology of horizontal subsurface flow and constructed wetland, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Load blockage and other problems, to achieve the effect of large particle size, convenient backwashing, and reducing hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

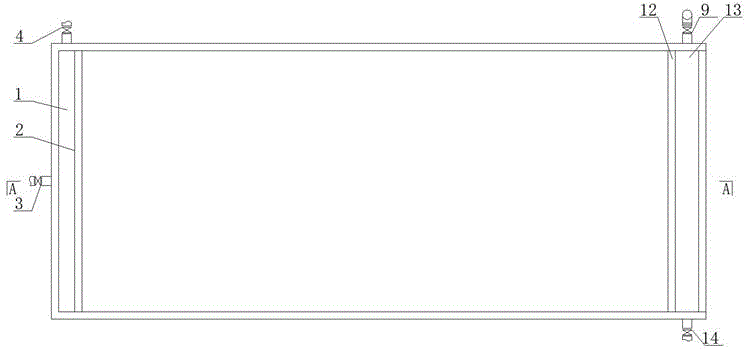

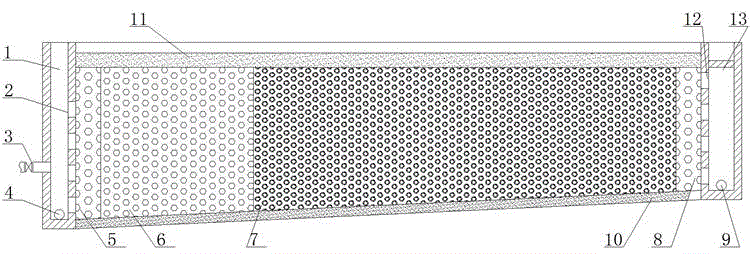

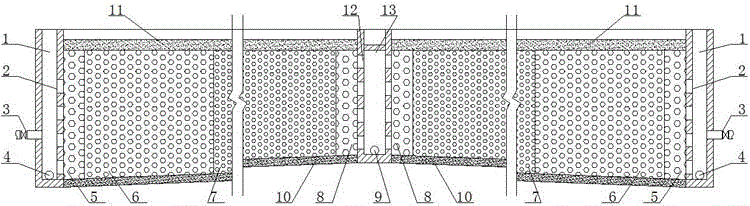

[0018] Method 1: if figure 1 and figure 2 As shown, it is an implementation of the present invention: same as the conventional constructed wetland, it has a large particle size uniform water distribution area 5, a large particle size uniform water collection area 8, an adjustable water level water outlet device 9, an anti-seepage layer 10 and surface soil 11. The first 1 / 3 section of the wetland is filled with matrix with a particle size of 16 mm to 25 mm, and the rear section is filled with matrix with a particle size of 4 mm to 8 mm. The top of the outlet channel 13 is sealed and the slope at the bottom is 0.5%.

[0019] When treating sewage in the wetland, it is necessary to close the backwash outlet valve 4 and the backwash valve 14, and the sewage enters the wetland matrix through the water inlet valve 3, the water inlet channel 1 and the water inlet perforated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com