Process for preparing porous functional ceramic material

A technology of porous ceramics and functional materials, which is applied in the field of preparation technology of porous ceramic functional materials, can solve the problems of cumbersome process, low oil removal rate, large equipment footprint, etc., and achieve the effect of simple preparation process and easy backwashing

Inactive Publication Date: 2014-09-03

格丰科技材料有限公司

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional degreasing method is not only cumbersome, but also requires a large area of equipment and high cost. Moreover, due to the low degreasing rate, a certain amount of oil will remain in the treated oily wastewater. The discharge of these treated water is also harmful to the environment. There will be some pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

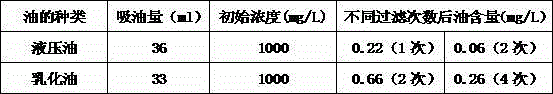

The invention relates to a process for preparing a porous functional ceramic material. The process comprises the following steps: 1) activating treatment of the porous ceramic material, namely soaking the porous ceramic material into a mixed solution of a dilute acid and hydrogen peroxide, of which the concentration is 0.1-15%, placing for 0.1-2 hours under the condition at 20-90 DEG C, and then drying for 10-120 minutes under the condition at 100-200 DEG C; 2) preparation of mother liquor, namely taking 1-50ml of silane coupling agent to 100ml of absolute ethyl alcohol, and then adding 1-10% of water and 0.1-2ml of acetic acid (HAC), placing for 0.1-3 hours at 20-80 DEG C; and 3) surface modification reaction. The porous functional ceramic material disclosed by the invention is simple in preparation technology, and the raw materials are subjected to modification treatment, so that the original hydrophily of the material is converted into strong hydrophobicity (lipophilicity), the water contact angle exceeds 120 degrees, the material has an ultra-strong adsorbing effect on oil, and has the characteristics of being easy for backwash after the oil is absorbed, and the prepared porous functional ceramic material can be widely applied to fine filtration treatment of an oily wastewater generated in the industries such as petrifaction, smelting and medicines.

Description

technical field [0001] The invention relates to a preparation process of a porous ceramic functional material, and the prepared porous ceramic functional material can be applied to the field of oil-water separation. Background technique [0002] At present, the treatment process of oily wastewater is basically completed by three steps: oil separation, coagulation and filtration. For the separation of emulsified oil, demulsification pretreatment is also required. The traditional degreasing method not only has cumbersome process, but also requires a large area of equipment and high cost. Moreover, due to the low degreasing rate, a certain amount of oil will remain in the treated oily wastewater. The discharge of these treated water is also harmful to the environment. There will be some pollution. As the country pays more and more attention to environmental issues, the country's sewage discharge standards have also been improved accordingly. Therefore, while putting forwa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B41/84

Inventor 郭磊奉向东

Owner 格丰科技材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com