Patents

Literature

165results about How to "Easy to backwash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

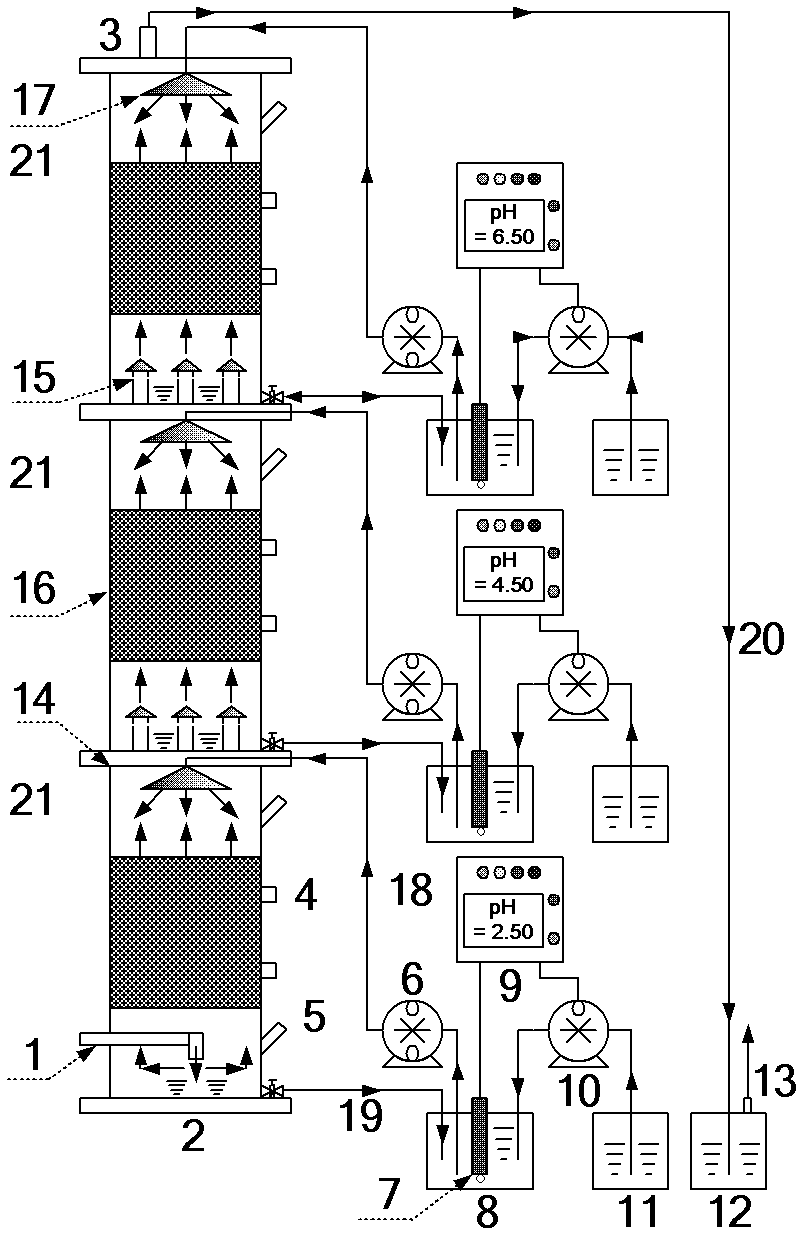

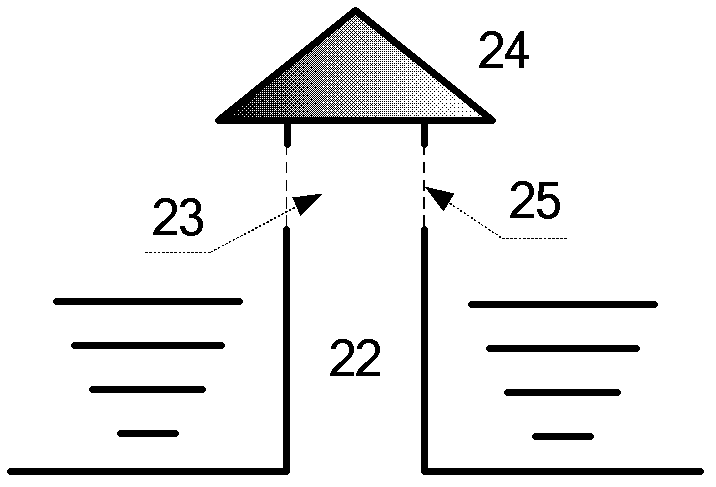

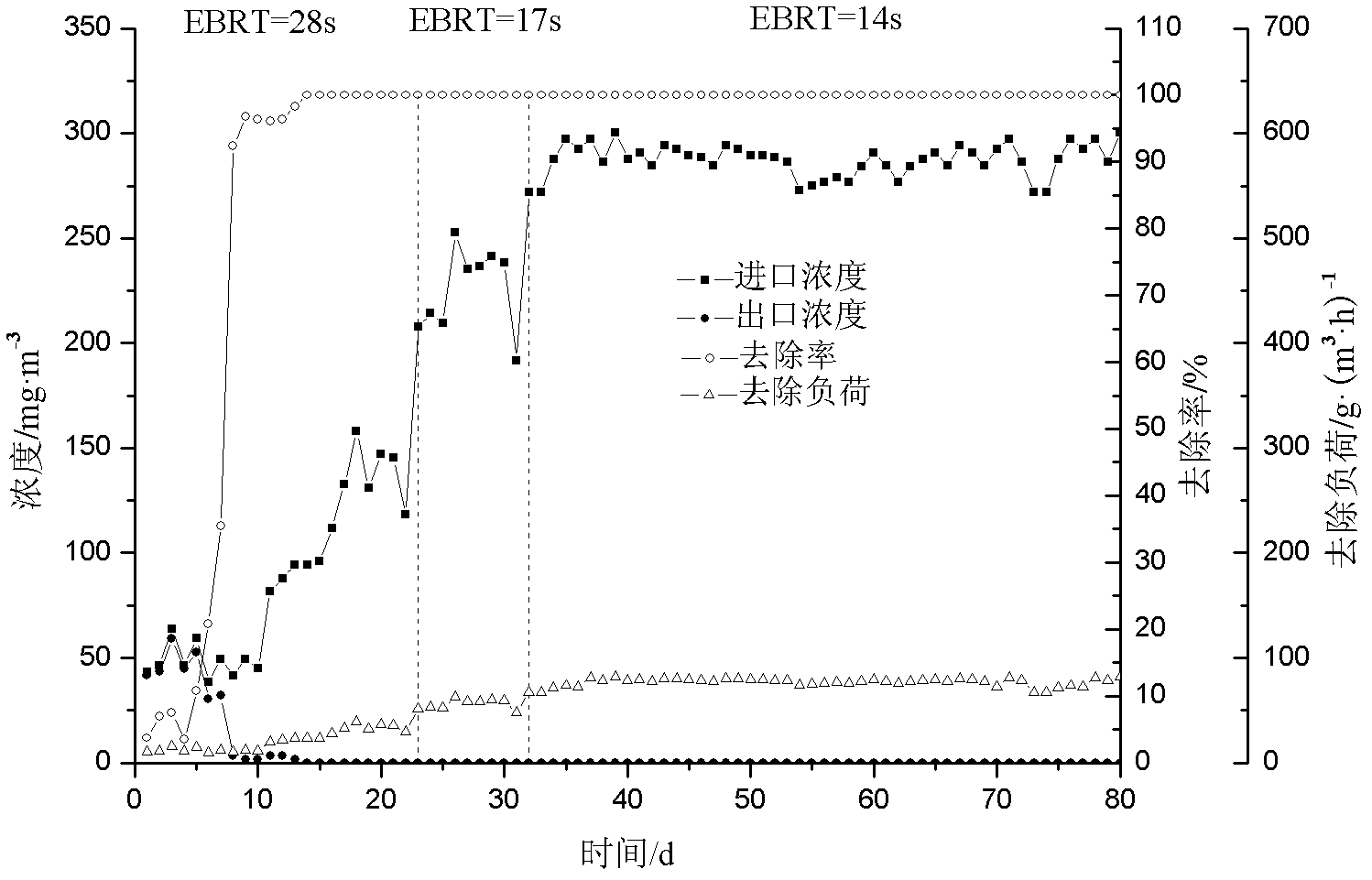

A method for treating waste gas with a biological trickling filter tower and its special device

InactiveCN102284245AImprove blockageEven contactDispersed particle separationAir quality improvementTemperature controlTrickling filter

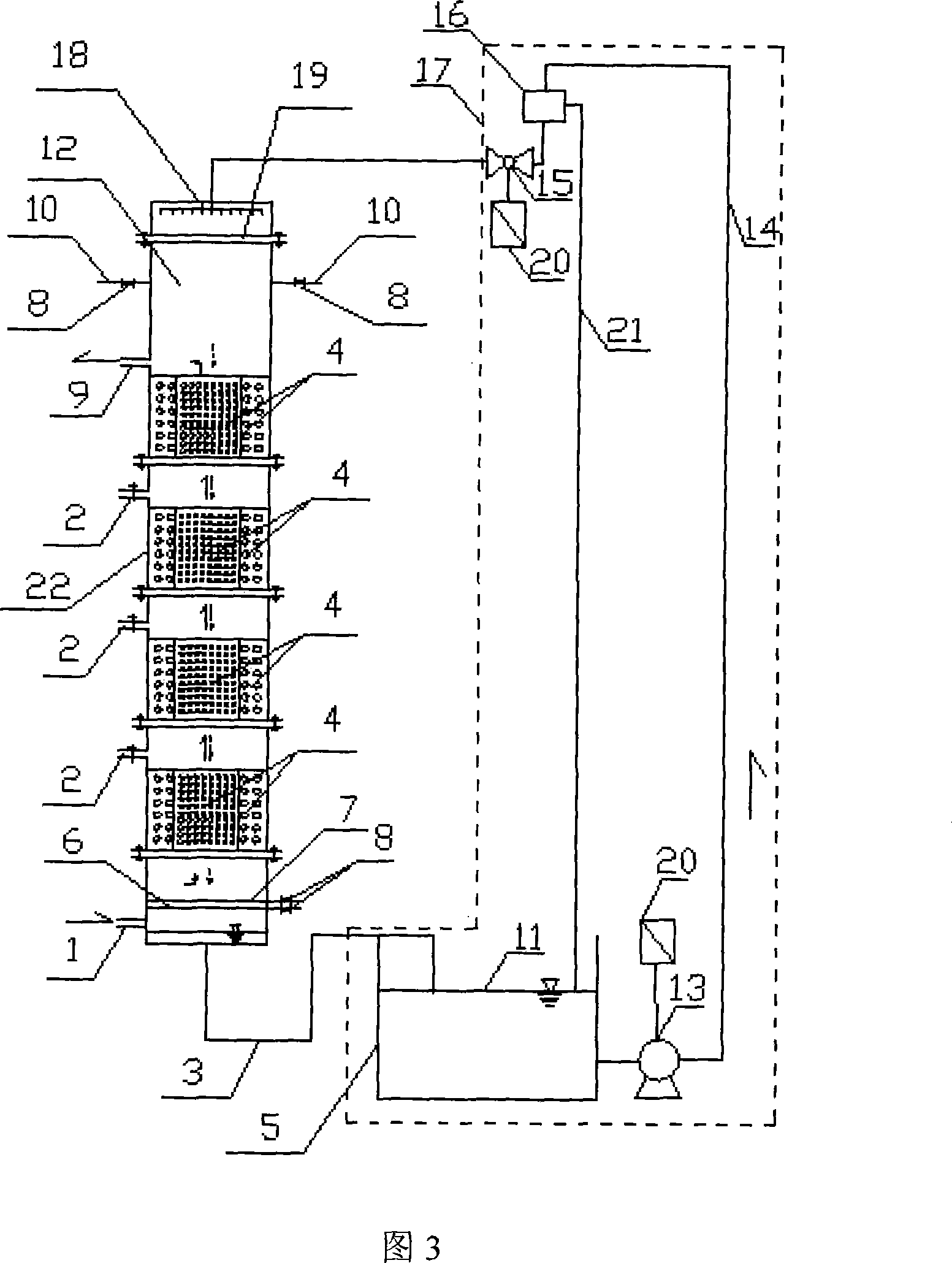

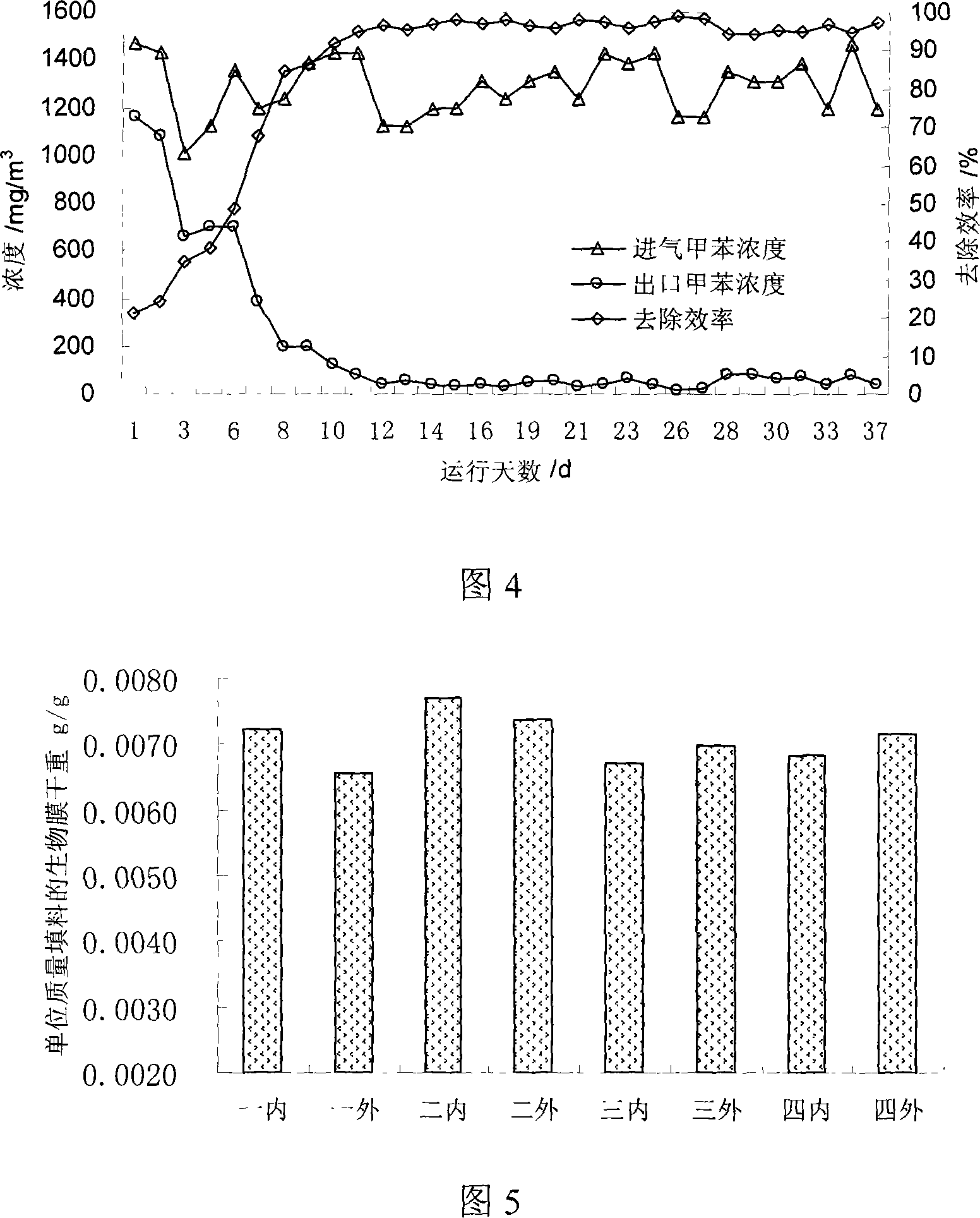

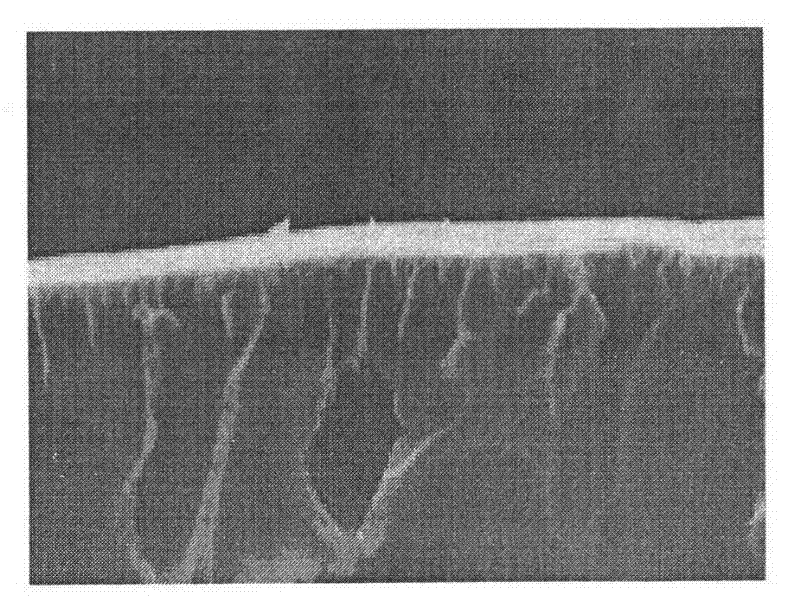

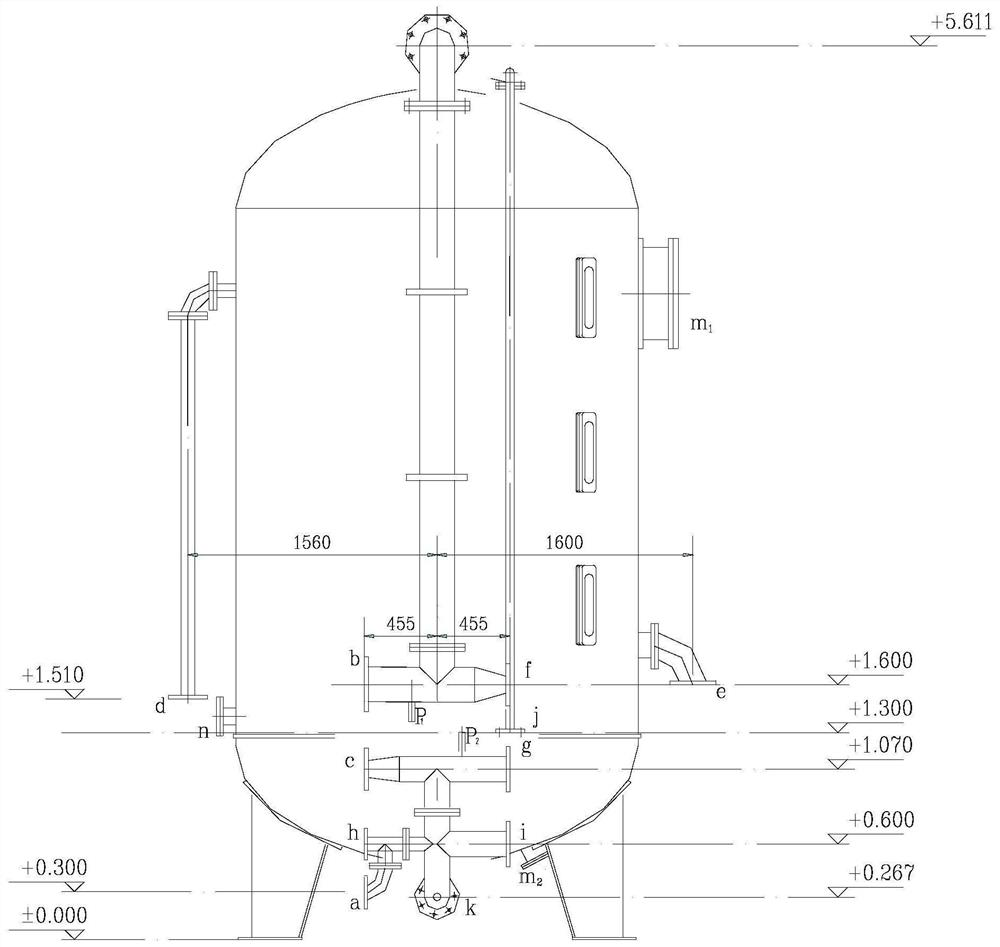

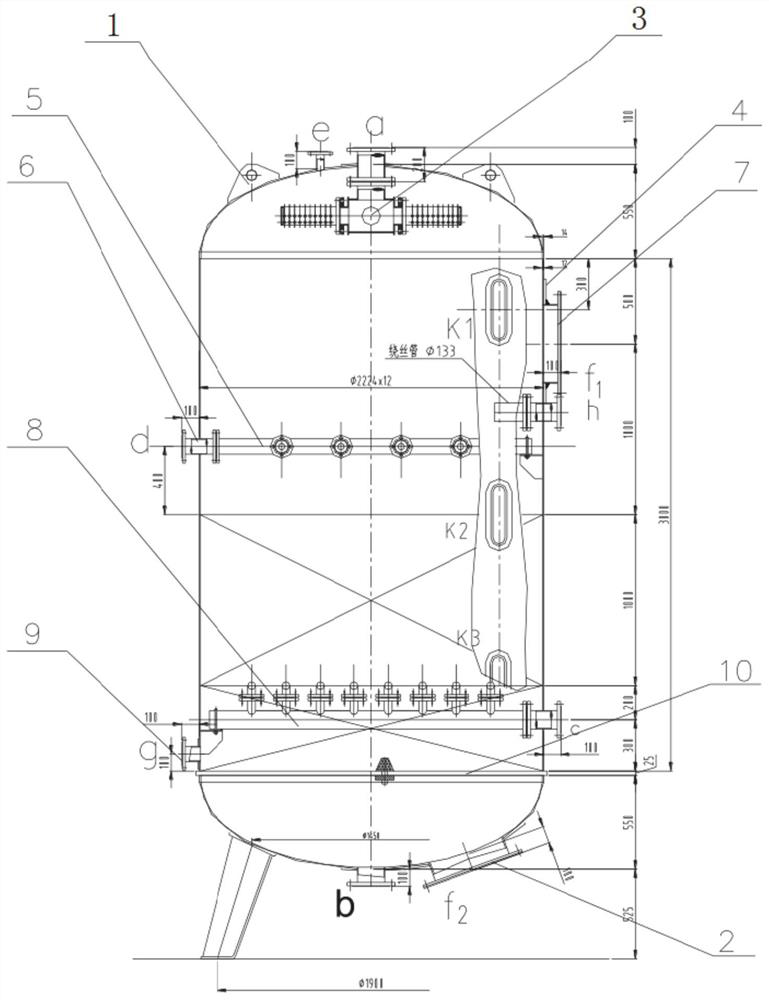

The invention discloses a method for treating waste gas with a biological trickling filter tower: the waste gas is passed through the bottom of the biological trickling filter tower, treated by the biological trickling filter tower, and the treated waste gas is discharged from the top, and the biological trickling filter tower is composed of The bottom of the tower with exhaust gas inlet, the tower body, and the top of the tower equipped with exhaust gas outlet are composed. The tower body is composed of several biological treatment units stacked from bottom to top, and the biological treatment units on adjacent layers are arranged There is a liquid interlayer, and the air vents for the adjacent layers are arranged on the liquid interlayer, and each layer of biological treatment units is independently equipped with a nutrient solution spray system and a temperature control device from top to bottom. Biological packing layer and nutrient solution receiving pool; the invention increases the processing load of the unit packing; improves the plugging problem of the packing layer, avoids the occurrence of channeling phenomenon, and has uniform and sufficient gas-liquid contact; packing replacement and backwashing are more convenient; the process Economical, suitable for the purification treatment of complex volatile organic mixed pollutants.

Owner:ZHEJIANG UNIV OF TECH

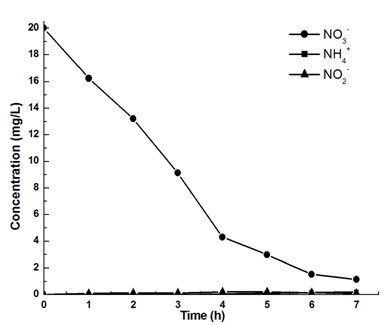

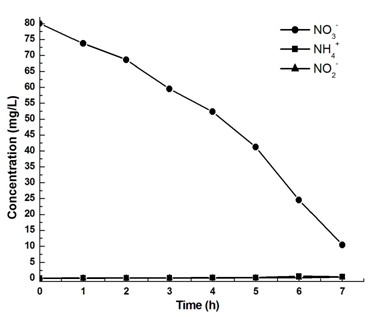

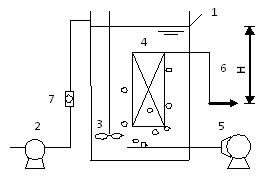

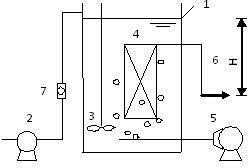

Compound three-dimensional electrode reactor and application thereof in treatment of nitrogenous organic wastewater

InactiveCN102020342AIncreased Joint Processing CapabilitiesLow stratificationWater/sewage treatmentIridiumPolyvinyl alcohol

The invention belongs to the technical field of environmental engineering, and relates to a device for treating wastewater, in particular to a three-dimensional electrode reactor which can effectively degrade nitrogenous organic wastewater and a treating process thereof. The main electrodes of the reactor respectively consist of two copper-zinc alloy electrodes and a titanium-iridium-platinum steady-state anode; active carbon is filled between the main electrodes; a part of active carbon is made into insulated particles through coating polyvinyl alcohol gel; and the proportion of the insulated active carbon particles to conductive active carbon particles is between 1: 6 and 6: 1. After a certain voltage is applied, the cathode undergoes nitrate reduction reaction, and the anode oxidizes ammonia nitrogen into nitrogen and mineralizes or converts COD into a simple organic matter. The existence of the filler can effectively strengthen the current efficiency of the reactor, reduce the energy consumption and improve the mass transfer efficiency; and therefore, the invention provides wastewater denitrification device and process with high current efficiency, simple operation, and capabilities of efficiently removing nitrate, ammonia nitrogen and COD and keeping energy consumption at an acceptable level.

Owner:NANJING UNIV

Dynamic membrane automatic water flow-out solid-liquid separation method applicable to domestic sewage treatment

ActiveCN102616986ACompact structureReduce energy consumptionMultistage water/sewage treatmentActivated sludgeWater flow

The invention provides a dynamic membrane automatic water flow-out solid-liquid separation method applicable to domestic sewage treatment. The method includes: adding powder particles with fine water permeable performance into activated sludge to form biological intensified powder mixed liquid to structurally improve the activated sludge; combining with the dynamic membrane separation technique to greatly improve the filtering capacity and water permeability of dynamic membrane filter cakes; performing solid-liquid separation of discharged water by allowing a dynamic membrane component to be driven by a water head having lower fixed gravity action and formed by liquid level waterhead between the upper liquid level of the immersed dynamic membrane component in a reaction device and a wateroutlet, stably controlling the unit area membrane filter flux of the dynamic membrane component to be more than 20-60L / m2h and the continuous operating time to be longer than 120h without action of external power; and allowing the dynamic membrane to completely shed with the air backwashing time being 1min-2min and the air inlet pressure being 9.8-49kPa. The dynamic membrane component does not need to be chemically cleaned regularly, and control and operation of the method can be automatically controlled in the whole process. The dynamic membrane solid-liquid separation technique can realize automatic water flowing out under differential pressure of low-liquid-level waterhead, energy consumption is greatly reduced, operation process is simplified, and discharged water is high in quality.

Owner:TONGJI UNIV

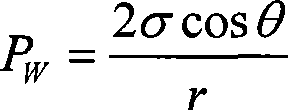

Method for carrying out oil dehydration by hydrophobic film

InactiveCN101530680ANot easy to polluteAchieve separationDewatering/demulsification with mechanical meansLiquid separationPetroleum productFilter media

The invention provides a method for removing free moisture or emulsified water by a hydrophobic film. In the method, the hydrophobic film is used as a filtering medium; petroleum products with higher content of water pass through the hydrophobic film under operating pressure which is not exceeding aqueous phase penetrating pressure by hydrophobic nature of the film; then moisture content is intercepted by the hydrophobic film, thus obtaining oil products with lower content of moisture. The method of the invention can be applicable to removal of moisture for many oil products avoiding of the effects of moisture content and temperature. The method of the invention is characterized in that removal of moisture content of the oil products can be carried out in real time in the process of oil delivery without adding any reagents, thus greatly reducing energy consumption, featuring in high dehydration rate and great operational flexibility; the whole manufacturing process is easy and large scale industrialized application of the method can be easily realized.

Owner:BEIJING UNIV OF CHEM TECH

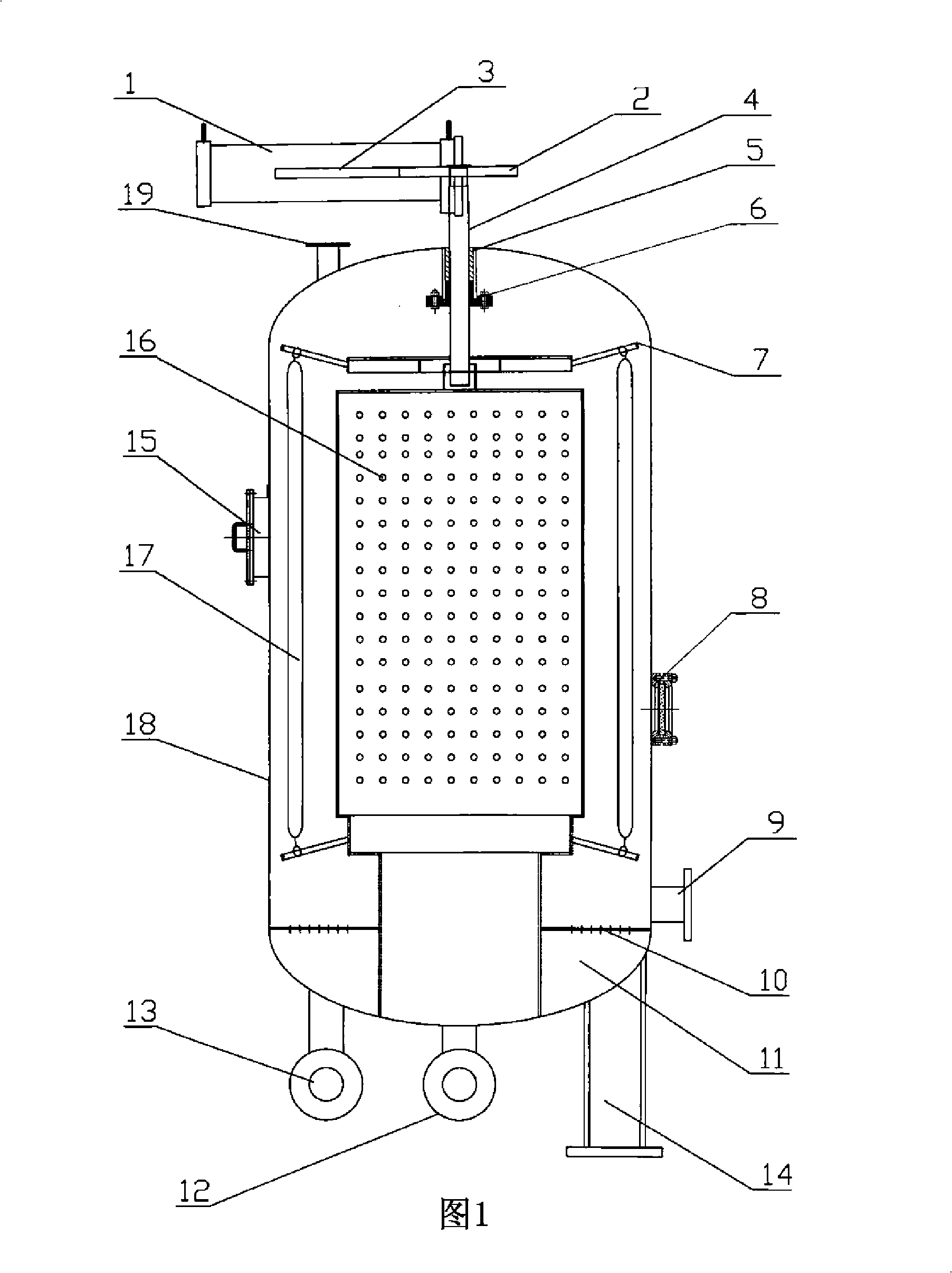

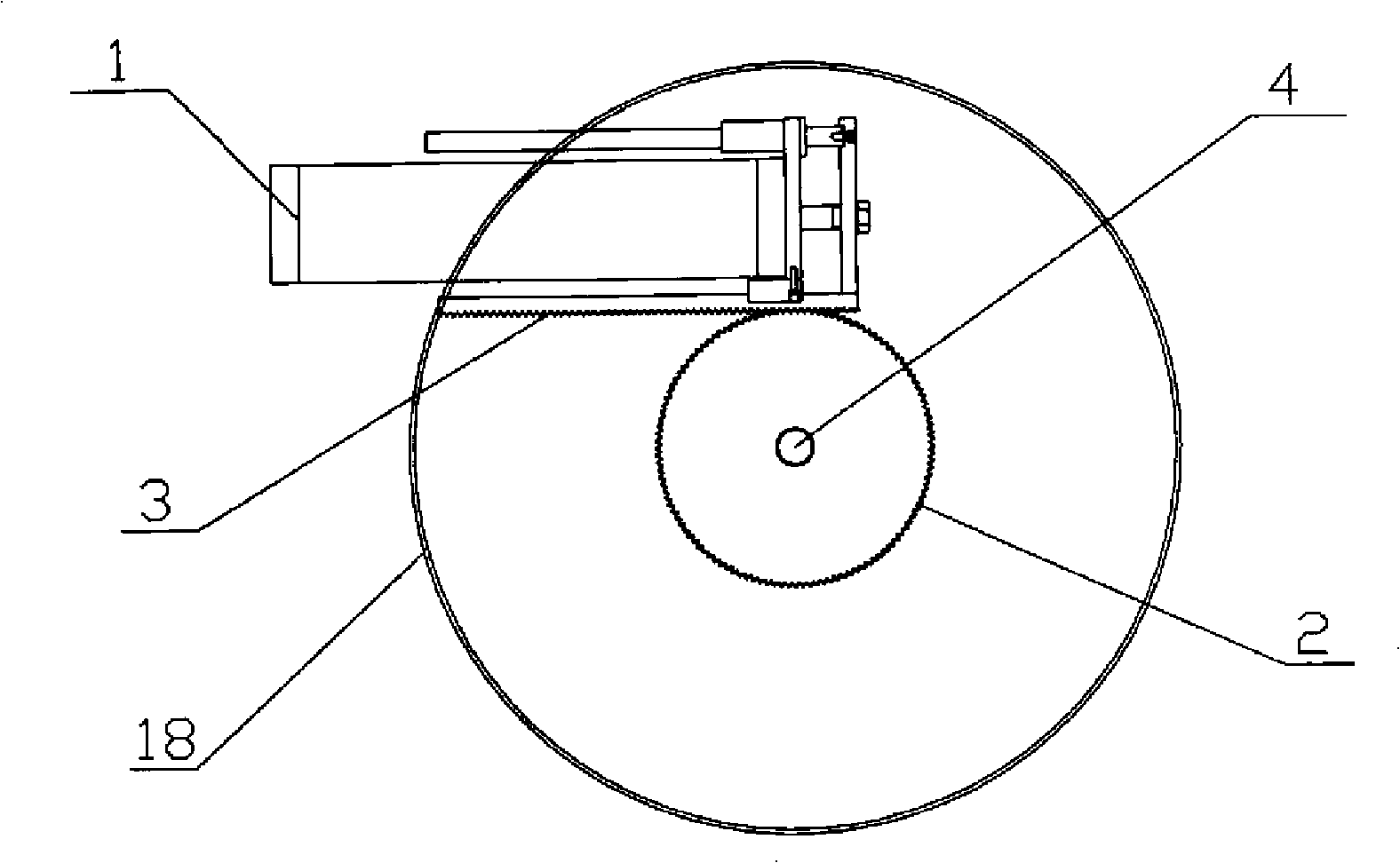

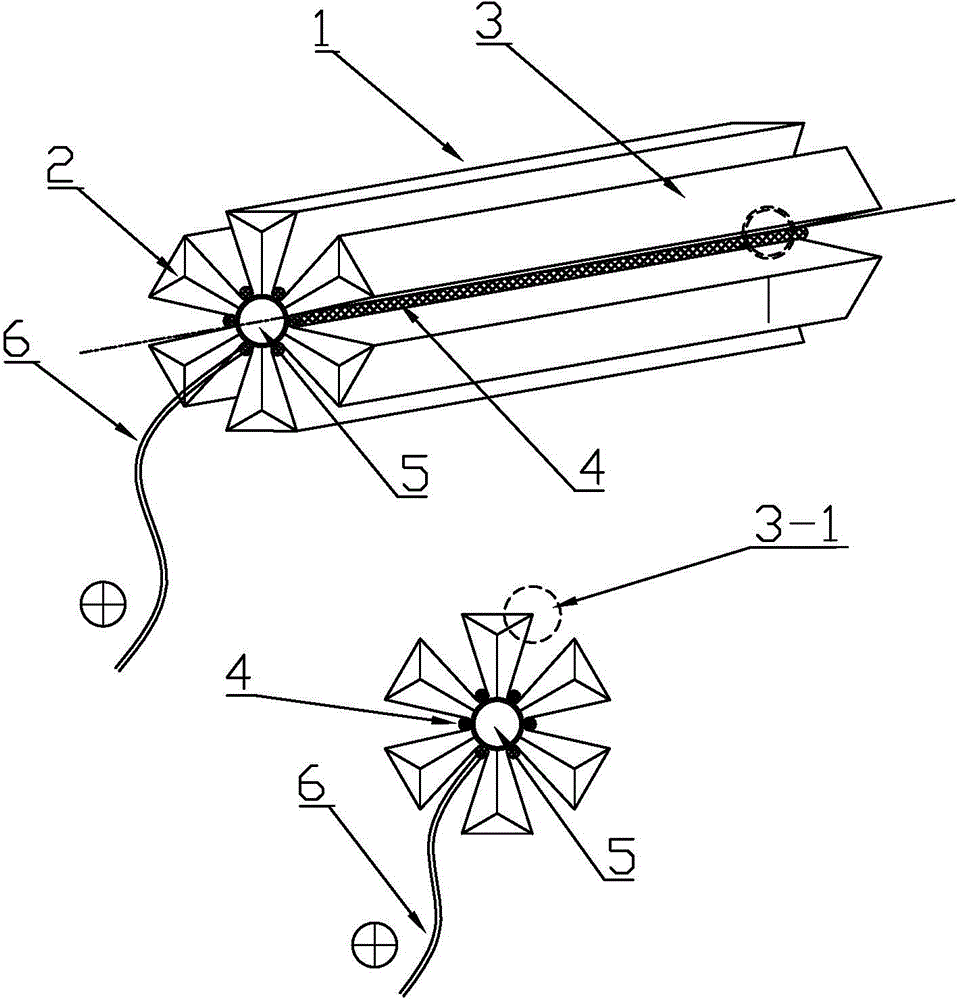

Biotrickling filter for treating volatile organic waste gas

InactiveCN101125280AEvenly distributedAvoid wall flowDispersed particle separationAir quality improvementVoltage dropEngineering

The present invention relates to a BTF used for dealing with the volatile waste gas, belonging to the field of treatment of the volatile waste gas, which aims at solving the problems that the prior BTF has uneven air flow distribution and biomass distribution, high center gas speed and voltage drop, and the prior BTF is easy to be blocked. The technic proposal is that: the volatile waste gas passes through an intake pipe (1) and then comes into a biofilter (22), and then being drained away by an exhaust pipe (9) after having the processes of degradation and purification; a nutrient solution (11) comes into the biofilter (22) through a nutrient solution shower (18) and a dropwise adding distributor device (19) having fixed quantities at fixed time; the present invention is characterized in that adopting a light and cheap packing (4) with different grain diameters, the biofilter (22) takes a homocentric column shape sleeve structure , the grain diameters of the filled packing (4) from the center to the edge are distributed from small to big, the centre area is filled with the packing (4) with small grain diameters, the ring area of the around close walls is filled with the packing (4) of big grain diameters. The present invention makes the distribution of the biomass in the biofilter even, thereby fully utilizing the useful space of the biofilter.

Owner:BEIJING UNIV OF TECH

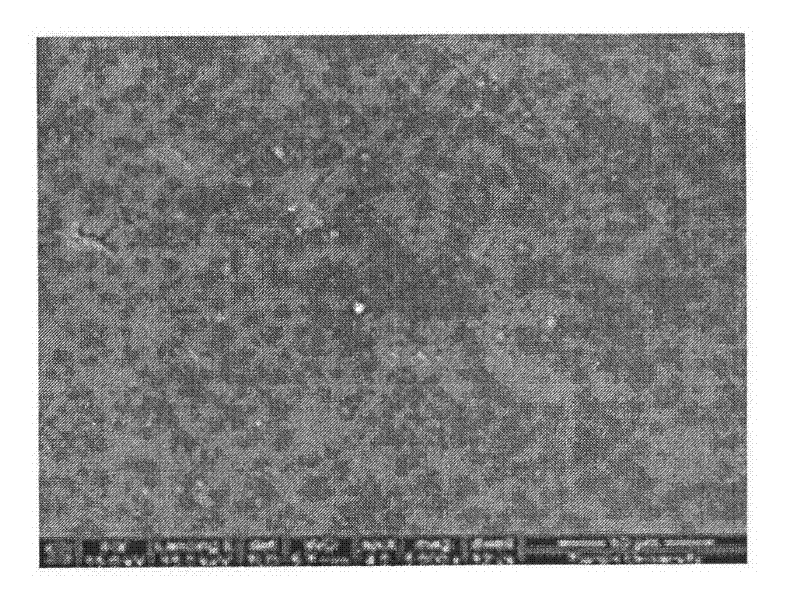

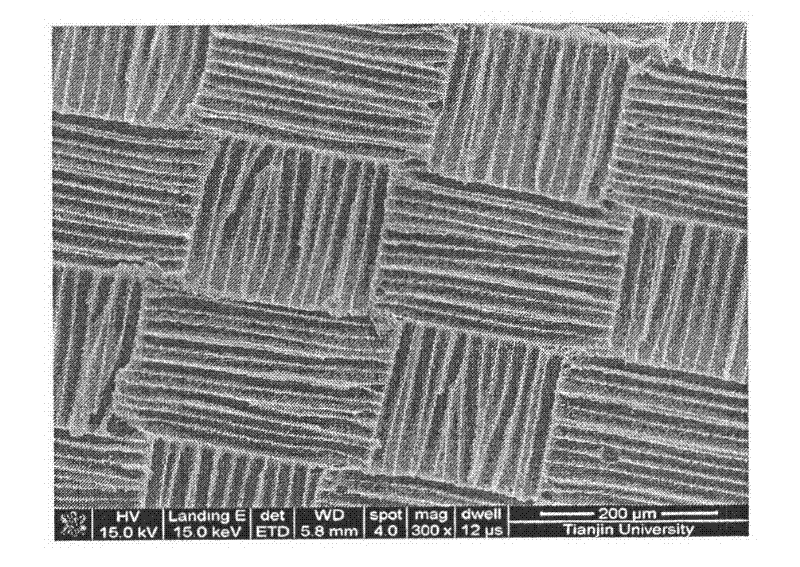

Non-woven fabric and woven fabric support ultra/micro-filtration membrane, preparation thereof and tubular composite filtration membrane

InactiveCN102371125AHigh porosityHigh strengthSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceFiltration

The invention relates to a non-woven fabric and woven fabric support ultra / micro-filtration membrane, a preparation method thereof and a tubular composite filtration membrane, belonging to the field of polymer microporous membranes. PVC (polyvinyl chloride) is taken as main raw materials for preparing membrane forming liquid, a primary support liquid membrane is prepared on non-woven fabric and is gelatinized in solidification liquid, and then is subjected to water-washing and extraction and finally dried to obtain the support membrane, and the support membrane is coated with a PE (polyethylene) tube for forming the tubular composite filtration membrane. The surface layer of the membrane is in the shape of a finger, one side in the membrane, which is close to a support layer, is in a high asymmetric pore structure with sponge-like pores, and the membrane is reversible in dry and wet performances, can hardly be blocked, has high bursting strength and excellent pollution resistance, and can be back-cleaned and regenerated easily; in addition, the pore diameter of the membrane is adjustable between 0.01 mu m and1.0 mu. The member is suitable for being used as membrane material for precision filtration, reclaimed water treatment, security filtration before RO (reverse osmosis), terminal precision filtration, direct drinking filtration of tap water, sewage treatment and liquid purification and filtration.

Owner:天津市宝钜净化设备工程有限公司

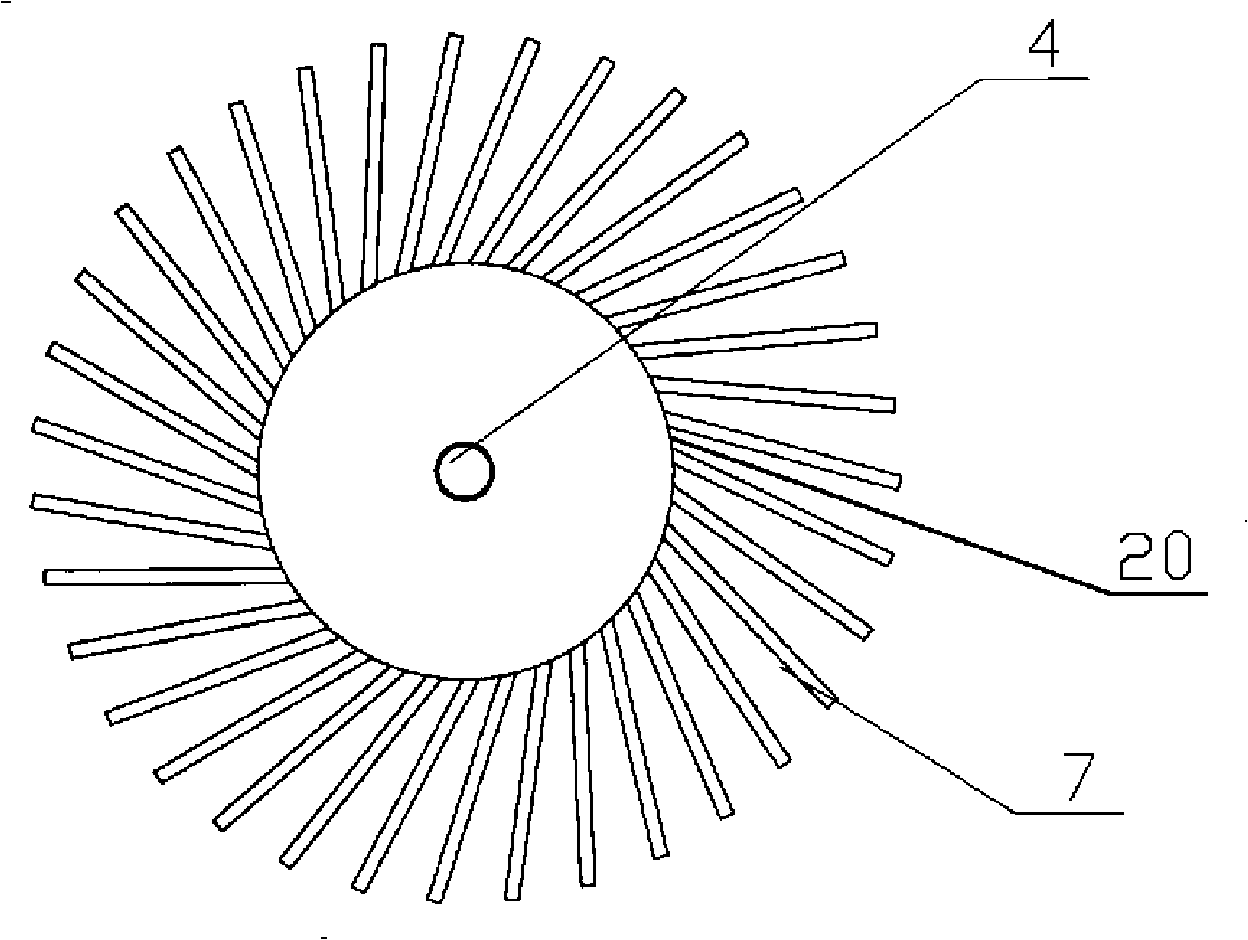

Twist system fiber filter

InactiveCN101249337AEasy to separateSimple structureStationary filtering element filtersFiberFiltration

A torsion type fiber filter includes a shell body, a fiber beam in the shell body and fiber beam supporting bodies, a water inlet pipe and a water outlet pipe are arranged on the shell body, the interior of the shell body is provided with at least one porous filter cylinder, one end part of each porous filter cylinder is connected with a transmission shaft, the transmission shaft penetrates out of the shell body and is connected with a torsion drive device by a transmission mechanism. The outside of the transmission shaft and the outlet end of the porous filter cylinder are respectively surrounded by a circle of fiber beam supporting body, the fiber beam supporting bodies include wire hanging rods which are evenly arranged in a horizontal radial pattern, and the fiber wires are evenly fastened between the two circles of fiber beam supporting bodies, so as to form a fiber beam filter layer which surrounds the outer wall of the porous filter cylinder. The filtration area of the torsion type fiber filter is the outer surface area of the porous filter cylinder, so as to eliminate the limitation of the diameter on the filtration area, greatly improve the filtration speed and reduce the area coverage.

Owner:郭建良

Dissolved air flotation-type pretreatment apparatus

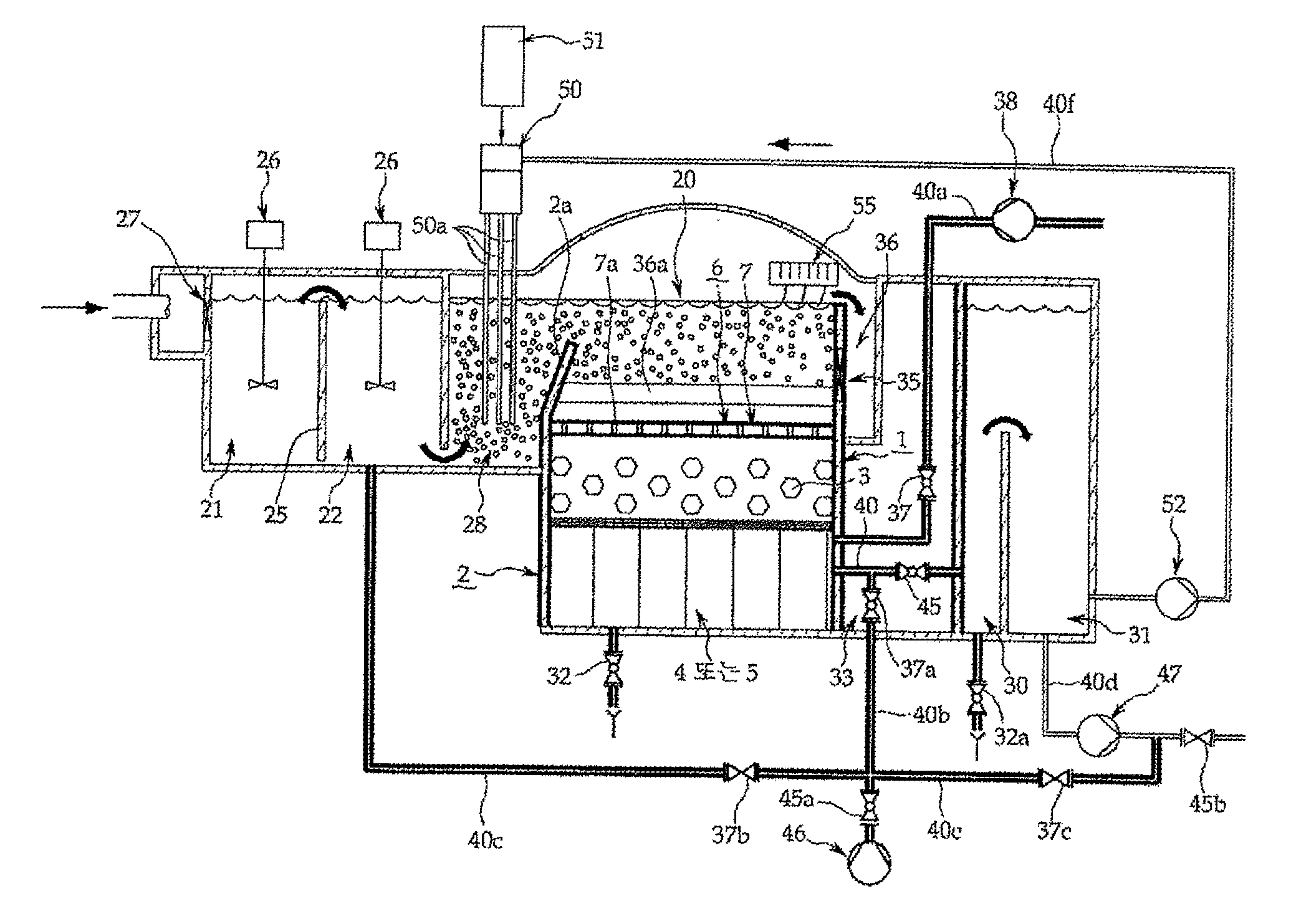

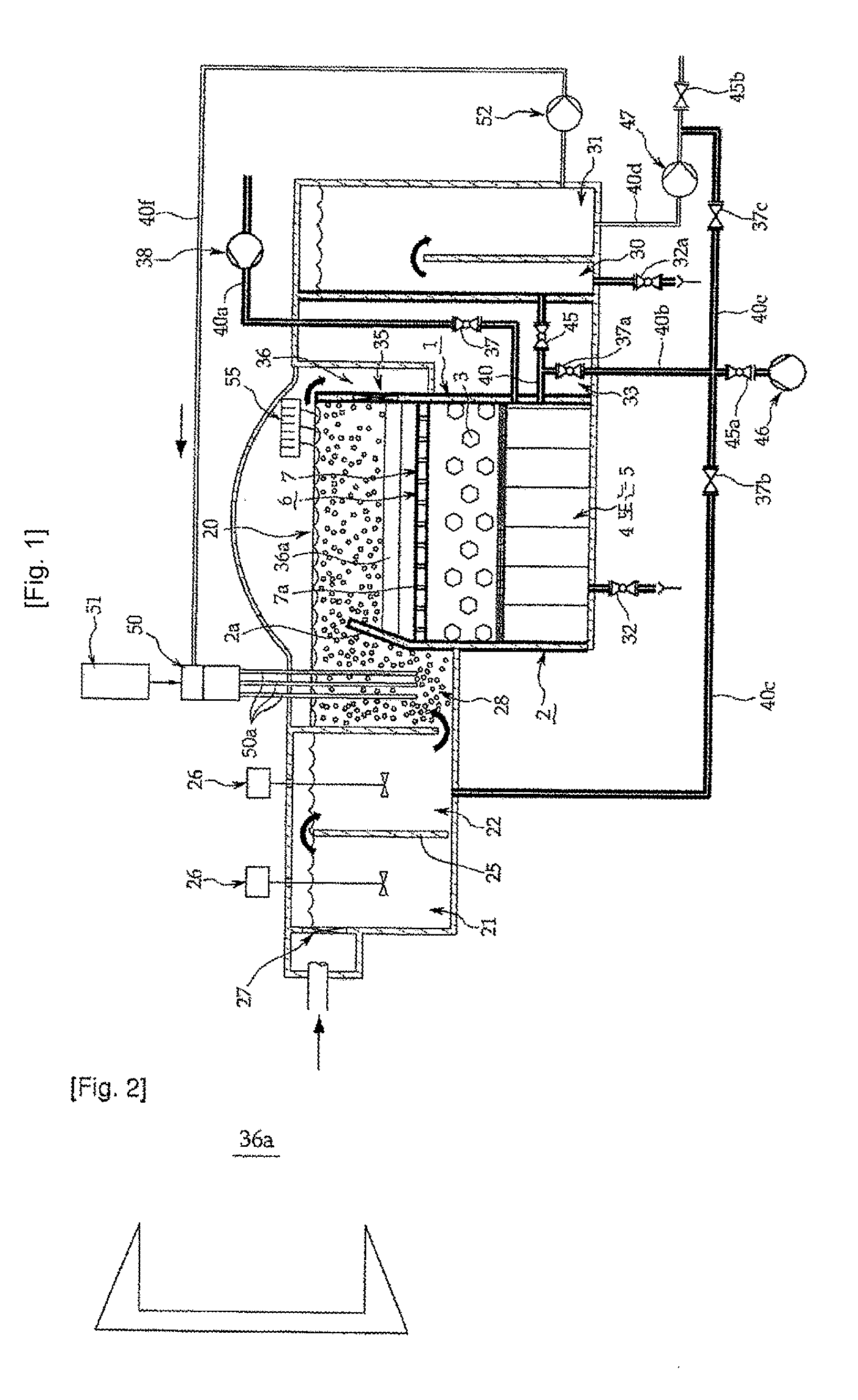

ActiveUS20140014562A1Improve reusabilityReduce operating expensesSeawater treatmentSpecific water treatment objectivesForeign matterSewage

Disclosed is a dissolved air floatation (DAF)-type pretreatment apparatus. The dissolved air floatation (DAF)-type pretreatment apparatus includes: a floatation tank for removing foreign objects of floating matter, turbid matter, or alga contained in raw water of seawater, sewage, or wastewater; a filtering compartment part provided in the floatation tank and having one surface and the other surface which are partially opened to allow treatment water obtained by primarily removing floating matter from raw water to pass therethrough; and a plurality of filtering balls confined in the filtering compartment part and including a fibrous or spongy material to filter turbid matter or floating or suspended solids remaining in the treatment water introduced to the interior of the filtering compartment part.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

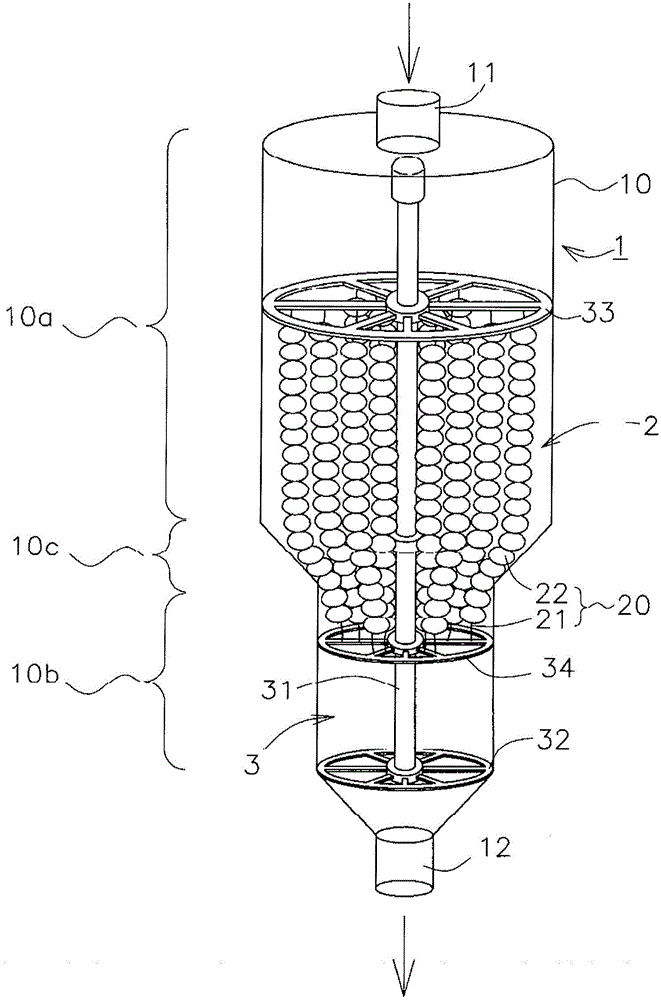

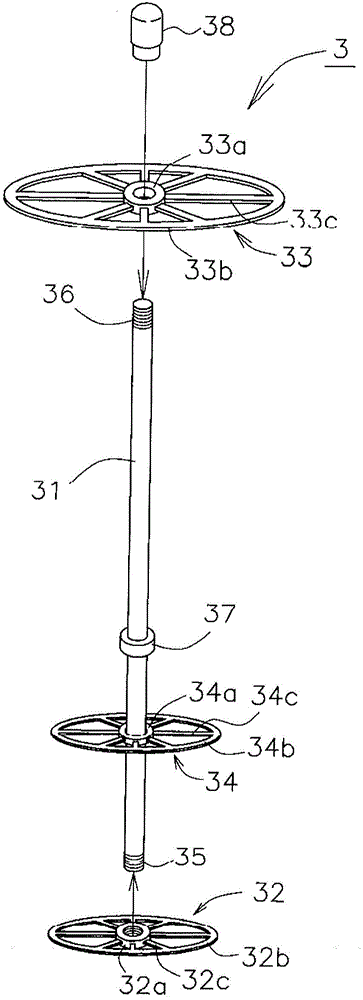

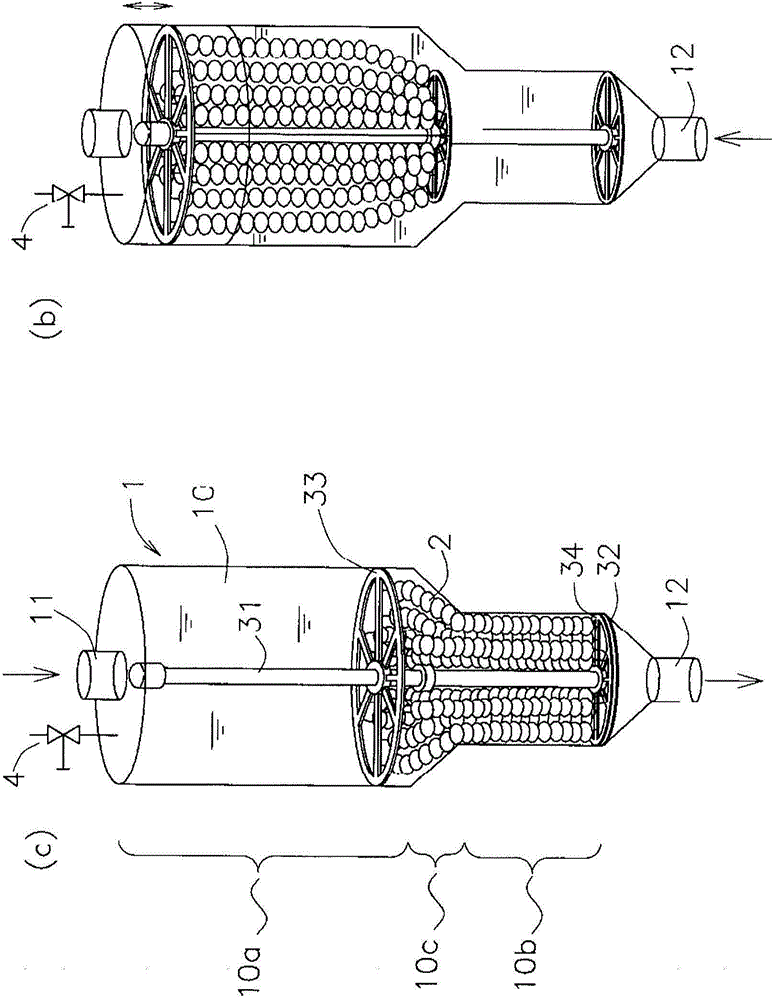

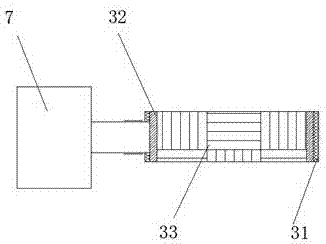

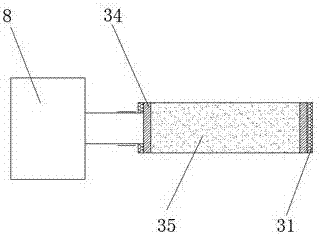

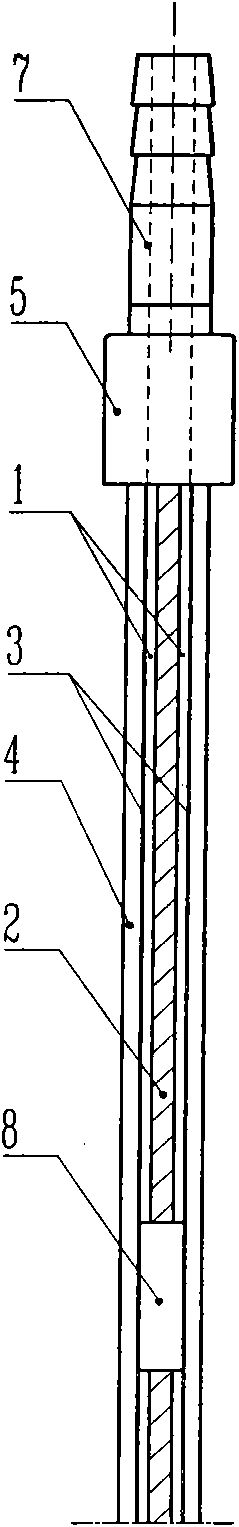

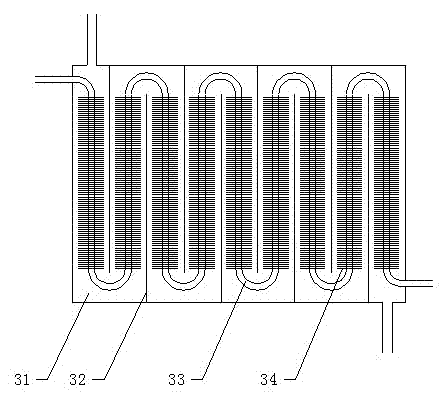

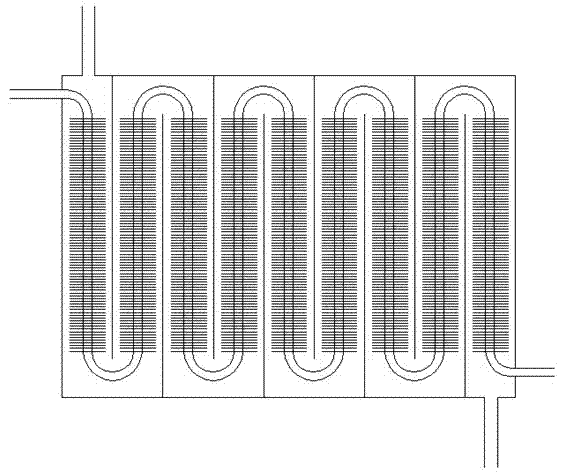

Filter device and backwashing method of filter materials

InactiveCN104056474ABackwashing is easy and cheapRegular and easy to vibrateLoose filtering material filtersGravity filtersEngineeringFilter material

The invention provides a filter device capable of obtaining adequate backwashing effect with a little backwashing water, and provides a backwashing method employing the filter device. The filter device comprises a base end side porous plate (32) capable of being arranged near an opening portion (12) at a downstream side of a shell (1), a pillar (31) supported to the base end side porous plate, an upstream side porous plate (33) supported to the pillar in a flange shape and capable of moving freely along the axis direction of the pillar, and a downstream side porous plate (34) configured between the base end side porous plate and the upstream side porous plate, the axis is configured to be along the water-conveying direction in the shell, the downstream side porous plate is supported to the pillar in a flange shape and can move freely along the axis direction of the pillar, one ends of core wires of filter materials are connected with the upstream side porous plate, and the other ends of the core wires are connected with the downstream side porous plate.

Owner:T B R

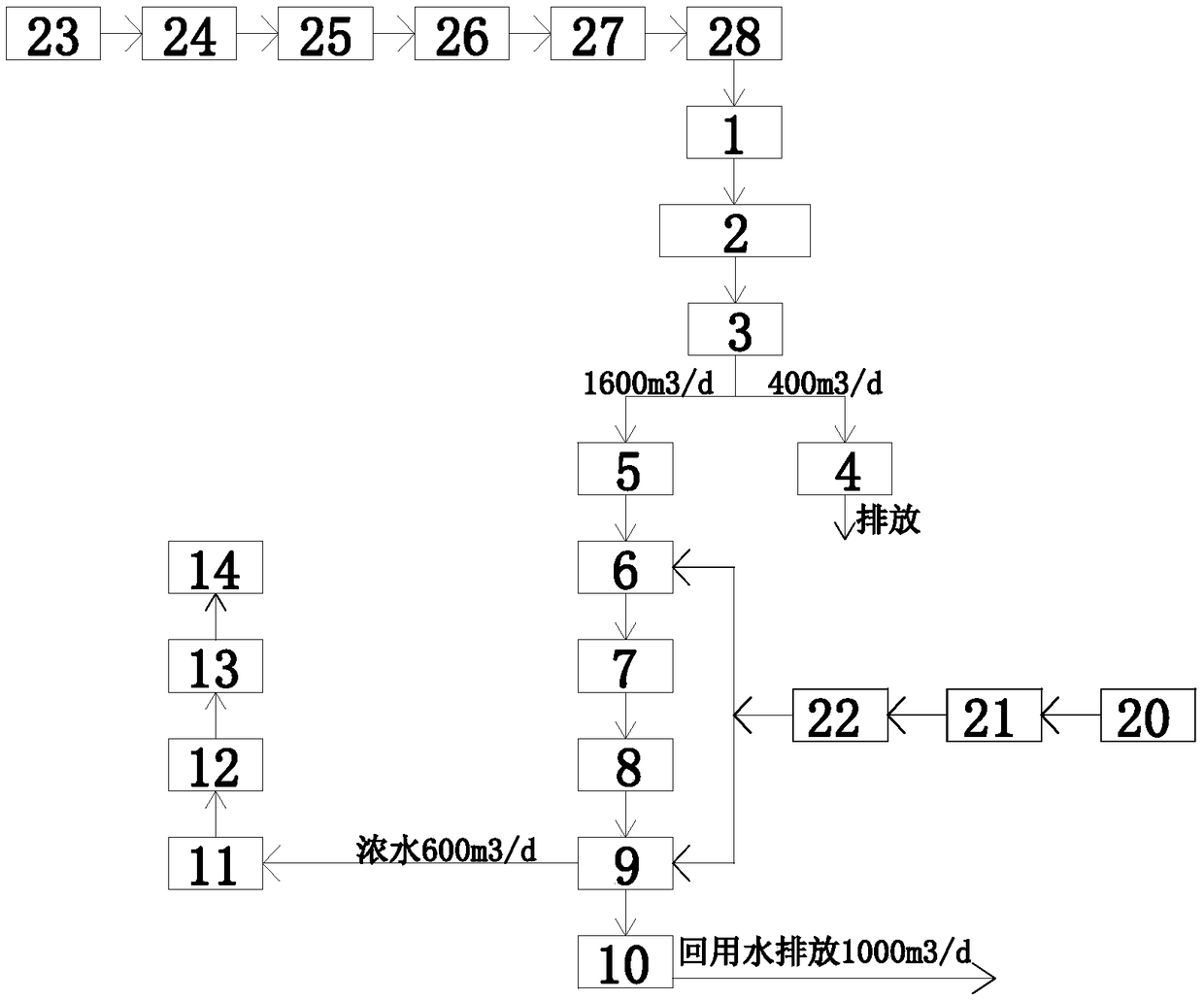

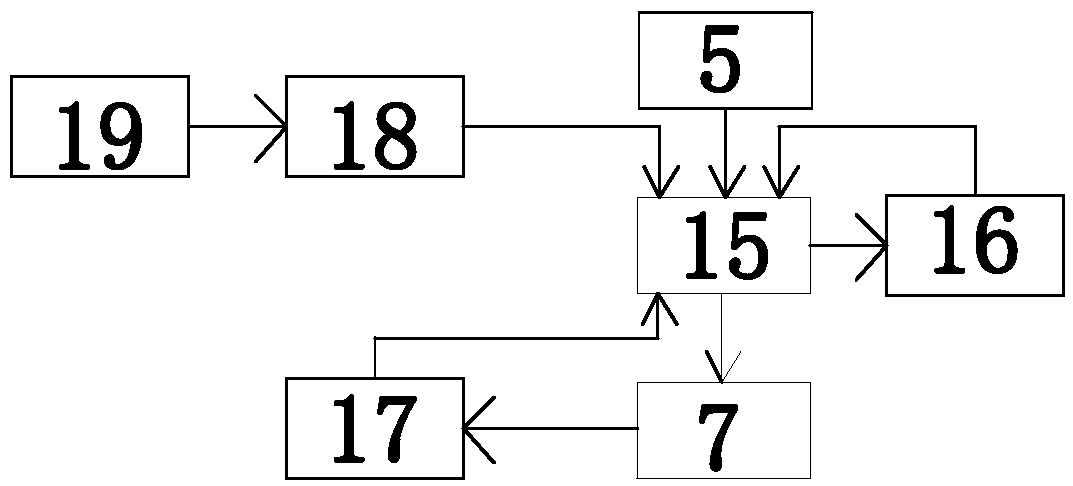

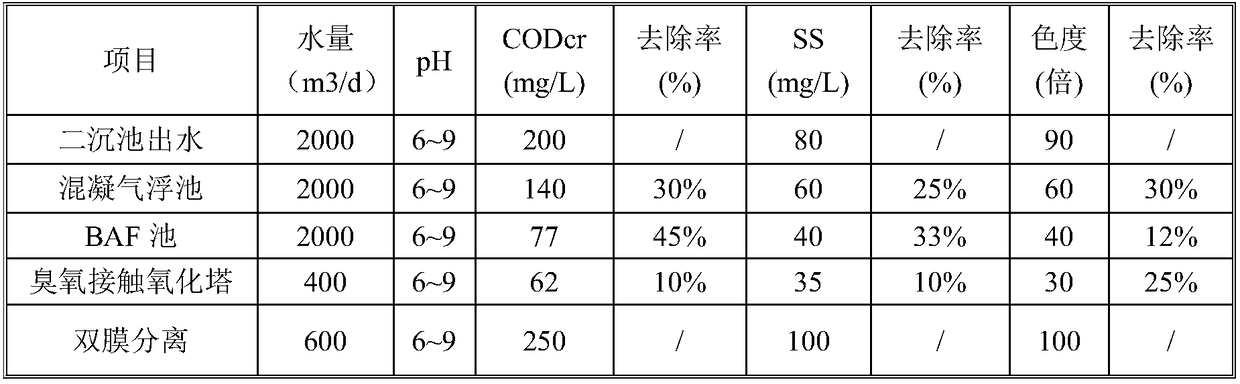

Printing and dyeing wastewater deep treatment system and printing and dyeing wastewater deep treatment method

PendingCN108793642AEasy to handleImprove processing efficiencyWater treatment compoundsTreatment involving filtrationSludgeWater production

The invention discloses a printing and dyeing wastewater deep treatment system and a printing and dyeing wastewater deep treatment method. The system includes a front treatment unit, a deep treatmentunit and a recycling treatment unit that are connected through a pipeline, wherein the deep treatment unit includes a coagulation floatation tank, a biological aerated filter, a clear water tank and an ozone contact oxidizing tower which are connected sequentially through a pipeline; the recycling treatment unit includes a quartz sand filter connected with the clear water tank through a pipeline;the quartz sand filter is connected with an ultrafiltration membrane module, an ultrafiltration water production tank, a security filter and a reverse osmosis device sequentially through a pipeline; the reverse osmosis device includes an RO water production tank and an RO concentrated water tank respectively through a pipeline; the RO concentrated water tank is sequentially connected with a Fenton reactor, a settling tank and a drain tank through a pipeline; the settling tank and the coagulation floatation tank are further connected with a sludge tank. The system and the method have the characteristic of greatly improving the wastewater treatment effect.

Owner:上一环保科技(杭州)有限公司 +1

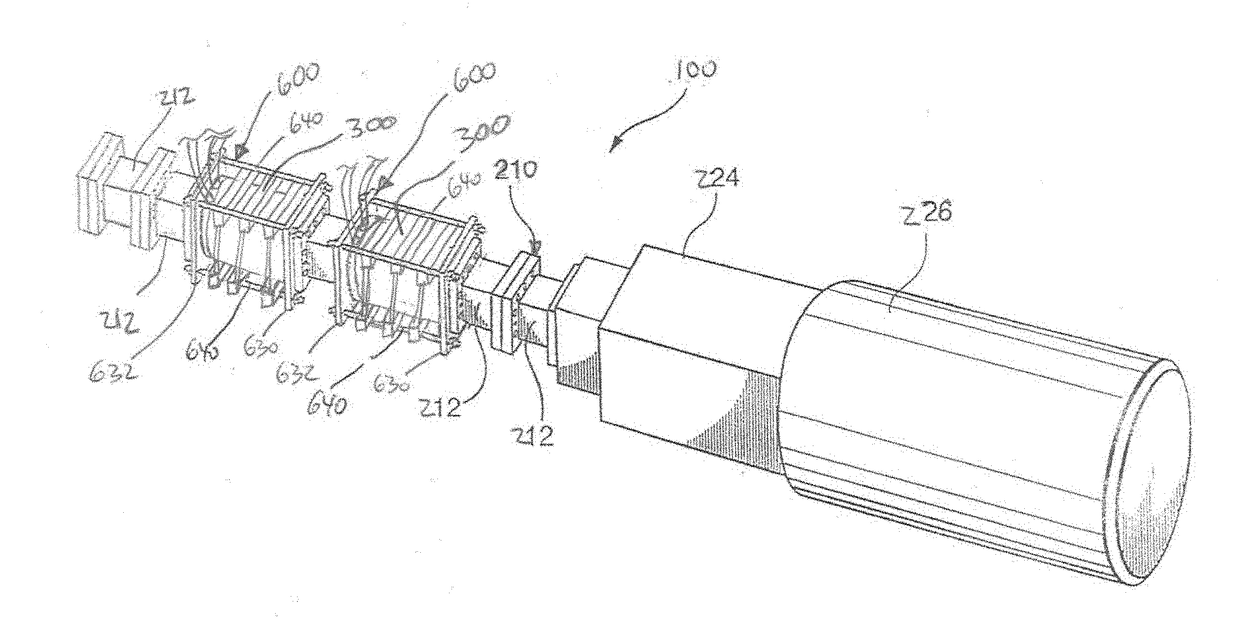

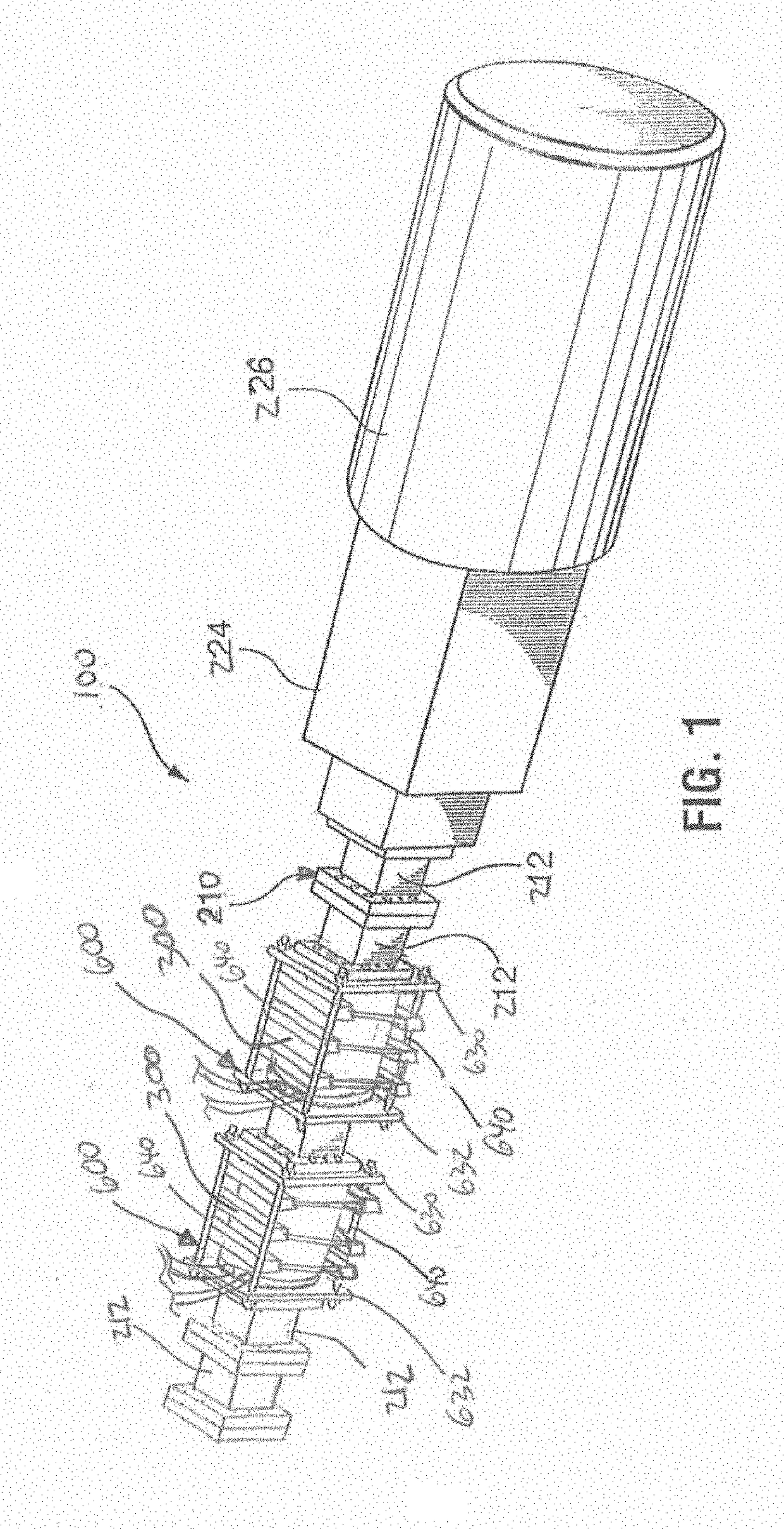

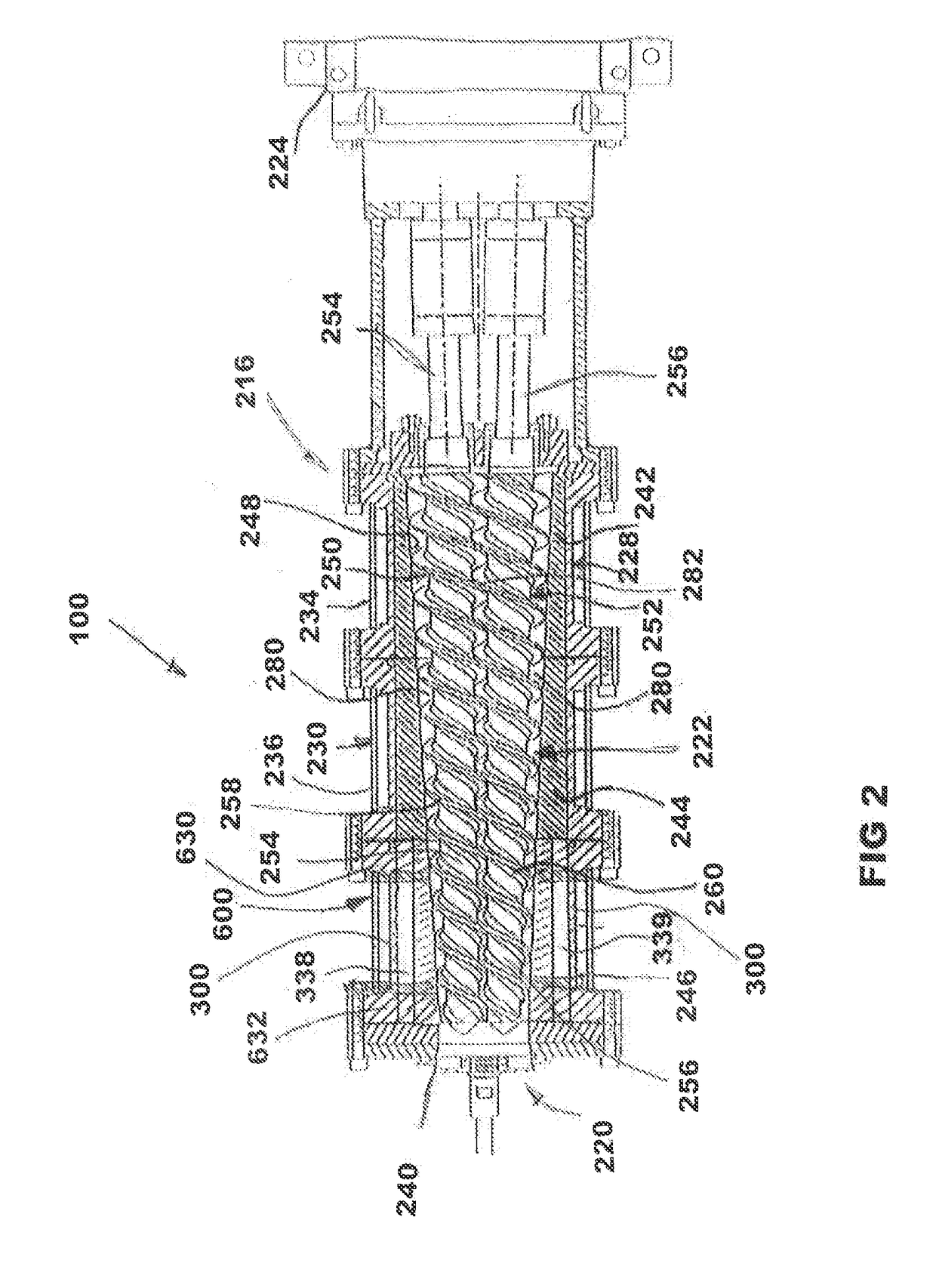

Filter for extruder press

ActiveUS20170312658A1Improve operationEasy maintenanceFiltration separationPressesSolid contentWaste management

A solid / fluid separation module and press enables treatment of solids with enclosed fluids to generate a filtered mass having a solids content above 50%. A split filter module with first and second filter blocks clamped together for forming barrel sections or filtering sections is disclosed for use in a solid / fluid separating device including a barrel and a conveyor screw in the barrel. The split filter module permits replacement, maintenance, or repair of the filter blocks without disassembly or the separating device, or removal of the conveyor screws.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Floor sewage filter device with good treatment effect

ActiveCN107313485AImprove sealingGuaranteed purification effectTreatment involving filtrationDomestic plumbingWater channelTherapeutic effect

The invention discloses a floor sewage filter device with good treatment effect, and belongs to the field of sewage filter devices. The floor sewage filter device with the good treatment effect comprises a purifying pipe, wherein the purifying pipe is fixedly connected with a buffer water pipe; the purifying pipe is mutually communicated with the buffer water pipe; the pipe diameter of the buffer water pipe is greater than the pipe diameter of the purifying pipe. According to the floor sewage filter device disclosed by the invention, the situations that when the flow is larger, a part of sewage enters the buffer water pipe, the buffer water pipe is in flow buffer, the sewage is enabled to stably enter the purifying pipe, and the sewage sequentially flows through a first overturn screen filter layer, a second overturn sponge filter layer and a third overturn filter membrane layer in the purifying pipe, so that sewage treatment is carried out can be realized; when the flow is smaller, an electromagnetic valve is used for controlling all filter layers to rotate by 290 to 320 degrees, flushing water enters the purifying pipe to carry out back flushing on the back surface of an isolated filter layer, a sewage draining electromagnetic valve is switched off to remove impurities, purifying effect is ensured, water channel pollution is effectively reduced, the sewage is not required to be transported to a sewage treatment plant by a long distance, and the resources are saved.

Owner:徐州腾盛新型建材有限公司

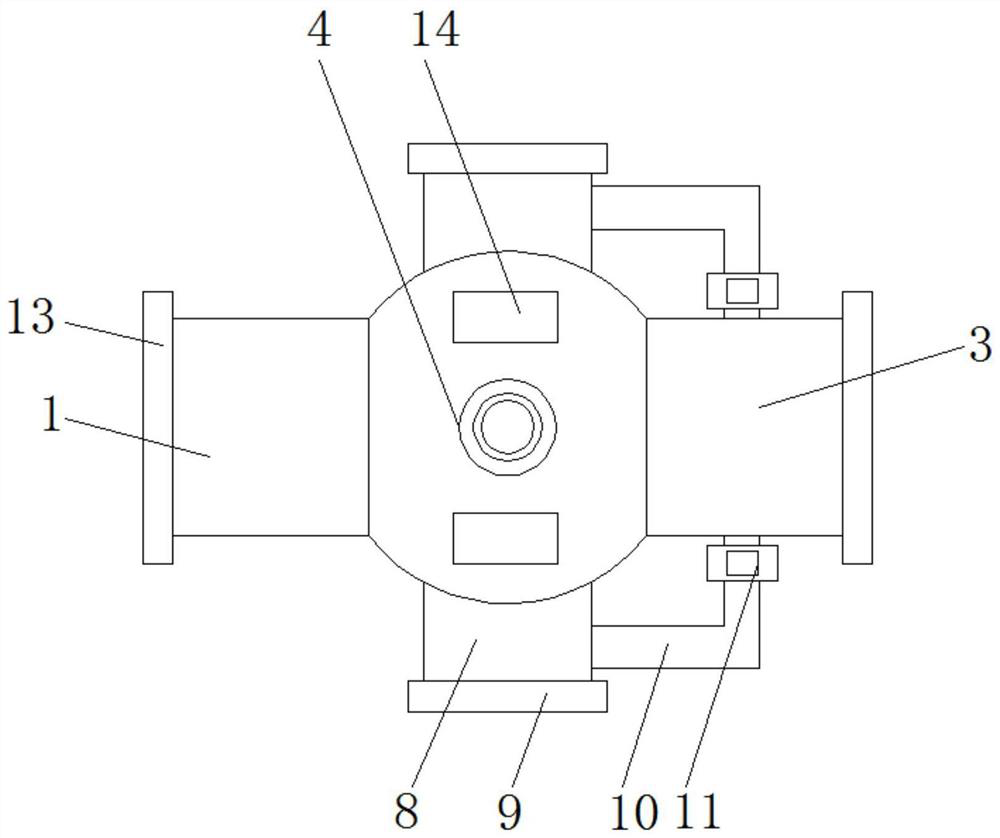

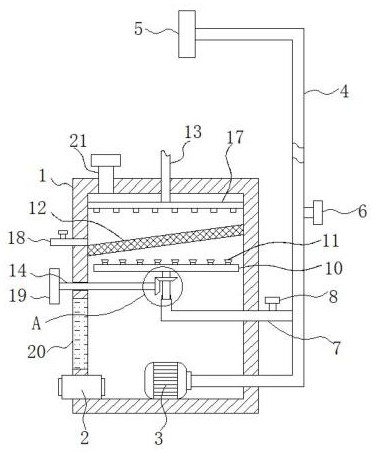

Sewage recycling and filtering device

InactiveCN112546689AEasy to backwashEasy to useStationary filtering element filtersWater dischargeElectric machine

The invention discloses a sewage recycling and filtering device, and belongs to the technical field of filtering devices. The device comprises a filter bin, a water inlet pipe is fixedly arranged on one side of the filter bin, a water discharge pipe is fixedly arranged on the other side of the filter bin, the top and the bottom of the filter bin are arc-shaped, a motor is fixed to the outer side of the filter bin, a rotating rod is fixedly installed at the output end of the motor and extends into the water discharge pipe, a first filter screen is fixed to the rotating rod, and baffles are fixed to the two ends of the first filter screen. Through the motor on the outer side of the filter screen, the angle between the rotating rod in the filter bin and the first filter screen can be driven to be adjusted, so that after the first filter screen is used for a long time, the orientation of the first filter screen can be changed, back washing is facilitated, the first filter screen in the device does not need to be disassembled and cleaned manually, and use is more convenient.

Owner:常州市大杰智能装备有限公司

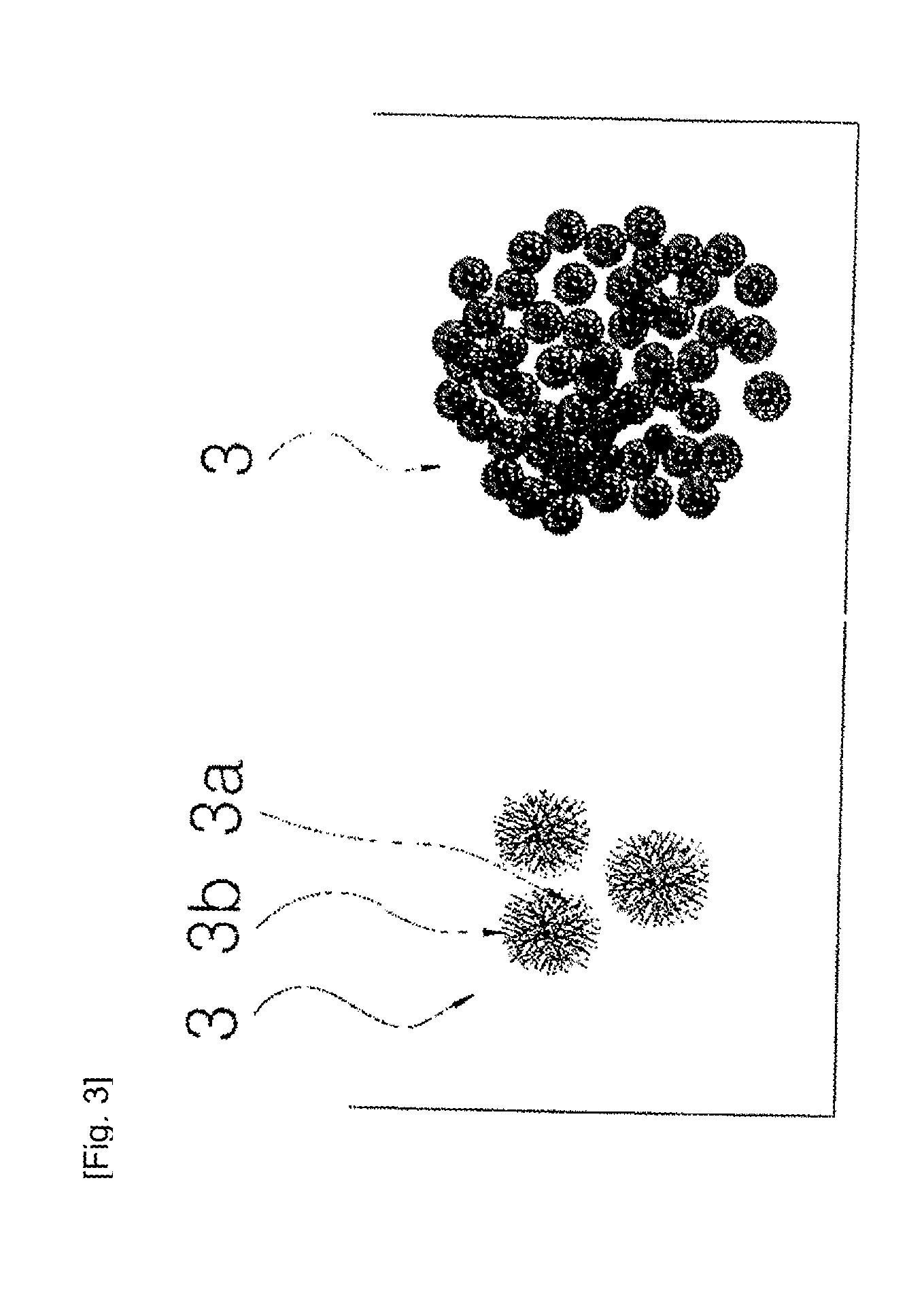

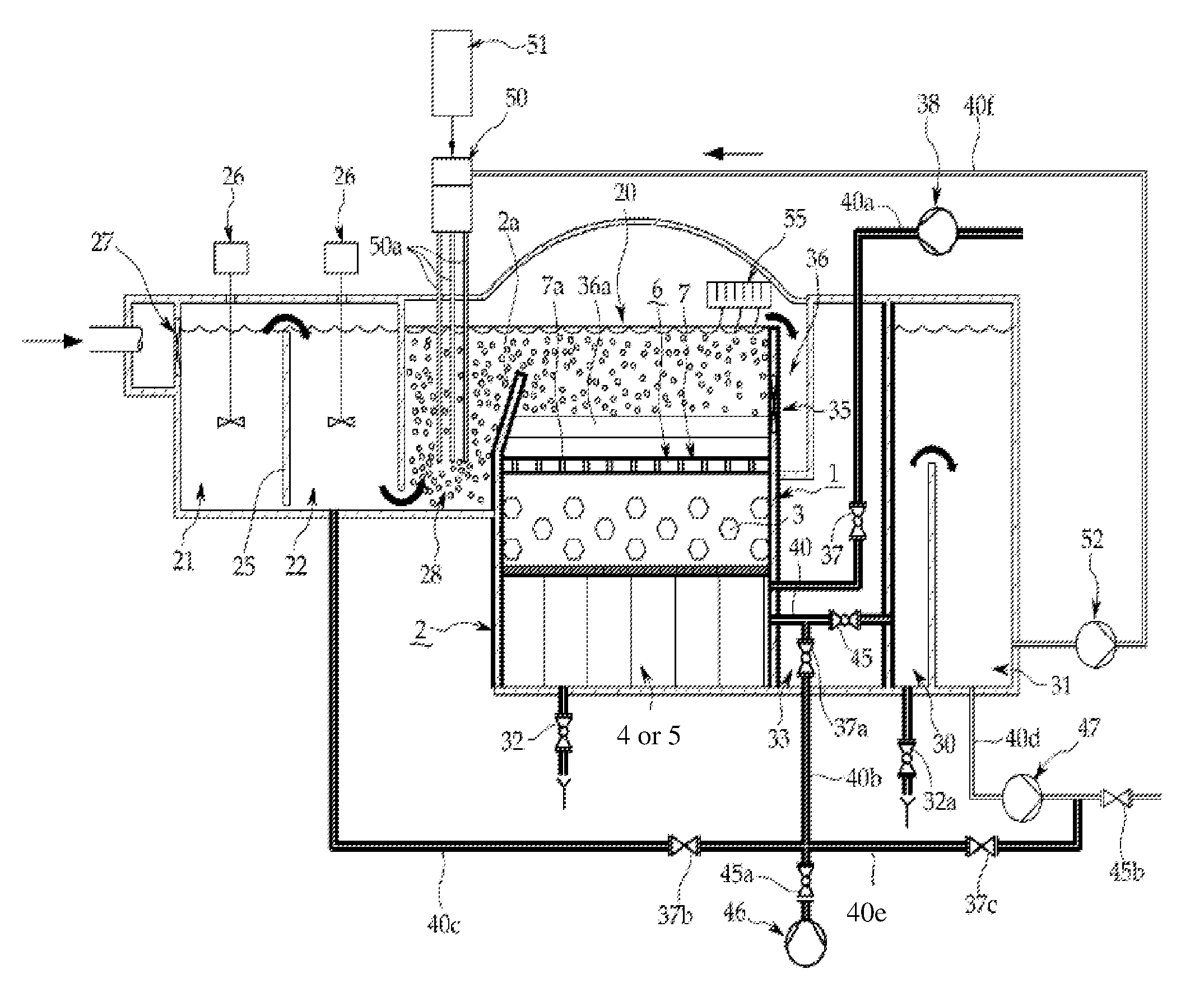

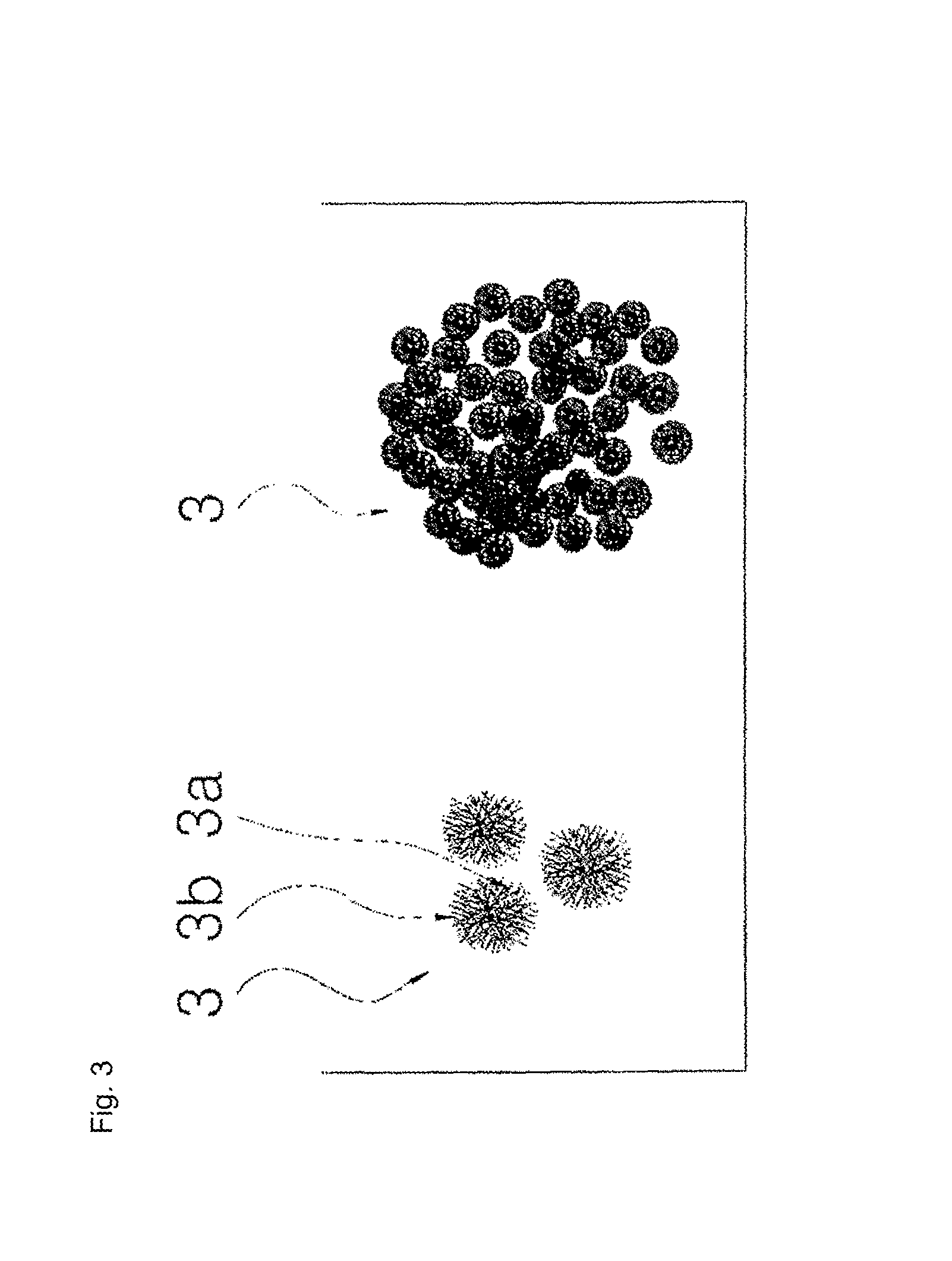

Dissolved air flotation-type pretreatment apparatus

ActiveUS9440864B2Easy to backwashInhibition releaseTreatment using aerobic processesSeawater treatmentFiberForeign matter

Disclosed is a dissolved air floatation (DAF)-type pretreatment apparatus. The dissolved air floatation (DAF)-type pretreatment apparatus includes: a floatation tank for removing foreign objects of floating matter, turbid matter, or alga contained in raw water of seawater, sewage, or wastewater; a filtering compartment part provided in the floatation tank and having one surface and the other surface which are partially opened to allow treatment water obtained by primarily removing floating matter from raw water to pass therethrough; and a plurality of filtering balls confined in the filtering compartment part and including a fibrous or spongy material to filter turbid matter or floating or suspended solids remaining in the treatment water introduced to the interior of the filtering compartment part.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

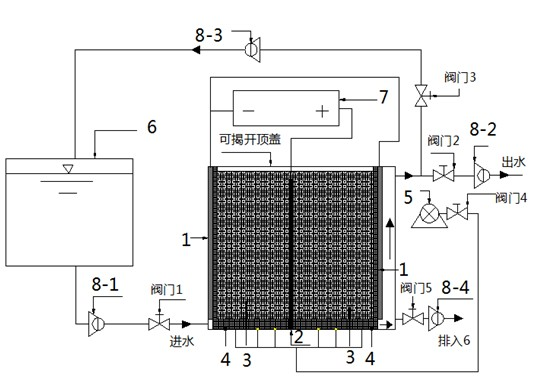

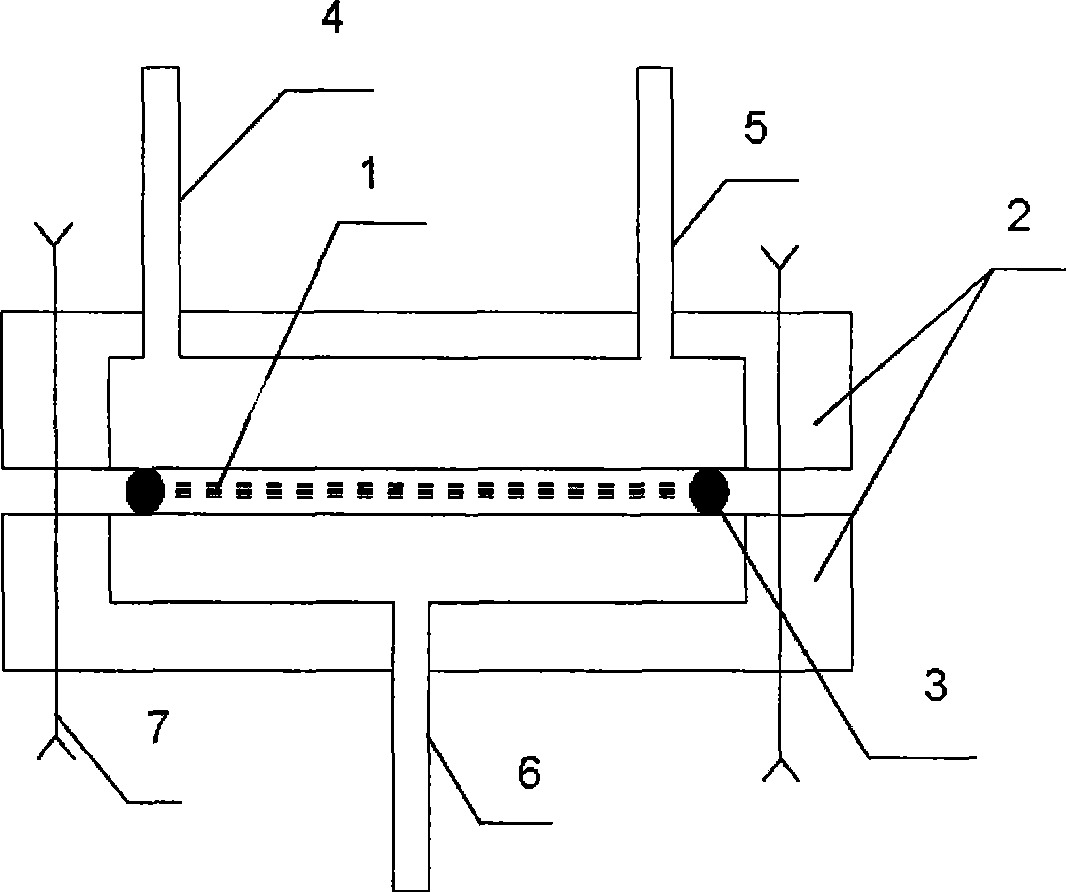

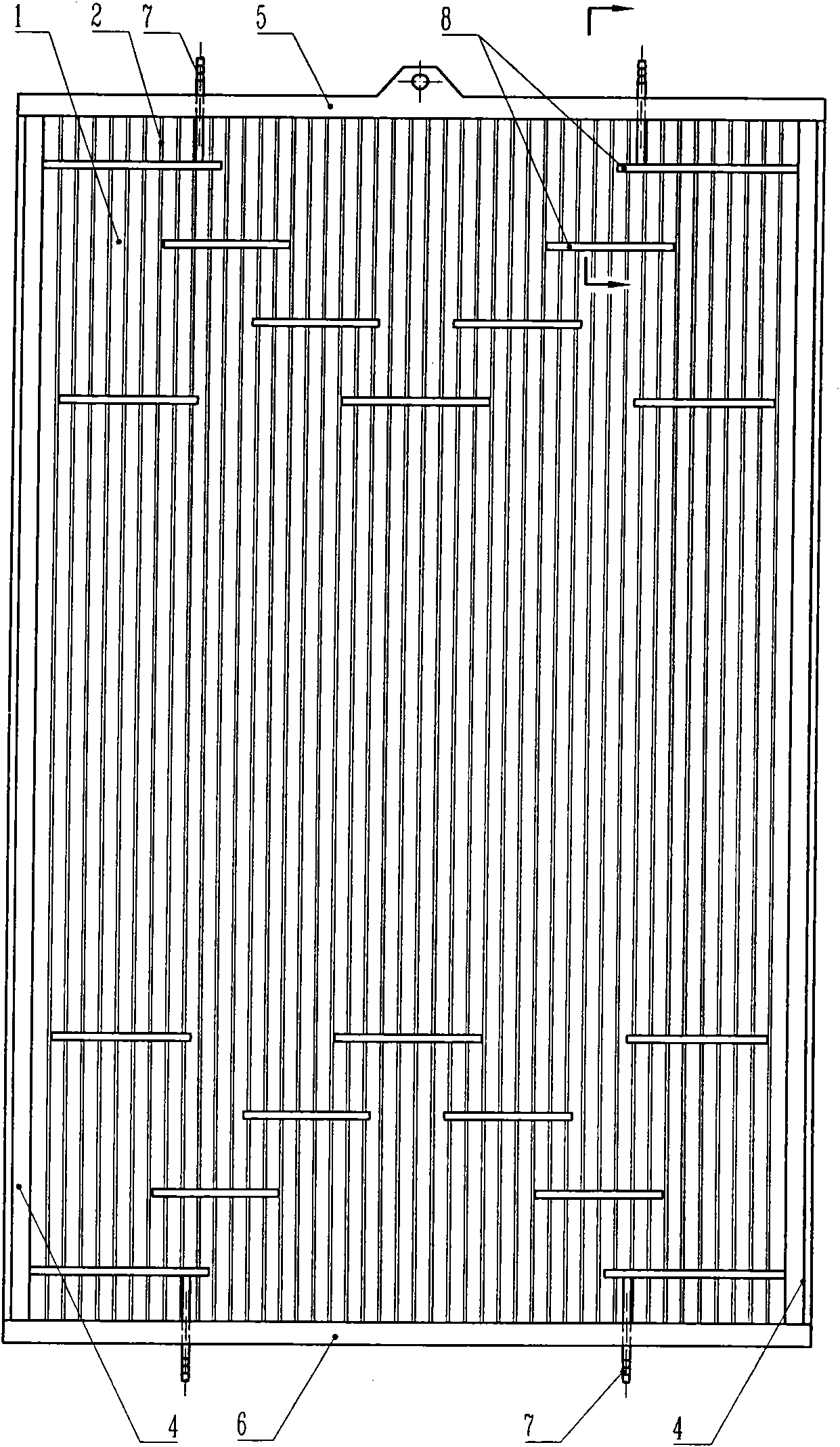

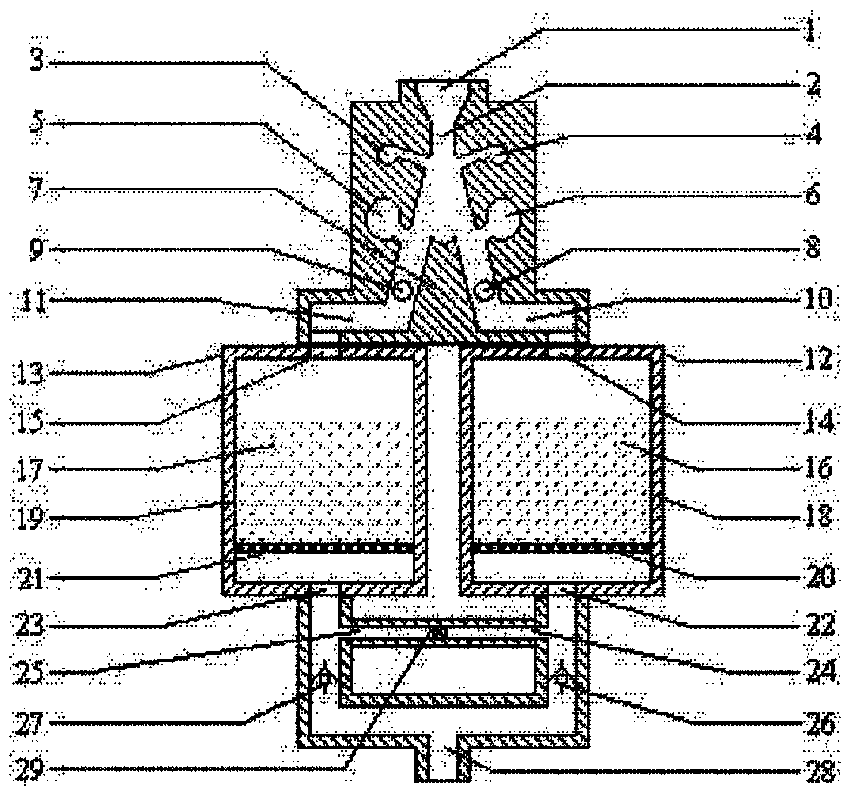

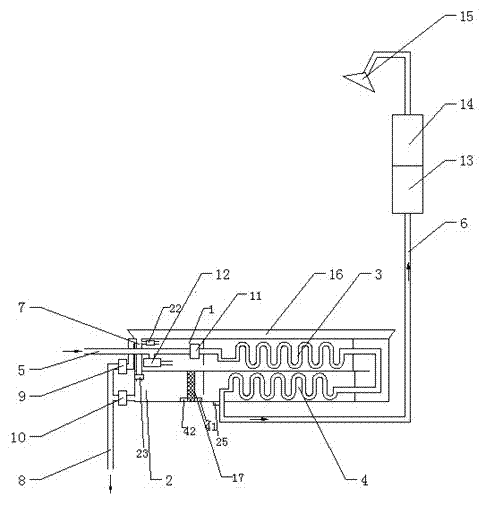

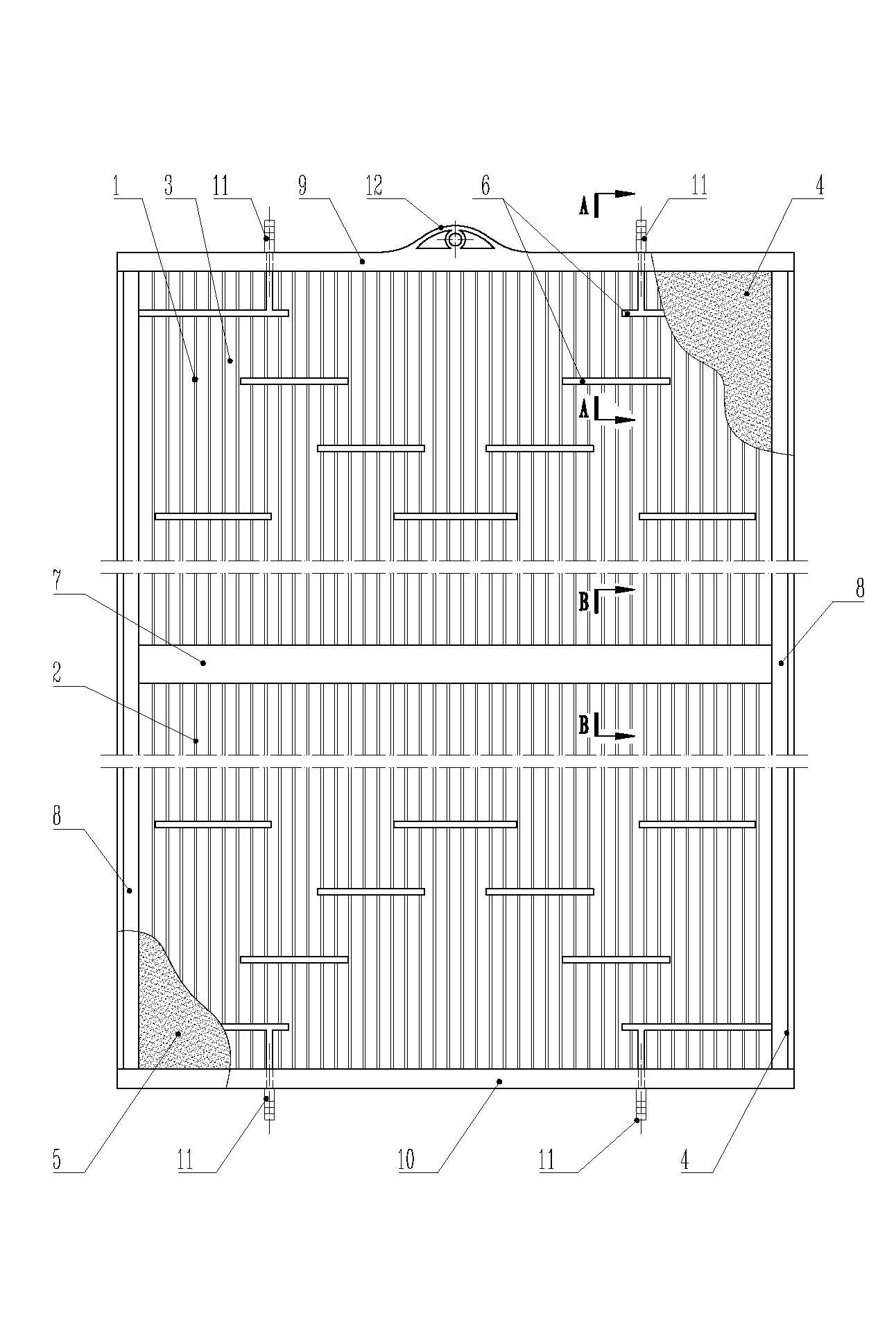

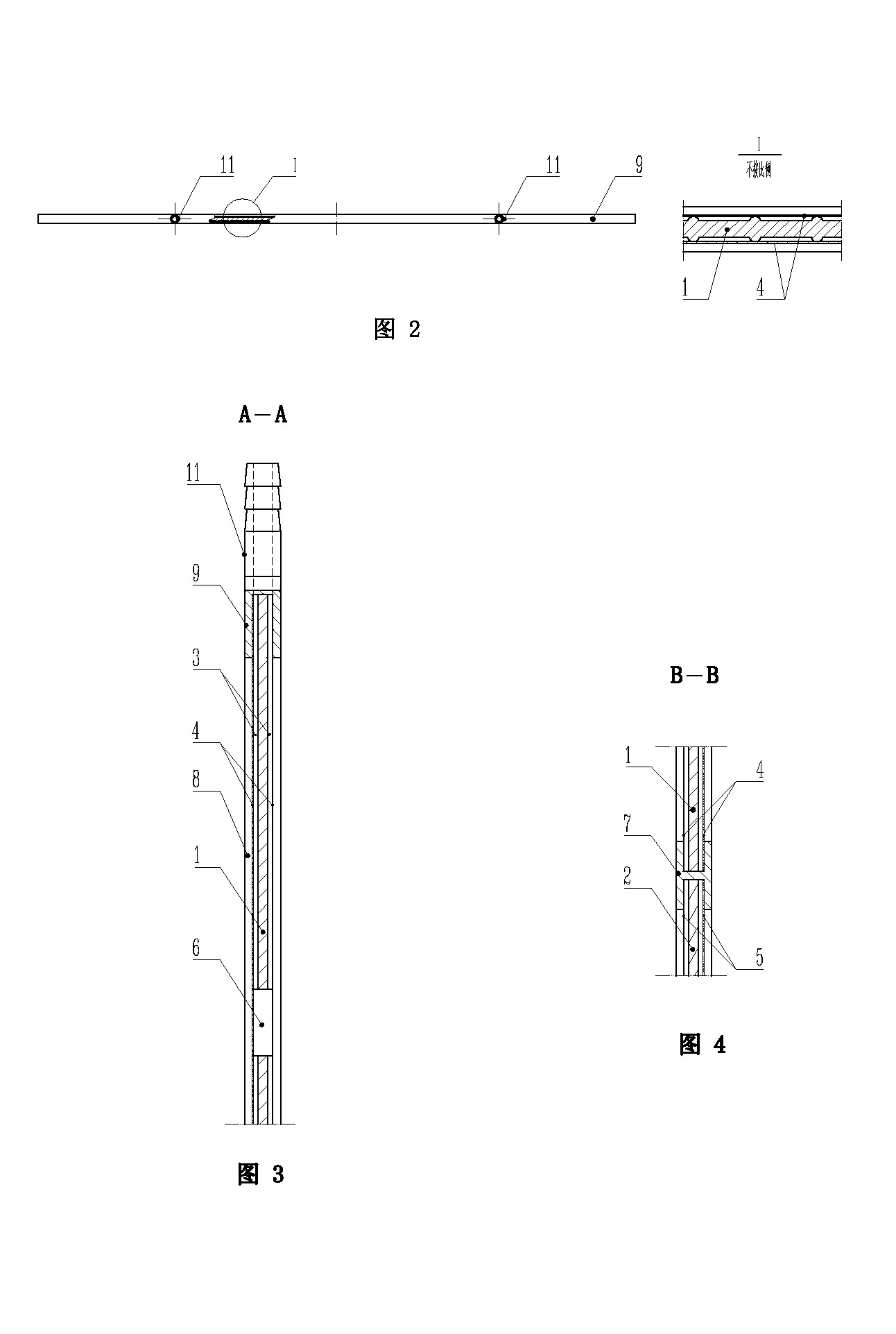

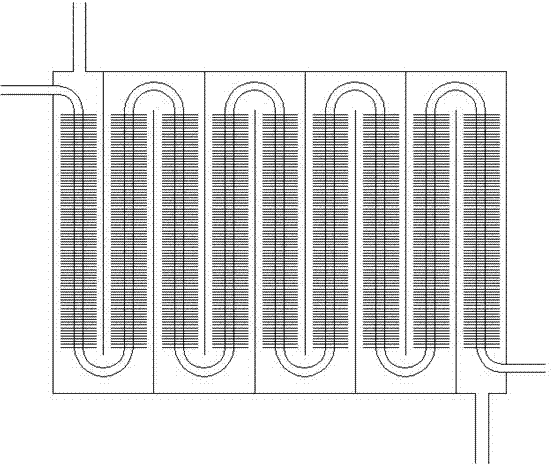

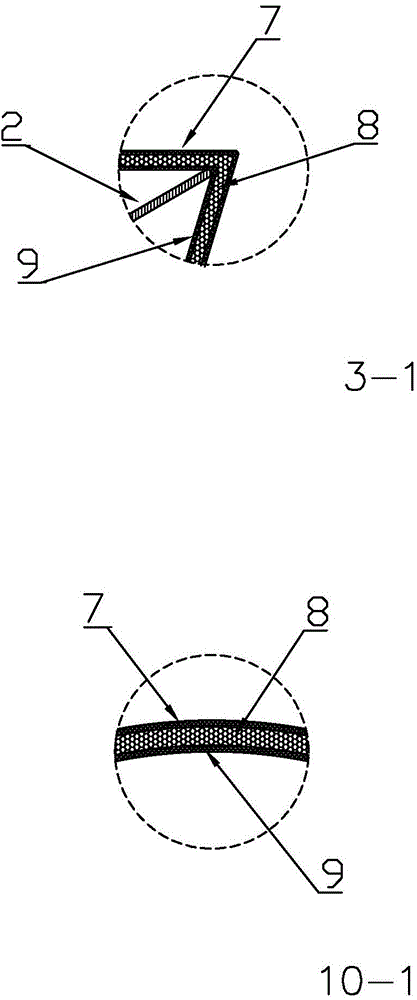

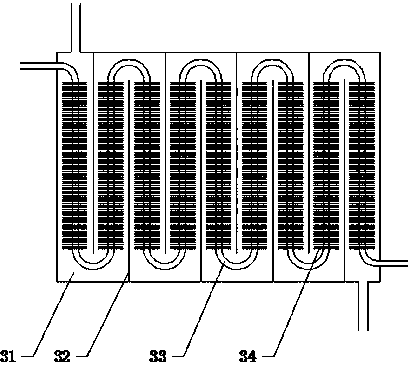

Novel submerged flat membrane element

ActiveCN101857302AEasy to backwashBackwashing is easySustainable biological treatmentBiological water/sewage treatmentBiochemical engineeringSewage treatment

The invention relates to a novel submerged flat membrane element, which comprises a middle support plate (2), wherein the two plate surfaces of the same plate are provided with a plurality of vertical guide channels (1); and the membranes (3) are arranged on the two surfaces of the middle support plate (2). The novel submerged flat membrane element is characterized in that: side compression bars (4) are arranged on the left and right sides of the middle support plate (2), and an upper end part (5) and a lower end part (6) are arranged on the upper and lower ends of the middle support plate (2) respectively; the upper end part (5) and the lower end part (6) are provided with two suction pipes (7) respectively; a plurality of water gathering channels (8) are formed on the middle support plate (2); and the membranes (3) are covered the outside of the water gathering channels (7). In the invention, four suction pipes adopted are favorable for the backwash of the membranes when the membranes are used for a period of time; the novel submerged flat membrane element has the characteristics of easy water outflow, large effective processing area, large flow and the like, improves the effective efficiency of aeration, reduces washing time and saves energy; the membranes can reach 2.5 meters at most; and the occupied area is smaller on the premise of identical sewage treatment amount.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

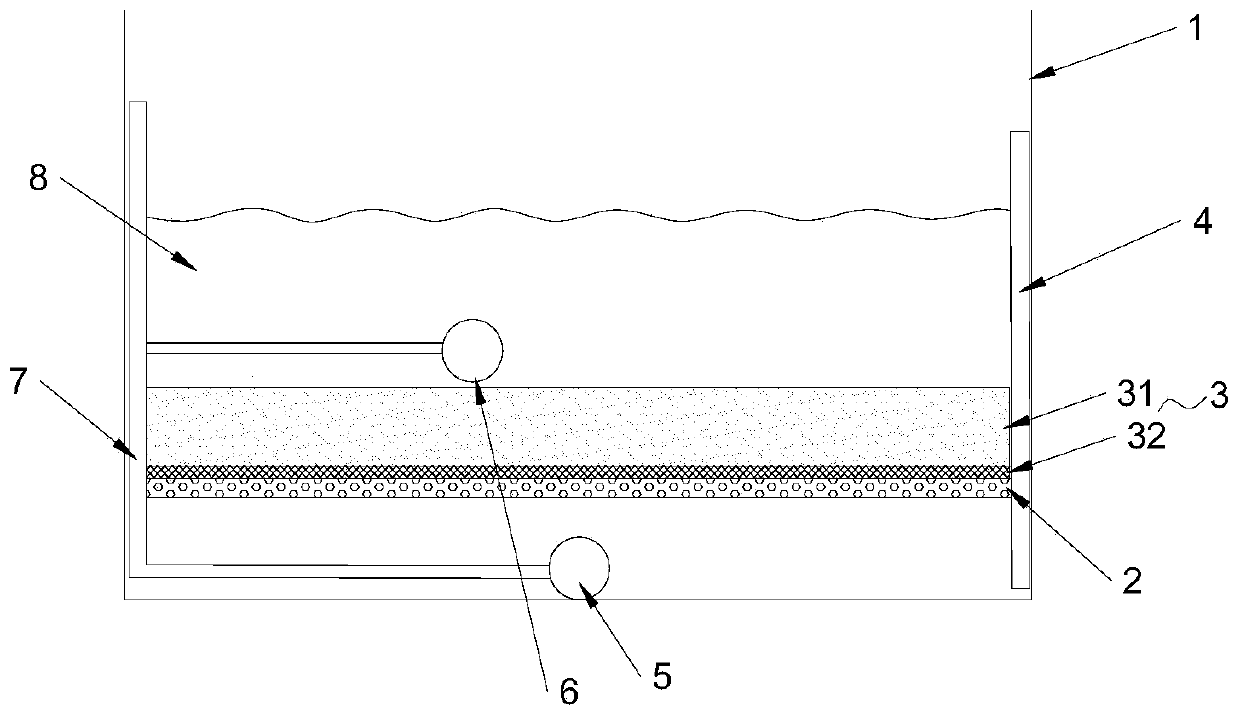

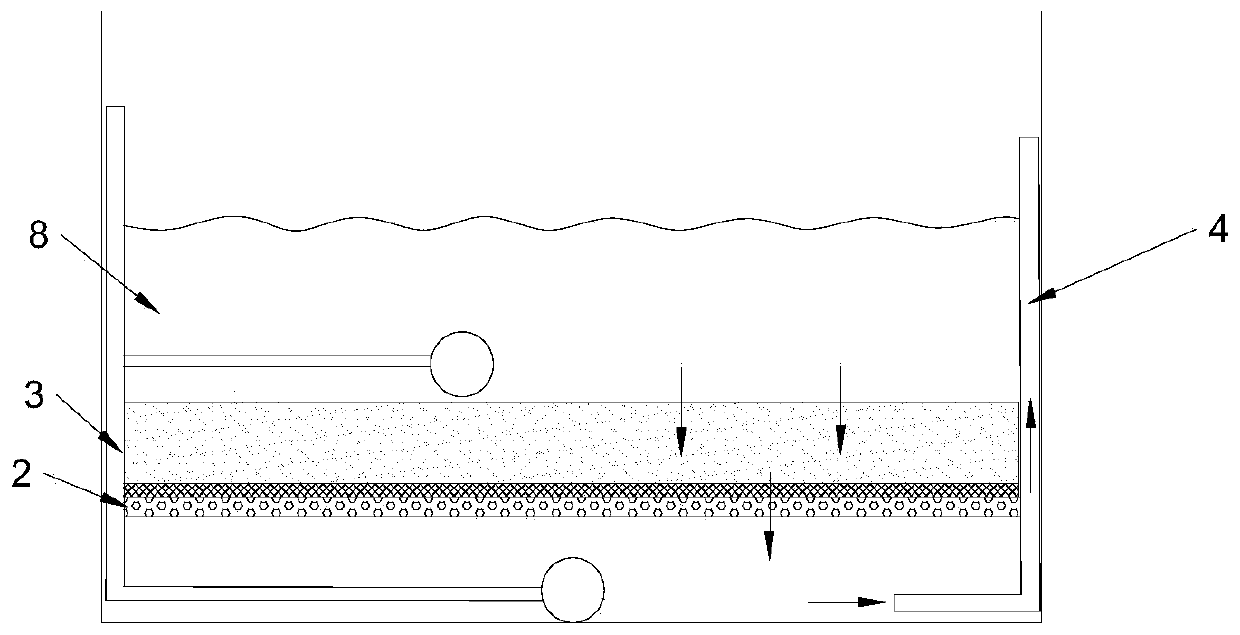

Filter bed breeding system and factory breeding method of buried-dwelling marine organisms

InactiveCN109744174AImprove bed attachment efficiencyPromote oxidative decompositionClimate change adaptationPisciculture and aquariaProbioticMarsupenaeus

The invention discloses a filter bed breeding system and a factory breeding method of buried-dwelling marine organisms, and belongs to the field of aquiculture. The breeding system comprises a breeding pond, an empty space is arranged at the bottom of the breeding pond, a sand layer filter bed is arranged on the empty space, and a breeding water layer is above the sand layer filter bed; the breeding pond is internally provided with an air-life tube, one end of the air-lift tube communicates with the bottom of the breeding pond, and the other end of the air-lift tube communicates with the breeding water layer; a first oxygen increasing tube is arranged at the bottom of the breeding pond; and a second oxygen increasing tube is arranged at the bottom of the breeding water layer. S and divinghabits of the buried-dwelling marine organisms such as Marsupenaeus japonicus and Babylonia can be satisfied, the problem of bottom substrate changing black during high-density breeding is advantageously solved, the adhesion and purification effect of probiotics are improved, breeding stability is improved, the filter bed breeding system and the factory breeding method of the buried-dwelling marine organisms are suitable for high-density factory breeding of the buried-dwelling marine organisms, and has a good application prospect.

Owner:XIAMEN UNIV

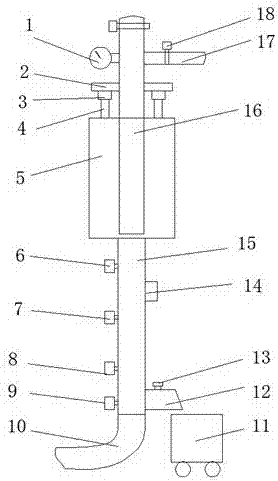

Vertical backwashing filter device

PendingCN109173423ASimple structureReasonable structureLoose filtering material filtersGravity filtersEngineeringFilter material

The invention provides a vertical backwashing filter device. The vertical backwashing filter device comprises a filter screen cylinder, and a water inlet pipeline and a water outlet pipeline which arearranged on the filter screen cylinder, a vertical middle separator plate divides the internal of the filter screen cylinder into a left chamber and a right chamber, each of the left chamber and theright chamber is filled with a filter material, the water inlet pipeline is arranged at the bottom of the filter screen cylinder, the water outlet pipeline is arranged on the top surface of the filterscreen cylinder, and the water inlet pipeline is provided with a water pump; and the filter screen cylinder is supported by a support. The backwashing device designed in the invention has a simple and reasonable structure, and integrates filtering and backwashing, adopts a bottom-to-top filtering mode and a top-to-bottom backwashing mode adopted in the invention ensure that a filtering element isnot obstructed by impurities, precipitating downwards under the action of gravity and accumulating, in water to be filtered, and facilitate the backwashing operation.

Owner:SHIHEZI UNIVERSITY

Production method of intestinal wall type heliciform hollow fiber filtering membrane

InactiveCN102389714ASimple processReasonable workmanshipSemi-permeable membranesFiberFiltration membrane

A production method of an intestinal wall type heliciform hollow fiber filtering membrane relates to the technical field of the filtering membrane production in the filtering technology. At first, a flat composite filtering membrane is produced, then the flat composite filtering membrane and propping materials are folded, wrinkled and scrolled together, and are spirally produced into the intestinal wall type heliciform hollow fiber filtering membrane. The product has higher heat resistance, noninflammability, prominent weather aging resistance, ozone resistance, irradiation resistance, ultraviolet light resistance and excellent corrosion resistance, and is not corroded by acid, alkali, strong oxidizer and halogen at room temperature.

Owner:JIANGSU QINGYI ENVIRONMENTAL PROTECTION EQUIPCO +1

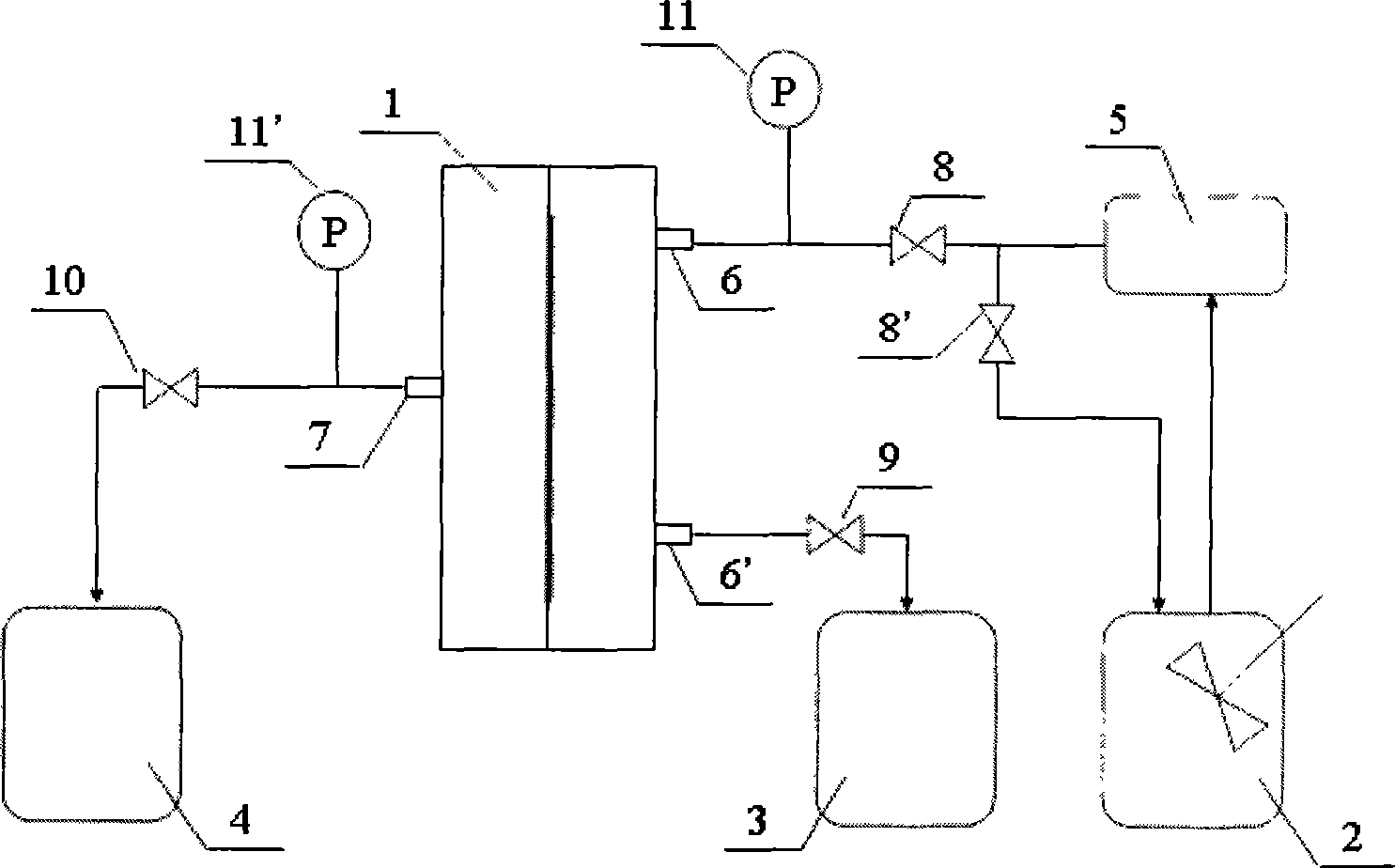

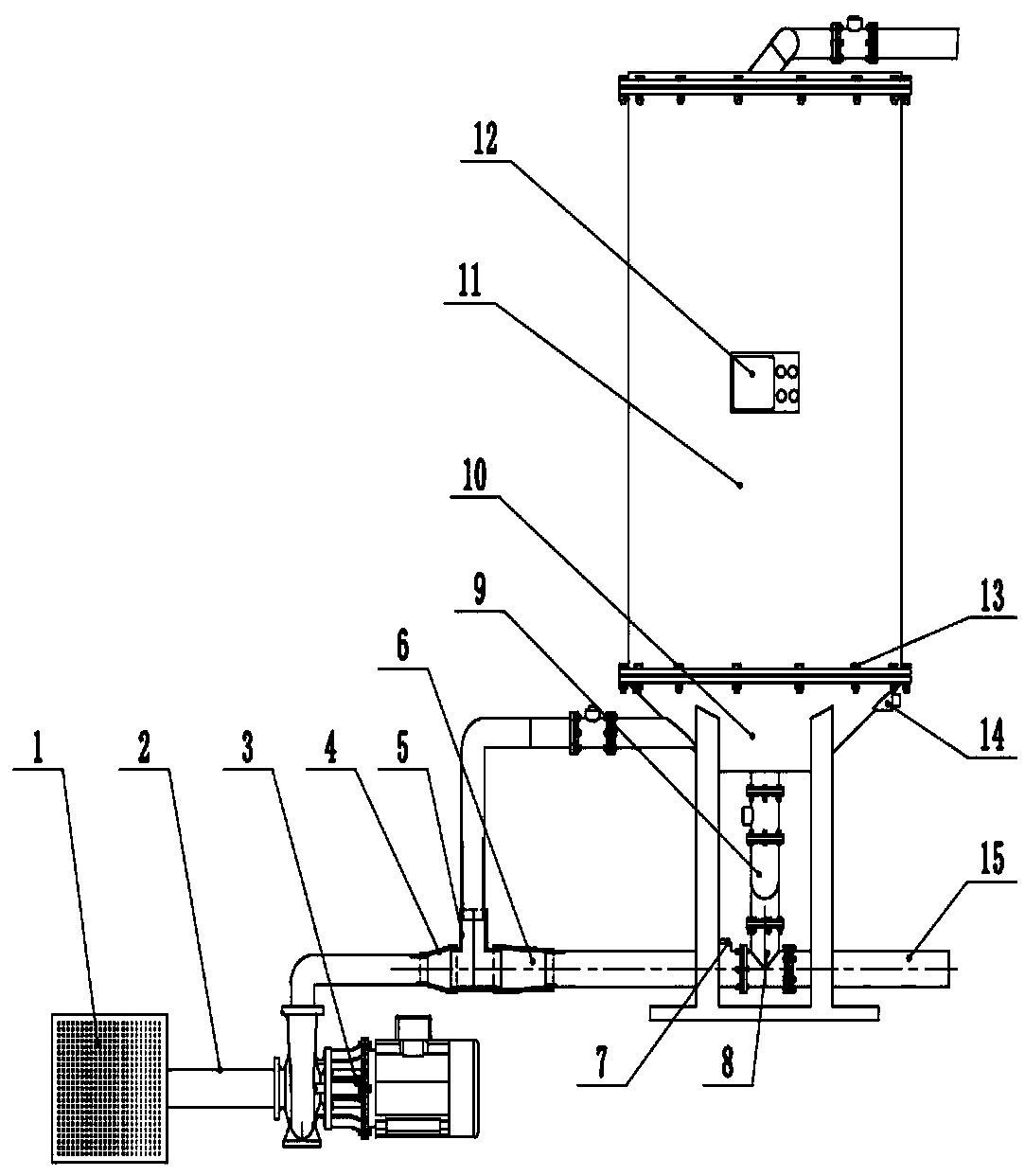

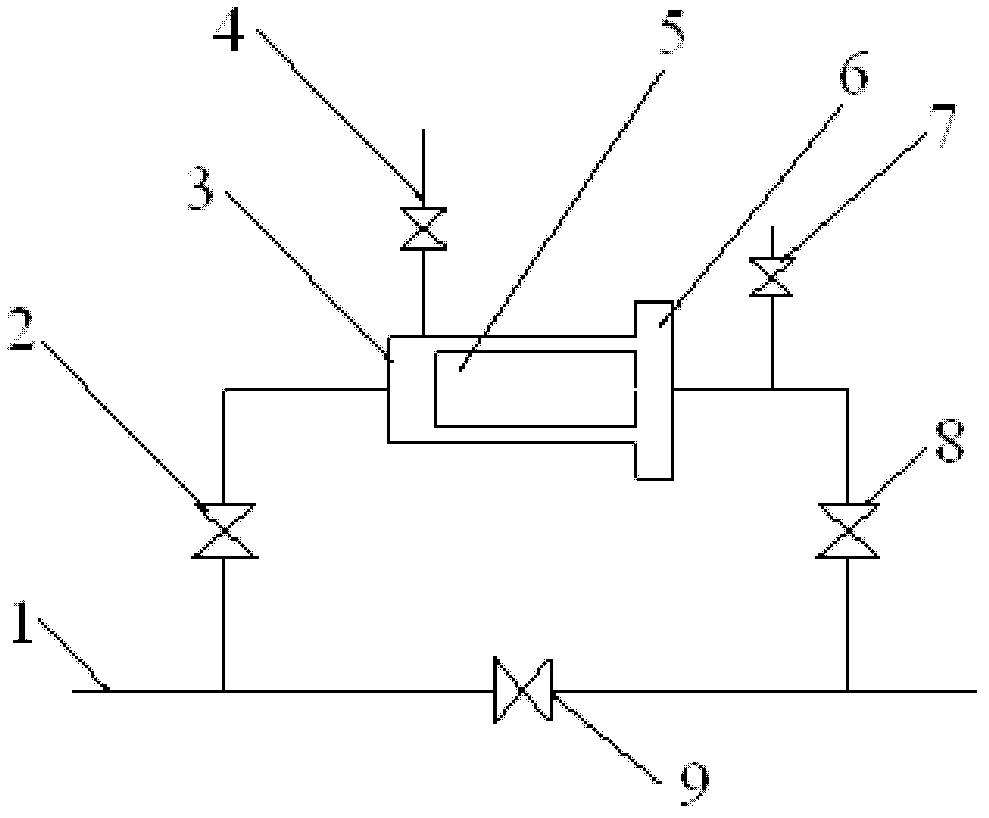

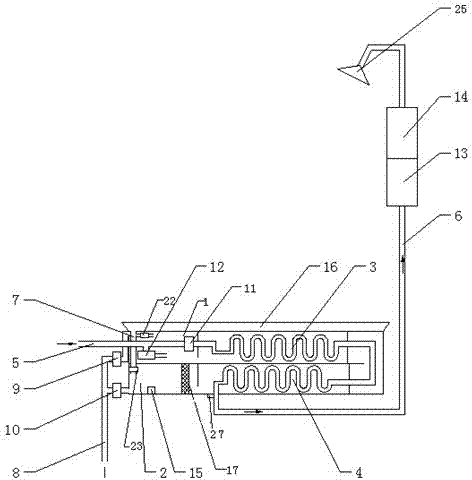

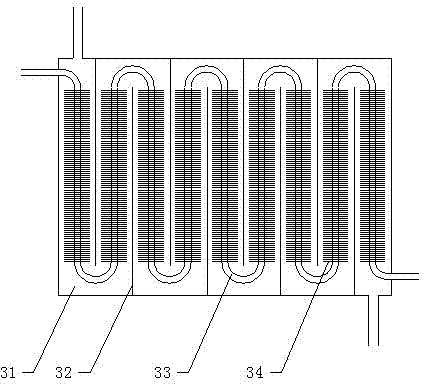

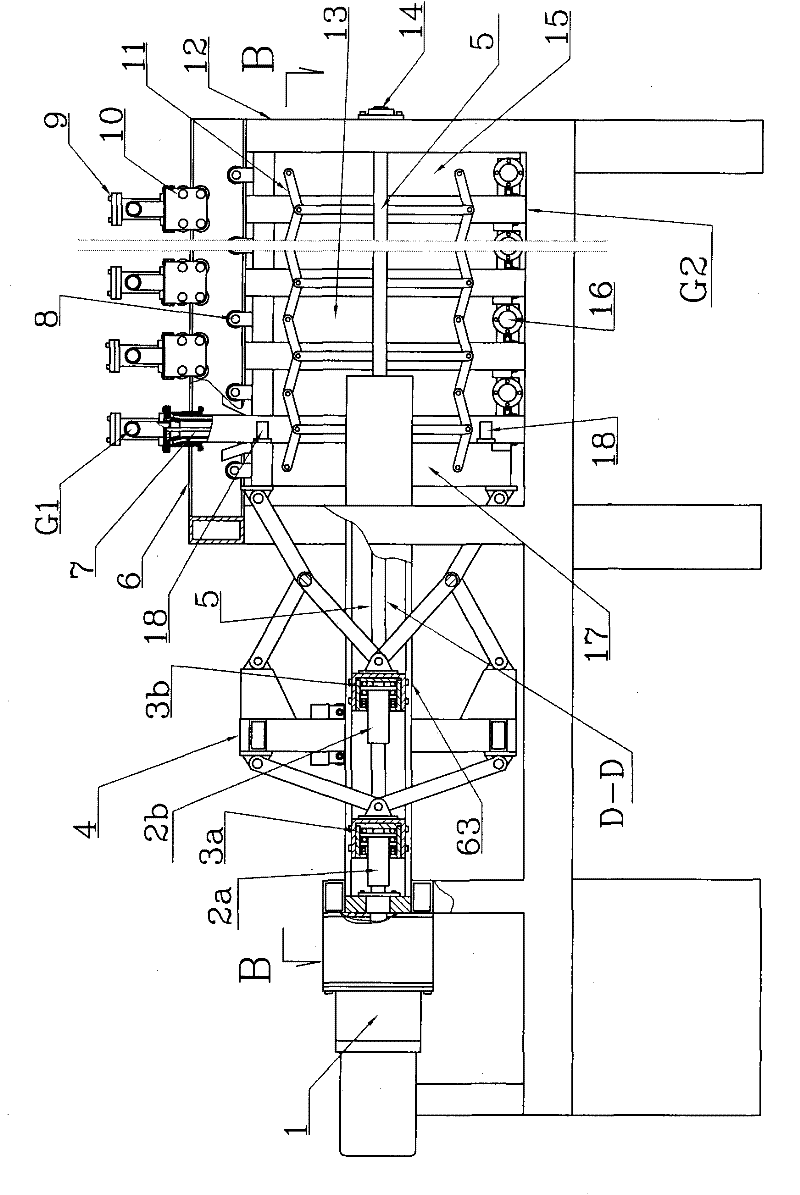

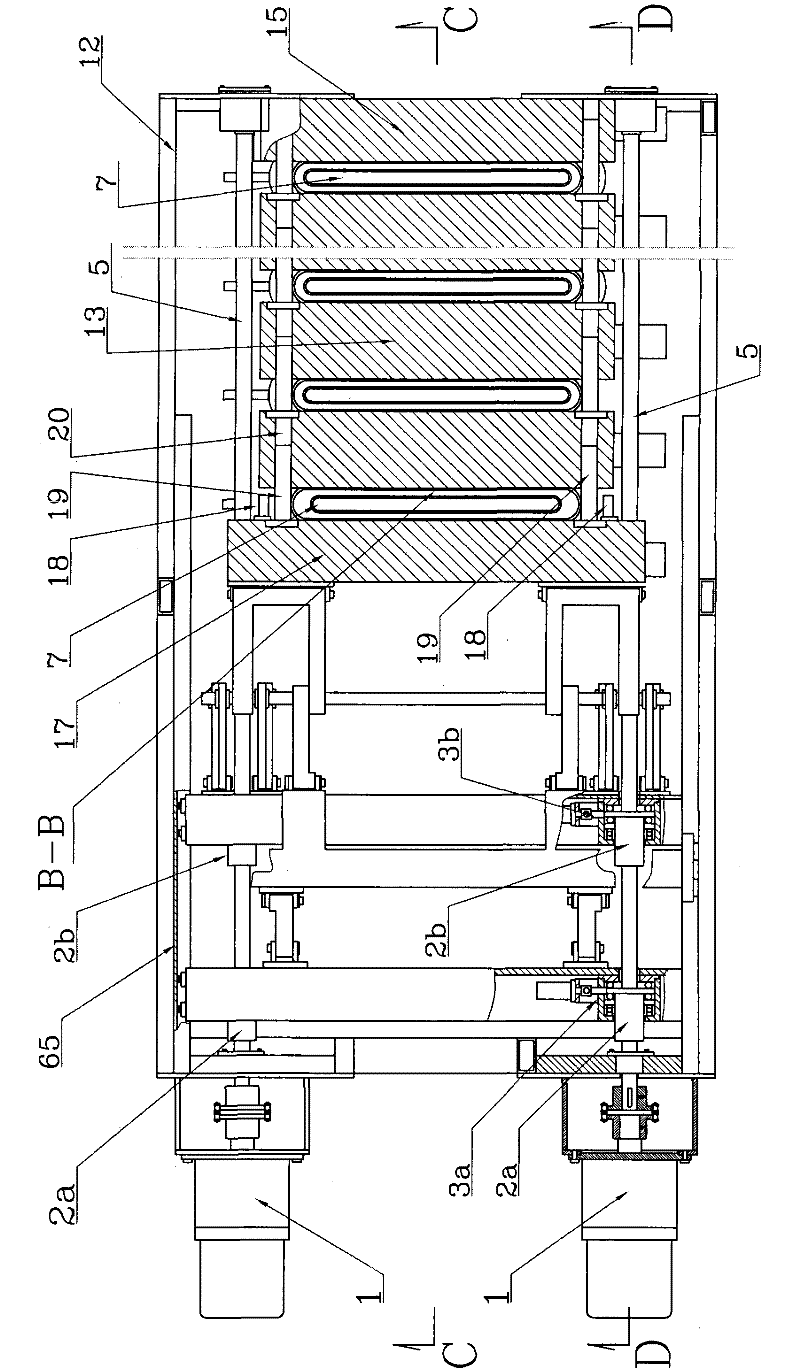

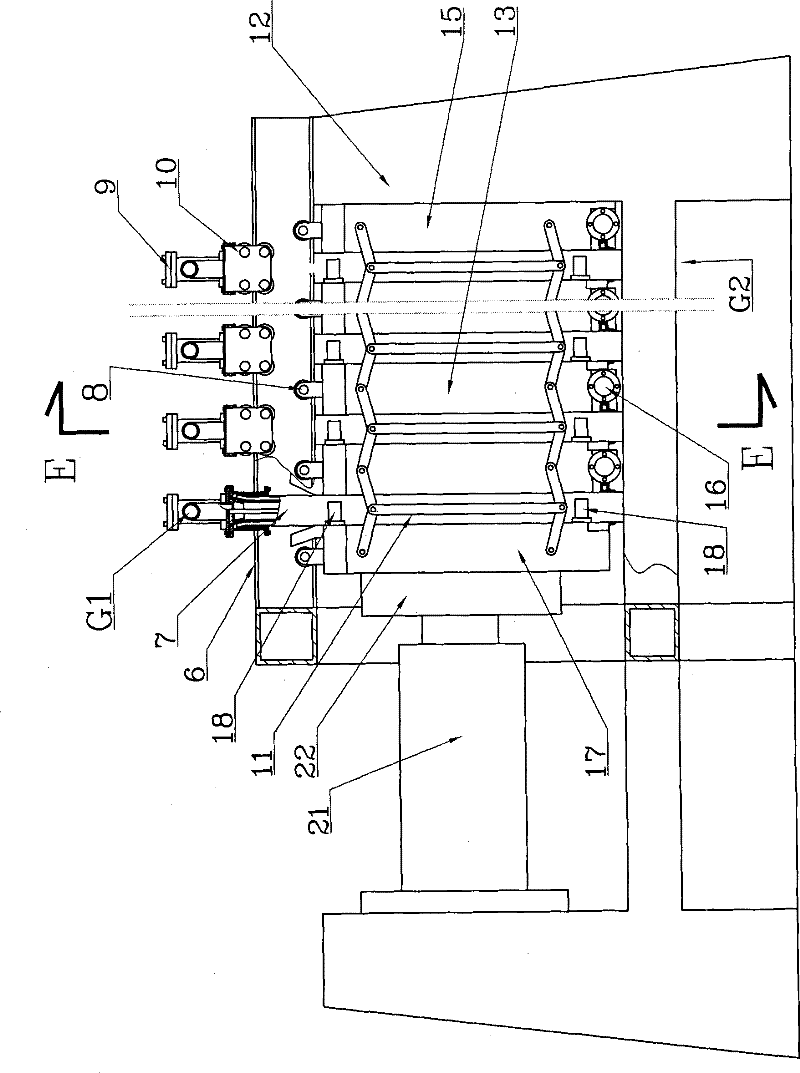

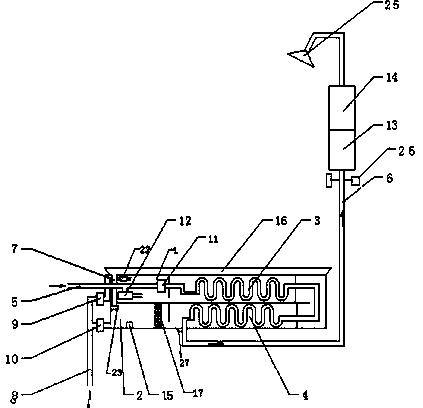

Backflushing type heat exchange system with water pressure and temperature detecting function

InactiveCN103528403AEasy to backwashEfficient backwashCorrosion preventionStationary tubular conduit assembliesWastewaterPore water pressure

The invention discloses a backflushing type heat exchange system with a water pressure and temperature detecting function. The backflushing type heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (15), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2), a detachable filter screen (17) is arranged in the lower heat exchange trough (2), a first pressure sensor (42) and a second pressure sensor (41) are arranged on two sides of the filter screen (17) and respectively connected with a controller (14), and the controller (14) comprises a comparing module (143) respectively connected with a setting module (144), the first pressure sensor (42), the second pressure sensor (41) and a temperature sensor (25). The backflushing type heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:许东雪 +2

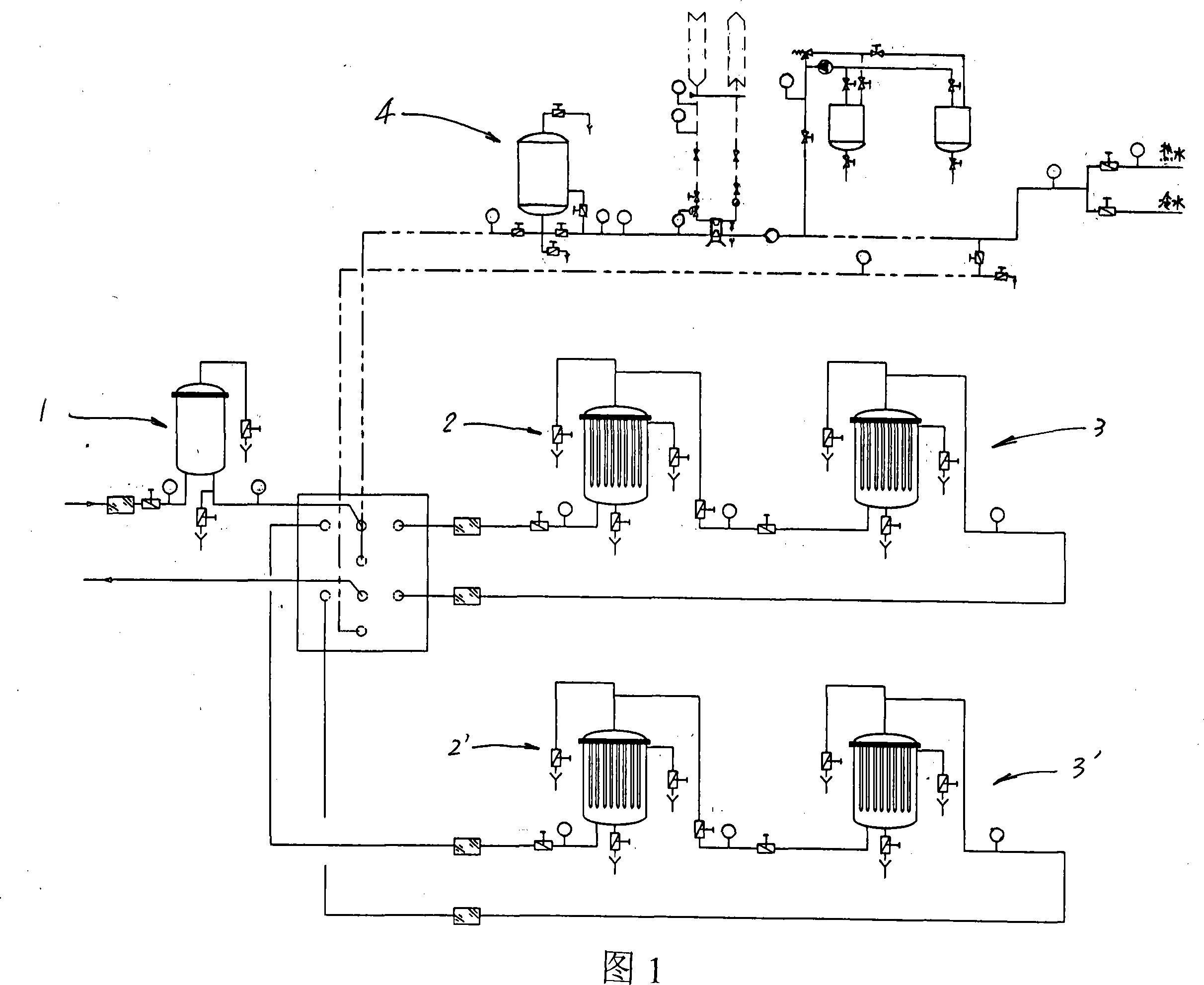

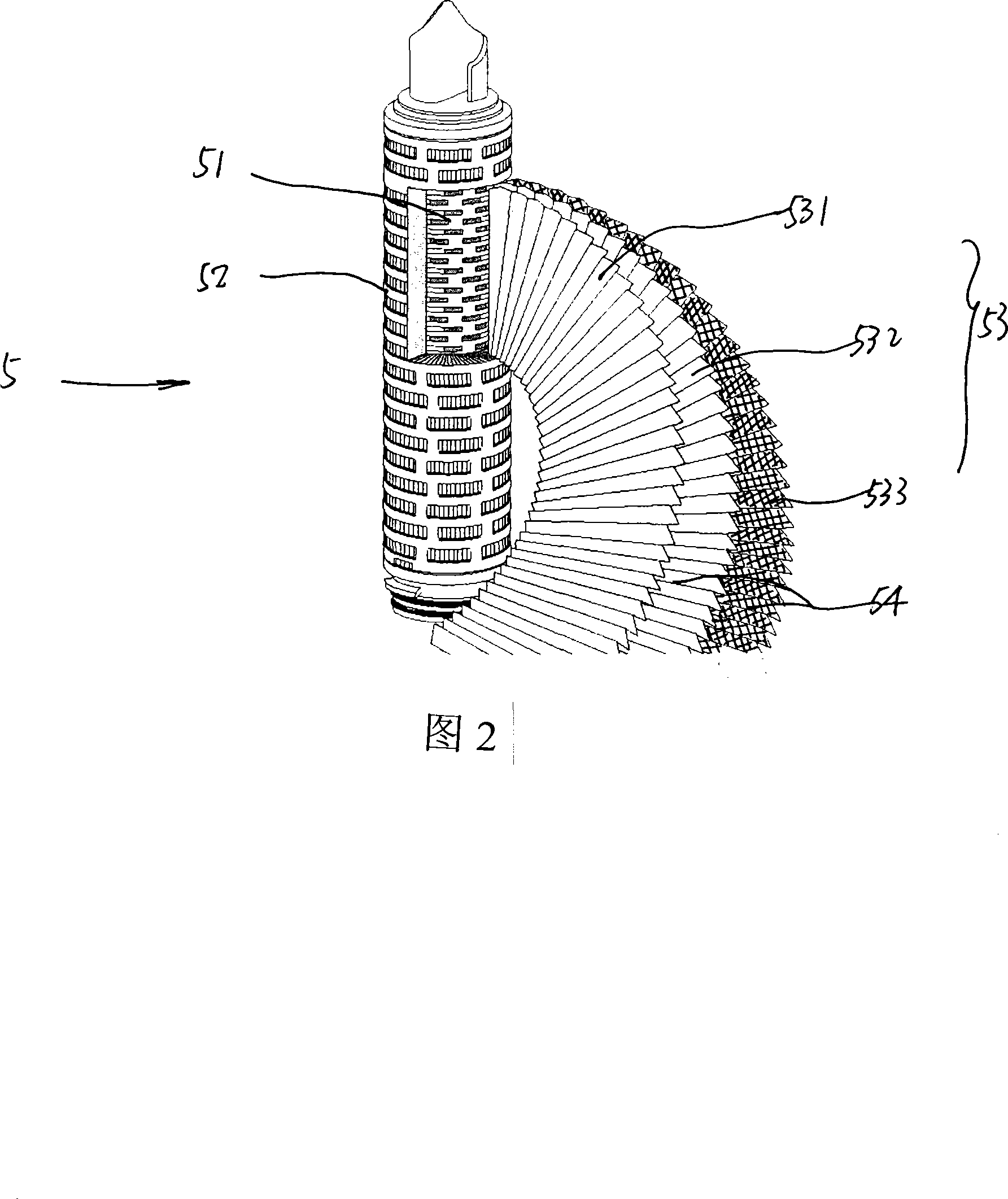

Technique and equipment for preparing tea beverage

InactiveCN101233881AReduce maintenance costsImprove processing productivityPre-extraction tea treatmentFlocculationFiltration

The invention relates to a method for preparing a tea drink and a device thereof. Raw materials of tea leaves after being immersed in liquor are made into rough materials, cooled, flocculated and settled; supernatant obtained is then screened to be prepared into the tea drink. The filtration procedures comprise: a primary filtration: the supernatant after the flocculation settlement is conveyed into a primary filtration device which is provided with a folded filter bag used for initial filtration; a secondary filtration: the supernatant obtained is then conveyed into a secondary filtration device which is internally provided with a folded filter element used for pre-filtration so as to obtain a primary clear liquor; a tertiary filtration: the primary clear liquor then enters into a tertiary filtration which is provided with a folded filter element; then fine filtration is carried out for the primary clear liquor so as to prepare the finish product of strong tea liquor. The strong tea liquor is then mixed with pure water with the volume 7-8 times of the tea liquor; additive is added to make the tea drink. The method has the advantages of low device cost, high production efficiency and low limitations for primary procedures as well as the advantages that the strong liquor can be re-filtered, with high yield and continuity for production; the filter element is liable to be treated with back flushing, with long service life and the finished product of the strong tea liquor can achieve 5-20 NTU in turbidity and the tea polyphenols content can be as much as 1,800.

Owner:上海微滤净化技术有限公司

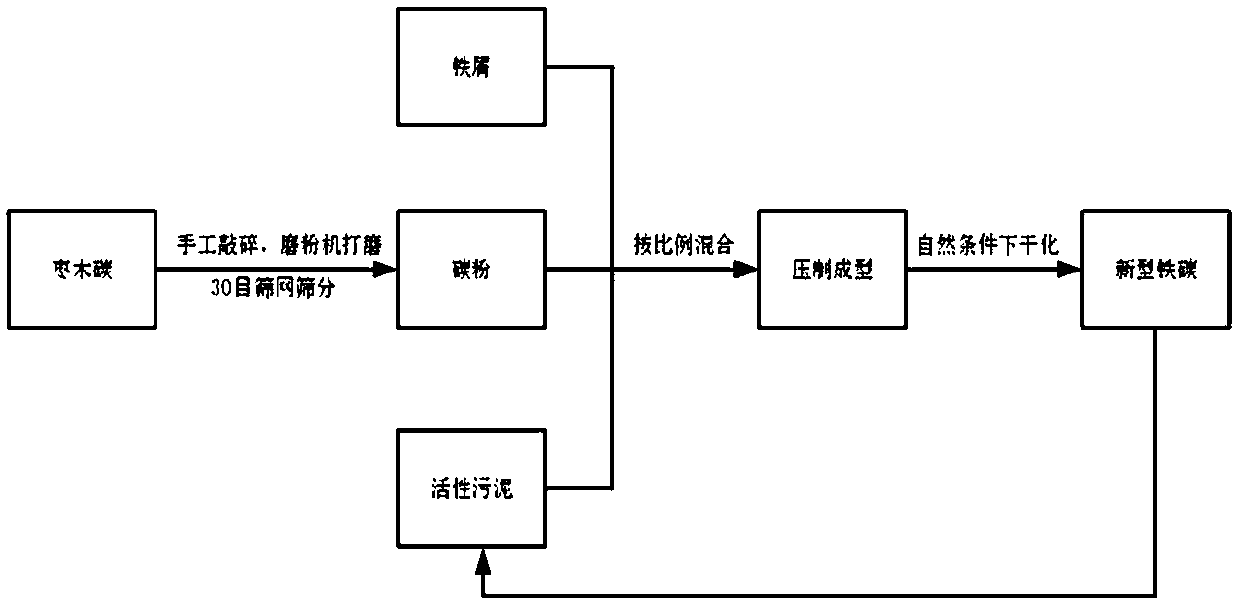

Iron-carbon micro-electrolysis filler and preparation method thereof

InactiveCN110627166AExcellent adhesionMeet strength requirementsWater/sewage treatment using germicide/oligodynamic-processBiological water/sewage treatmentActivated sludgeElectrolysis

The invention relates to an iron-carbon micro-electrolysis filler; the iron-carbon micro-electrolysis filler takes activated sludge as an adhesive, and is prepared by the following steps: 1) manuallycracking whole section of jujube charcoal into small particles, putting the small particles into a powder mill, grinding into powder, and sieving the powder with a 30-mesh sieve to obtain carbon powder; 2) taking waste iron scraps generated in an iron product machining process as iron powder; 3) taking residual sludge as an adhesive; 4) putting the charcoal powder and the iron powder into a container according to a ratio, and fully and uniformly mixing; 5), adding activated sludge into the mixed charcoal powder and iron powder according to a certain ratio and uniformly stirring; 6), putting the mixed material into a mold, beating for several times, and demolding; and 7), drying after standing in a natural state for 24 h, and thus obtaining the iron-carbon filler. The iron-carbon filler hasthe advantages of simple process, convenient preparation, low cost, energy saving and environmental protection.

Owner:ZHEJIANG UNIV OF TECH

Cooling device for mechanical part machining

InactiveCN113021068AGuaranteed cooling effectGuaranteed Filtration EfficiencyMaintainance and safety accessoriesPhysicsEngineering

The invention relates to the technical field of mechanical part machining, and discloses a cooling device for mechanical part machining. The cooling device for mechanical part machining comprises a circulating box, wherein a refrigerator is fixedly installed on the side wall, close to the bottom, of the circulating box, the hot end of the refrigerator is arranged at the outer side of the circulating box, and the cold end of the refrigerator is arranged at the inner side of the circulating box; a circulating pump is fixedly installed on the lower surface in the circulating box, an output end of the circulating pump is fixedly connected with a conveying pipe, the other end of the conveying pipe penetrates through the side wall of the circulating box and extends outwards to be fixedly communicated with a spray head, a first valve is fixedly installed on the conveying pipe, and a branch pipe is fixedly communicated with the pipe wall of the conveying pipe; and the branch pipe is located below the first valve, and a second valve is fixedly installed on the branch pipe. According to the invention, a filtering plate in the circulating cooling device can be conveniently and reversely washed and is prevented from being blocked, so that the filtering efficiency of the filtering plate is increased, and the circulating utilization effect of cooling liquid is ensured.

Owner:西安汇龙中鼎机械设备有限公司

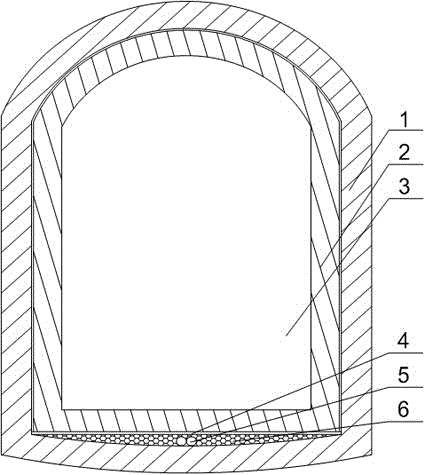

Subsurface tunnel drainage treatment method

InactiveCN105909308AConvenient post-constructionImprove efflux efficiencyUnderground chambersDrainageWater collectionPrecipitation

The invention discloses a subsurface tunnel drainage treatment method. The method includes the following sequential steps that a, a plurality of precipitation wells are disposed in the middle of a tunnel firstly, and primary lining construction is performed after the water level in the tunnel descends to the safety position; b, after the primary lining construction is finished and silt on the bottom surface of a primary lining is removed, a water filtering layer is paved on the primary lining bottom surface; c, a plurality of drainage conduits extending to a vertical shaft water collection pit are laid in the water filtering layer; and d, a water-proof layer is paved on the upper surface of the water filtering layer, and C25 concrete is poured on the water-proof layer. During application, accumulated water remained on the primary lining is filtered through the water filtering layer and then enters the drainage conduits, and the accumulated water is drained into the vertical shaft water collection pit after being subjected to centralized treatment through the multiple drainage conduits; and in the drainage process, the water-proof layer and the concrete layer are disposed on the upper portion of the water filtering layer, so that the effect that the bottom surface of a secondary lining is kept dry is guaranteed, and later stage construction in the tunnel is facilitated.

Owner:CHINA MCC5 GROUP CORP

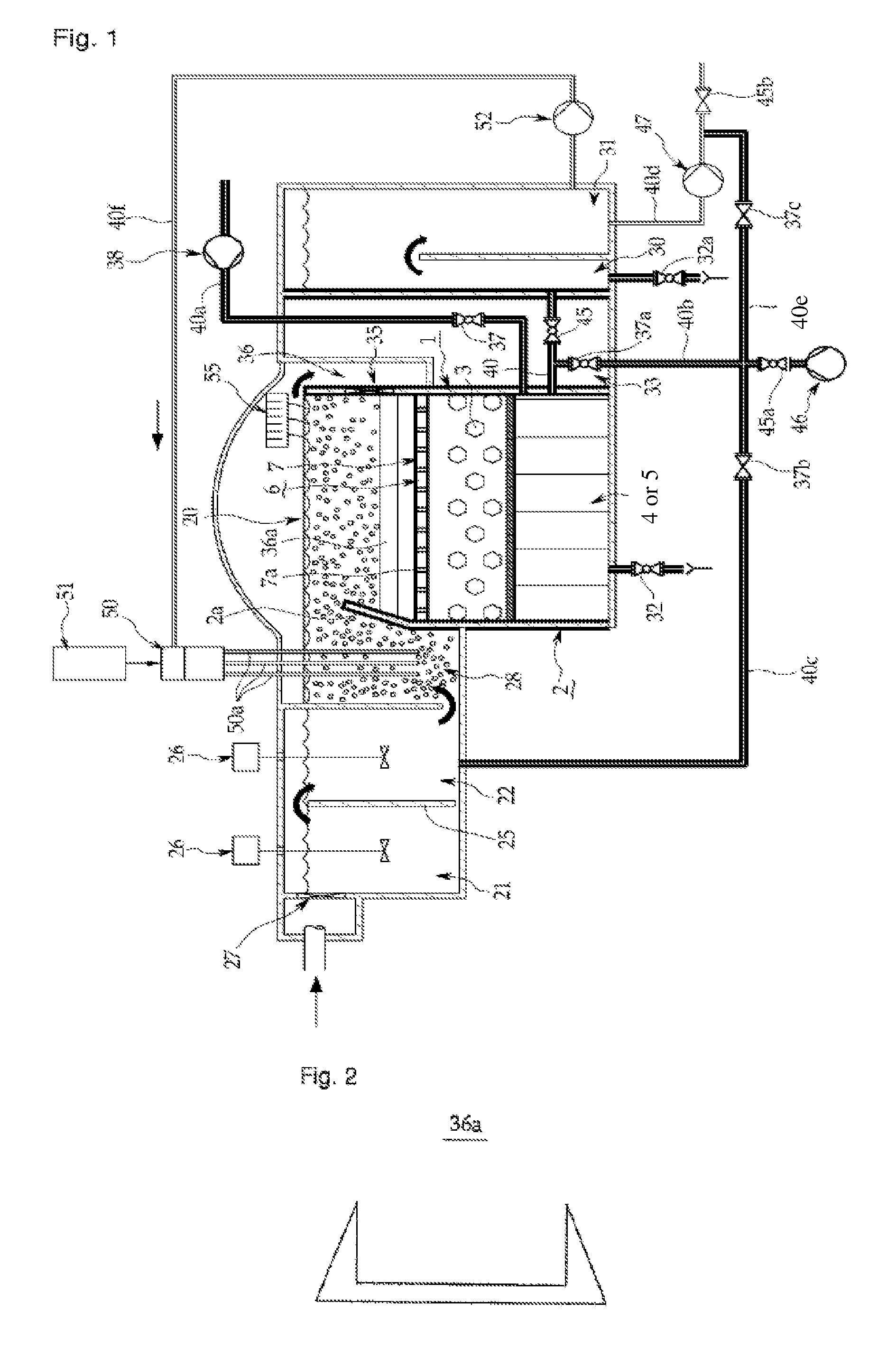

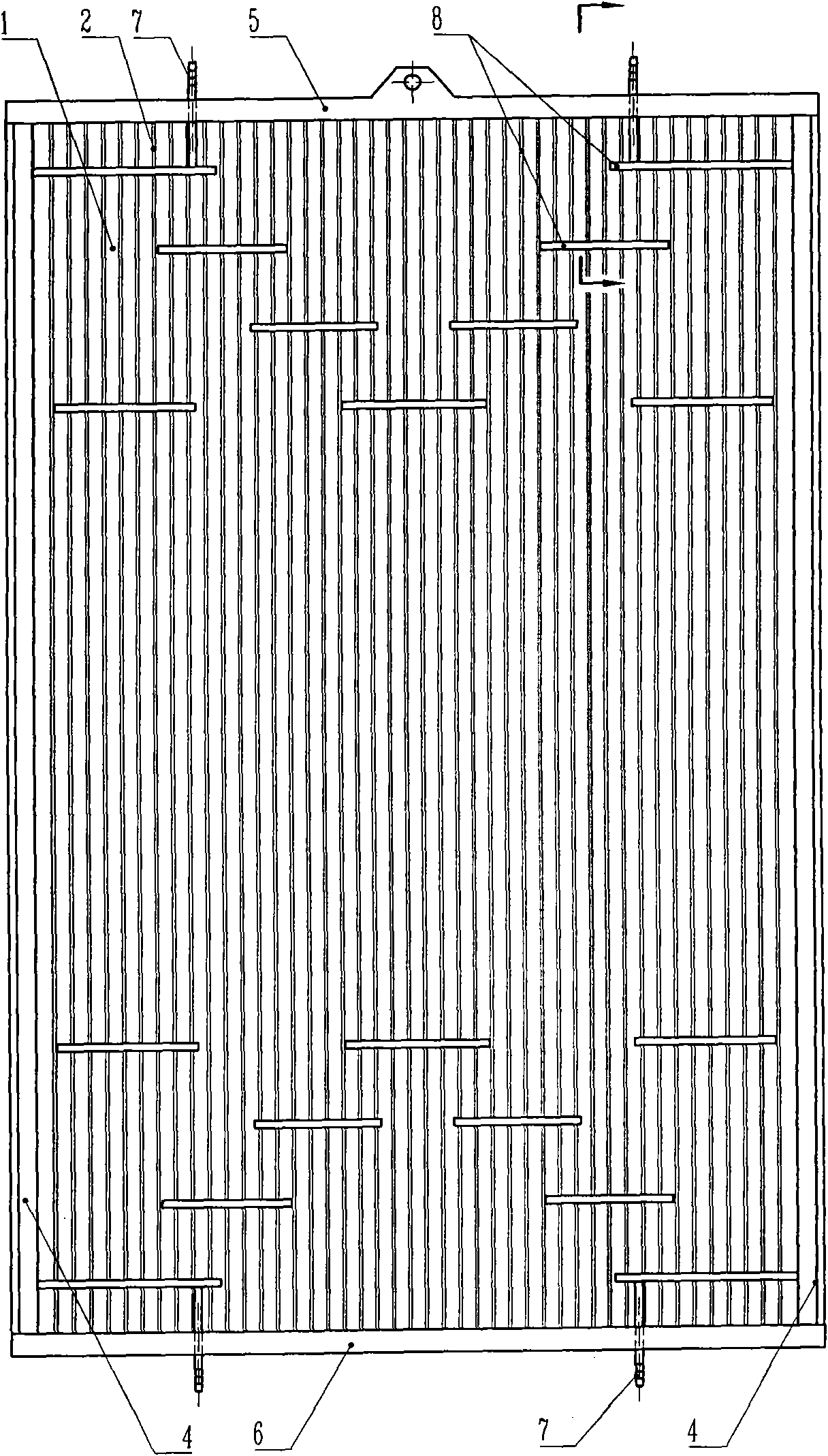

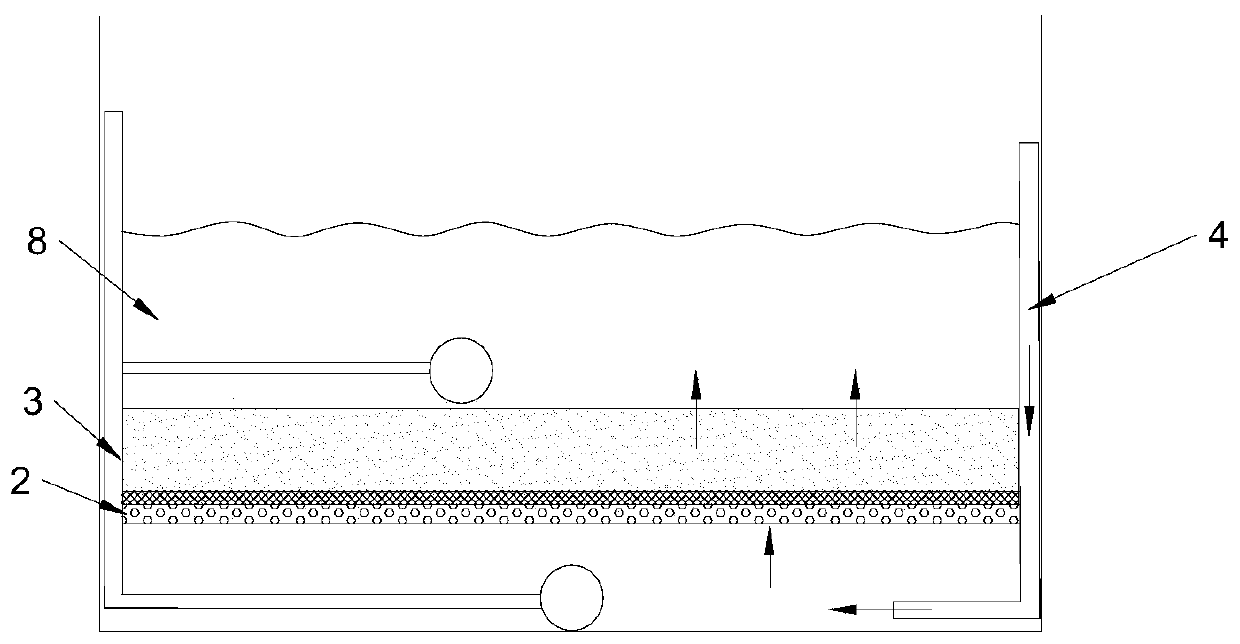

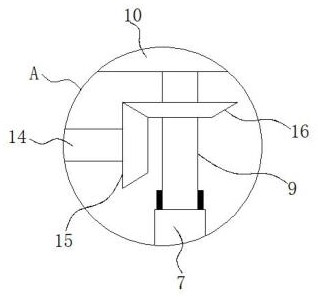

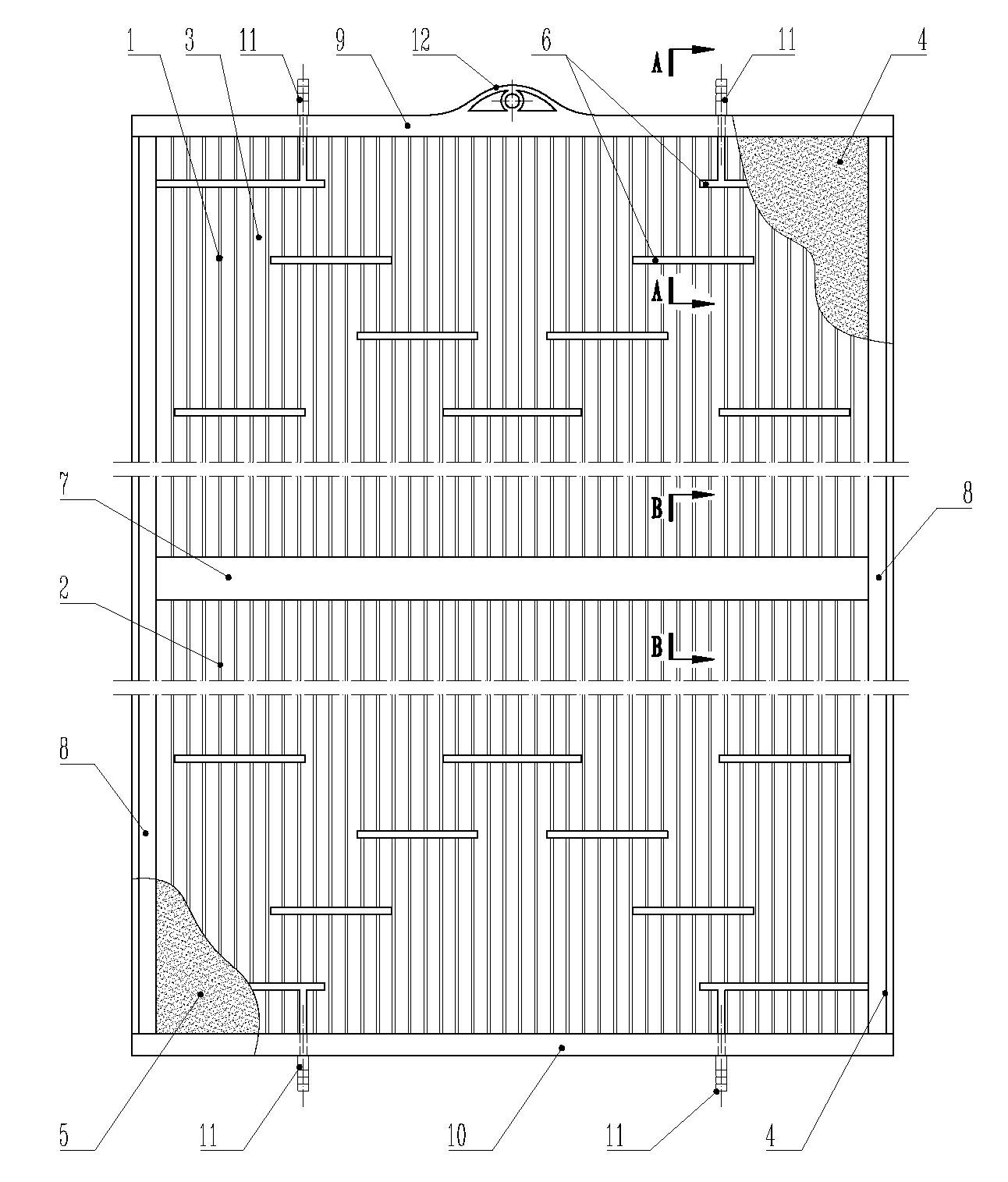

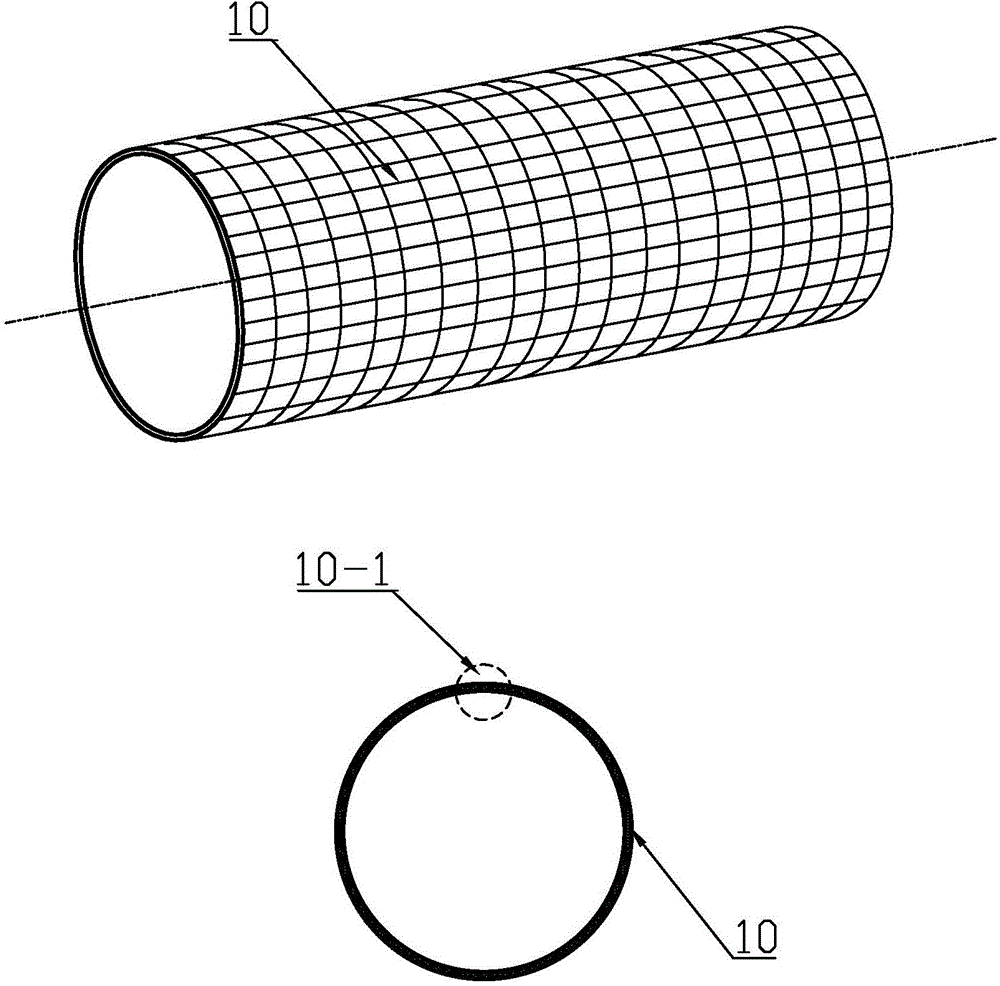

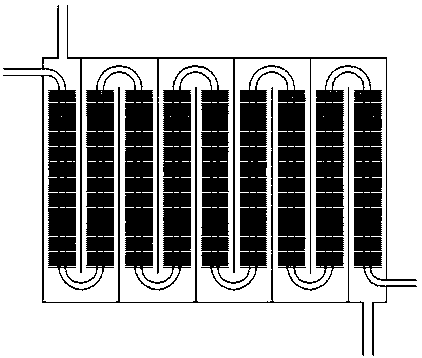

Novel superposed immersion type flat membrane element

InactiveCN102070246AEasy access to waterEasy to backwashSustainable biological treatmentBiological water/sewage treatmentFiltrationBiochemical engineering

The invention relates to a novel superposed immersion type flat membrane element. The element comprises an upper part middle support board (1), a lower part middle support board (2), a middle installation and connecting strip (7), two side edge pressing strips (8), an upper end piece (9) and a lower end piece (10), wherein the two boards, namely the upper part middle support board (1) and the lower part middle support board (2) are provided with a plurality of vertical diversion channels (3), the upper and lower ends of each board are provided with a plurality of water-collecting grooves (6); the two boards are provided with diaphragms (4, 5) respectively; and the cross section of the middle installation and connecting strip (7) is H-shaped, and the upper and lower middle support board (1,2) are separately connected and assembled with the H-shaped middle installation and connecting strip (7). The assembled immersion type flat membrane module has two independent membrane filtration systems of which pumping pressures can be set to be different, thus the normal operation of the immersion type flat membrane module can be ensured; and the immersion type flat membrane module is suitable for the large and medium sewage treatment projects.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

Secondary cooling water purification device for continuous casting machine and method for operating and using secondary cooling water purification device

InactiveCN102631806ASolve easy blockageQuality improvementStationary filtering element filtersWater flowInlet valve

The invention discloses a secondary cooling water purification device for a continuous casting machine. A bypass valve and a filtering pipeline are arranged on a secondary cooling water pipeline, the filtering pipeline crosses over the secondary cooling water pipeline in front and at the back of the bypass valve, a filter is arranged on the filtering pipeline, a water inlet valve is arranged on the filtering pipeline at a water inlet end of the filter, and a water outlet valve is arranged on the filtering pipeline at a water outlet end of the filter. The invention further discloses a method for operating and using the purification device. By the aid of the technical scheme, the problem of a pipeline is easily blocked when secondary cooling water flows through the pipeline is solved, the atomizing effect of a nozzle is more uniform and stable, and further continuous casting billets with high quality are obtained. Filtering processes are conveniently switched, back flushing is convenient, a filter barrel is rapidly replaced without affecting use, the quality of the cooling water is improved and stabilized, a filtering device is rapidly replaced and maintained, the quality of the secondary cooling water can be ensured under the condition of quite low investment, and the quality of the continuous casting billets is stabilized.

Owner:WUHU XINXING DUCTILE IRON PIPES

Mixed bed regeneration improvement process, system and application

ActiveCN112295611AImprove backwashing effectEasy to backwashGeneral water supply conservationFeed water supplyWater productionProcess engineering

The invention belongs to the field of water production, and relates to a mixed bed regeneration improvement process, a system and application. The process comprises air scrubbing, backwashing pre-layering, primary drainage, alkali feeding failure, backwashing layering, standing, secondary drainage, pre-injection, acid and alkali feeding, replacement, after-replacement drainage, regeneration mixing, regeneration irrigation, regeneration forward washing, and operation. The backwashing effect is enhanced by compressed-air scrubbing, so that the resin is fully loosened. The subsequent backwashingis facilitated. Meanwhile, in the alkali feeding failure step, the alkali feeding mode is adjusted, a positive discharge valve is changed into a middle discharge valve, alkali can fully and only exchange with upper-layer anion resin, meanwhile, a small amount of upper-layer cation resin fails, the alkali feeding time is shortened, the alkali consumption can be reduced, and the regeneration effectis improved.

Owner:YANKUANG GRP CO LTD

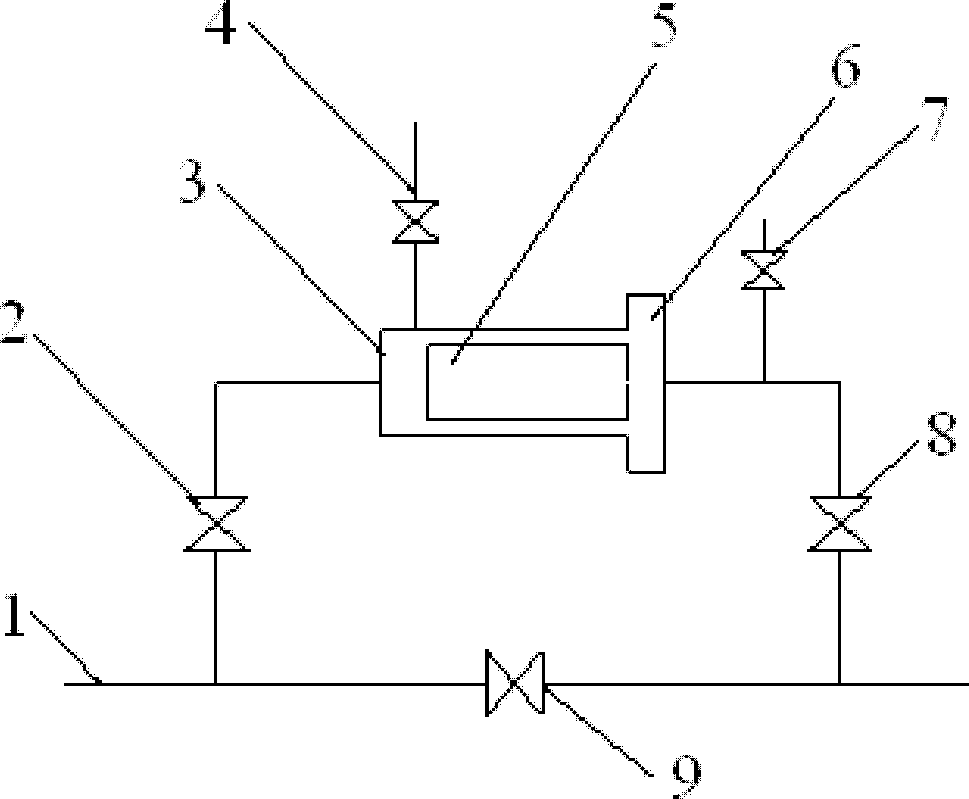

Backflushing type heat exchange system with water quality and temperature detecting function

ActiveCN103528401AEasy to backwashEfficient backwashCorrosion preventionStationary tubular conduit assembliesWastewaterWater quality

The invention discloses a backflushing type heat exchange system with a water quality and temperature detecting function. The backflushing type heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (25), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough 92). The hot water outlet pipe (6) is provided with a heater (13), a detector (15) is arranged in the lower heat exchange trough (2) and used for detecting water quality and is connected with a controller (14), and the controller (14) comprises a comparing module (143) respectively connected with a setting module (144), the detector (15) and a temperature sensor (27). The backflushing type heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:安徽宇测线缆质检技术有限公司

Flexible tube press for sludge cake discharge by extrusion method with multi-layer permeable panels

InactiveCN102284205AReduce moistureSealing problem avoidanceStationary filtering element filtersSlagFilter media

The invention discloses a flexible tube presser for discharging a mud cake by using a multi-layer water permeable plate through an extrusion method. A filter element of the flexible tube presser comprises an upper flange, a filter tube unit, a filter chamber forward and backward limiting structure, a filter chamber leftward and rightward limiting mechanism, a horizontal filtrate collection tray and a mechanical slag removal assembly, wherein the upper flange comprises a filter chamber upper sealing structure and a traveling mechanism; guide wheels of the traveling mechanism are arranged on the left side and the right side of the upper flange and are engaged with a stand guide rail respectively; in the machinery, the mud cake is discharged by using the extrusion method; at least one water permeable plate and a collection tube are arranged in a filter chamber; each water permeable plate comprises at least three layers of plate-shaped filter mediums, a plate locking strip, a suspension assembly, a filter cloth tightening mechanism, an edge covering corner strip, a water discharge conduit port and a fluid inlet orifice; and a treatment process is automatically finished by the water permeable plate due to the small size, simple structure, high pressure resistance, light weight, reliable sealing, large water absorption area, long life, high filtering speed, high efficiency, large treatment scale and low running cost of the water permeable plate.

Owner:TIANJIN ZHONGLISHI PURFICATION & SEPARATION TECH

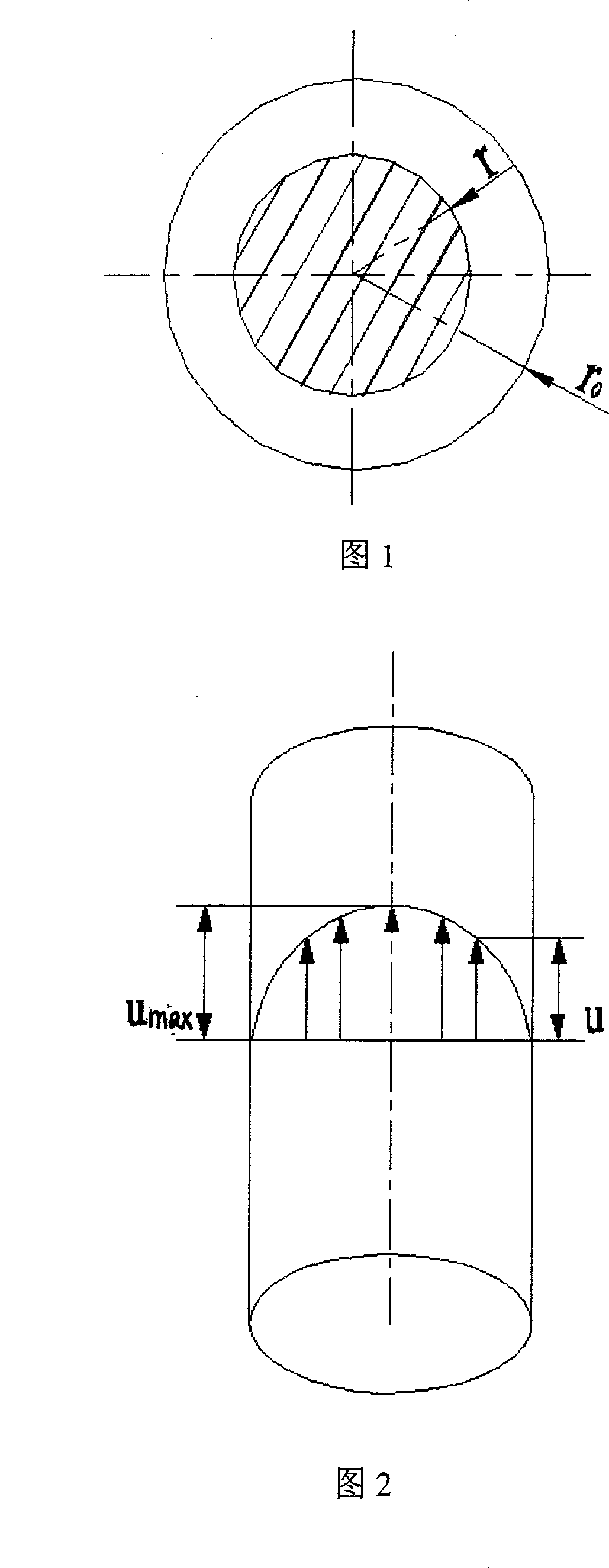

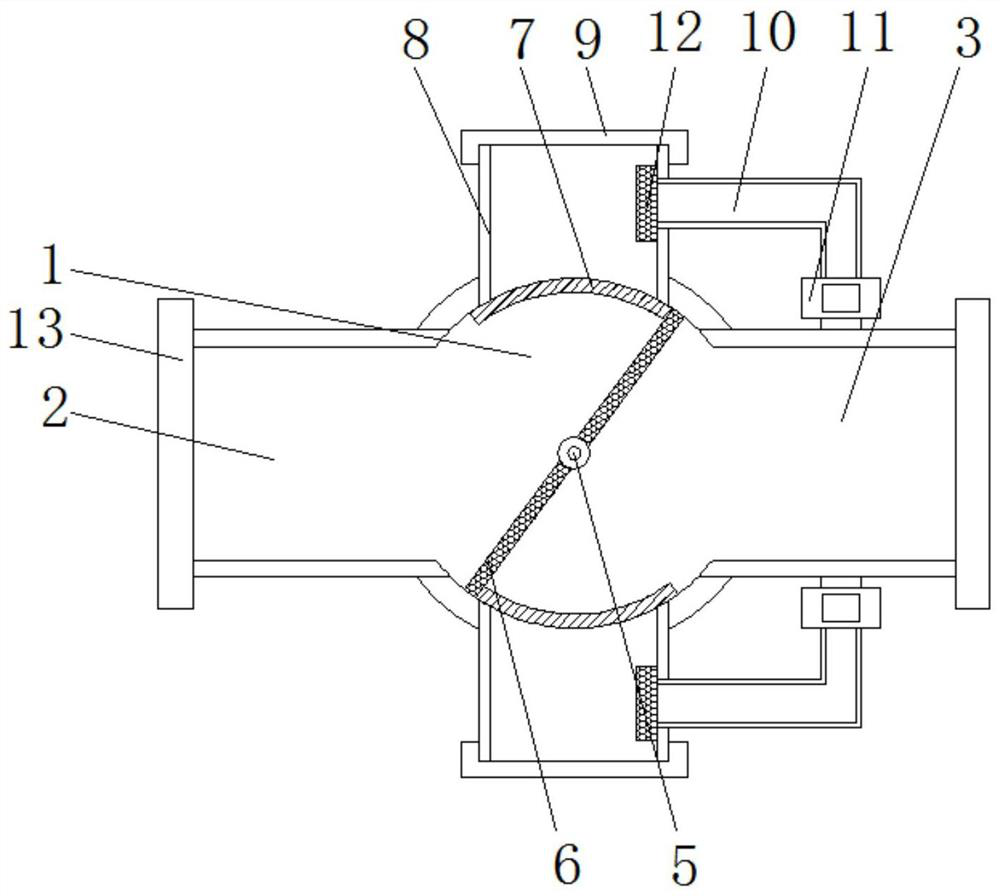

Externally pressed six-wing tubular membrane and method for manufacturing same

ActiveCN104667752ASolve the problem of spatial three-dimensional distributionDoes not affect effective filtration efficiencySemi-permeable membranesBiological water/sewage treatmentEpoxyFiltration

The invention discloses an externally pressed six-wing tubular membrane and a method for manufacturing the membrane. The externally pressed six-wing tubular membrane comprises a six-wing tubular membrane body, a six-wing lined pipe, a composite filter membrane, a depression bar, a core tube, an electrode lead, an external layer carbon net, an organic filter membrane, an internal layer carbon net, and a prefabricated membrane tube. The composite filter membrane is composed of the internal layer carbon net, the organic filter membrane, the external layer carbon net and the electrode lead. The six-wing membrane is composed of the six-wing lined pipe, the composite filter membrane, the depression bar, the core tube and an end cover; flow guide circular holes are arranged between adjacent wing boards outside the core tube; the composite filter membrane is fixed between two adjacent wing boards by the depression bar and distributed on the outer surface of the six-wing lined pipe in a rising and falling way; both ends of the six-wing tubular membrane are sealed and fixed by the end cover and an epoxy resin; the electrode lead is led out from the sealed position of the epoxy resin. According to the externally pressed six-wing tubular membrane, the high-efficiency filtration, and pollution-preventing and self-cleaning functions are realized, and the manufacturing process is simple, thus the externally pressed six-wing tubular membrane is applied to the large polluted water or waste water treatment engineering.

Owner:苏州市和源环保科技有限公司

Back-flushable type heat exchange system having flow velocity and temperature detecting functions

ActiveCN103542530AEasy to backwashEfficient backwashFluid heatersFlush cleaningWater channelWastewater

The invention discloses a back-flushable type heat exchange system having flow velocity and temperature detecting functions. The back-flushable type heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a spraying head (25), an upper heat exchange water channel (1) and a lower heat exchange water channel (2), wherein an upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange water channel (1) and the lower heat exchange water channel (2). A heater (13) is further arranged on the hot water outlet pipe (6), and a detector (15) is arranged in the lower heat exchange water channel (2) and used for detecting flow velocity. The detector (15) is connected with a controller (14). The controller (14) comprises a comparison module (143) connected with a setting module (144), the detector (15) and a temperature sensor (27) respectively. The technical problem that stains easily accumulates inside the heat exchange devices and cannot be automatically cleaned is solved.

Owner:江阴戴勒姆动力设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com