Novel superposed immersion type flat membrane element

A submerged, flat membrane technology, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc. Simple and compact structure, the effect of more floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

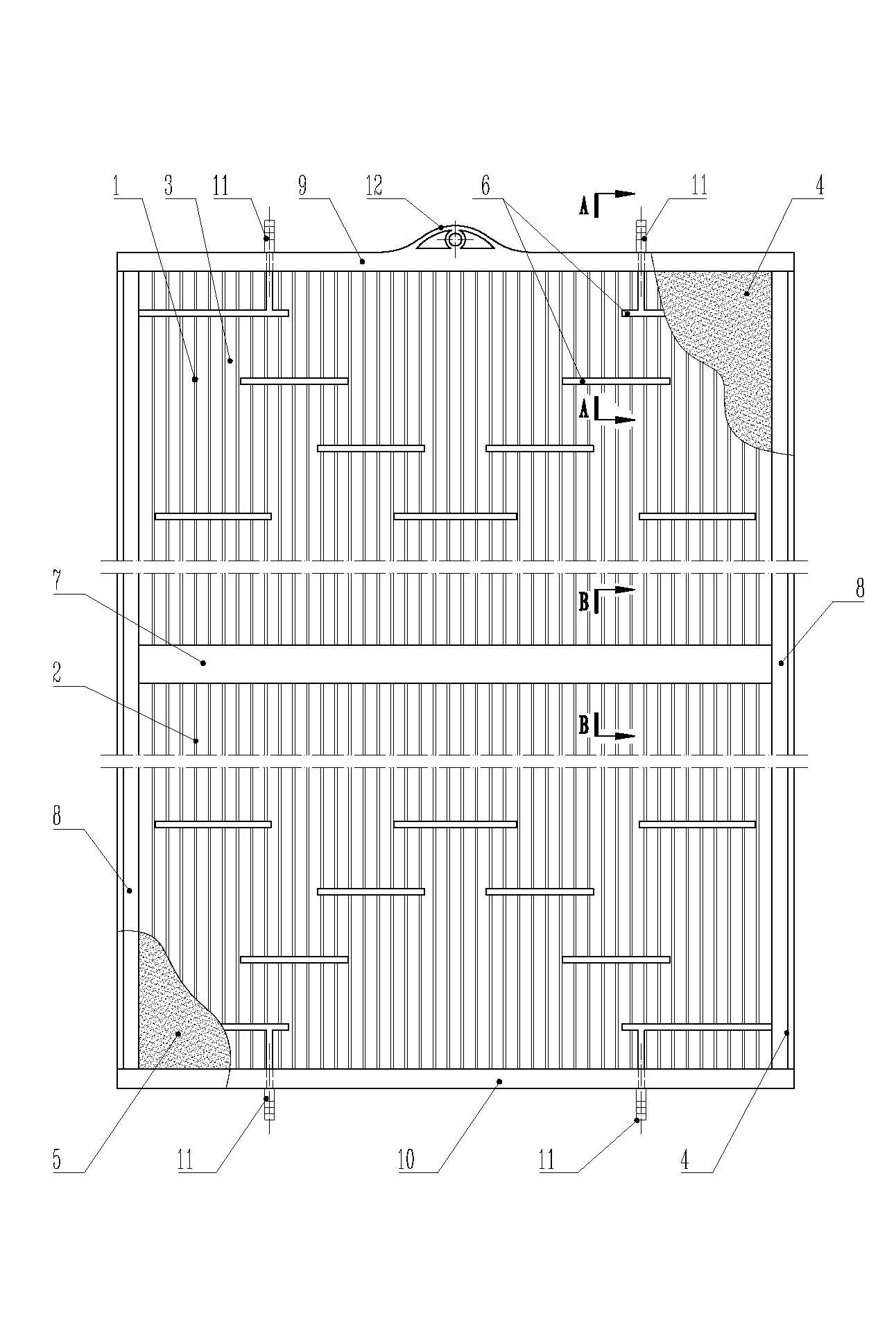

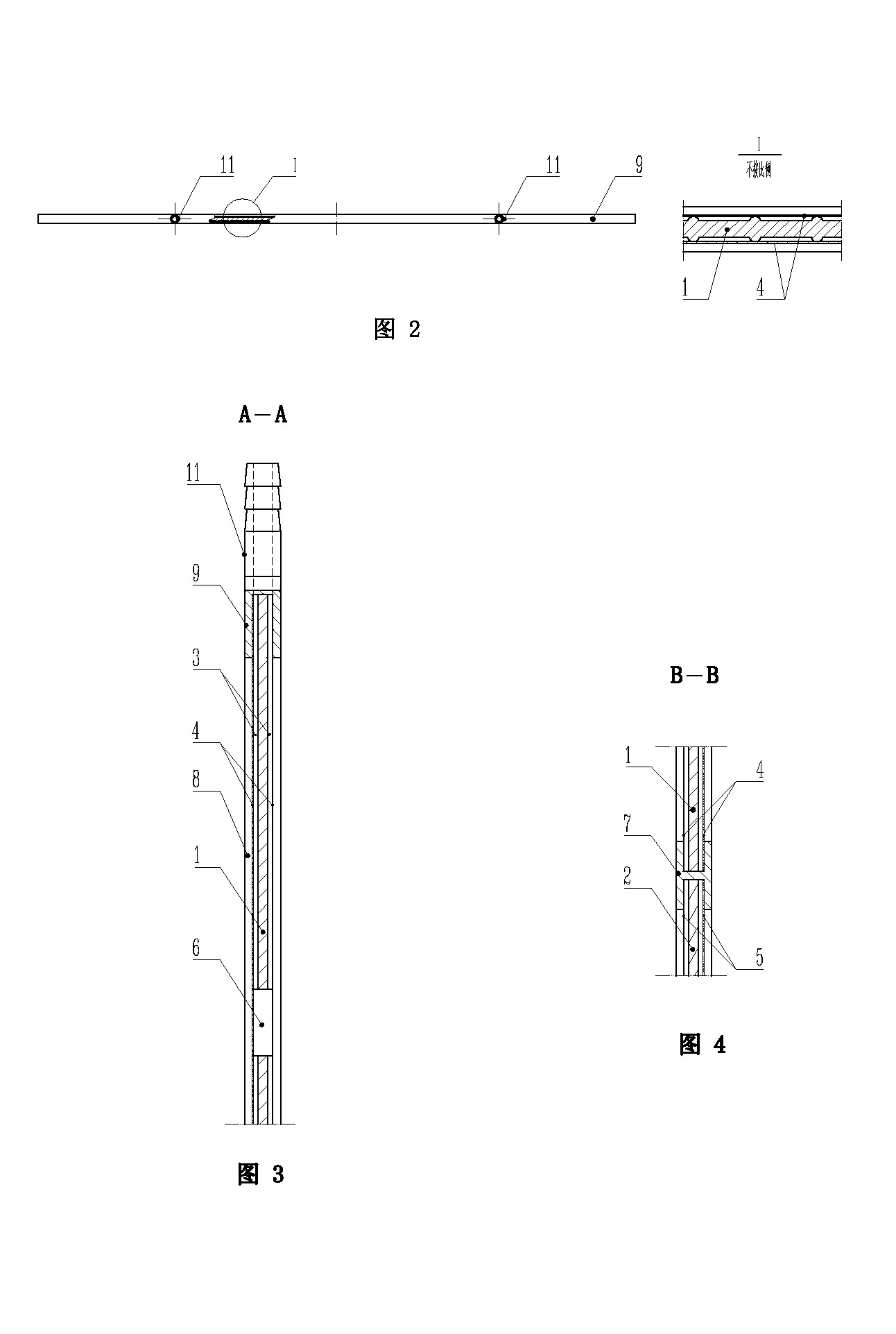

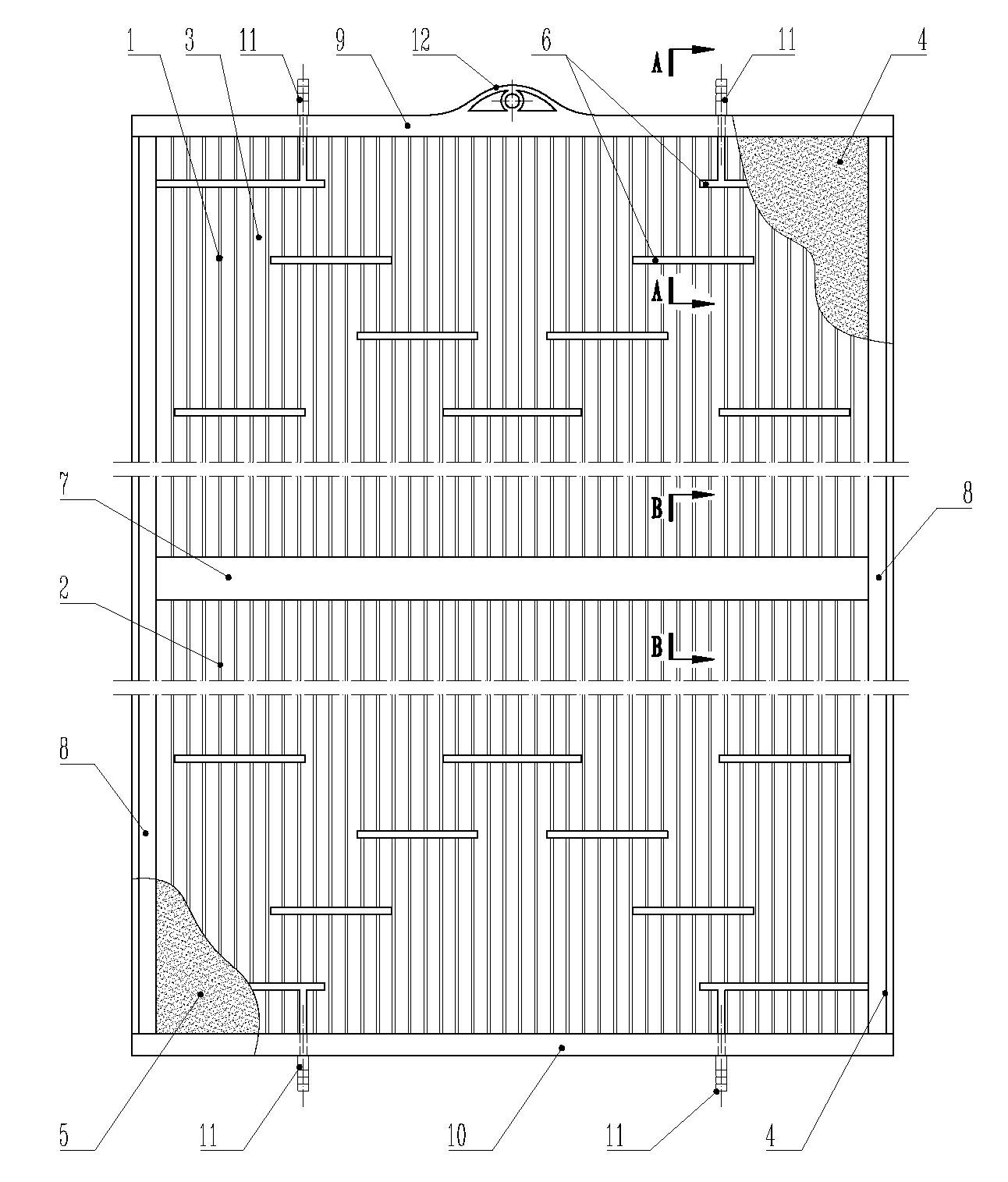

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

[0015] Such as Figure 1-4 As shown, the two sides of the upper intermediate support plate 1 of the present invention are provided with multiple vertical guide grooves 3; in order to improve the water absorption efficiency, a plurality of water collecting channels 6 are arranged on the upper end of the upper intermediate support plate 1, which can be added The water flux is greatly improved; the structure, shape and size of the lower middle support plate 2 and the upper middle support plate 1 are the same except that a plurality of water collecting channels 6 are arranged at the lower end thereof.

[0016] Diaphragms 4 and 5 are installed on both sides of the upper intermediate support plate 1 and the lower intermediate support plate 2 respectively; the connecting strip 7 is installed in the middle, and its cross section is an "H" type section, and the diaphragm 4 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com