Mixed bed regeneration improvement process, system and application

A mixed-bed and process technology, applied in the field of mixed-bed regeneration improvement process, can solve the problems of affecting the regeneration effect of the regeneration solution, the mixed-bed backwashing effect is poor, and affecting the production of desalinated water, etc., so as to shorten the alkali feeding time and improve the regeneration effect. , the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

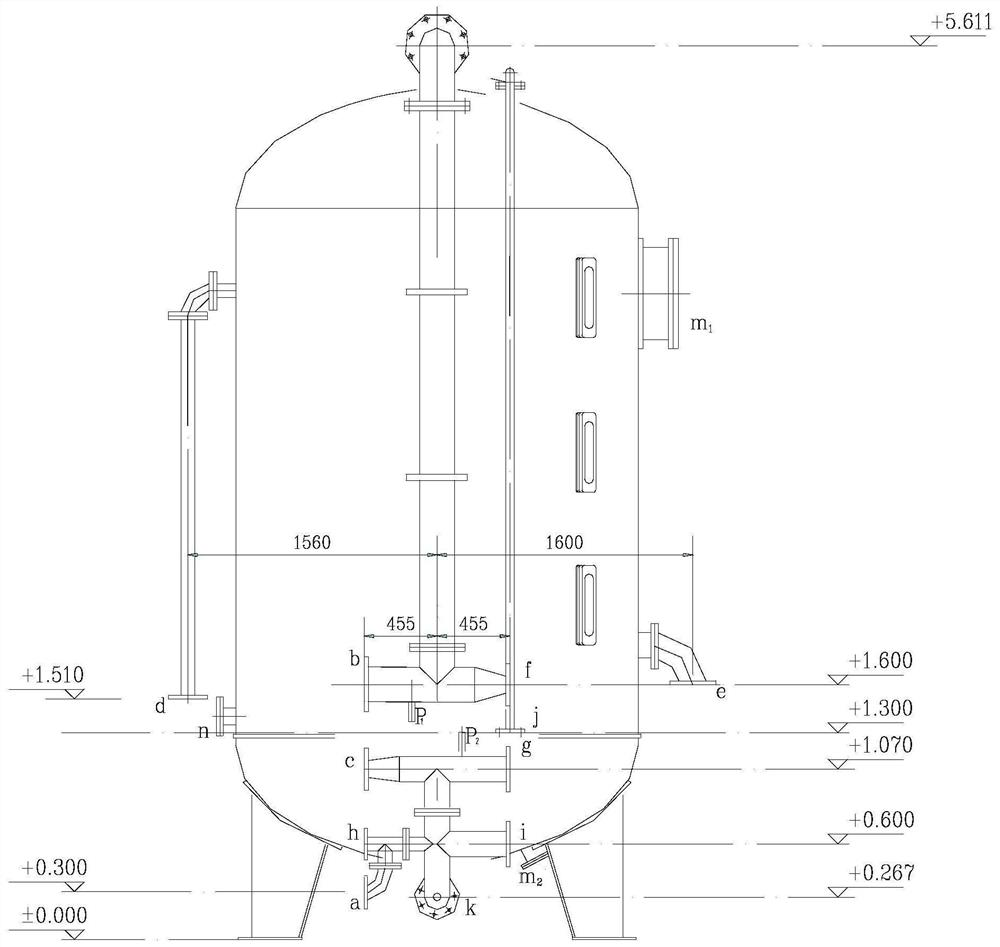

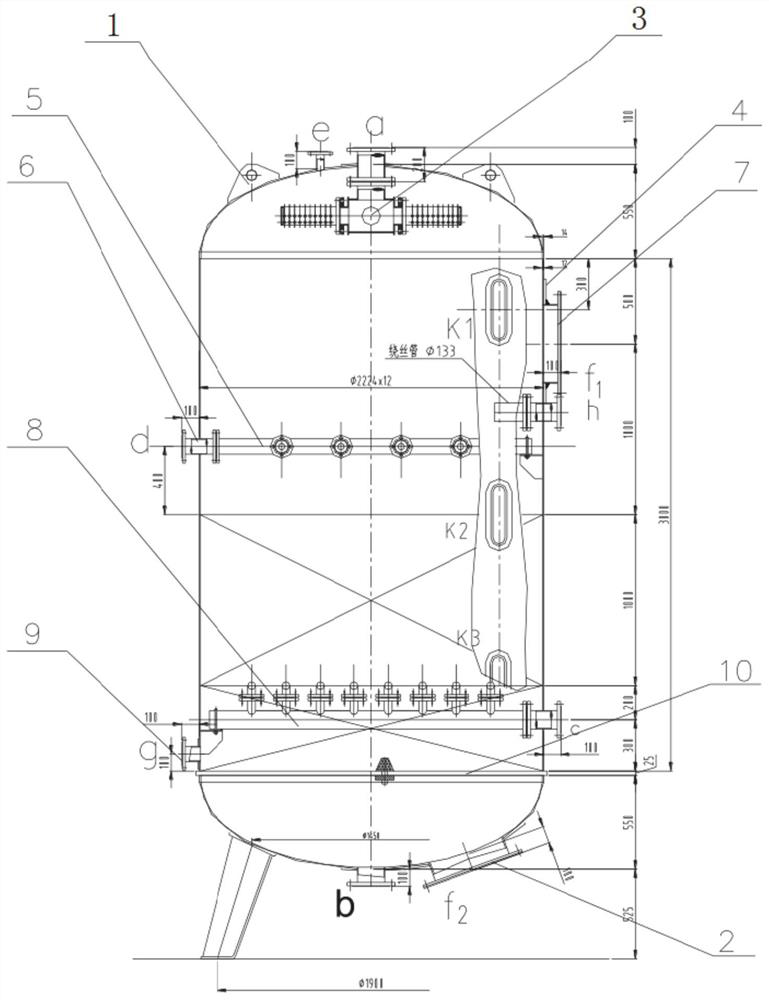

[0078] Mixed bed regeneration steps:

[0079] a. Air scrubbing: Drain to the height of 50cm of the resin layer, close all valves, open the intake valve, exhaust valve, and reverse discharge valve; the intake pressure is controlled at 0.08Mpa, and the flow rate is 2.5m 3 / m 2 . S, the mixing time is 300s (confirm that the resin is loose). After the air stops, close the intake valve, reverse discharge valve and exhaust valve. Drain immediately and quickly, forcing the entire resin bed down quickly.

[0080] b. Backwash pre-layering: close the water inlet valve and water production valve; close the manual water production valve and the drain valve of the resin trap; open the backwash water inlet valve and backwash drain valve, and start the intermediate water pump to make the resin in full Flowing state, backwash broken resin away. Control the manual backwash valve to control the backwash flow. The normal granular resin is not washed out by the water flow. The backwash end p...

Embodiment 2

[0097] The desalinated water station has two Roots blowers to supply air to the filter, and a DN100 bypass is added at the outlet of the blower to connect with the compressed air inlet main to the mixed bed to realize dual air sources to ensure air supply. When the compressed air supply is stopped, the regeneration air source is switched to the Roots blower to ensure the normal regeneration of the mixed bed.

[0098] Roots blower: model L52LD air volume 22m 3 / min wind pressure P=68.6KPa. Meet gas supply requirements.

[0099] Effectively solve the problem of shutting down the compressed air source of the pipeline network, and ensure the stable and sustainable source of the mixed bed regeneration gas source.

Embodiment 3

[0101] The difference from Example 1 is that the air intake pressure of air scrubbing is controlled at 0.08Mpa, and the flow rate is 2m 3 / m 2. S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com