Patents

Literature

33results about How to "Reduce backwash water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

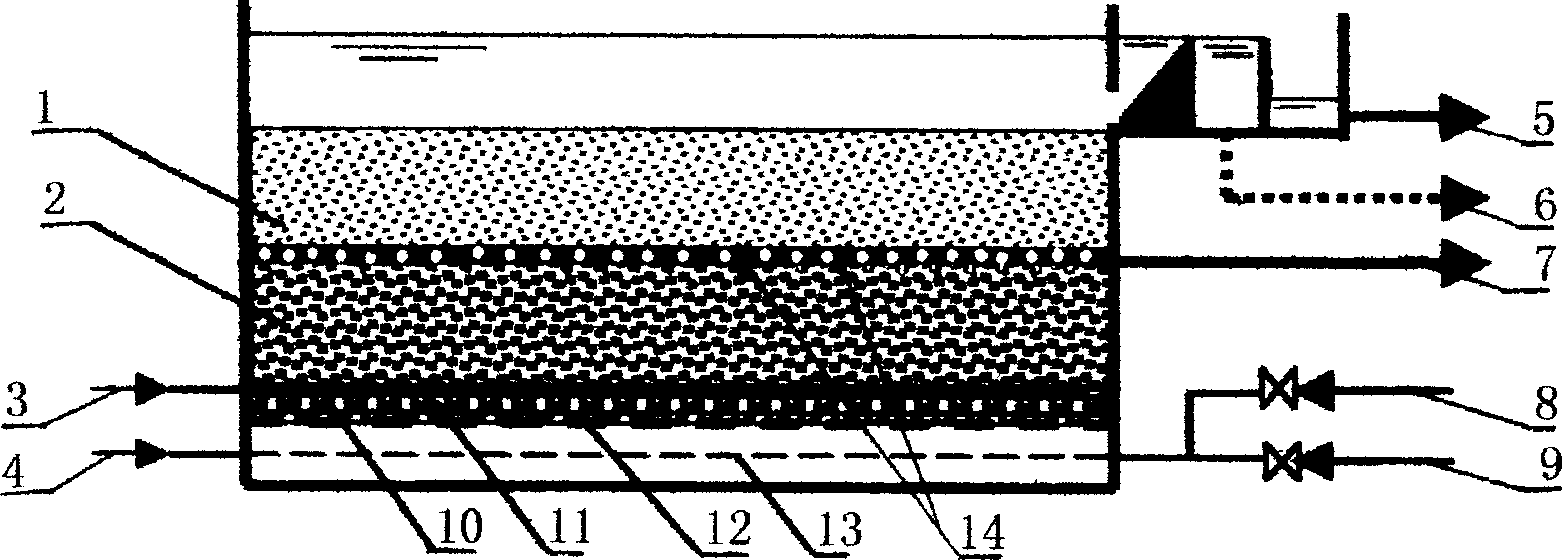

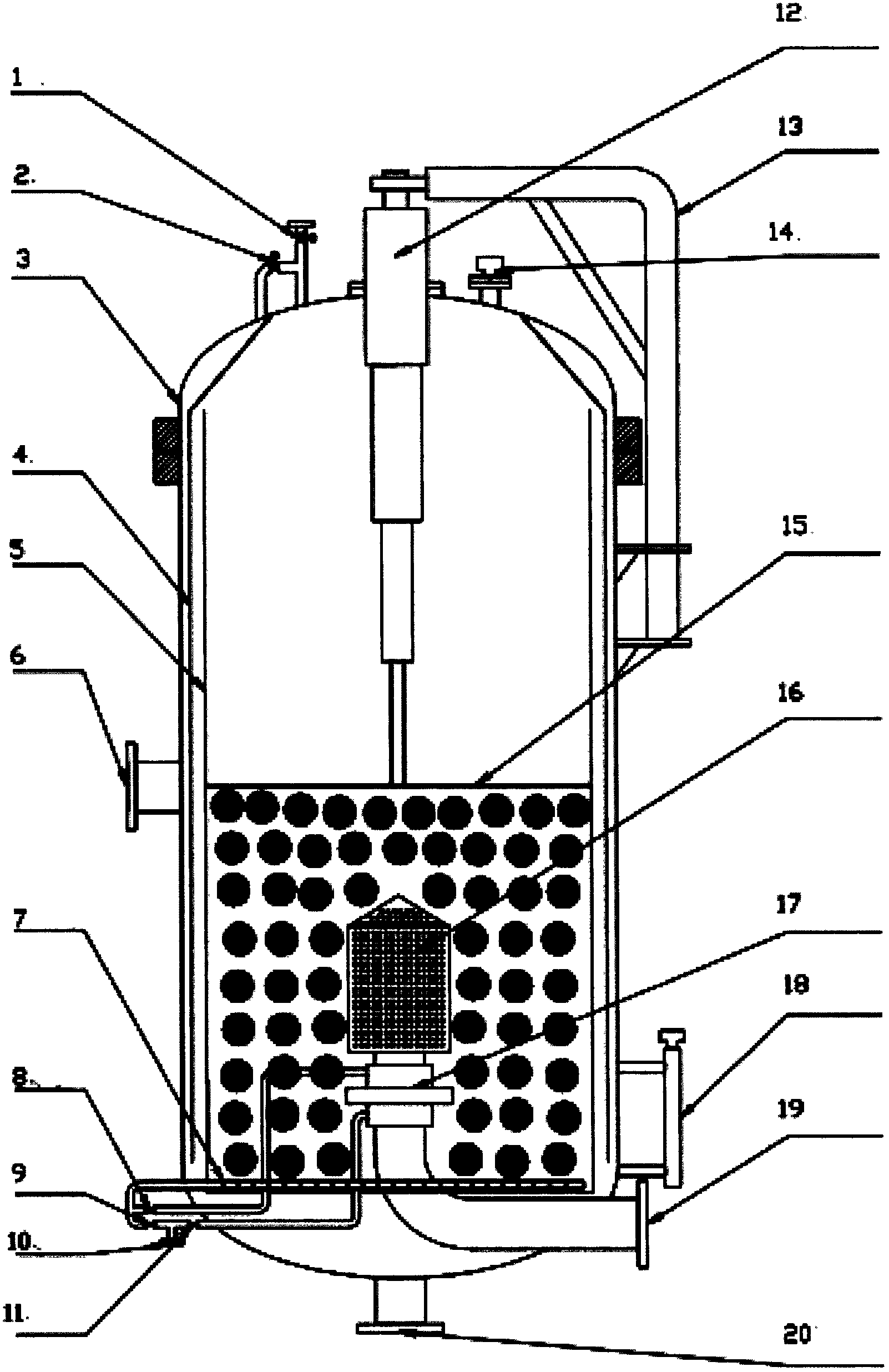

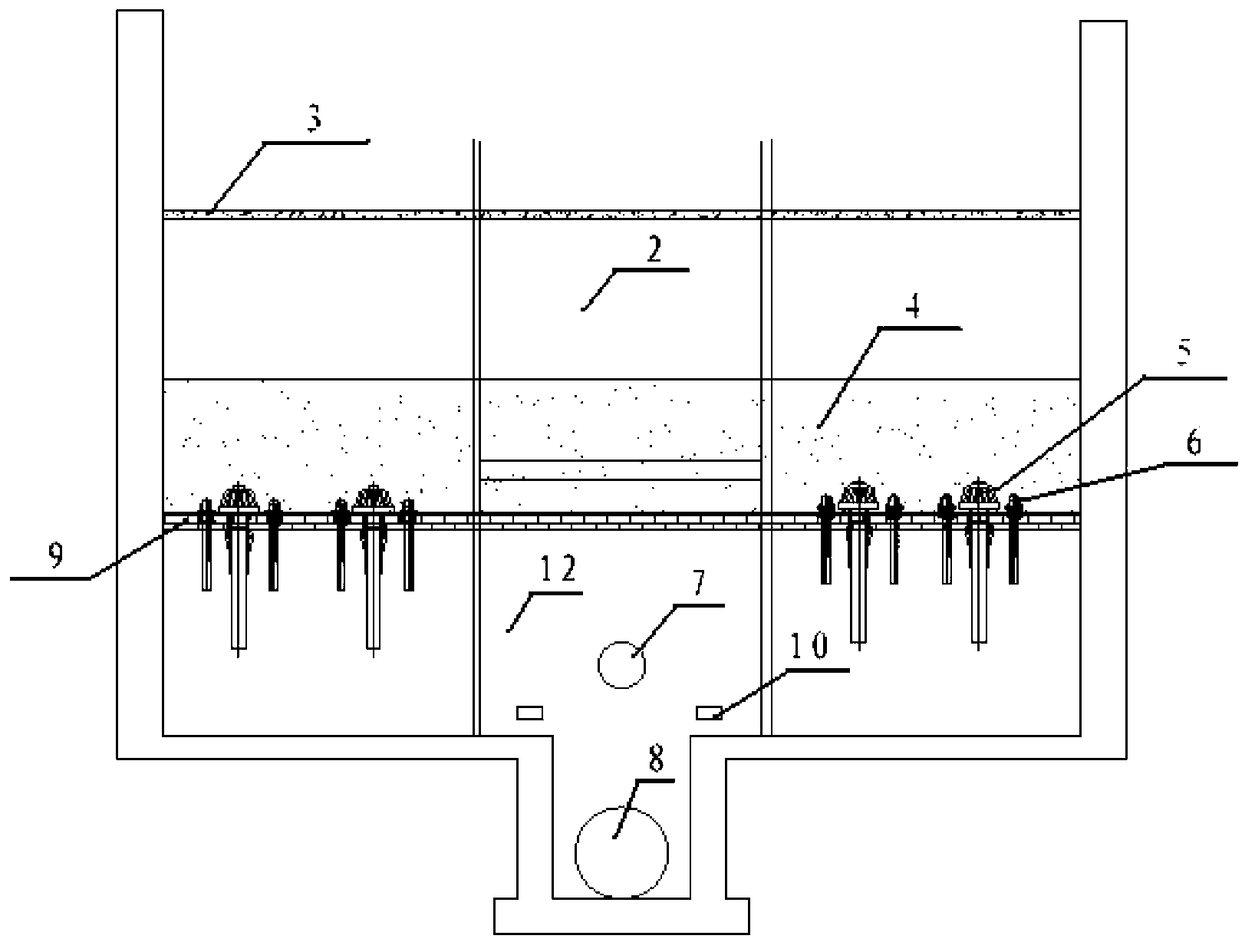

Double-layer filter material biological aeration filter pond

InactiveCN1401592ASmall running resistanceReduce backwash water consumptionTreatment using aerobic processesSustainable biological treatmentGranularitySludge

An aerating biologic filter pool with dual layers of filter material for treating sewage is characterized by that two filter materials with different granularities are used, middle discharge tubes with water holes are arranged between two filter layers, and air and water are alternatively used for flushing. Its advantages are both decarbonating and nitrifying functions, high effect, simple system and low cost.

Owner:TSINGHUA UNIV +1

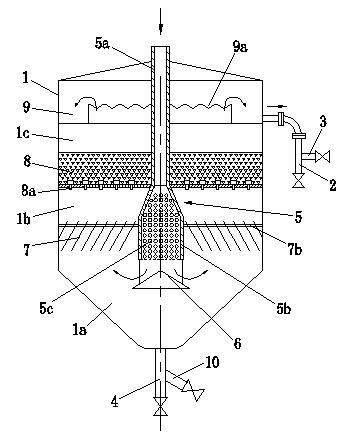

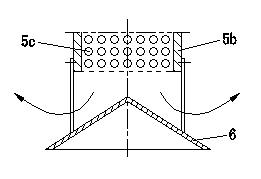

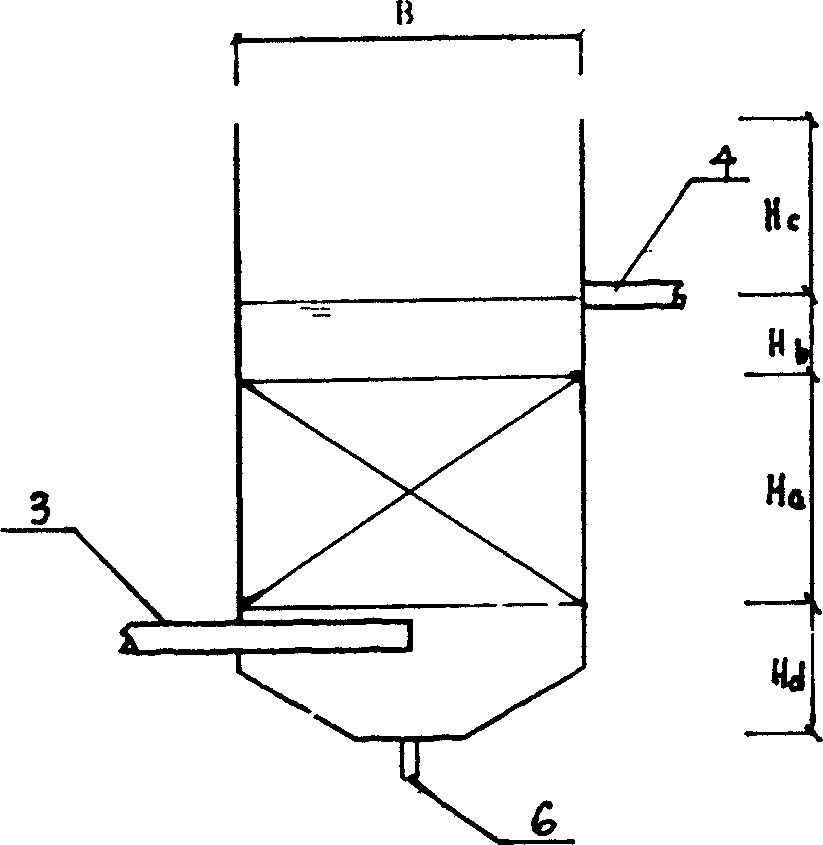

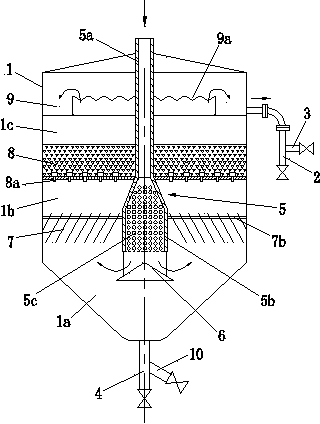

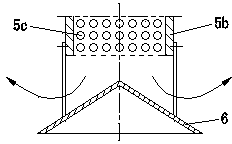

Integrated water treatment purifier

ActiveCN102583677AReduce the overall heightSmall footprintWater/sewage treatment by flocculation/precipitationFlocculationWater quality

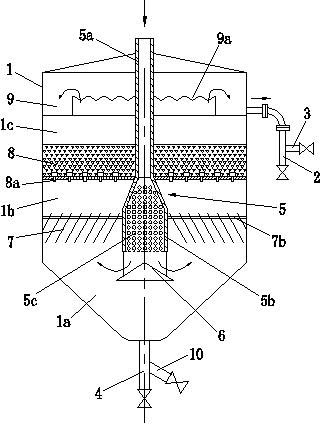

The invention discloses an integrated water treatment purifier which comprises a shell (1) with an inner chamber, wherein the upper part of the shell is connected with a water outlet pipe (2), the lower part of the shell is connected with a mud outlet pipe (4), and the inner chamber of the shell (1) is provided with a flocculation reaction device (5); the flocculation reaction device (5) comprises a water inlet pipe section (5a) and a reactor body (5b), wherein the inner chamber of the reactor body is provided with flocculated packing (5c), the lower part of the reactor body is provided with an upper tapered flow guide component (6), an inclined plate assembly (7) is formed on the outside of the periphery of the reactor body (5b), a lower chamber (1a) is formed in the inner chamber of the shell by the inclined plate assembly, the bottom of the lower chamber (1a) is a concentrated mud collection zone, a filter layer (8) is arranged above the inclined plate assembly (7), a middle chamber (1b) and an upper chamber (1c) are formed in the inner chamber of the shell by the filter layer (8), and the upper chamber (1c) is communicated with the water outlet pipe (2). The integrated water treatment purifier integrates flocculation, sedimentation, filtering and concentrated mud collection, and has the advantages of no mutual interference of functional zones, simple and compact structure and small floor area, which is favorable for enhancing the water quality of output water.

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

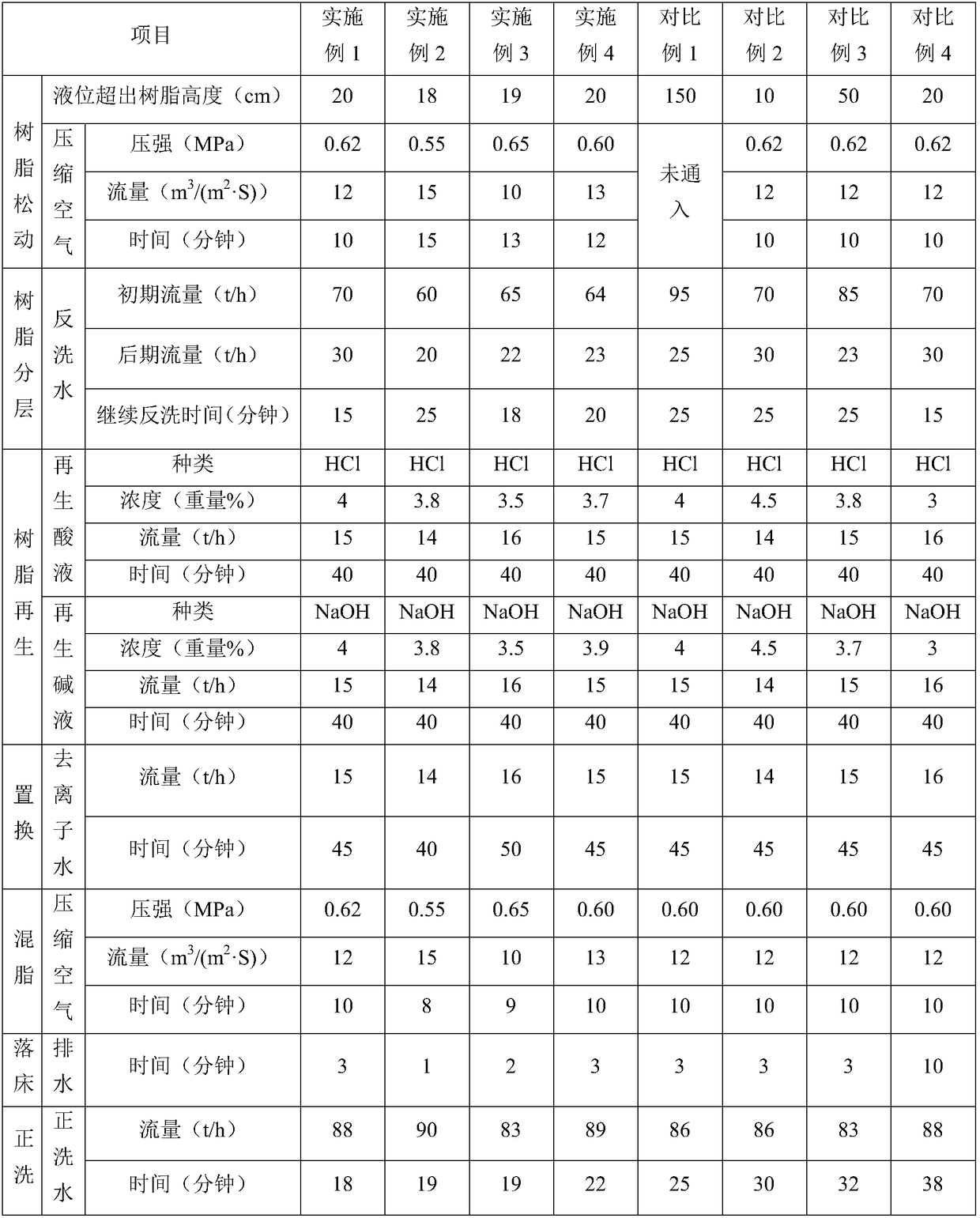

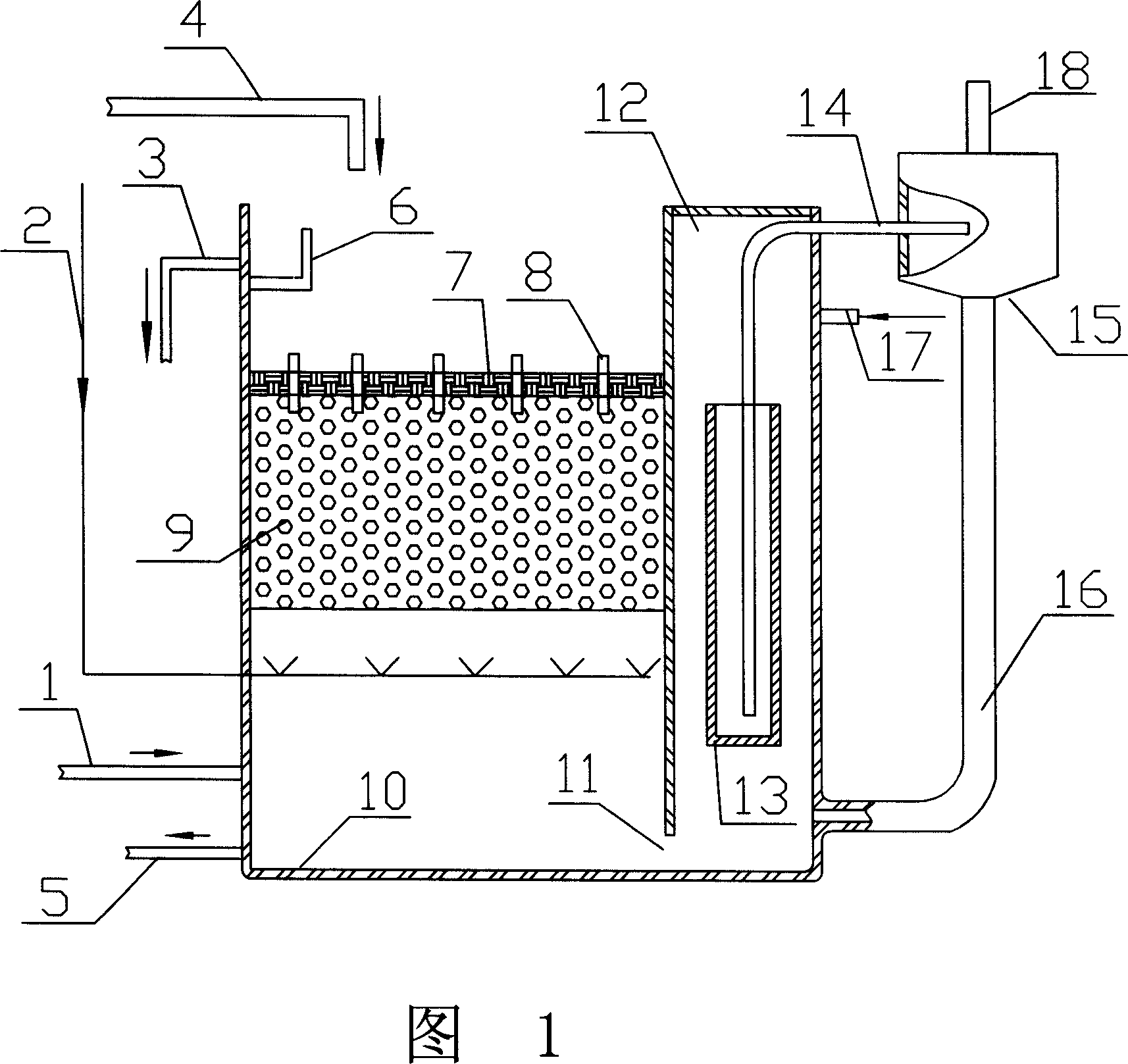

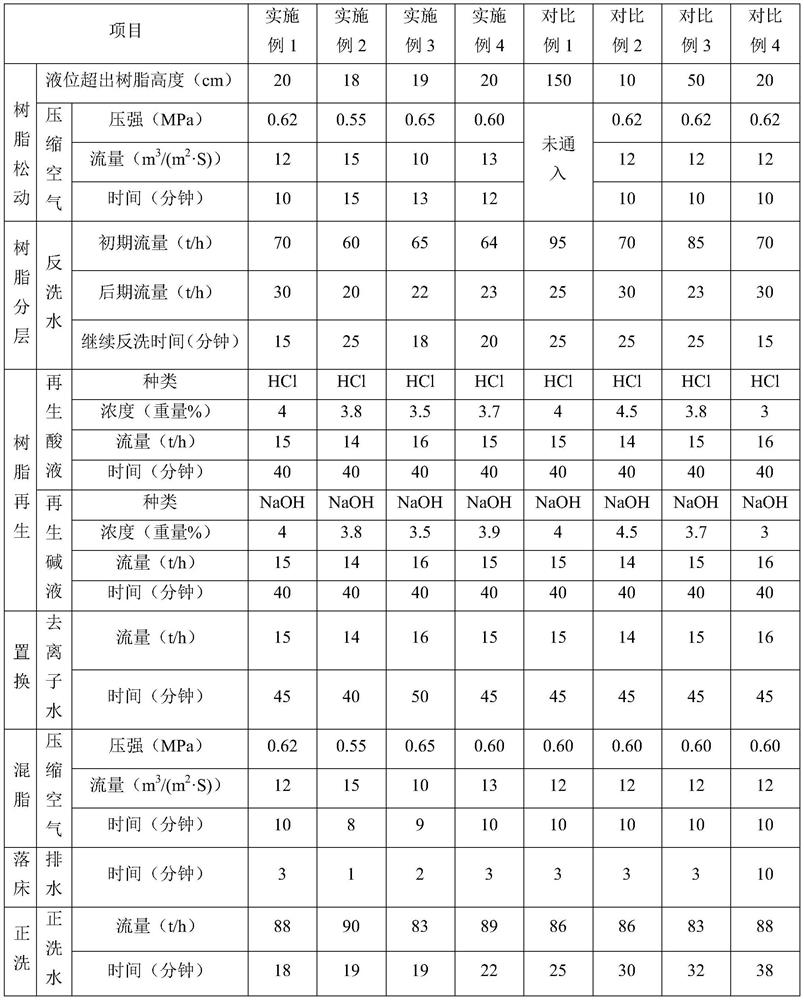

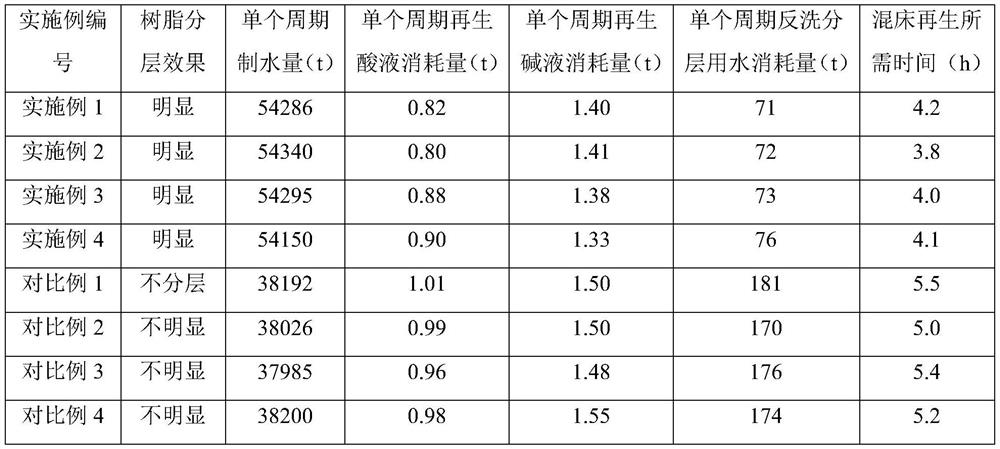

Method for regenerating desalting mixed bed

ActiveCN108178240AShort regeneration timeIncrease water productionSpecific water treatment objectivesWater/sewage treatment by ion-exchangePower stationWater production

The invention relates to the field of chemical water production in power plants, and discloses a method for regenerating a desalting mixed bed. In the method, the liquid level in a mixed bed tank reduces to the top of a resin layer before the resin layer is subjected to hydrodynamic backwashing layering, and compressed air is introduced into the mixed bed tank to perform air washing, so the resinis effectively loosened, the water injection pressure of the subsequent backwashing step is reduced, the backwashing layering effect is enhanced, the backwashing layering time is significantly shortened, and the consumption of backwashing water in the resin backwashing layering process is reduced. After the resin is backwashed with water, the control of the concentrations and the flow amounts of aregeneration alkali solution and a regeneration alkali solution can significantly reduce the consumptions of the regeneration alkali solution and the regeneration alkali solution in the resin regenerating process and greatly shortens the regeneration time of the desalting mixed bed. The water production volume of the desalting mixed bed in a single period is high, and the outlet water of the regenerated desalting mixed bed has excellent quality.

Owner:CHINA SHENHUA ENERGY CO LTD +2

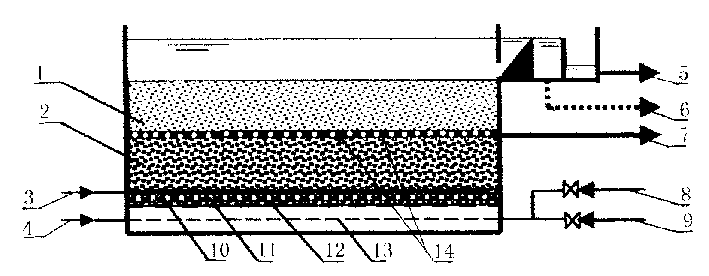

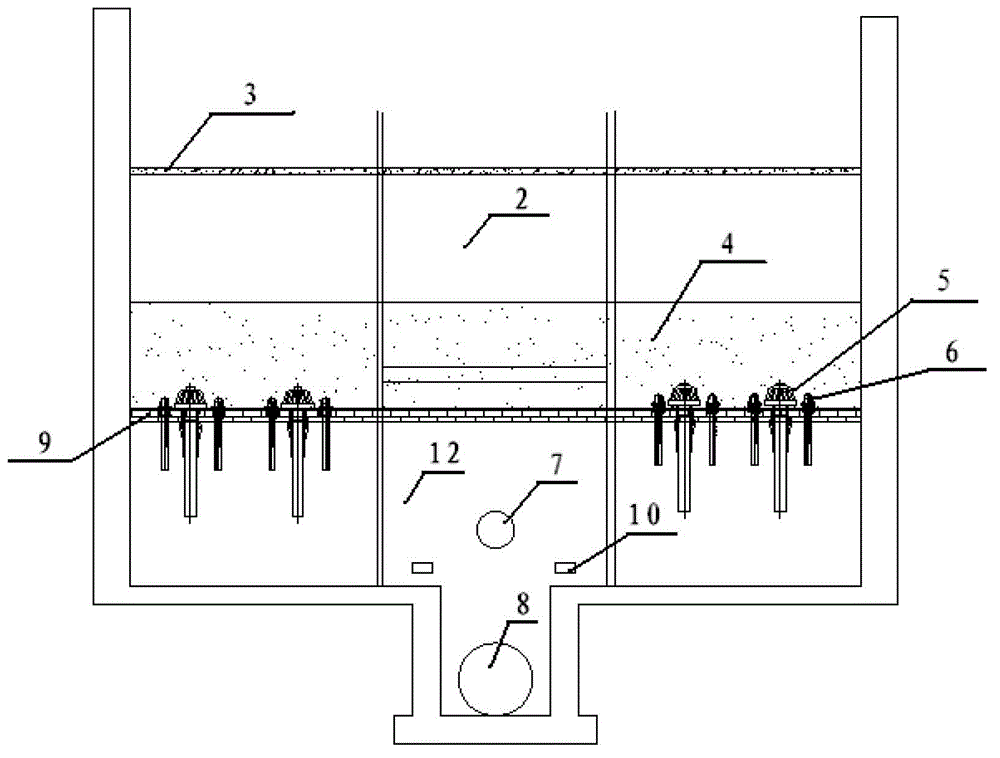

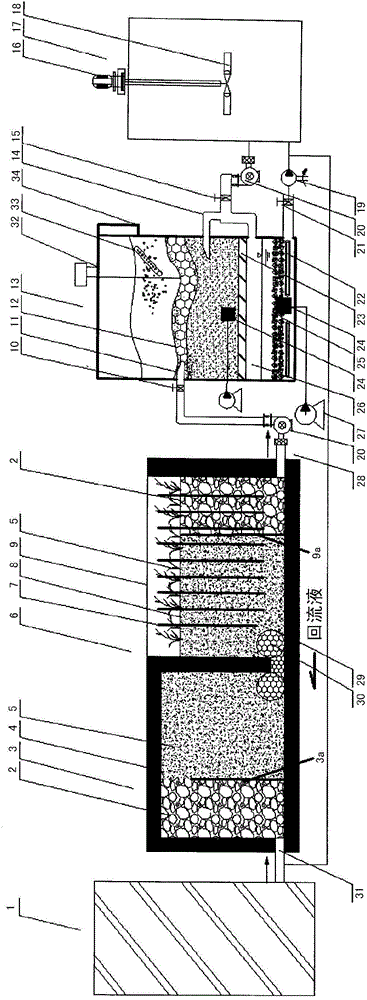

Aerating biological filter

InactiveCN1923724ASimple structureReduce manufacturing costTreatment using aerobic processesSustainable biological treatmentBiological filterWater treatment

The invention discloses an aerating biological filter pool in the water disposal device domain, which comprises the following parts: filter pool within aerating device and filtering device, water inlet pipe on the bottom of filter pool, backwash drainage pipe on the bottom of filter pool, pulse air-chamber to interconnect bottom of filter pool through backwash inlet pipe and vent pipe, wherein the vent pipe lies in one end of water sealing pipe in the pulse air-chamber; the other end of vent pipe connects gas-water separator, whose top possesses connection pipe with bottom interconnecting the bottom of pulse air-chamber through connection pipe.

Owner:SHANDONG JIANZHU UNIV

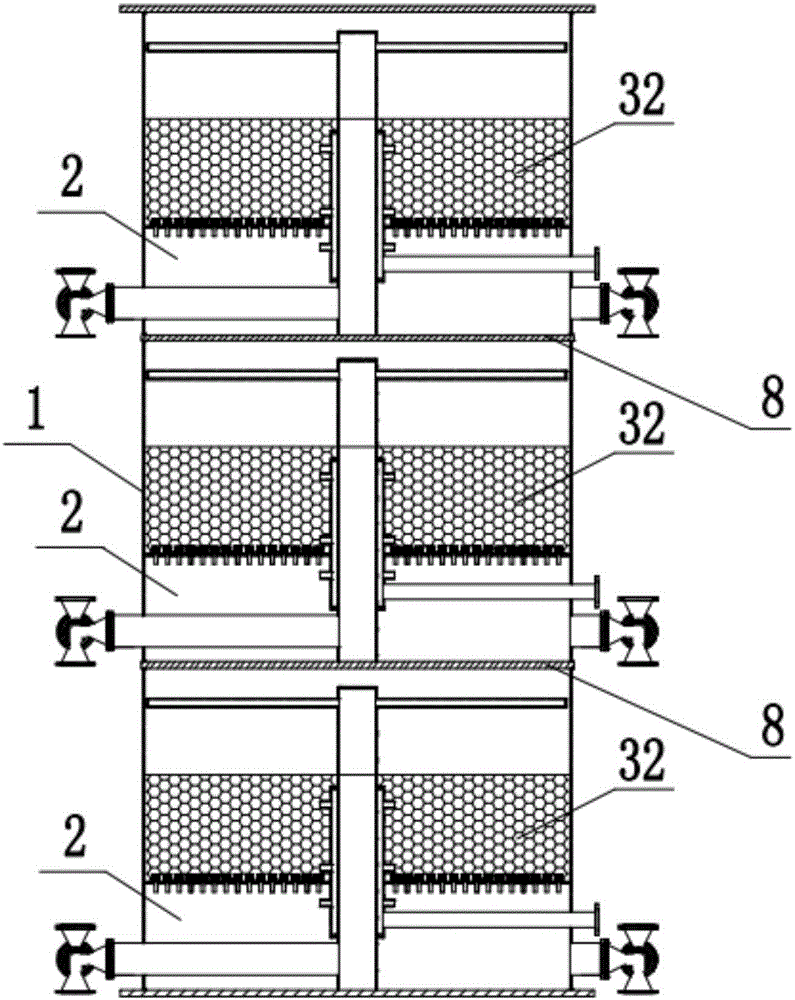

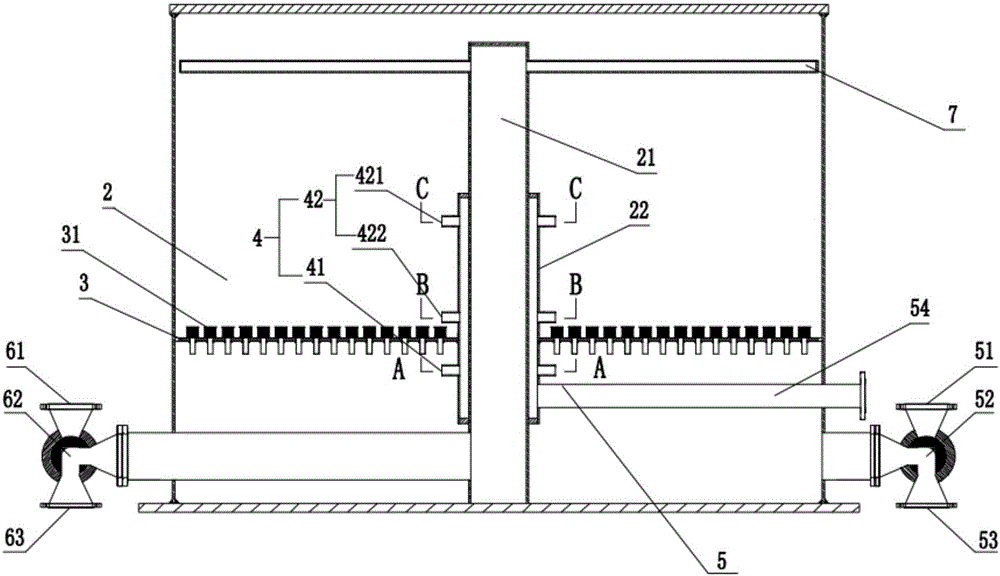

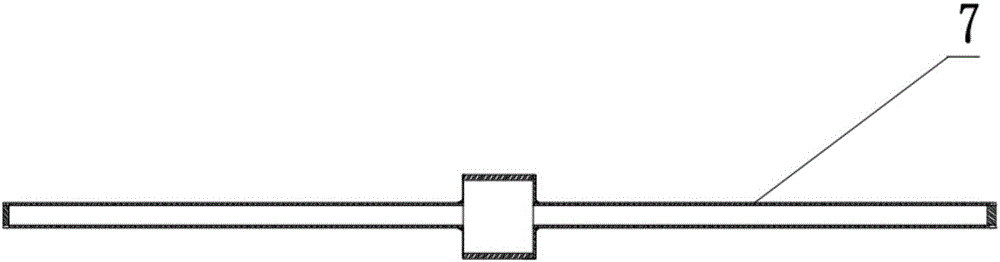

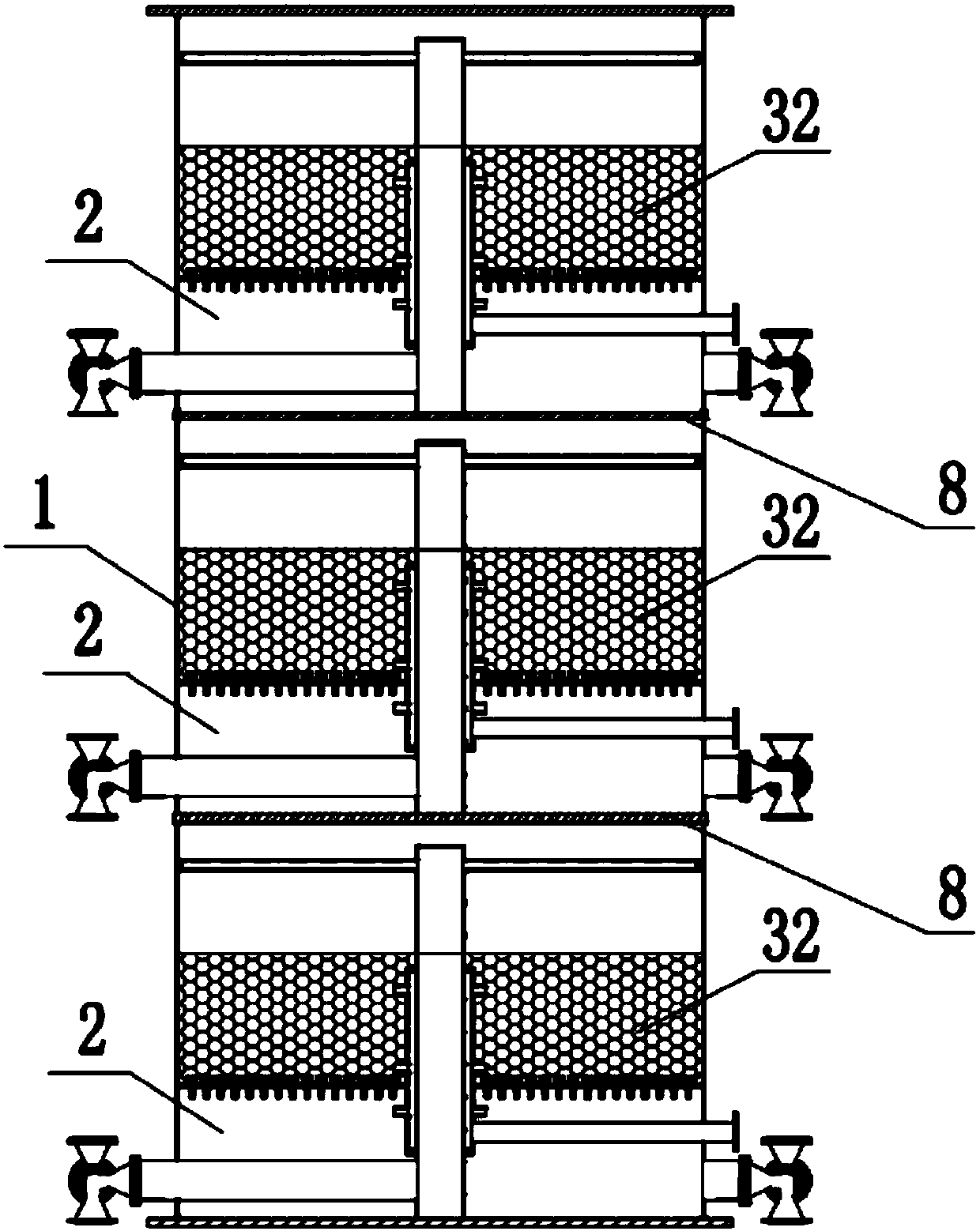

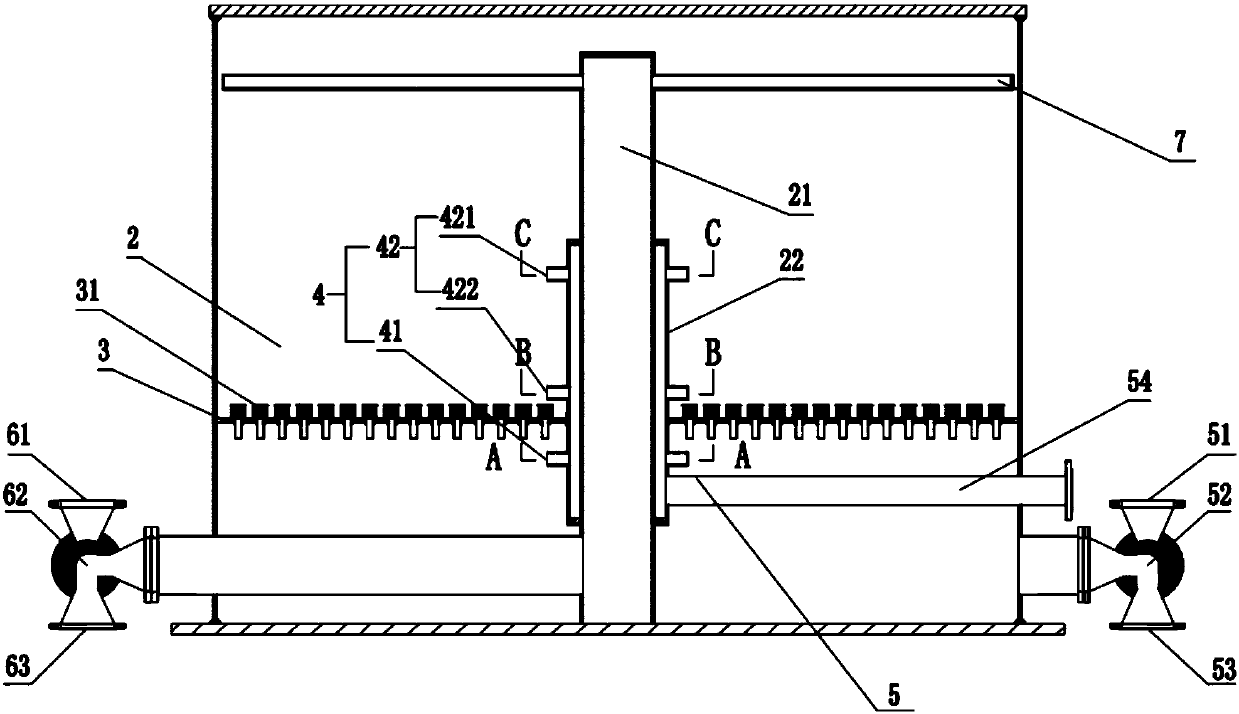

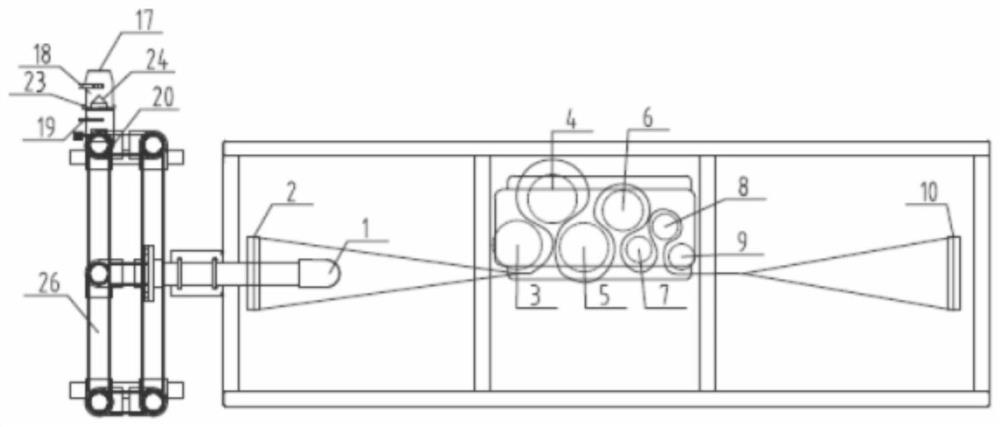

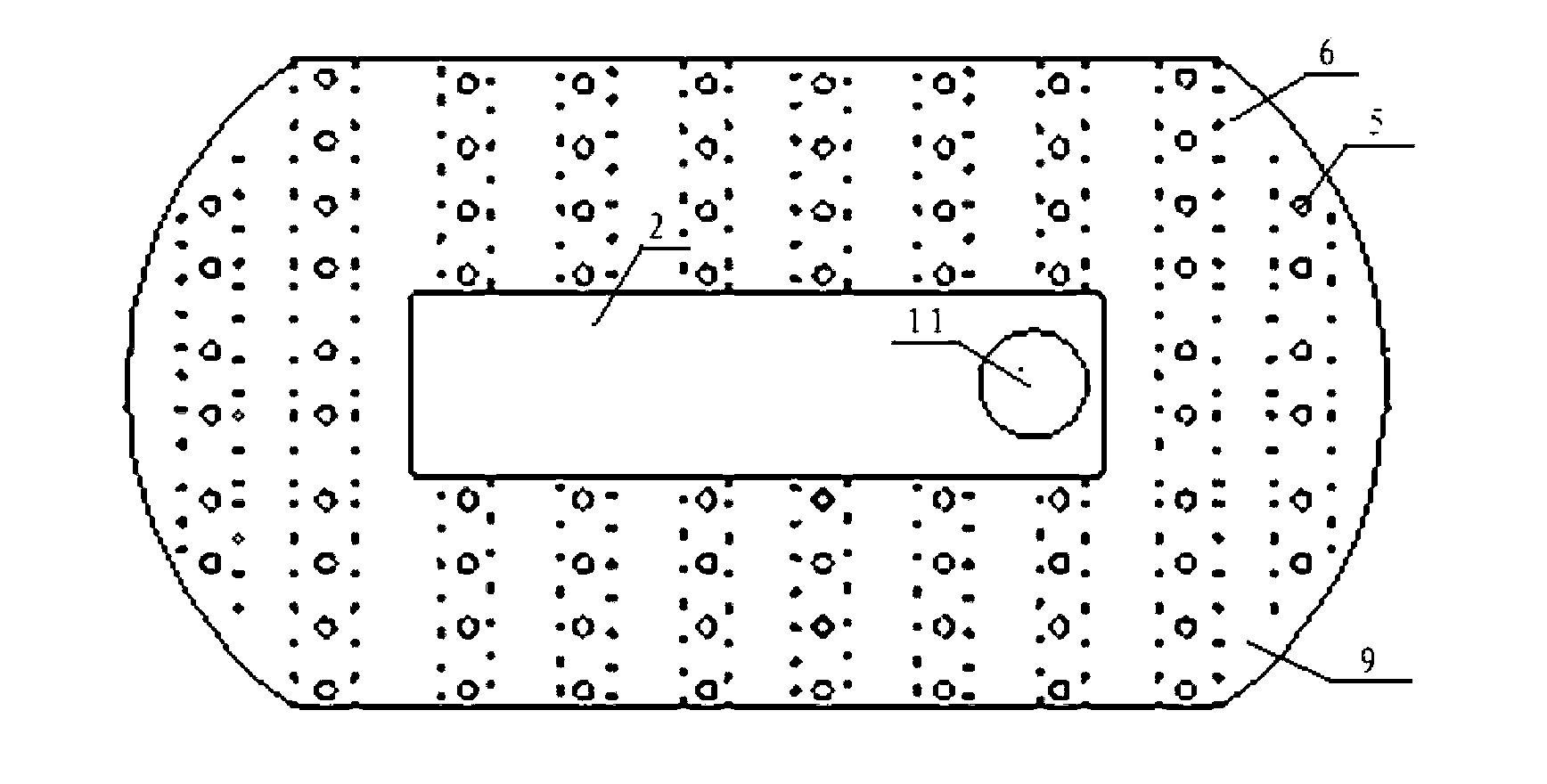

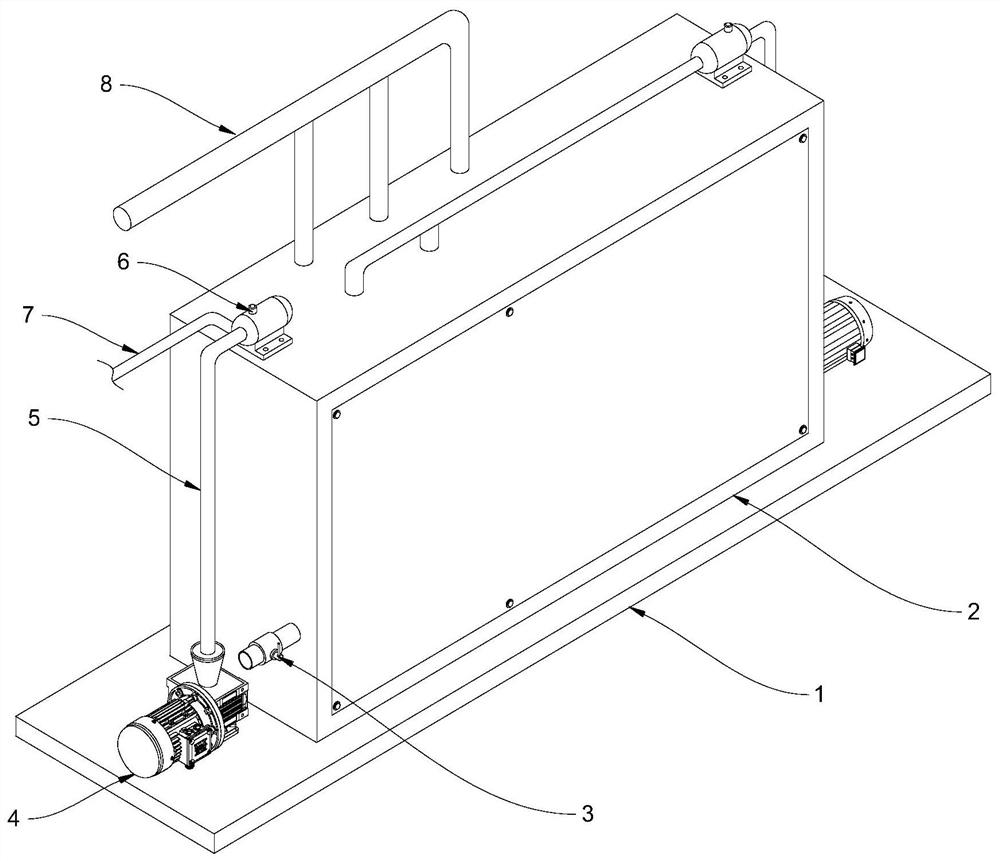

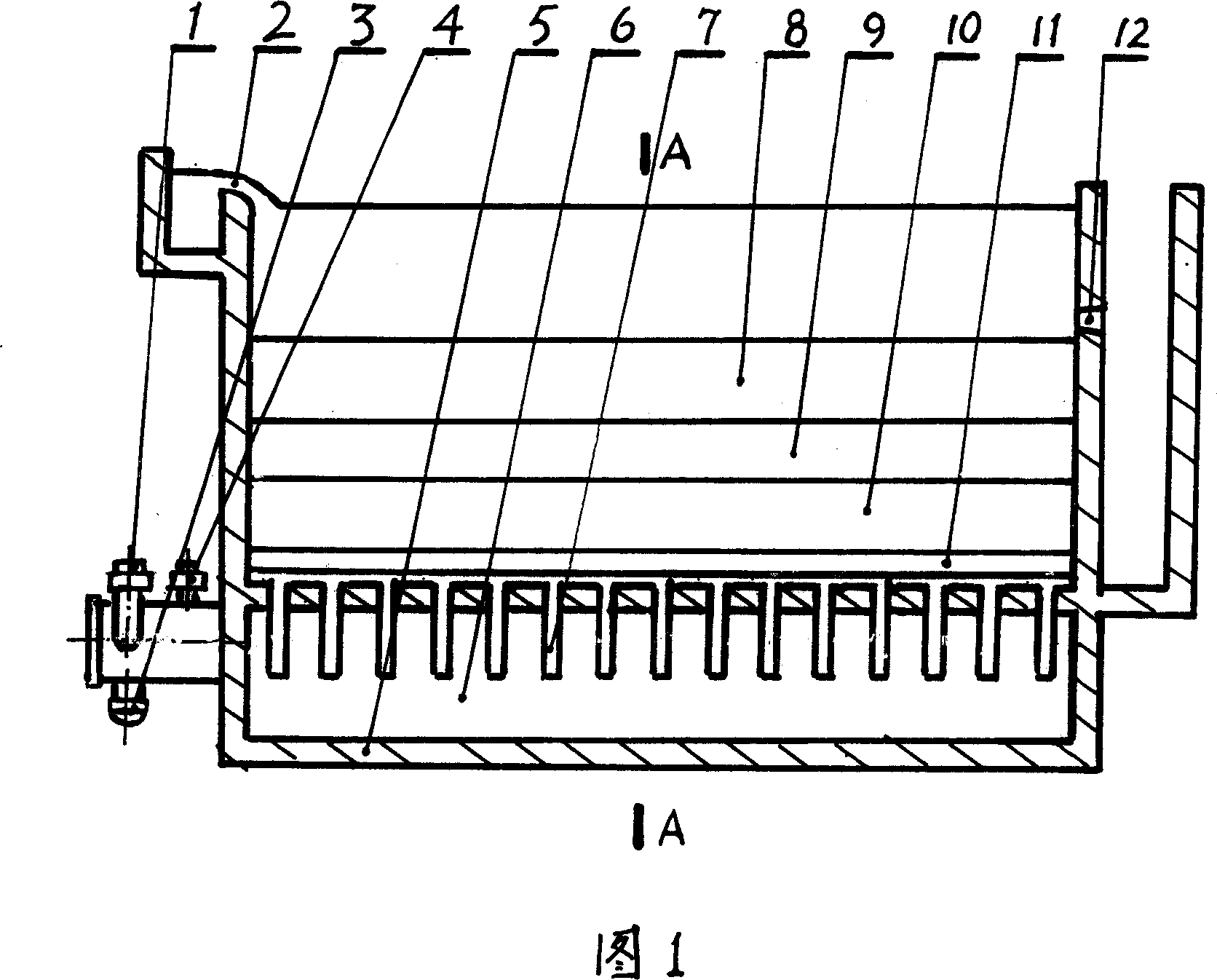

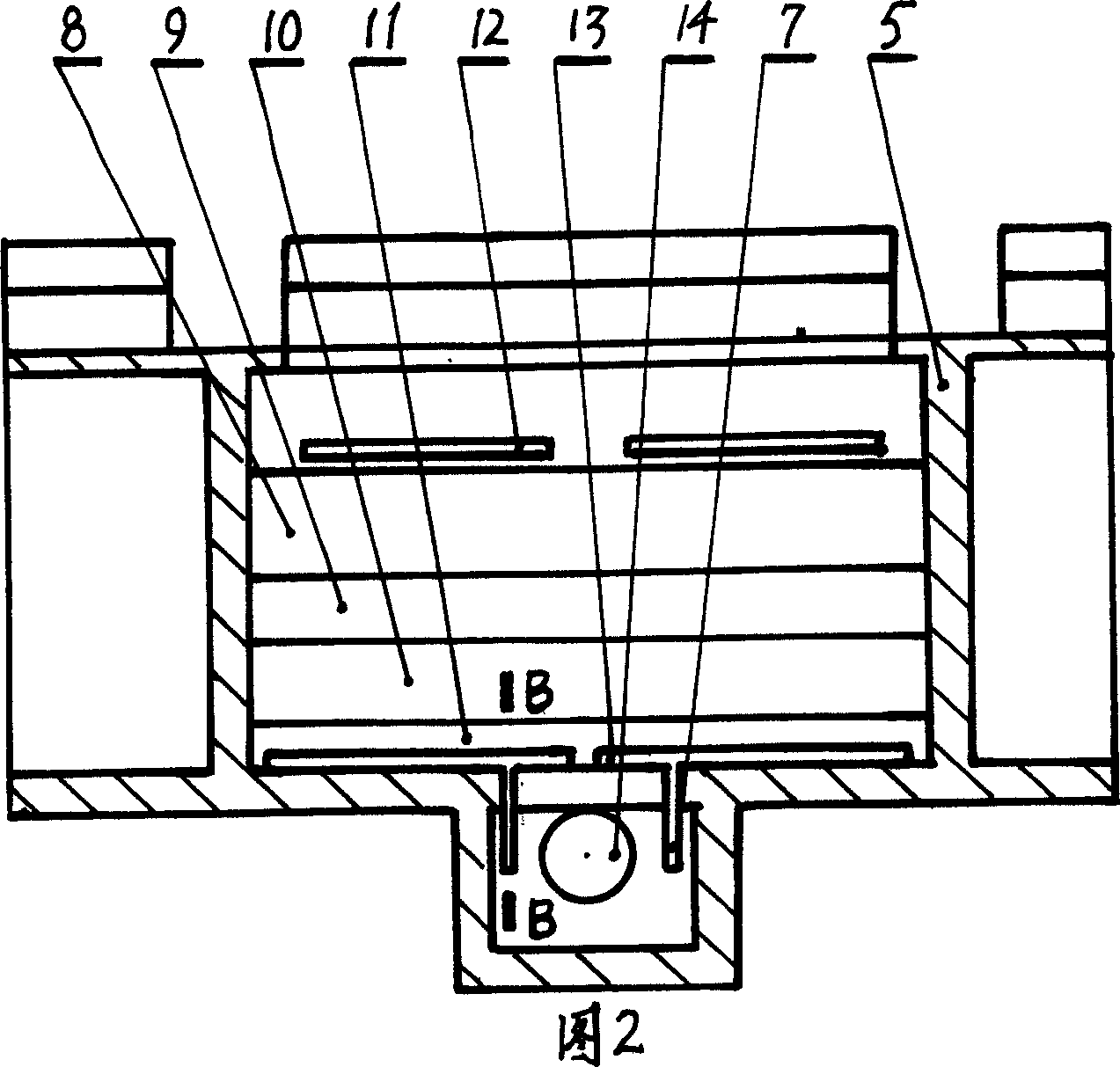

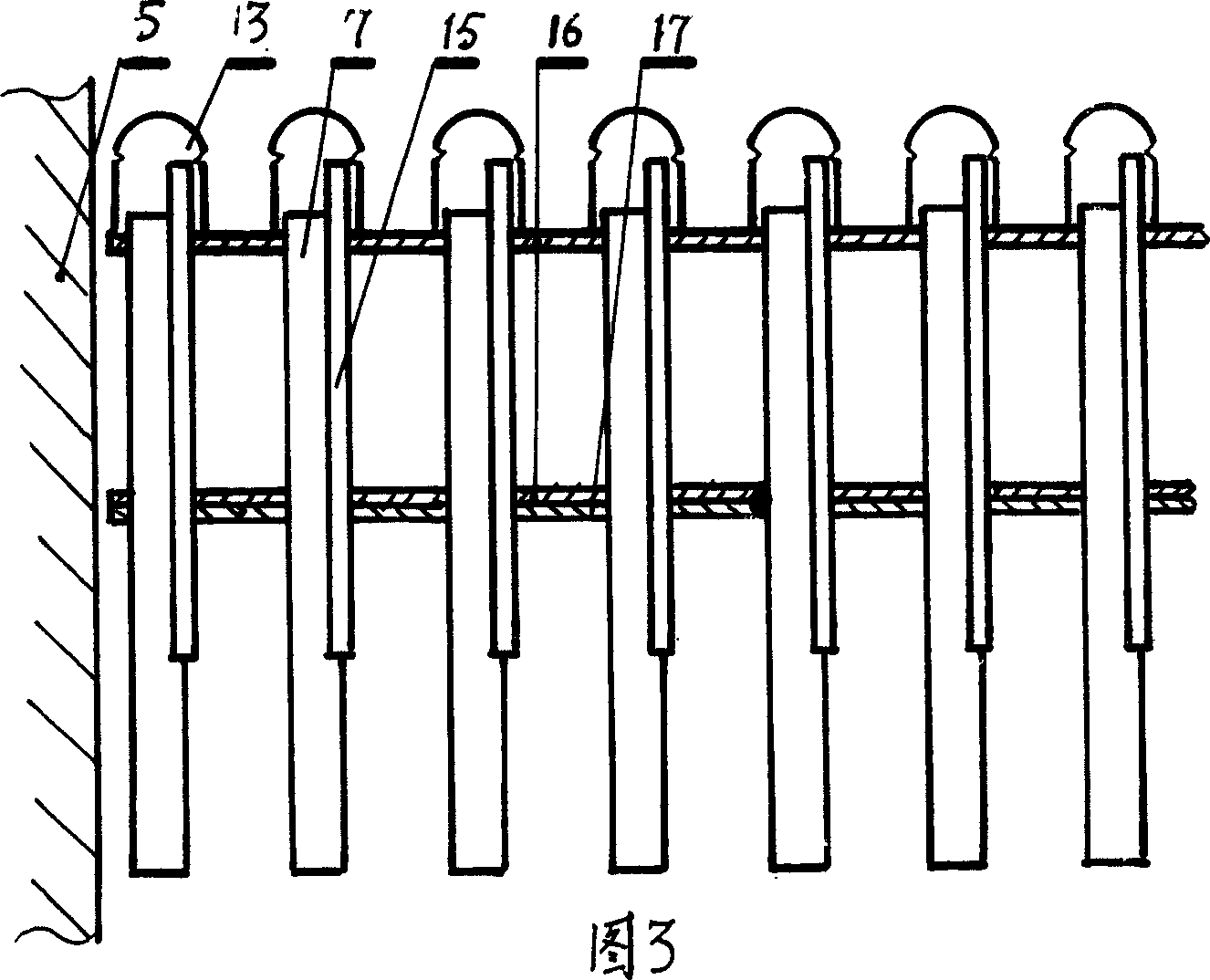

Efficient backwashing filtering device and multilayered filter provided with device

ActiveCN106267931AAchieve regenerationImprove filtering effectLoose filtering material filtersGravity filtersWater useFiber

The invention relates to an efficient backwashing filtering device and a multilayered filter provided with the device. The efficient backwashing filtering device is provided with a filtering unit, so that high-turbidity circulating water can be filtered and backwashing can be carried out on a fiber filtering material, and therefore, regeneration of the fiber filtering material is realized and the filtering effect is enhanced; in a backwashing process of the fiber filtering material, high-pressure air in a high-pressure airflow pipeline is sprayed out from a nozzle on an outer sleeve, and suspension matters and oil, which are intercepted by the fiber filtering material, can be completely removed, so that the fiber filtering material is completely regenerated; the backwashing time can be greatly shortened and the water use amount of backwashing is saved; the backwashing and pollutant removing effects are relatively good; and the multilayered filter provided with the device comprises a plurality of stacked filtering units, so that the occupied areas of a filter is reduced, the utilization rate of a land is increased and the filtering efficiency is improved.

Owner:秦皇岛德创节能环保科技有限公司

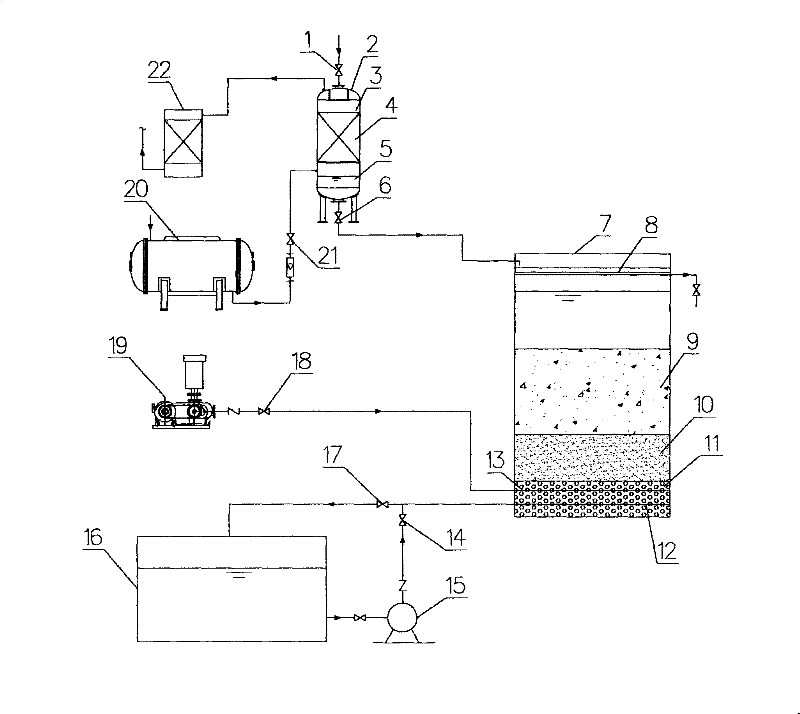

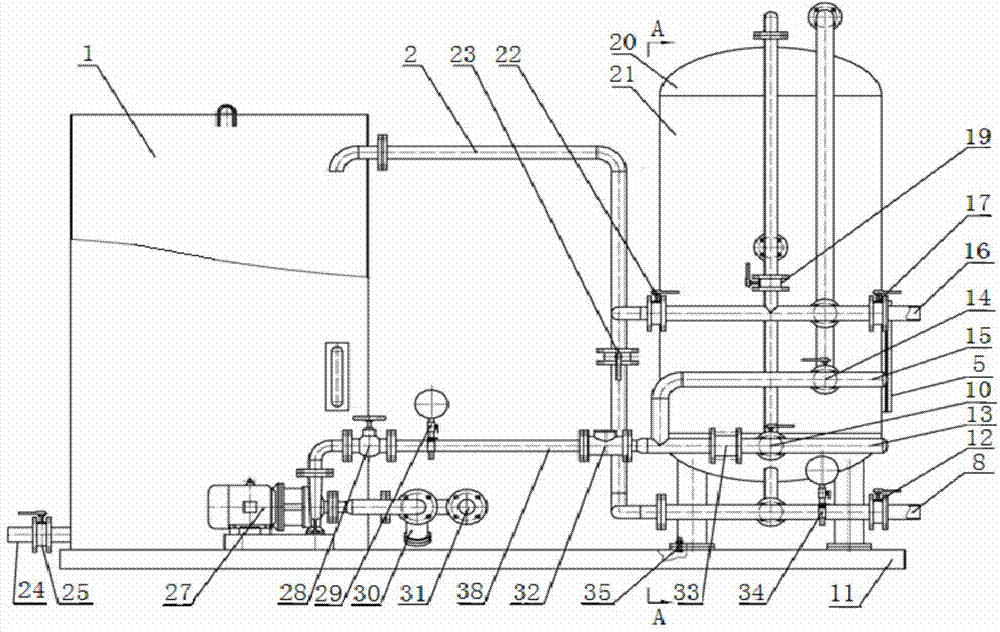

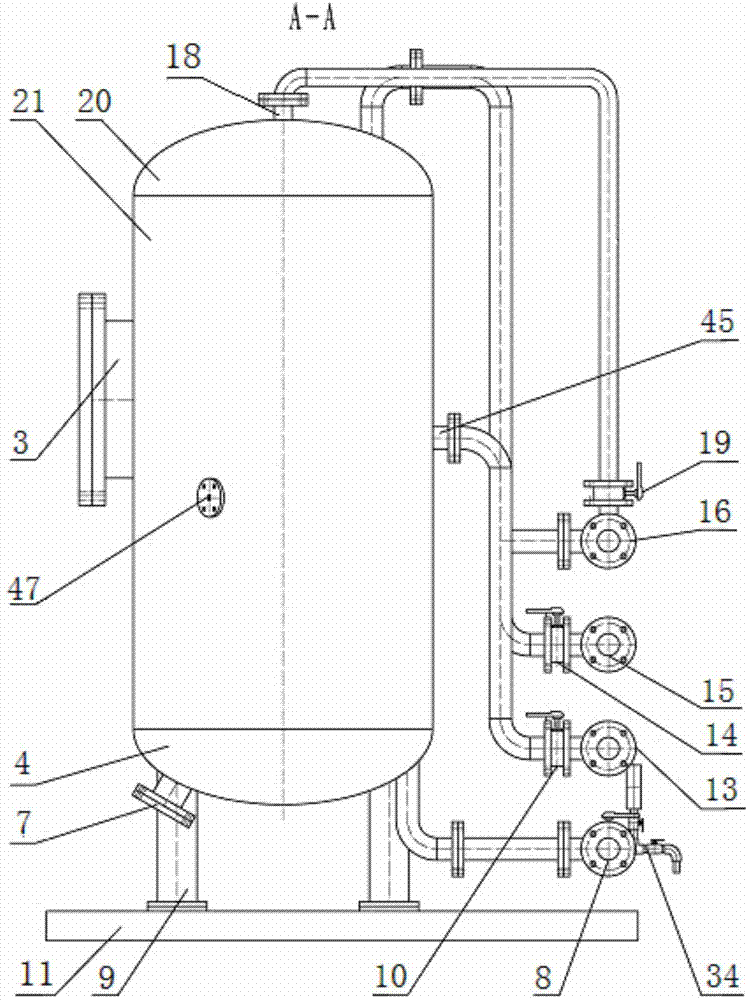

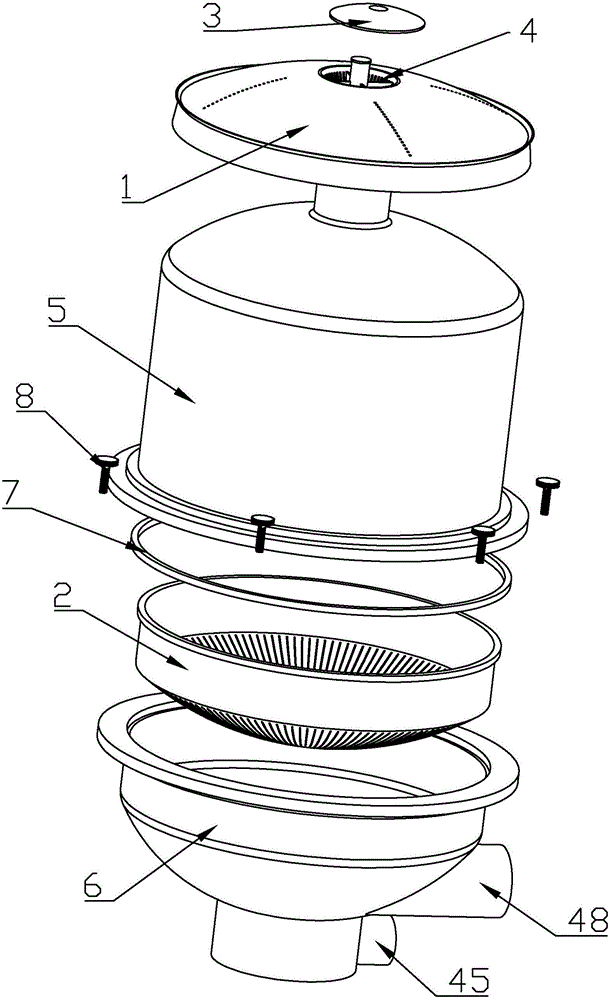

High-efficiency energy-saving granular filter

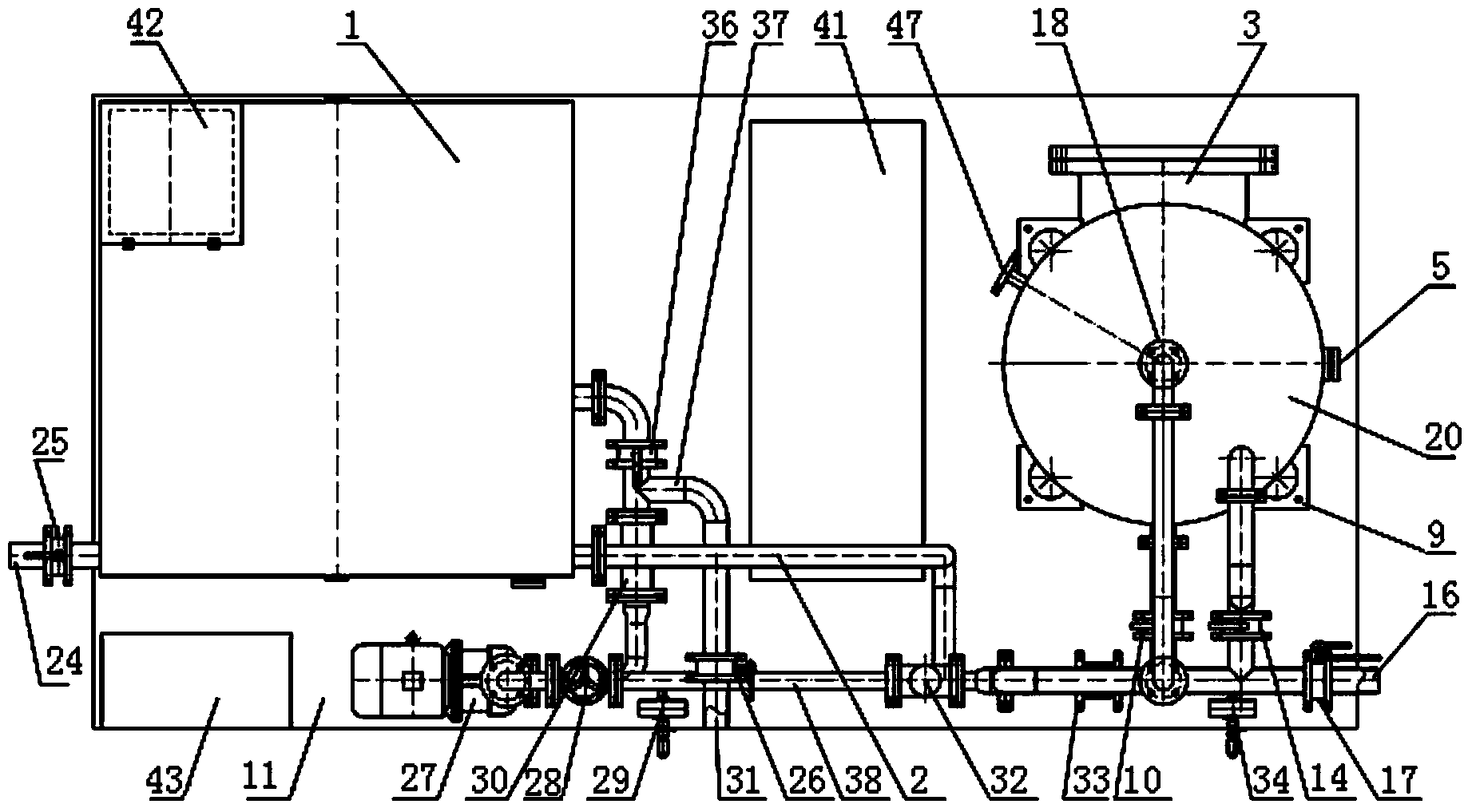

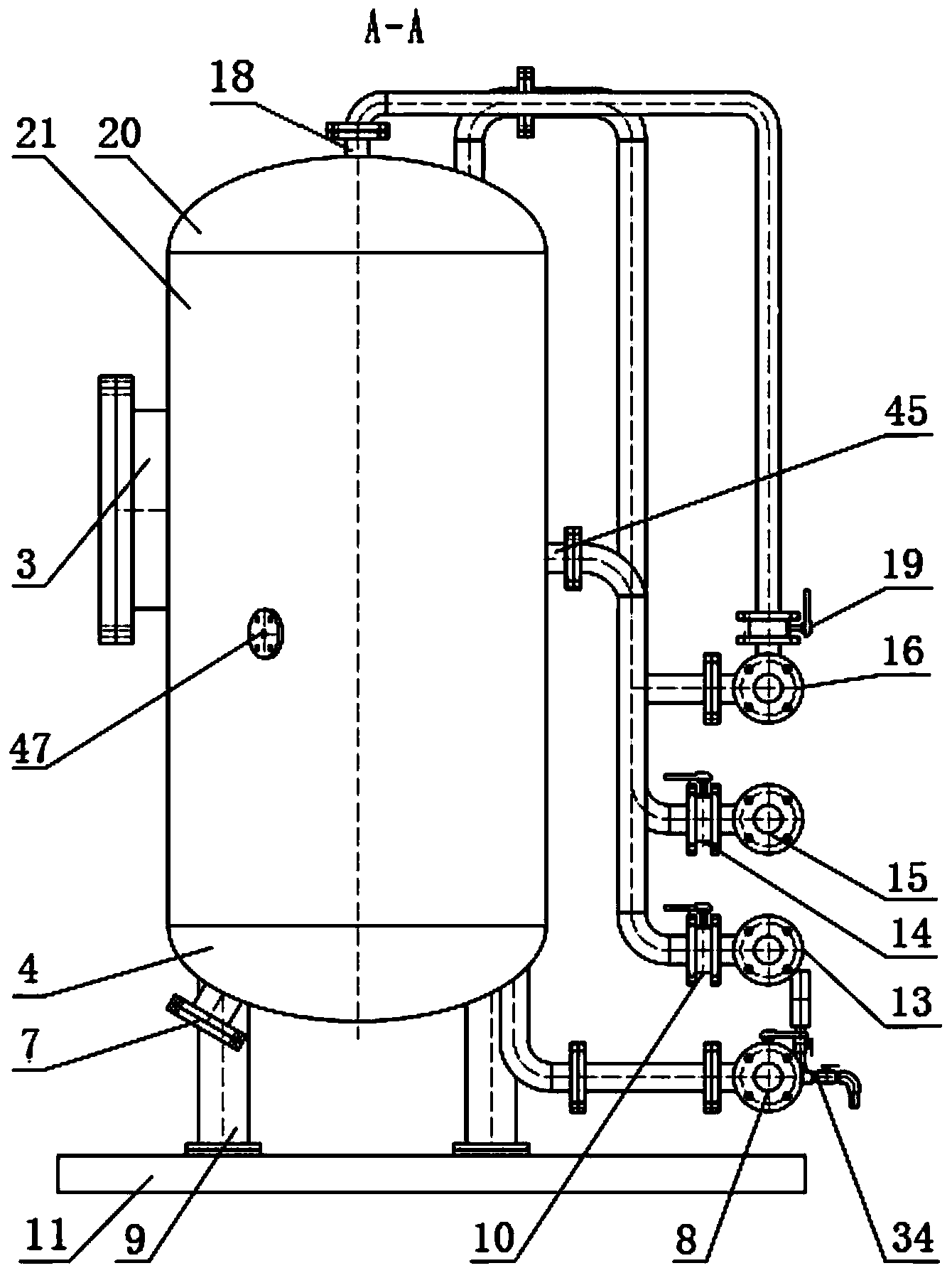

ActiveCN103623626ASimple structureEliminate the defect of stirring seal leakageLoose filtering material filtersGravity filtersWater sourceControl system

The invention relates to a high-efficiency energy-saving granular filter which comprises a filter body, a backwashing assembly, a backwashing water tank, an air compressor and a control system. A tank body and upper and lower oval sealing heads are arranged on the filter body; upper and lower sieve tubes / plates are arranged in the tank body; an oil / gas discharge port and a sewage inlet assembly are arranged at the top of the upper oval sealing head; a water outlet, a discharge port and supporting legs are arranged at the end of the lower oval sealing head; a backwashing water inlet and a backwashing gas inlet are arranged on the backwashing assembly; after being connected with a water inlet pipe, a backwashing water inlet pipe is connected with a backwashing spray nozzle; the backwashing water tank is connected with a filter by a return pipe; after being connected with a gas control valve, a gas check valve and the like, the air compressor is connected with the backwashing gas inlet by pipelines; by the control system, each valve, a backwashing water source and a backwashing gas source are automatically controlled to carry out operation according to the program. The filter disclosed by the invention has a simple structure, adopts a three-phase flow backwashing technology, is convenient to operate, is low in backwashing water consumption, is effective and energy-saving to backwash and has long equipment service life.

Owner:武汉市汉江石油物资技术开发有限责任公司

Sewage three-level effluent advanced treatment device and treatment method

InactiveCN104150657ADurable and safe disinfection and degradationIncrease concentrationMultistage water/sewage treatmentThree levelUltrafiltration

The invention relates to a sewage three-level effluent advanced treatment device. The device mainly comprises a coagulating basin, wherein the upper end of the coagulating basin is connected with a chemical dosing device, the water outlet of the coagulating basin is connected with a surface turbulence filtering device, the water outlet of the surface turbulence filtering device is connected with a photocatalytic degradation reaction device, the water outlet of the photocatalytic degradation reaction device is connected with a secondary nanometer aeration advanced oxidation device, and the water outlet of the secondary nanometer aeration advanced oxidation device is connected with an ultrafiltration device. The invention also discloses a sewage three-level effluent advanced treatment method.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

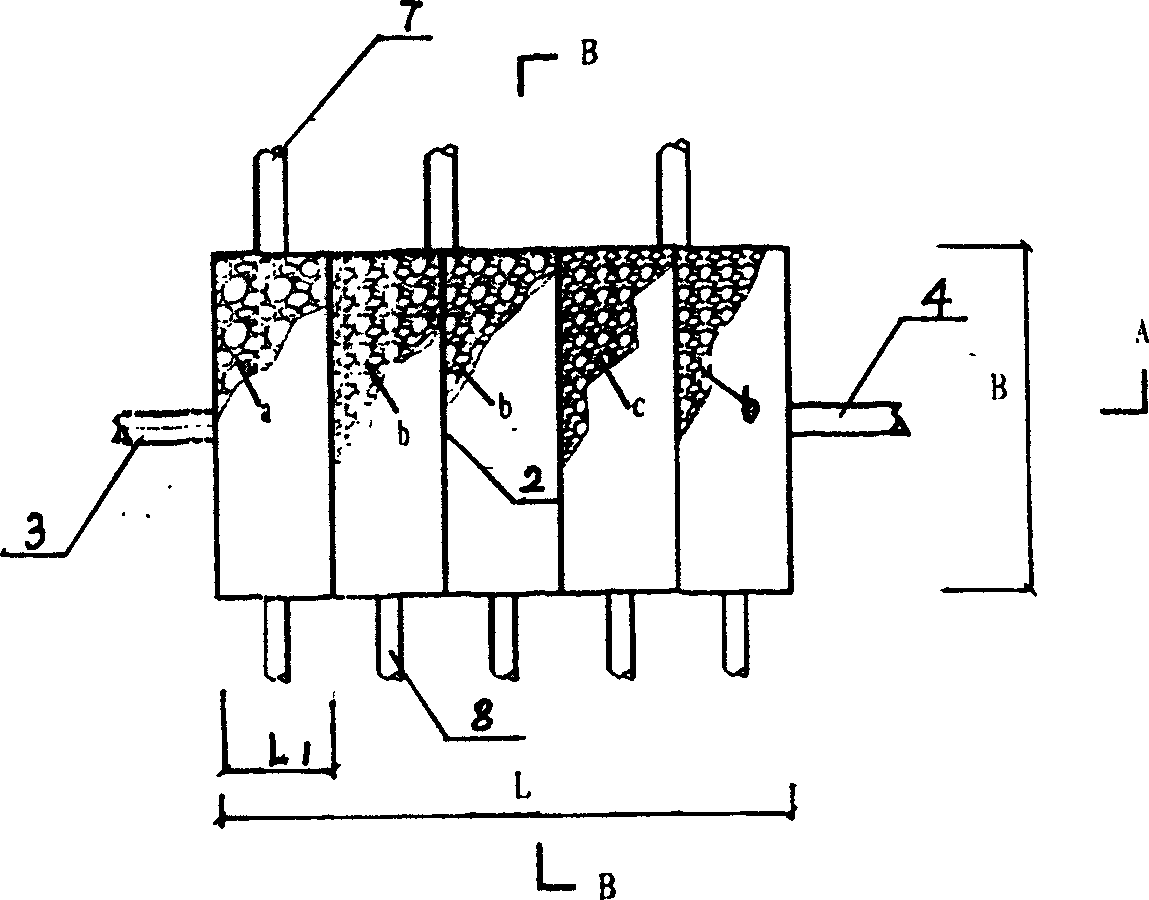

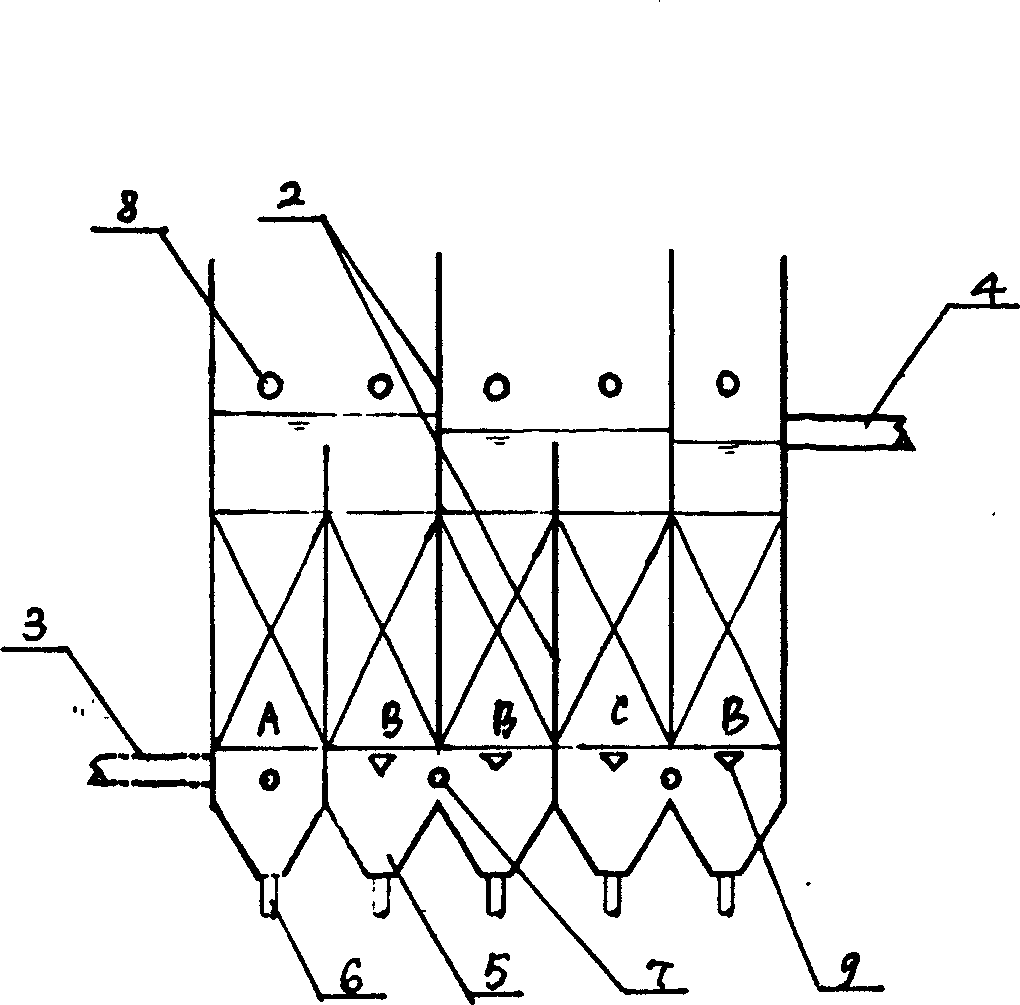

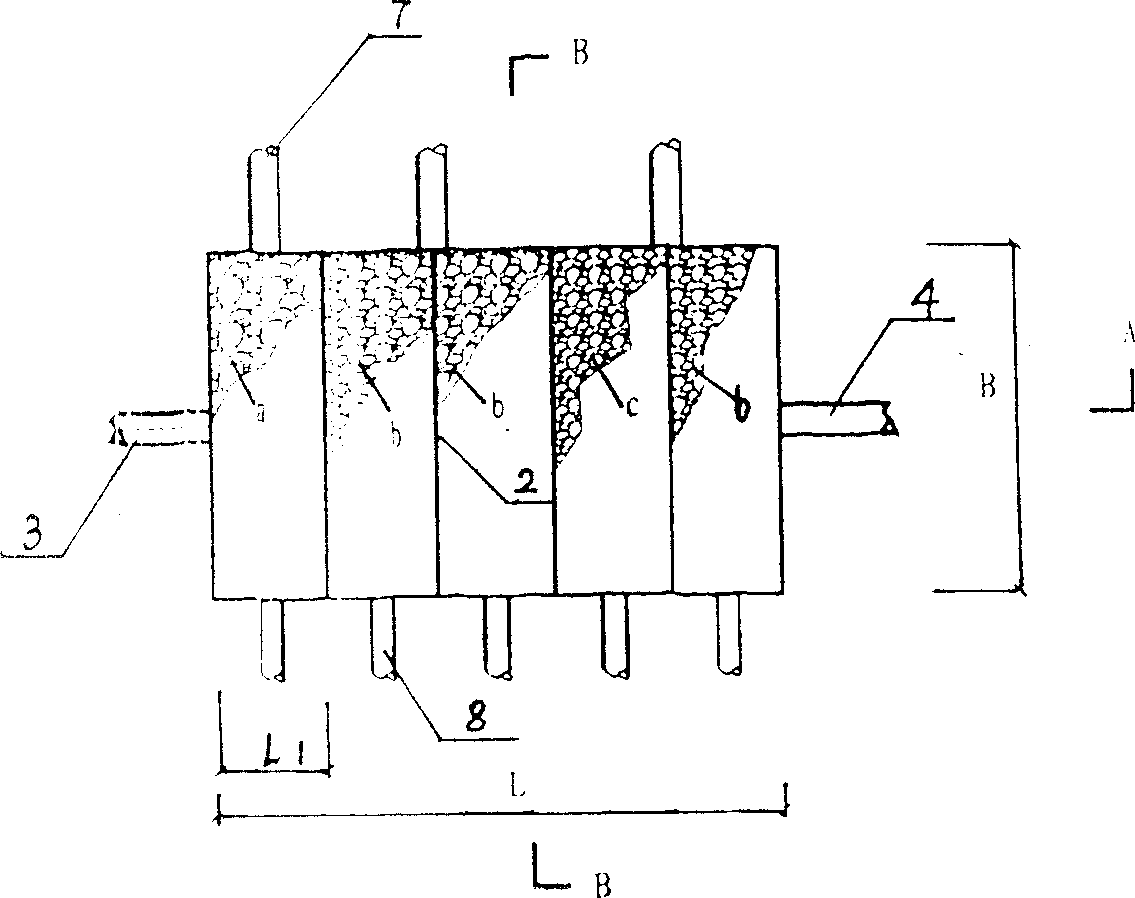

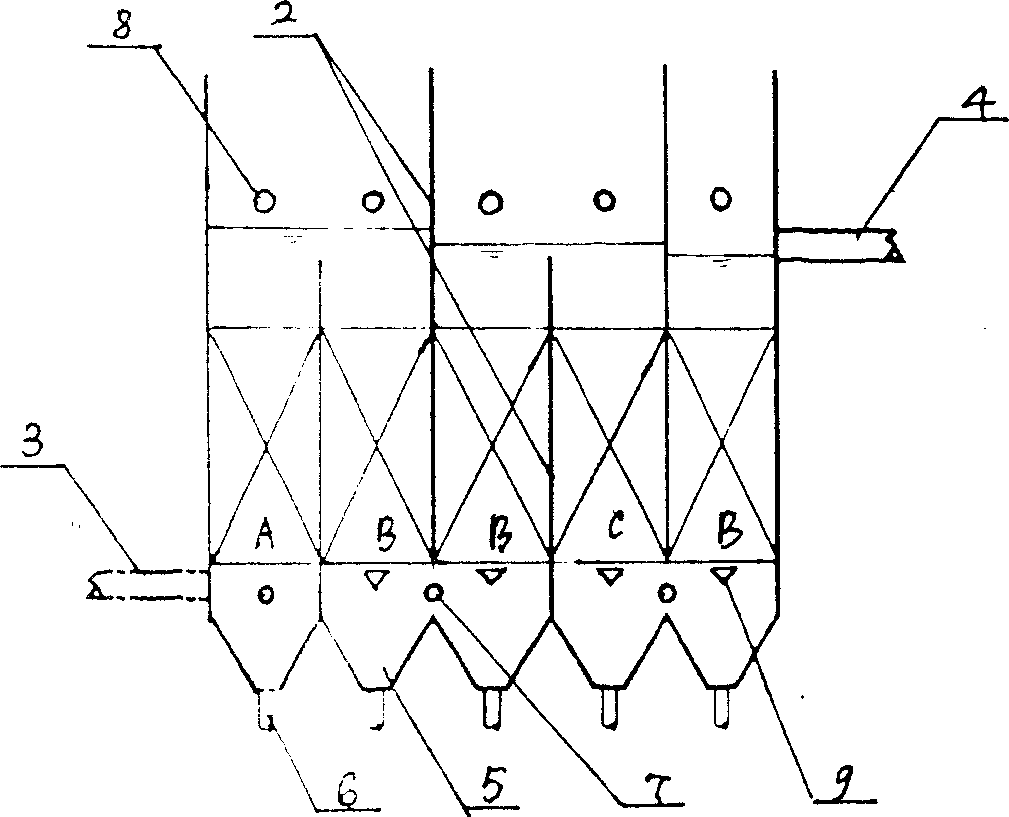

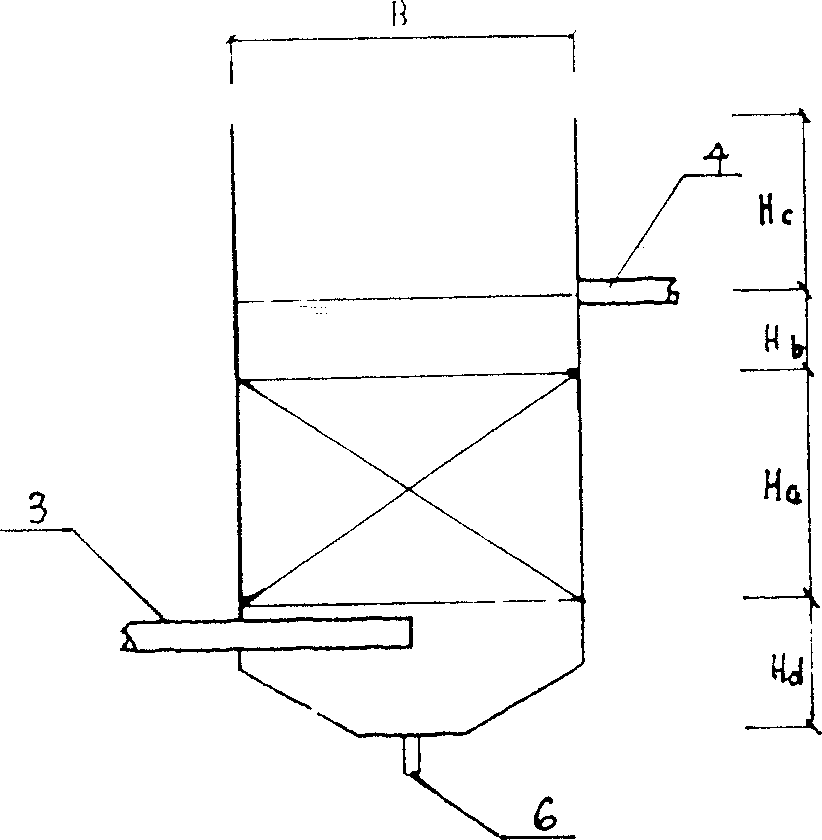

Vertical deflector combined Filtration type dephosphorization and nitrogen rejection facility

InactiveCN1562802AGuaranteed thicknessGuaranteed process lengthSustainable biological treatmentBiological water/sewage treatmentFiltrationNitrogen

The device contains at least two single filter tanks connected each other, water entrance pipe connected with first single filter tank and water exit pipe connected with last single filter tank, devision plates are used to separate the single filter tanks up and down crisscrossed, sewage up and down baffling passageway is preset. Bottom of single filter tank are mud collector, mud sludging pipe and filling layer is the middle part, the fillings are anaerobic filling, aerobic filling and high-grad iron filling, at least two of them are combined to put into the filter tanks, each fillings combination is put to one filter tank to form different function area. The design of sewage up and down baffling passageway is to ensure obtaining length of flow path required by process, the combination of mutiple fillings is suited for requirements of different water quality.

Owner:CHONGQING UNIV

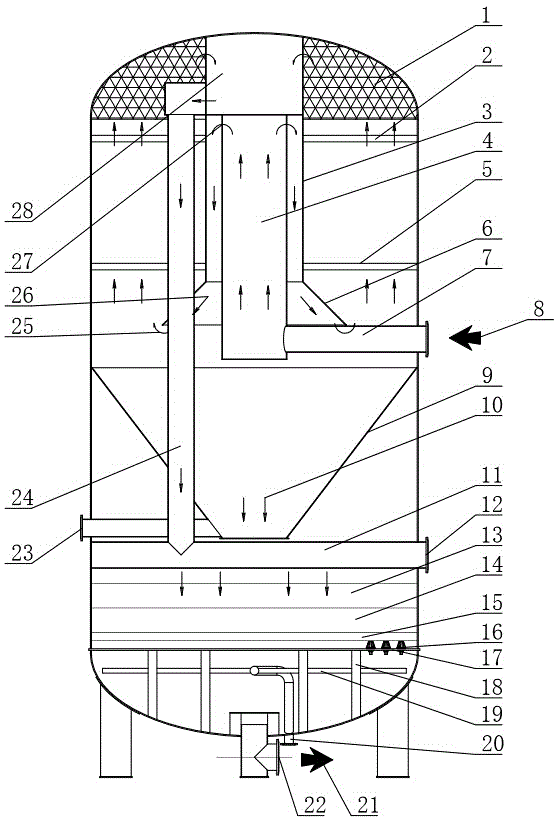

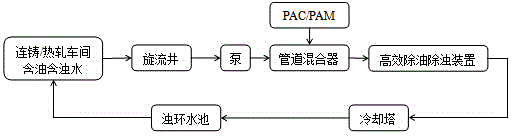

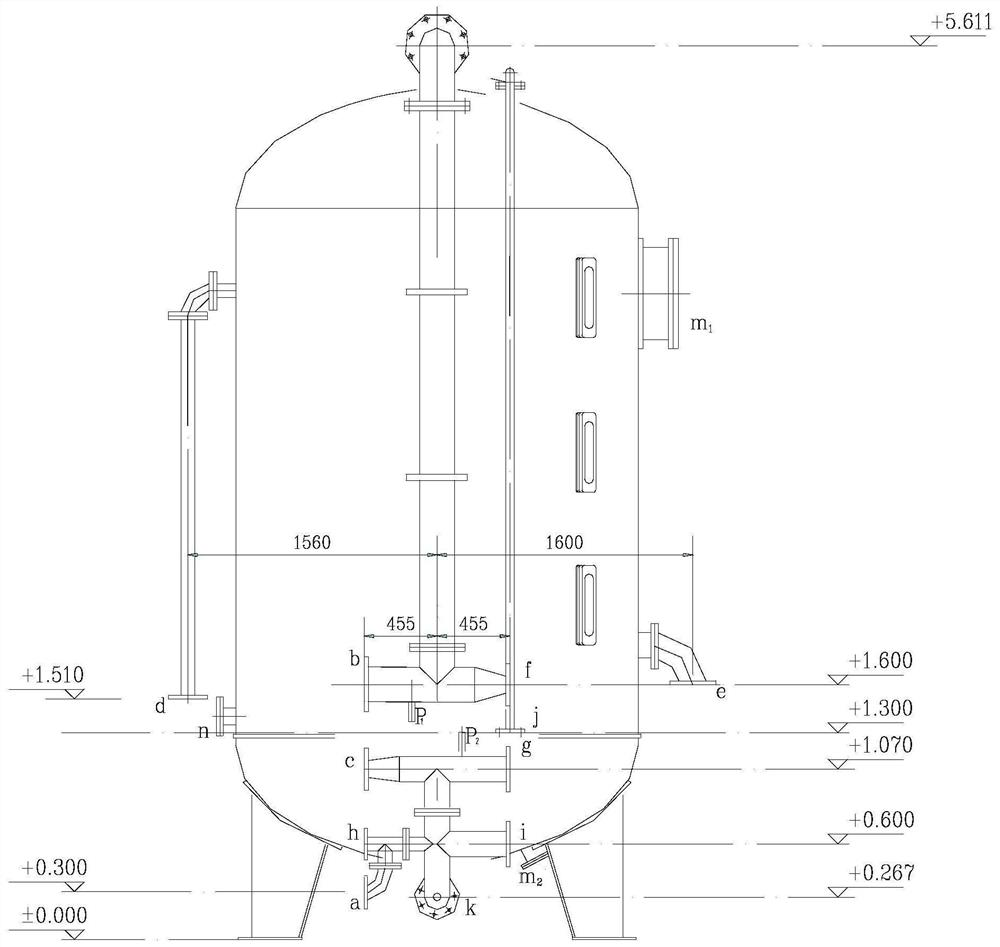

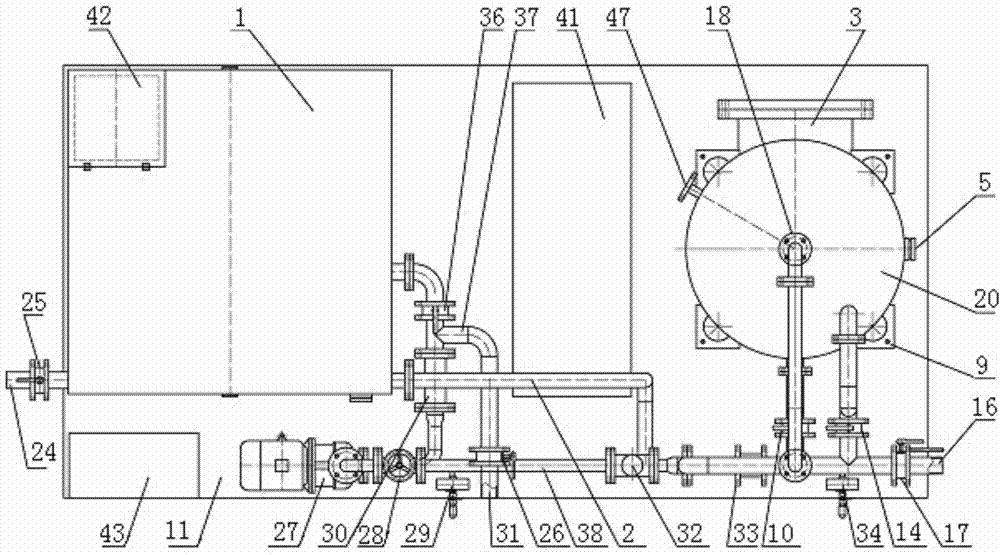

High-efficiency oil removal and turbidity removal device and oil-containing and turbidity-containing wastewater treatment process

InactiveCN104556485AHigh degree of automationSmall footprintMultistage water/sewage treatmentFlocculationAutomatic control

The invention discloses a high-efficiency oil removal and turbidity removal device. The high-efficiency oil removal and turbidity removal device has an integrated tank body structure; a water inlet mixing reactor and a clarifying device are arranged at the upper part of the tank body; a sludge collecting and discharging device is arranged at the middle part of the tank body; a filter and a backwashing system are arranged at the lower part of the tank body. According to the device, a chemical oil removal device and a high-speed filter are integrated; a hot water tank and a conveying pump are not required to be matched; the occupied area is small; the project investment is greatly reduced; the operating cost is reduced. The device integrates the functions of coagu-flocculation reaction, clarification and sedimentation, sludge discharging, filtering, backwashing and the like; the operating, backwashing and sludge discharging processes of the system is controlled by a PLC by matching an full-automatic control system; the operating, sludge discharging and backwashing processes of all pieces of equipment can be completed by operating on a matched control of the equipment; the operation is convenient; the automation degree is high; the water outlet quality is higher than a technical standard requirement.

Owner:宜兴市苏嘉环保设备有限公司

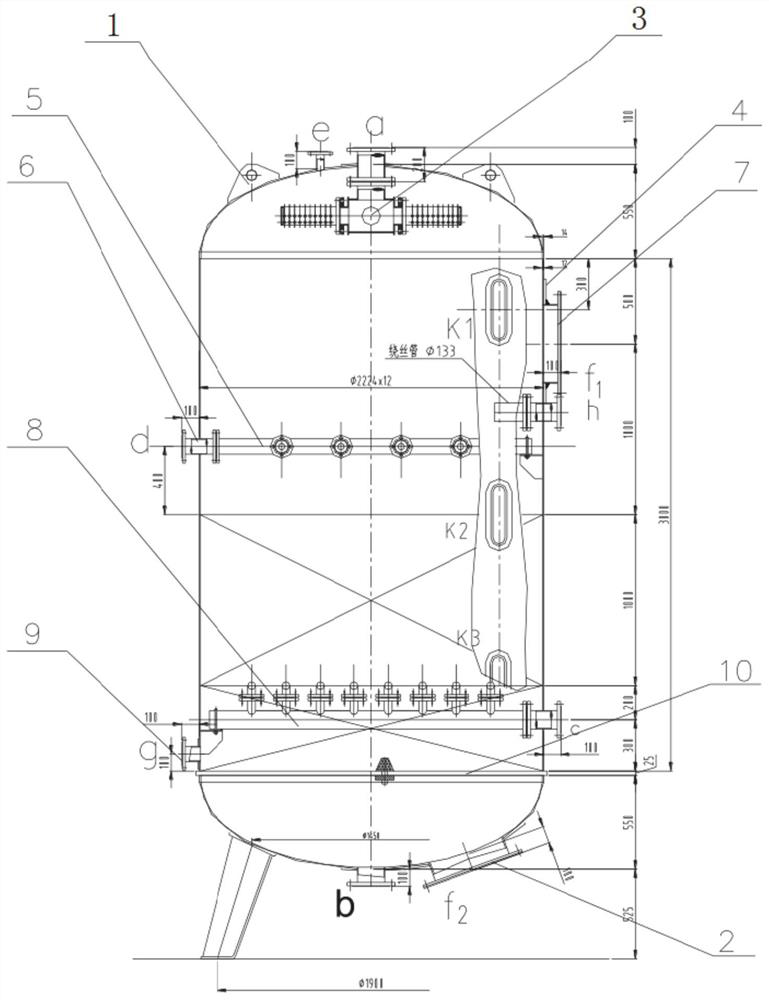

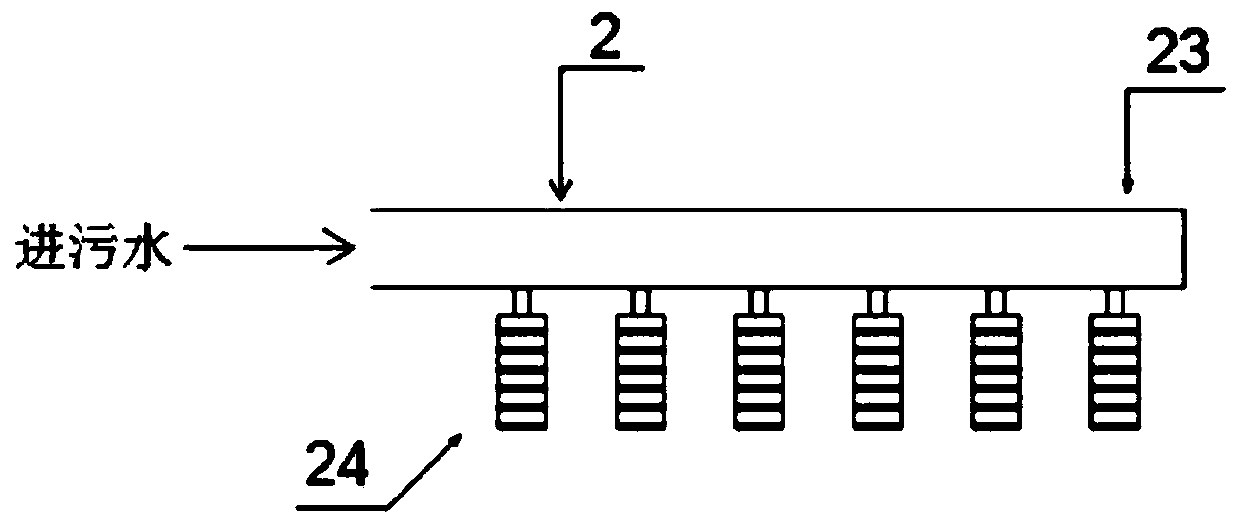

Oily sewage filter and filtering method

ActiveCN103418183AEfficient removalClear disposal siteFatty/oily/floating substances removal devicesGeneral water supply conservationFilter mediaSewage

Disclosed are an oily wastewater filter for advanced treatment of large amounts of oily wastewater and a filtering method for the oily wastewater. The filter comprises a tank and a water inlet. Arranged within the tank is a swirl baffle. Arranged on the inside of the swirl baffle is a perforated mesh forming a filter media-filled area. Arranged within the perforated mesh is a perforated platen. The upper portion of the filter media-filled area and the upper portion of a swirl area are a slick accumulation area. The lower portion of the filter media-filled area is a sediment accumulation area. Arranged within the tank is a cylinder. Also arranged above the tank is a connection pipe connecting the swirl area and the filter media-filled area. Arranged at the bottom of the tank is a backwash discharge outlet. Employment of this structure provides the slick and sediment with definitive disposal sites, reduces pollution of filter media, reduces backwash water energy consumption and backwash water consumption, while the technical solution of suspended filter media, forced stirring, and entirely discharged backwash bottom allows for greatly improved regeneration effect of the filter media and prevents a compaction phenomenon, thus greatly extending the service life of the filter media and reducing operating costs.

Owner:SHENZHEN BUSTIN TECH

Mixed bed regeneration improvement process, system and application

ActiveCN112295611AImprove backwashing effectEasy to backwashGeneral water supply conservationFeed water supplyWater productionProcess engineering

The invention belongs to the field of water production, and relates to a mixed bed regeneration improvement process, a system and application. The process comprises air scrubbing, backwashing pre-layering, primary drainage, alkali feeding failure, backwashing layering, standing, secondary drainage, pre-injection, acid and alkali feeding, replacement, after-replacement drainage, regeneration mixing, regeneration irrigation, regeneration forward washing, and operation. The backwashing effect is enhanced by compressed-air scrubbing, so that the resin is fully loosened. The subsequent backwashingis facilitated. Meanwhile, in the alkali feeding failure step, the alkali feeding mode is adjusted, a positive discharge valve is changed into a middle discharge valve, alkali can fully and only exchange with upper-layer anion resin, meanwhile, a small amount of upper-layer cation resin fails, the alkali feeding time is shortened, the alkali consumption can be reduced, and the regeneration effectis improved.

Owner:YANKUANG GRP CO LTD

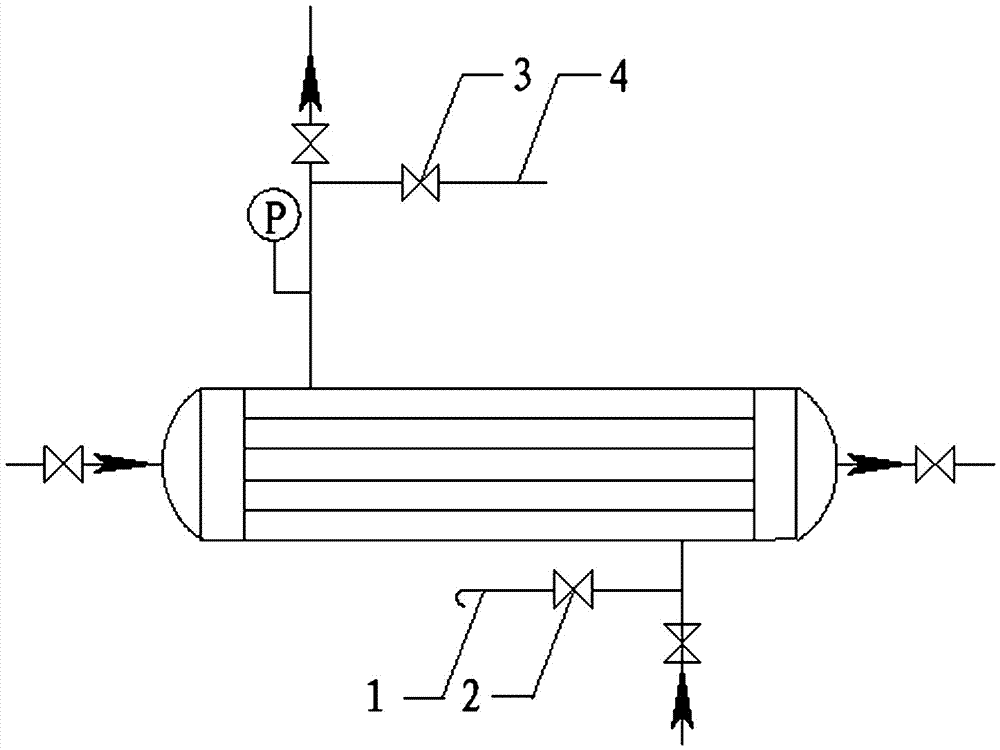

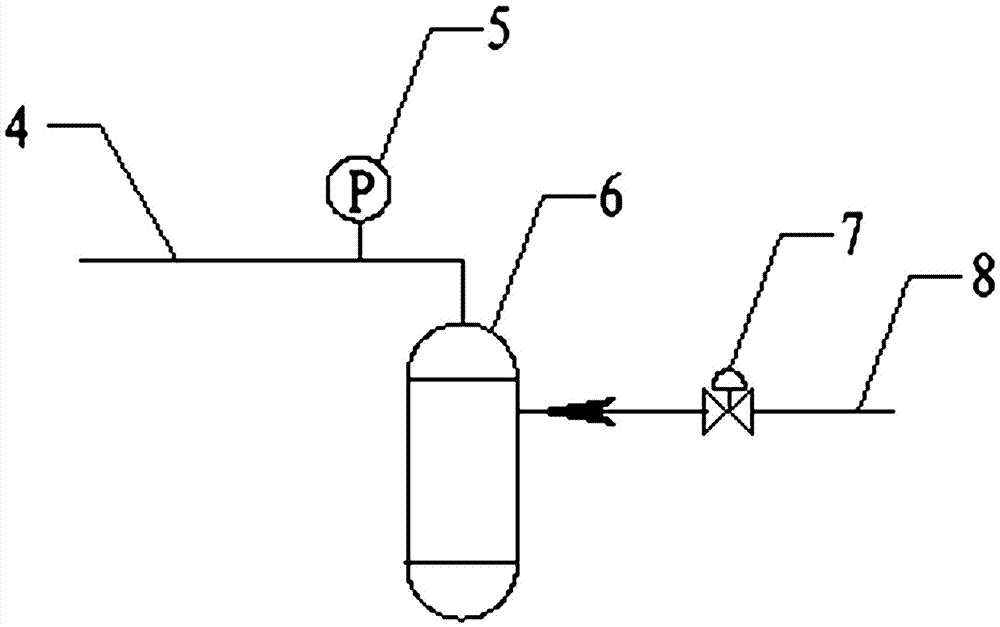

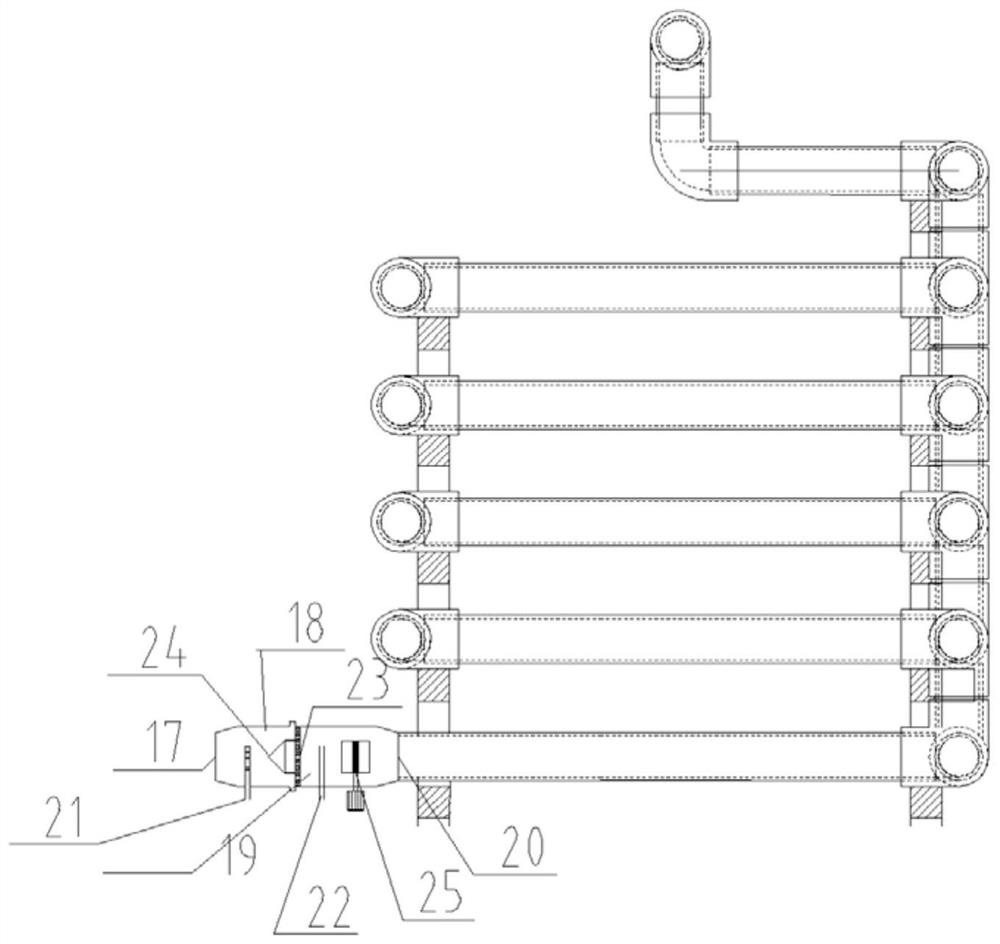

Device for improving heat exchanging effect of water cooling type cooler

InactiveCN107120991AGuaranteed heat exchange effectImprove flushing efficiencyStationary tubular conduit assembliesHeat exchange apparatusEngineeringWater cooling

The invention discloses a device for improving the heat exchange effect of a water-cooled cooler. The cooling water inlet of the water-cooled cooler is connected with a reverse discharge pipe, and a reverse discharge valve is installed on the reverse discharge pipe. The cooling water outlet of the water-cooled cooler There is also a gas filling pipeline connected to the gas filling pipeline, and a gas filling valve is installed on the gas filling pipeline. The device also includes an air source storage tank, a pressure gauge is installed on the air source storage tank, the air source storage tank is connected with a supplementary air source through an air supply pipeline, and a self-adjusting valve is installed on the air supply pipeline. When in use, close the water inlet valve at the cooling water inlet of the water cooler, open the reverse discharge valve, then open the gas filling valve, and feed the gas through the gas filling pipe. The gas and water are mixed in the water cooler and flow in reverse direction to remove the adhesion to the inner wall of the water cooler. , The slimy dirt on the outer wall of the heat exchange tube is discharged out of the system through the reverse discharge pipe to ensure the heat exchange effect of the water cooler. By setting the self-adjusting opening, the pressure of the aerated buffer tank is guaranteed to be higher than the cooling water pressure.

Owner:HUBEI SANNING CHEM

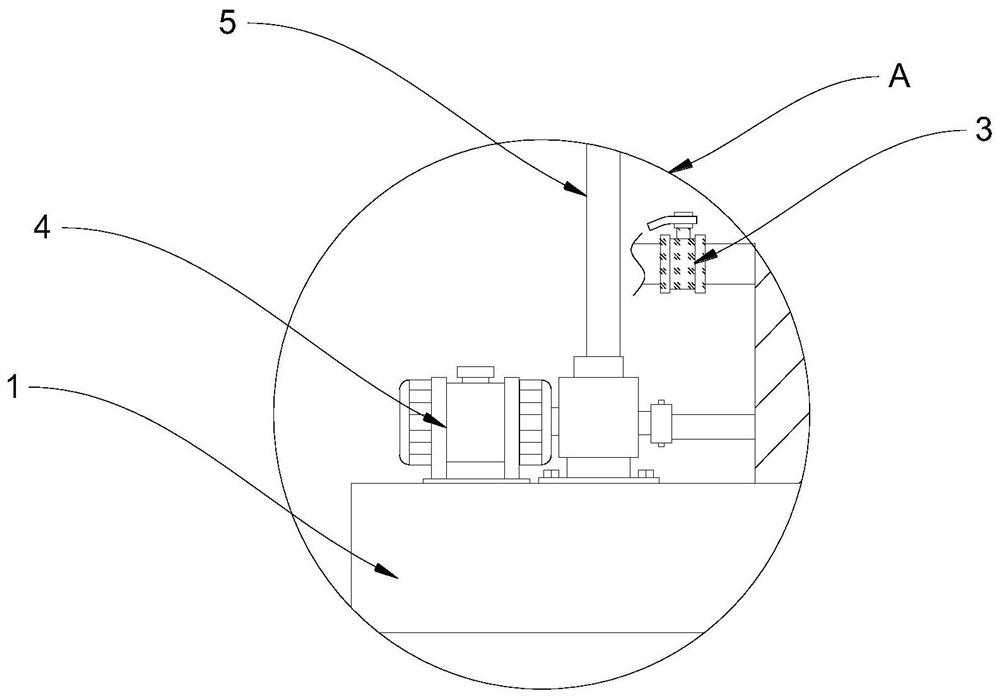

Ozone catalytic oxidation reactor and sewage treatment method thereof

PendingCN110590019AAchieve regenerationAdd backwash functionTreatment involving filtrationMultistage water/sewage treatmentOzone generatorWater discharge

The invention discloses an ozone catalytic oxidation reactor. The ozone catalytic oxidation reactor comprises a sewage distributor, a sand filter layer and a catalyst layer which are arranged in a reactor body sequentially from top to bottom; an ozone aeration disk, and a backwash water inlet distributor are arranged on the lower side of the catalyst layer; a backwash gas distributor is arranged in the sand filter layer; the upper side and the lower side of the sand filter layer communicate with differential pressure gauges; the sewage distributor is connected with a sewage water inlet pipe; awater discharging pipeline is arranged on the lower part of the reactor body; the ozone aeration disk is connected with an ozone generator through an ozone pipeline; the backwash water inlet distributor is connected with a backwash water inlet pump through a backwash pipeline; the upper part of the reactor body is connected with a backwash water discharging pipe; the backwash gas distributor is connected with a backwash gas pipeline; and the top of the reactor body is connected with a tail gas discharging pipe. The reactor integrates filtering and ozone catalytic oxidation functions, and hasan efficient backwash regeneration function. Meanwhile, the invention also provides a sewage treatment method. By the sewage treatment method, the use amount of water for backwash can be reduced and the backwash regeneration efficiency can be improved.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

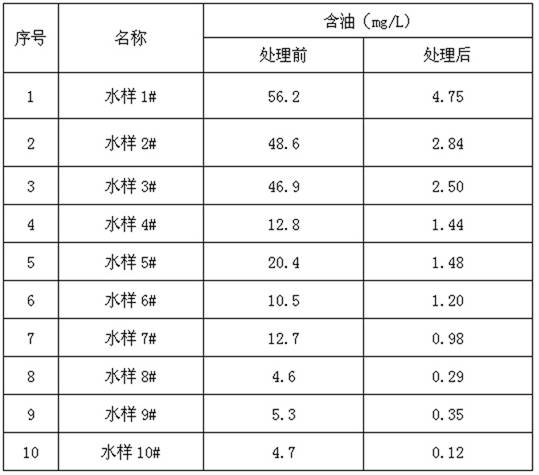

A modified filter material for petroleum sewage treatment

ActiveCN111359310BSurfactantHydrophilic and oleophobicWaste water treatment from quariesFatty/oily/floating substances removal devicesSulfonatePolyvinyl alcohol

The invention relates to a modified filter material for sewage treatment in petroleum industry. The technical solution is that the modified formula is made of the following components by weight: 0.5 parts of polyvinyl alcohol PVA, 6.2 parts of polyethylene glycol PEG, 0.12 parts of polydiallyl dimethyl ammonium chloride PDDA; Sodium styrene sulfonate PSS: 5.3 parts. The beneficial effects are: 1. The coating has the property of self-cleaning and anti-oil adhesion; 2. The modified filter material has surface activity, is hydrophilic and oleophobic, and the effect of degreasing sewage is significantly improved; 3. After the surface activity of the filter material is reduced It can be re-modified to prolong the service life; 4. The filter material has a wider application range and wider application field, and the modified filter materials of different materials can be mixed to improve the overall effect; 5. The backwashing water consumption is small, the pressure is low, and it can be broken 6. Greatly shorten the oilfield sewage treatment process, simplify the sewage treatment process, save costs and reduce energy consumption; 7. Pressure resistance, wear resistance, and low maintenance costs in the later period.

Owner:东营远洁环保科技有限公司 +1

Integrated water treatment purifier

ActiveCN102583677BReduce the overall heightSmall footprintWater/sewage treatment by flocculation/precipitationFiltration circuitsFlocculationWater filter

The invention discloses an integrated water treatment purifier which comprises a shell (1) with an inner chamber, wherein the upper part of the shell is connected with a water outlet pipe (2), the lower part of the shell is connected with a mud outlet pipe (4), and the inner chamber of the shell (1) is provided with a flocculation reaction device (5); the flocculation reaction device (5) comprises a water inlet pipe section (5a) and a reactor body (5b), wherein the inner chamber of the reactor body is provided with flocculated packing (5c), the lower part of the reactor body is provided with an upper tapered flow guide component (6), an inclined plate assembly (7) is formed on the outside of the periphery of the reactor body (5b), a lower chamber (1a) is formed in the inner chamber of the shell by the inclined plate assembly, the bottom of the lower chamber (1a) is a concentrated mud collection zone, a filter layer (8) is arranged above the inclined plate assembly (7), a middle chamber (1b) and an upper chamber (1c) are formed in the inner chamber of the shell by the filter layer (8), and the upper chamber (1c) is communicated with the water outlet pipe (2). The integrated water treatment purifier integrates flocculation, sedimentation, filtering and concentrated mud collection, and has the advantages of no mutual interference of functional zones, simple and compact structure and small floor area, which is favorable for enhancing the water quality of output water.

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

A device and method for advanced treatment of tertiary effluent of sewage

InactiveCN104150657BLarge amount of processingGood removal effectMultistage water/sewage treatmentThree levelUltrafiltration

The invention relates to a sewage three-level effluent advanced treatment device. The device mainly comprises a coagulating basin, wherein the upper end of the coagulating basin is connected with a chemical dosing device, the water outlet of the coagulating basin is connected with a surface turbulence filtering device, the water outlet of the surface turbulence filtering device is connected with a photocatalytic degradation reaction device, the water outlet of the photocatalytic degradation reaction device is connected with a secondary nanometer aeration advanced oxidation device, and the water outlet of the secondary nanometer aeration advanced oxidation device is connected with an ultrafiltration device. The invention also discloses a sewage three-level effluent advanced treatment method.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

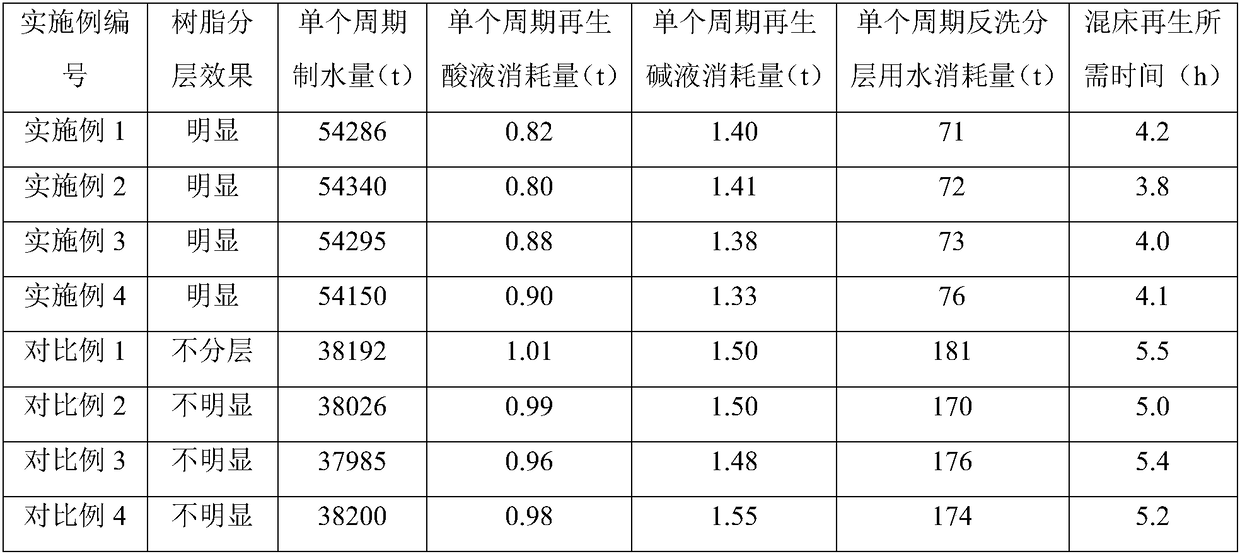

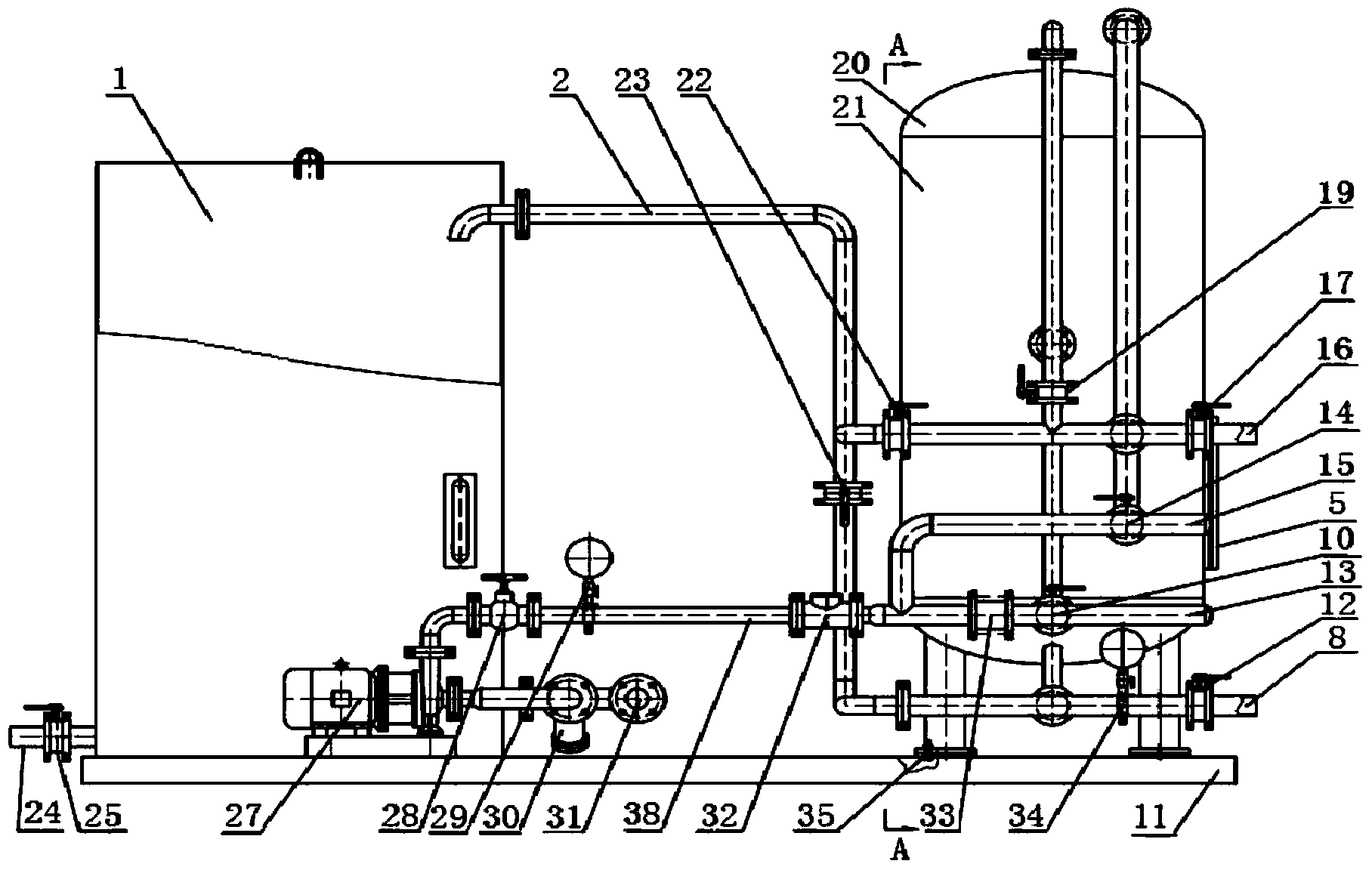

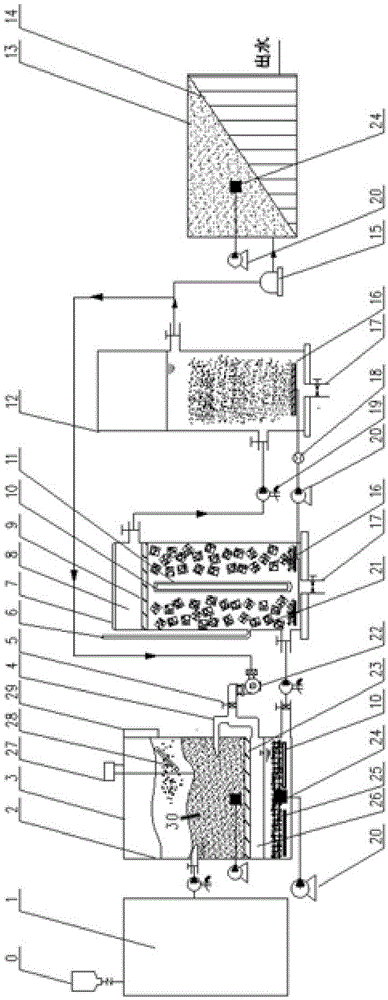

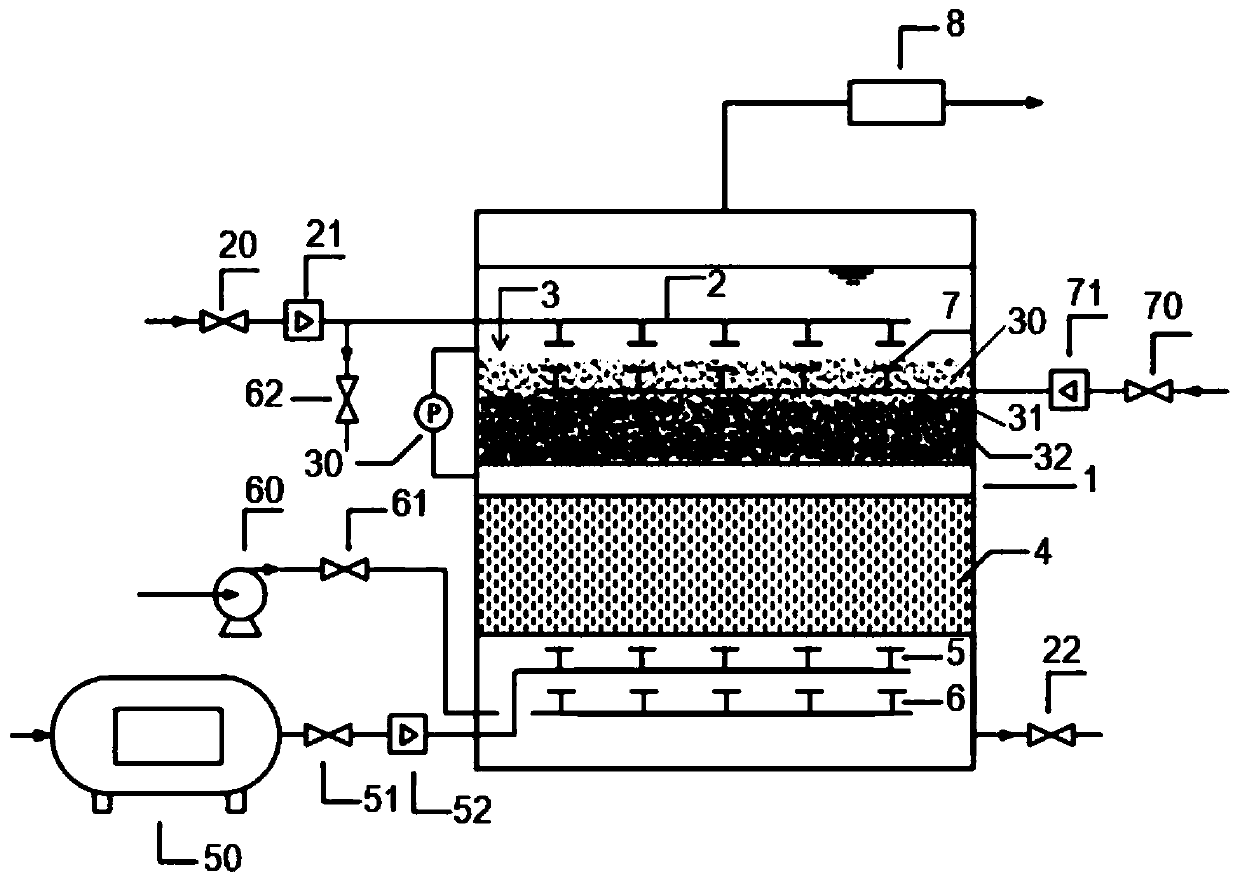

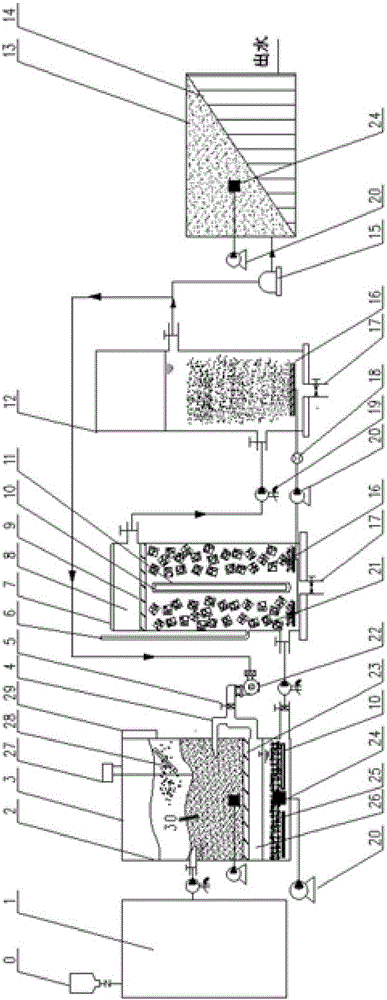

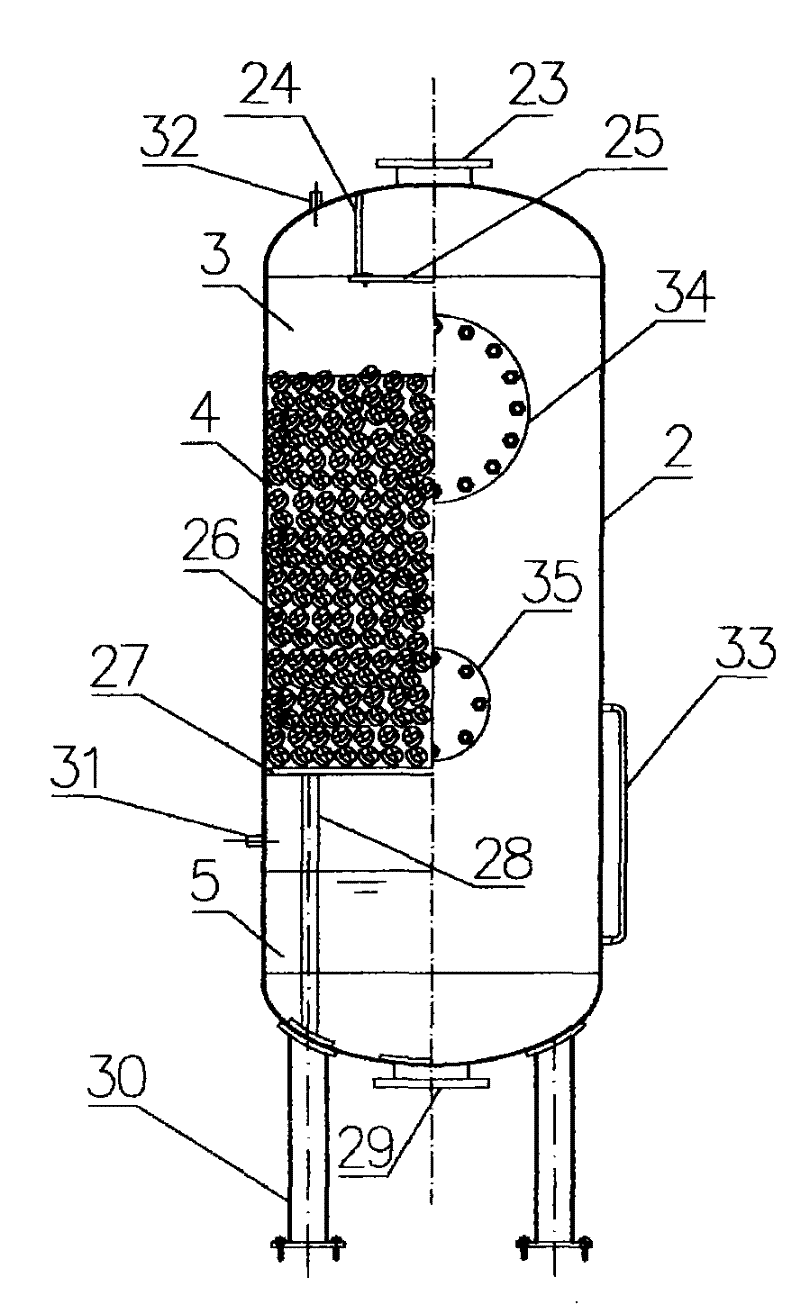

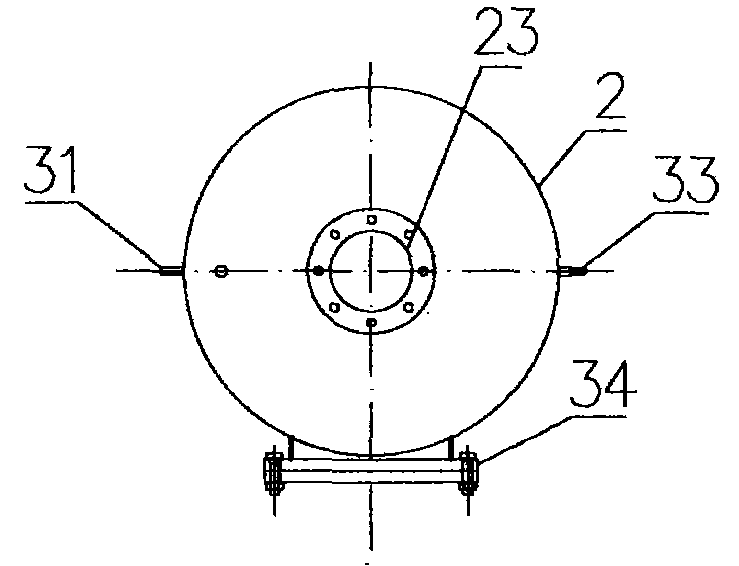

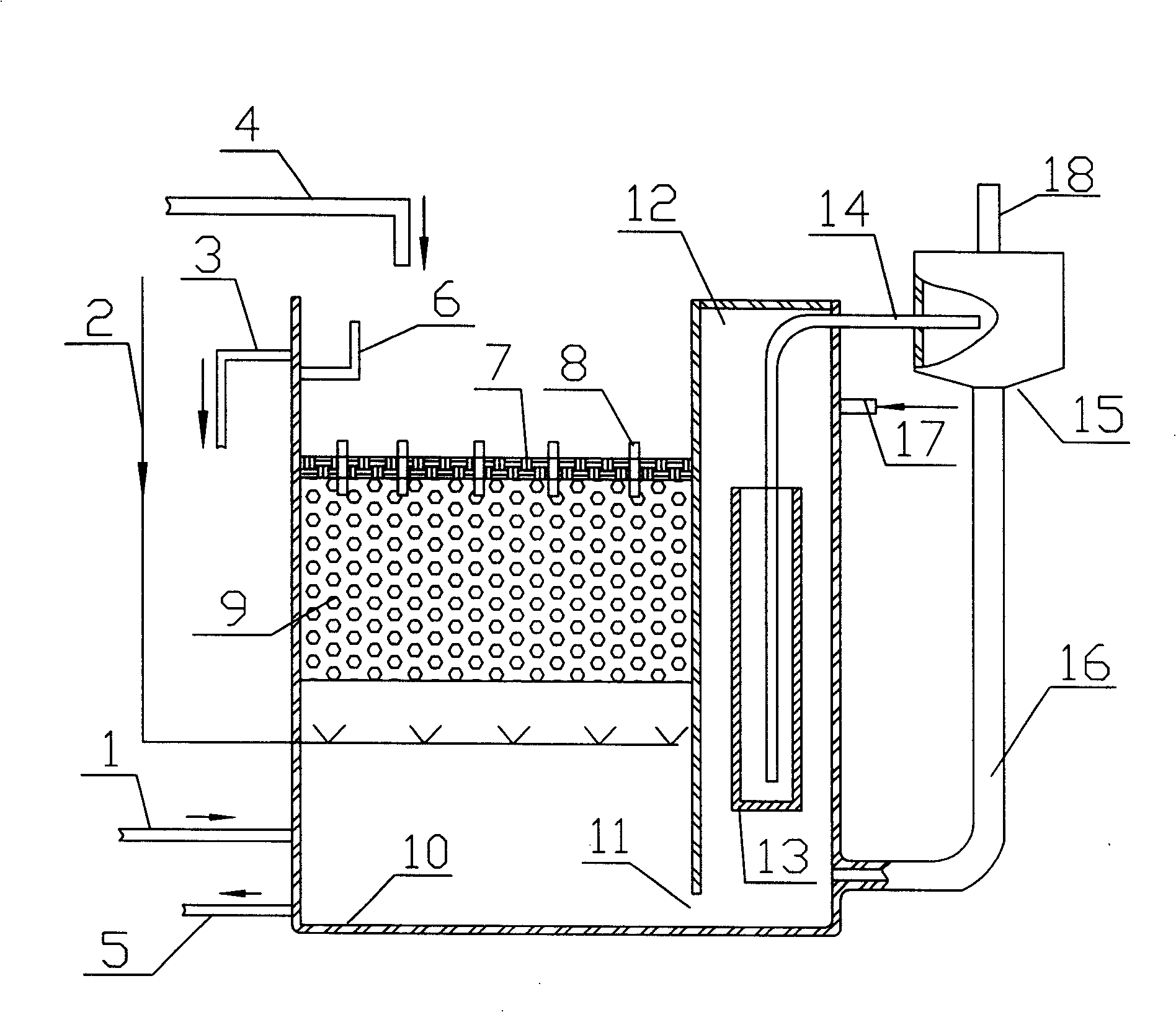

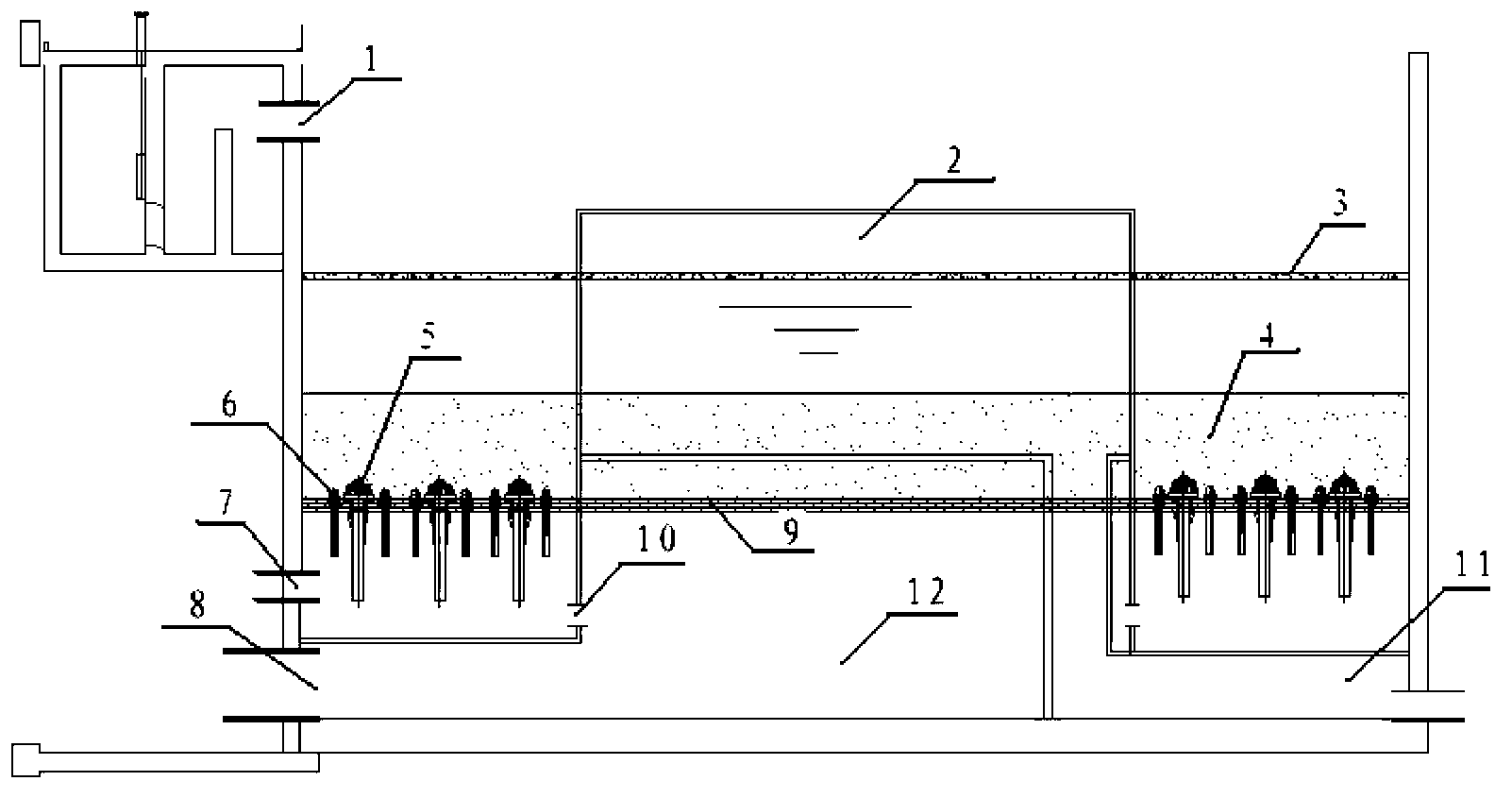

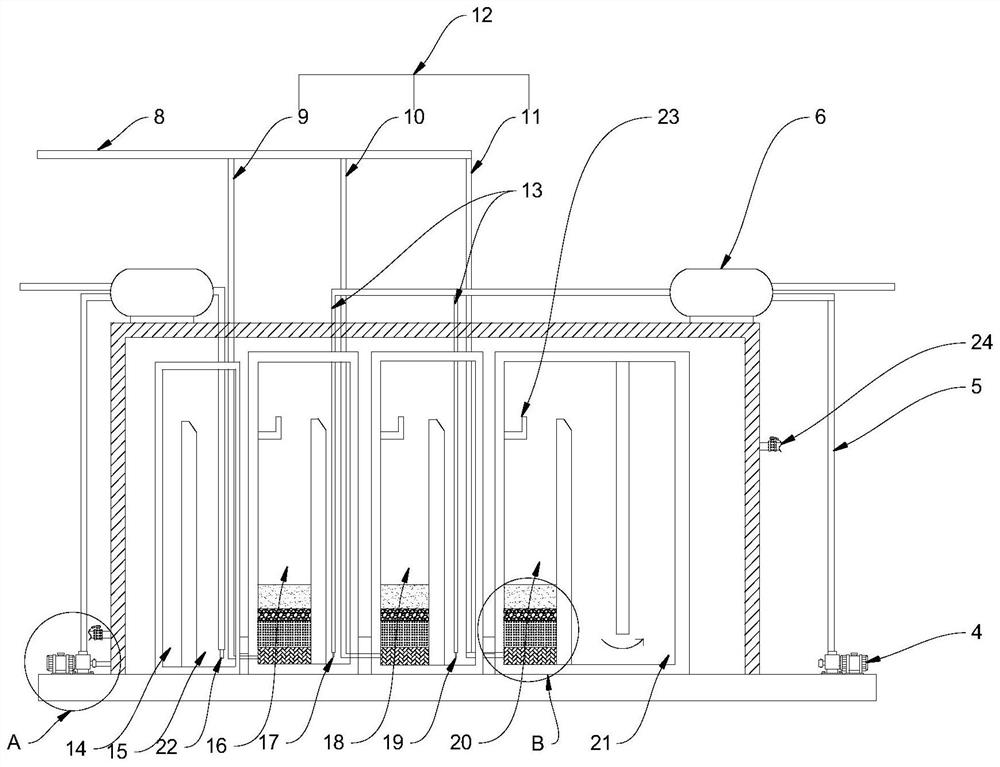

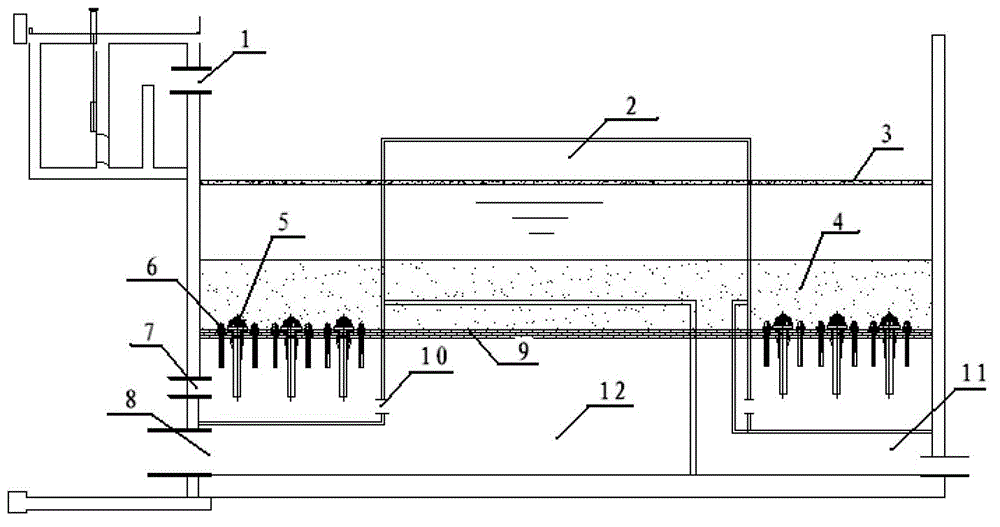

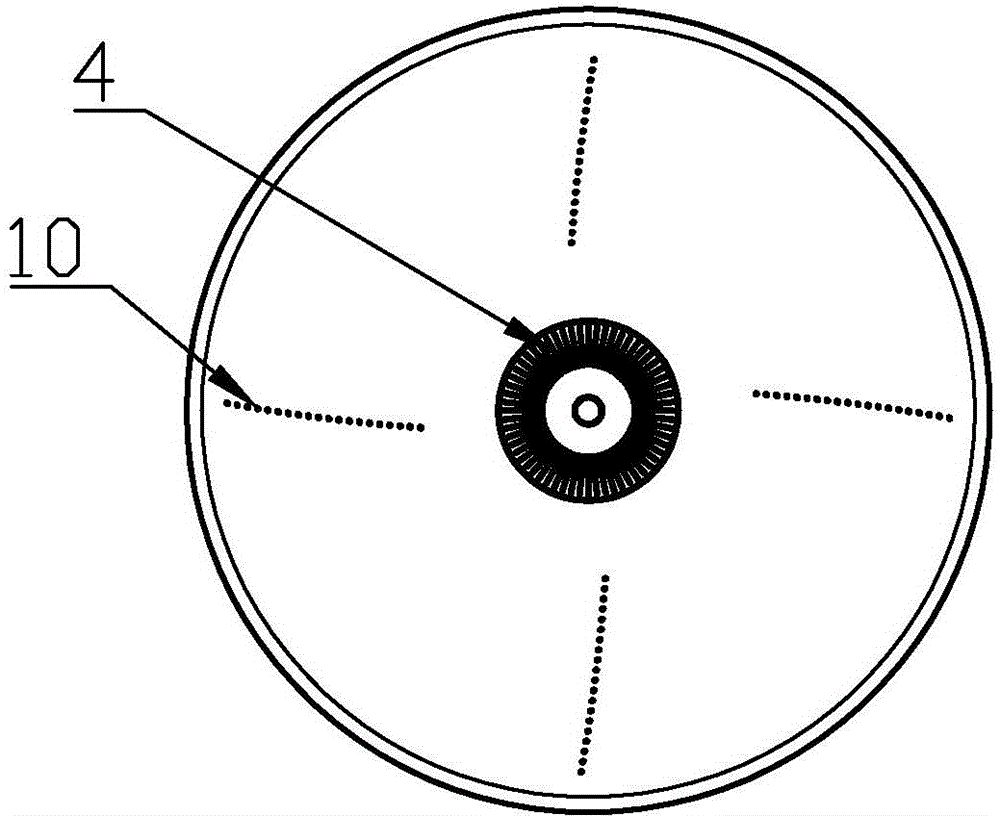

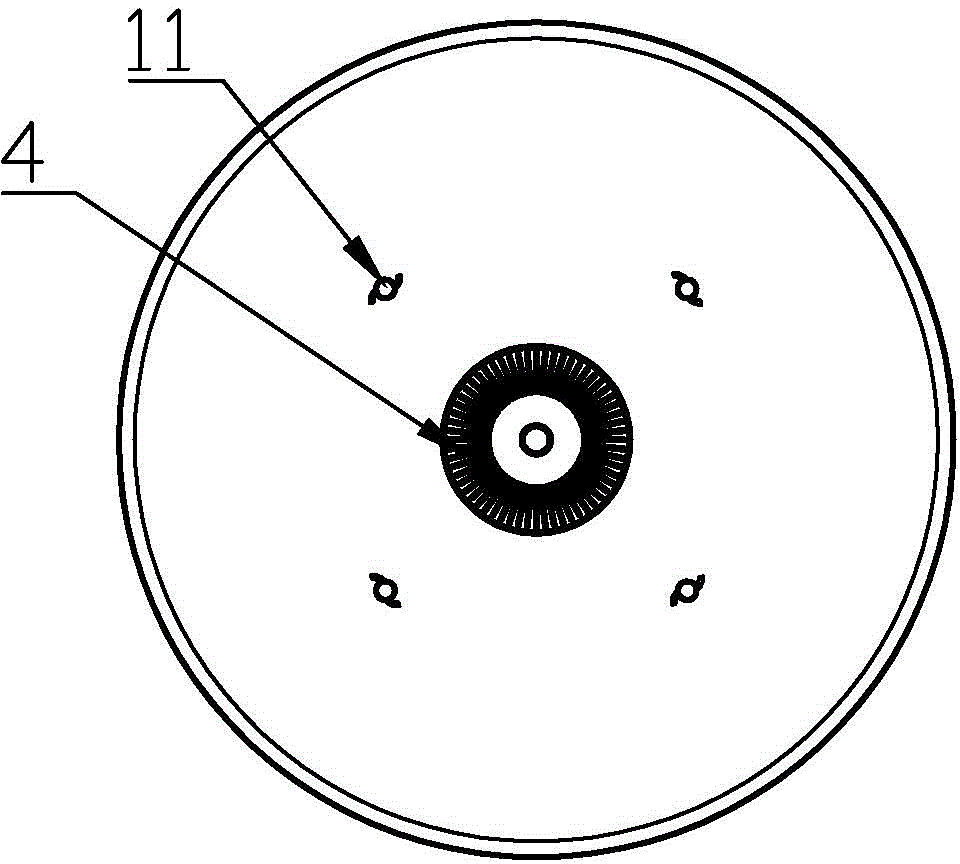

Ozone-bacteria filter system for advanced treatment of hardly-degradable organic wastewater

InactiveCN101538102BHigh densityImprove uniformityMultistage water/sewage treatmentSustainable biological treatmentOzone generatorInlet valve

The invention provides an ozone-bacteria filter system for advanced treatment of hardly-degradable organic wastewater, relating to a device for advanced treatment of the wastewater. The ozone-bacteria filter system comprises an ozone contact reactor (2), an ozone generator (20), a bacteria filter (7), a blast blower (19) and a backwash water pump (15), wherein the ozone contact reactor (2) which is provided with a water distribution layer (3), a packing layer (4) and a water storage layer (5) is connected with an ozone tail gas breaking device (22); the bacteria filter (7) comprises an upper water distribution device (8), an active carbon layer (9), an iron and manganese removal filter material layer (10), and a lower water distribution device (12) and a gas distribution device (13) whichare arranged in a bearing layer (11); and the bacteria filter (7) is sequentially connected with a backwash valve (14), a backwash water pump (15), a clean water valve (17) thereof and a clean water tank (16), and is connected with the blast blower (19) by a gas inlet valve (18). The ozone-bacteria filter system has the advantages that the ozone absorption efficiency is more than 90 percent, and residual ozone can be prevented from causing secondary pollution. The ozone-bacteria filter system can be widely used for the deep and recycling treatment of various hardly-degradable organic wastewater.

Owner:TONGJI UNIV +1

Regeneration method of mixed bed for desalination

ActiveCN108178240BShort regeneration timeIncrease water productionSpecific water treatment objectivesWater/sewage treatment by ion-exchangeDesalinationWater production

The invention relates to the field of chemical water production in power plants, and discloses a method for regenerating a desalting mixed bed. In the method, the liquid level in a mixed bed tank reduces to the top of a resin layer before the resin layer is subjected to hydrodynamic backwashing layering, and compressed air is introduced into the mixed bed tank to perform air washing, so the resinis effectively loosened, the water injection pressure of the subsequent backwashing step is reduced, the backwashing layering effect is enhanced, the backwashing layering time is significantly shortened, and the consumption of backwashing water in the resin backwashing layering process is reduced. After the resin is backwashed with water, the control of the concentrations and the flow amounts of aregeneration alkali solution and a regeneration alkali solution can significantly reduce the consumptions of the regeneration alkali solution and the regeneration alkali solution in the resin regenerating process and greatly shortens the regeneration time of the desalting mixed bed. The water production volume of the desalting mixed bed in a single period is high, and the outlet water of the regenerated desalting mixed bed has excellent quality.

Owner:CHINA SHENHUA ENERGY CO LTD +2

A high-efficiency backwash filter device and a multi-layer filter with the device

ActiveCN106267931BAchieve regenerationImprove filtering effectLoose filtering material filtersGravity filtersWater useFiber

The invention relates to an efficient backwashing filtering device and a multilayered filter provided with the device. The efficient backwashing filtering device is provided with a filtering unit, so that high-turbidity circulating water can be filtered and backwashing can be carried out on a fiber filtering material, and therefore, regeneration of the fiber filtering material is realized and the filtering effect is enhanced; in a backwashing process of the fiber filtering material, high-pressure air in a high-pressure airflow pipeline is sprayed out from a nozzle on an outer sleeve, and suspension matters and oil, which are intercepted by the fiber filtering material, can be completely removed, so that the fiber filtering material is completely regenerated; the backwashing time can be greatly shortened and the water use amount of backwashing is saved; the backwashing and pollutant removing effects are relatively good; and the multilayered filter provided with the device comprises a plurality of stacked filtering units, so that the occupied areas of a filter is reduced, the utilization rate of a land is increased and the filtering efficiency is improved.

Owner:秦皇岛德创节能环保科技有限公司

Multi-medium filter backwashing technology

InactiveCN102078714AShort time out of bedShorten backwash process timeLoose filtering material filtersGravity filtersAutomatic controlProcess engineering

Owner:JINAN YUXING CHEM

Aerating biological filter

InactiveCN100412003CSimple structureReduce manufacturing costTreatment using aerobic processesSustainable biological treatmentBiological filterWater treatment

The invention discloses an aerating biological filter pool in the water disposal device domain, which comprises the following parts: filter pool within aerating device and filtering device, water inlet pipe on the bottom of filter pool, backwash drainage pipe on the bottom of filter pool, pulse air-chamber to interconnect bottom of filter pool through backwash inlet pipe and vent pipe, wherein the vent pipe lies in one end of water sealing pipe in the pulse air-chamber; the other end of vent pipe connects gas-water separator, whose top possesses connection pipe with bottom interconnecting the bottom of pulse air-chamber through connection pipe.

Owner:SHANDONG JIANZHU UNIV

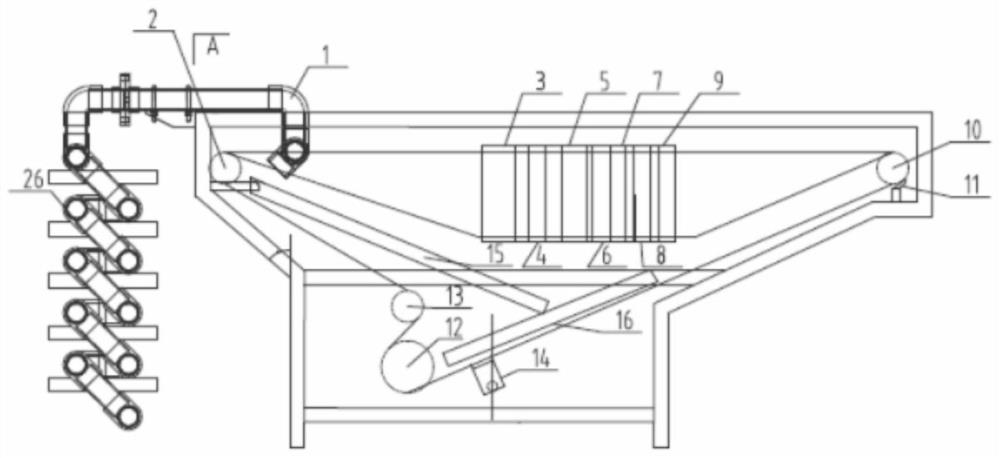

V-shaped belt type dewatering equipment self-adaptive to sludge concentration and application of V-shaped belt type dewatering equipment

ActiveCN113292219ARealize automatic proportional dosingLess investmentWater treatment parameter controlSludge treatmentSludgeSewage

The invention provides V-shaped belt type dewatering equipment self-adaptive to sludge concentration. The V-shaped belt type dewatering equipment is sequentially provided with a first mixing unit, a second mixing unit and a filter pressing dewatering unit in the sludge feeding direction, and the first mixing unit is sequentially provided with a first mixing pipe body and a second mixing pipe body in the sludge feeding direction. The second mixing unit is a pipeline mixing part or a mechanical mixing part, and the filter pressing dewatering unit comprises a rack and a filter cloth operation area arranged in the rack. The invention further provides a dehydration method self-adaptive to sludge concentration. According to the V-shaped belt type dewatering equipment self-adaptive to the sludge concentration and the application thereof, the equipment is low in energy consumption, low in site requirement, convenient to migrate and convenient for subsequent treatment, and is particularly suitable for dewatering treatment of sludge and solid waste generated by a small town sewage plant.

Owner:SHANGHAI SHENYAO ENVIRONMENTAL PROTECTION ENG

High-efficiency energy-saving granular filter and backflushing method

ActiveCN103623626BSimple structureEliminate the defect of stirring seal leakageLoose filtering material filtersGravity filtersWater sourceControl system

The invention relates to a high-efficiency energy-saving granular filter which comprises a filter body, a backwashing assembly, a backwashing water tank, an air compressor and a control system. A tank body and upper and lower oval sealing heads are arranged on the filter body; upper and lower sieve tubes / plates are arranged in the tank body; an oil / gas discharge port and a sewage inlet assembly are arranged at the top of the upper oval sealing head; a water outlet, a discharge port and supporting legs are arranged at the end of the lower oval sealing head; a backwashing water inlet and a backwashing gas inlet are arranged on the backwashing assembly; after being connected with a water inlet pipe, a backwashing water inlet pipe is connected with a backwashing spray nozzle; the backwashing water tank is connected with a filter by a return pipe; after being connected with a gas control valve, a gas check valve and the like, the air compressor is connected with the backwashing gas inlet by pipelines; by the control system, each valve, a backwashing water source and a backwashing gas source are automatically controlled to carry out operation according to the program. The filter disclosed by the invention has a simple structure, adopts a three-phase flow backwashing technology, is convenient to operate, is low in backwashing water consumption, is effective and energy-saving to backwash and has long equipment service life.

Owner:武汉市汉江石油物资技术开发有限责任公司

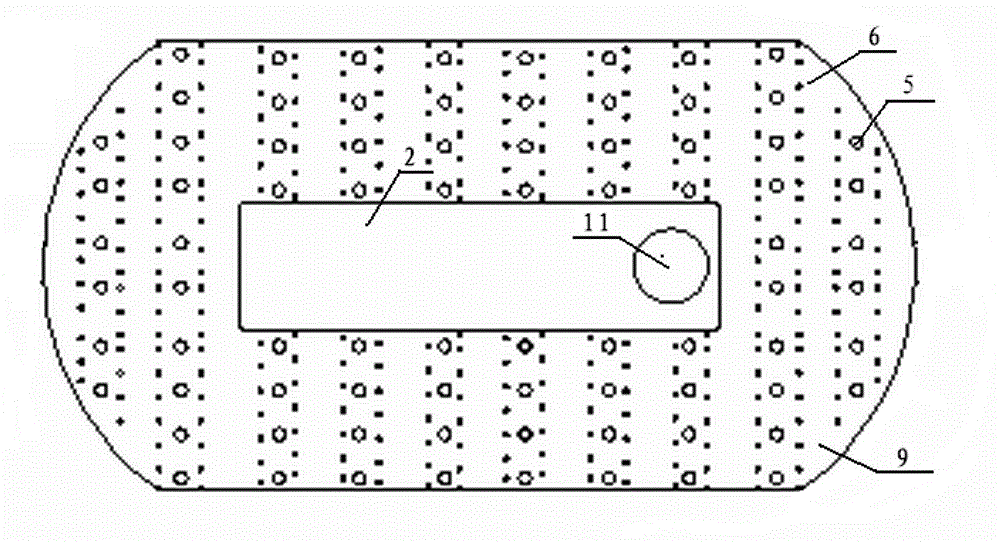

O-shaped filter chamber

InactiveCN103316511AReduce resistanceSmall footprintLoose filtering material filtersGravity filtersFiberSewage outfall

The invention particularly discloses an O-shaped filter chamber, wherein a water inlet is arranged above the filter chamber; a sewage outfall is arranged at the center of the filter chamber and communicated to two ends of the bottom of the filter chamber; one end is communicated with a water outlet; the other end is communicated with a drain outlet; a filter material intercept board is arranged at the top of the filter chamber; a filter material layer is arranged below the filter material intercept board; a filter plate is arranged below the filter material layer; a water distributing filter head and a backlash air pipe are arranged on the filter plate; and an air inlet is arranged at the lower wall of the filter chamber and arranged above the water outlet. By adopting the O-shaped filter chamber, a fiber filter chamber is formed into an O shape of a capital letter; and two ends are formed into arcs, so that the running resistance of the filter material is effectively reduced. The sewage outfall, an outlet channel and a backlash intake channel are merged together, formed into a mode of a guide wall, and put in the middle of the filter chamber, so that not only is the floor area of the filter chamber effectively reduced, but also a 'track' can be provided for movement of the filter material, so as to play a guide role.

Owner:山东金博士环境科技有限公司

Efficient catalytic ozonation system for treatment of refractory wastewater

InactiveCN113845203ALarge specific surface areaHigh mechanical strengthWater treatment compoundsSpecific water treatment objectivesCatalytic oxidationOxidation pond

The invention discloses an efficient ozone catalytic oxidation system for treatment of refractory wastewater. The system comprises a base and ozone contact oxidation pond equipment, wherein the ozone contact oxidation pond equipment is fixedly welded on the top of the base, one side of the ozone contact oxidation pond equipment is fixedly connected with a water inlet, the other side of the ozone contact oxidation pond equipment is fixedly connected with a water outlet, jet pumps are symmetrically arranged on the two sides of the ozone contact oxidation pond equipment respectively, the jet pumps are connected to the two ends of the base through bolts, the tops of the jet pumps are fixedly connected with a first connecting pipe, one end of the first connecting pipe is fixedly connected with a high-efficiency dissolved gas adding device body, and the high-efficiency dissolved gas adding device body is in bolted connection with the top of the ozone contact oxidation pond equipment. The ozone catalytic oxidation system for treatment of refractory wastewater is simple in equipment structure, novel in design and high in wastewater treatment efficiency.

Owner:北京弘昇达环境科技有限公司

O-shaped filter chamber

InactiveCN103316511BReduce resistanceSmall footprintLoose filtering material filtersGravity filtersFiberDistributed filtering

The invention particularly discloses an O-shaped filter chamber, wherein a water inlet is arranged above the filter chamber; a sewage outfall is arranged at the center of the filter chamber and communicated to two ends of the bottom of the filter chamber; one end is communicated with a water outlet; the other end is communicated with a drain outlet; a filter material intercept board is arranged at the top of the filter chamber; a filter material layer is arranged below the filter material intercept board; a filter plate is arranged below the filter material layer; a water distributing filter head and a backlash air pipe are arranged on the filter plate; and an air inlet is arranged at the lower wall of the filter chamber and arranged above the water outlet. By adopting the O-shaped filter chamber, a fiber filter chamber is formed into an O shape of a capital letter; and two ends are formed into arcs, so that the running resistance of the filter material is effectively reduced. The sewage outfall, an outlet channel and a backlash intake channel are merged together, formed into a mode of a guide wall, and put in the middle of the filter chamber, so that not only is the floor area of the filter chamber effectively reduced, but also a 'track' can be provided for movement of the filter material, so as to play a guide role.

Owner:山东金博士环境科技有限公司

Novel suspension filter and filtering system comprising the same

The invention discloses a novel suspension filter and a filtering system comprising the same. By arranging a movable partition and a filter screen, a housing is divided in order into an upper clear water region, a middle filtering region and a lower dirt-collecting region. Under the action of the inlet water pressure at the lower end of the housing and the action of buoyancy of suspending filtering media, the movable partition suspends at the top end of the housing, and the filtration effect is achieved by the multi-layer suspending filtering media. The filtered water enters the upper clear water region through the filter screen which is arranged in the center of the movable partition. During back-flushing, the pressure of the upper clear water region is higher than that of the middle filtering region, and the movable partition gradually moves down, so that the upper clear water region is enlarged and the middle filtering region is compressed to the minimum extent, the clear water enters the middle filtering region through a water distributor, undergoes vortex agitation and flushes the suspending filtering media, thus achieving the back-flushing effect. The system of a conventional settlement-type filter is simplified, a back-flushing water pump or air pump required for a back-flushing system is omitted, and the consumption of back-flushing water is greatly reduced. The novel suspension filter is simple, practical and free of extra energy consumption.

Owner:SOLIS HIGHT TECH INC SHENZHEN

Vertical deflector combined Filtration type dephosphorization and nitrogen rejection facility

InactiveCN1246233CGuaranteed thicknessGuaranteed process lengthSustainable biological treatmentBiological water/sewage treatmentFiltrationNitrogen

The device contains at least two single filter tanks connected each other, water entrance pipe connected with first single filter tank and water exit pipe connected with last single filter tank, devision plates are used to separate the single filter tanks up and down crisscrossed, sewage up and down baffling passageway is preset. Bottom of single filter tank are mud collector, mud sludging pipe and filling layer is the middle part, the fillings are anaerobic filling, aerobic filling and high-grad iron filling, at least two of them are combined to put into the filter tanks, each fillings combination is put to one filter tank to form different function area. The design of sewage up and down baffling passageway is to ensure obtaining length of flow path required by process, the combination of mutiple fillings is suited for requirements of different water quality.

Owner:CHONGQING UNIV

Tilting plate type filtering pool

ActiveCN1319620CReduce backwash water consumptionShort timeLoose filtering material filtersGravity filtersFlushing timeWater quality

The present invention relates to a filter characterizing mutually arranged filter elements, and is especially tilting plate type filtering pool for use in water works. The tilting plate type filtering pool consists of filtering pool, reverse flush system, filtering system, sewage draining system and water influent and effluent system. The reverse flush system includes reverse flush valve, flushing air valve, water and air distributing transverse pipes, water distributing longitudinal pipes and air distributing longitudinal pipes; the filtering system includes anthracite layer, quartzite layer, coarse sand layer and pebble layer; the water influent and effluent system includes overflow weir plate, water effluent valve and water canal; and the sewage draining system includes tilting plate valve and canal. The present invention has less reverse flush water amount, short reverse flush time, high water effluent quality, low cost and other advantages.

Owner:杜加富

A device and method for treating phosphorus-containing organic wastewater with an A/O soil infiltration system

InactiveCN104193078BImprove pass rateImprove effluent qualityMultistage water/sewage treatmentOrganic matter mineralizationWater quality

The invention discloses a device for treating phosphorus-containing organic wastewater by using an A / O soil percolation system. A centrifuge guides layered discharged water into the A / O soil percolation system; the A / O soil percolation system comprises an anaerobic soil percolation area and an aerobic soil percolation area, respectively; and water discharged from the centrifuge is guided into the bottom in the anaerobic soil percolation area by a water inlet pipe; water discharged from the A / O soil percolation systems is sprayed into a surface turbulent flow screening and filtering device, so that viruses and heavy metals in the water are removed, and organic matters are mineralized or decomposed; then the water enters a rotary sand removal device to carry out sand removal, and finally clean water reaching the standard is discharged. According to the invention, an A / O process is used in a soil percolation system, and the soil percolation system is improved by using the A / O process and an alternate vertical flow concept, so that the cost and expense of deep treatment of sewage are reduced, the production of secondary pollution in the treatment process is avoided, and the effluent water quality of sewage is enhanced.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com