Efficient catalytic ozonation system for treatment of refractory wastewater

A technology of ozone catalytic oxidation and wastewater treatment, applied in water/sewage treatment, special compound water treatment, oxidized water/sewage treatment, etc., can solve the problems of high investment and operation cost, complex reaction tank structure, low ozone conversion efficiency, etc. To achieve the effect of improving the utilization rate of ozone, speeding up the oxidation reaction rate, and strengthening the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

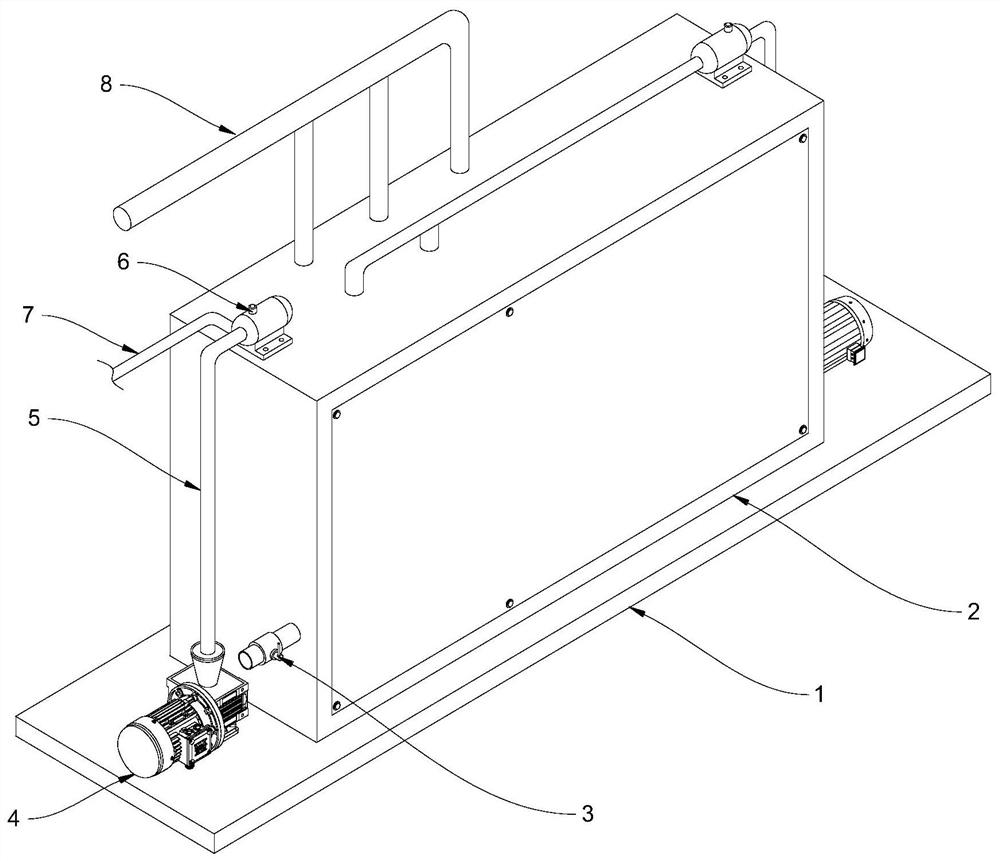

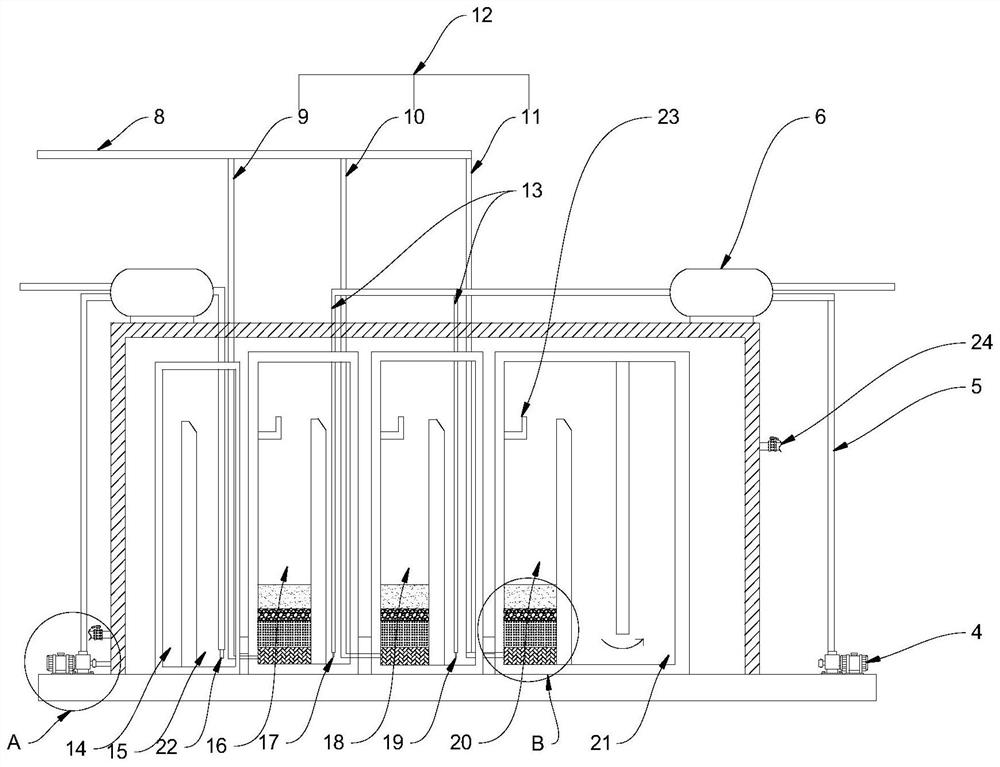

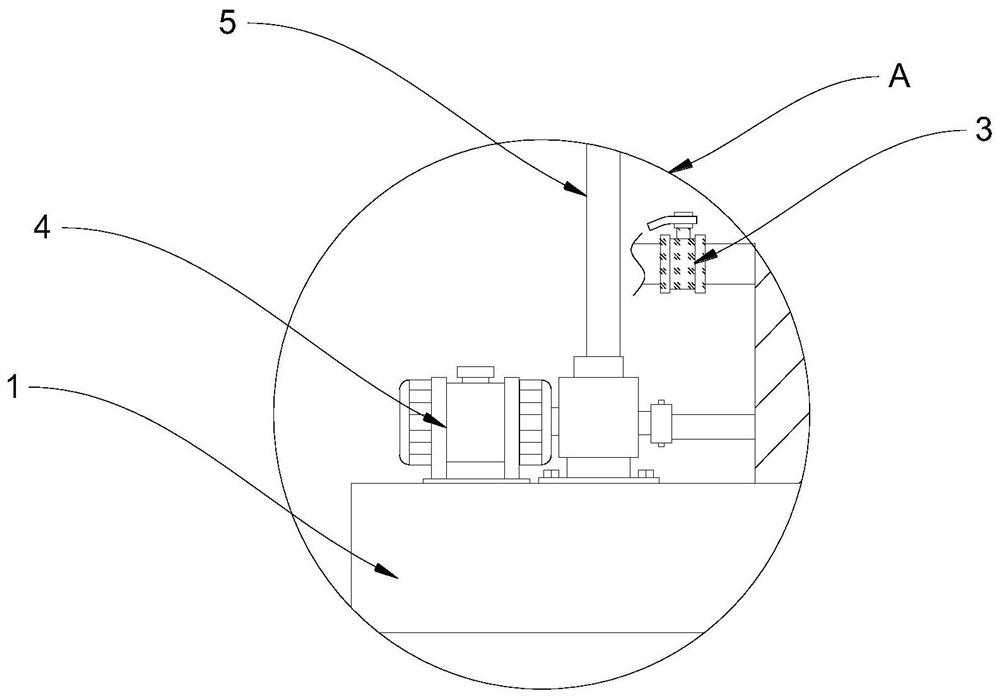

[0027] Example: such as Figure 1-4As shown, the present invention is a high-efficiency ozone catalytic oxidation system for refractory wastewater treatment, including a base 1 and an ozone contact oxidation tank device 2, the ozone contact oxidation tank device 2 is fixedly welded on the top of the base 1, and the ozone contact oxidation tank device One side of 2 is fixedly connected with water inlet 3, and the other side of ozone contact oxidation tank equipment 2 is fixedly connected with water outlet 24, and both sides of ozone contact oxidation tank equipment 2 are respectively symmetrically provided with jet pump 4, and jet pump 4 bolts Connected to both ends of the base 1, the top of the jet pump 4 is fixedly connected to the first connecting pipe 5, and one end of the first connecting pipe 5 is fixedly connected to the high-efficiency dissolved air dosing device body 6, and the high-efficiency dissolved air dosing device body 6 The bolt is connected to the top of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com