Integrated water treatment purifier

A water purifier and water treatment technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of affecting the subsequent unit treatment effect, difficult to distribute water uniformly, complicated piping system, etc., achieving significant technical effects, reducing land occupation, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

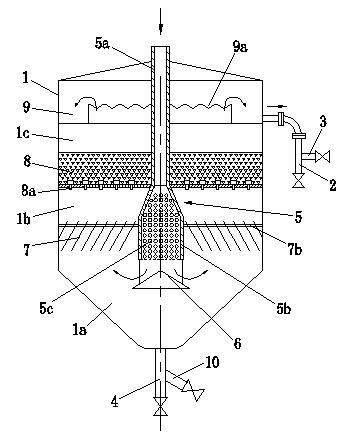

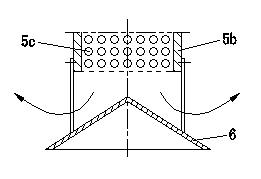

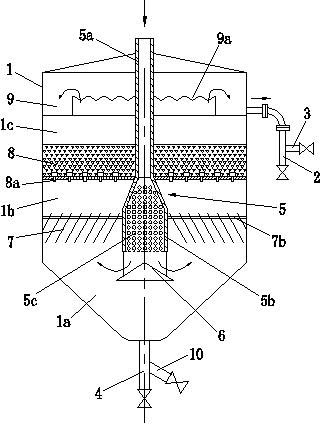

[0027] See attached picture. The present invention includes:

[0028] A housing 1 containing an inner cavity, the upper part of the housing 1 is connected to a water outlet pipe 2, and the water outlet pipe 2 is connected to a backwash water inlet pipe 3;

[0029] The main body of the housing 1 is a cylindrical structure, and the lower part is a conical structure;

[0030] The lower part of the housing 1 is connected to the mud discharge pipe 4. During the backwashing process, the mud discharge pipe 4 can also be used as a backwash drain pipe. The effect of flushing drainpipe 10 is, when carrying out backwashing, close mud discharge pipe 4 and open backwashing drainpipe 10, the water of backwashing is then discharged by backwashing drainpipe 10, can avoid the drainage of backwashing and the discharged Sludge mixing is beneficial to the follow-up treatment of the discharged sludge and backwashed water;

[0031] The inner cavity of the housing 1 is provided with a flocculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com