Regeneration method of mixed bed for desalination

A mixed bed and acid regeneration technology, applied in ion exchange regeneration, chemical instruments and methods, ion exchange bed cleaning/flushing, etc., can solve the problem of long stratification time, poor hydraulic backwash stratification effect, waste of desalinated water, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

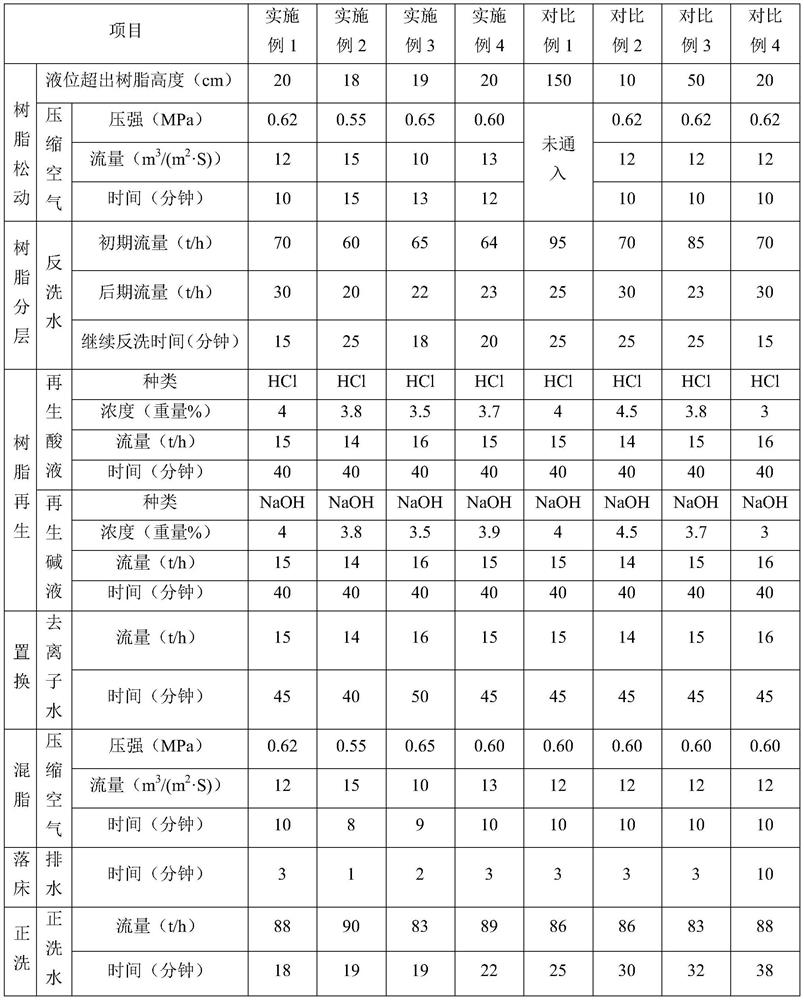

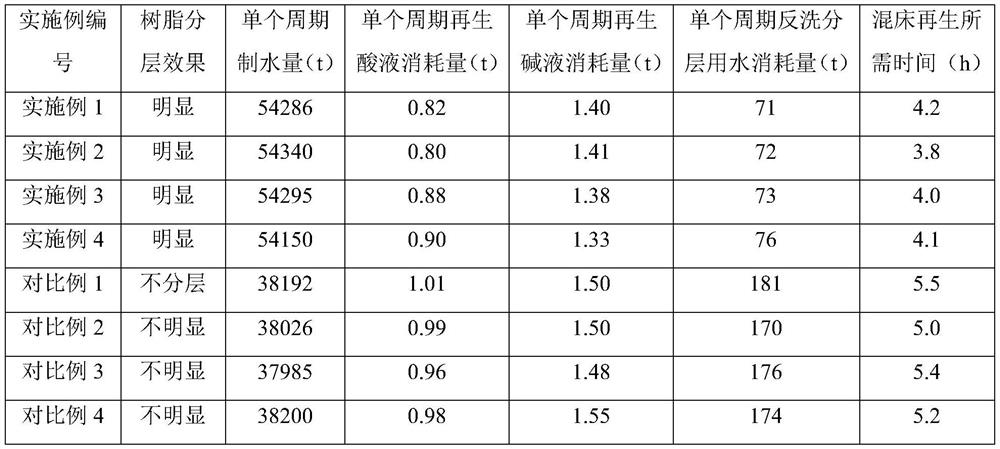

Embodiment 1-4 and comparative example 1-4

[0060] (1) Reduce the water level and resin loosening: reduce the liquid level in the mixed bed tank, feed compressed air into the mixed bed tank, and perform continuous air washing;

[0061] (2) Resin stratification: pour backwash water into the mixed bed tank, wait until the liquid level at the top of the resin layer expands to within the range of the upper observation window of the mixed bed tank, gradually reduce the injection flow rate of backwash water, and gradually close the backwash Water into the water, confirm the layering effect of anion exchange resin and cation exchange resin;

[0062] (3) Resin regeneration: Pre-spray deionized water into the mixed bed tank, adjust the concentration and flow rate of the regenerated acid solution and regenerated lye, and feed the regenerated acid solution and regenerated lye into the mixed bed tank to make the anion Exchange resin and cation exchange resin regeneration;

[0063] (4) Replacement: Pass deionized water into the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com