Ozone-bacteria filter system for advanced treatment of hardly-degradable organic wastewater

A biofilter and organic wastewater technology, which is applied in the direction of sustainable biological treatment, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problem of high water consumption for filter recoil, low ozone absorption rate, and limited promotion Application and other issues to achieve the effect of preventing secondary pollution, increasing the effective contact area, and accelerating the process of dissolved gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

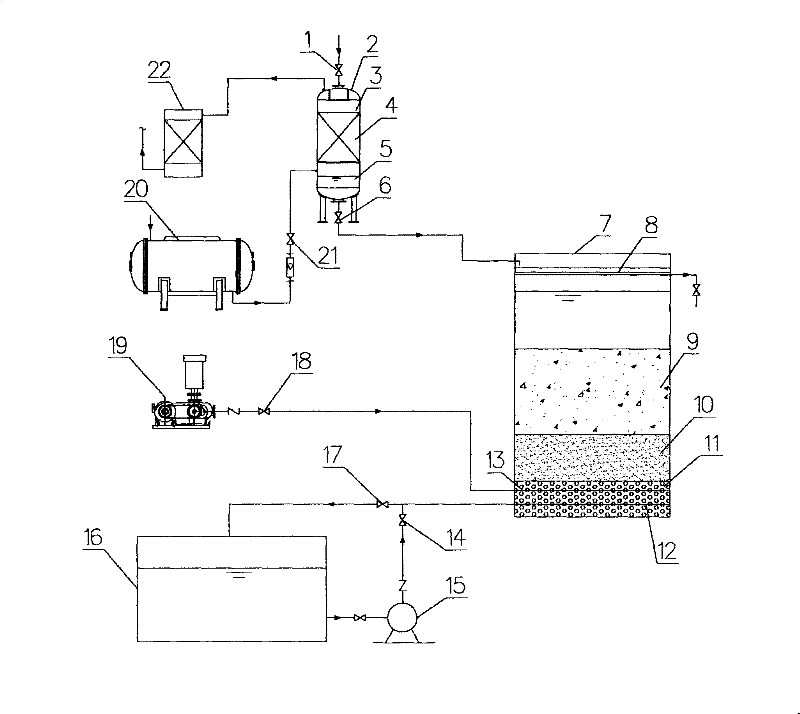

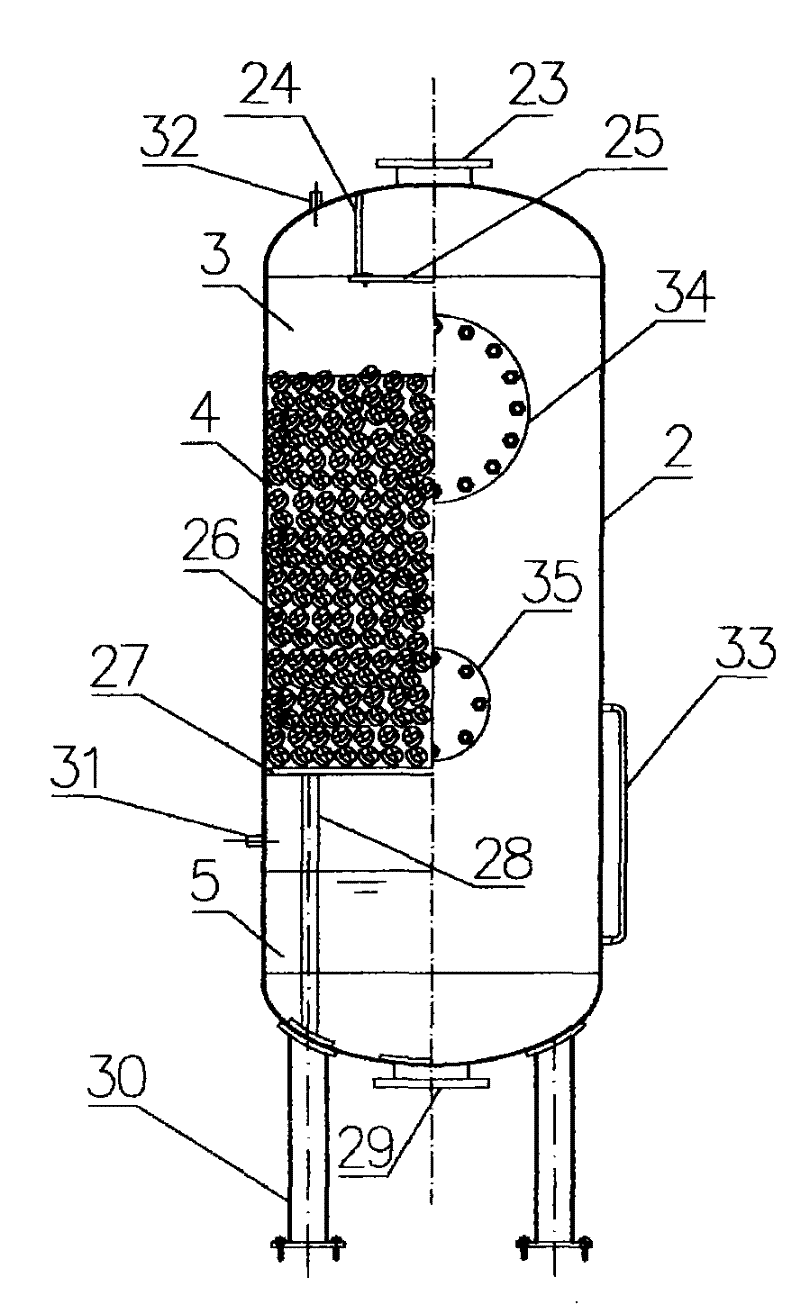

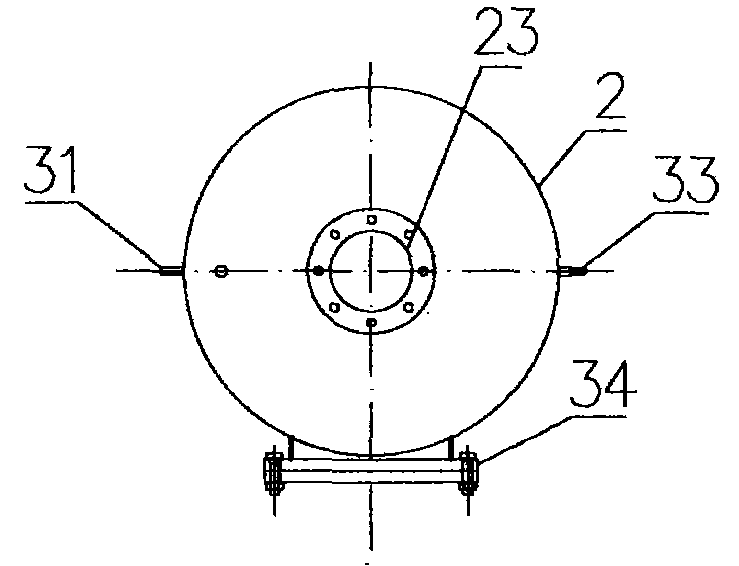

[0027] see figure 1 .

[0028] The present invention is composed of an ozone contact reactor 2, an ozone generator 20, an ozone tail gas destruction device 22, a biofilter 7, a blower 19, a backwash water pump 15 and a clear water pool 16. The gas source of the ozone generator 20 can adopt air or oxygen. When an air source ozone generator is used, pretreatment measures such as purification, degreasing and cold drying must be set before the air enters the ozone generator 20 . The ozone generator 20 is connected with the ozone contact reactor 2, and the ozone is sent into the ozone contact reactor 2 to react with the refractory organic wastewater entering. The top of the ozone contact reactor 2 is connected with the ozone tail gas destruction device 22 through a pipeline, and the remaining Ozone absorption. The ozone tail gas destroying device 22 all adopts anti-ozone corrosion materials, and various types of ozone absorbing and destroying devices such as activated carbon ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com