Patents

Literature

83 results about "Capital Letter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Letter case (or just case) is the distinction between the letters that are in larger upper case (also uppercase, capital letters, capitals, caps, large letters, or more formally majuscule) and smaller lower case (also lowercase, small letters, or more formally minuscule) in the written representation of certain languages.The writing systems that distinguish between the upper and lower case ...

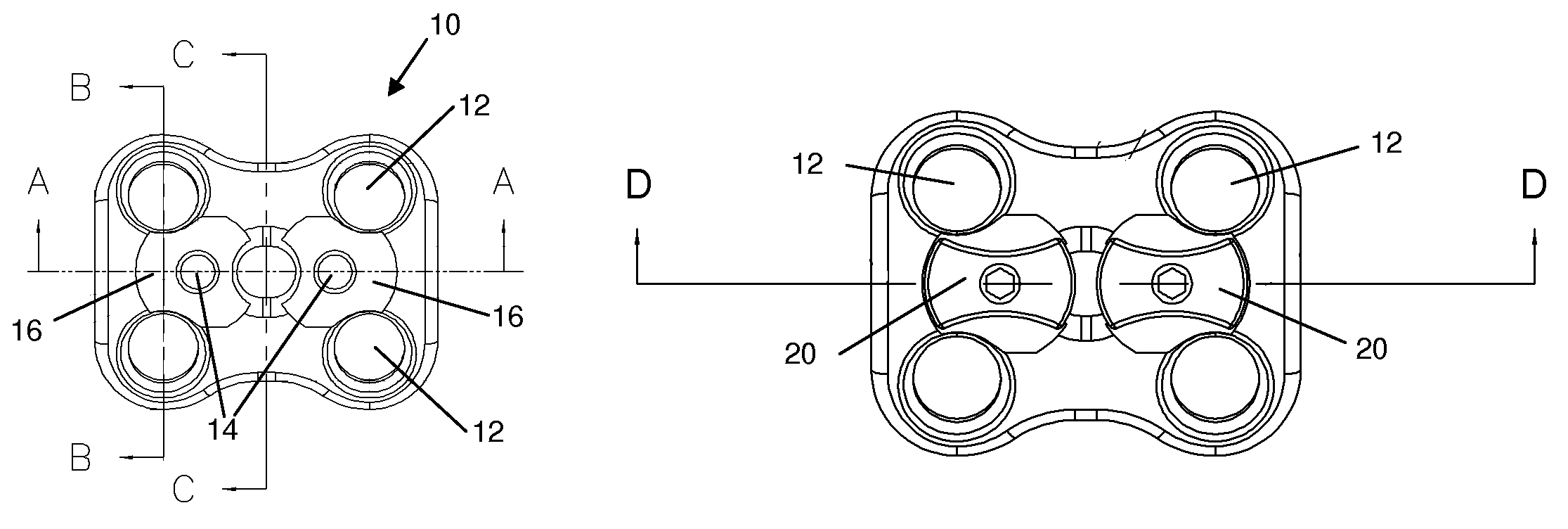

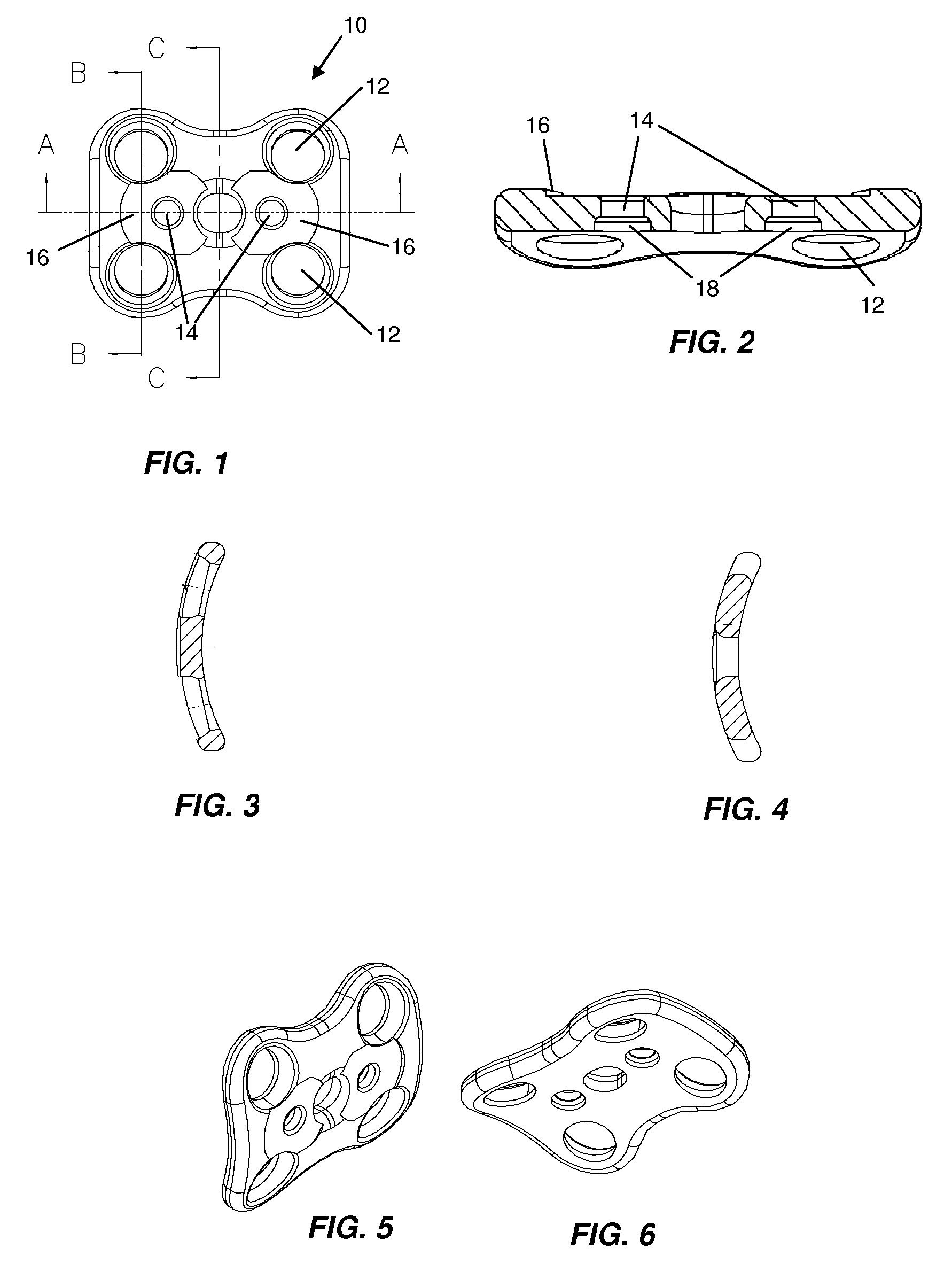

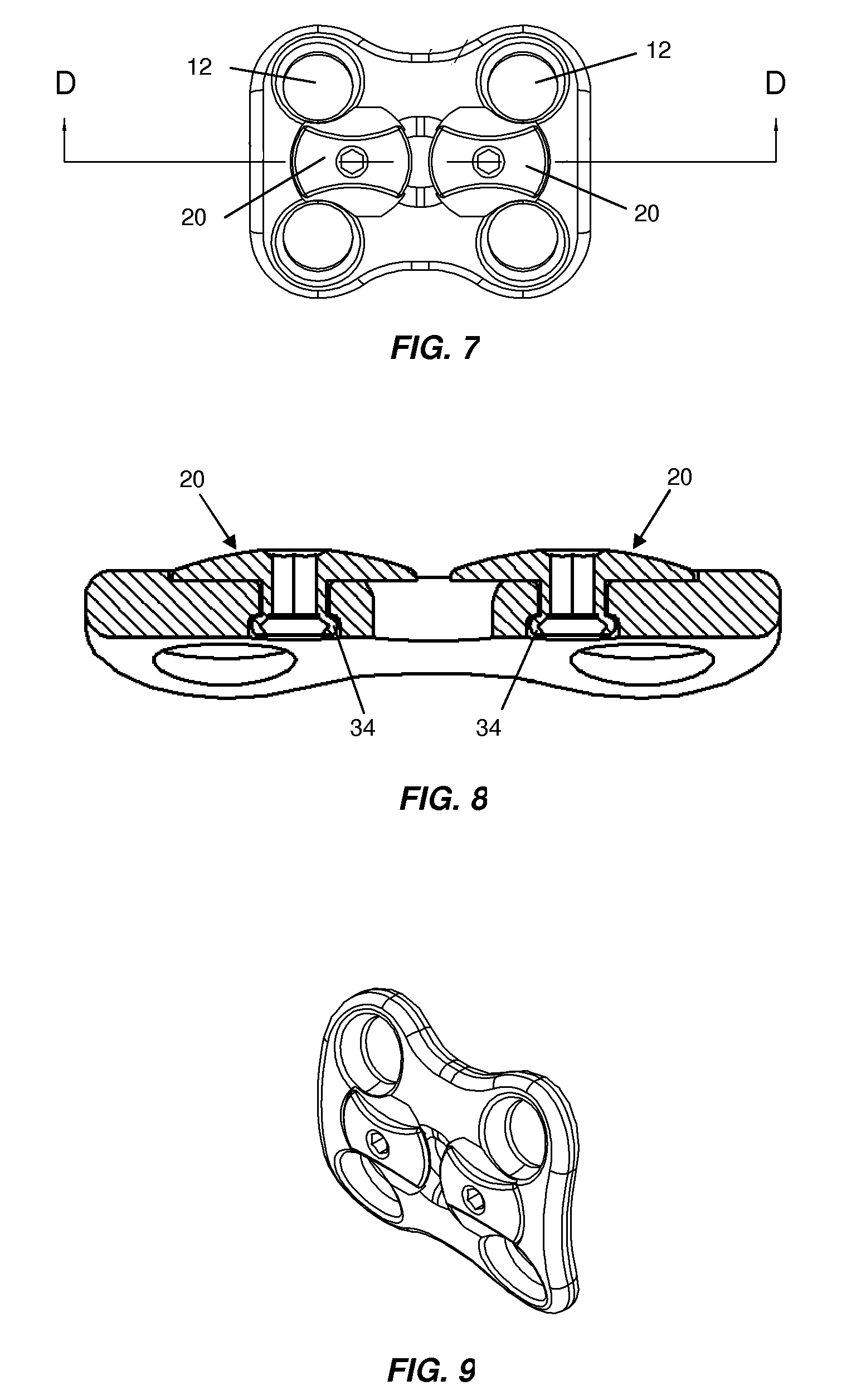

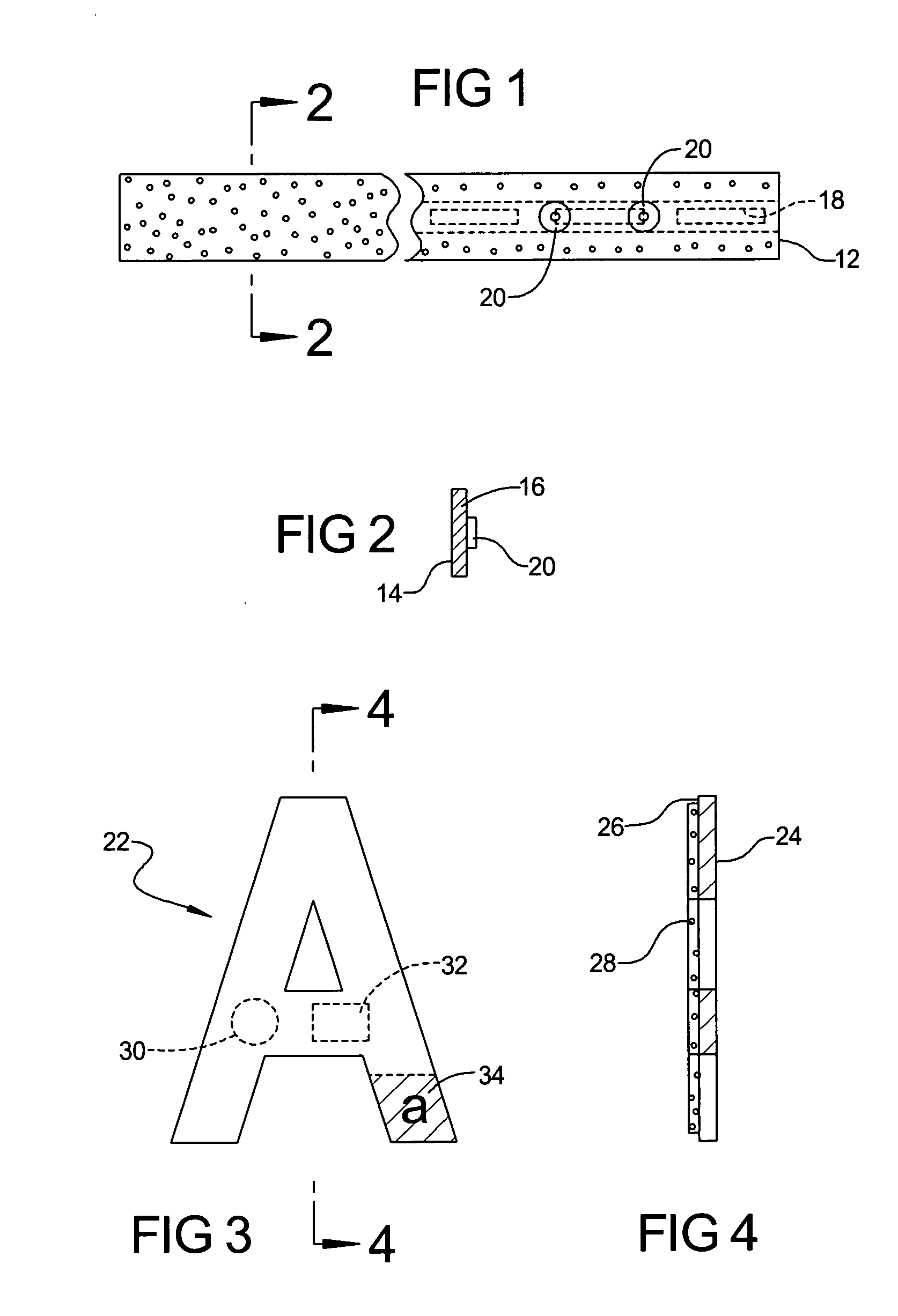

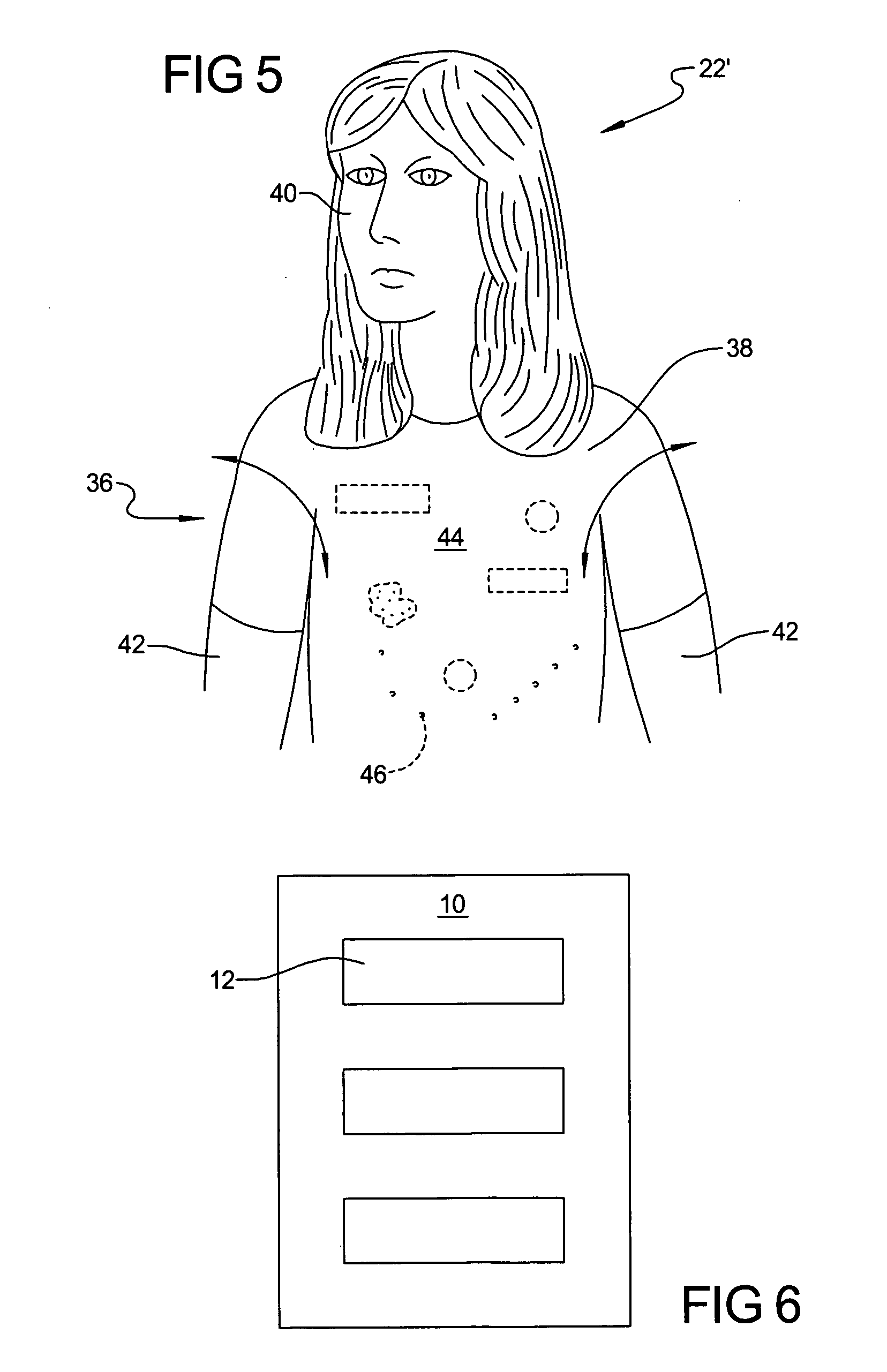

Bone plate

A bone plate includes one or more locking devices which rotate to inhibit or prevent bone screws from backing out of the plate when installed on a patient. The locking devices can be in the shape of a bow tie or a capital letter I.

Owner:SPINAL US

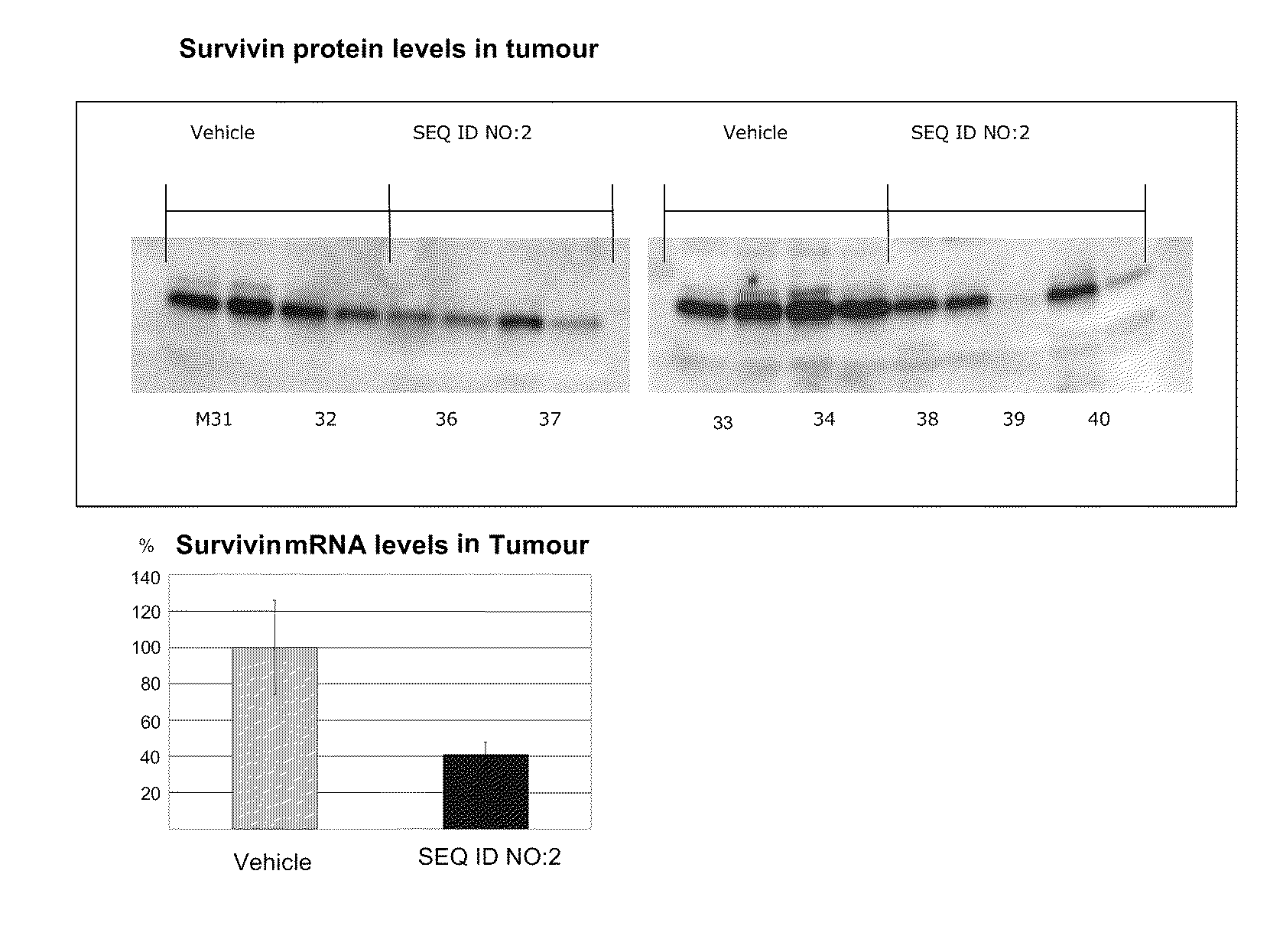

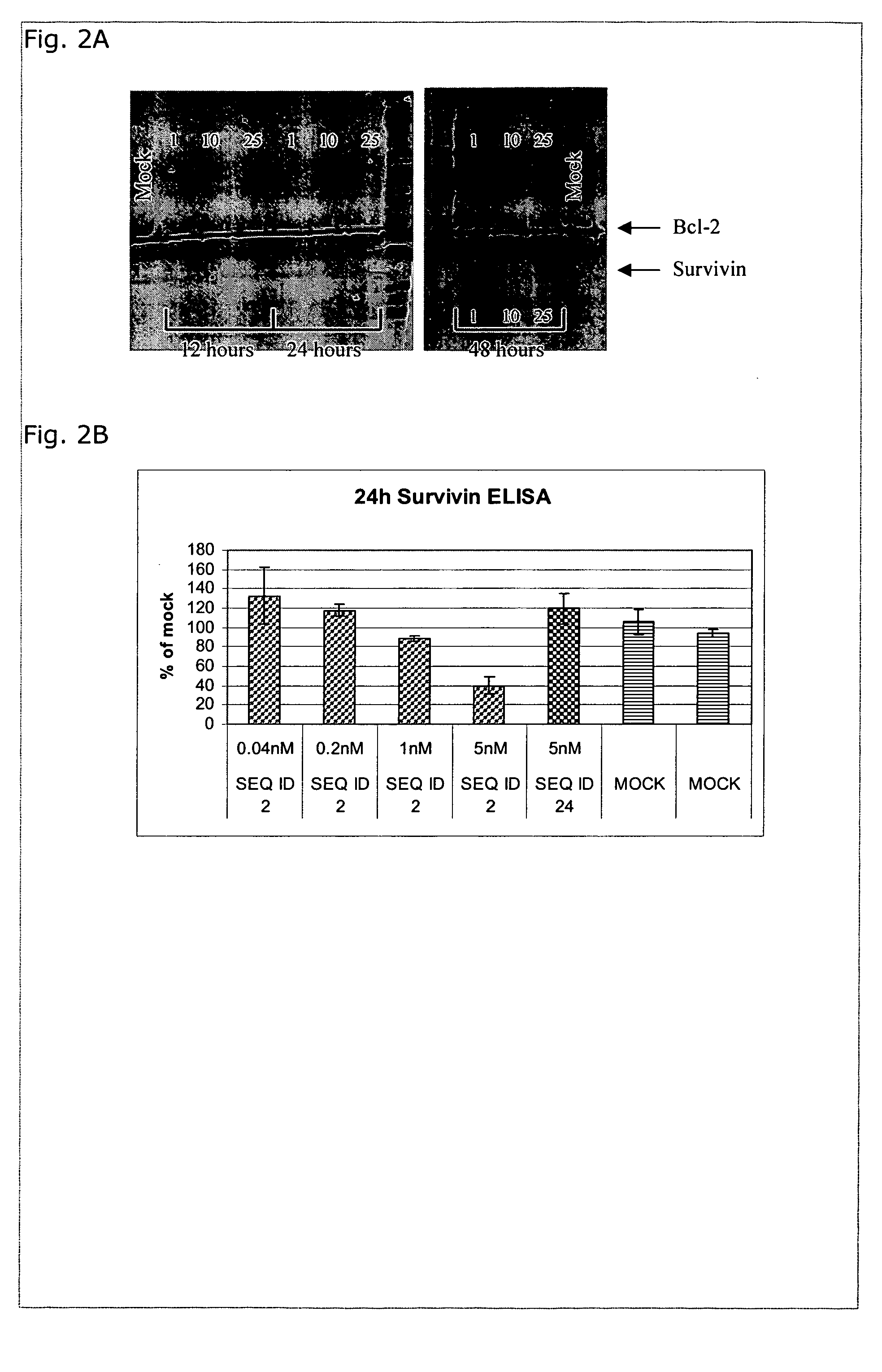

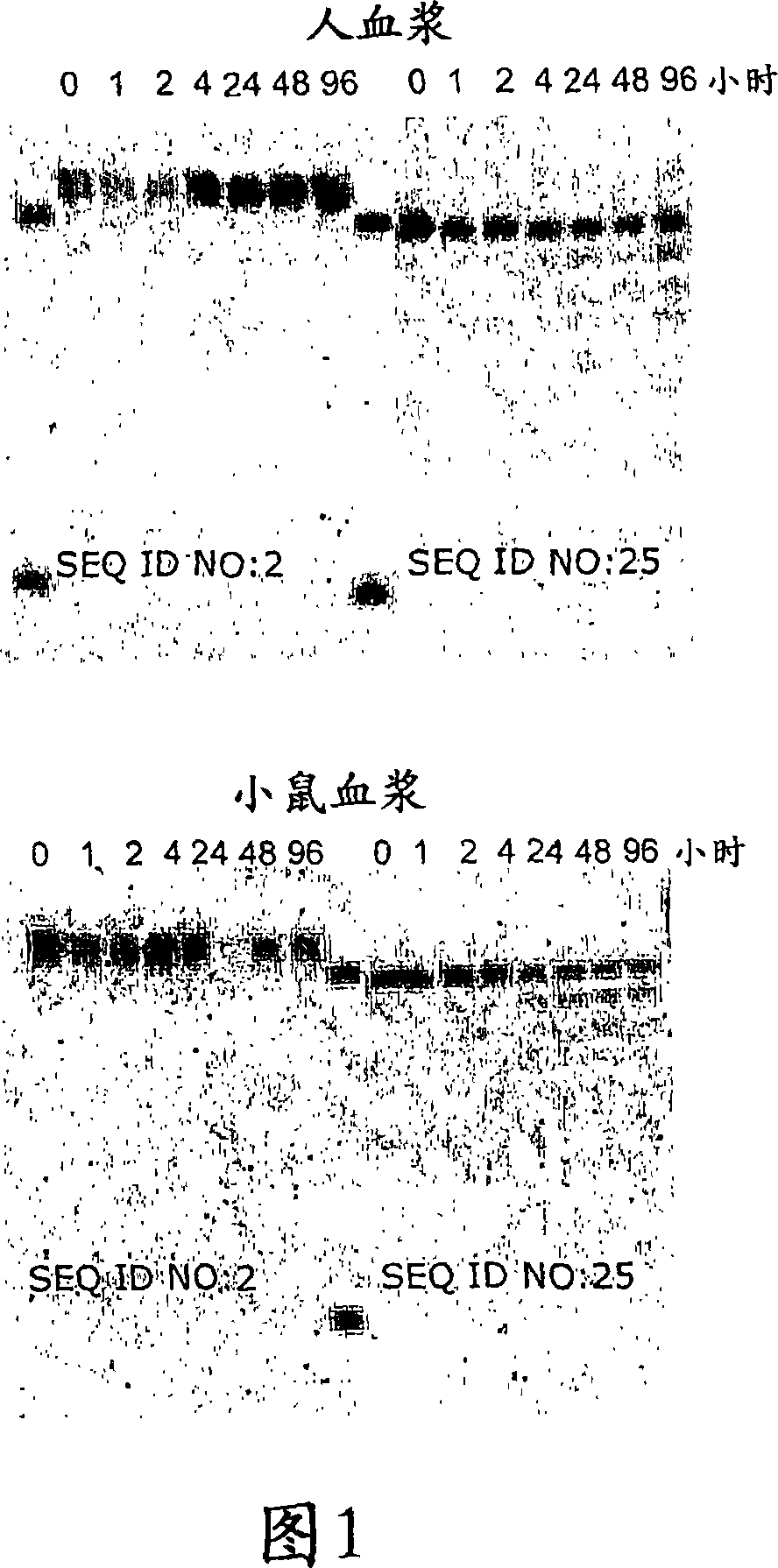

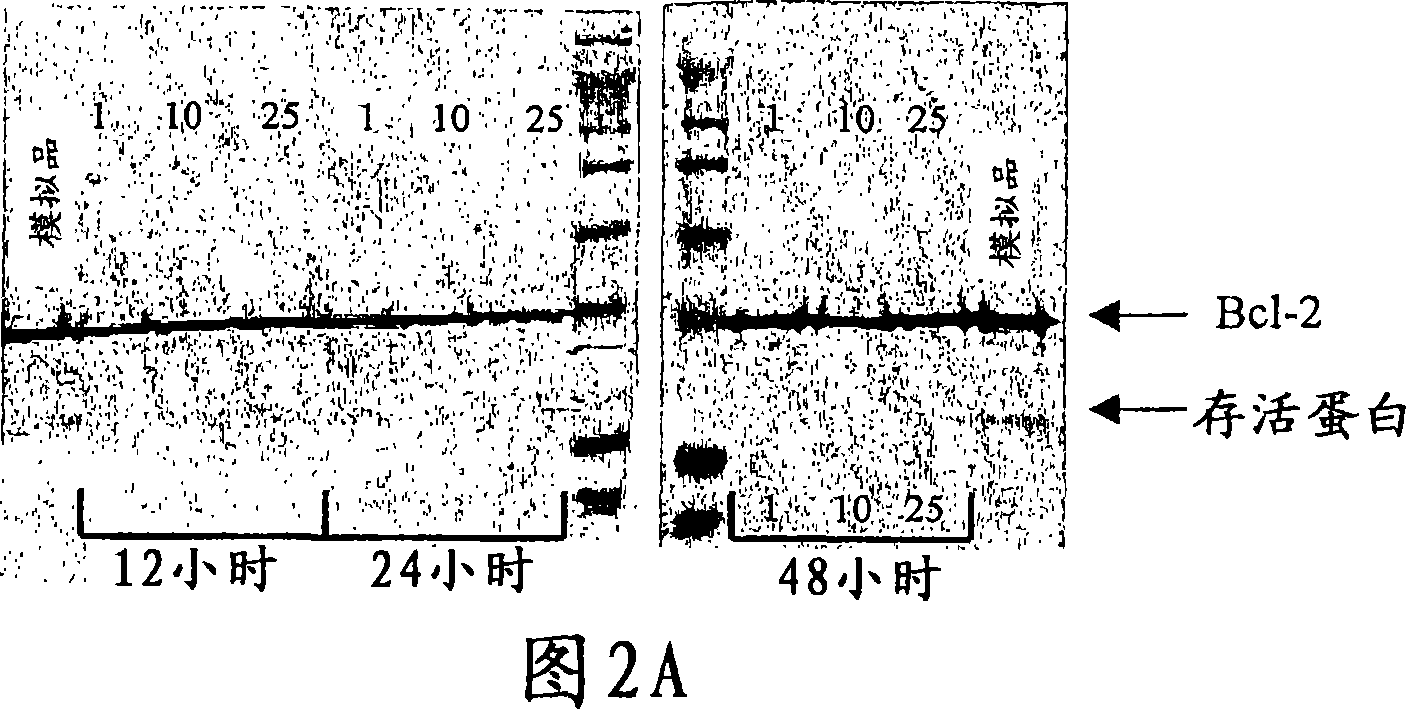

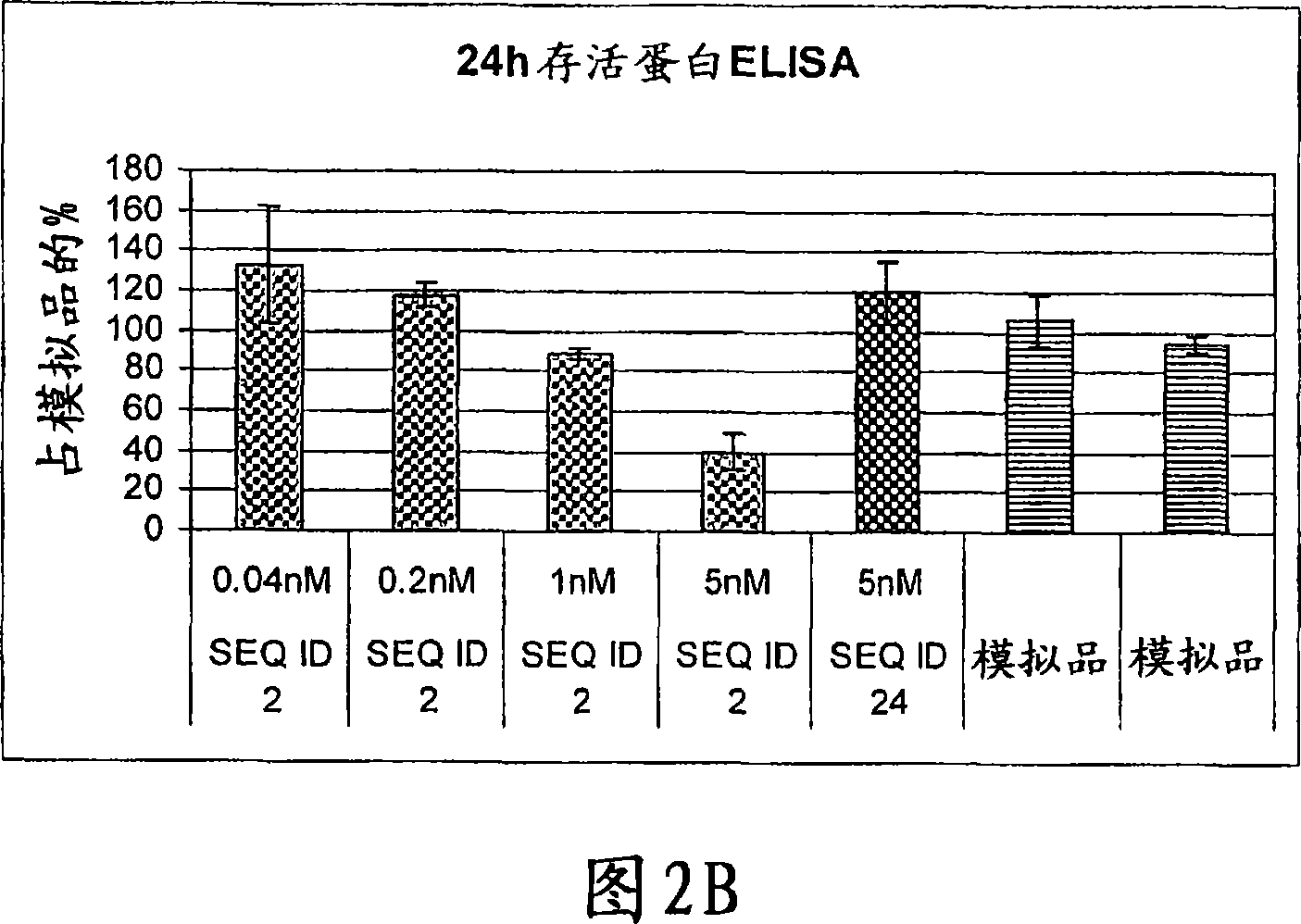

Lna oligonucleotides and the treatment of cancer

Owner:ENZON PHARM INC

LNA oligonucleotides and the treatment of cancer

InactiveUS20060154888A1Organic active ingredientsPeptide/protein ingredientsCancer cell linesApoptosis induction

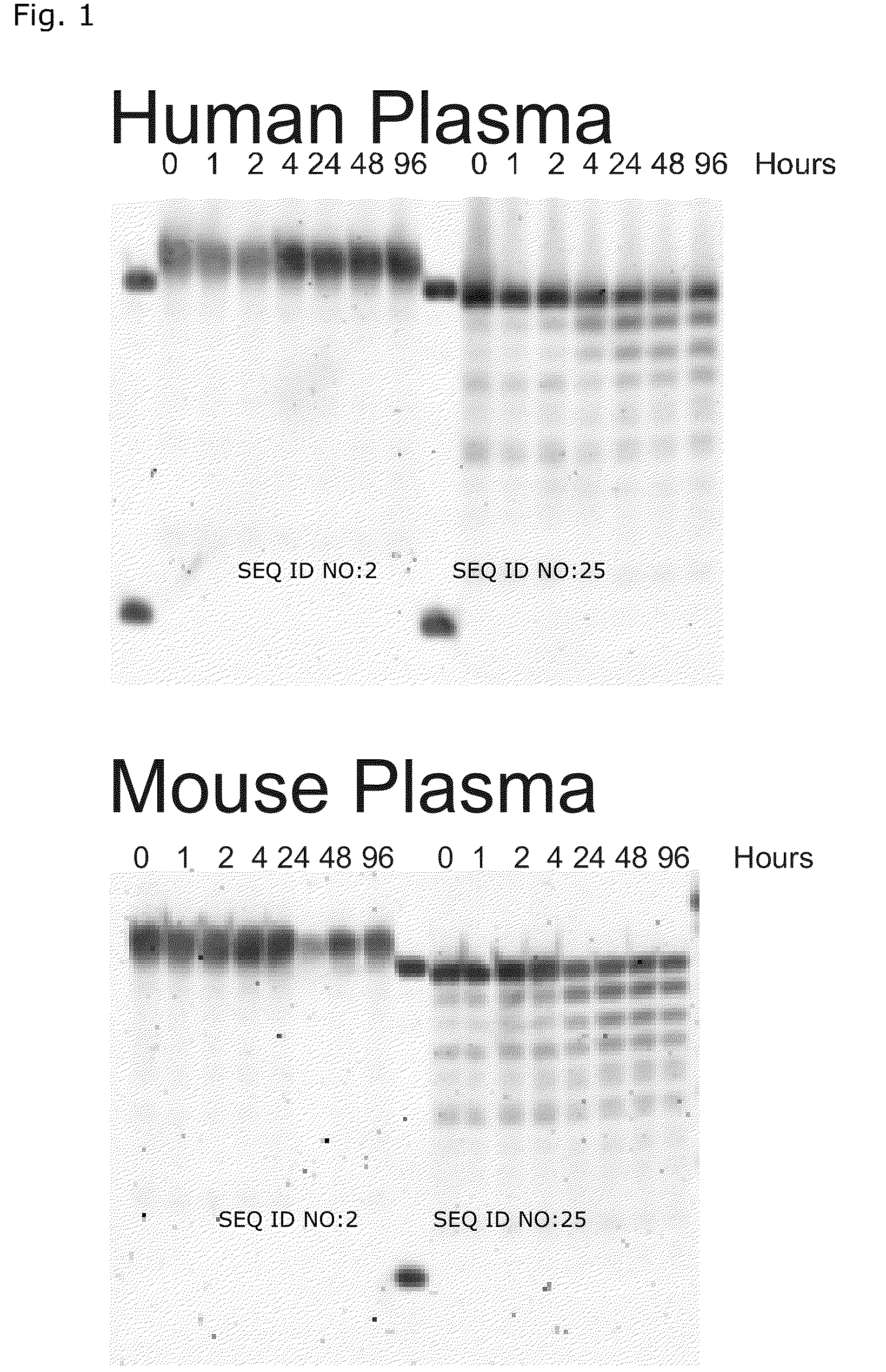

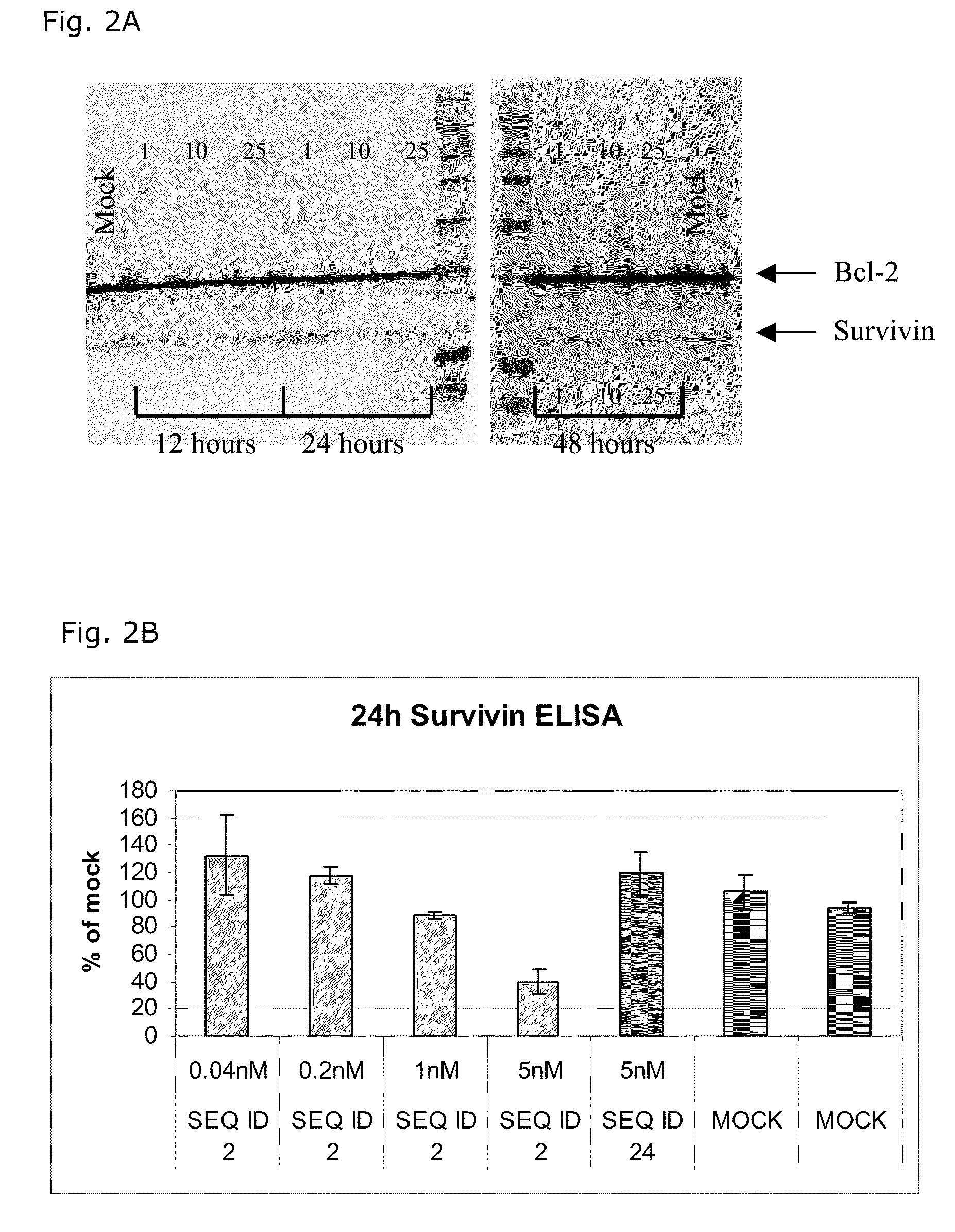

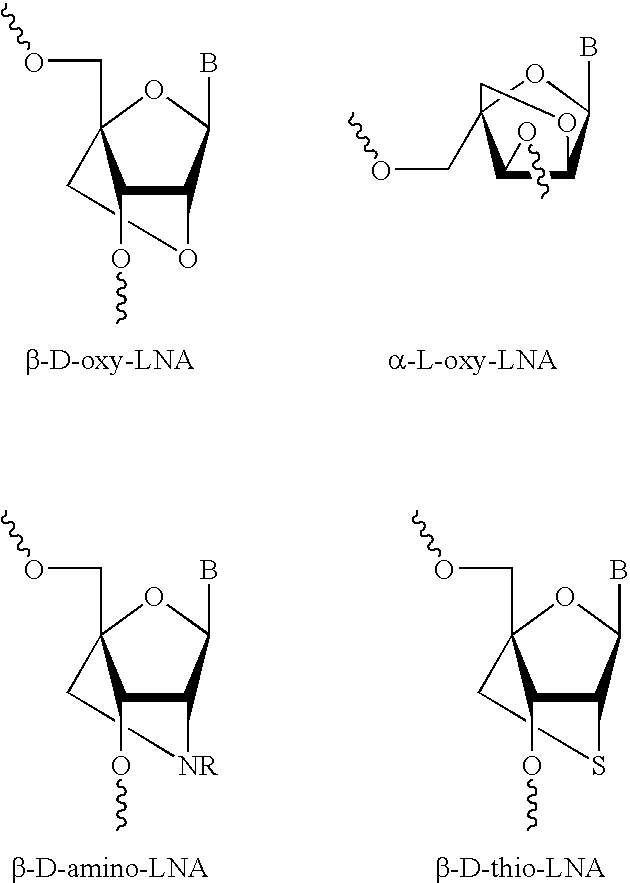

The present disclosure concerns LNA oligonucleotides having a (sub)sequence of the general formula 5′-(MeCx)(Tx)MeCxAsAstscscsastsgsgsMeCxAx(Gx)(c)-3′, and preferably of the general formula 5′-MeCxTxMeCxAsastscscsastsgsgsMeCxAxGxc-3′, wherein capital letters designate an LNA nucleotide analogue selected from β-D-oxy-LNA, β-D-thio-LNA, β-D-amino-LNA and α-L-oxy-LNA, small letters designate a deoxynucleotide, and underline designates either an LNA nucleotide analogue as defined above or a deoxynucleotide. Such LNA oligonucleotides exhibit surprisingly good properties with respect to inhibition of the expression of Survivin by means of an anti-sense mechanism, and thereby lead to reduction or inhibition of tumour development in vivo. The LNA oligonucleotides are superior to other LNA oligonucletides targeting Surviving mRNA measured by functional read outs such as apoptosis induction and proliferation inhibition, and is potent in down-regulating Survivin mRNA and protein in transfected cancer cell lines, and induce apoptosis in combination with Taxol superior compared to other LNA oligonucleotides.

Owner:ENZON PHARM INC

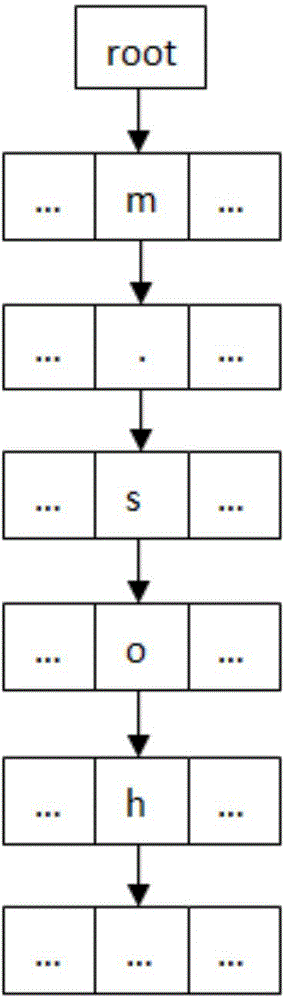

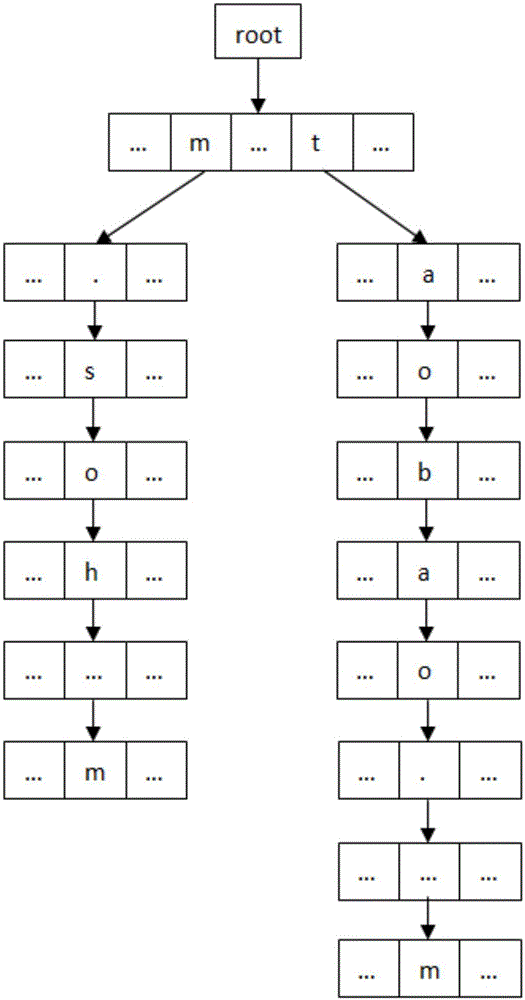

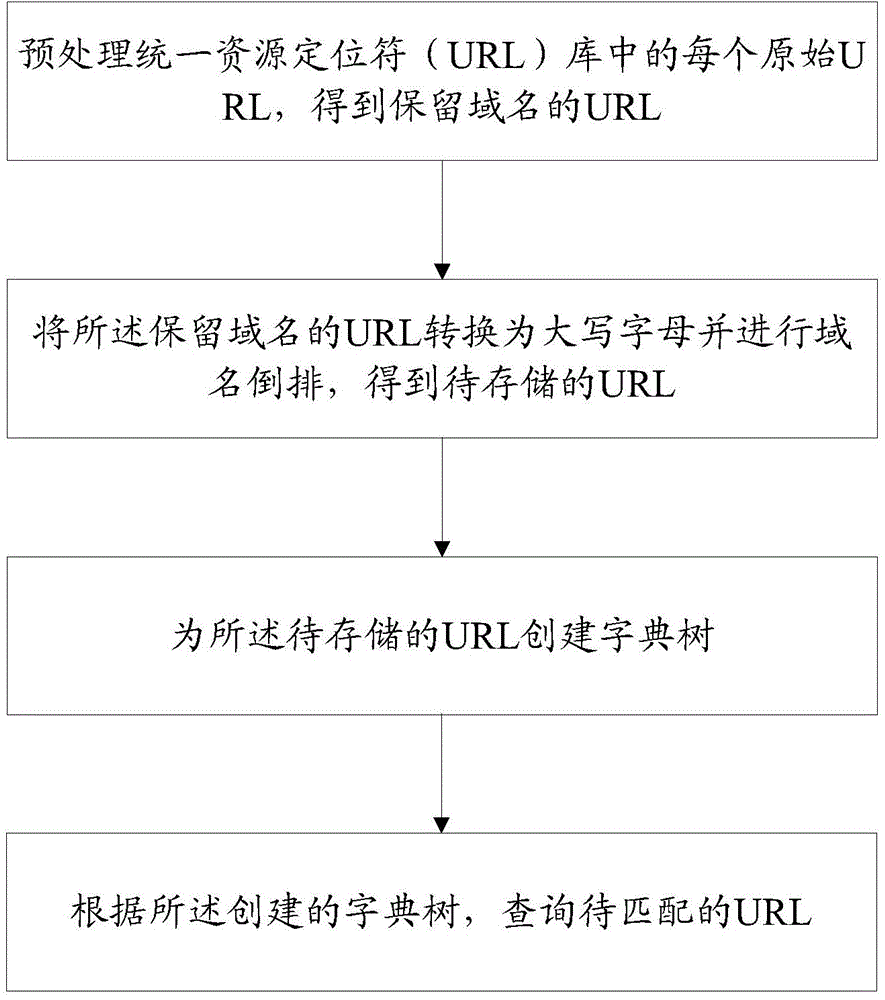

URL storage matching method and device

InactiveCN104537107AAvoid the problem of low matching accuracyAvoid exact URL matchesSpecial data processing applicationsDomain nameCapital Letter

The invention discloses a URL storage matching method and device. The method includes the following steps: each original URL in a URL bank is preprocessed to obtain a URL with a reserved domain name; the URLs with the reserved domain names are converted into capital letters, and domain name inverted ranging is carried out to obtain to-be-stored URLs; a dictionary tree is created for the to-be-stored URLs; to-be-matched URLs are inquired according to the created dictionary tree. By means of the URL storage matching method and device, the problems that an existing URL storage matching method cannot achieve accurate matching, large space is occupied, and the partial matching accuracy is not high are solved.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

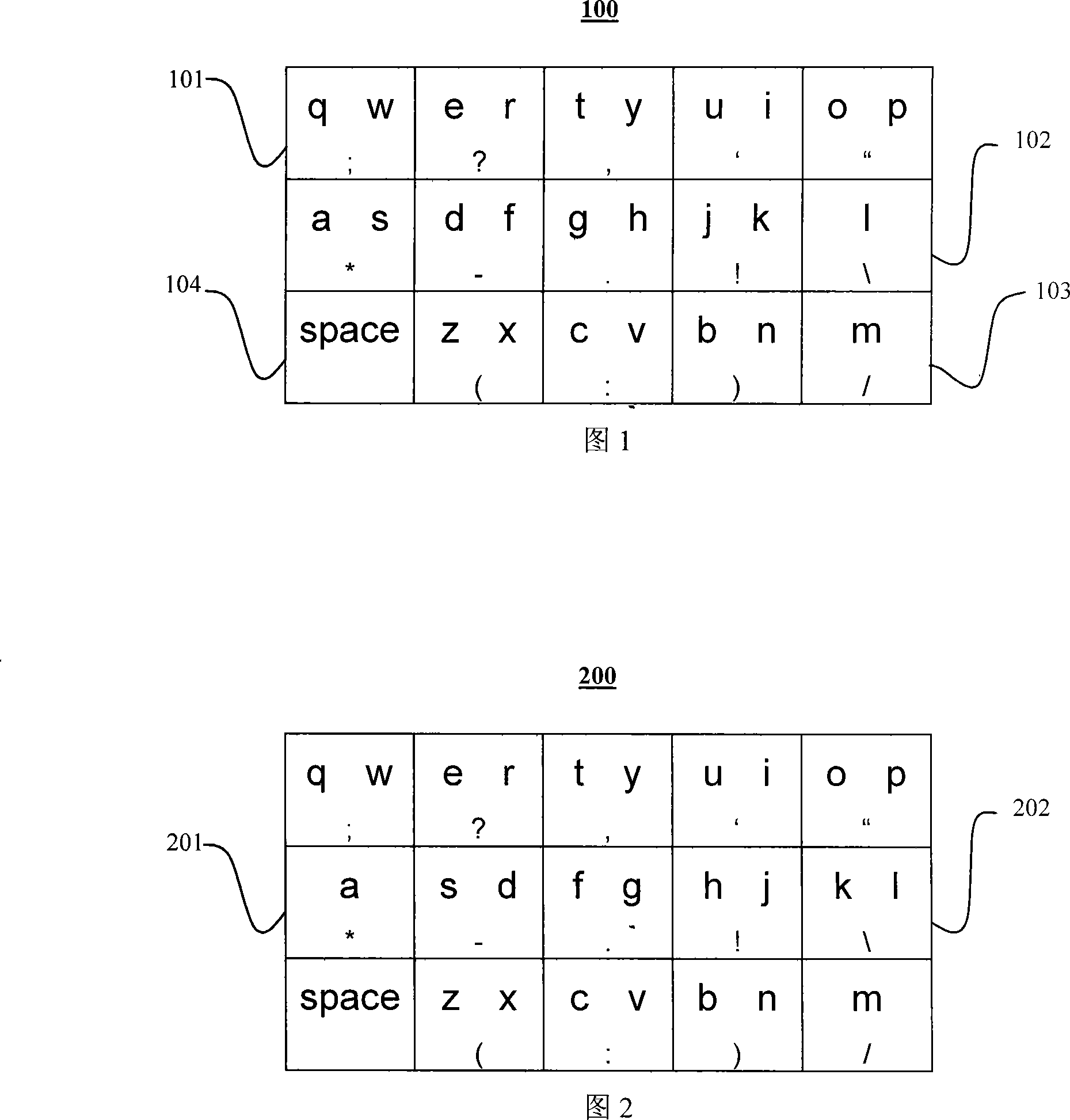

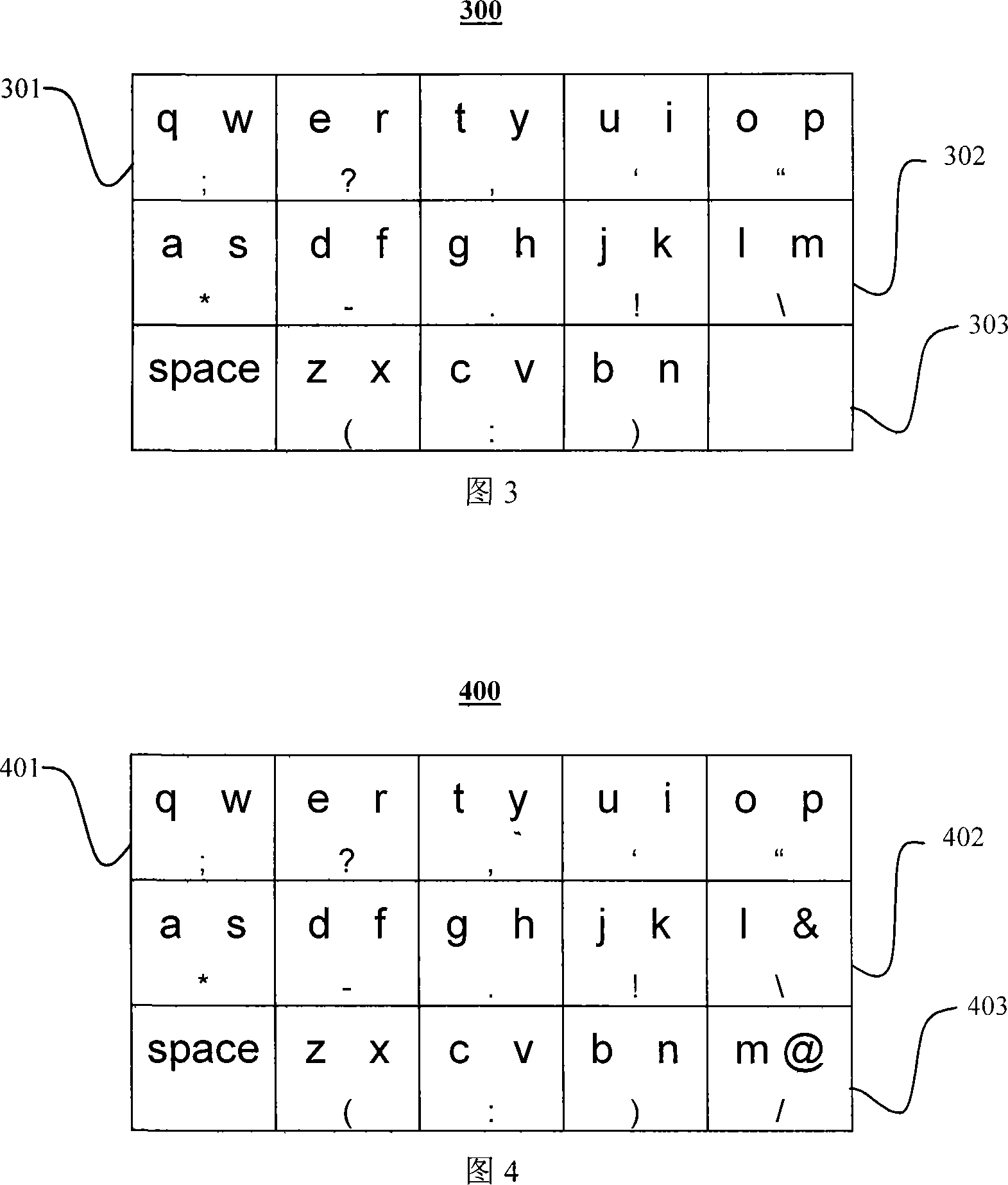

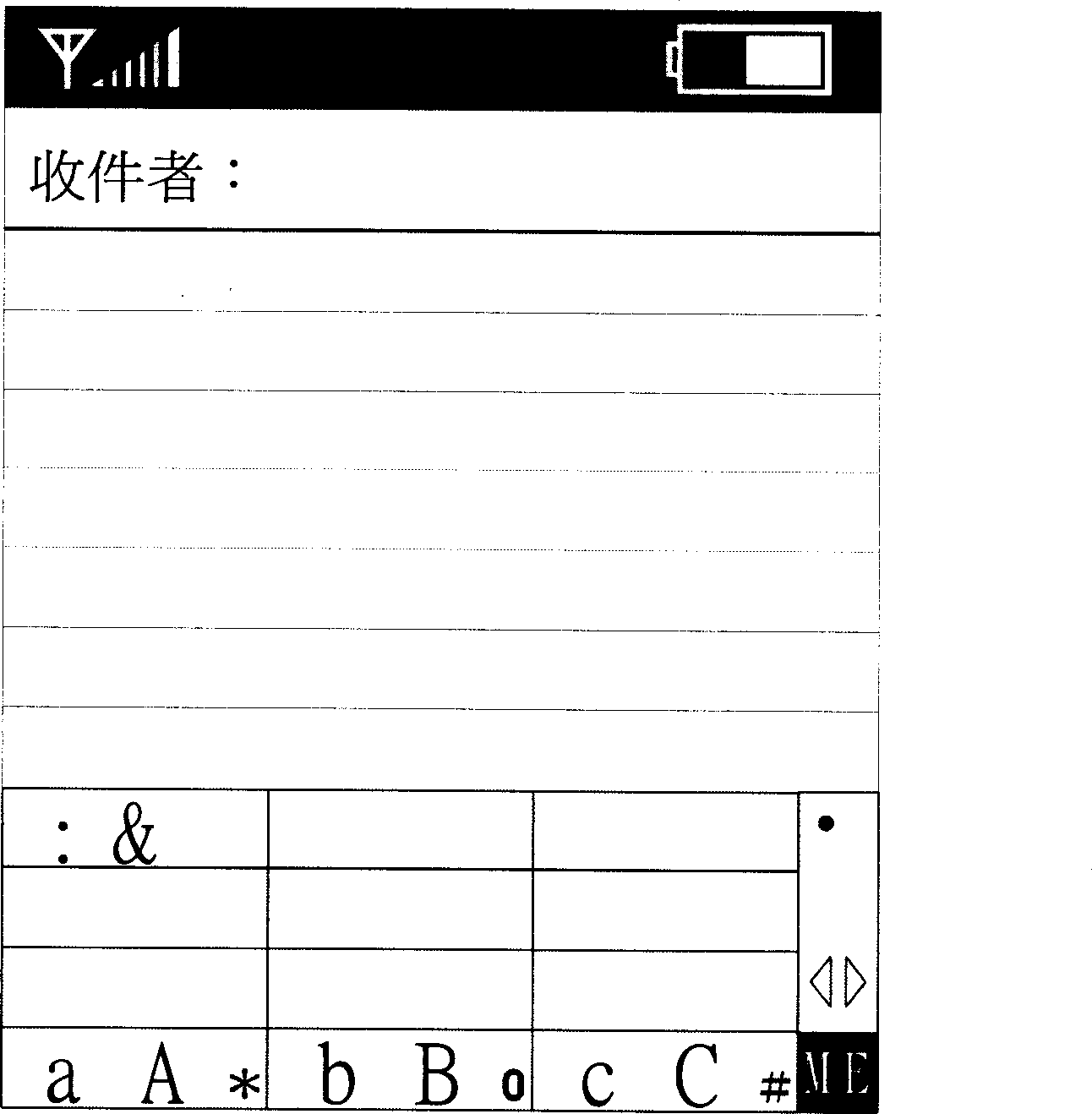

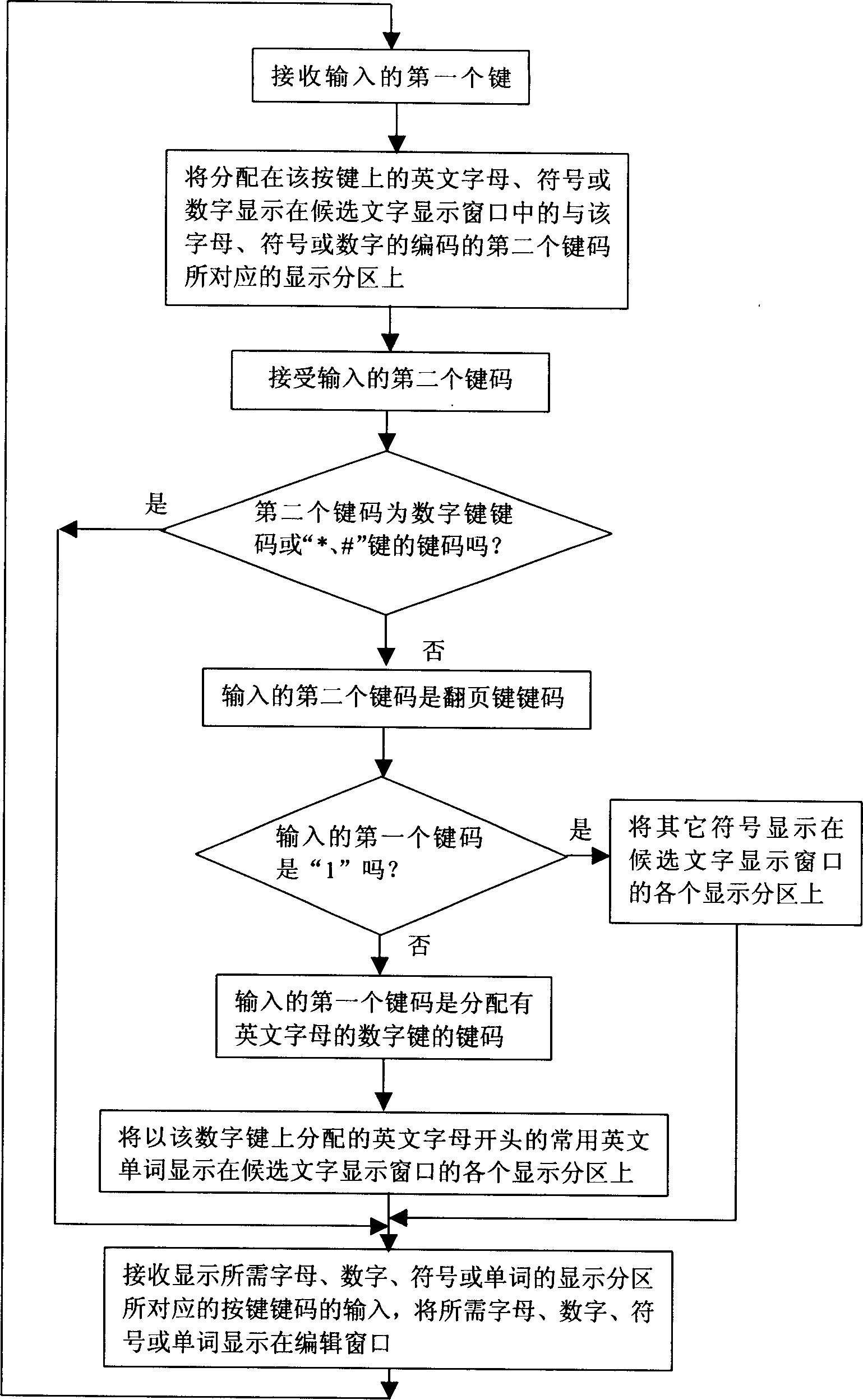

Software keyboard entry method for implementing composite key on screen of electronic equipments

ActiveCN101174190AConvenient and accurate information inputThe implementation process is simpleInput/output processes for data processingCompound keyComputer science

The invention relates to a software-based input method for the onscreen keyboard, which enables compound key-press on the screen of electronic equipment. The invention is realized as follows: two letters are arranged on a key position; the user clicks the key position directly to perform fuzzy input, and then moves the contact to perform exact input; furthermore, the symbols are selected or the capital letters are switched quickly through the contact movement. The invention enables the user to input text quickly, conveniently and efficiently, and has the advantages of convenient and accurate information input on the screen of electronic equipment, and convenient, quick and flexible input.

Owner:SHANGHAI CHULE (COOTEK) INFORMATION TECH CO LTD

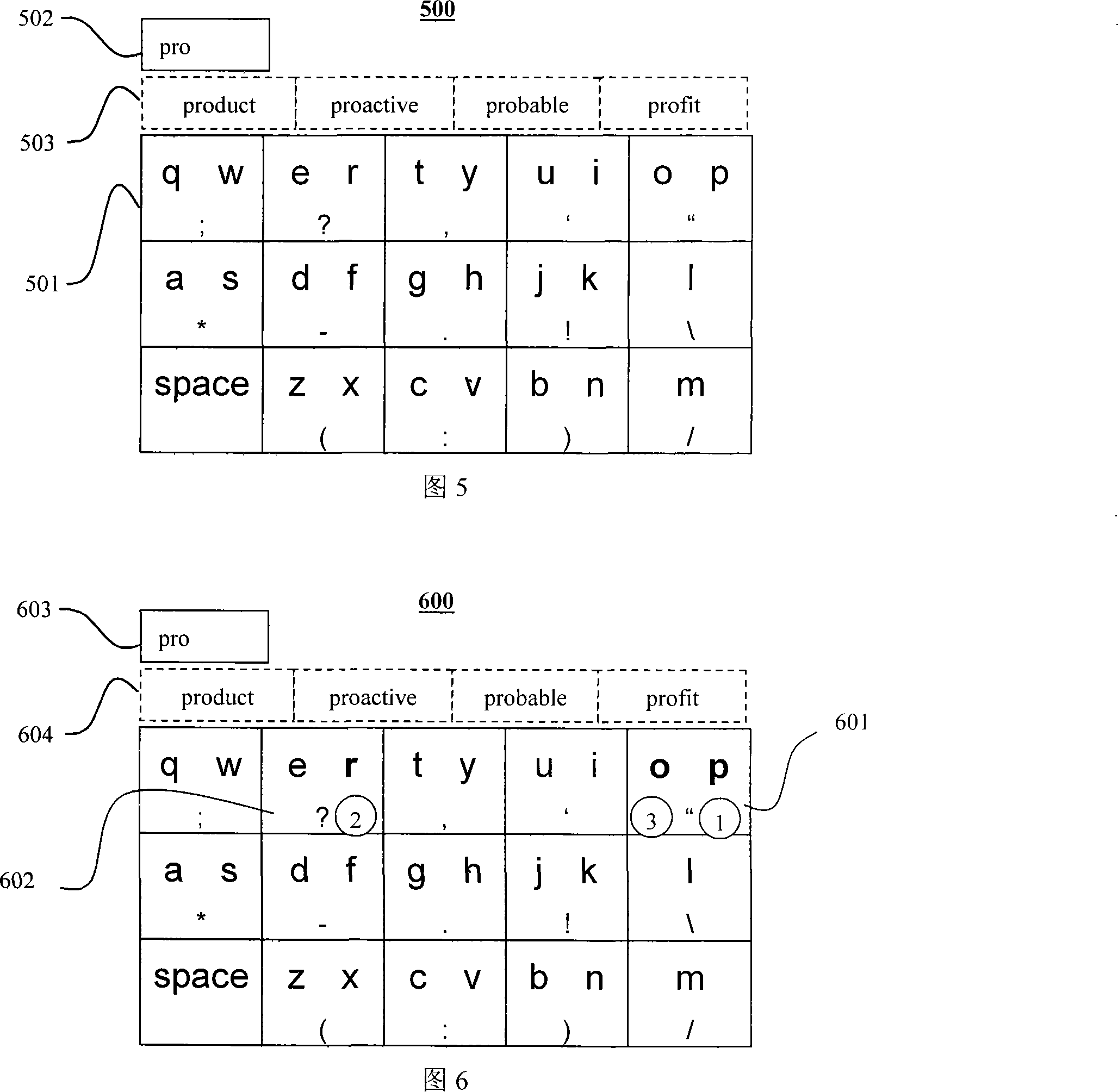

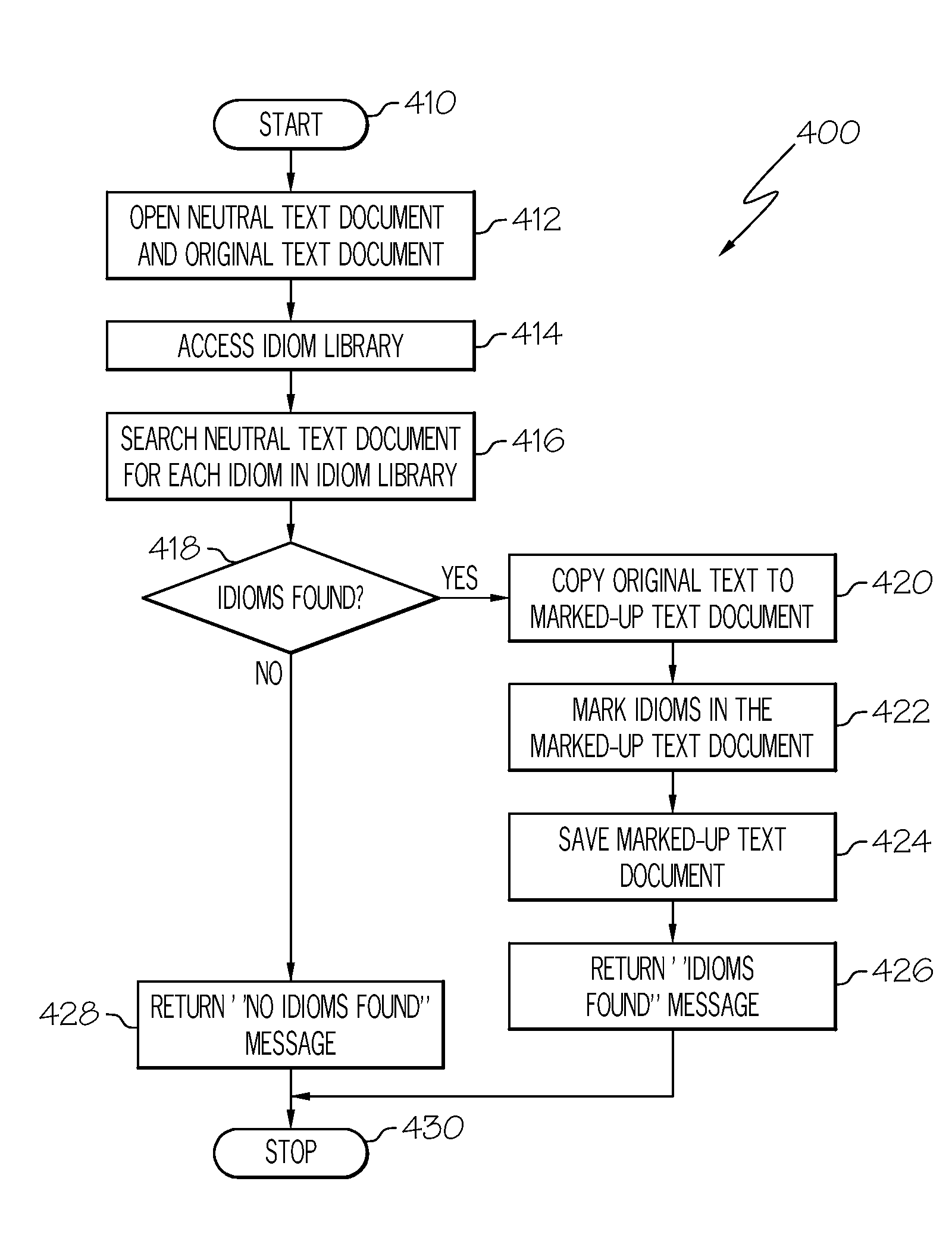

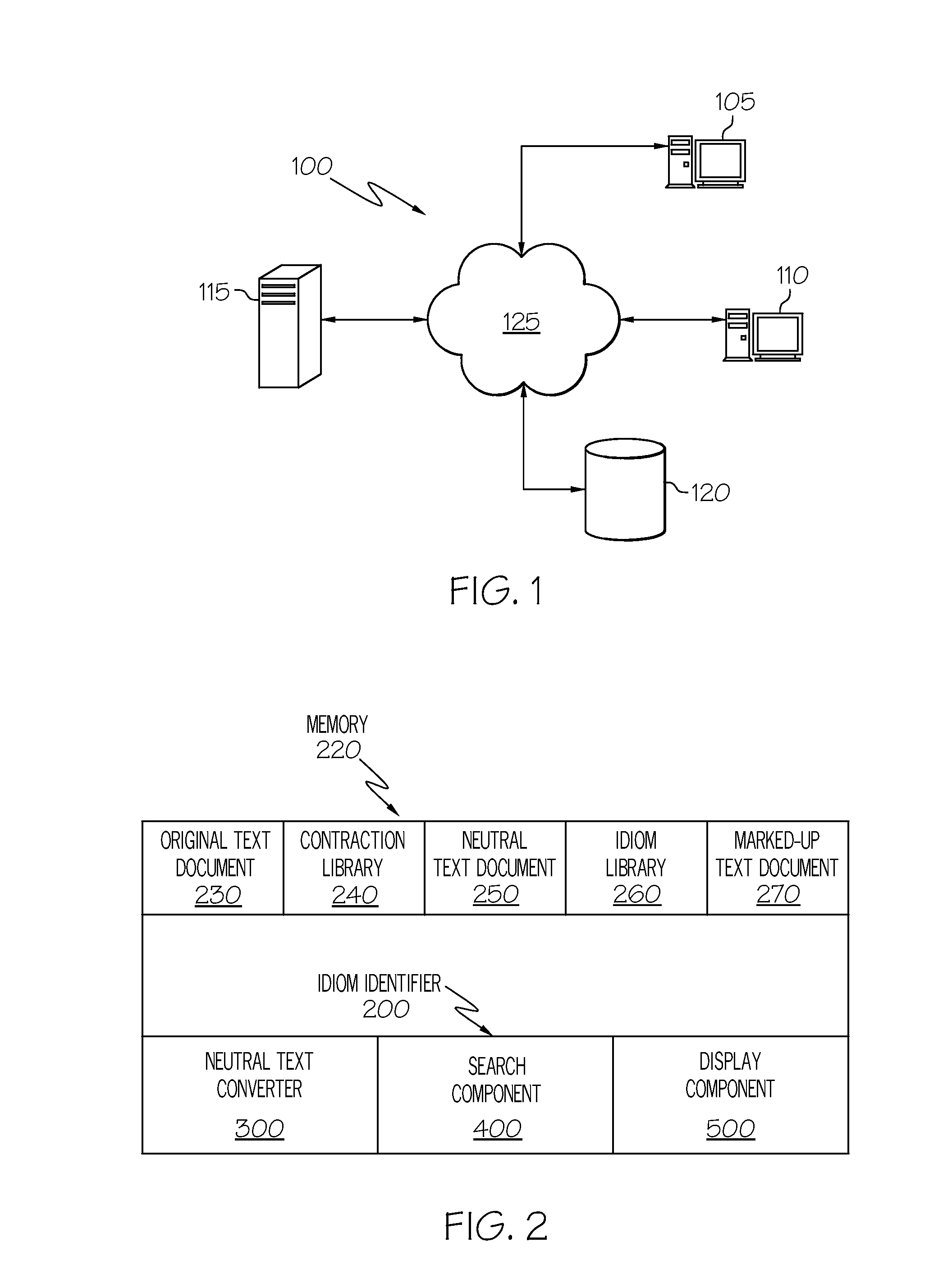

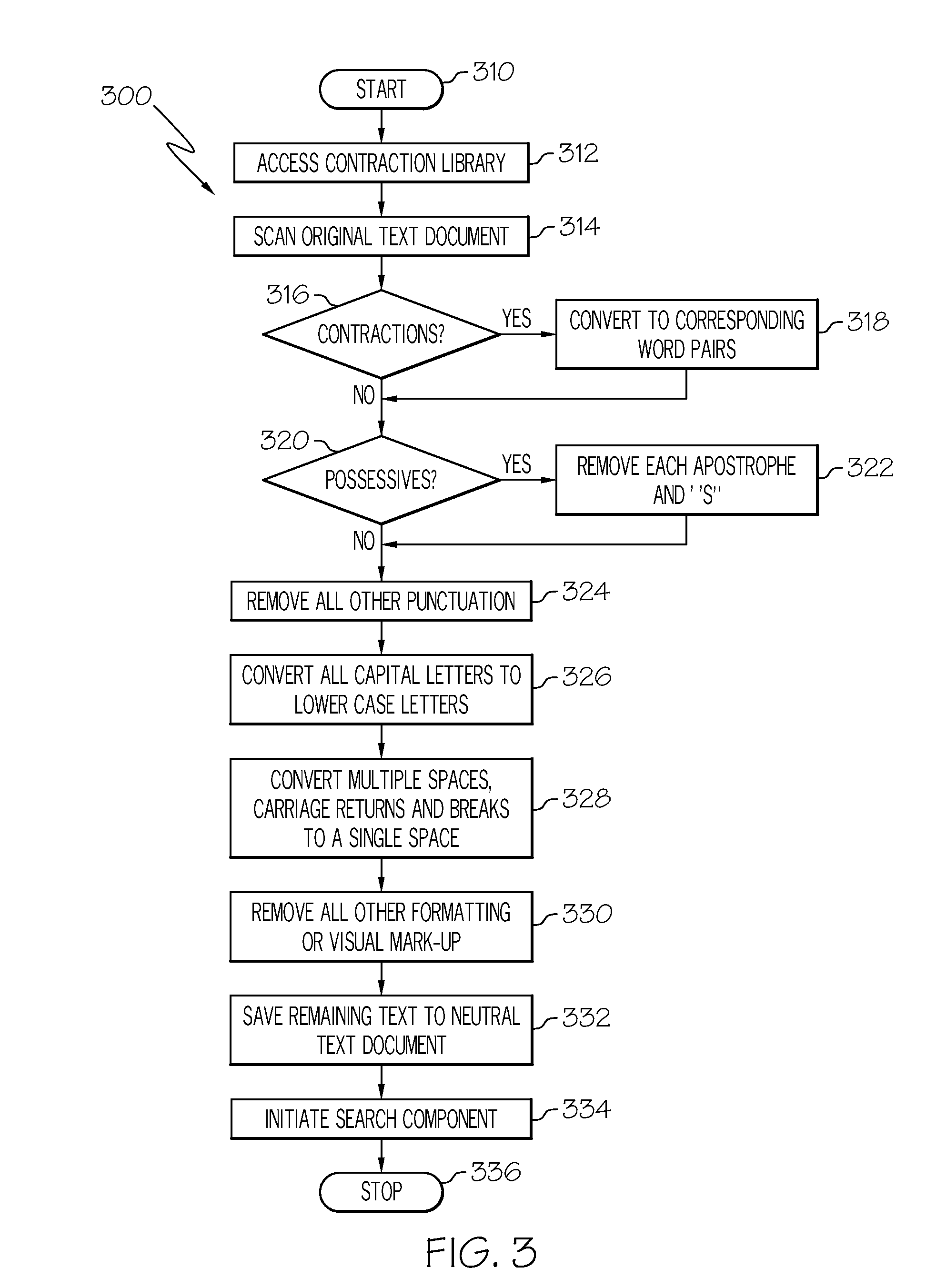

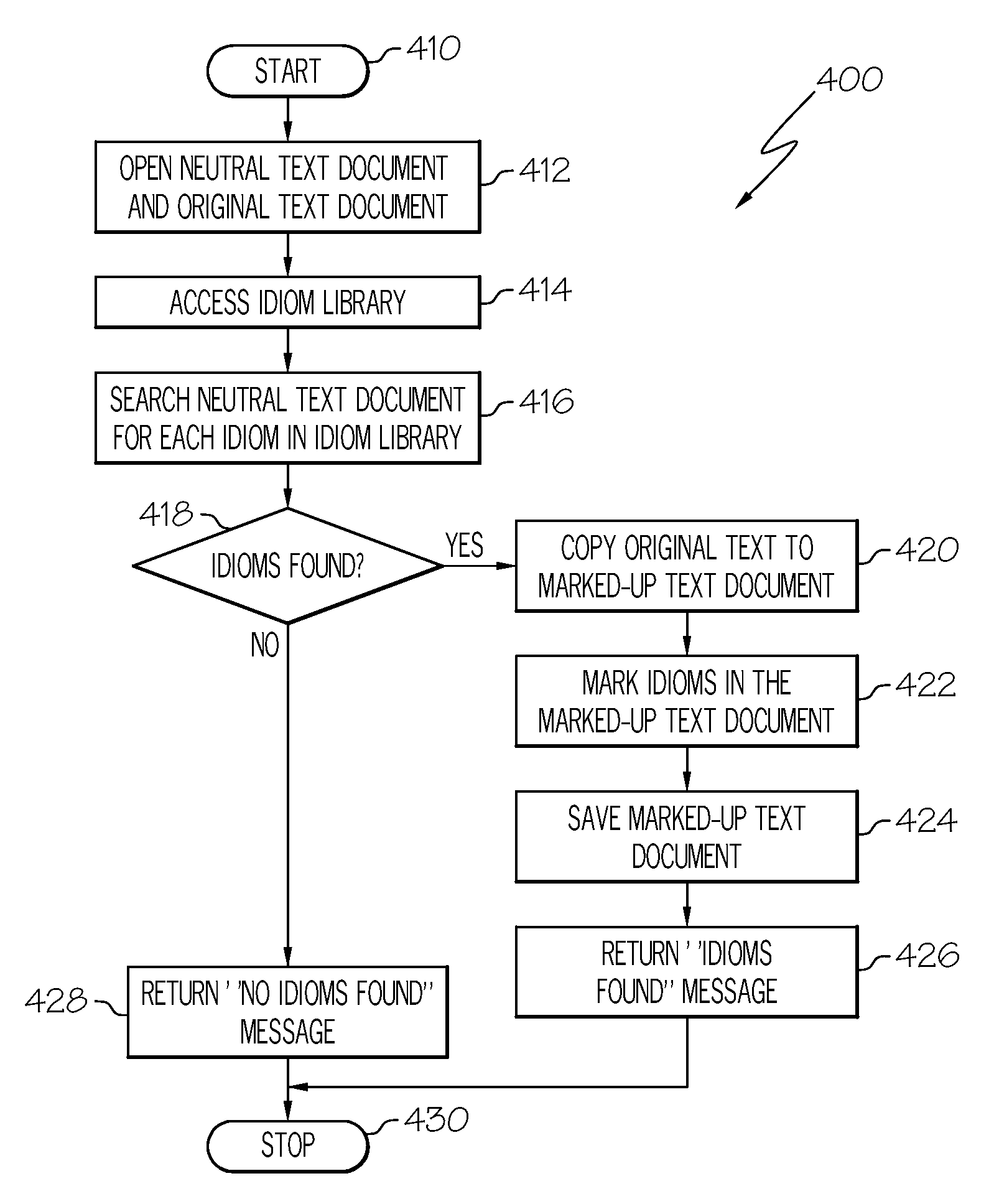

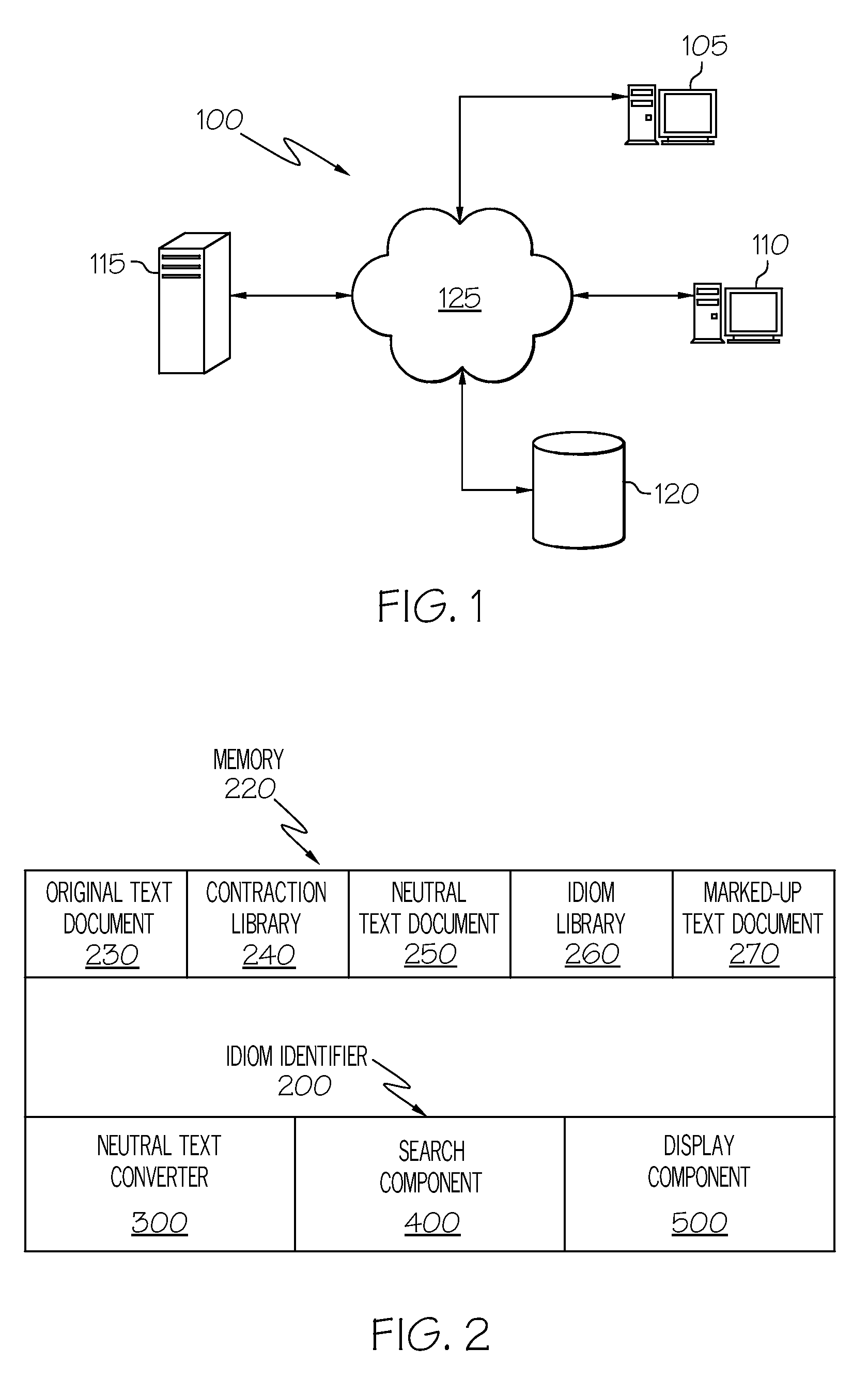

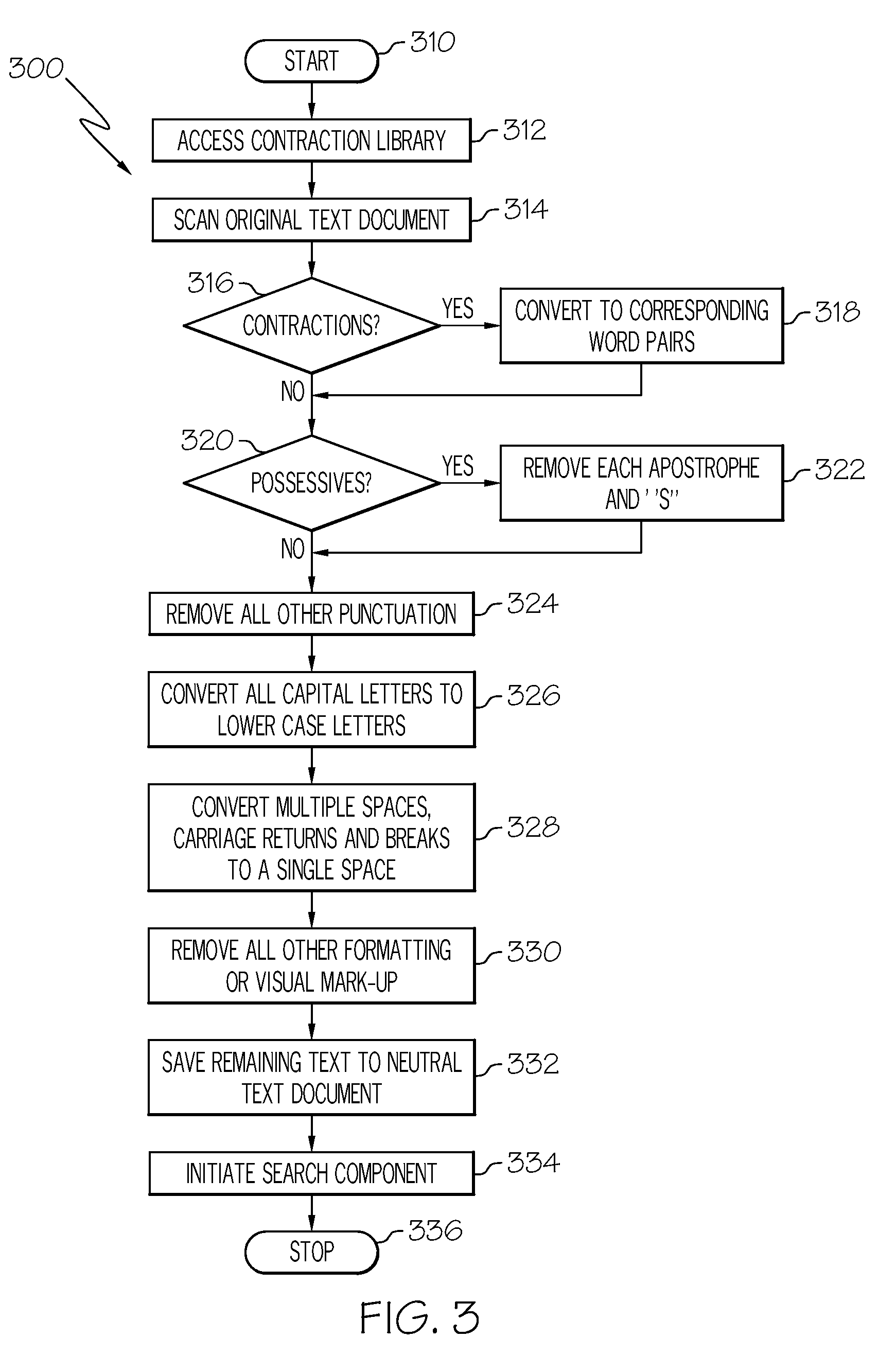

System and Method for Identifying And Defining Idioms

ActiveUS20080004862A1Natural language data processingSpecial data processing applicationsDocument preparationDocumentation

The “Idiom Identifier” converts an original text document to a “neutral” form containing no punctuation, no capital letters, and having only a single space between each word. Neutral form text also removes hidden markup such as line breaks, paragraph breaks or page breaks. The Idiom Identifier performs an enhanced text search to locate idioms listed in a library file. The Idiom Identifier marks each identified idiom in a marked-up copy of the original text document. A reader can click on the marked-up idiom to see a definition of the idiom.

Owner:TWITTER INC

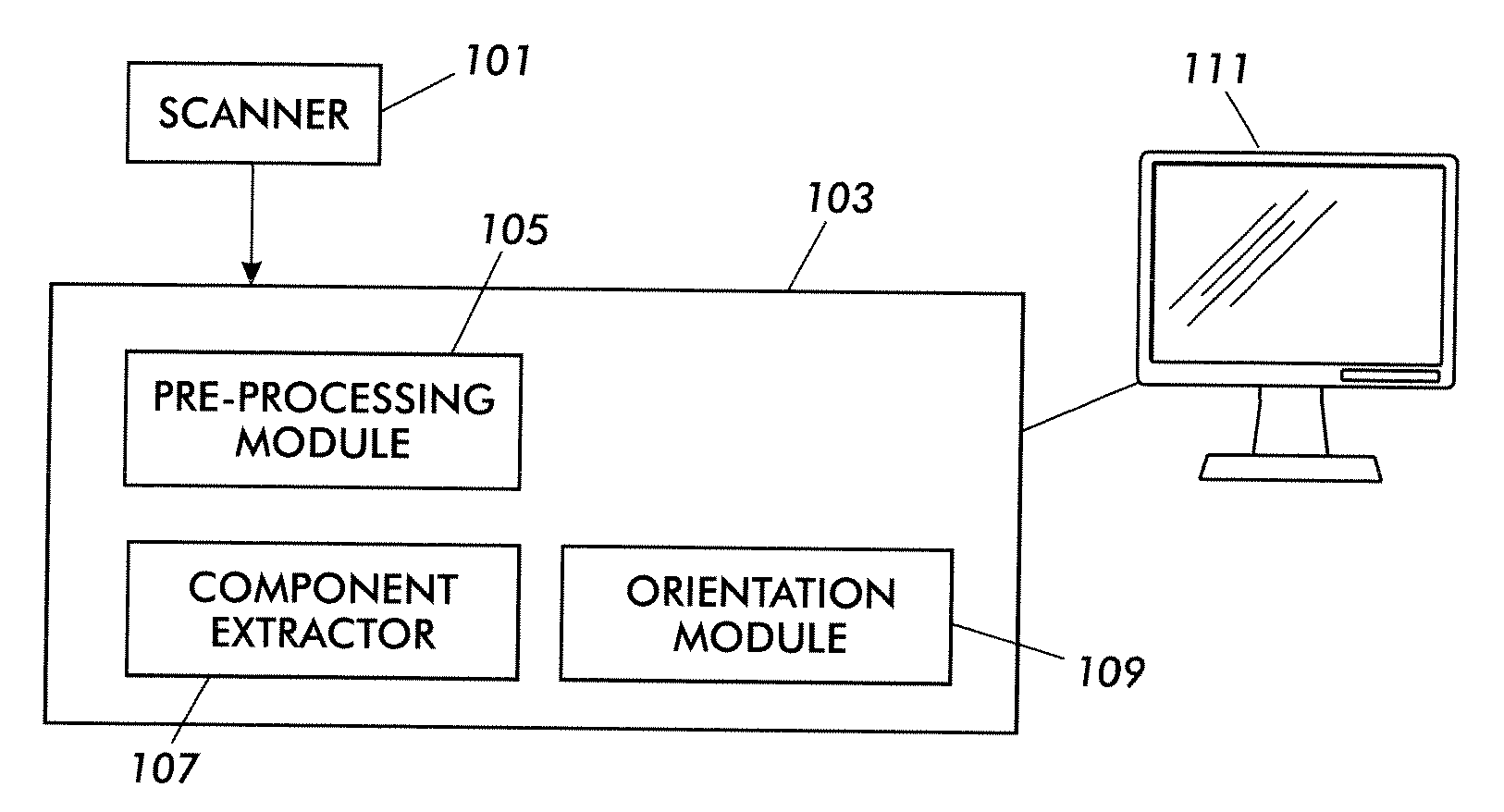

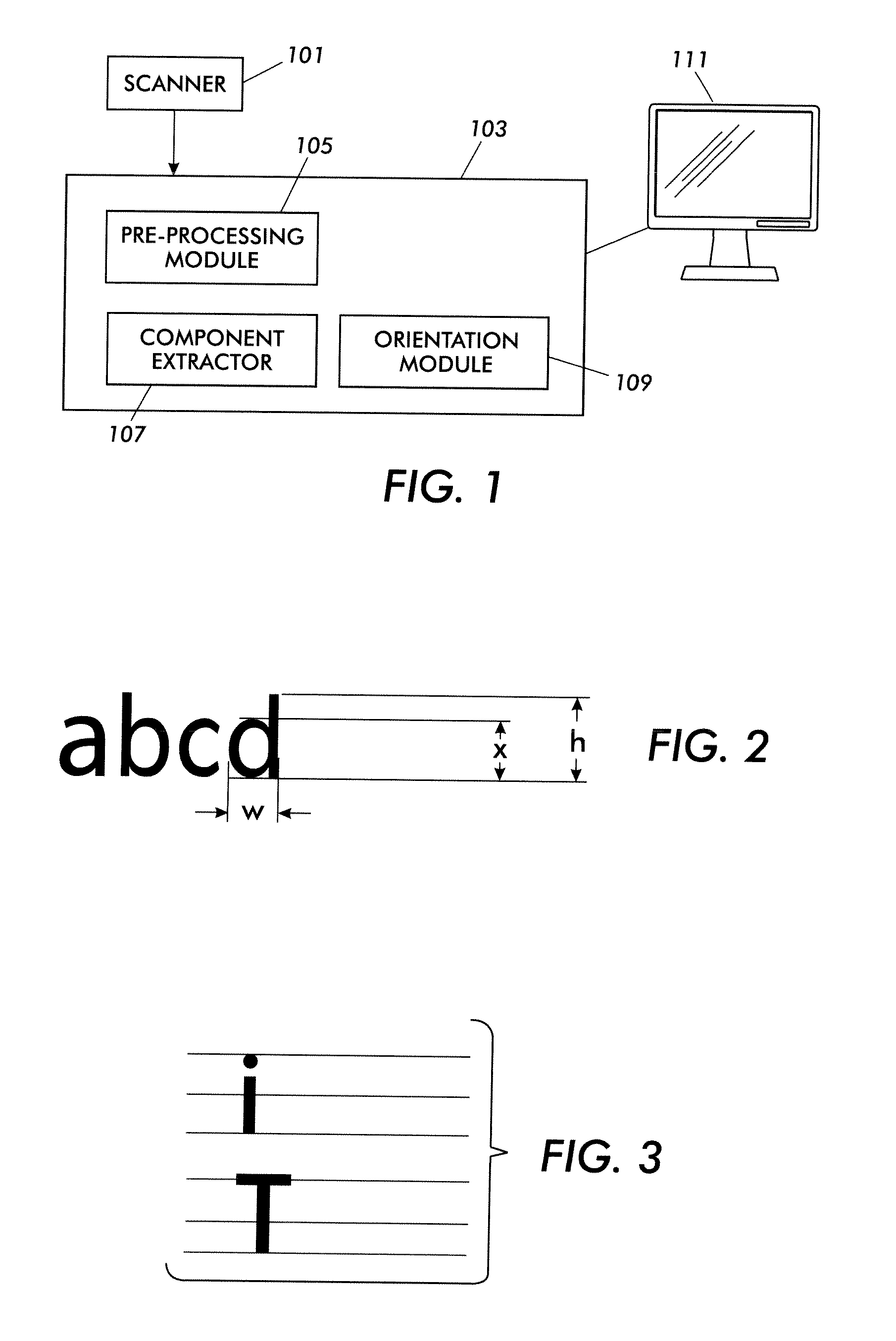

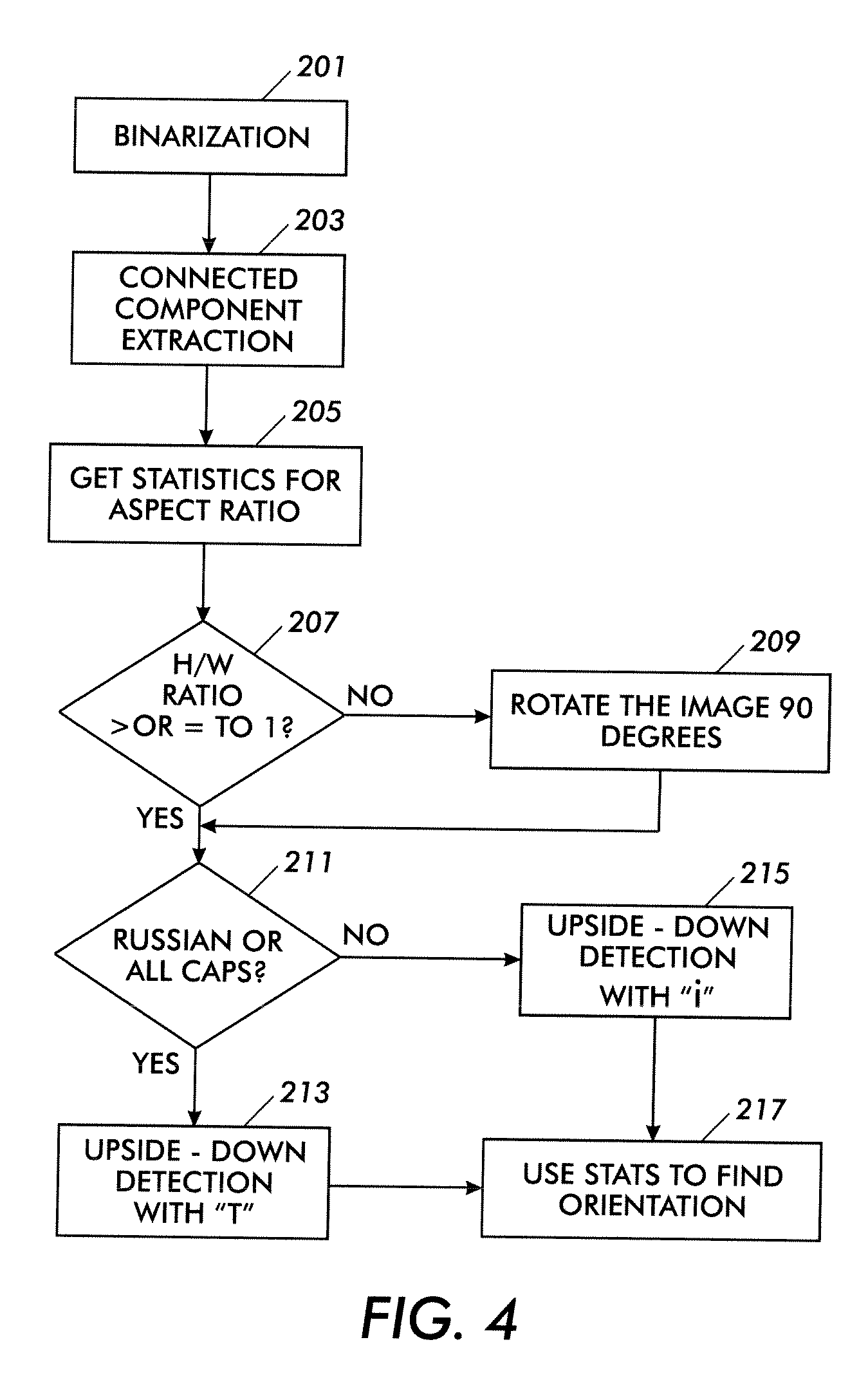

Page orientation detection based on selective character recognition

A system and method for character recognition with document orientation determination is shown. The method is a detection of simple page orientation based on a limited version of character recognition. The method includes binairizing an input image which has a plurality of alphanumeric characters with a first orientation. The method continues with extracting the connected components and determining a second orientation where the second orientation is based on a 90° turn clockwise or counterclockwise or, in the alternative, no turn from the first orientation. The second orientation will result in a 180° variance from the proper orientation or it will be the proper orientation. The method continues with implementing a limited version of optical character recognition for an analysis of a character and determining if that second orientation is upside down, based at least in part on the analysis. This method generally uses the character “i” for analysis. However, for documents that have a limited number of “i”s, e.g. such as Russian documents or documents with all capital letters, the “T” may also be used.

Owner:XEROX CORP

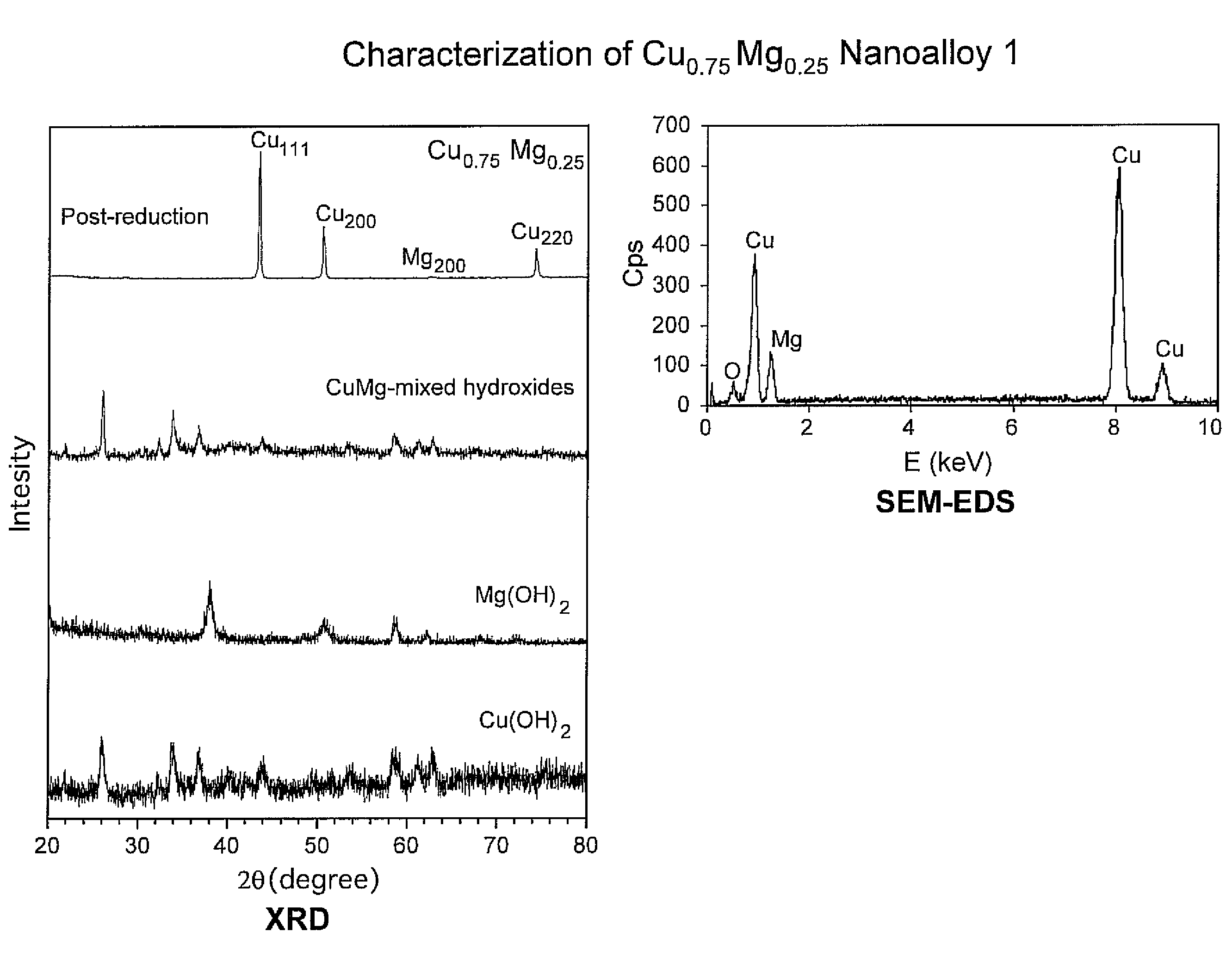

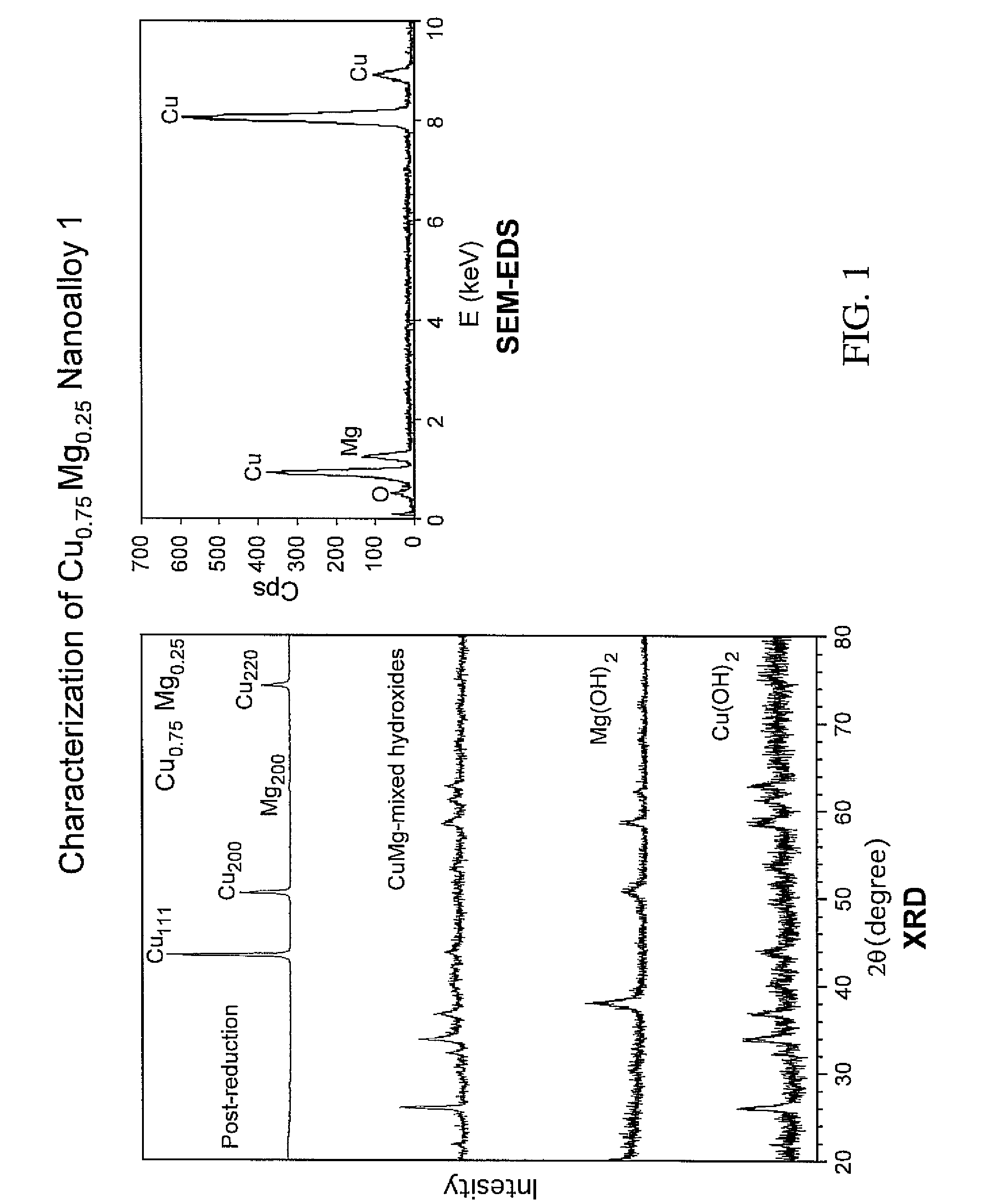

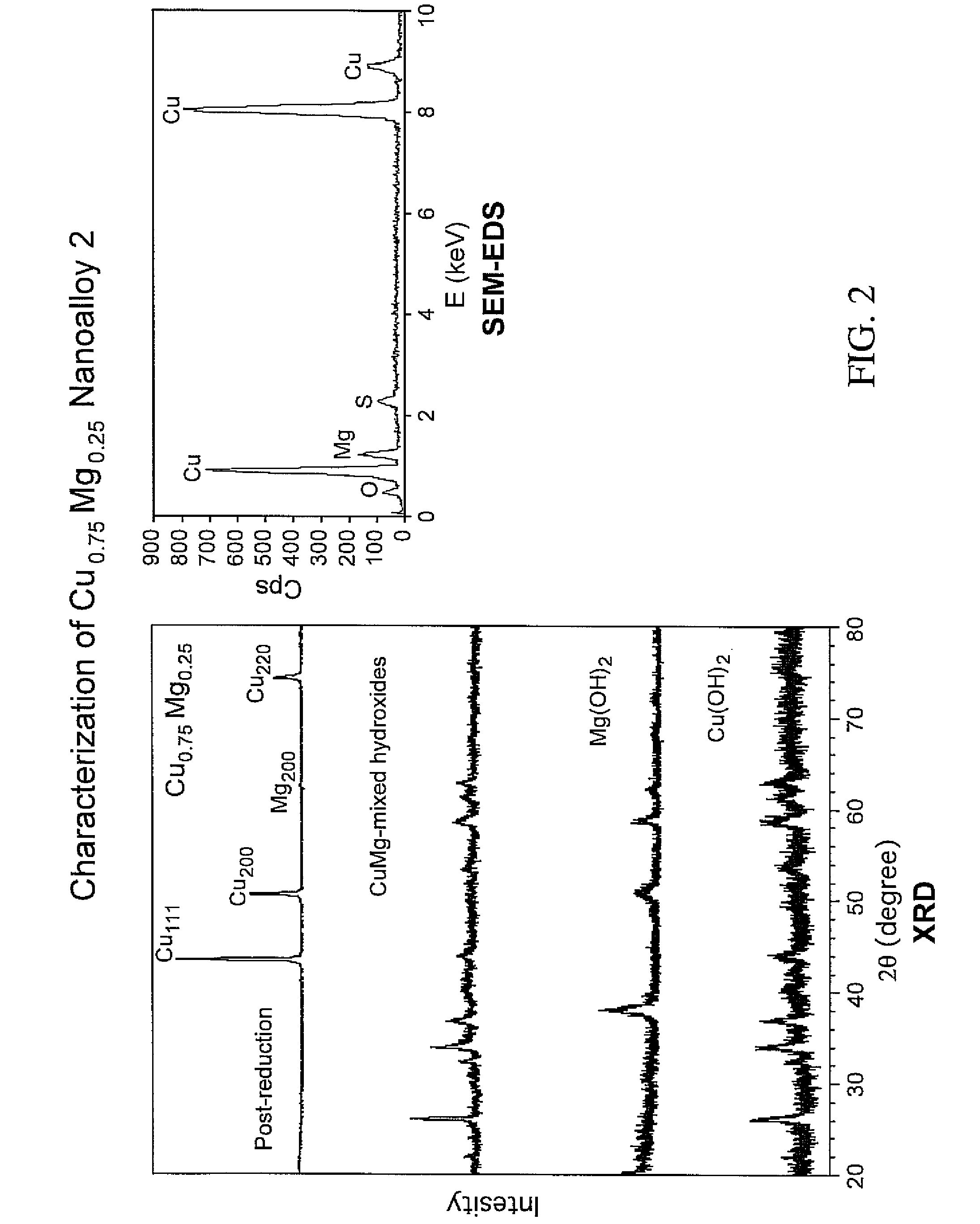

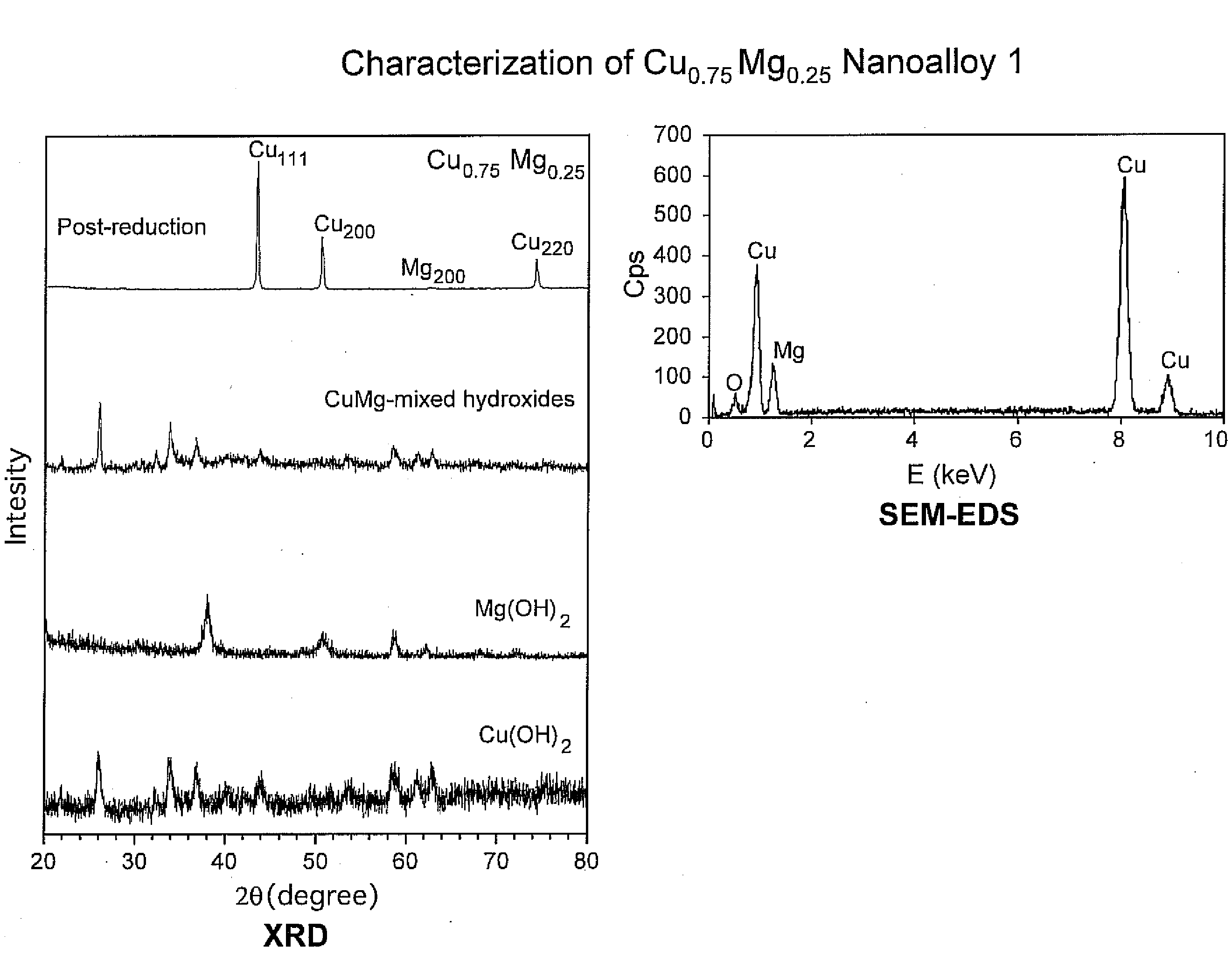

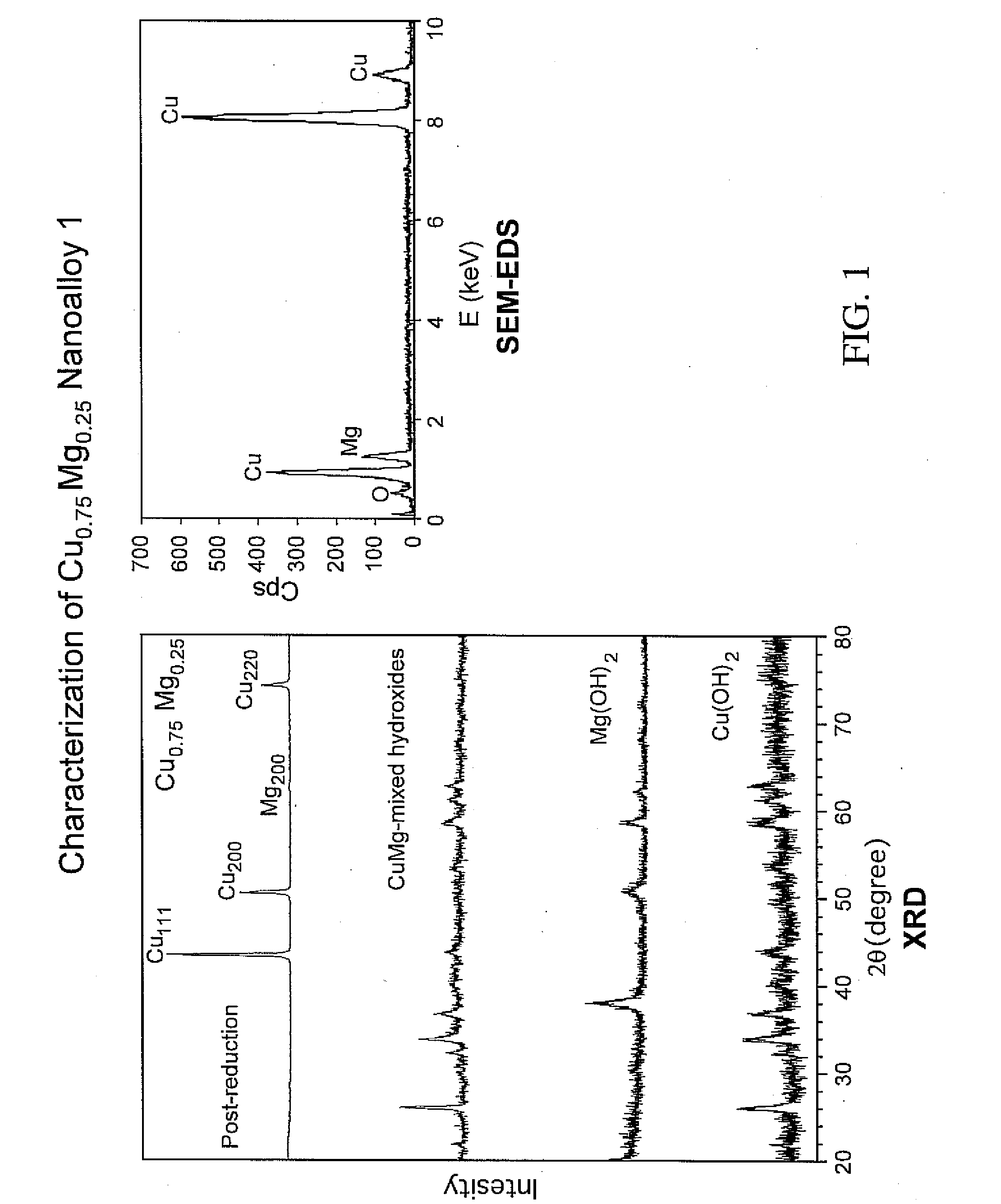

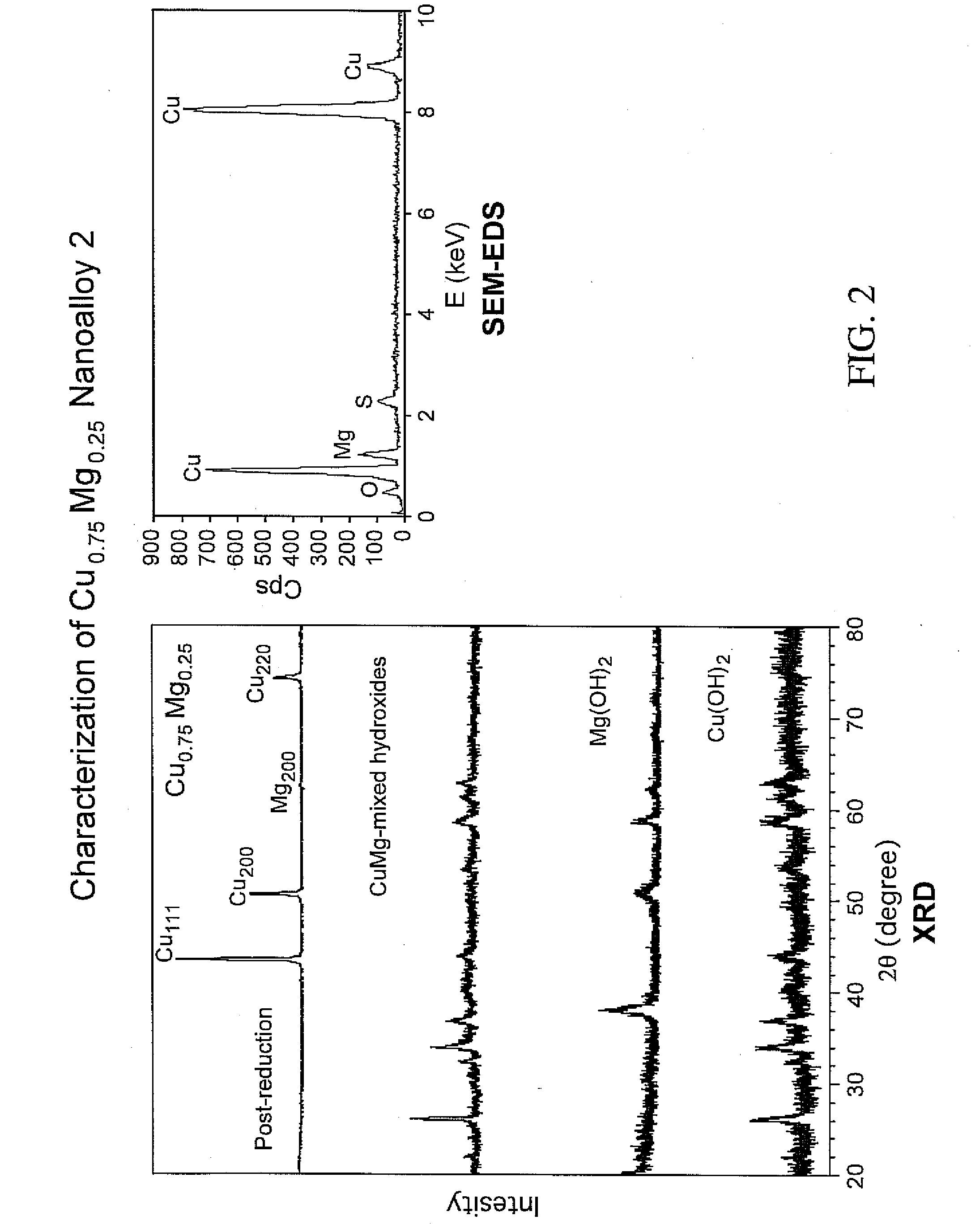

Nanoalloy fuel additives

There is disclosed a composition comprising an alloy represented by the following generic formula (Aa)n(Bb)n(Cc)n(Dd)n( . . . )n; wherein each capital letter and ( . . . ) is a metal; wherein A is a combustion modifier; B is a deposit modifier; C is a corrosion inhibitor; and D is a combustion co-modifier / electrostatic precipitator enhancer; wherein each subscript letter represents compositional stoichiometry; wherein n is greater than or equal to zero; and wherein the alloy comprises at least two different metals; and with the proviso that if the metal is cerium, then its compositional stoichiometry is less than about 0.7. There is also disclosed a fuel additive comprising an alloy; a fuel composition comprising the fuel additive composition; methods of making the fuel additive composition; and methods of using the disclosed alloy.

Owner:AFTON CHEMICAL

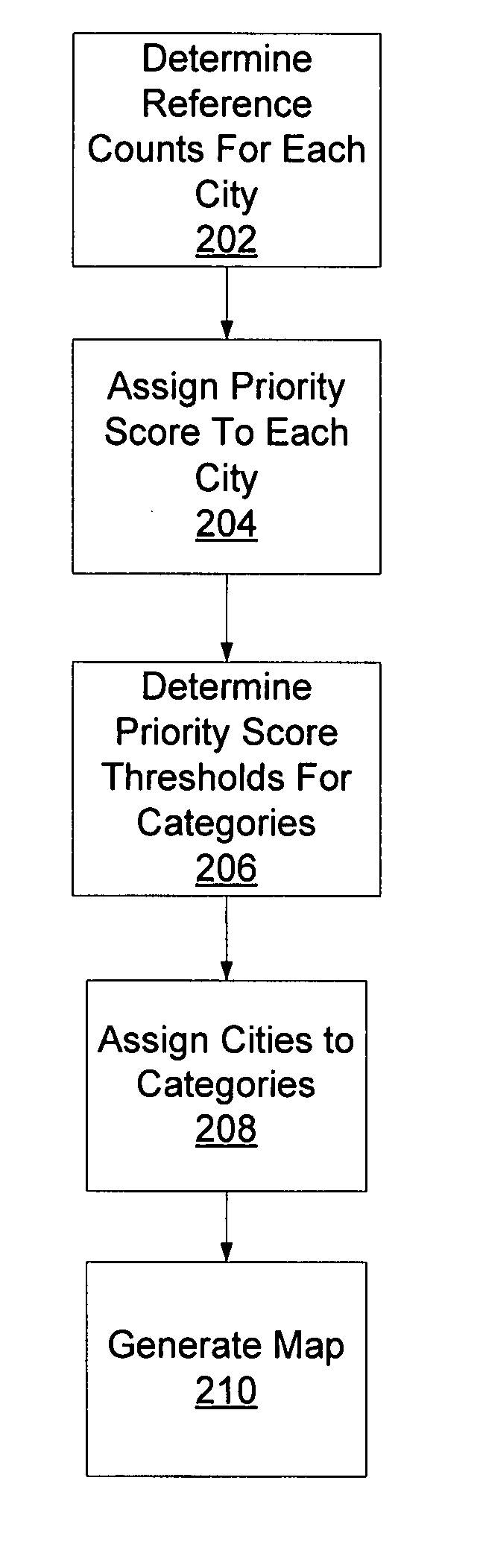

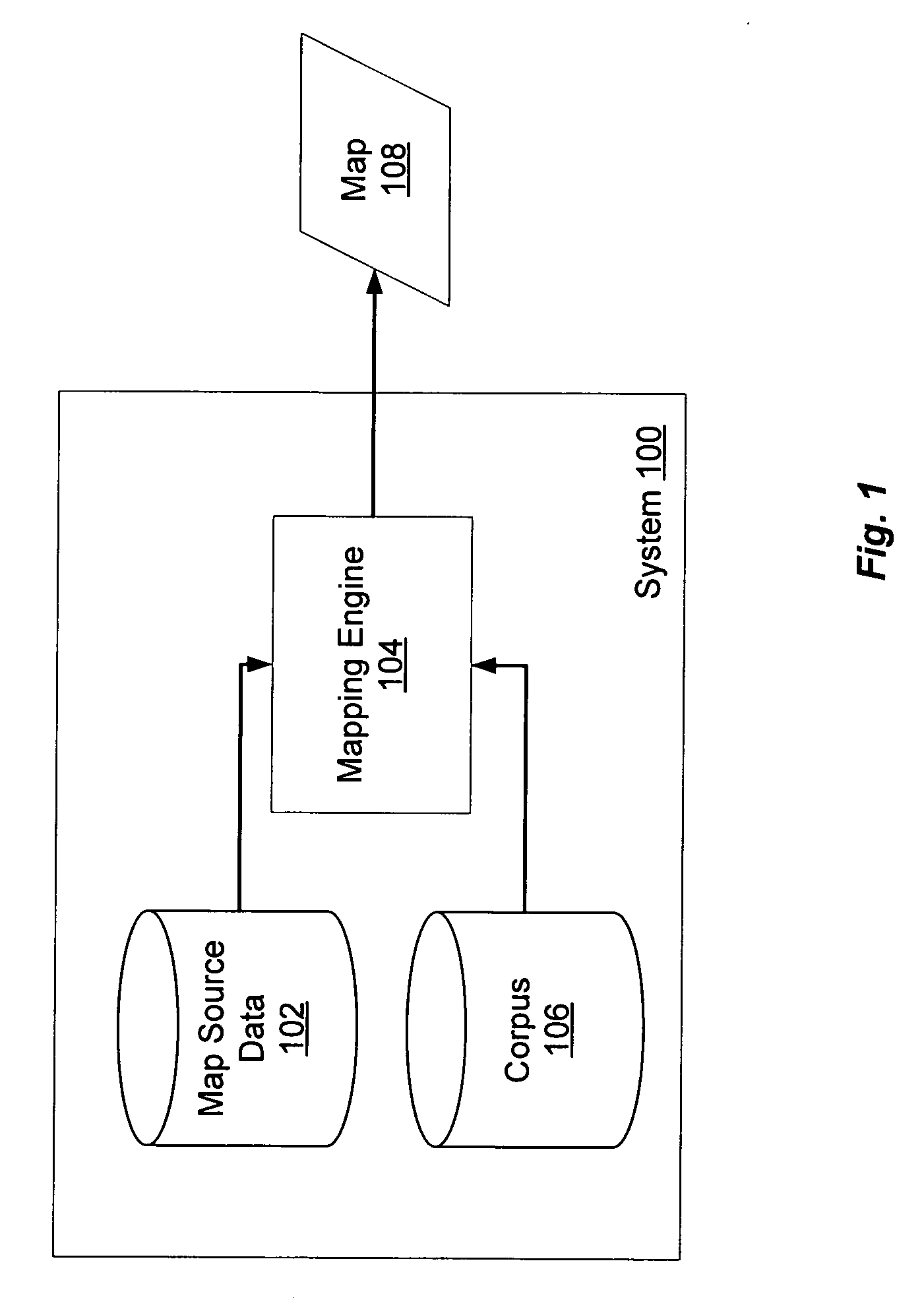

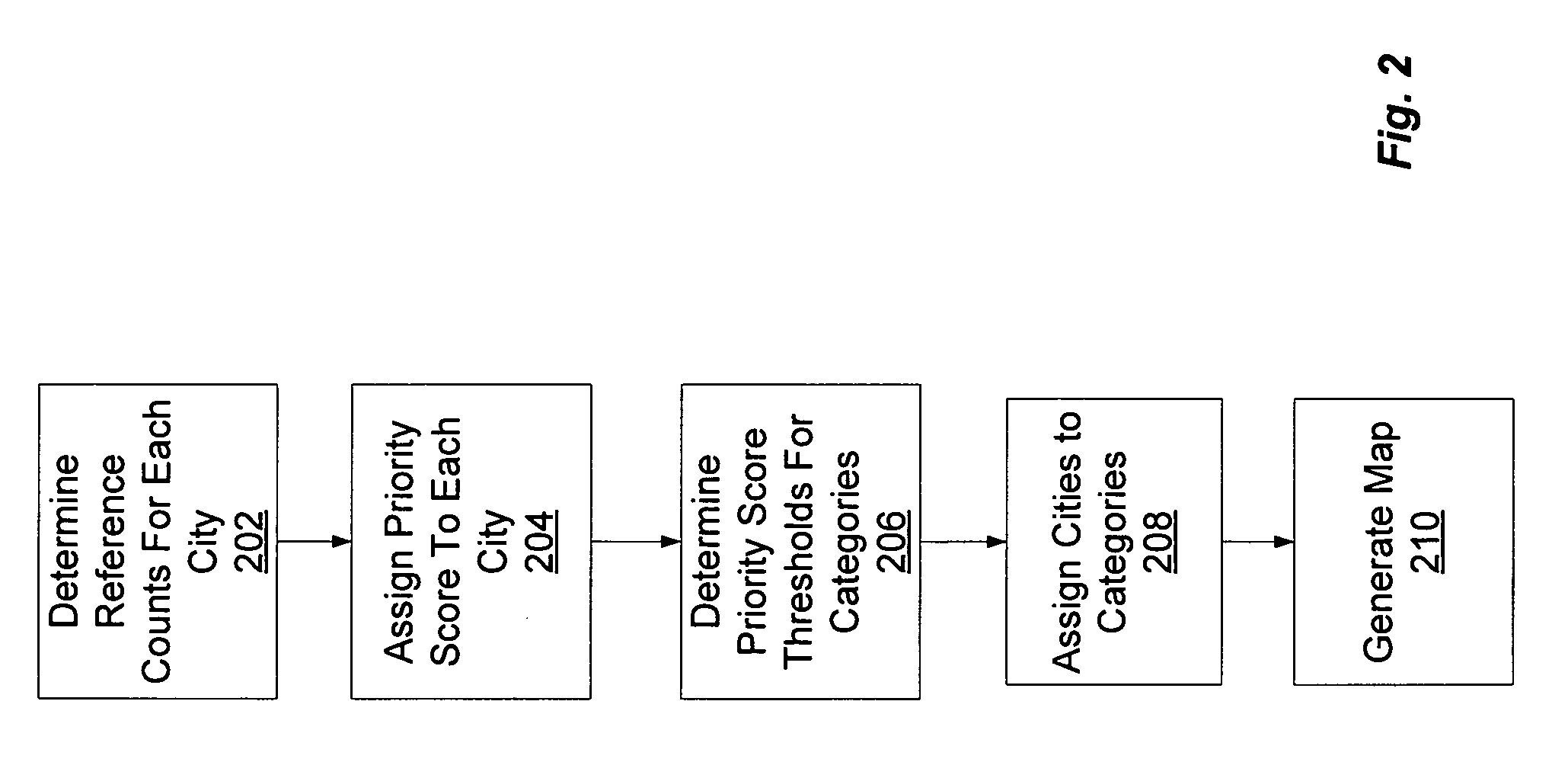

Automated prioritization of map objects

ActiveUS20060041376A1Instruments for road network navigationRoad vehicles traffic controlPaper documentDocument preparation

Automatic map generation is enabled by assigning priorities to each city in a list of cities under consideration for display on a map. A mapping engine determines a reference count for each city, indicating how frequently the city appears in one or more corpora of documents. Based on the reference count, and optionally upon other data such as population and political importance, a priority score is assigned to each city. Each city is then assigned to one of a plurality of categories according to the city's priority score. A map is then generated including cities from a specified highest number of categories. In one embodiment, cities from a higher-scored category are presented in a more significant way, e.g., in capital letters, bold type, etc., than are those in the next-highest scored category.

Owner:UBER TECH INC

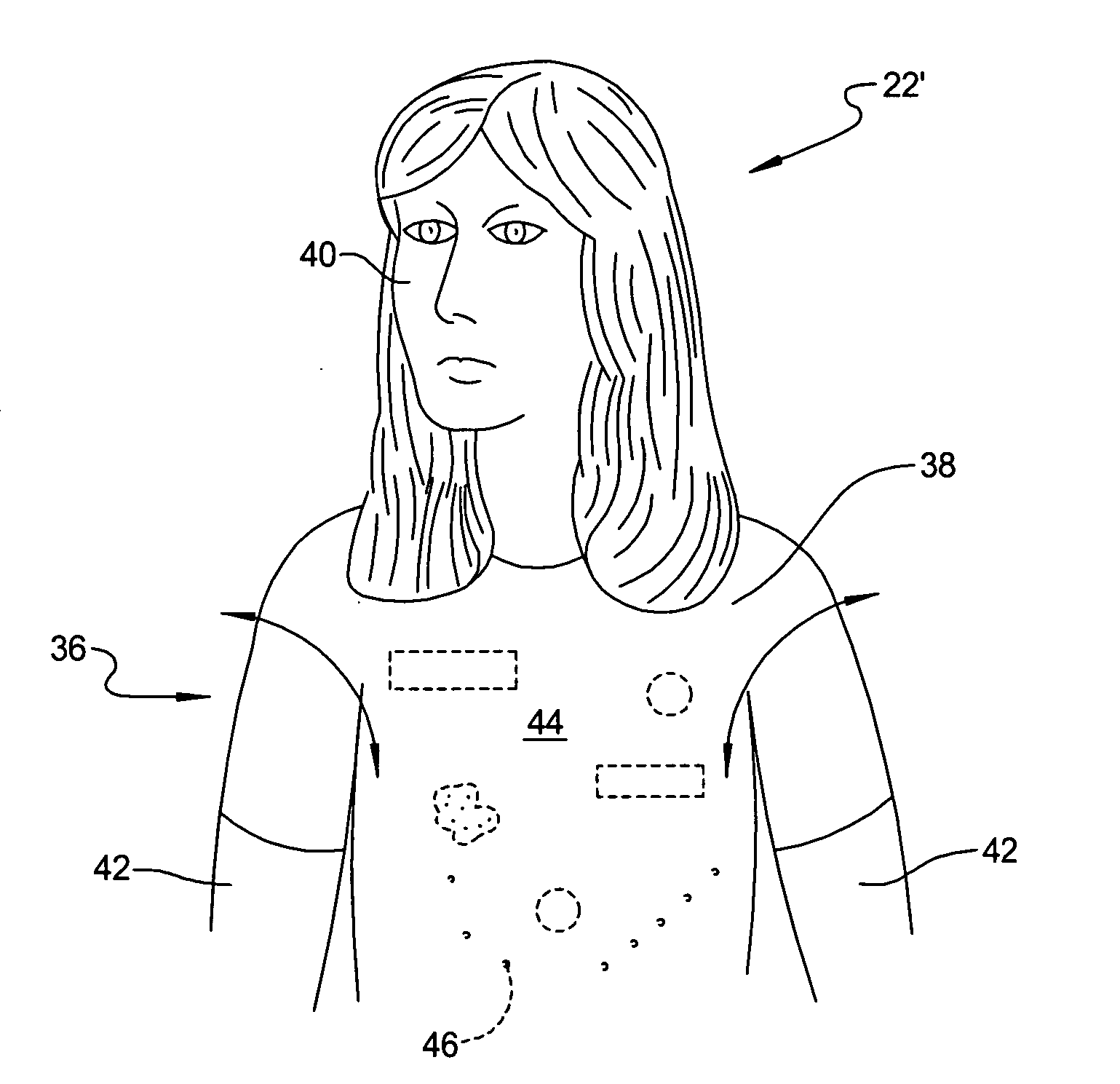

Education and entertainment kit

A kit or system for promoting both education and entertainment includes at least one elongated surface mountable strip which is utilized to removably mount or attach alphabetical, numerical and / or entertainment devices thereon. At least one strip has a first surface for mounting the strip to a wall or similar support and a second or opposite surface to which the devices are removably adhered. Optimally, the second surface is a “Velcro” surface. The Velcro surface may also have embedded therein a plurality of magnets as well as a plurality of snaps for assuring securement of the items to the strips. The alpha-numeric devices are configured such that each letter of the alphabet capital letter having a script or cursive version of that same letter disposed thereon, the main portion of each letter being of a first color and the script portion being of a contrasting color. The numerical devices all be colored as well, but where the minor portion has the numeral spelled out.

Owner:SHARP MOMMEUT REBECCA A

Nanoalloy fuel additives

There is disclosed a composition comprising an alloy represented by the following generic formula (Aa)n(Bb)n(Cc)n(Dd)n( . . . )n; wherein each capital letter and ( . . . ) is a metal; wherein A is a combustion modifier; B is a deposit modifier; C is a corrosion inhibitor; and D is a combustion co-modifier / electrostatic precipitator enhancer; wherein each subscript letter represents compositional stoichiometry; wherein n is greater than or equal to zero; and wherein the alloy comprises at least two different metals; and with the proviso that if the metal is cerium, then its compositional stoichiometry is less than about 0.7. There is also disclosed a fuel additive comprising an alloy; a fuel composition comprising the fuel additive composition; methods of making the fuel additive composition; and methods of using the disclosed alloy.

Owner:AFTON CHEMICAL

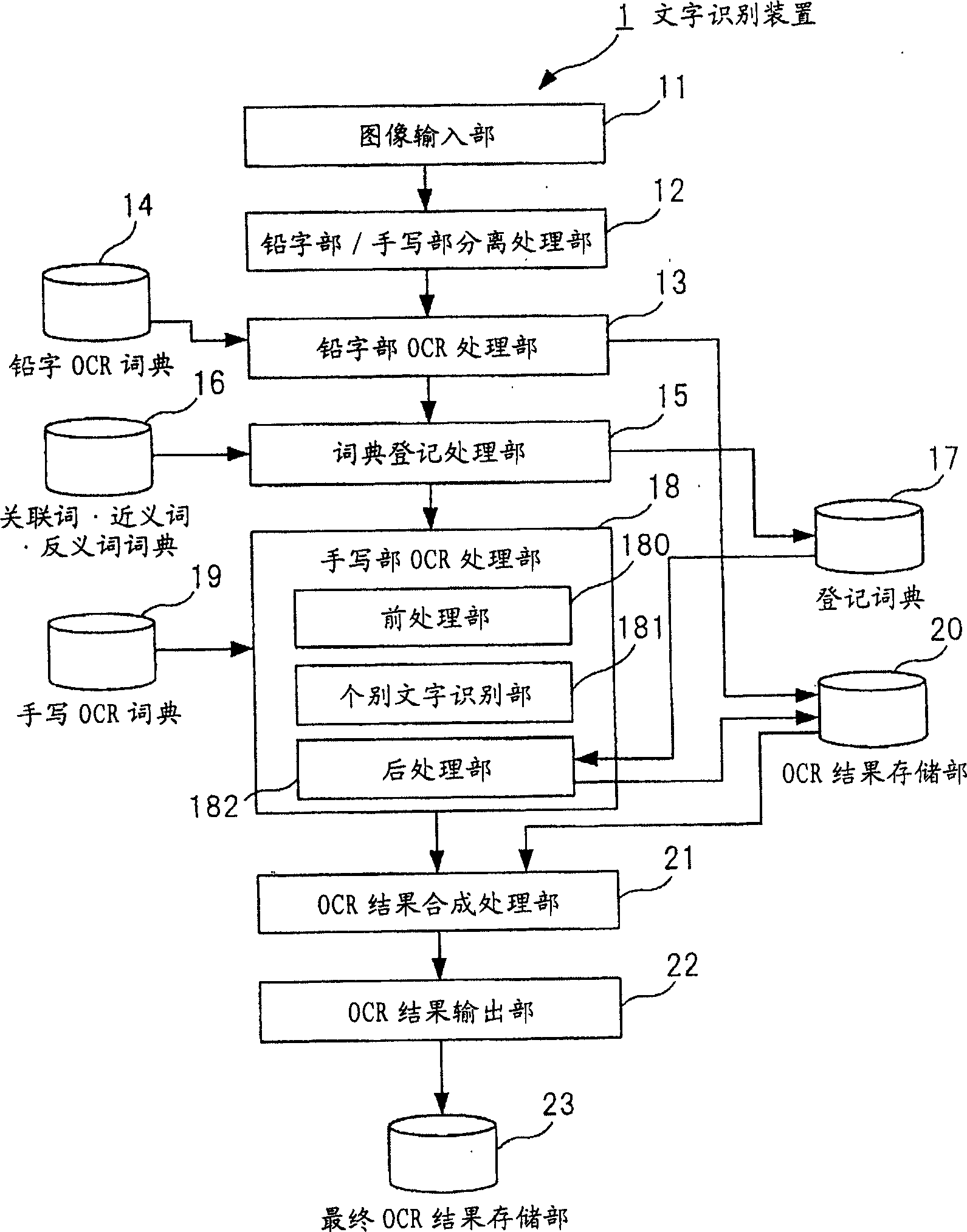

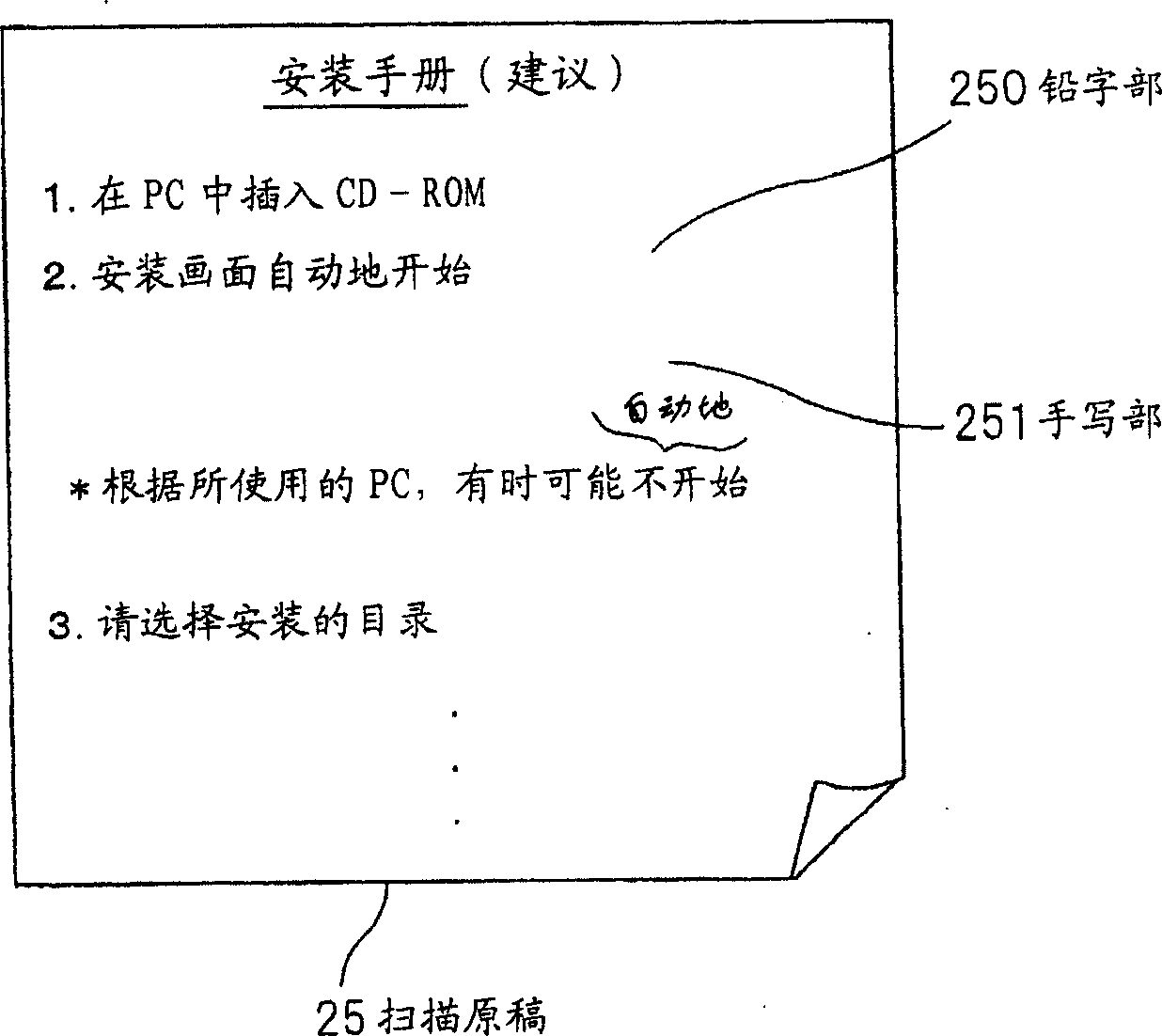

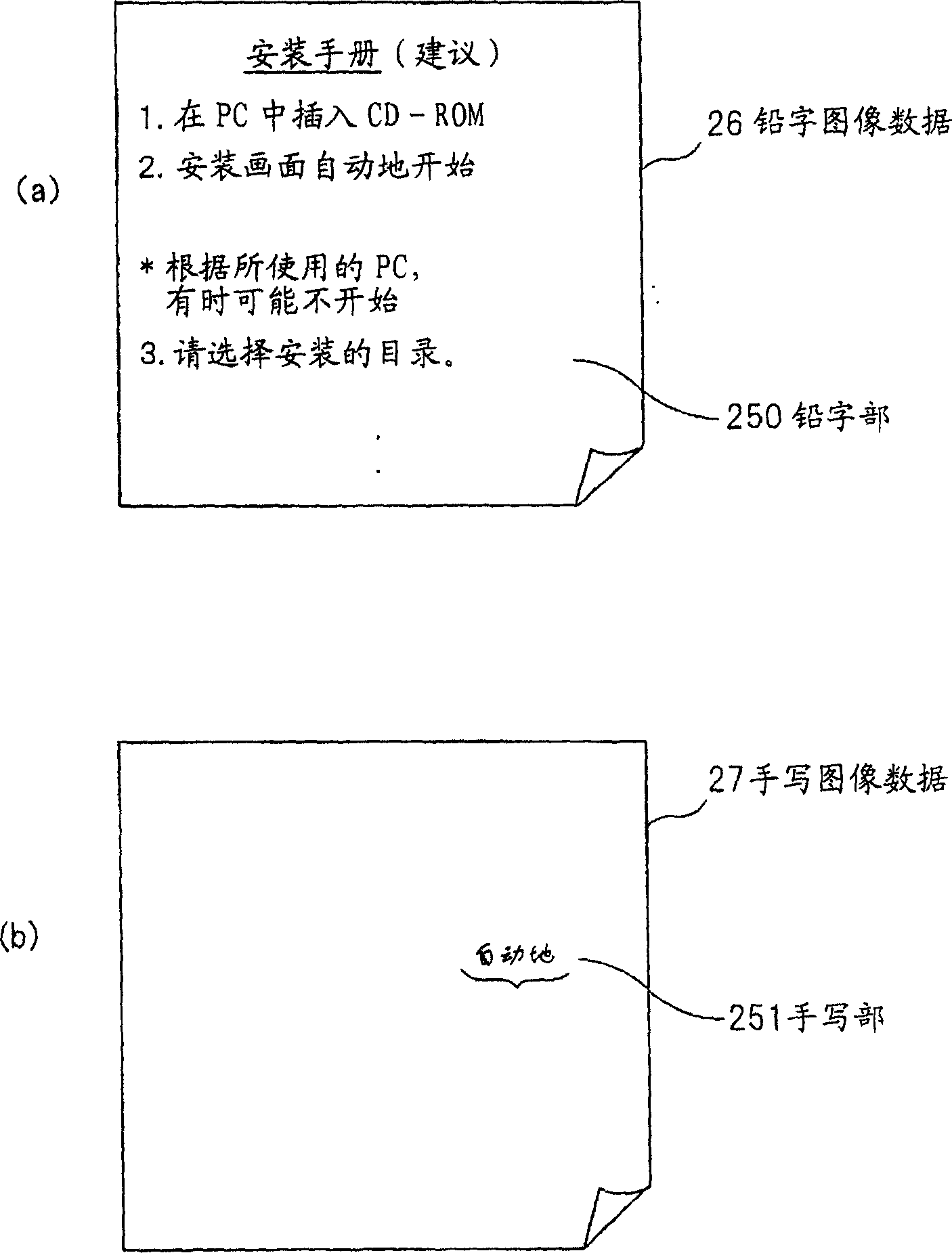

Character recognition apparatus, character recognition method, and character recognition program

To provide a capital letter recognizing device, a capital letter recognizing method and a capital letter recognizing program for generating an electronic document where types and handwritten characters coexist. The image of an original where types and handwritten characters coexist is generated by an image inputting part 11, and the image is divided into a type section constituted of the types and a handwritten section constituted of the handwritten characters by a type section / handwritten section separation processing part 12. Those sections are OCR-processed by a type section OCR processing part 13 and a handwritten section OCR processing part 18, and the result of the type OCR is registered in a registration dictionary 17. When there are a plurality of the recognition candidates of the handwritten section by the handwritten section OCR processing part 18, and any type is matched with the type OCR result in the neighborhood, the OCR processing of the handwritten section is carried out by using the type, and the result is composed with the type OCR by the OCR result composition processing part 21.

Owner:FUJIFILM BUSINESS INNOVATION CORP

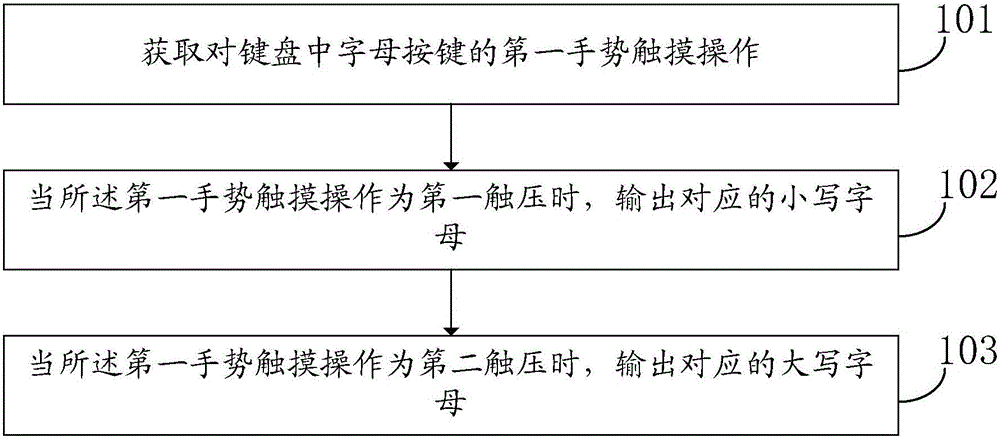

Input control method and terminal

ActiveCN106168880AImprove the efficiency of entering charactersImprove experienceInput/output processes for data processingInput controlCapital Letter

The invention discloses an input control method including that a terminal acquires a first gesture touch operation for the letter buttons in a keyboard, when the first gesture touch operation is a first touch press, a corresponding small letter is output, when the first gesture touch operation is a second touch press, a corresponding capital letter is output, wherein the first touch press and the second touch press indicate gesture touches that represent different pressure to the screen of the terminal. In this way, the terminal performs the distinction between the first touch press and the second touch press by the different pressure on the display screen generated by the gesture operation of a user, and the input instructions generated by the triggering with different pressure are different, so that the user can input small letters or capital letters by touching the screen with different force, greatly improving the letter input efficiency of the user through a virtual keyboard, and improving the user experience.

Owner:MEIZU TECH CO LTD

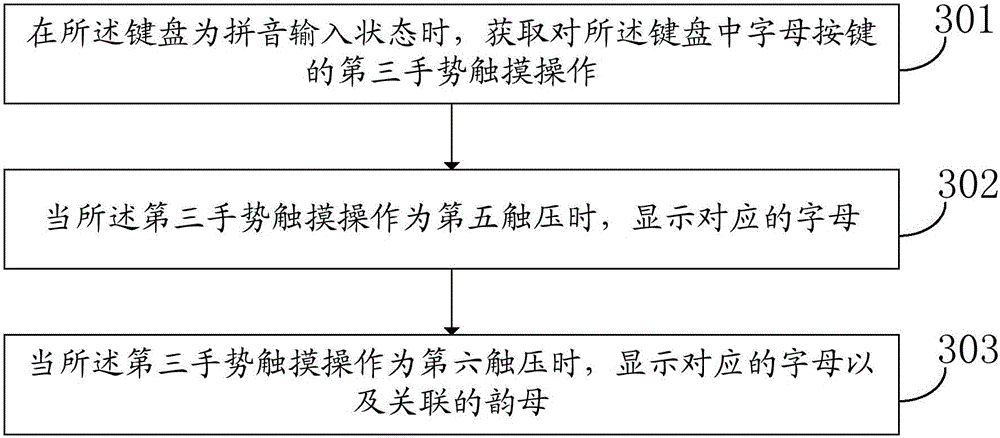

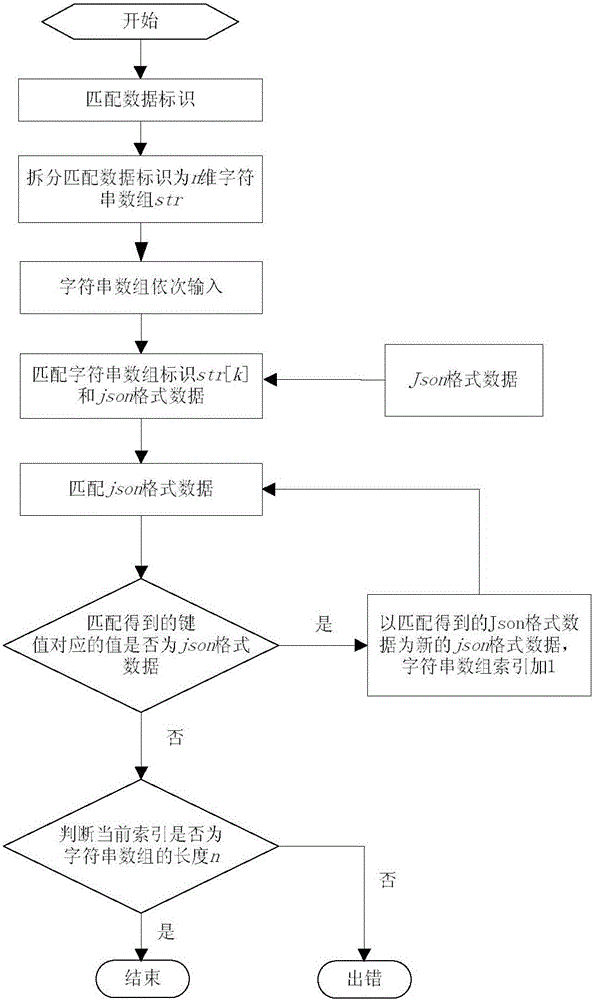

Json format data-based naming matching method

ActiveCN105808262AEffective protectionImprove experienceSoftware designSpecific program execution arrangementsArray data structureAlgorithm

The invention discloses a json format data-based naming matching method. The method comprises the following steps: establishing a data source on the basis of n-layer nested json format data, the key value initial of which is capitalized; carrying out setting to ensure that a search key value is formed by a key value of a layer of a to-be-searched value and an own key value in sequence through splicing; splitting the search key value by taking capital letters as separators so as to form a key value array str[n], and carrying out sequential search by taking a result of judging whether the search value is json format data or not as an ending condition, wherein the search frequency is k; finally judging whether k is equal to n, and indicating that to-be-matched data is searched if k is equal to n. The json format data-based naming matching method provided by the invention has the effects of effectively protecting the data, improving the data transmission efficiency and enhancing the user experience.

Owner:ZHEJIANG UNIV OF TECH

Method for inputting Chinese and English character strings

The invention thoroughly changes the existing Chinese character coding input method as well as the mode of inputting Chinese and English characters. The input English character string directly displays behind a cursor, thus realizing what you see is what you type; at the same time, English lowercase and capital letters are directly input by skillfully using 'shift' keys and 'Ctrl' keys of a computer keyboard; moreover, confusion and interference of software can not be increased, thus being convenient for remembering, for example, 'shift' stands for an English word 'small-lower case', 'Ctrl' stands for an English word 'capital-capital letters'. The invention is simple and fast, leads an introducer to immediately find and correct input errors thereof, can increase efficiency for the blending inputting of Chinese and English character and is significant for editing Chinese and English dictionaries.

Owner:HETUALA INFORMATION TECH LTD ZHANGJIAGANG CITY

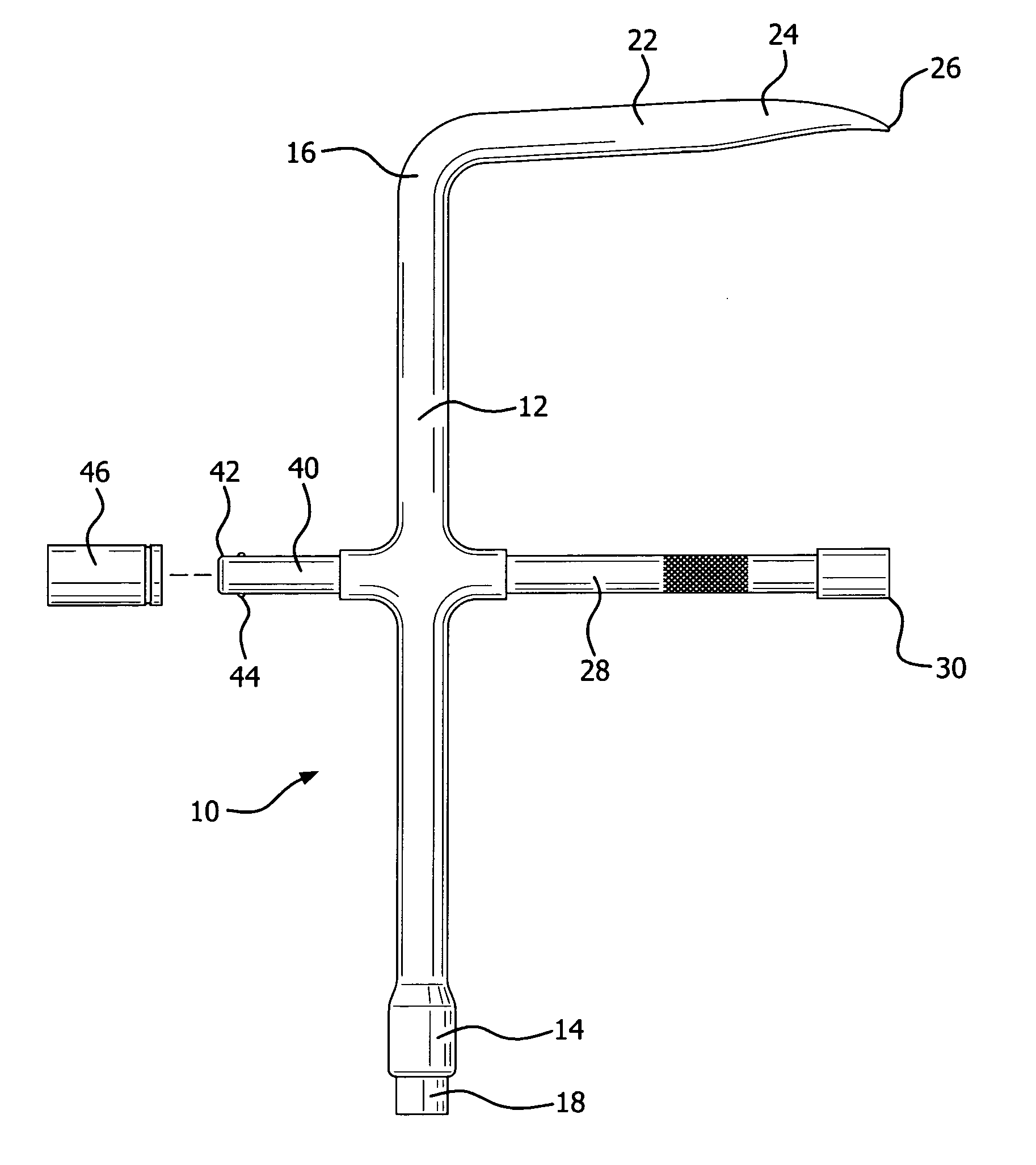

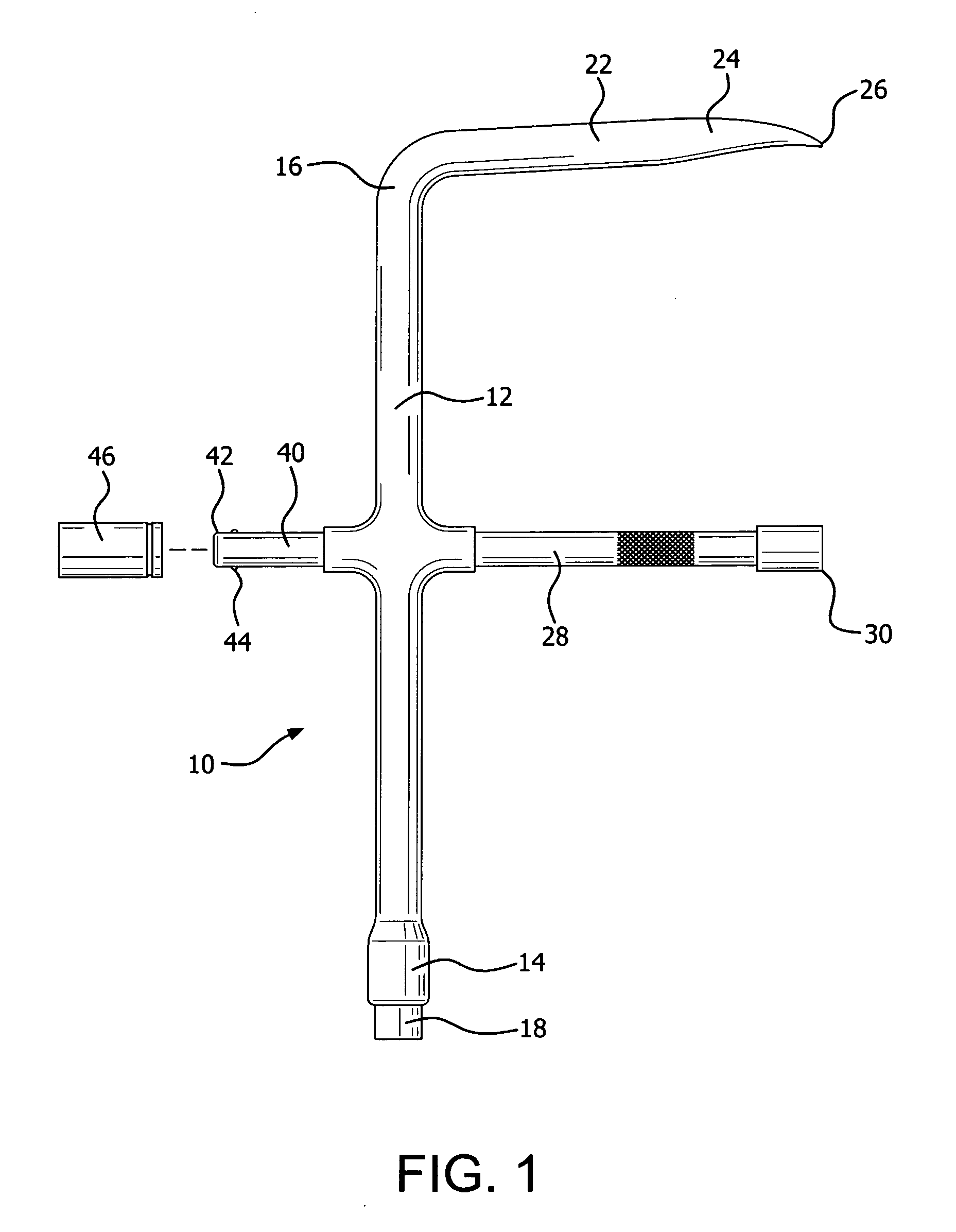

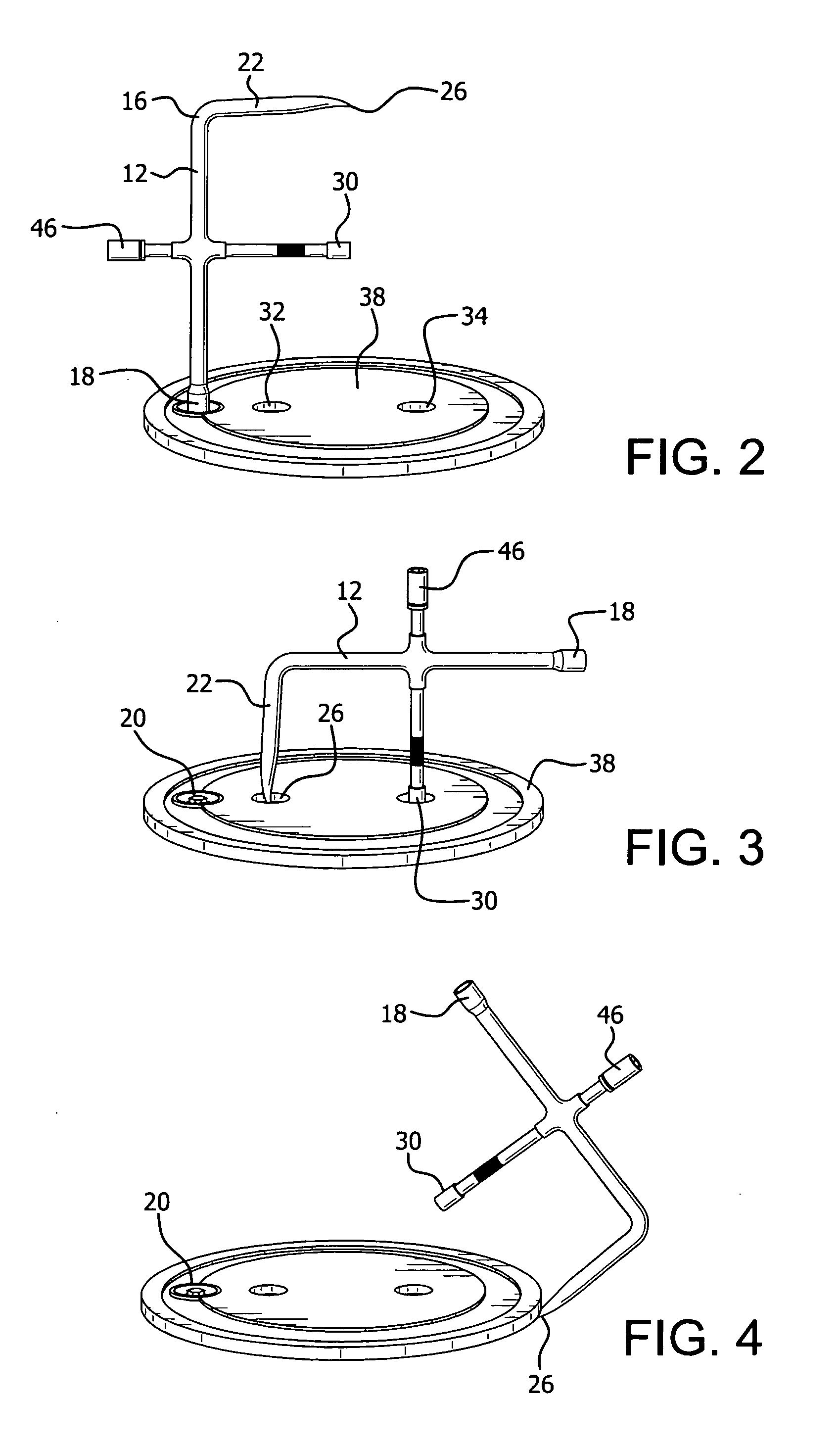

Tool for removing lids from in-ground service boxes

A tool for removing lids from in-ground service boxes includes an elongated shaft having first and second ends, the first end including and open wrench socket. A first bar is rigidly connected to and extends from the second end of the shaft in a direction perpendicular to the axis of the shaft and ends in a pry tip. A second bar is also rigidly connected to and extends from the shaft at a position intermediate the two ends thereof. The said second bar extends in the same direction as and parallel to the first bar so that the device resembles the capital letter “F.” The shaft, and the first and second bars lie in the same plane so that the pry tip and the distal end of the second bar are can be simultaneously inserted into spaced apart openings in the lid to rotate the lid.

Owner:HUHN RAYMOND A

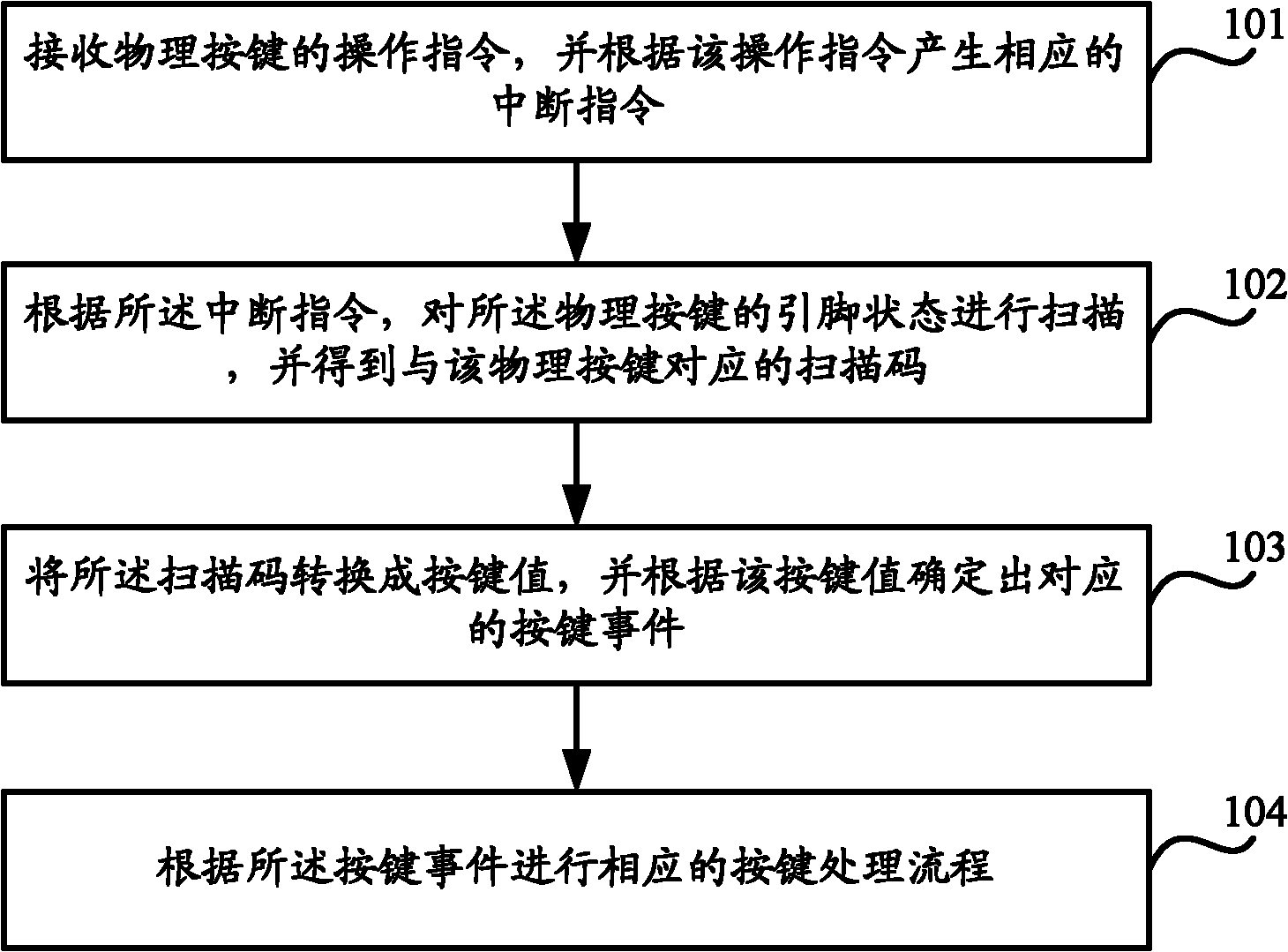

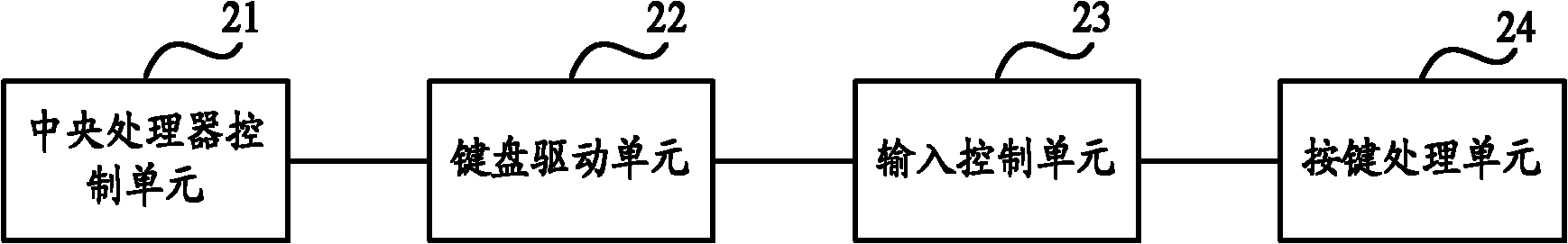

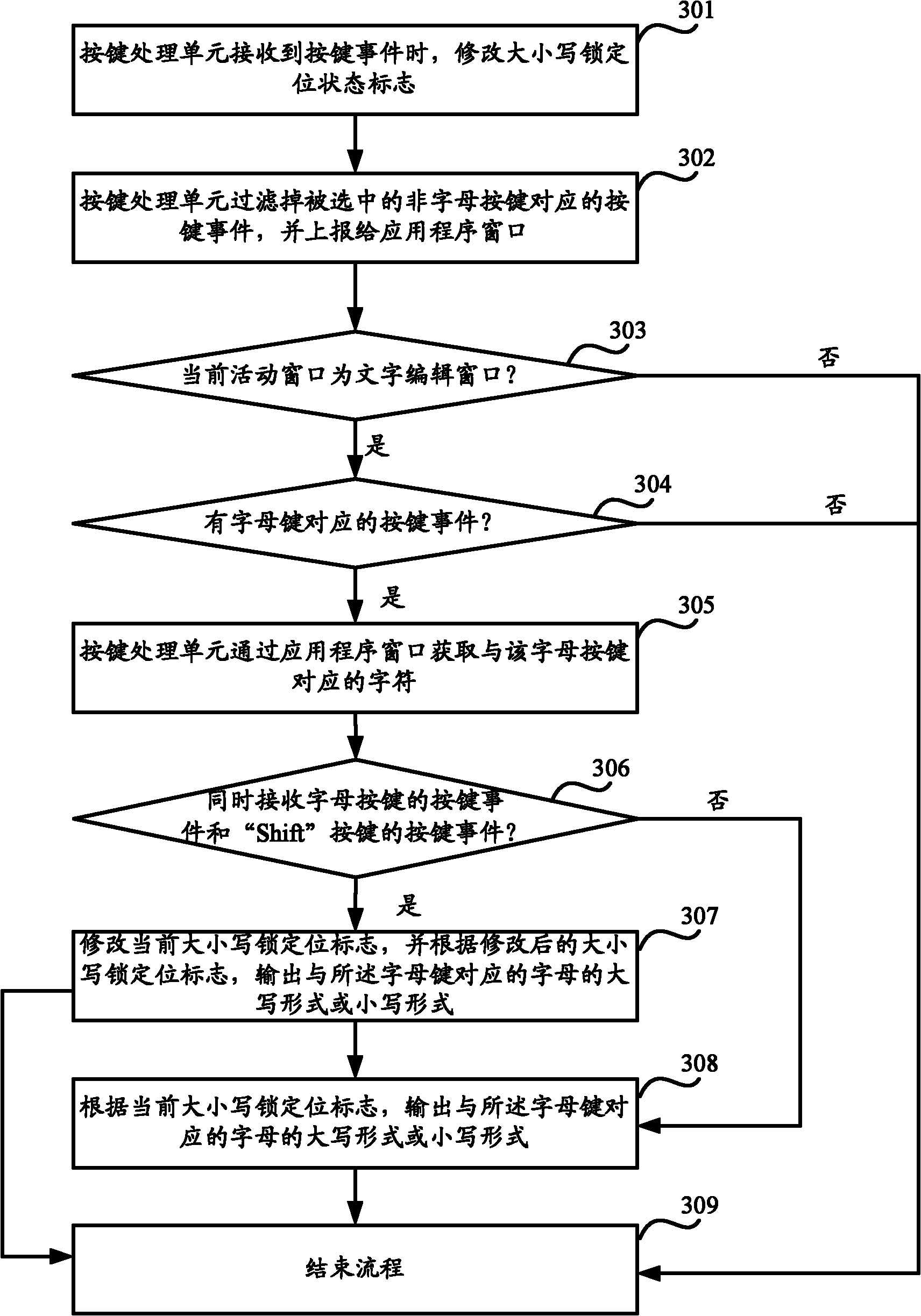

Method and device for processing keyboard instruction, keyboard and terminal equipment

InactiveCN101995964AImprove efficiencyImprove convenienceInput/output processes for data processingMachine execution arrangementsKey pressingThe Internet

The invention discloses a method and a device for processing a keyboard instruction, a keyboard and terminal equipment, which aim to improve the efficiency and the convenience of performing internet surfing operation and text operation in the terminal equipment. The method comprises the following steps of: receiving an operation instruction transmitted by a physical key and generating a corresponding interruption instruction according to the operation instruction, wherein the physical key comprises one or more of the following keys: a capital letter and small letter switching key for realizing a switching function of a capital letter or small letter, a status bar switching key for realizing a status bar switching function and a copy or paste key for realizing a copy or paste function; scanning the lead status of the physical key to acquire a corresponding scan code according to the interruption instruction; converting the scan code into a key value and determining a corresponding key event according to the key value; and performing a corresponding key processing flow according to the key event. By using the technical scheme of the invention, the efficiency and the convenience of performing the internet surfing operation and the text operation in the terminal equipment are improved.

Owner:ZTE CORP

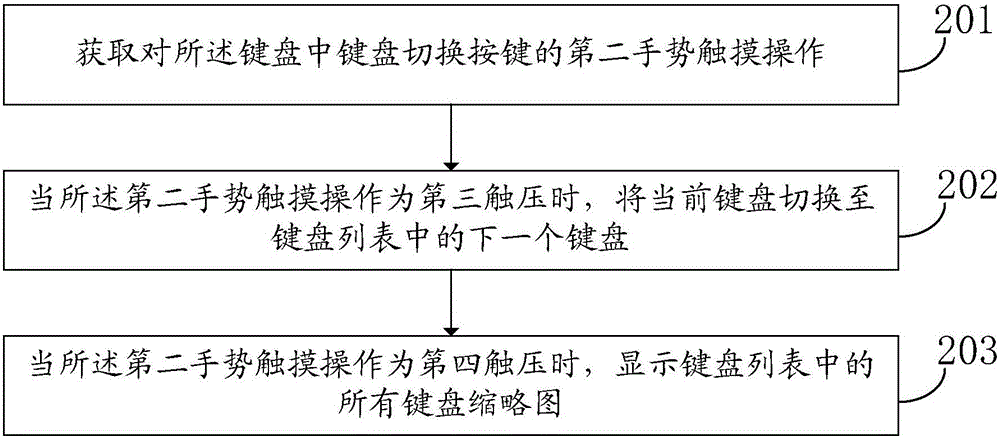

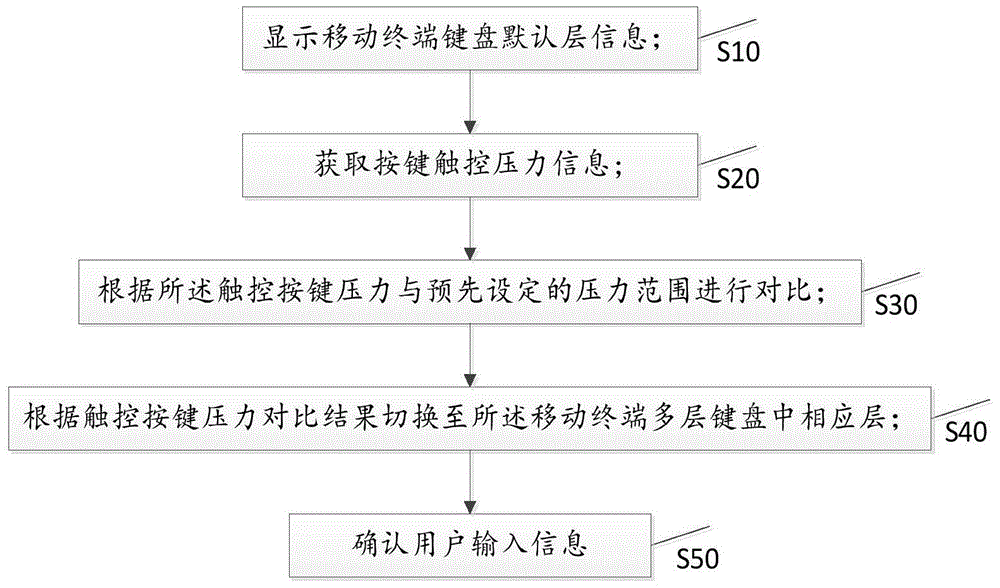

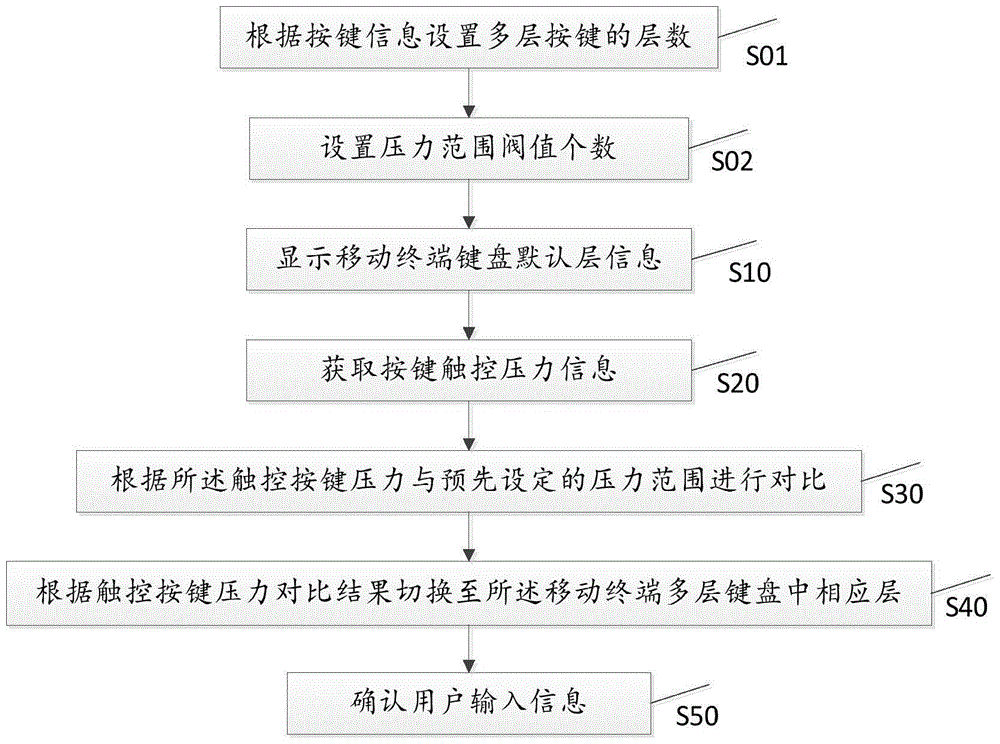

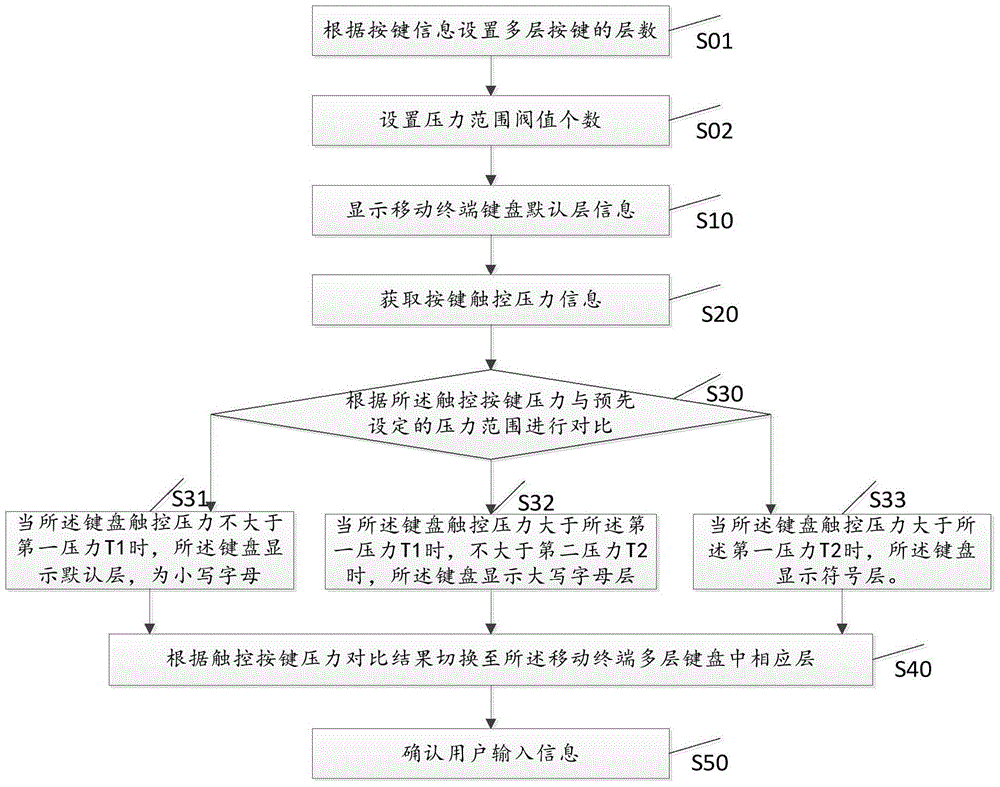

Multi-layer input method of intelligent terminal and intelligent terminal

InactiveCN105677204AImprove input experienceEasy inputInput/output processes for data processingUser inputComputer terminal

A multi-layer input method of an intelligent terminal includes the steps that keyboard default layer information of the mobile terminal is displayed; touch pressure information of a keyboard is acquired; the keyboard touch pressure is compared with a preset pressure range; according to the keyboard touch pressure comparison result, operation is switched into a corresponding layer in the multi-layer keyboard of the mobile terminal; user inputting information is confirmed. The method further includes the steps that the multi-layer keyboard is set to be provided with at least three layers according to the keyboard default layer information; according to the number of the layers of the multi-layer keyboard, different thresholds for pressure range partition are set. The method further includes the steps that when the keyboard touch pressure is not larger than first pressure T1, a default layer of the keyboard is displayed, and lowcase letters can be input; when the keyboard touch pressure is larger than first pressure T1 and not larger than second pressure T22, a capital letter layer of the keyboard is displayed; when the keyboard touch pressure is larger than second pressure T2, the keyboard displays a symbol layer.

Owner:PHICOMM (SHANGHAI) CO LTD

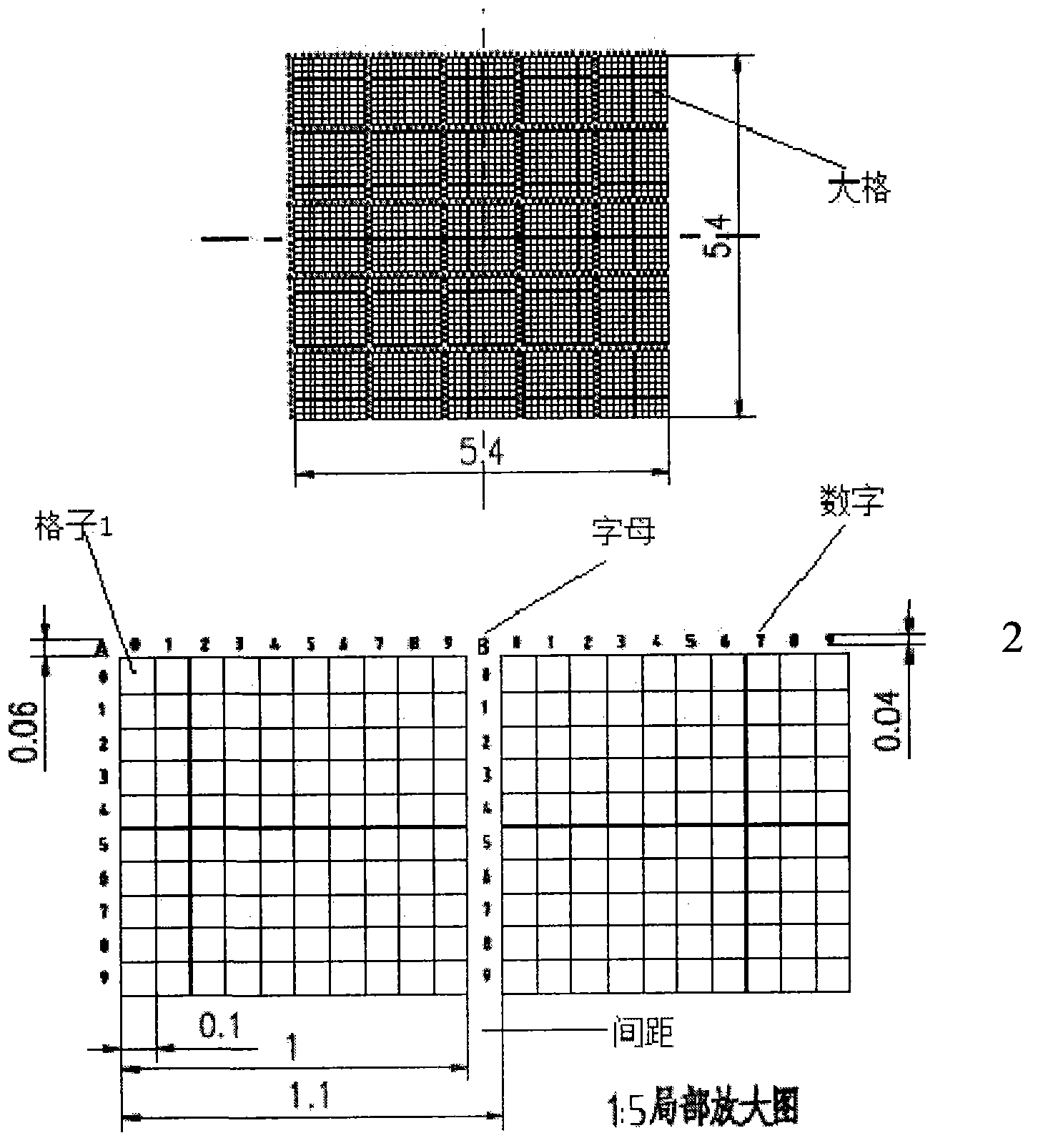

Grid positioning sheet capable of detecting sperms quickly

InactiveCN103627619AFor long-term storageBioreactor/fermenter combinationsBiological substance pretreatmentsSperm morphologyArabic numerals

The invention belongs to the field of cytobiology research, and specifically belongs to the field of sperm morphology positioning research. A grid positioning sheet disclosed in the invention comprises a glass substrate, and a polished glass sheet; the glass substrate and the polished glass sheet are glued together; the polished glass sheet is provided with a square grid zone via drawing; the square grid zone comprises 25 1mmX1mm big grids arranged with intervals of 0.1mm; the top left of each big grid is marked with a capital letter selected from A to Y; each big grid comprises 100 0.1mmX0.1mm square small grids; along the side frame of each big grid from the top to the bottom and from the left to the right, the small grids are marked with numbers from 0 to 9; the numbers and grid lines on the grid positioning sheet are all displayed via highlight black lines. The sperm grid positioning sheet is suitable for observing of sperm morphology under a high-power microscope; accurate positioning of the observed sperms can be realized via the big and the small grids which are marked with English letters and Arabic numerals; and it is extremely convenient to find target sperms when repeated checking on specific sperms is necessary.

Owner:徐元诚

Computer Chinese phonetic double-click rapid input method

The invention relates to a computer Chinese (consonant-vowel double- click) tone-participative coding quick input method, developed by deep research mainly for the requirements of Ministry Of Labour And Social Security and Ministry of Information Industry for professional skills of Chinese short-hand experts on compute: the primary input 140 Chinese characters per minute, the medium input 180 Chinese characters per minute and the senior input 220 Chinese characters per minute. And the invention overcomes the defect that the traditional phonetic English small letters correspond to on-keyboard English capital letters to input Chinese characters, and adopts a truly original design solution, and proceeds in all cases from raising Chinese character input speed and makes computer Chinese character input reach the limit. And its main principle and features: 1. fully considering English key frequency of the main region of a keyboard, where the middle row is higher than the top row, the top row is higher than the bottom row, and the middle is higher than the four sides; 2. fully considering human hand flexibility, where the right-hand is higher than the left-hand; 3. fully considering use frequencies of initial consonants and vowels and make integral optimized settings from high to low corresponding to the keyboard frequency and flexibility of left and right hands; 4. fully considering rules of daily spoken language and written language and giving punctuations to part of speech classification recognizing function. And it has also features of visual input, strong regularity, low memory quantity, large coding capacity, good word composing effect, low repeated code rate, high input speed, etc.

Owner:孙莹莹

Method of using nanoalloy additives to reduce plume opacity, slagging, fouling, corrosion and emissions

A process for improving the operation of combustors includes the steps of burning a carbonaceous fuel in a combustor system and determining combustion conditions within the combustor system that can benefit from a targeted treatment additive, wherein the determinations are made by calculation including computational fluid dynamics and observation The process further includes locating introduction points in the combustor system where introduction of the targeted treatment additive could be accomplished. Based on the previous steps, a treatment regimen for introducing the targeted treatment additive to locations within the combustor system results in one or more benefits selected from the group consisting of reducing the opacity of plume, improving combustion, reducing slag, reducing LOI and / or unburned carbon, reducing corrosion, and improving electrostatic precipitator performance. The targeted treatment additive comprises an alloy represented by the following generic formula (Aa)n(Bb)n(Cc)n(Dd)n( . . . )n, wherein each capital letter and ( . . . ) is a metal, wherein A is a combustion modifier, B is a deposit modifier; C is a corrosion inhibitor; and D is a combustion co-modifier / electrostatic precipitator enhancer, wherein each subscript letter represents compositional stoichiometry, wherein n is greater than or equal to zero and the sum of n's is greater than zero, and wherein the alloy comprises at least two different metals, with the proviso that if the metal is cerium, then its compositional stoichiometry is less than about 0.7.

Owner:AFTON CHEMICAL

System and method for identifying and defining idioms

ActiveUS7657421B2Natural language data processingSpecial data processing applicationsDocumentationPage break

The “Idiom Identifier” converts an original text document to a “neutral” form containing no punctuation, no capital letters, and having only a single space between each word. Neutral form text also removes hidden markup such as line breaks, paragraph breaks or page breaks. The Idiom Identifier performs an enhanced text search to locate idioms listed in a library file. The Idiom Identifier marks each identified idiom in a marked-up copy of the original text document. A reader can click on the marked-up idiom to see a definition of the idiom.

Owner:TWITTER INC

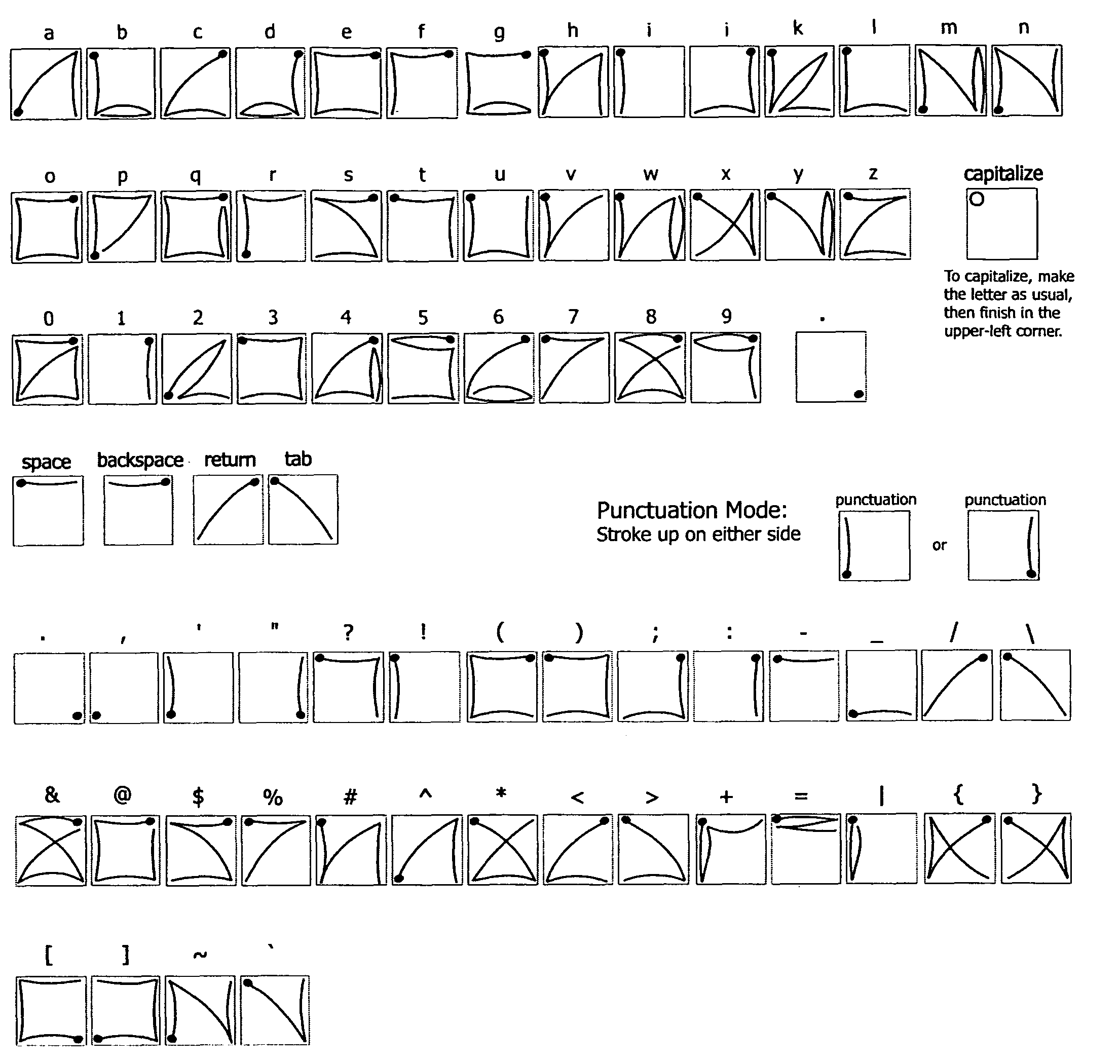

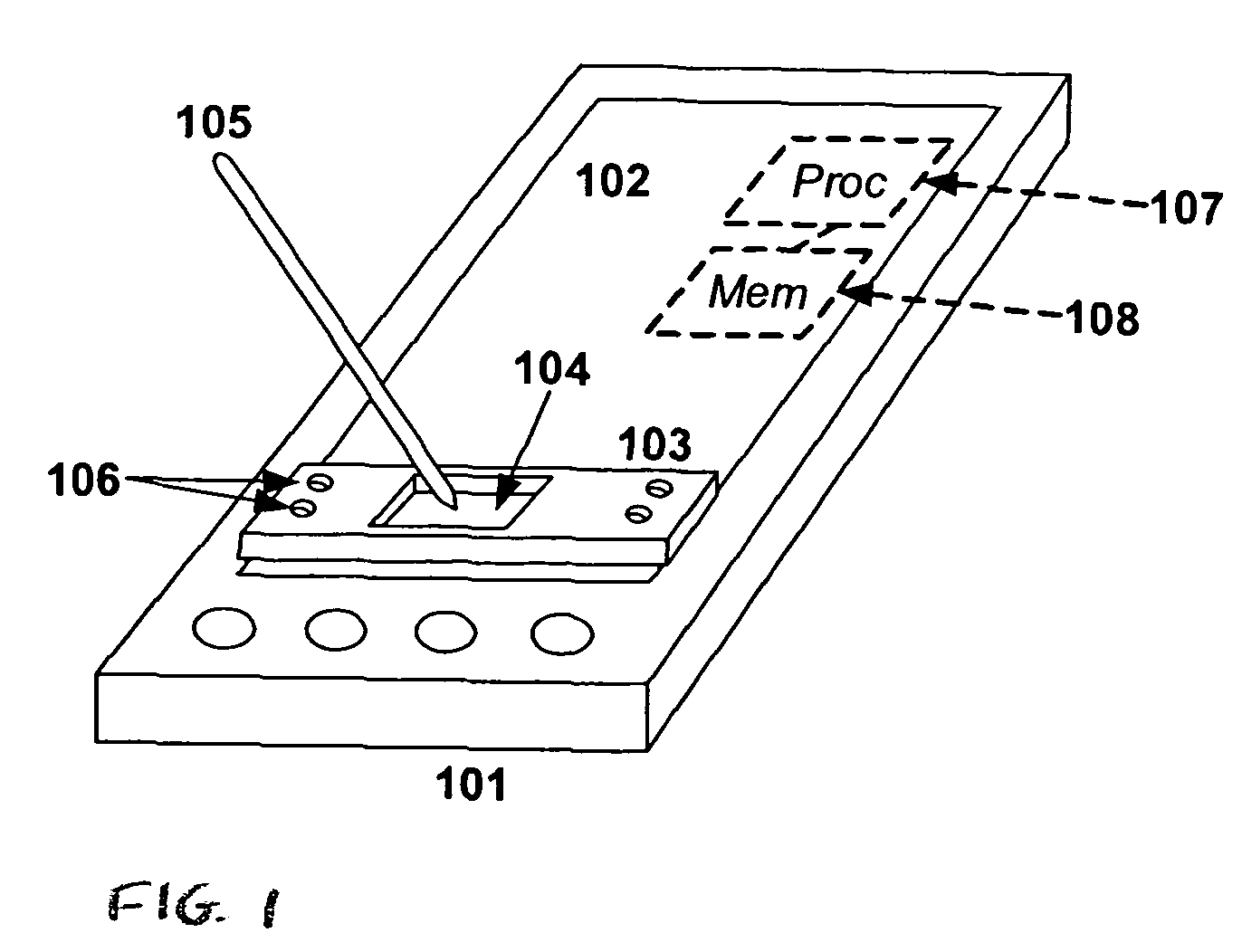

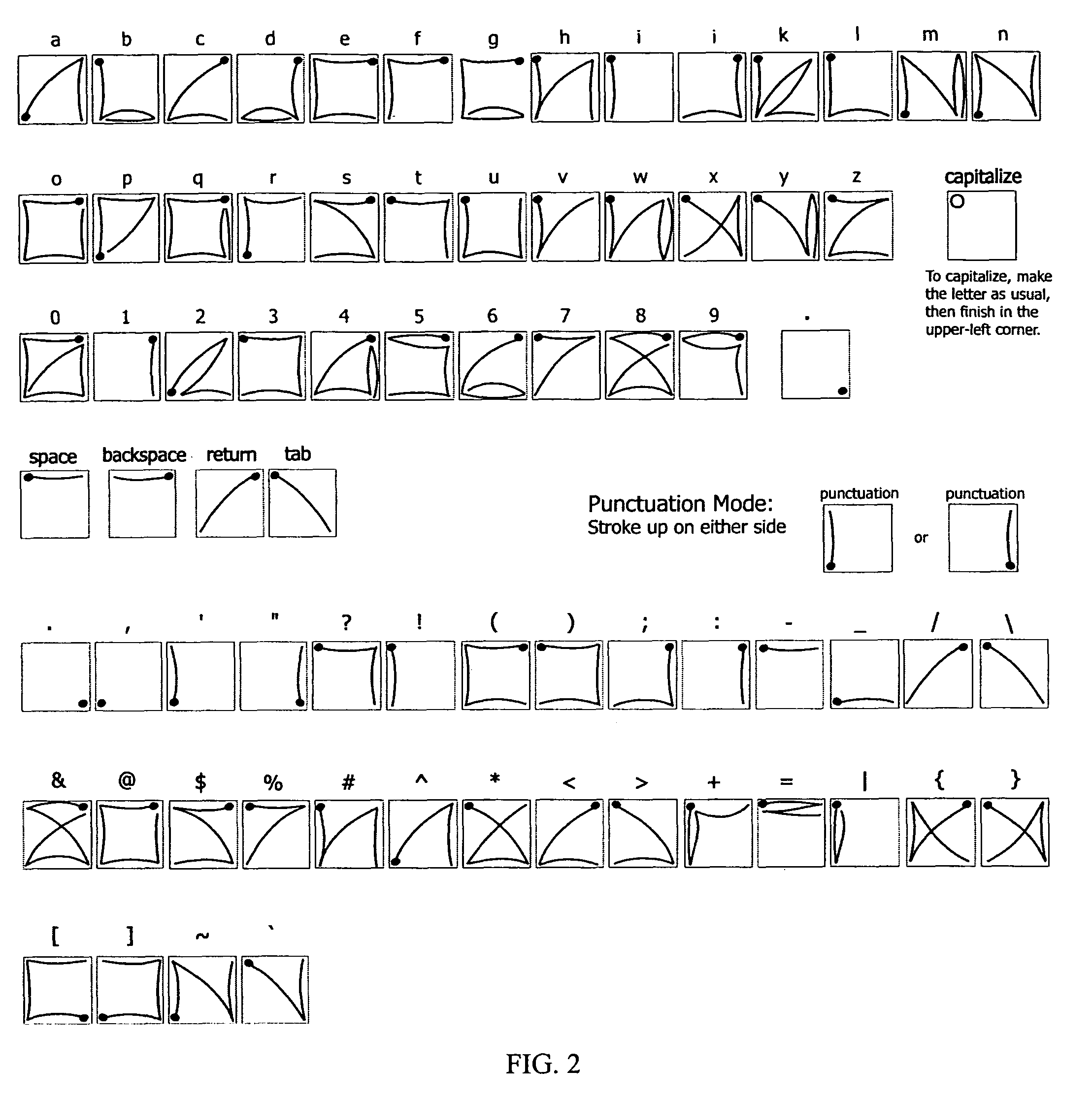

Using edges and corners for character input

ActiveUS7729542B2Quality improvementImprove stabilityCharacter and pattern recognitionCathode-ray tube indicatorsJoystickText entry

A new unistroke text entry method for handheld or wearable devices is designed to provide high accuracy and stability of motion. The user makes characters by traversing the edges and diagonals of a geometric pattern, e.g. a square, imposed over the usual text input area. Gesture recognition is accomplished not through pattern recognition but through the sequence of corners that are hit. This means that the full stroke path is unimportant and the recognition is highly deterministic, enabling better accuracy than other gestural alphabets. This input technique works well using a template with a square hole placed over a touch-sensitive surface, such as on a Personal Digital Assistant (PDA), and with a square boundary surrounding a joystick, which might be used on a cell-phone or game controller. Another feature of the input technique is that capital letters are made by ending the stroke in a particular corner, rather than through a mode change as in other gestural input techniques. Because of the rules governing abstracts, this abstract should not be used to construe the claims.

Owner:CARNEGIE MELLON UNIV

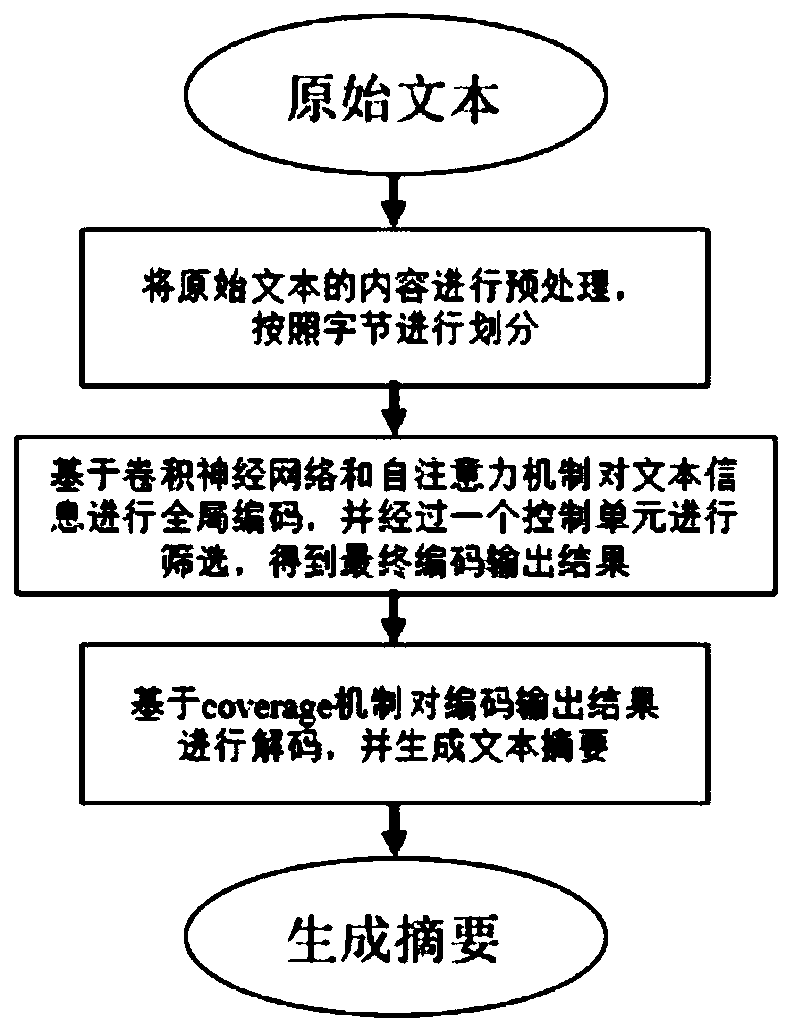

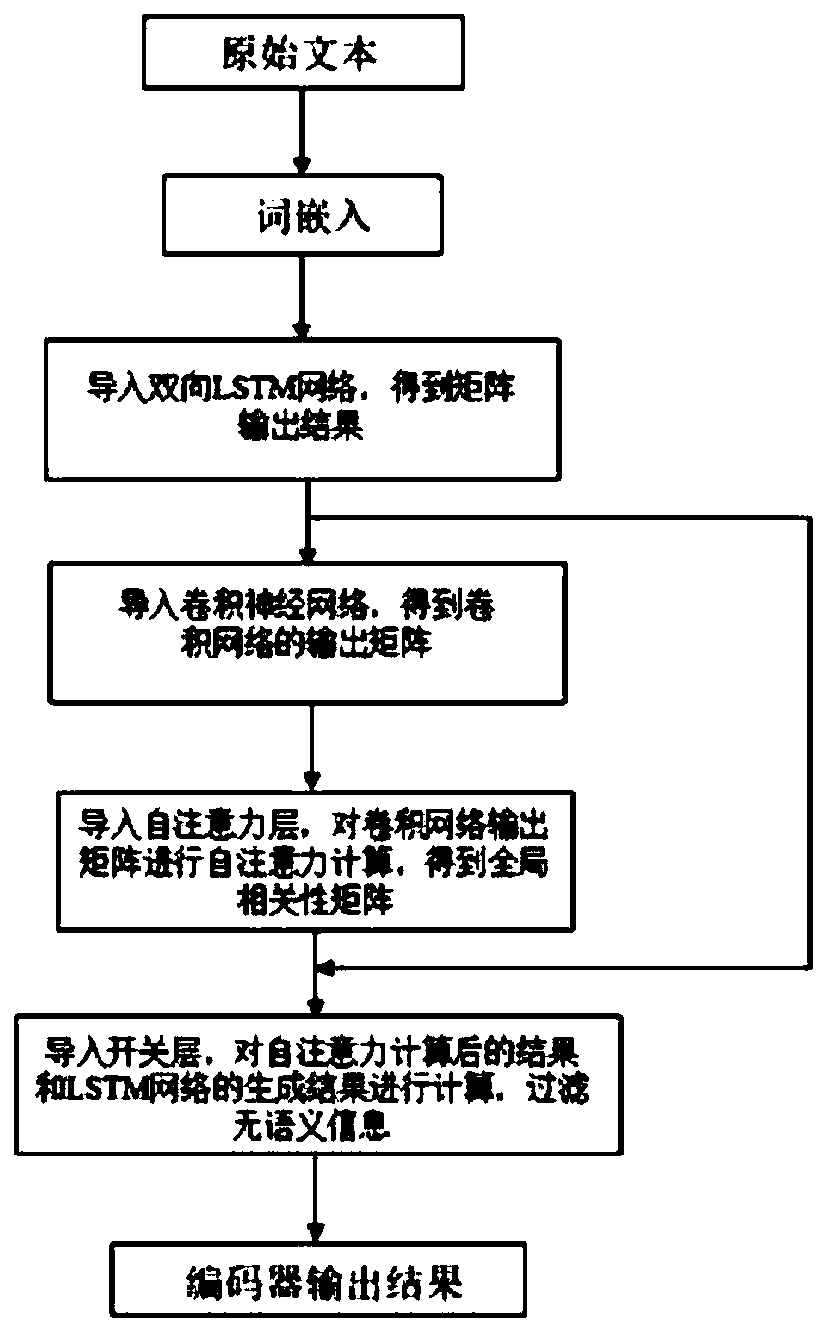

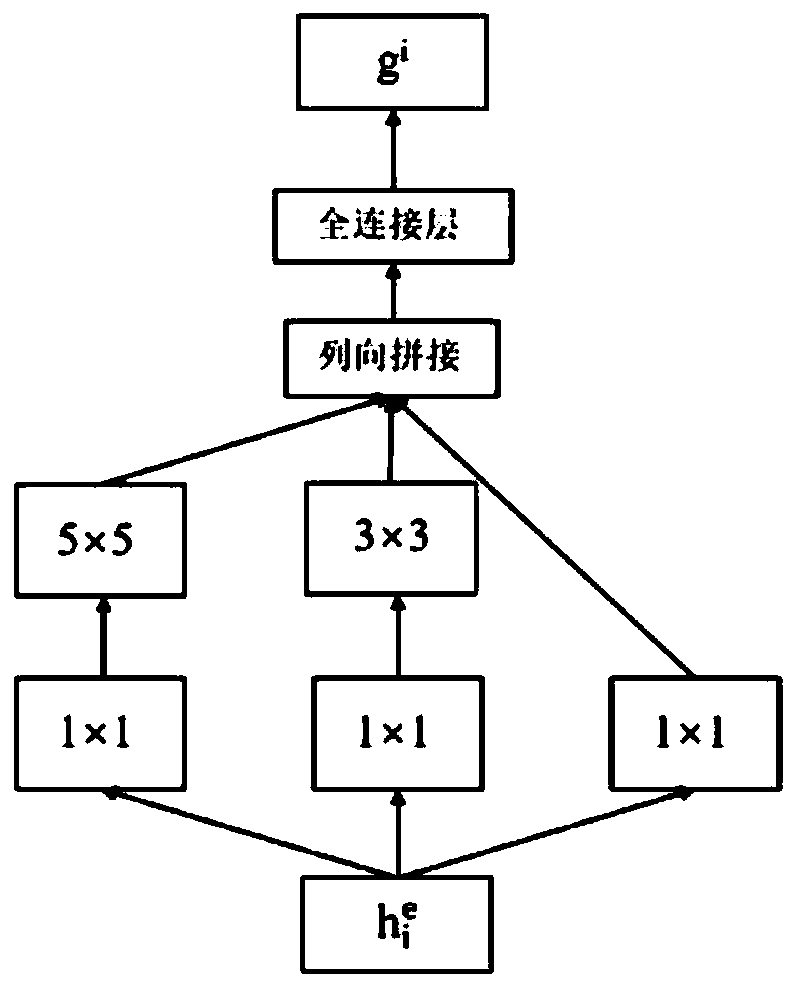

Automatic text abstracting method and device based on global semantics, medium and equipment

ActiveCN111563160AMitigate Duplicate IssuesThe semantics of the abstract are clearSemantic analysisEnergy efficient computingAlgorithmConvolution filter

The invention provides an automatic text abstracting method and device based on global semantics, a medium and equipment. The method comprises the following steps: preprocessing the content of an original text, dividing the content according to bytes, and replacing capital letters in the original text with lowercase letters to obtain text information; by an encoder, performing global encoding on the text information based on a convolutional neural network and a self-attention mechanism, and performing screening through a control unit to obtain a final encoding output result; and by the decoder, decoding the encoded output result based on a repetitive punishment mechanism and generating a text summary. According to the method, a convolution filter is added to athe encoder, and the repetitive punishment mechanism is used in the decoder part to further suppress repetitive words so that the smoothness of abstract text semantics can be improved, the repeated punishment mechanism can greatlyinhibit already appeared words, the repeatability problem of abstract generation is reduced, and therefore the readability of abstract generation is improved.

Owner:SOUTH CHINA UNIV OF TECH

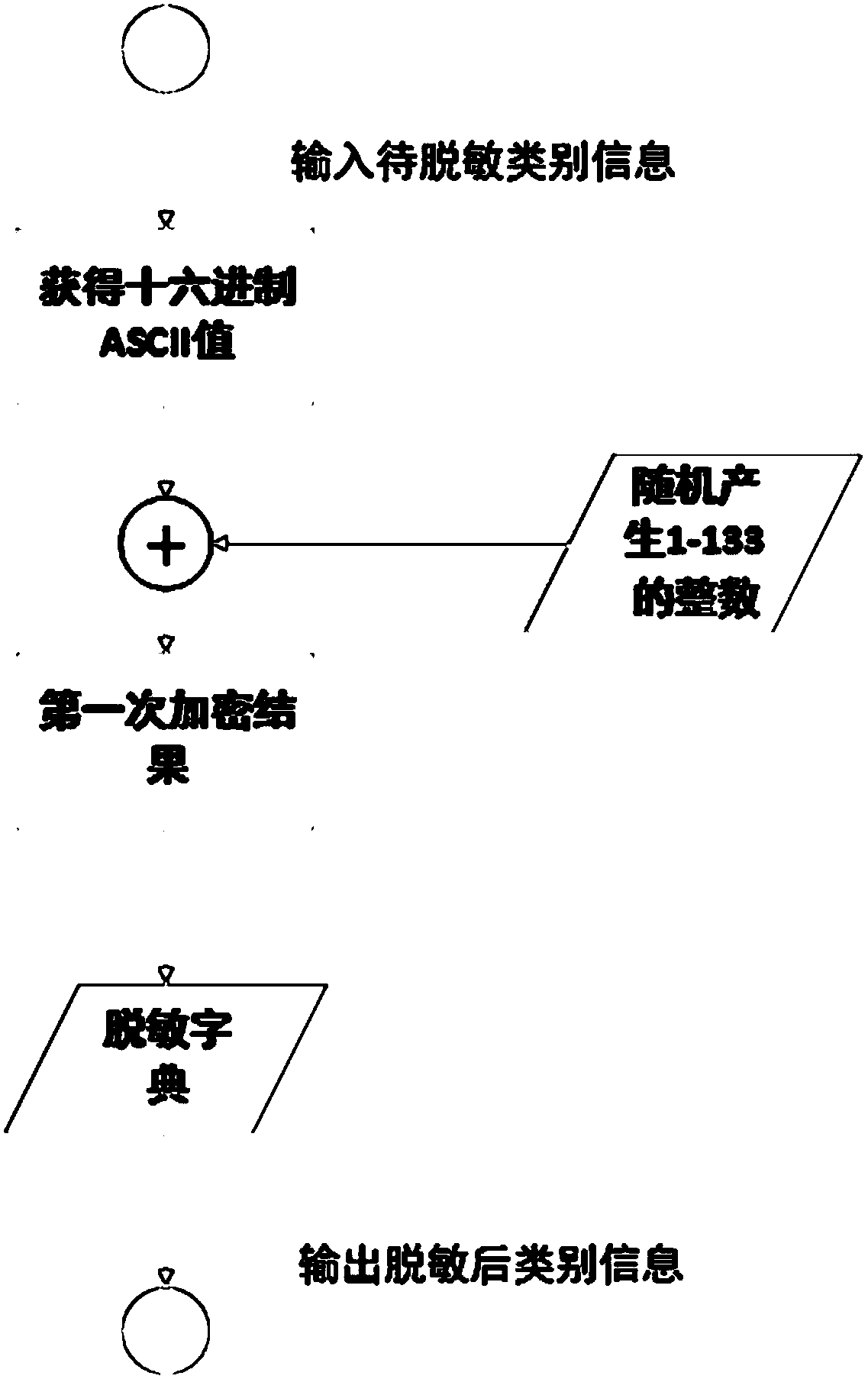

Data desensitization method for class information

ActiveCN108416229ARetention frequencyRetention percentageDigital data protectionNatural language data processingAlgorithmControl character

The invention discloses a data desensitization method for class information. The data desensitization method for the class information includes the following steps that 1) the class information is obtained, and ASCII values corresponding to control characters are obtained according to an ASCII comparison table; 2) decimal integers are randomly generated, the decimal integers are converted into numbers with the same scale with the ASCII values in the step 1), and then the obtained numbers and the ASCII values in the step 1) are summed; 3) a dictionary is established, wherein keys of the dictionary are characters between 0-9 and a-f, and values in the dictionary are 16 randomly-selected non-repetitive English capital letters; 4) every summation operation result serves as corresponding valuessearched by keys in the dictionary established in the step 3), then all the searched values are combined in sequence to form character strings, and finally, the character strings serve as data desensitization results for the class information. By means of the data desensitization method for the class information, the frequency and the percentage of the class information after desensitization canbe reserved, and data analysis values are not reduced.

Owner:XIDIAN UNIV

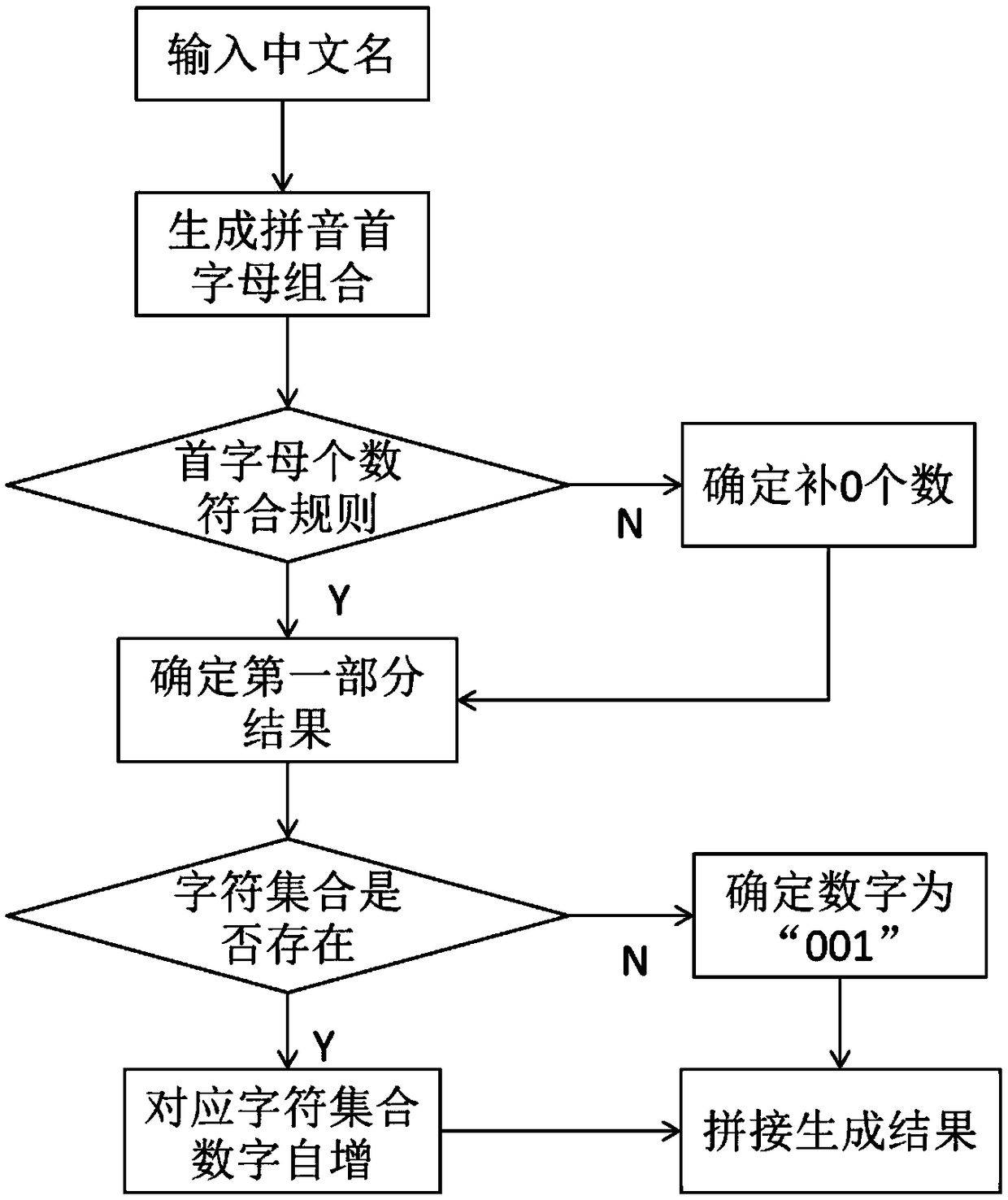

Automatic generation mode of data table and data field naming

InactiveCN109375900AUniform styleUnified naming processProgram documentationRequirement analysisProgramming languageData field

The invention relates to the technical field of computer, in particular to an automatic generation mode of data table and data field naming, which comprises automatic generation of data table naming and automatic generation of data field naming. The naming of data table and data field is generated by the combination of Pinyin initial capital letters and numerals corresponding to Chinese characters. It is generated automatically in a fixed format for table and field names in the database, Chinese phonetic alphabet initial let first two digits are selected from that data table name, the first four digits are selected from the data field name, if the correspond letter digits are insufficient, 0 is supplemented, and the following three digits are self-incremented in the correspond character set to generate a naming by selecting several Chinese phonetic alphabet initial letters corresponding to the Chinese phonetic alphabet capital letters combined with digits; it can make the style of table name and field name consistent in the project, unify naming process, form naming convention, and facilitate the later maintenance and secondary development of the project.

Owner:广州市南方人力资源评价中心有限公司

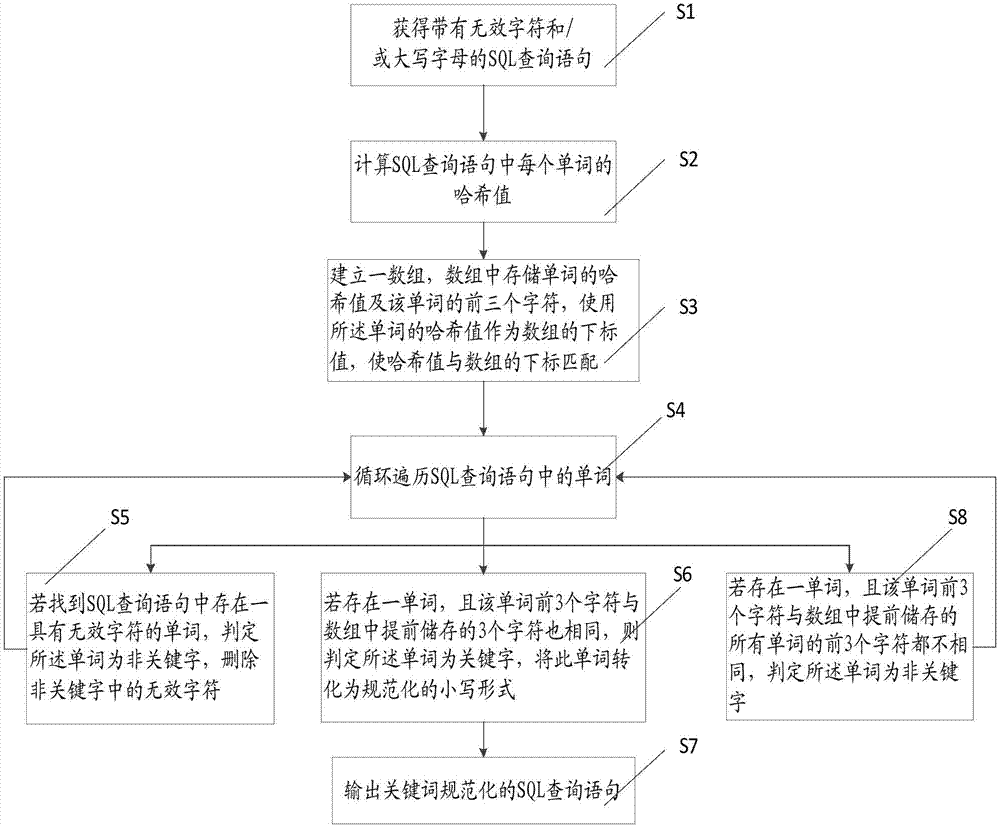

Query optimization method based on MySOL database

InactiveCN104123354AIncrease profitEliminate the disadvantage of low query reusabilitySpecial data processing applicationsArray data structureAlgorithm

The invention provides a query optimization method based on a MySOL database. The query optimization method based on the MySOL database is used for improving the utilization ratio of the MySQL query reusing optimization technology. The method comprises the following steps that (S1) SQL query sentences with invalid characters and / or capital letters are obtained; (S2) the Hash value of each word in the SQL query sentences is calculated; (S3) an array is established, the Hash value of each word and the first three letters of the corresponding word are stored in the array; (S4) words in the SQL query sentences are traversed in a circulation mode; (S5) one word with the invalid characters is found in the SQL query sentences; (S6) if the word with the first three letters identical with the three characters pre-stored in the array exists, the word is judged to be a keyword, and the word is converted into a normalized lower case format; (S7) the SQL query sentences with the keywords normalized are output; (S8) if the word with the first three letters different from the three characters of all the words pre-stored in the array exists, the word is judged to be a non-keyword.

Owner:DALIAN UNIVERSITY

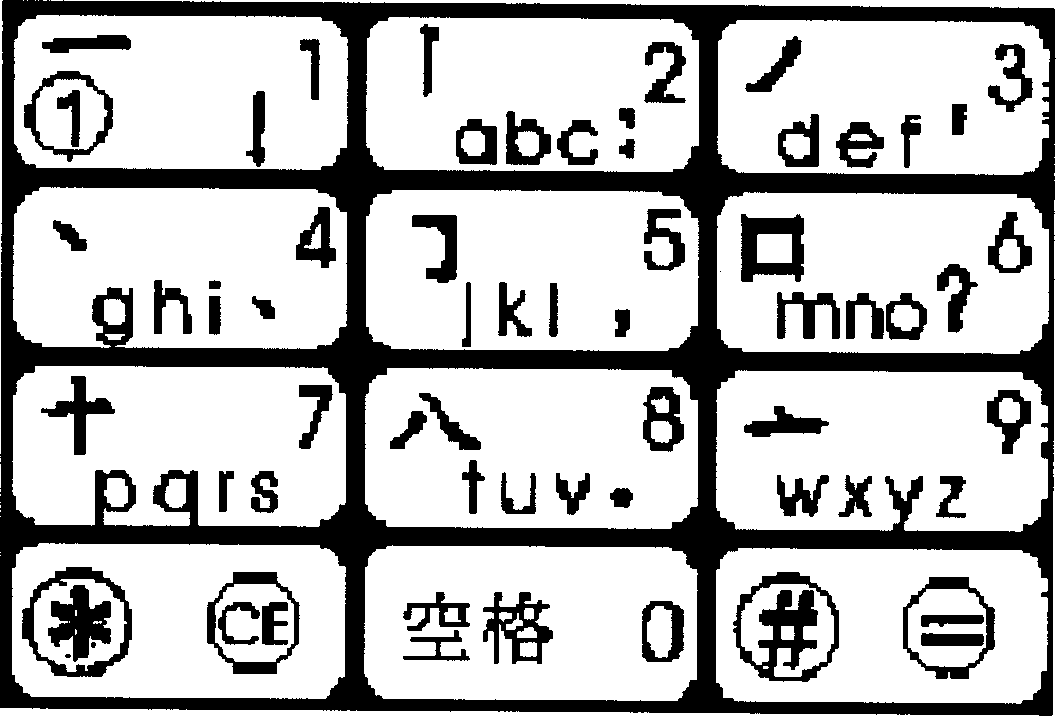

English inputting method

InactiveCN1779607AEasy to useIncrease typing speedTelephone set constructionsInput/output processes for data processingComputer scienceCapital Letter

An English input method includes distributing the first corresponding layer of four English letters or punctuation mark on each 2 ¿C 9 digit keys and not distributing letter or symbol on í‹1,í¨,0 andúúíŒ keys to form sixteen types of different coding, then distributing another sixteen types of coding at the second corresponding layer for corresponding to capital and small of 26 English letters as well as 12 normally used symbols by digital keys of 2 ¿C 9. It the method, capital letter and small letter as well as symbols can be inputted directly and switch over of capital and small letter input is no longer required.

Owner:黄金富

LNA oligonucleotides and the treatment of cancer

The present disclosure concerns LNA oligonucleotides having a (sub)sequence of the general formula 5'- ( Me Cx )(Tx,) Me CXAs Astscscsastsgsgs MeCXAX (G x) (c)-3',and preferably of the general formula 5'- Me C XTX), MeCXAsastscscsastsgsgs Me CxAx G x c-3', wherein capital letters designate a n LNA nucleotide analogue selected from .beta. -D-oxy-LNA, .beta. -D-thio-LNA, .beta.-D-amino-LNA and a-L-oxy-LNA, small letters designate a deoxynucleotid e, and underline designates either an LNA nucleotide analogue as defined above or a deoxynucleotide. Such LNA oligonucleotides exhibit surprisingly good properties with respect to inhibition of the expression of Survivin by means of an anti-sense mechanism, and thereby lead to reduction or inhibition of tumour development in vivo. The LNA oligonucleotides are superior to other L NA oligonucletides targeting Surviving mRNA measured by functional read outs such as apoptosis induction and proliferation inhibition, and is potent in down- regulating Survivin mRNA and protein in transfected cancer cell lines, and induce apoptosis in combination with Taxol superior compared to other LNA oligonucleotides.

Owner:SANTARIS PHARMA AS +1

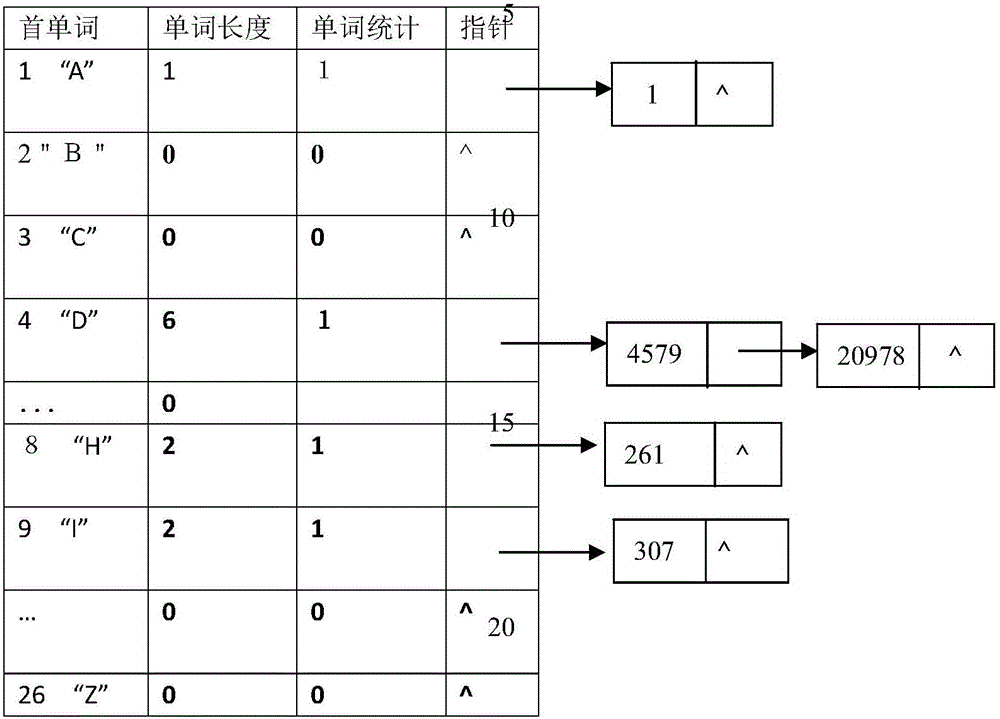

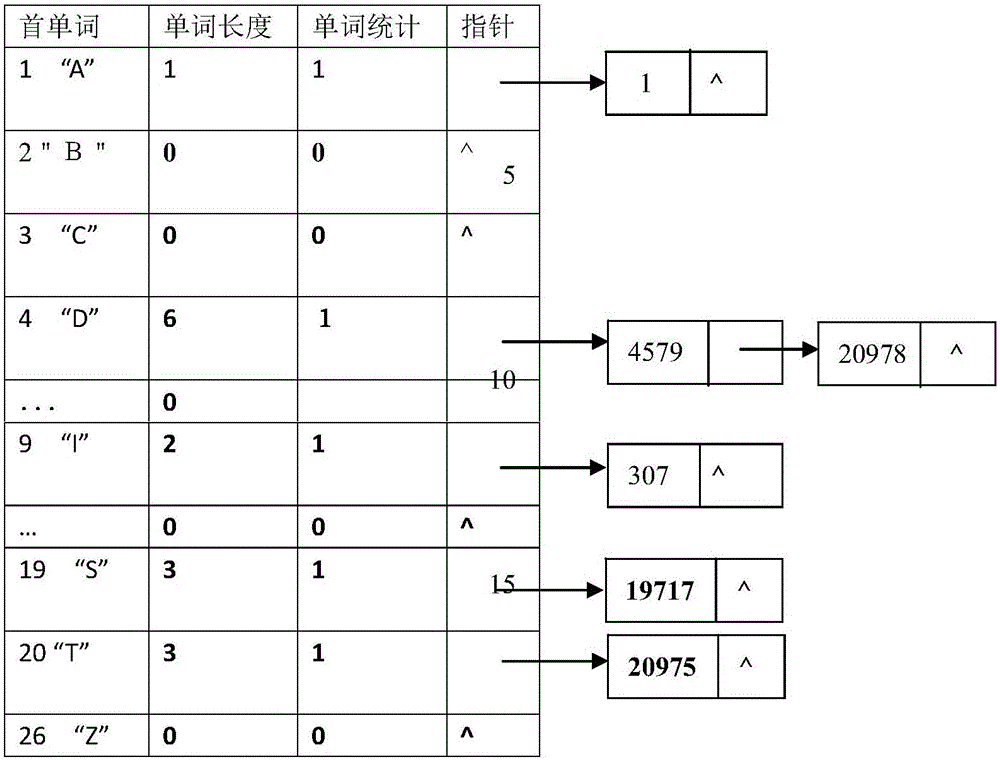

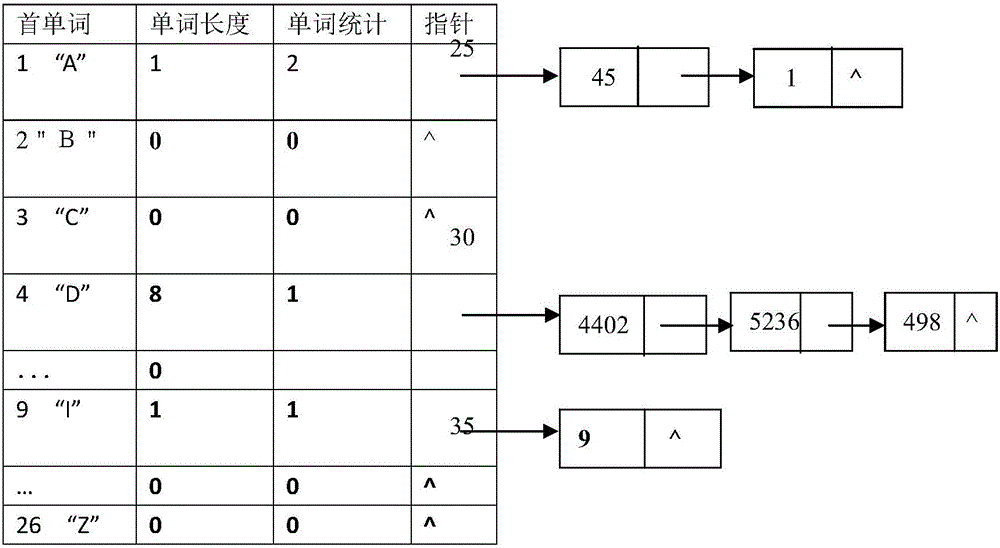

Code storage method, data storage structure of texts and method for compressed storage of texts and statistics output

ActiveCN105938469AText processingSpecial data processing applications16-bitTheoretical computer science

The invention discloses a code storage method, a data storage structure of texts, and a code storage method, data storage structure of texts with the core based on users' codes in a duotricemary notation set by capital letters and necessary punctuation marks. Users' codes in a duotricemary notation corresponding to every three characters in each word are converted according to binary system and stored in a 16-bit binary storage unit. In the data storage structure of texts, texts are stored in a hash tree. The hash tree comprises multiple table nodes orderly corresponding to users' codes in the duotricemary notation; each table node is a head node of a first-order link table and words with same initials or same characters can be stored in the first-order link table; as word nodes of subsequent nodes in the first-order link table, word nodes comprise fields for recording word lengths and the number of repeated words in texts; each word node is a first node of a second-order link table; as storage nodes of subsequent nodes in the second-order link table, each storage node is used for storing binary storage units for current words and character groups for repeated words divided by the rule in the code storage method applied in the claim 2.

Owner:DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com