A modified filter material for petroleum sewage treatment

A sewage treatment and filter material technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc., can solve the problems of inability to achieve sewage reinjection resource utilization, single filter material performance, and water quality oil content Advanced problems, to achieve the effect of shortening the sewage treatment process, low pressure, and small backwashing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

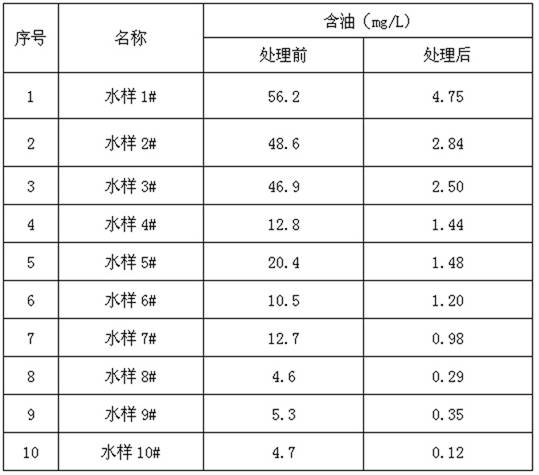

Examples

Embodiment 1

[0032] Embodiment 1, a kind of petroleum sewage treatment that the present invention mentions uses the modified filter material, and its modified formula adopts the composition of following parts by weight to make:

[0033] 0.5 parts of polyvinyl alcohol PVA, 6.2 parts of polyethylene glycol PEG, 0.12 parts of polydiallyl dimethyl ammonium chloride PDDA; polystyrene sulfonate sodium PSS: 5.3 parts.

[0034] A kind of petroleum sewage treatment that the present invention mentions uses the modified filter material, and the filter material modification process is as follows:

[0035] (a) Put 0.5 parts of polyvinyl alcohol PVA in water, stir and heat until boiling, dissolve it completely, and cool;

[0036] (b) Put 6.2 parts of polyethylene glycol PEG in water, stir and heat to dissolve it completely, and cool;

[0037] (c) Mix the above-mentioned polyvinyl alcohol PVA and polyethylene glycol PEG solutions according to the same volume, and set aside;

[0038] (d) Put 0.12 parts ...

Embodiment 2

[0045] Embodiment 2: The difference between the present invention and Embodiment 1 is: the modified formula of the filter material is made of the following components by weight, which improves the oleophobic effect and has a better effect on the treatment of sewage with high oil content:

[0046] 0.7 parts of polyvinyl alcohol PVA, 6.0 parts of polyethylene glycol PEG, 0.11 parts of polydiallyl dimethyl ammonium chloride PDDA; polystyrene sulfonate sodium PSS: 5.4 parts.

[0047] The modification process of the above-mentioned filter material is as follows:

[0048] (a) Put 0.7 parts of polyvinyl alcohol PVA in water, stir and heat until boiling, dissolve it completely, and cool;

[0049] (b) Put 6.0 parts of polyethylene glycol PEG in water, stir and heat to dissolve it completely, and cool;

[0050] (c) Mix the above-mentioned polyvinyl alcohol PVA and polyethylene glycol PEG solutions according to the same volume, and set aside;

[0051] (d) Put 0.11 parts of polydiallyld...

Embodiment 3

[0059] The difference between the present invention and Example 1 is that the modified formula of the filter material is made of the following components by weight, and it is aimed at the treatment of sewage containing light oil components in water and thorough oil-water emulsification:

[0060] 0.8 parts of polyvinyl alcohol PVA, 5.9 parts of polyethylene glycol PEG, 0.13 parts of polydiallyl dimethyl ammonium chloride PDDA; polystyrene sulfonate sodium PSS: 5.0 parts.

[0061] The modification process of the above-mentioned filter material is as follows:

[0062] (a) Put 0.8 parts of polyvinyl alcohol PVA in water, stir and heat until boiling, dissolve it completely, and cool;

[0063] (b) Put 5.9 parts of polyethylene glycol PEG in water, stir and heat to dissolve it completely, and cool;

[0064] (c) Mix the above-mentioned polyvinyl alcohol PVA and polyethylene glycol PEG solutions according to the same volume, and set aside;

[0065] (d) Put 0.13 parts of polydiallyldime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com