High-efficiency energy-saving granular filter and backflushing method

A high-efficiency and energy-saving technology for filter material filters, applied to loose filter material filters, gravity filters, chemical instruments and methods, etc., can solve the problems of frequent replacement of filter materials, complex scrubbing structure, and easy damage of scrubbing pumps, etc. Achieve the effect of backwashing with high efficiency and energy saving, eliminate backwashing dead angle, and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

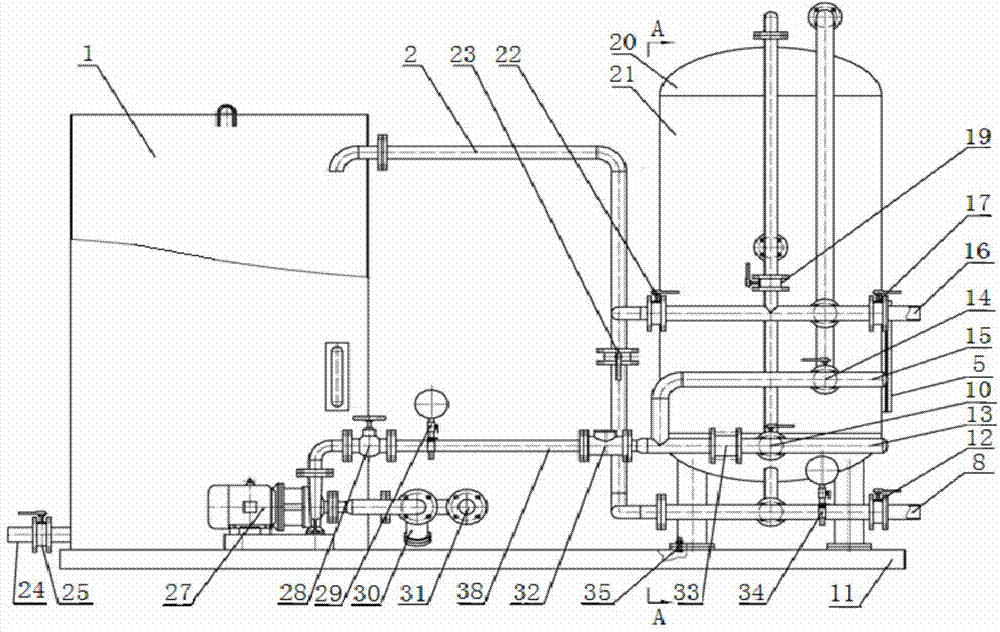

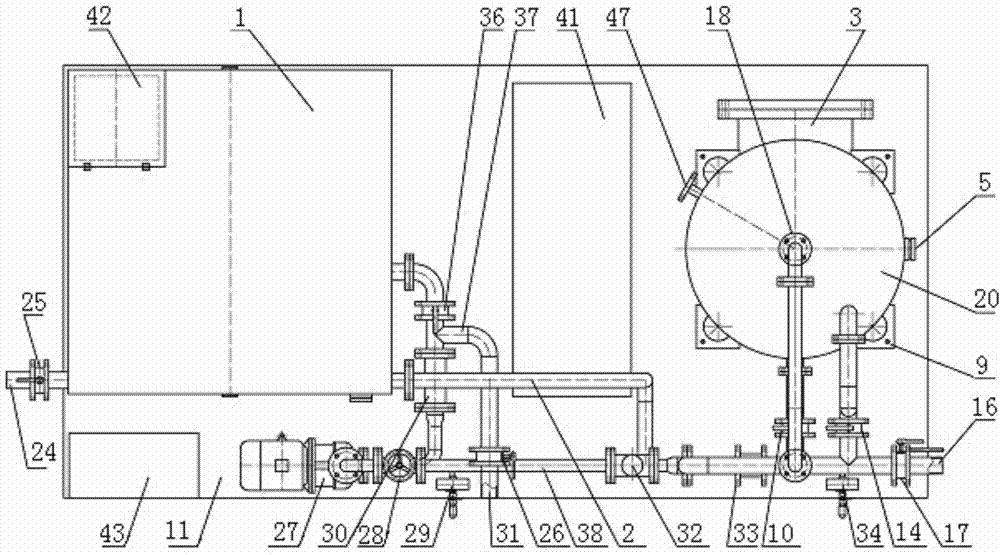

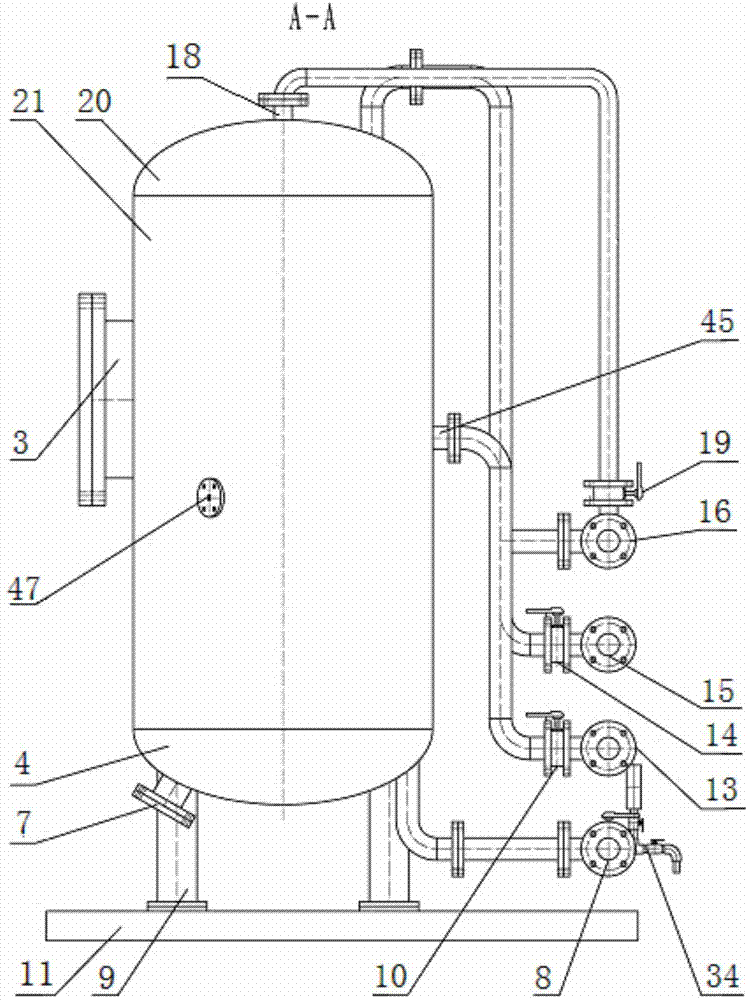

[0037] Embodiment 1: a kind of high-efficiency and energy-saving granular filter material filter and backwashing method provided by the present invention, the filter structure that it uses is as follows figure 1 , 2 , Shown in 3 and 4, comprise filter body, backwash assembly, backwash water tank 1, air compressor 41 and control system 43, granular filter material selects walnut shell as filter material in the present embodiment. The filter body is composed of an upper oval head 20 , a tank body 21 and a lower oval head 4 . In this embodiment, an upper screen tube / plate 44 of a screen structure is installed at the junction of the tank body 21 and the upper oval head 20 in the filter body; a screen is also installed at the junction of the tank body 21 and the lower oval head 4. The lower screen tube / plate 49 of the tube structure; the top center of the upper oval head 20 is provided with an oil discharge / air outlet 18, and the top of the upper oval head 20 is also provided with...

Embodiment 2

[0049] Embodiment 2: a kind of high-efficiency and energy-saving granular filter material filter provided by the present invention, its structure is basically the same as that of embodiment 1, the difference is only that the upper screen tube / plate 44 and the lower screen tube / plate 49 all adopt a The structure of the entire sieve plate and 16 backwashing nozzles are installed, and only one row of nozzles 54 is arranged on the cylinder 53 of the backwashing nozzle 48, and there are 18 nozzles in total. The central angles between the two nozzles are equal, α= 20°.

Embodiment 3

[0050] Embodiment 3: a kind of high-efficiency and energy-saving granular filter material filter provided by the present invention, its structure is basically the same as embodiment 2, the difference is that 10 backwash nozzles are installed, and on the cylindrical body 3 of backwash nozzle 48 There are 3 rows of nozzles 4, each row has 6 nozzles, the central angles between the two nozzles are equal, α=11°, the first row of nozzles is aligned with the third row of nozzles, the second row of nozzles is aligned with the first and third rows The nozzles are misplaced, and the misalignment angle is (1 / 2)α=30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com