V-shaped belt type dewatering equipment self-adaptive to sludge concentration and application of V-shaped belt type dewatering equipment

A sludge concentration and belt-type dehydration technology, which is applied in water/sludge/sewage treatment, sludge treatment, water treatment parameter control, etc., can solve the difficult problems of sludge energy-saving and reduction treatment, high energy consumption, and flushing water volume Larger requirements, etc., to achieve stable sludge dewatering effect, small workshop area, and guaranteed flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

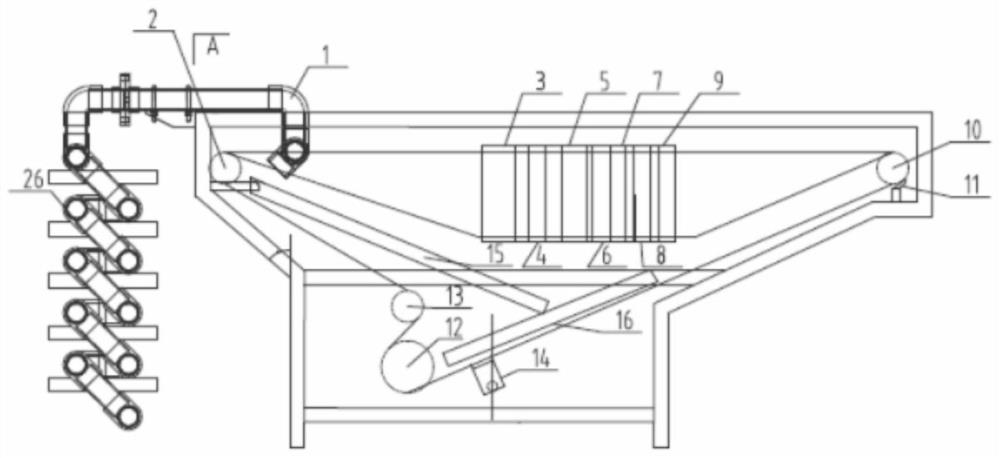

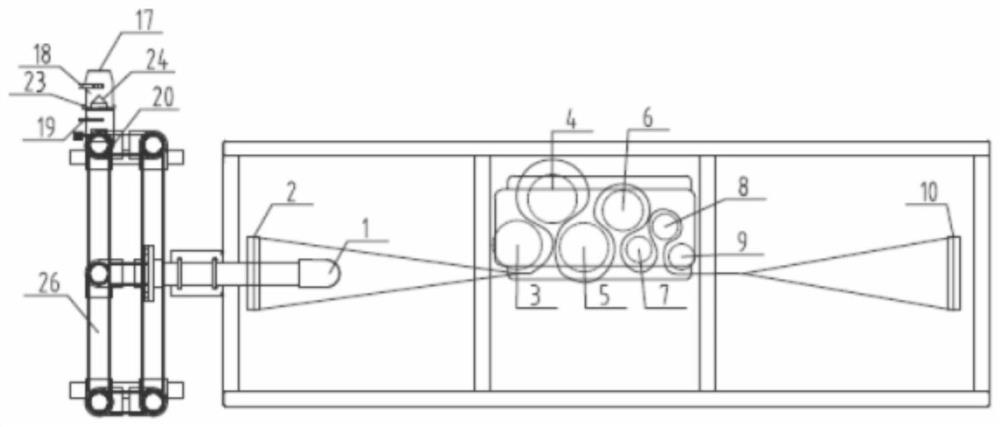

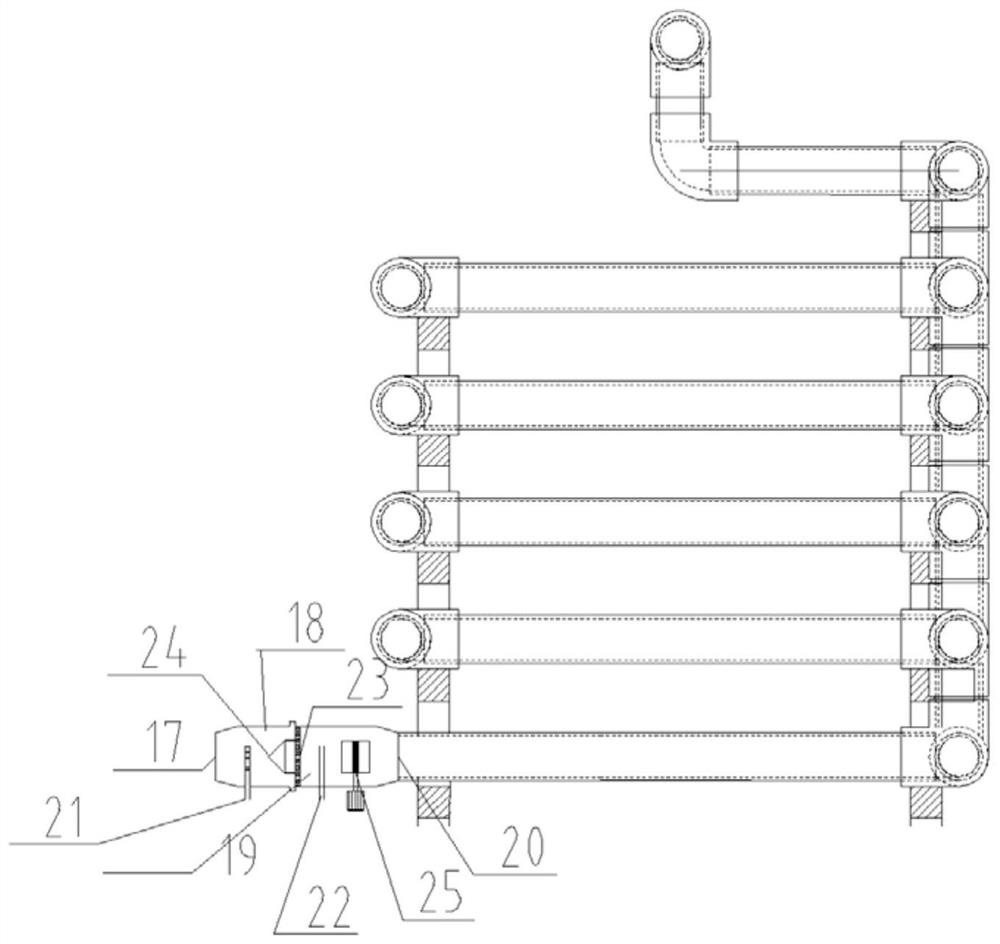

[0143] In the V-belt dewatering equipment with adaptive sludge concentration provided by the present invention, the sludge from the process flow of the sewage plant is input into the first mixing pipe body 18 of the first mixing unit through the sludge inlet 17, and the sludge is mixed with the The flocculant input from the first flocculant inlet pipe 21 is mixed in the first mixing pipe body 18 and enters into the second mixing pipe body 19 through the baffle plate 24 with a cone angle and the porous partition plate 23 . In the second mixing pipe body 19, the sludge is again mixed with the flocculant introduced into the second flocculant introduction pipe 22, and the stirring mechanism 25 is rotated and stirred by the stirring paddle driven by the motor, so that the sludge is fully mixed and coagulated thoroughly. Then, it is input into the second mixing unit 26 through the mud discharge port 20 for mixing, and the second mixing unit 26 is selected as a pipeline mixing part or...

Embodiment 2

[0146] The designed sewage treatment scale of a municipal sewage treatment plant is 50,000 m 3 / d, the sludge output is about 40t / d (based on the sludge moisture content of 80%). It is planned to dry the sludge after dehydration. The above-mentioned V-belt dehydration equipment with self-adaptive sludge concentration can automatically adjust the dosing amount according to the sewage influent water quality. When the influent water quality changes, the sludge produced is also different. In order to better remove the sewage The water in the mud should be added with coagulant according to the situation of the sludge, so as to turn the suspended matter of small molecules into aggregates of macromolecules. Using the first mixing unit and the second mixing unit 26 to modify the sewage sludge is more conducive to subsequent pressing and dehydration.

[0147] Choose two sets of V-belt dewatering equipment with adaptive sludge concentration with a bandwidth of 0.75m. When operating at ...

Embodiment 3

[0149] The designed sewage treatment scale of a municipal sewage treatment plant is 40,000 m 3 / d, the sludge output is about 32t / d (based on the sludge moisture content of 80%). The sludge of this plant needs to be dehydrated before being transported abroad, and due to its limited scale, its water plant occupies a relatively small area. The above-mentioned V-belt dehydration equipment with adaptive sludge concentration is adopted. The sewage plant mainly collects urban sewage, the total amount of sewage changes little, and the water quality fluctuates in a small range. And because the overall scale of the water plant is small, the use of the above-mentioned V-belt dewatering equipment that adapts to the sludge concentration can reduce operation and maintenance, reduce the number of staff, and can monitor the sludge inflow, change the dosage of chemicals in real time, and reduce the amount of chemicals inputs.

[0150] Two sets of V-belt dewatering equipment with adaptive s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com