Patents

Literature

41results about How to "Small extension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

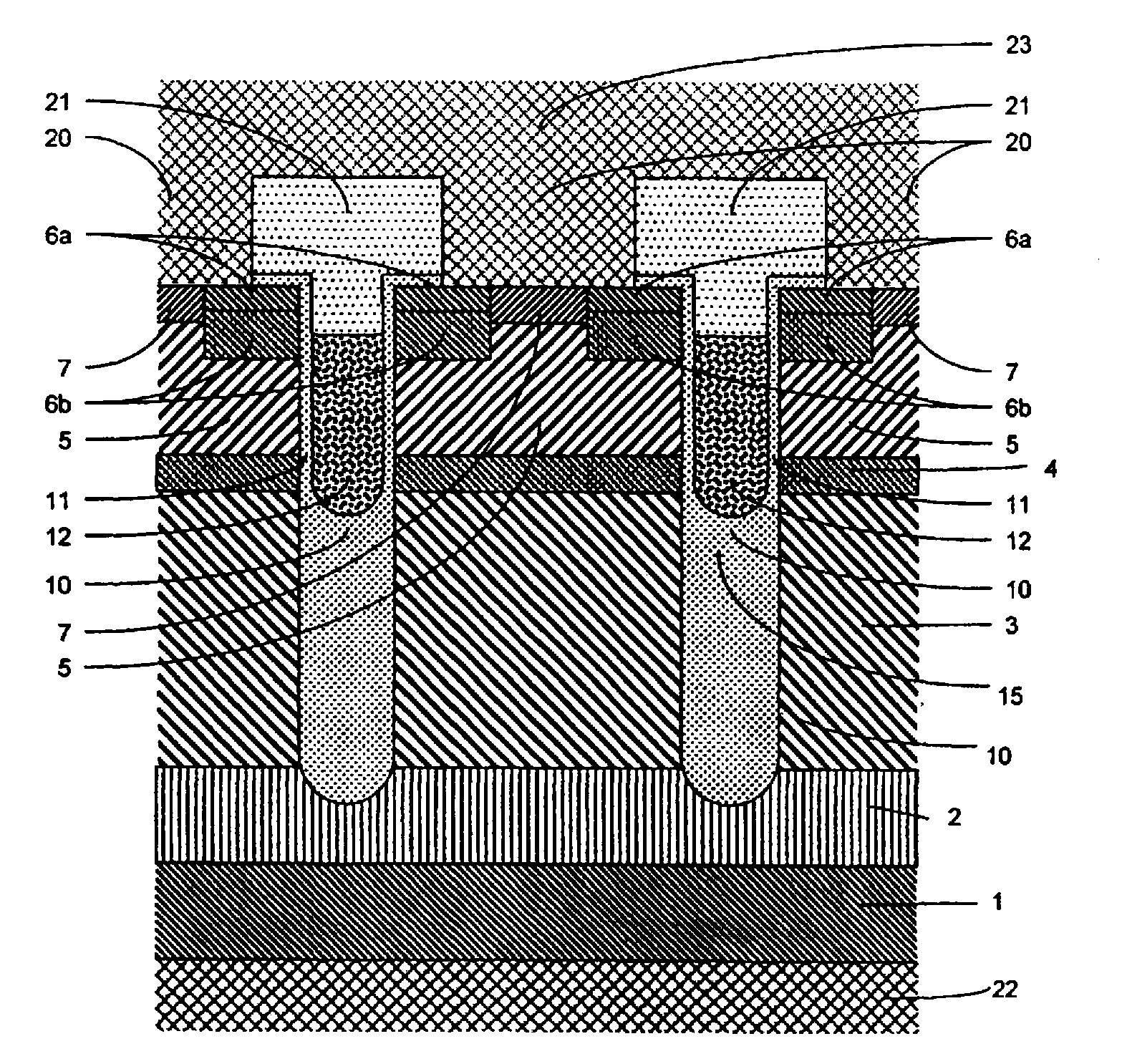

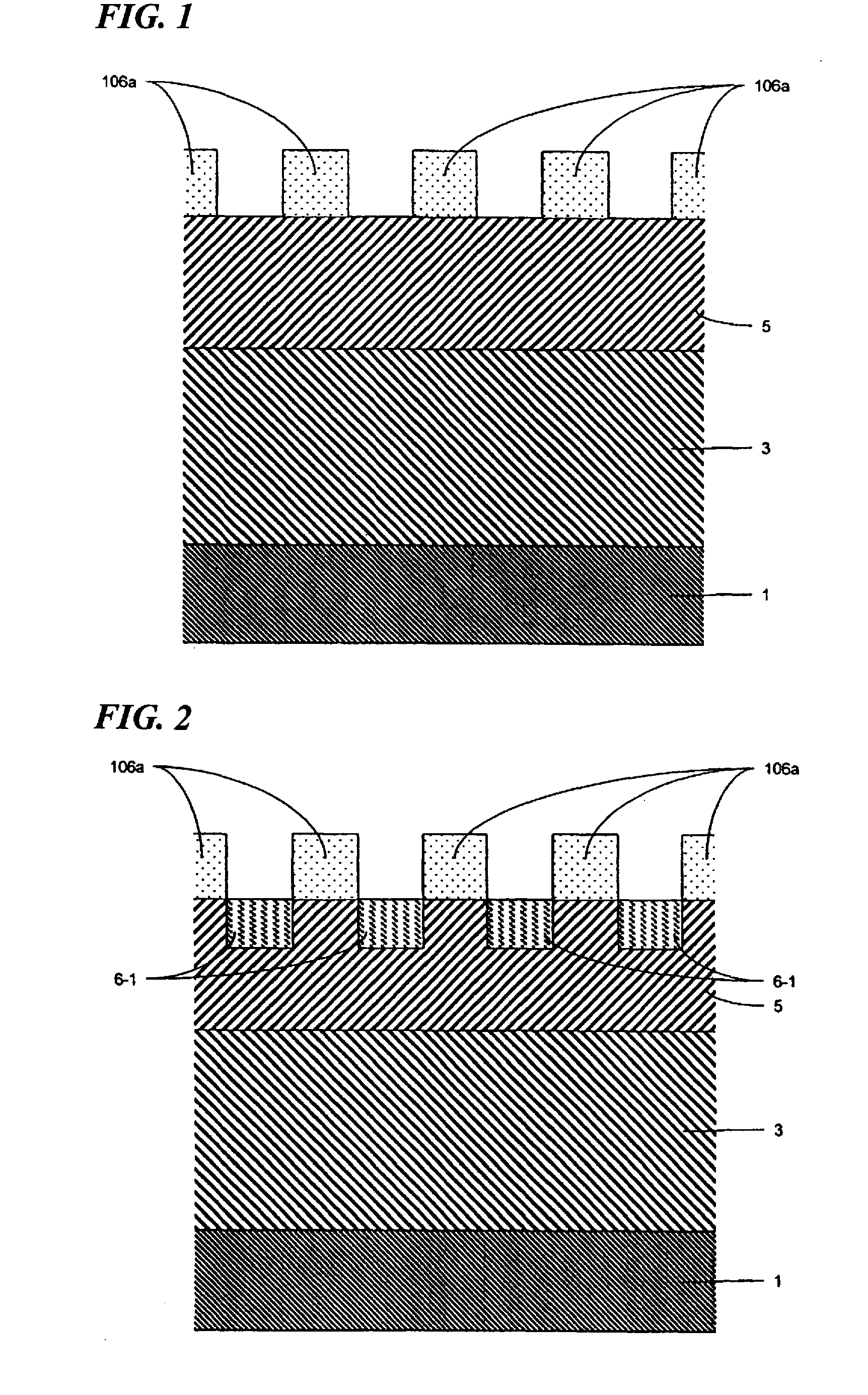

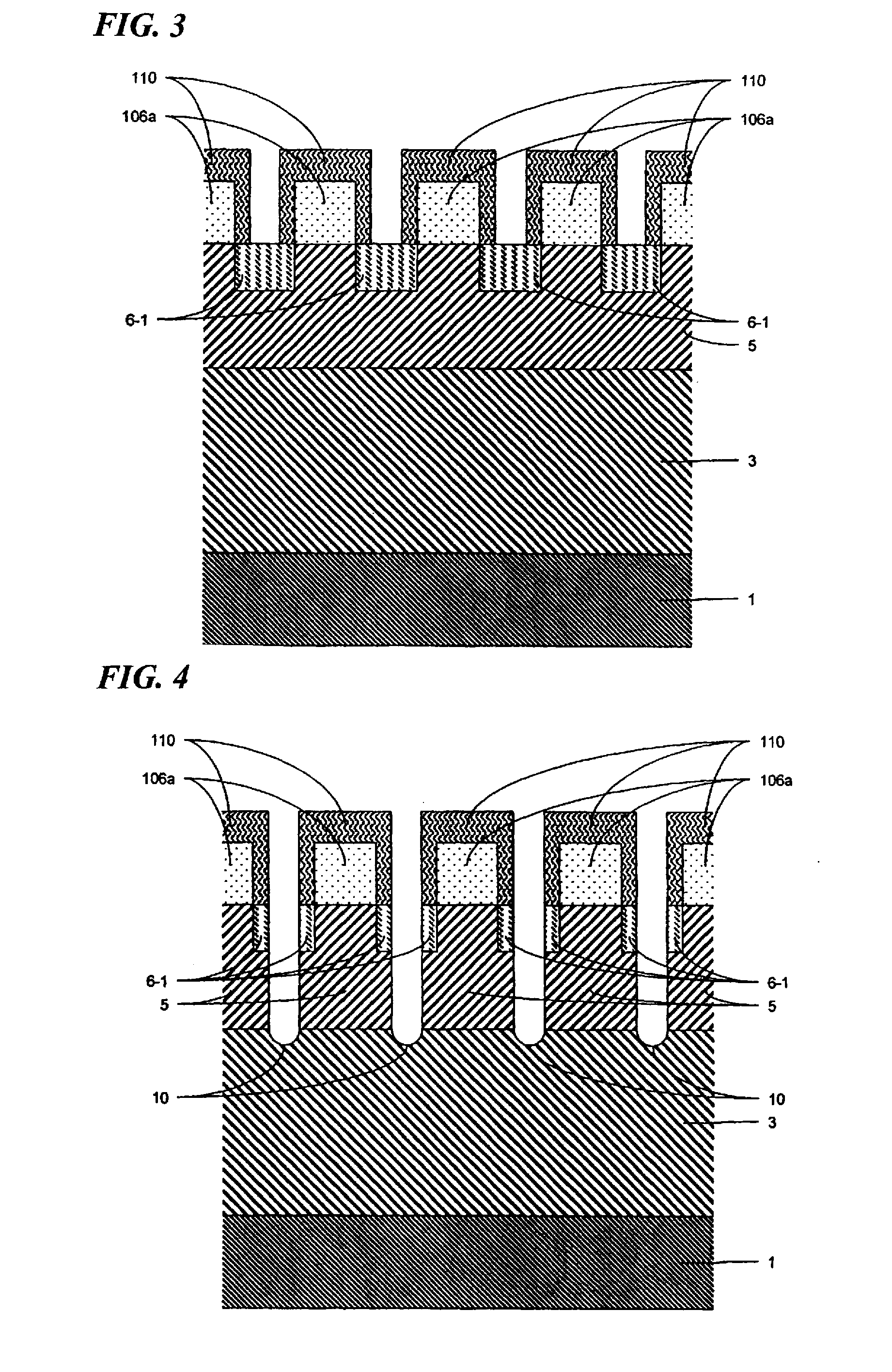

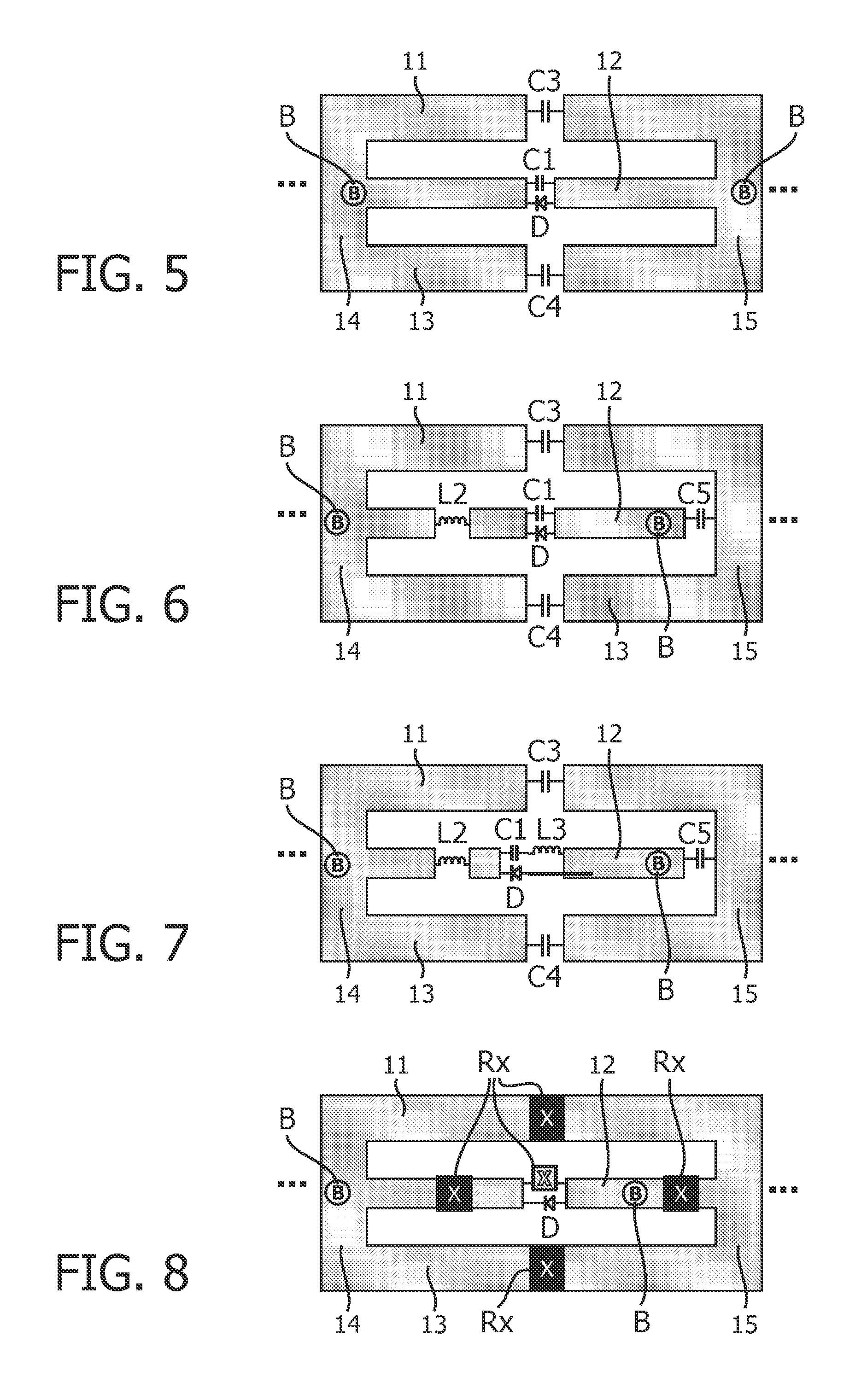

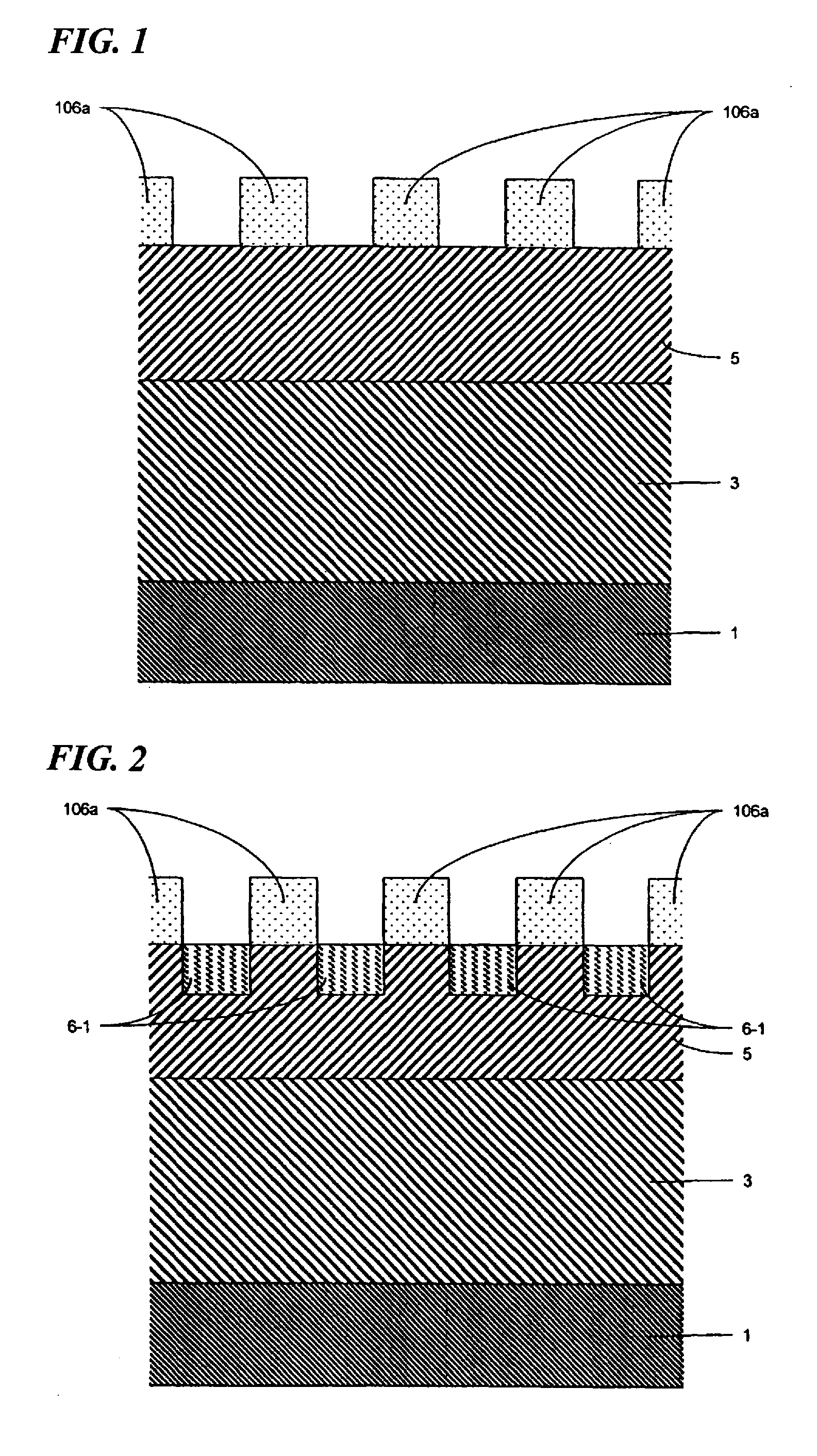

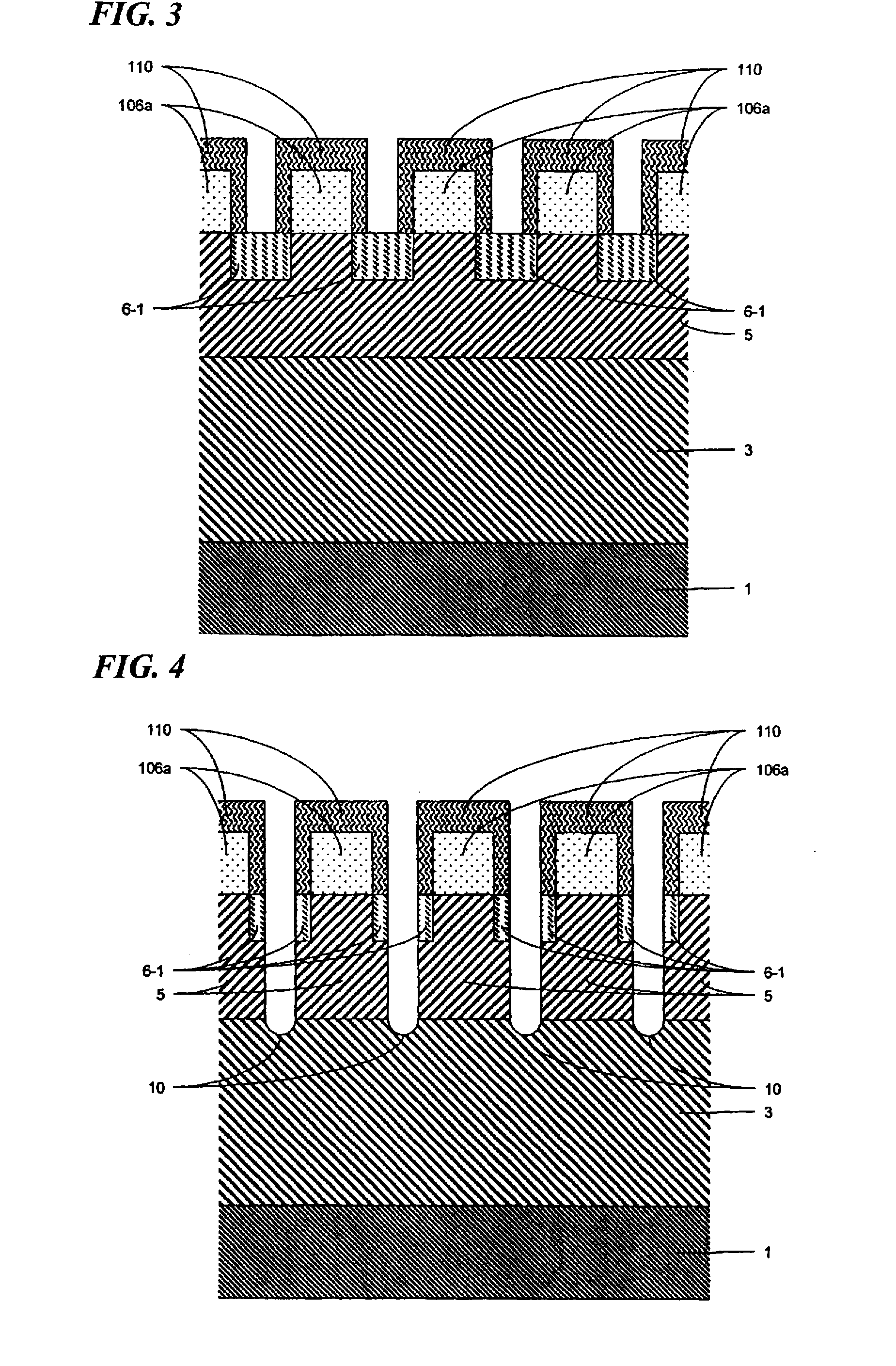

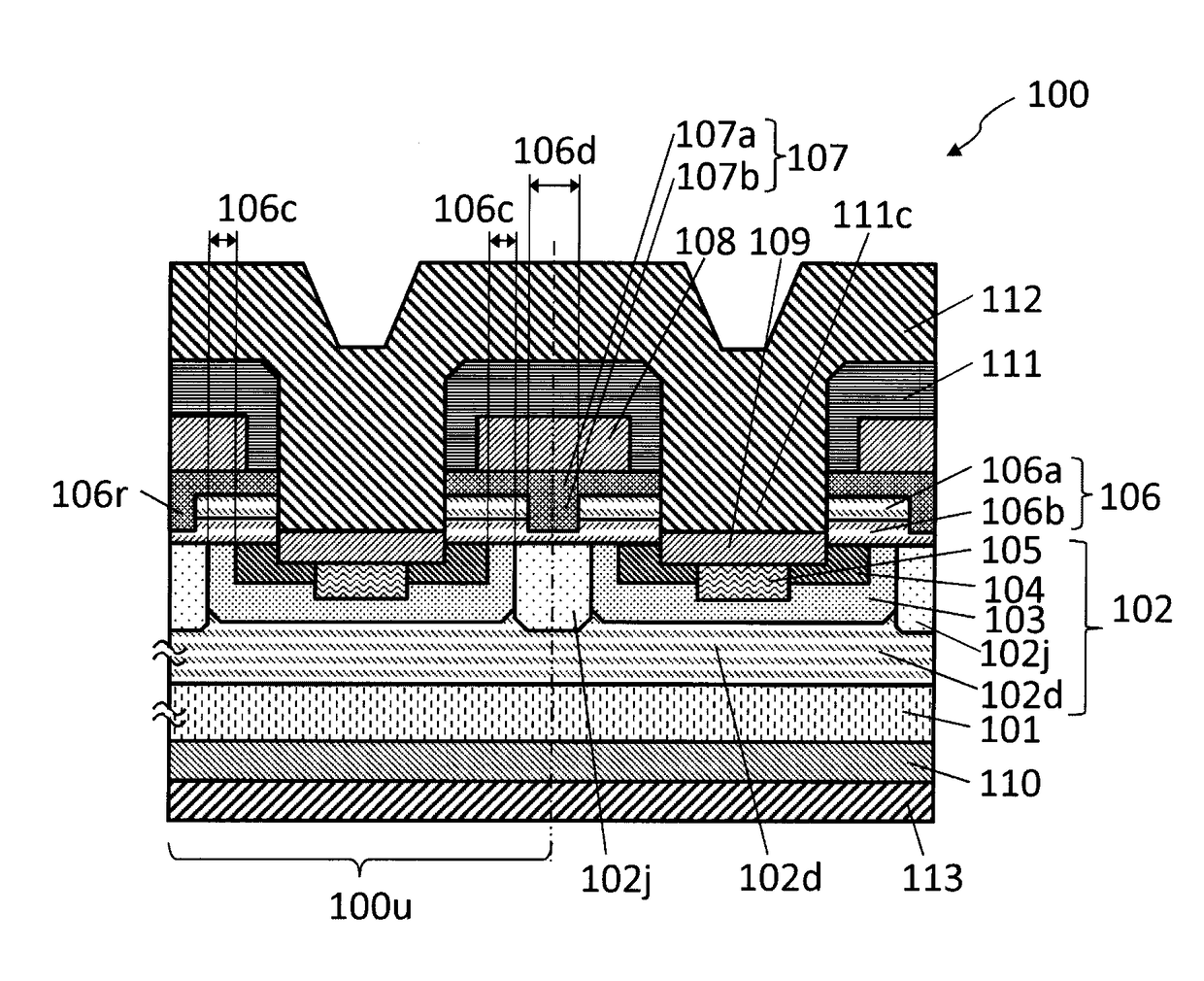

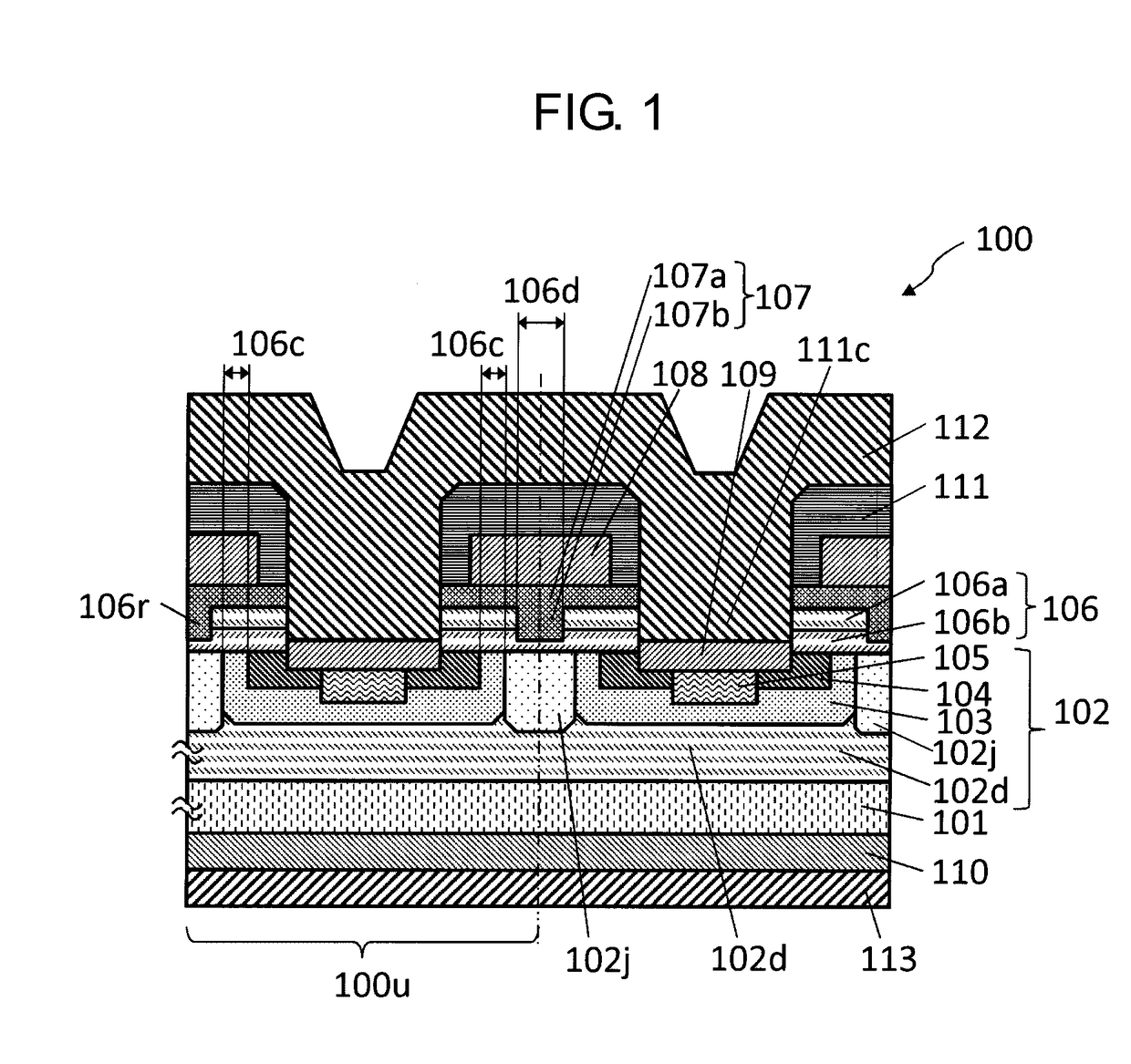

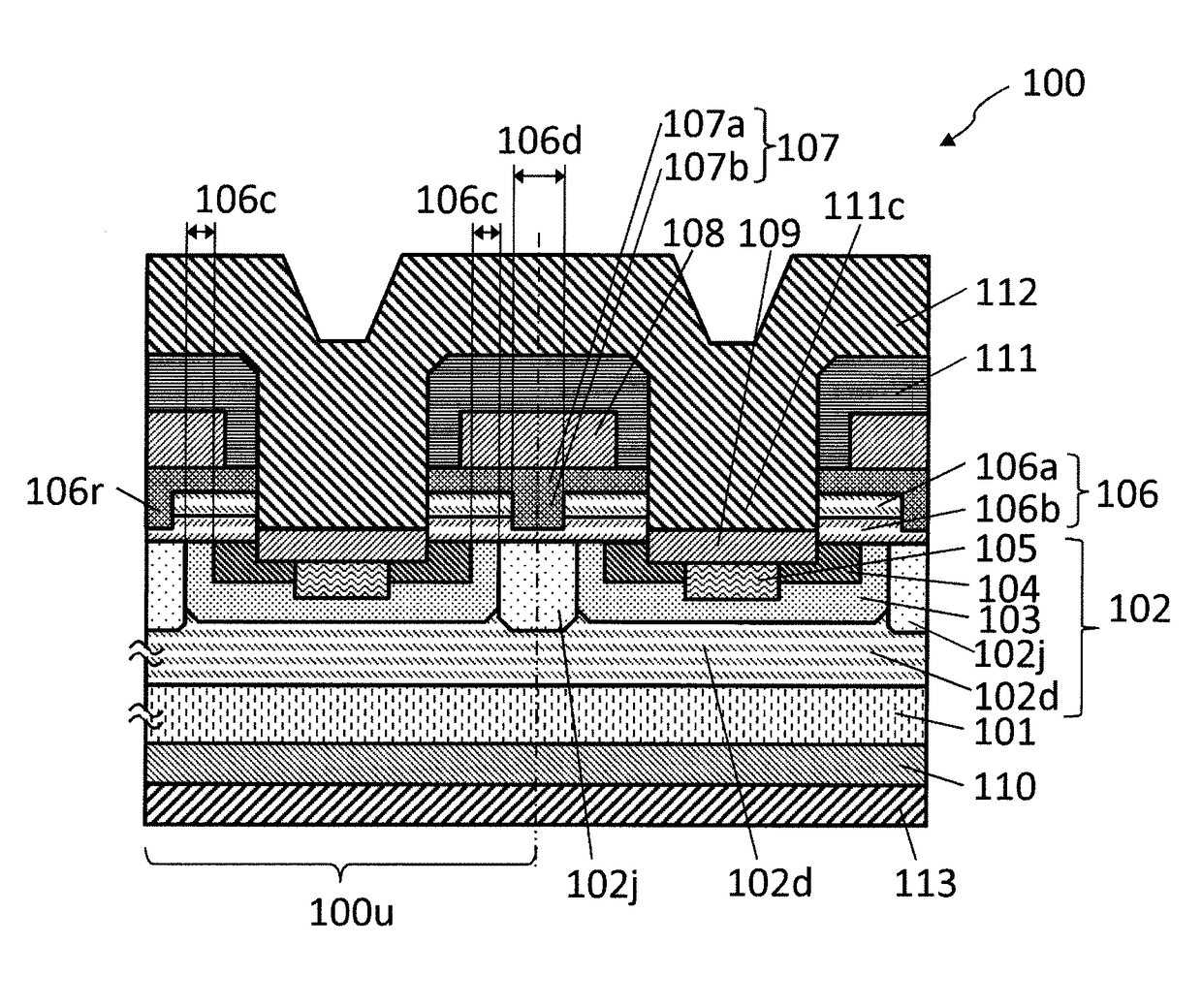

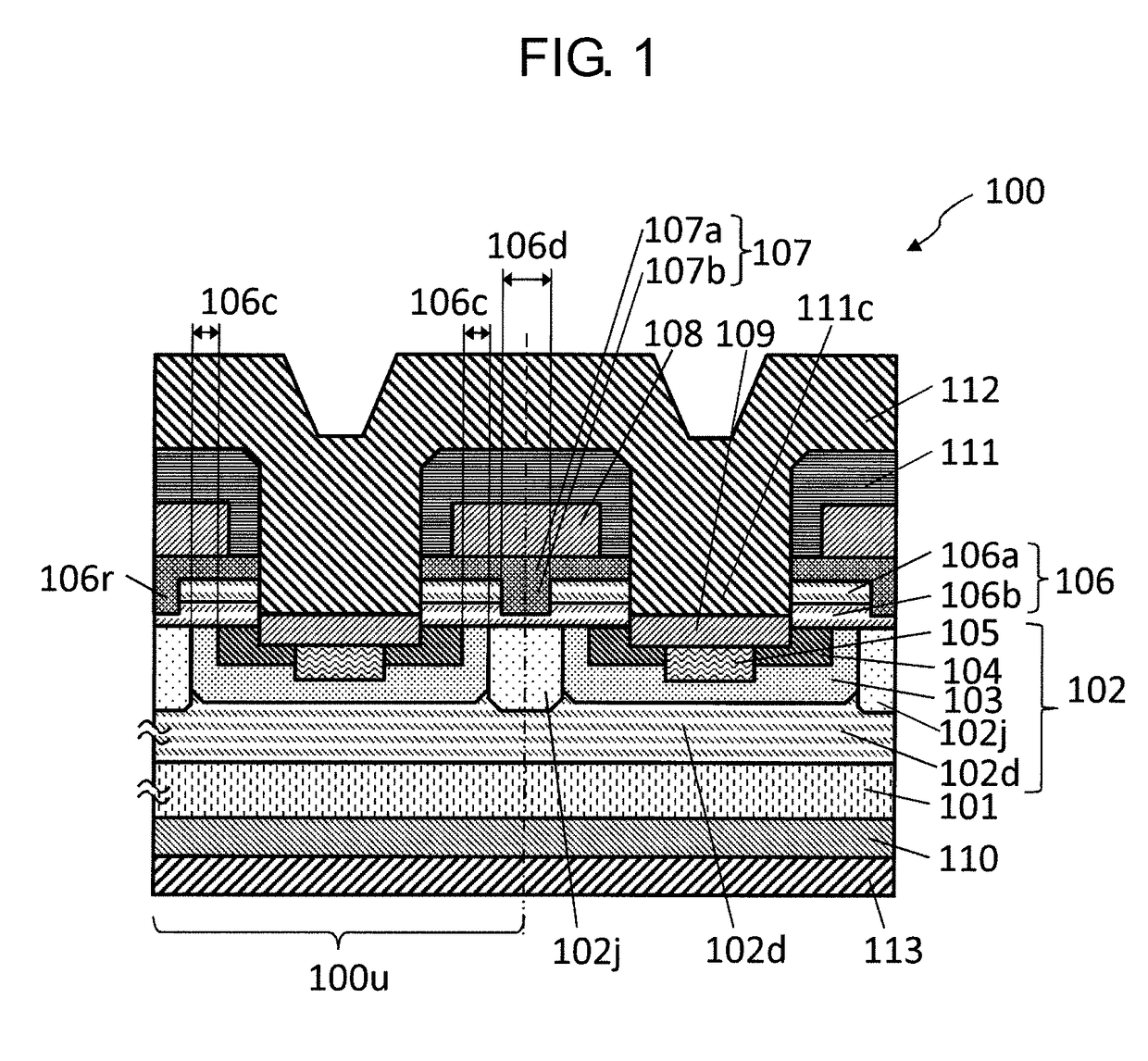

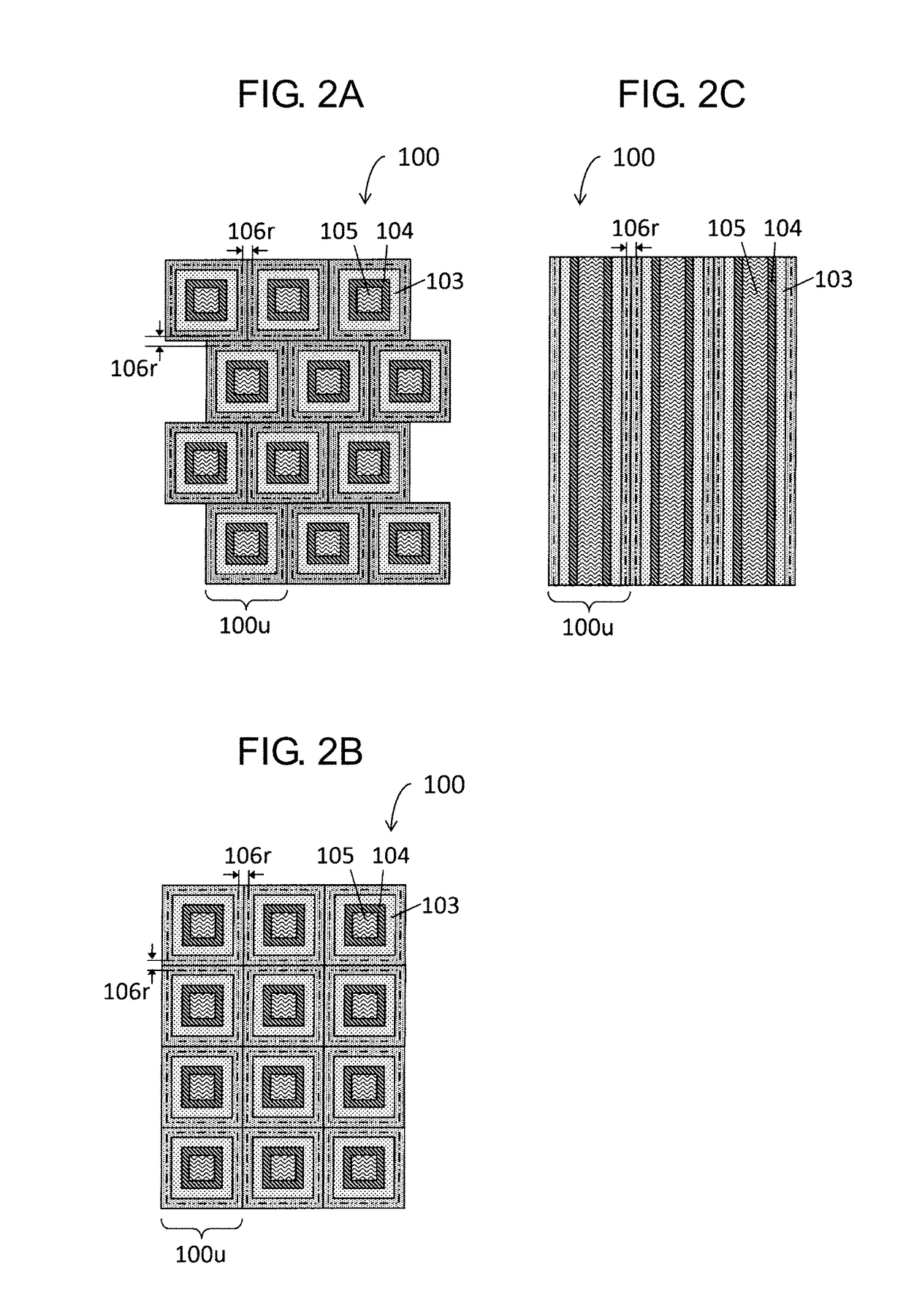

Trench gate type semiconductor device and method of producing the same

InactiveUS20090272982A1Good ohmic contactExcessive electric field is preventedTransistorSemiconductor/solid-state device manufacturingMOSFETOhmic contact

A method of producing a trench gate type MOSFET is provided in which each intersection trench is formed as a two-stage trench structure. A gate trench is backfilled with a mask material and the mask material is then patterned to form a mask used for forming each intersection trench. The intersection trench intersecting the gate trench is provided so as to be deeper than the gate trench. A Schottky electrode is provided in the bottom of each intersection trench 10p. In this manner, there is provided a trench gate type semiconductor device and a method of producing the same, in which: the cell pitch can be reduced even when a wide band gap semiconductor is used as a main semiconductor substrate; good ohmic contacts can be obtained; and an excessive electric field is prevented from being applied to an insulating film in the bottom of each trench.

Owner:FUJI ELECTRIC CO LTD

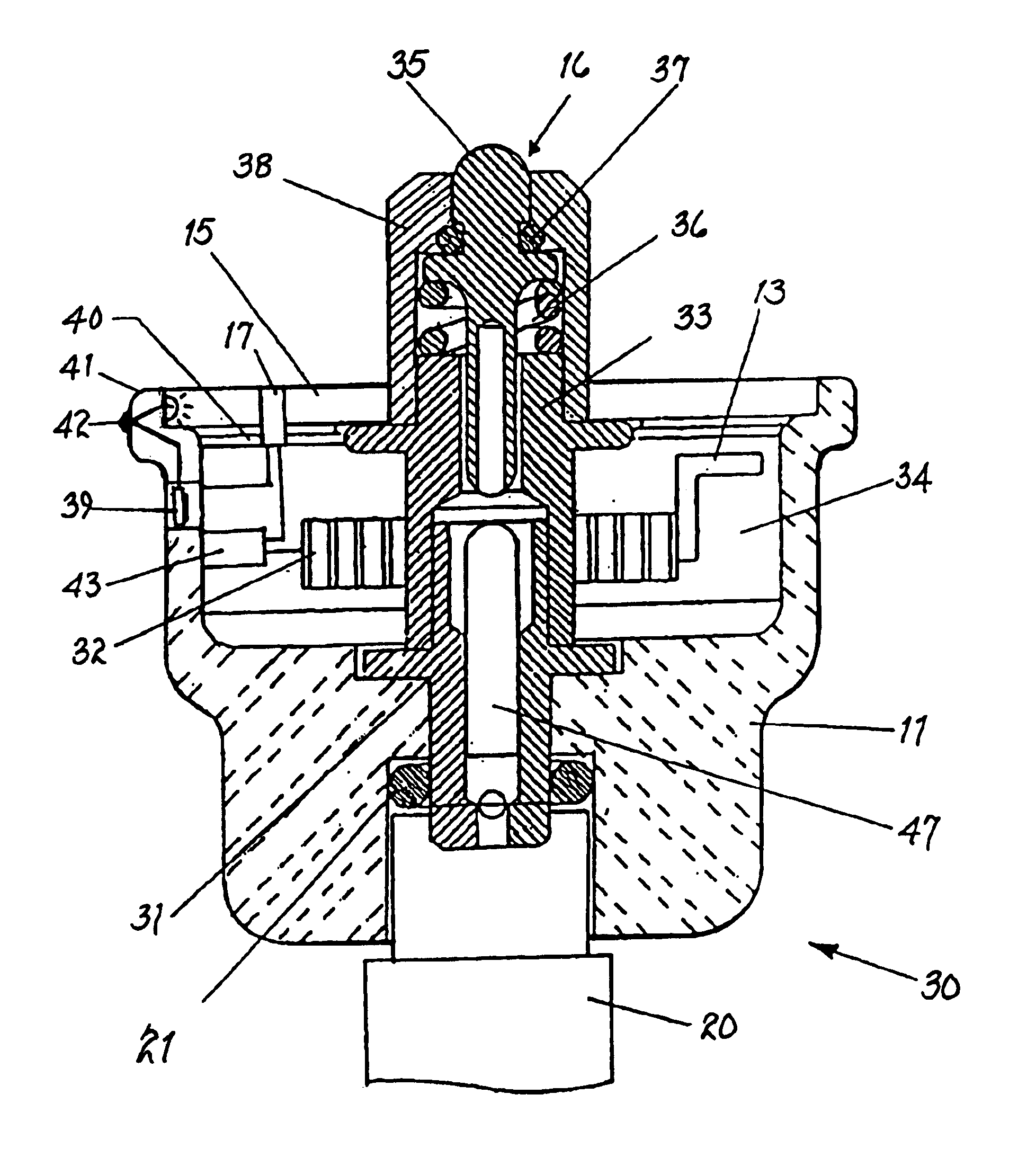

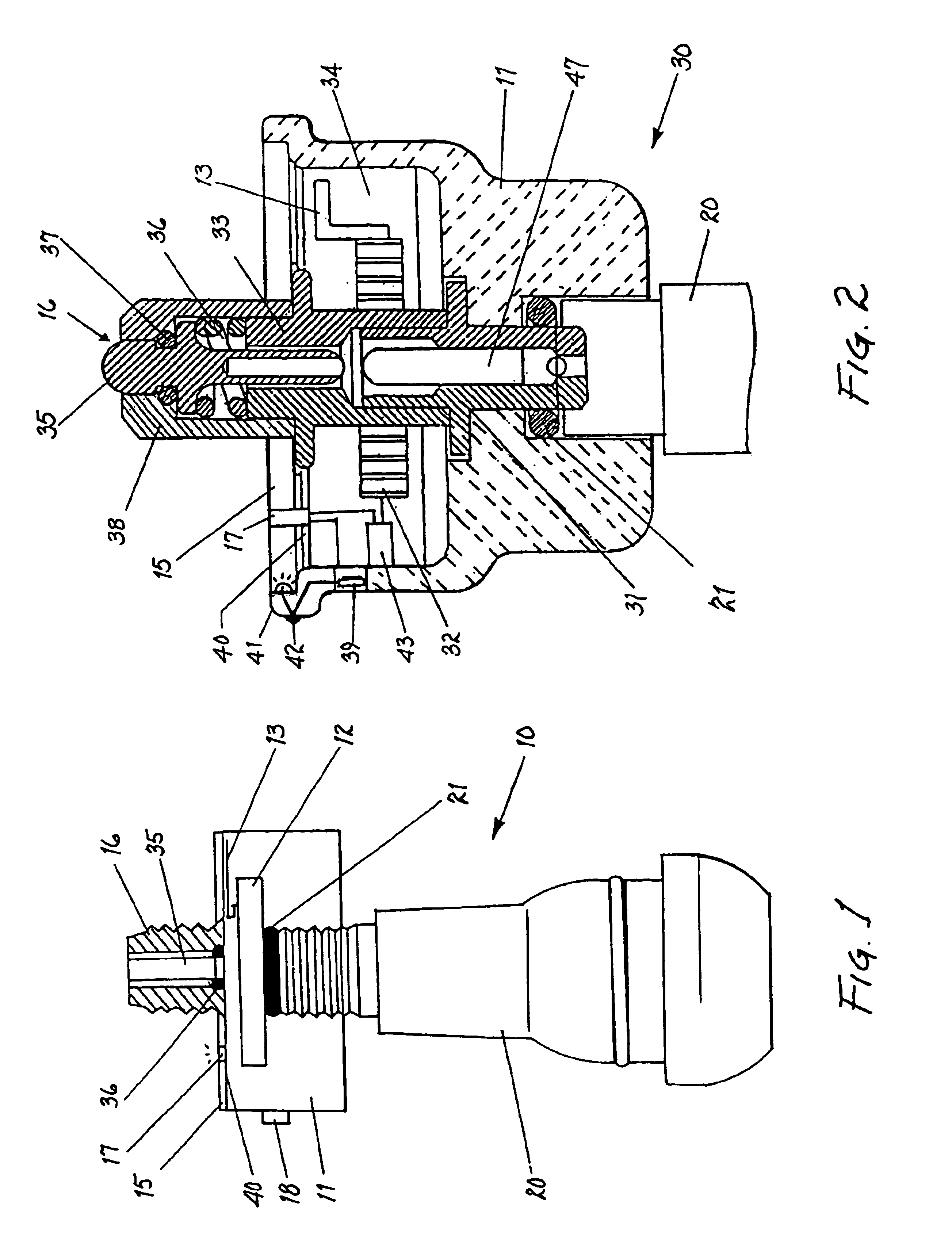

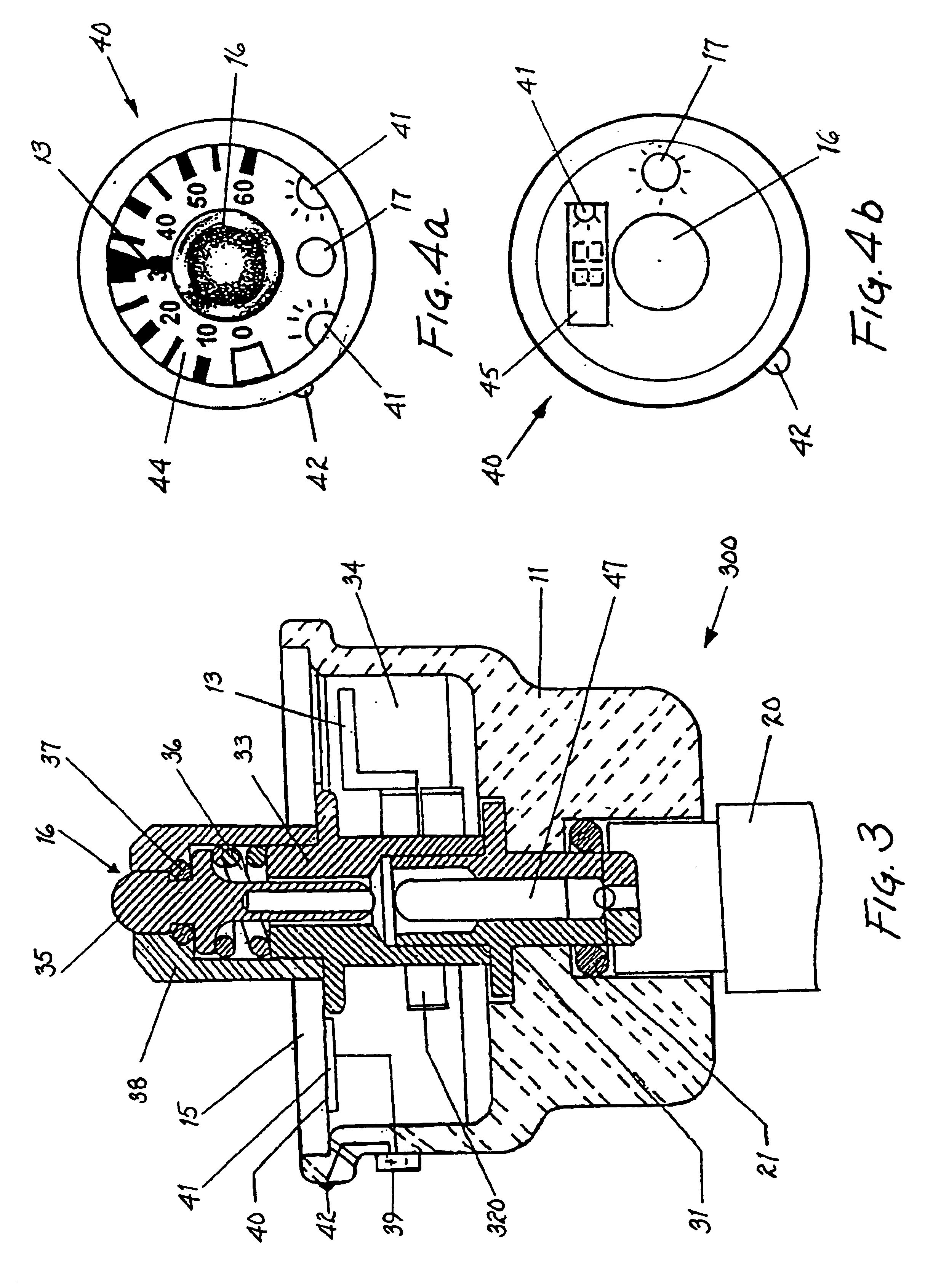

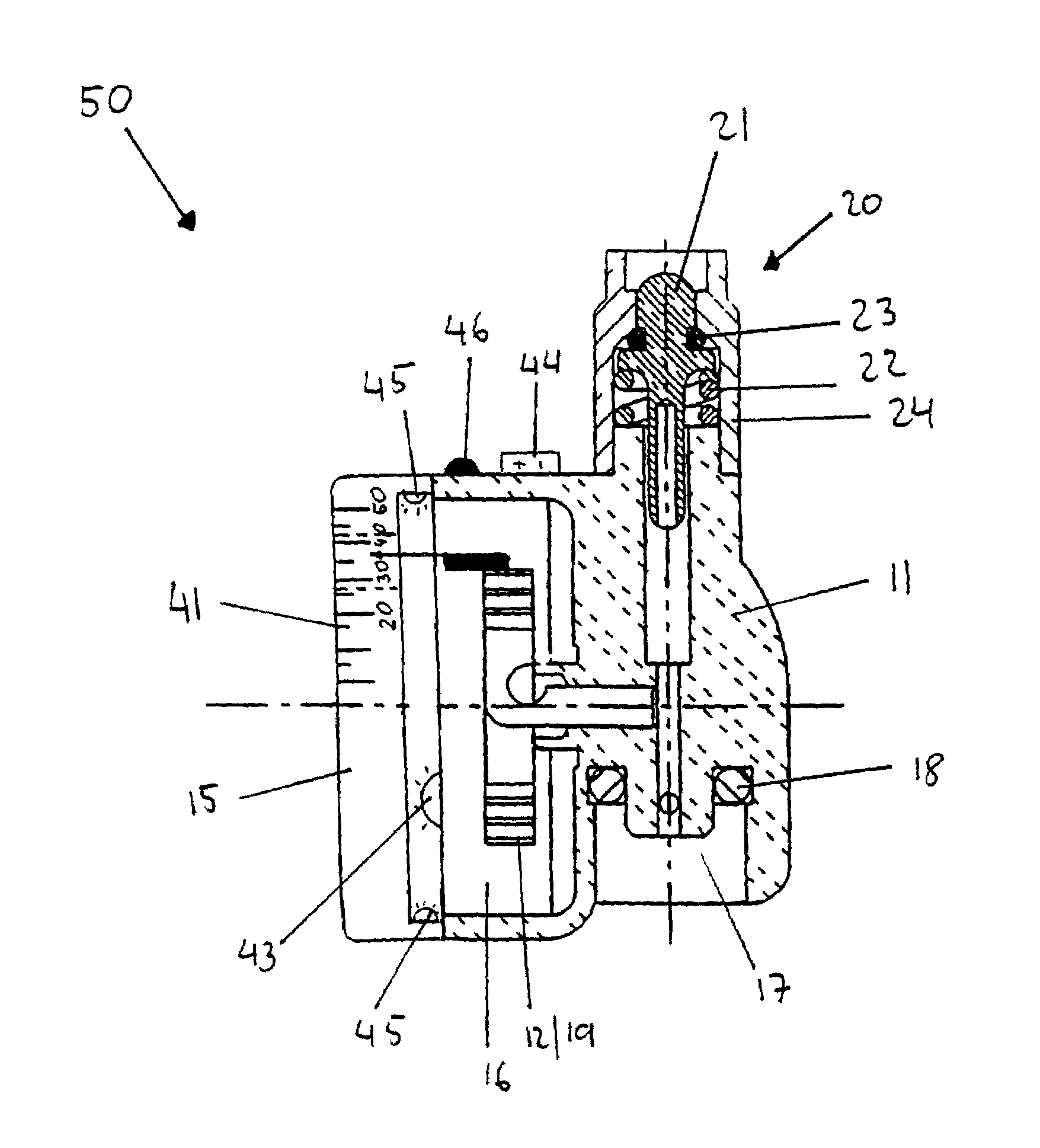

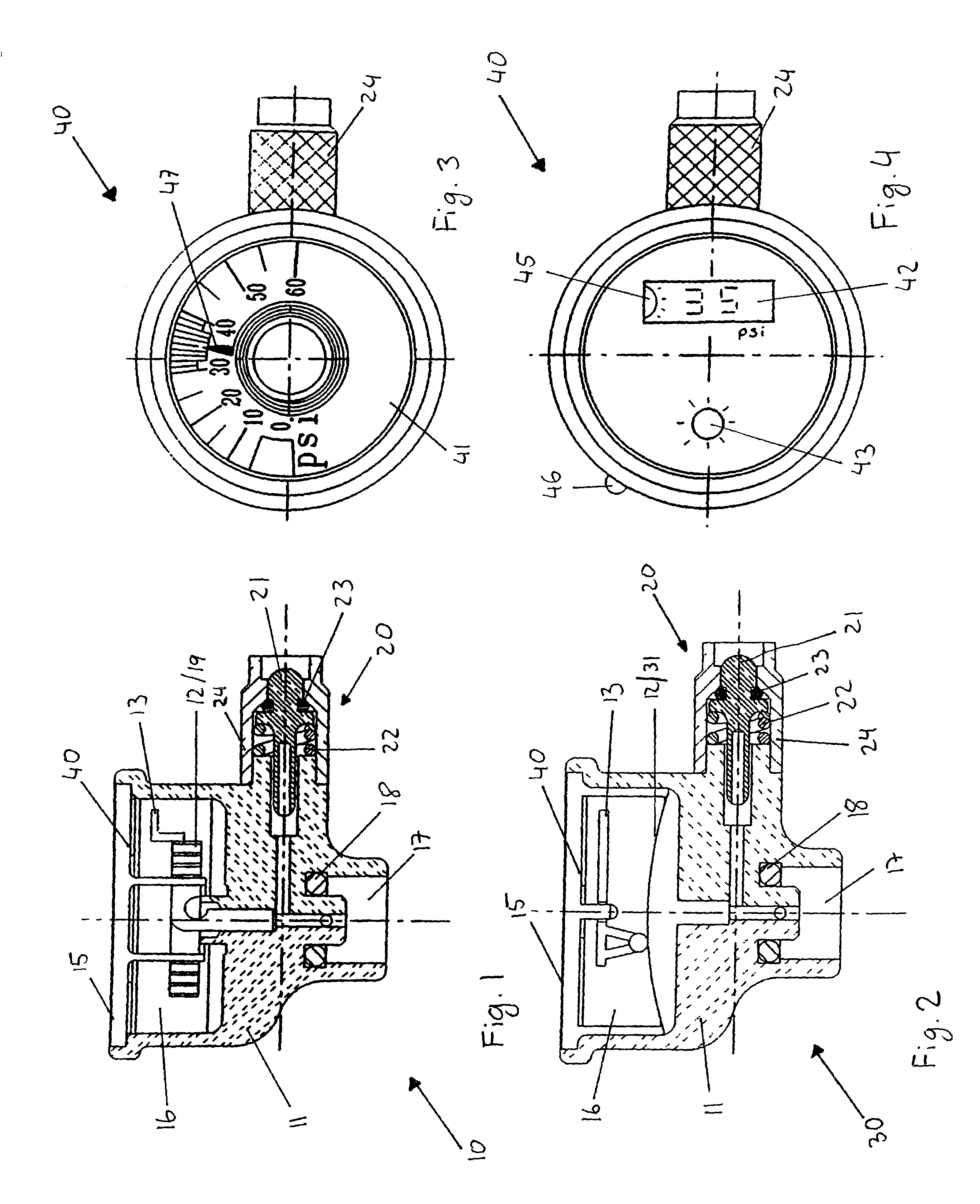

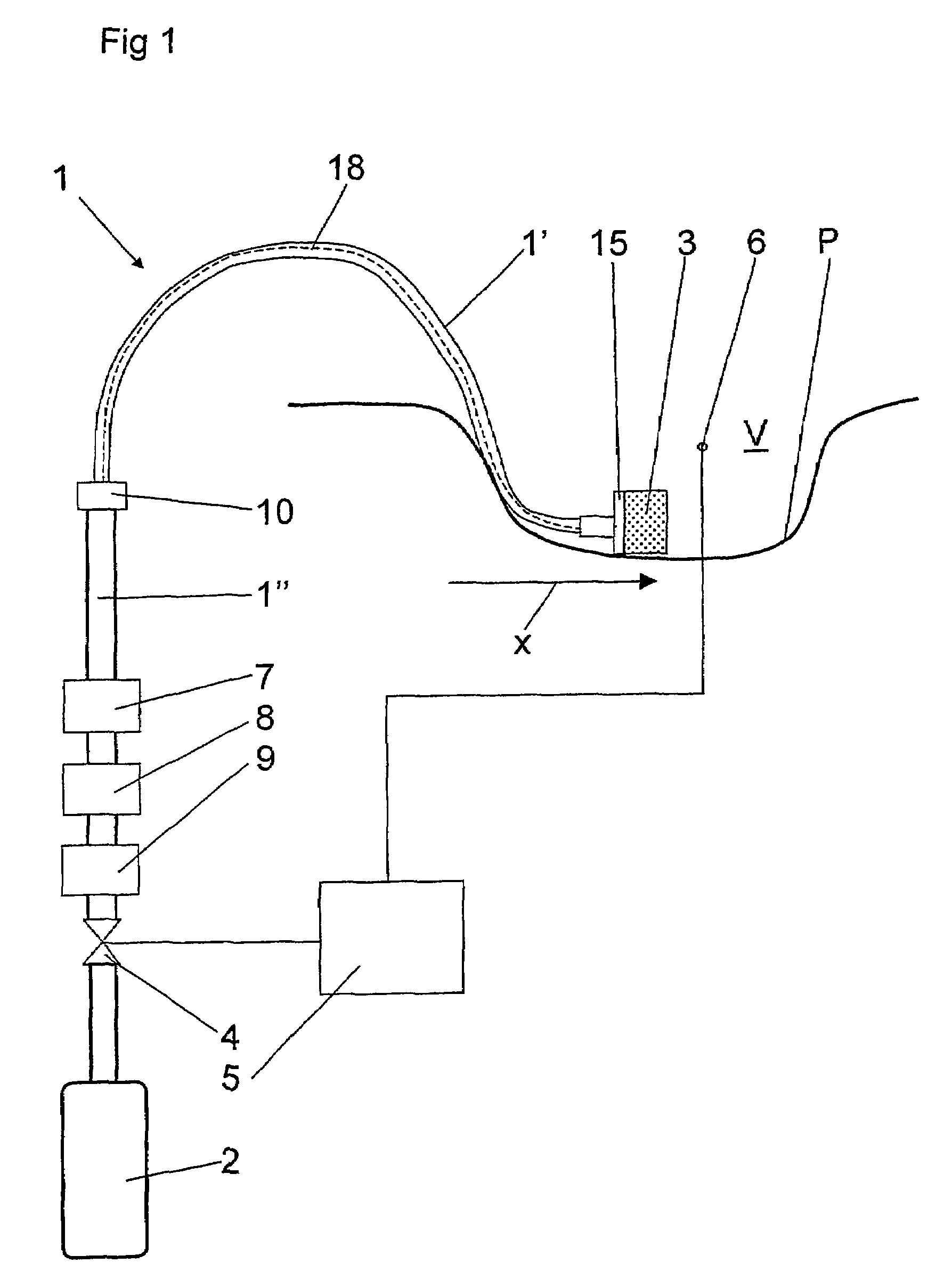

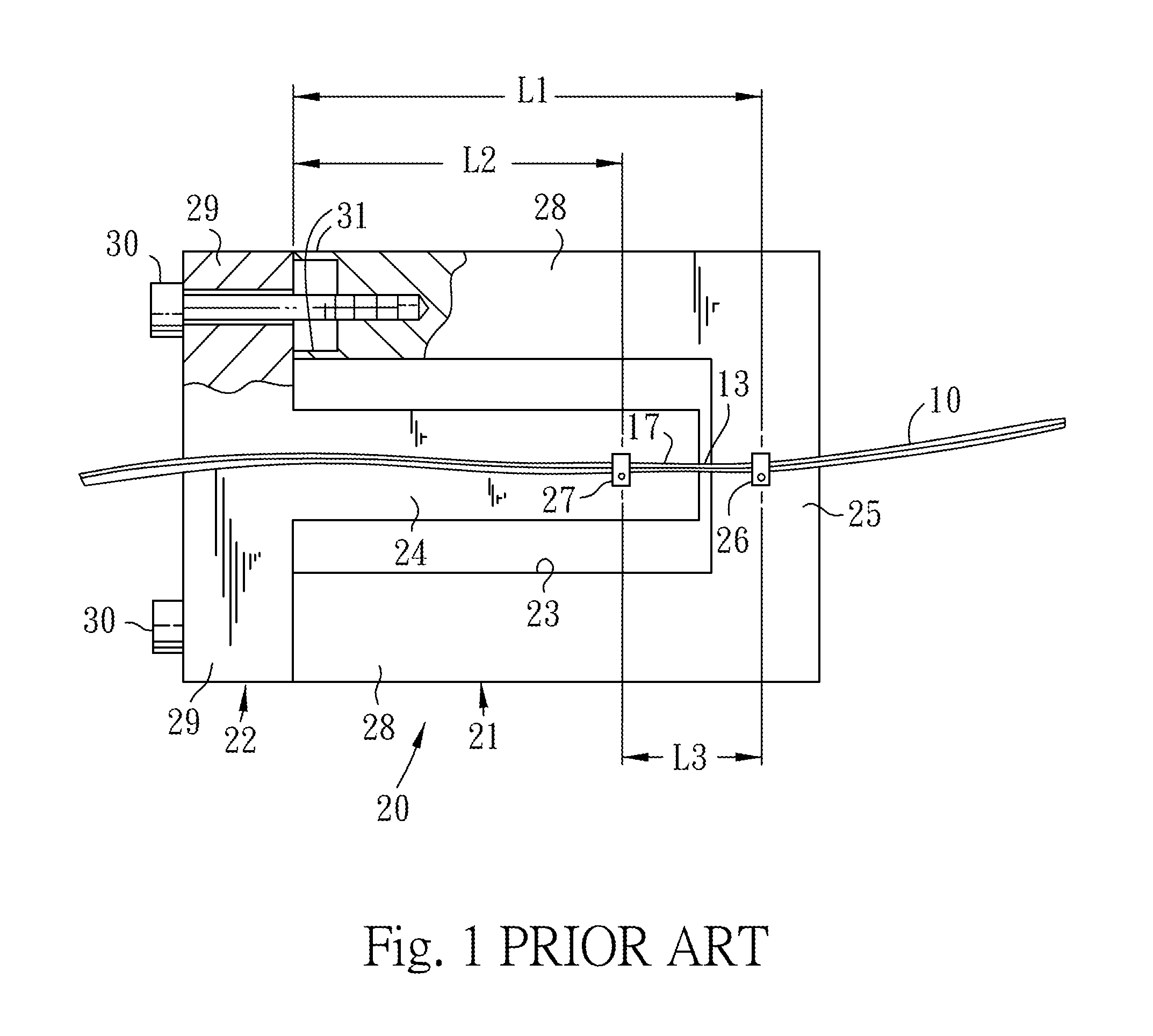

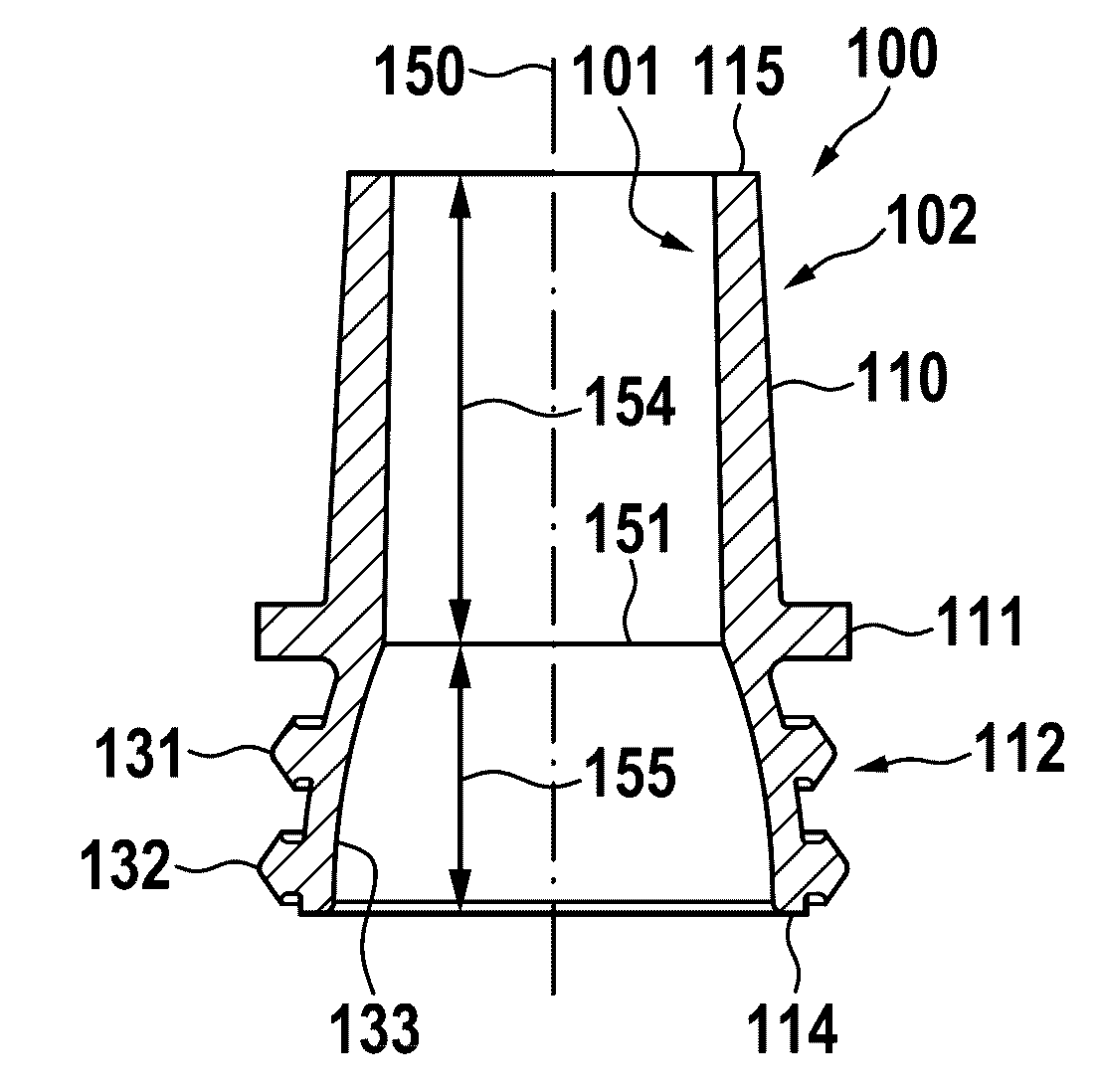

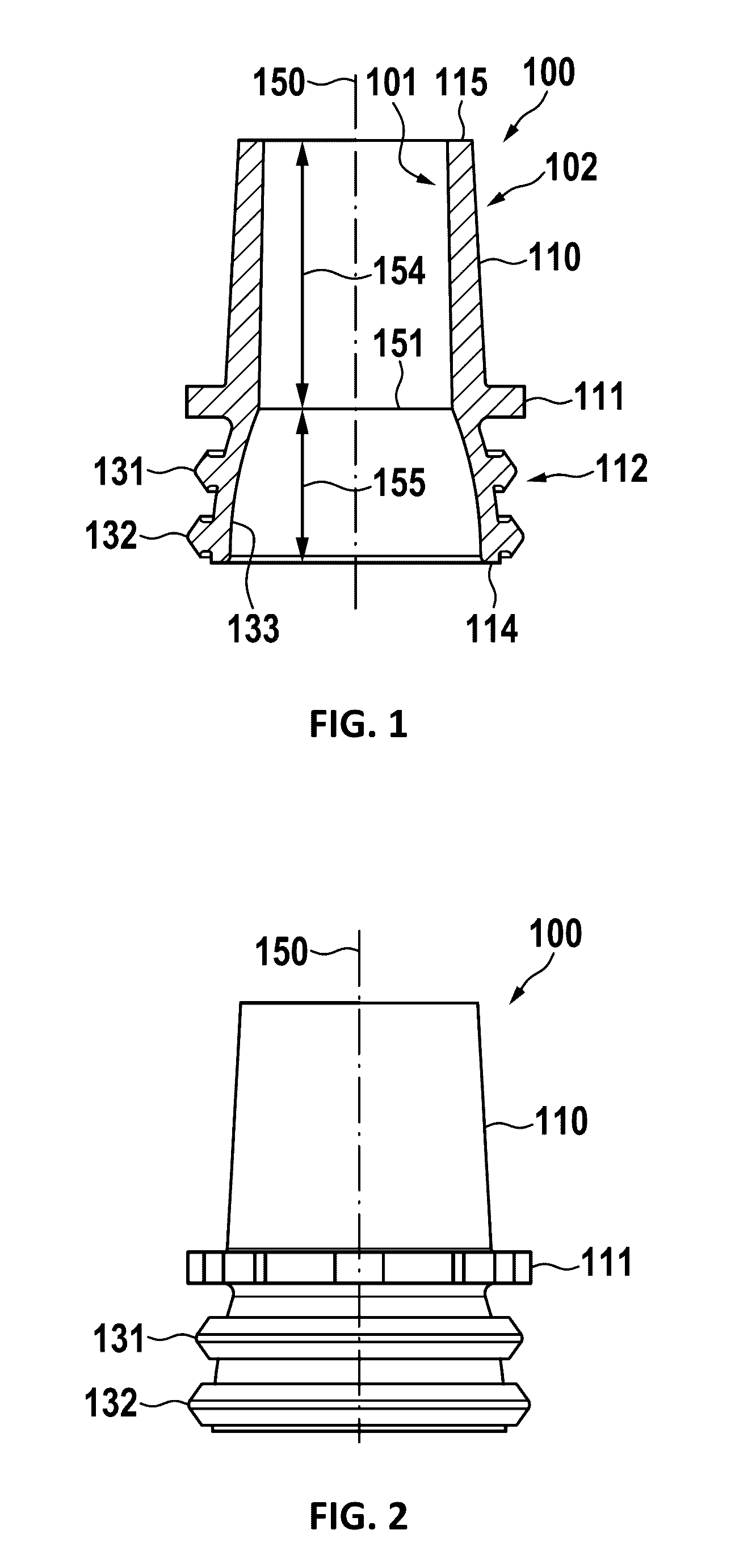

Air pressure gauge assembly for continuous monitoring of tire inflation pressure

InactiveUS6843115B2Easy to readSmall extensionFluid pressure measurement by mechanical elementsTyre measurementsEngineeringCheck valve

An air pressure gauge assembly is mounted to the valve stem of a tire or integrated into a wheel rim for continuous monitoring of the tire inflation pressure. The gauge assembly includes a check valve functionally coupled to the valve stem so that the check valve provides the common function of the valve stem, including allowing for inflation and deflation. The assembly also includes a pressure sensor coupled to a visually perceptible pressure indicator on a dial face.

Owner:TIRO TECH

SBS (Styrene-Butadiene-Styrene) modified asphalt and production method thereof

The invention discloses SBS (Styrene-Butadiene-Styrene) modified asphalt and a production method thereof. The SBS modified asphalt mainly comprises the components of matrix asphalt No.70, linear SBS, a solubilizer and a stabilizer, wherein the linear SBS accounts for 3.6% to 4.2% be weight of the of matrix asphalt No.70, the solubilizer accounts for 2.0% to 3.0% by weight of the matrix asphalt No.70, and the stabilizer accounts for 0.16-0.18% be weight of the matrix asphalt No.70. The production method of the SBS modified asphalt comprises the following steps of: (1) heating the matrix asphalt No.70 to 175 DEG C to 185 DEG C; (2) adding the linear SBS and uniformly stirring; and (3) adding the solubilizer and the stabilizer and thoroughly grinding twice by using a colloid mill to obtain the SBS modified asphalt. The production method adopted in the invention effectively shortens the modified time and is low in production cost.

Owner:XUZHOU CITY LUXING HIGHWAY ENG

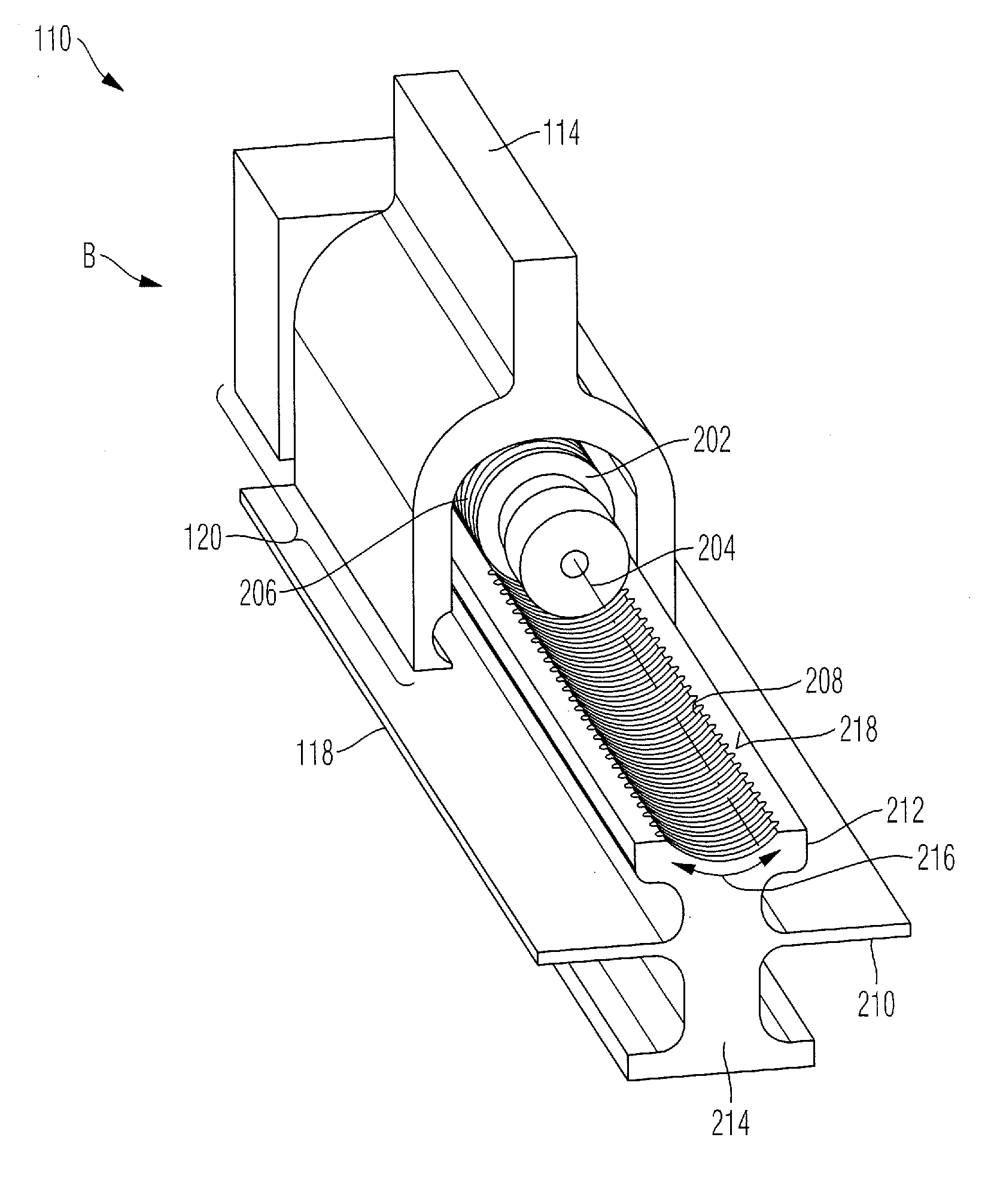

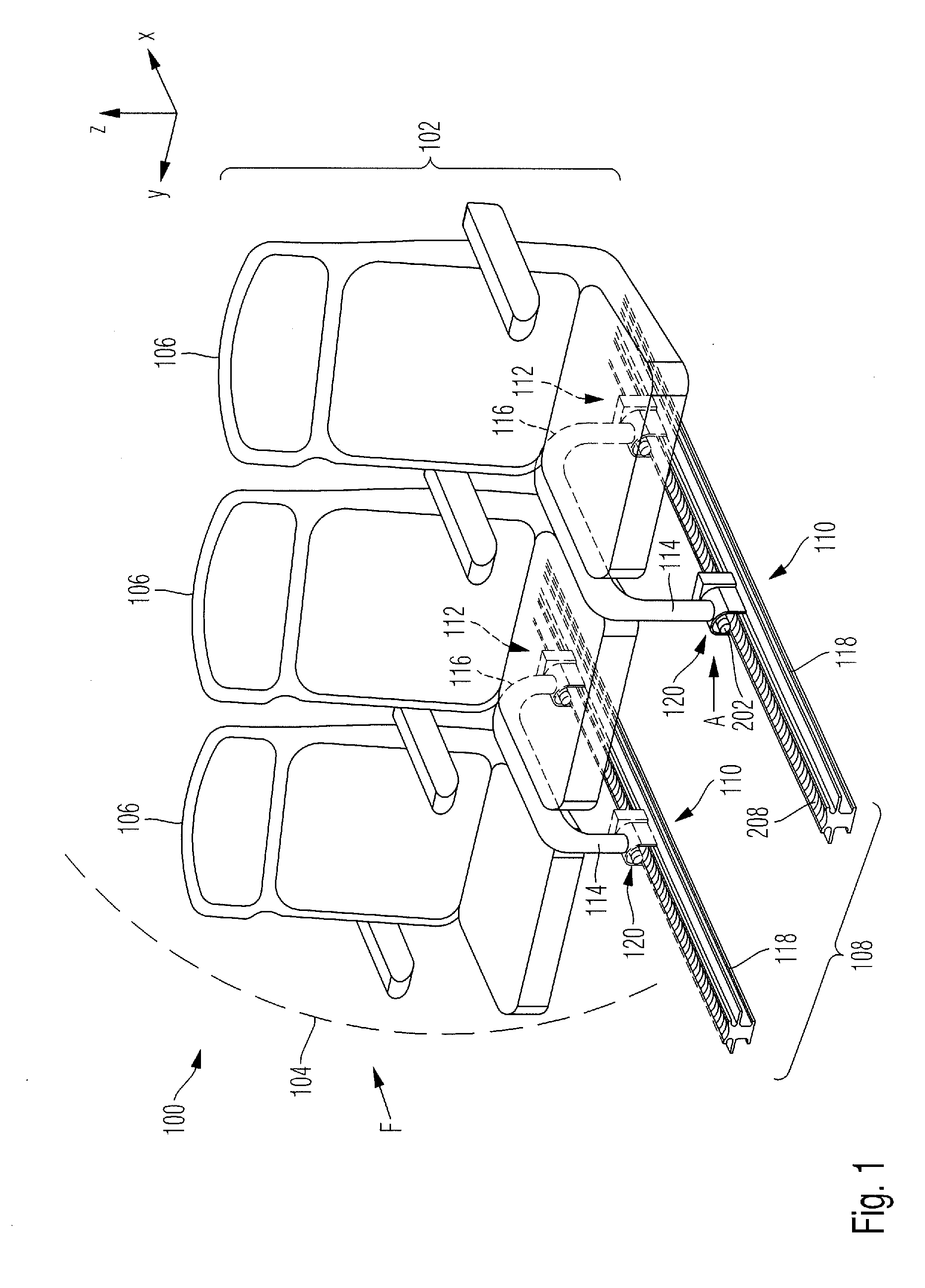

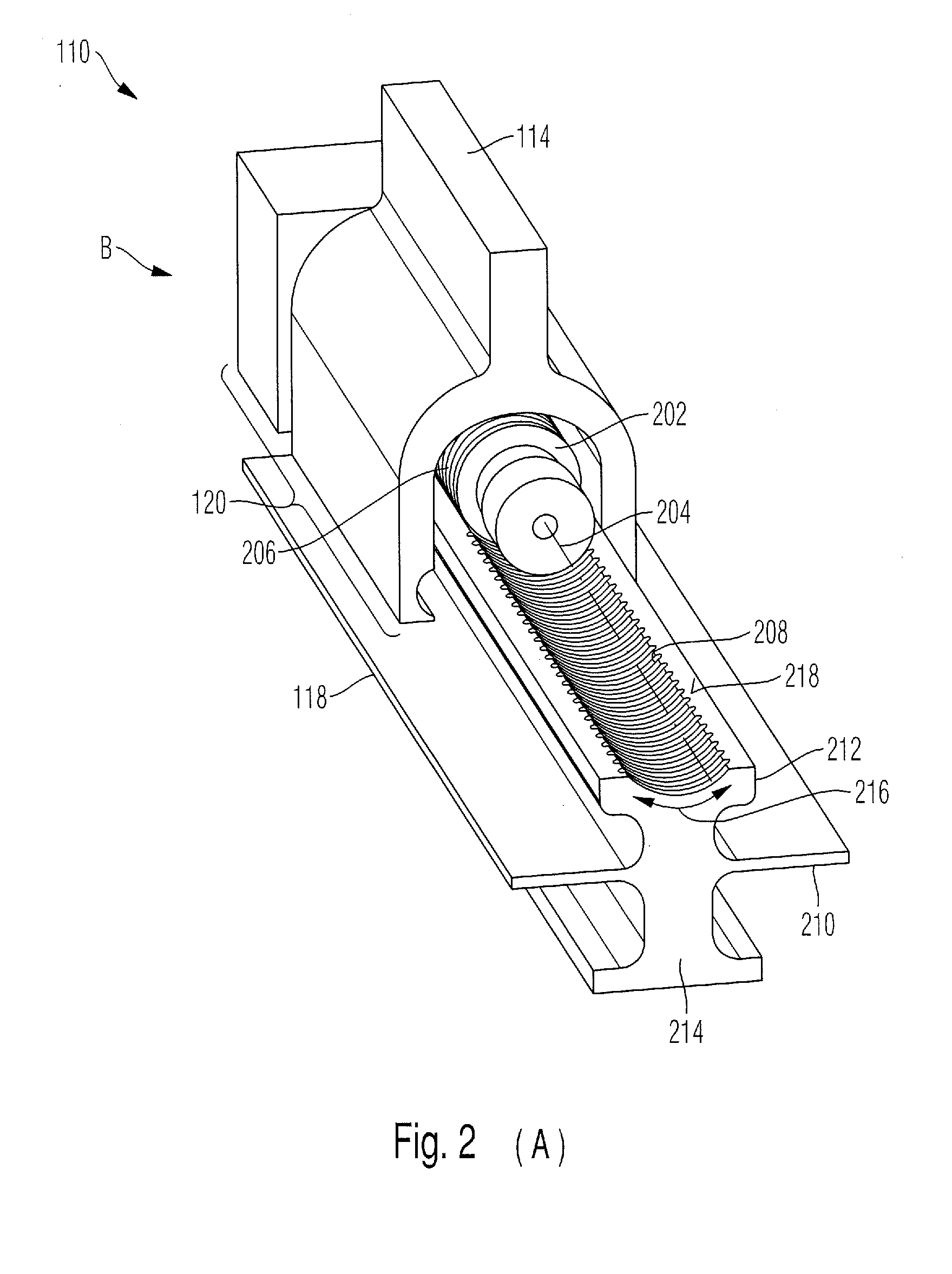

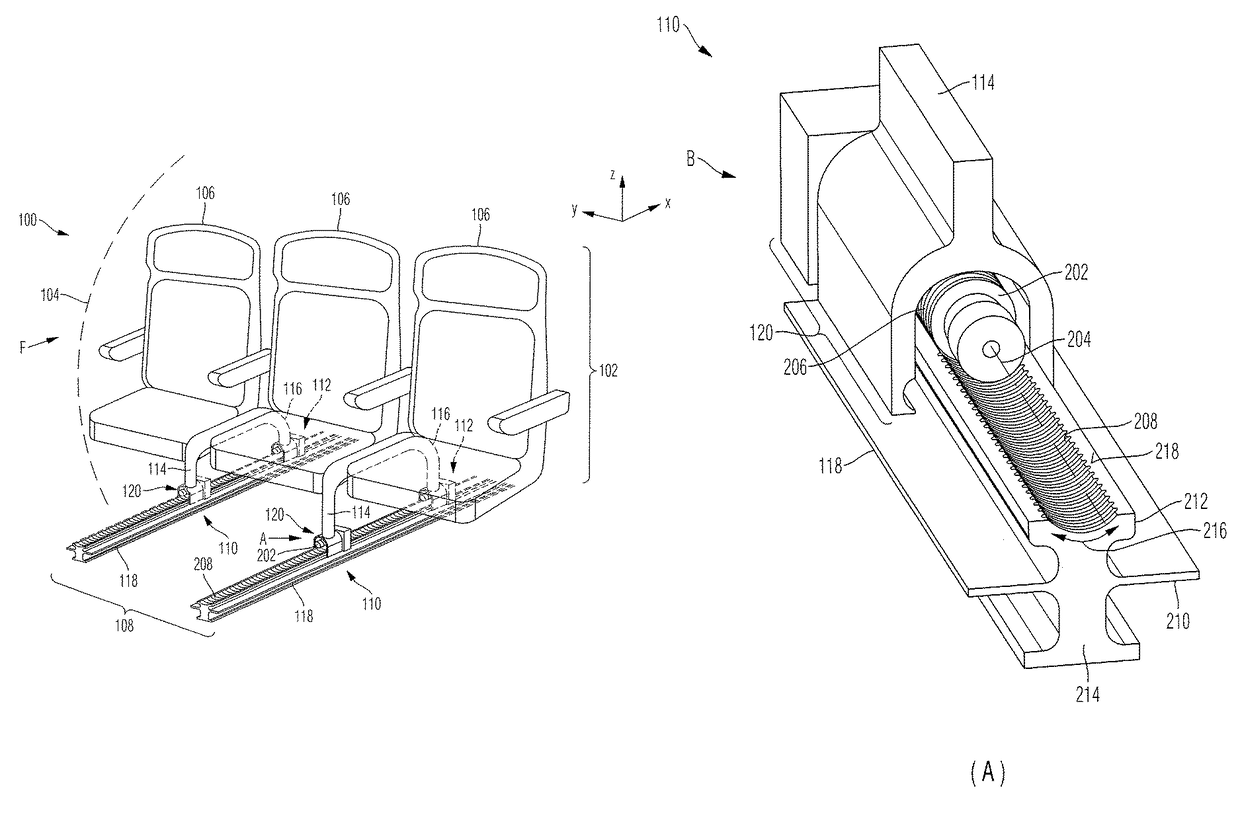

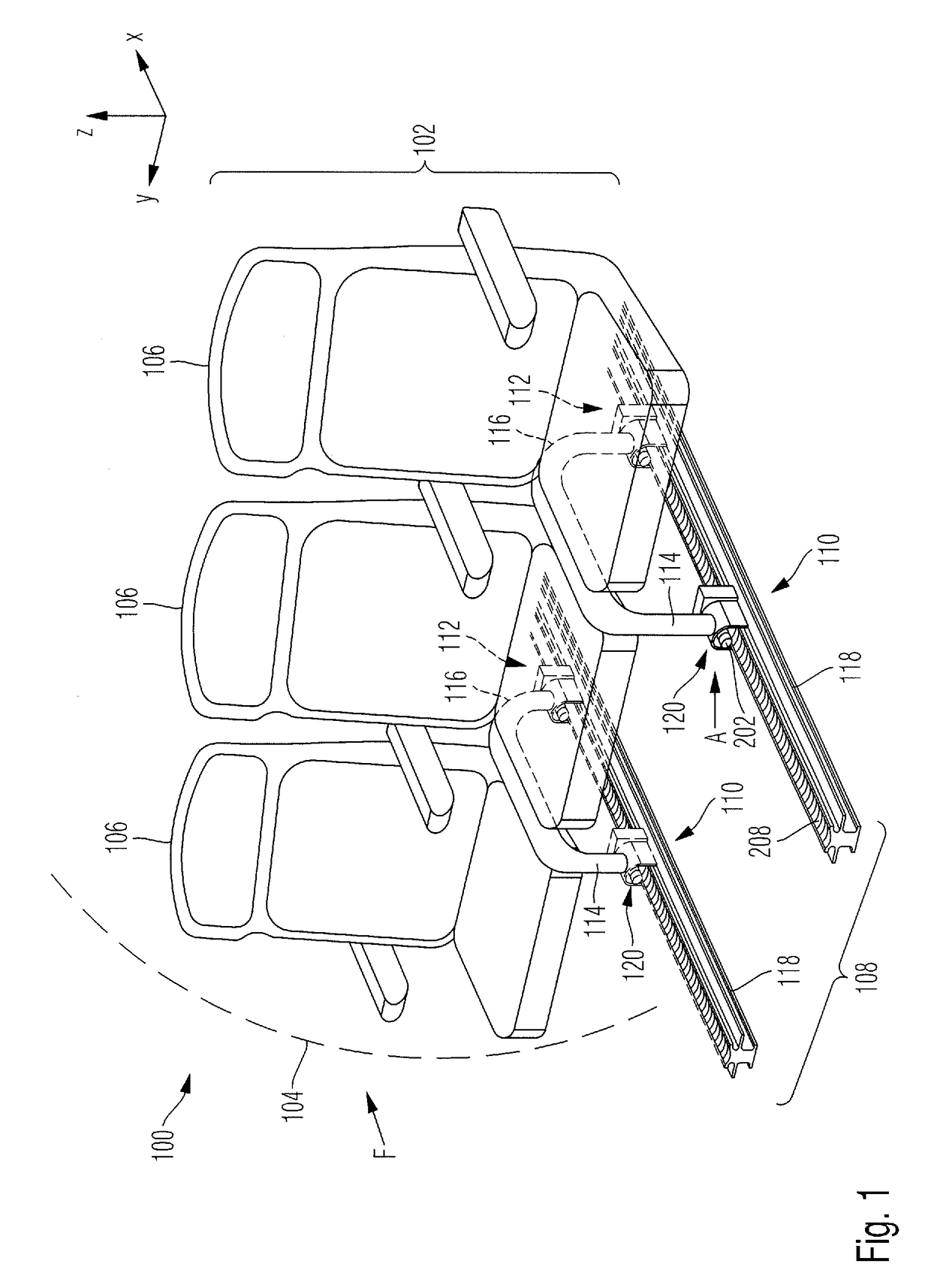

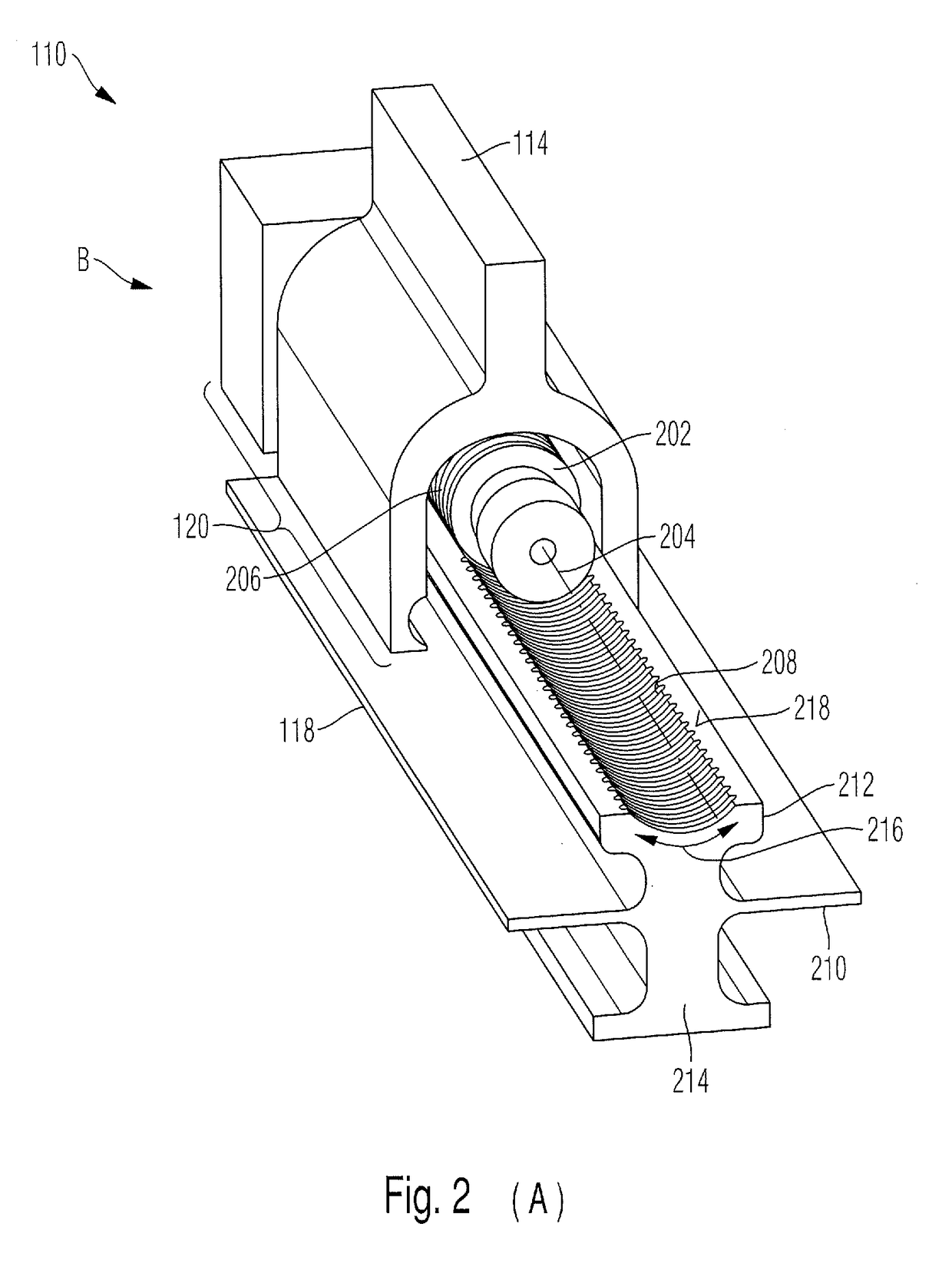

Seat adjustment device and aircraft or spacecraft

ActiveUS20120145867A1Simple displaceabilityIncrease gear ratioVehicle seatsFreight handlingEngineeringAirplane

The present invention provides a seat adjustment device for an aircraft or spacecraft, comprising:a seat rail for connection to a floor; anda seat connection for connection to at least one seat;and a worm is provided which can be actuated to adjust the seat connection relative to the seat rail.

Owner:AIRBUS OPERATIONS GMBH

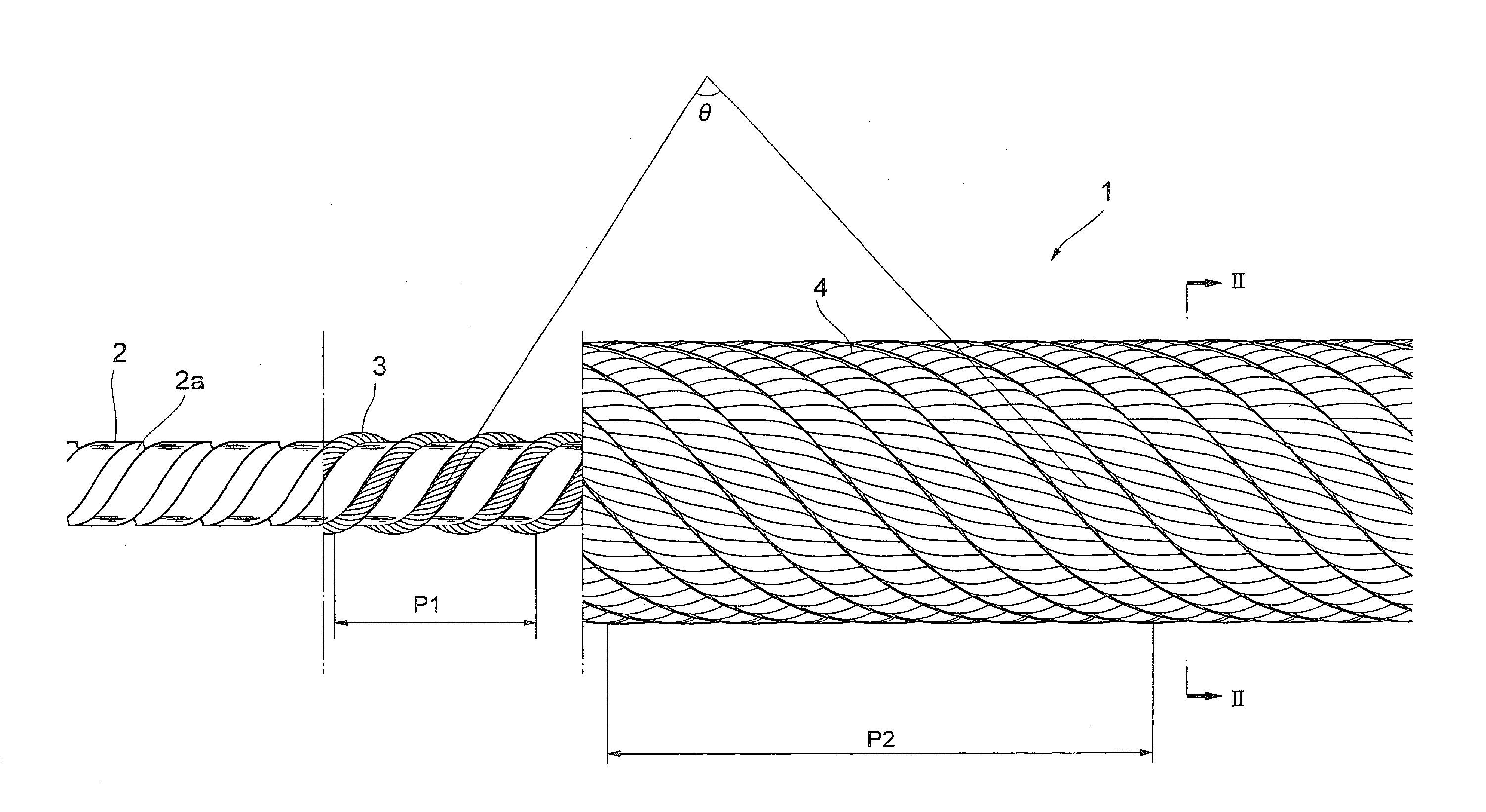

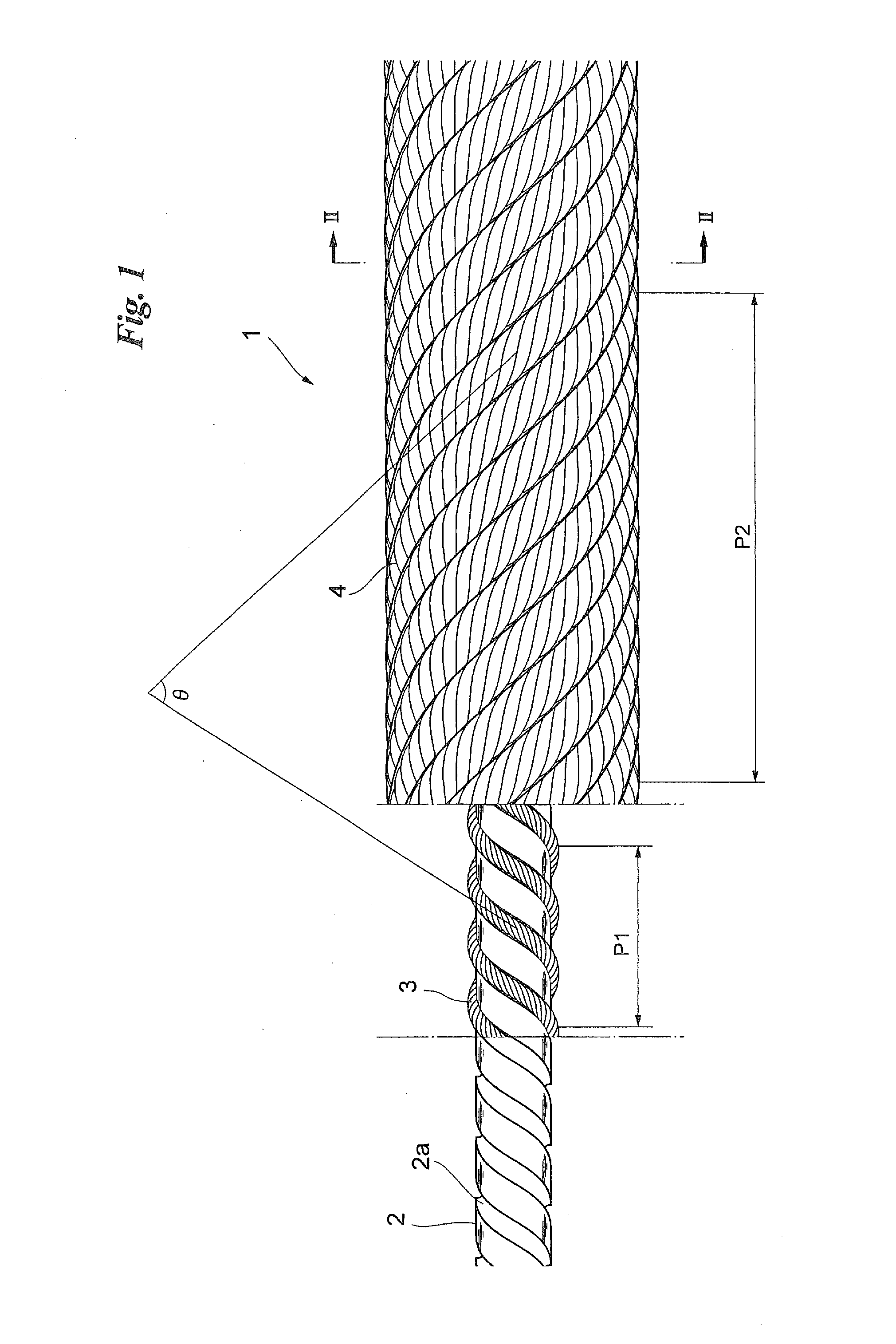

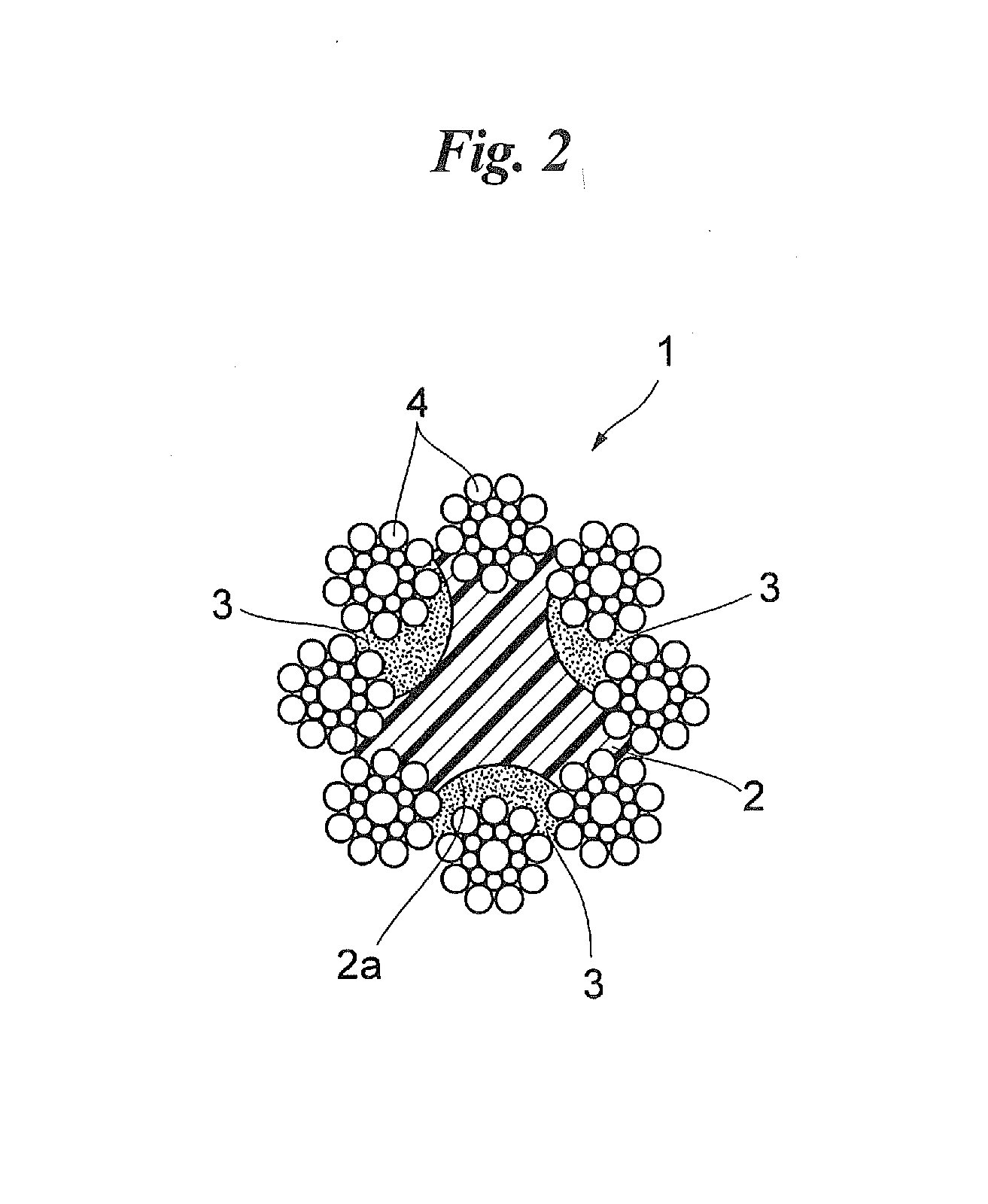

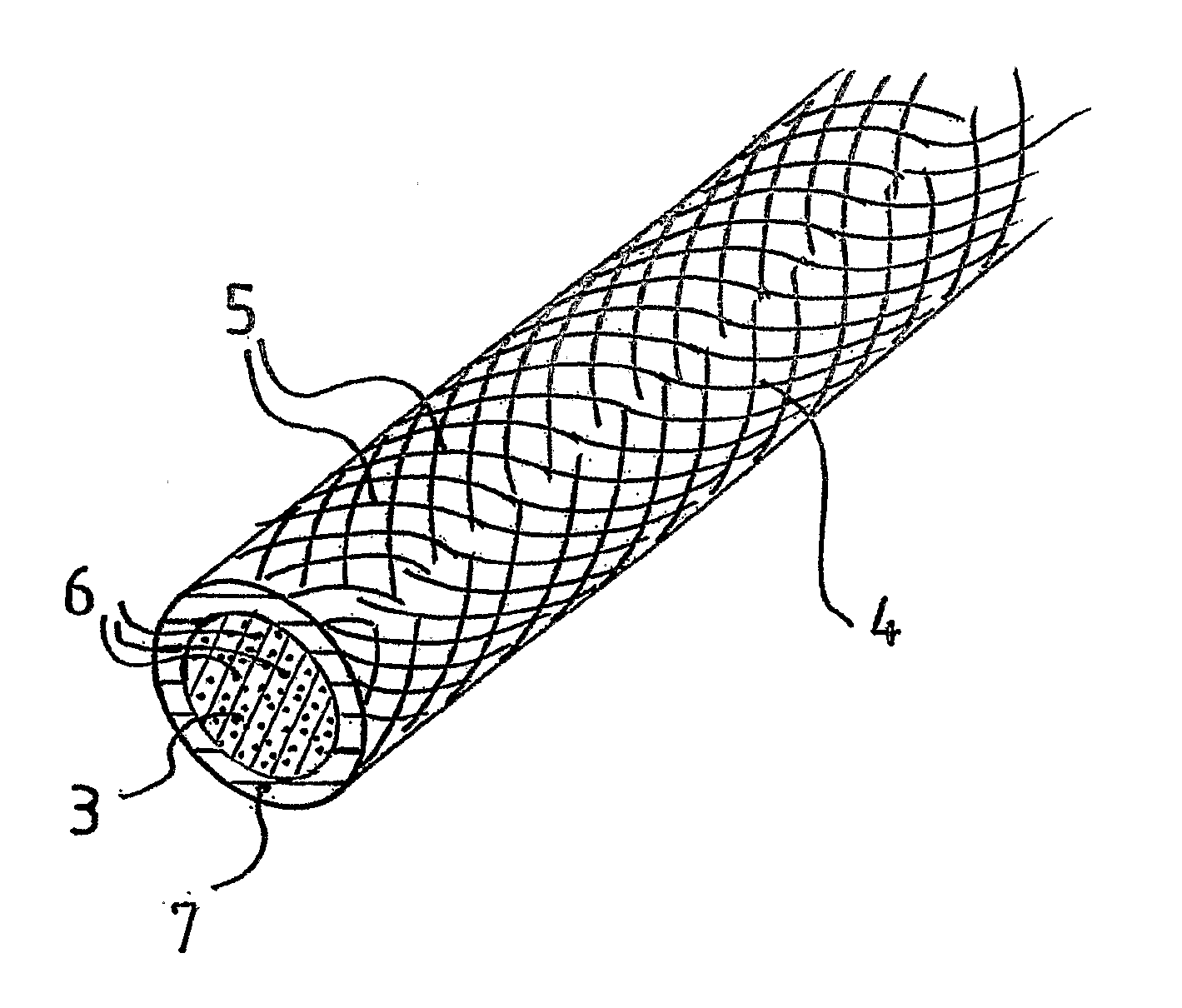

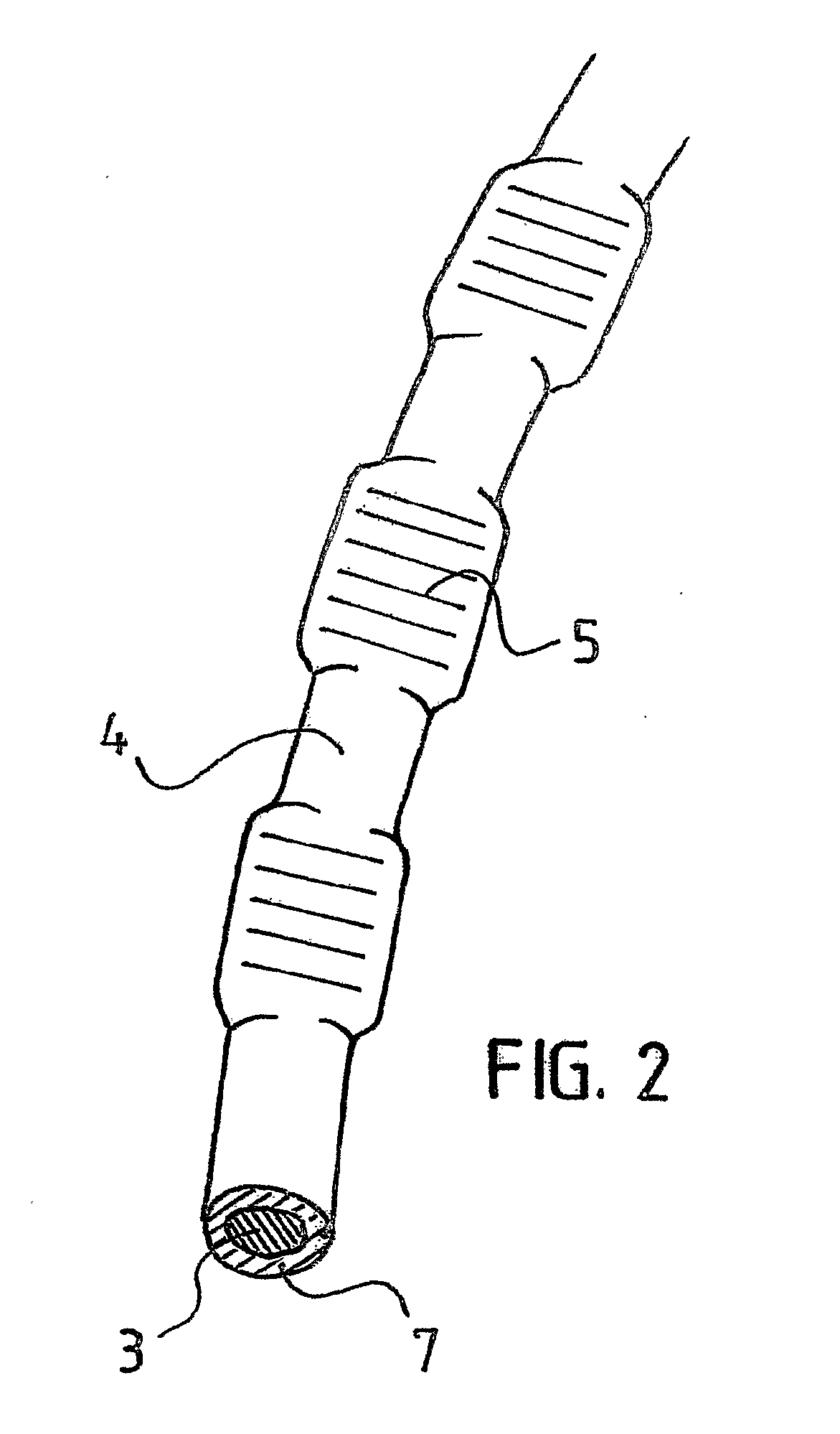

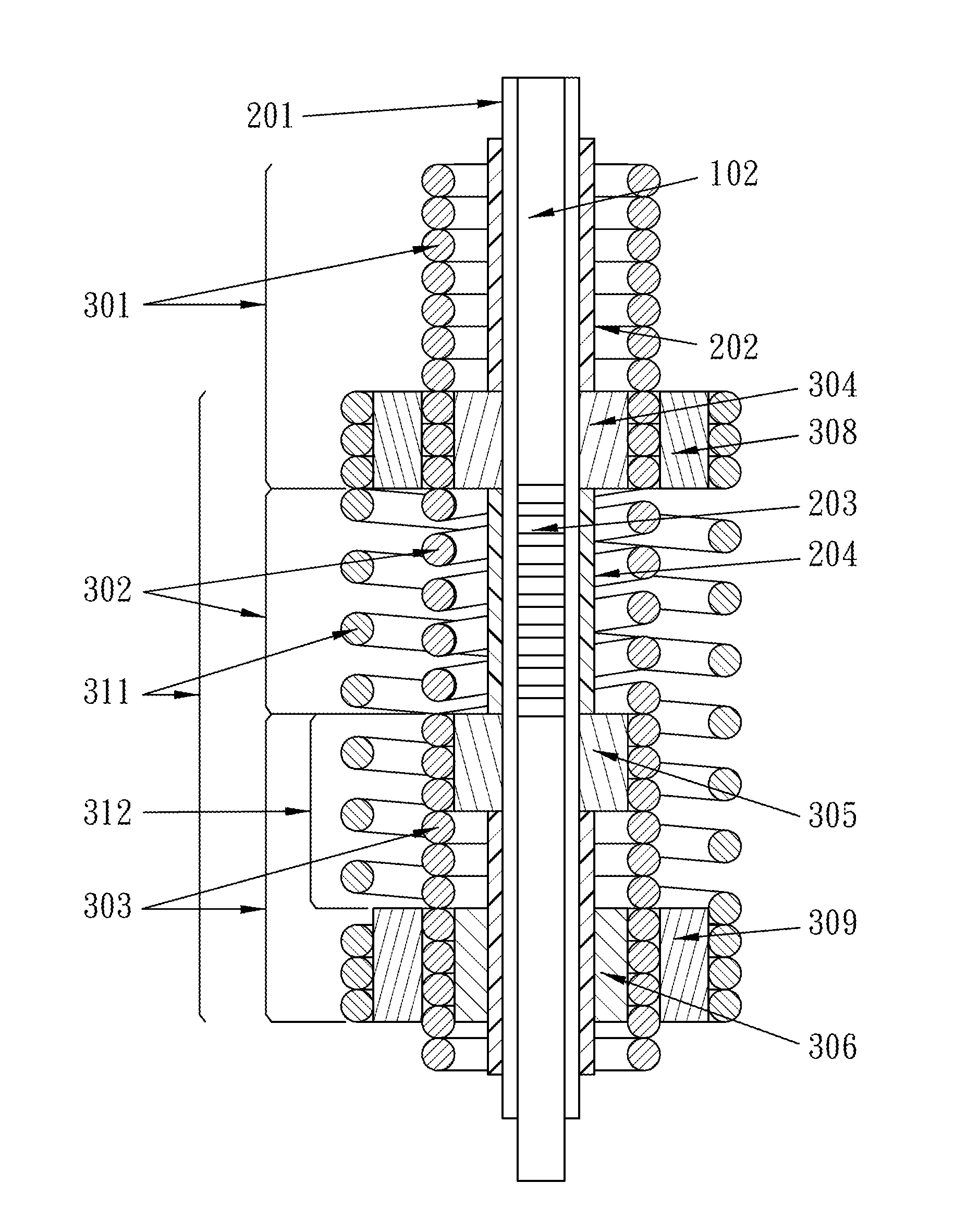

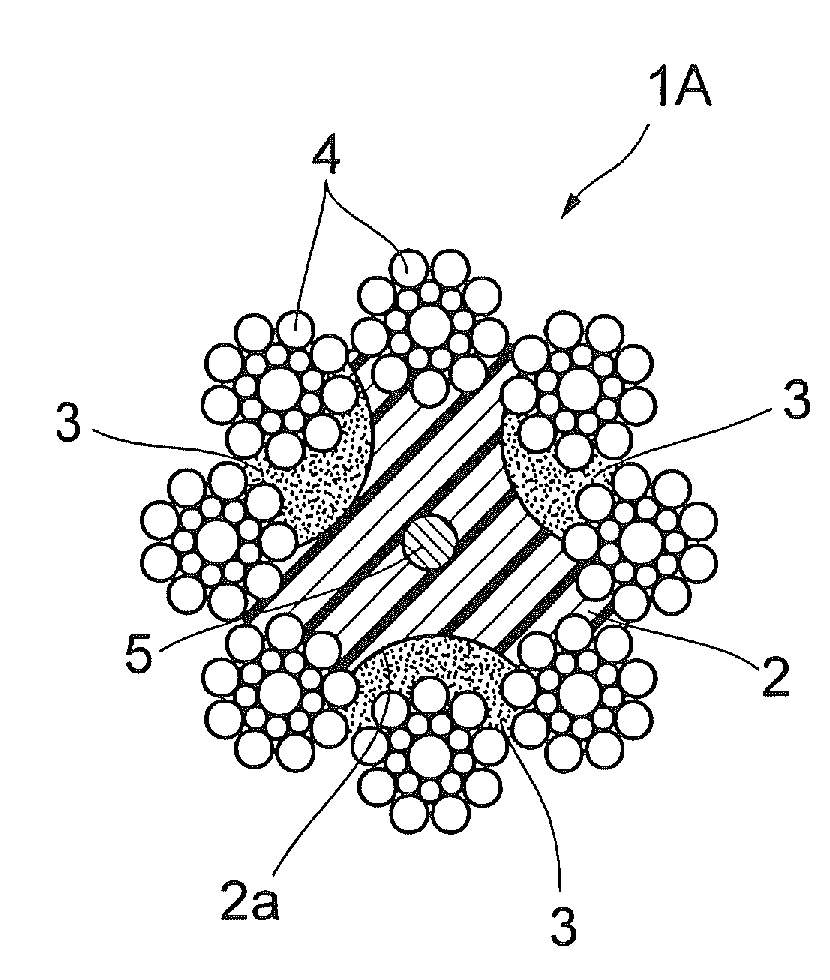

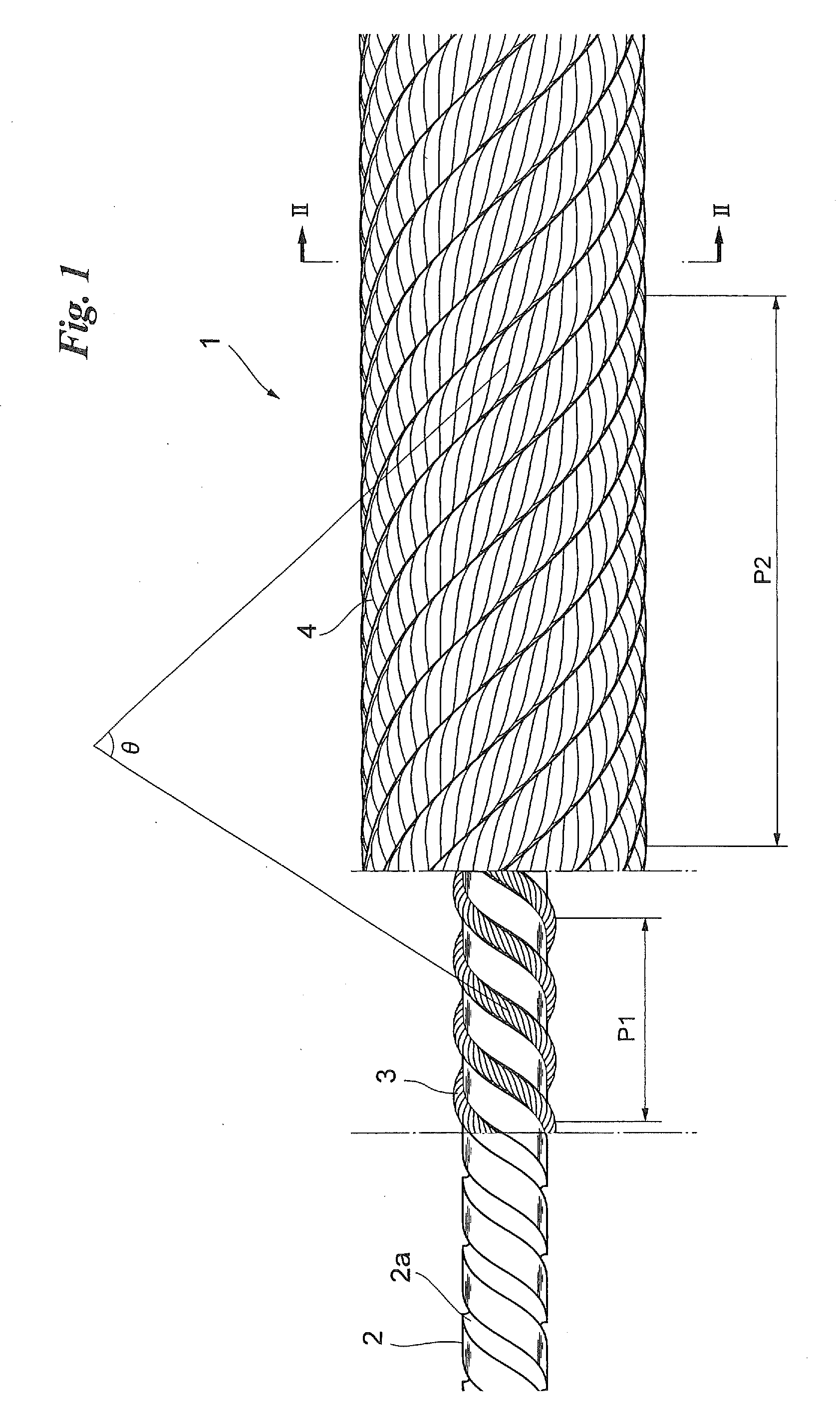

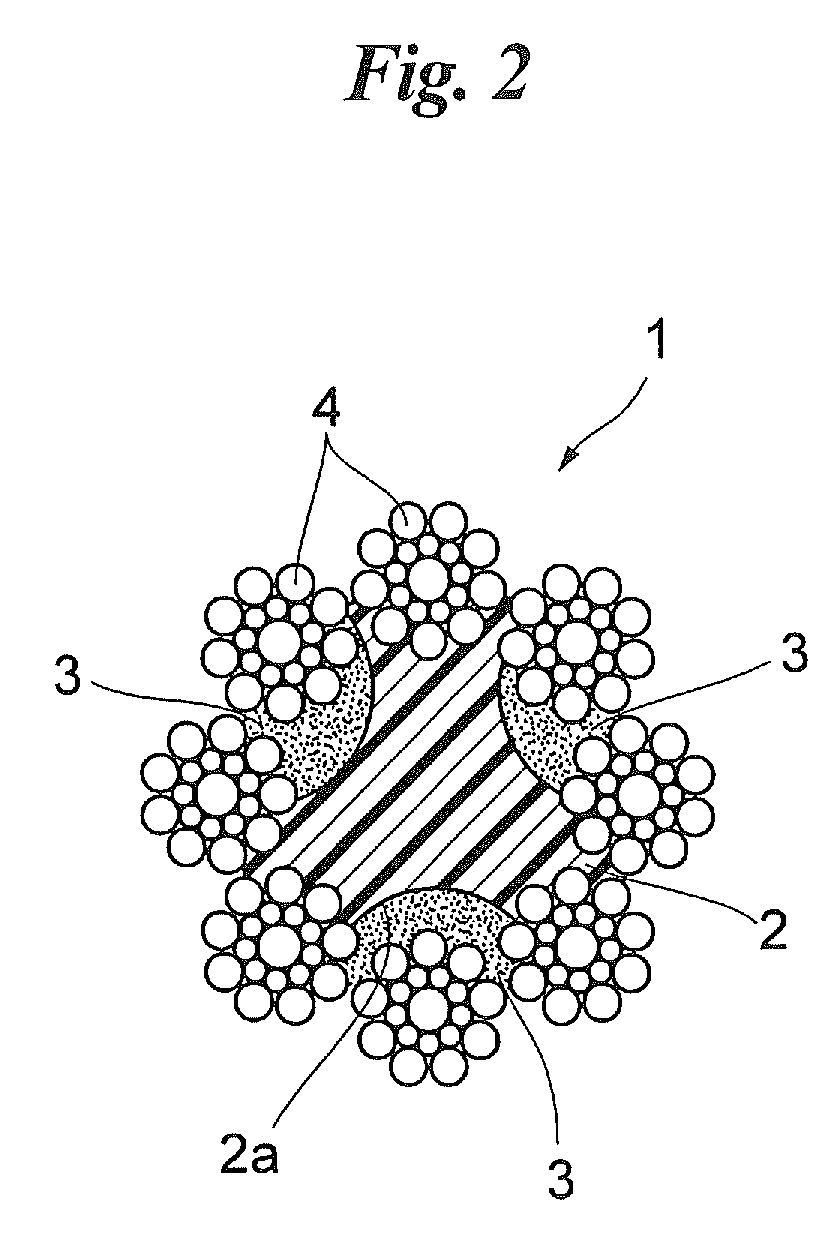

Hybrid core rope

ActiveUS20130318937A1Accelerate the rate of decreaseReduce maintenance tasksRope making machinesYarnFiber bundleEngineering

The present invention is to provide a hybrid core rope which does not require maintenance or a hybrid core rope capable of reducing a maintenance task. The hybrid core rope includes a resin solid core in which a plurality of spiral grooves is formed in the longitudinal direction on an outer peripheral surface thereof, a plurality of fiber bundles respectively spirally wound around the outer peripheral surface of the resin solid core along the plurality of spiral grooves, the fiber bundles having thickness to fill the spiral grooves, and a plurality of steel strands spirally wound around the outer peripheral surface of the resin solid core around which the fiber bundles are wound. The fiber bundles and the strands are respectively wound so as to have angles which are not parallel to each other.

Owner:TOKYO ROPE MFG

Seat adjustment device and aircraft or spacecraft

ActiveUS9789965B2Increase gear ratioSignificant positive effectFuselage framesMachine supportsEngineeringAirplane

The present invention provides a seat adjustment device for an aircraft or spacecraft, comprising:a seat rail for connection to a floor; anda seat connection for connection to at least one seat;and a worm is provided which can be actuated to adjust the seat connection relative to the seat rail.

Owner:AIRBUS OPERATIONS GMBH

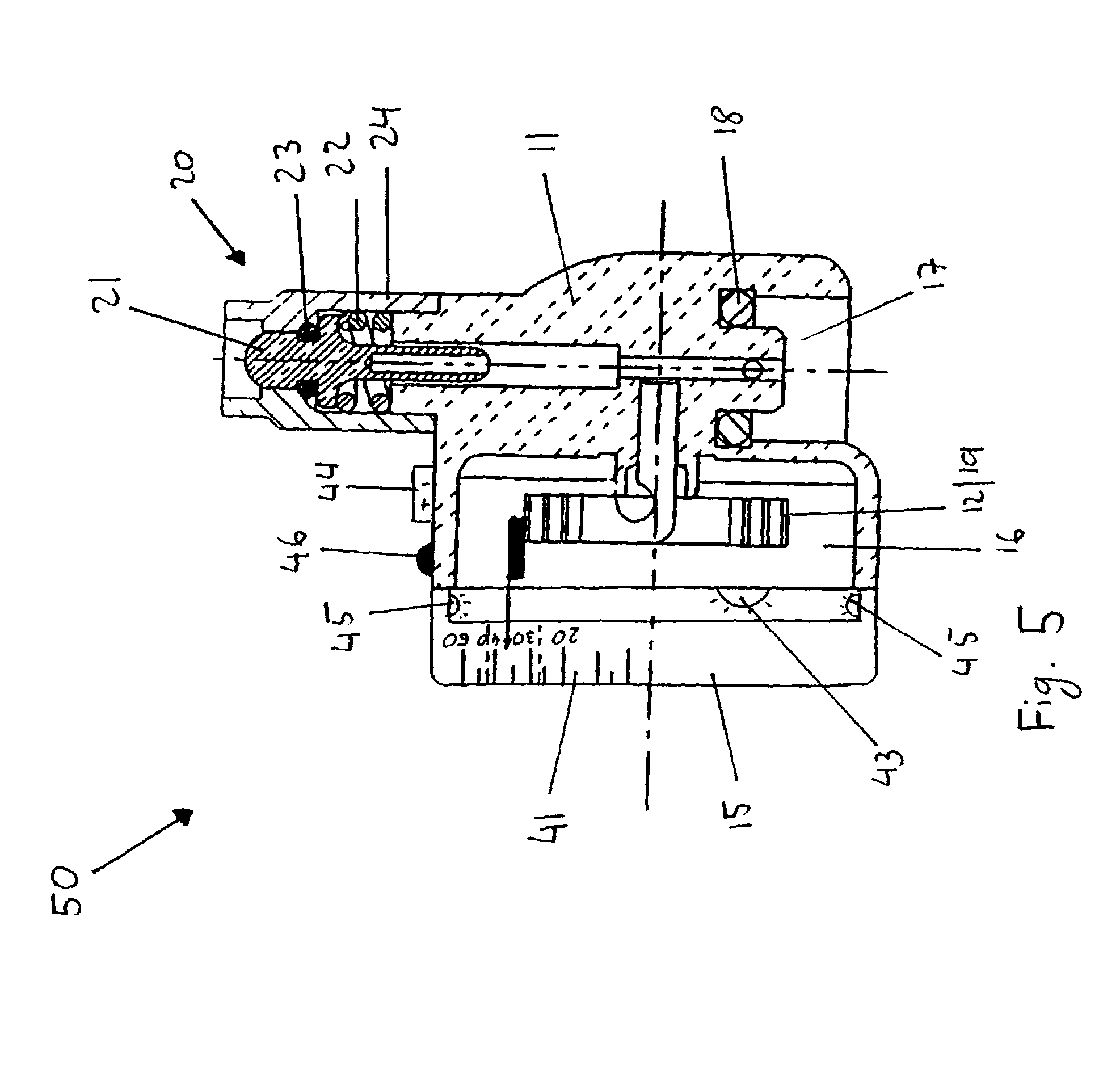

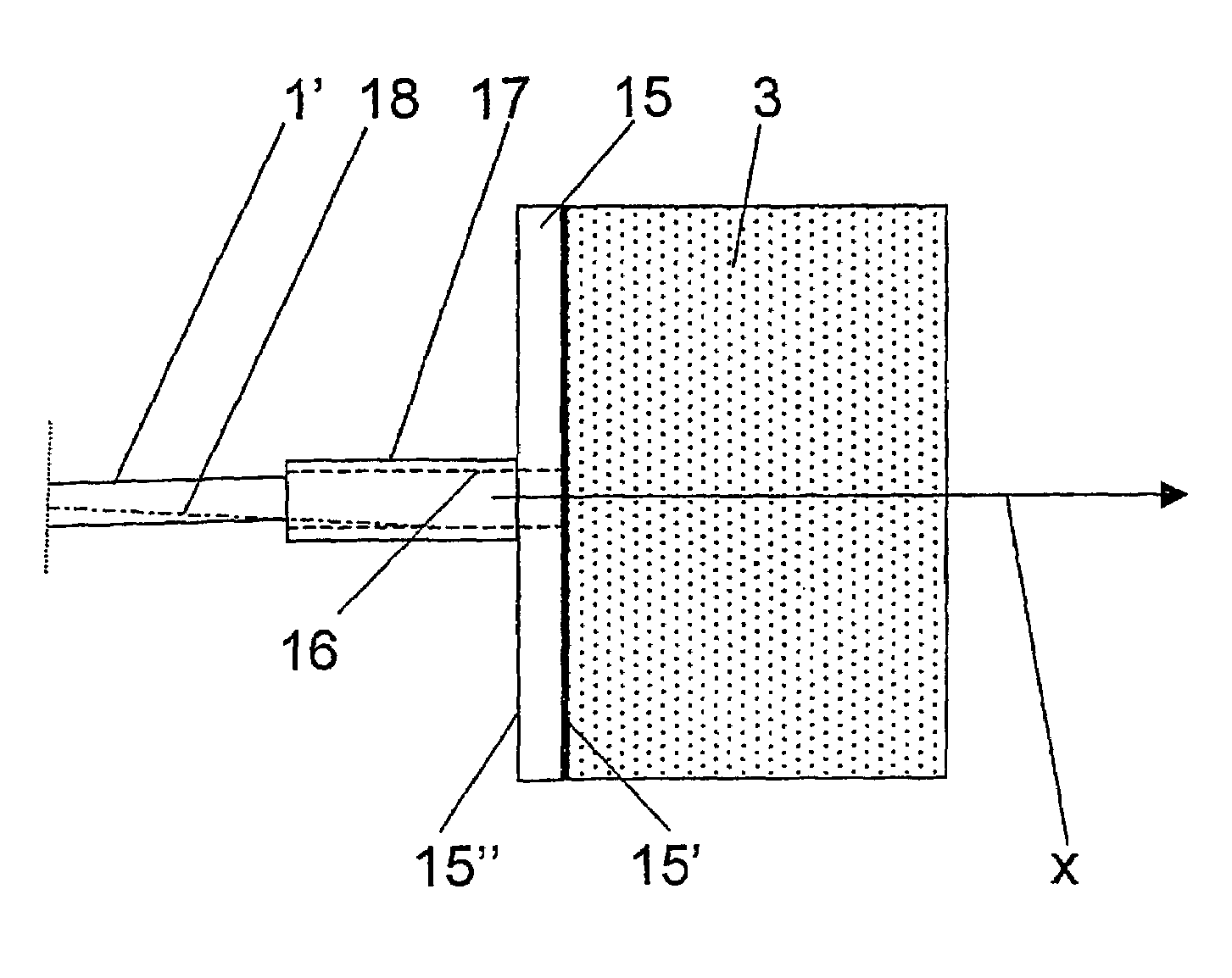

Pneumatic tire air pressure gauge assembly

InactiveUS7040152B2Avoid contactAvoid interferenceInflated body pressure measurementRoads maintainenceBarographMechanical design

A compact air pressure gauge assembly mountable to the valve stem of a inflatable tire or mountable through the rim of a wheel for continuous monitoring of the tire inflation pressure. The air pressure gauge assembly has a compact design to extend the valve stem or wheel rim relatively little to avoid curb contact and interference with the wheel balance. By positioning the air intake in a right angle with the opening for receiving a standard valve stem or by positioning the air intake straight across the opening for receiving the valve stem while the dial face is positioned in an right angle, the air intake is separated from the airtight chamber housing the sensing element. A diaphragm having a simple mechanical design is provided as sensing element. The diaphragm includes a membrane being connected with a pressure indicator that moves up and down according to the tire pressure. The compact air pressure gauge assembly is designed to withstand substantial impact and to seal the tire in case the gauge body is accidentally broken off or fractured. Furthermore, the compact air pressure gauge assembly is relatively inexpensive, reliable, and of little or no maintenance.

Owner:CREATIVE AUTO RESOURCES

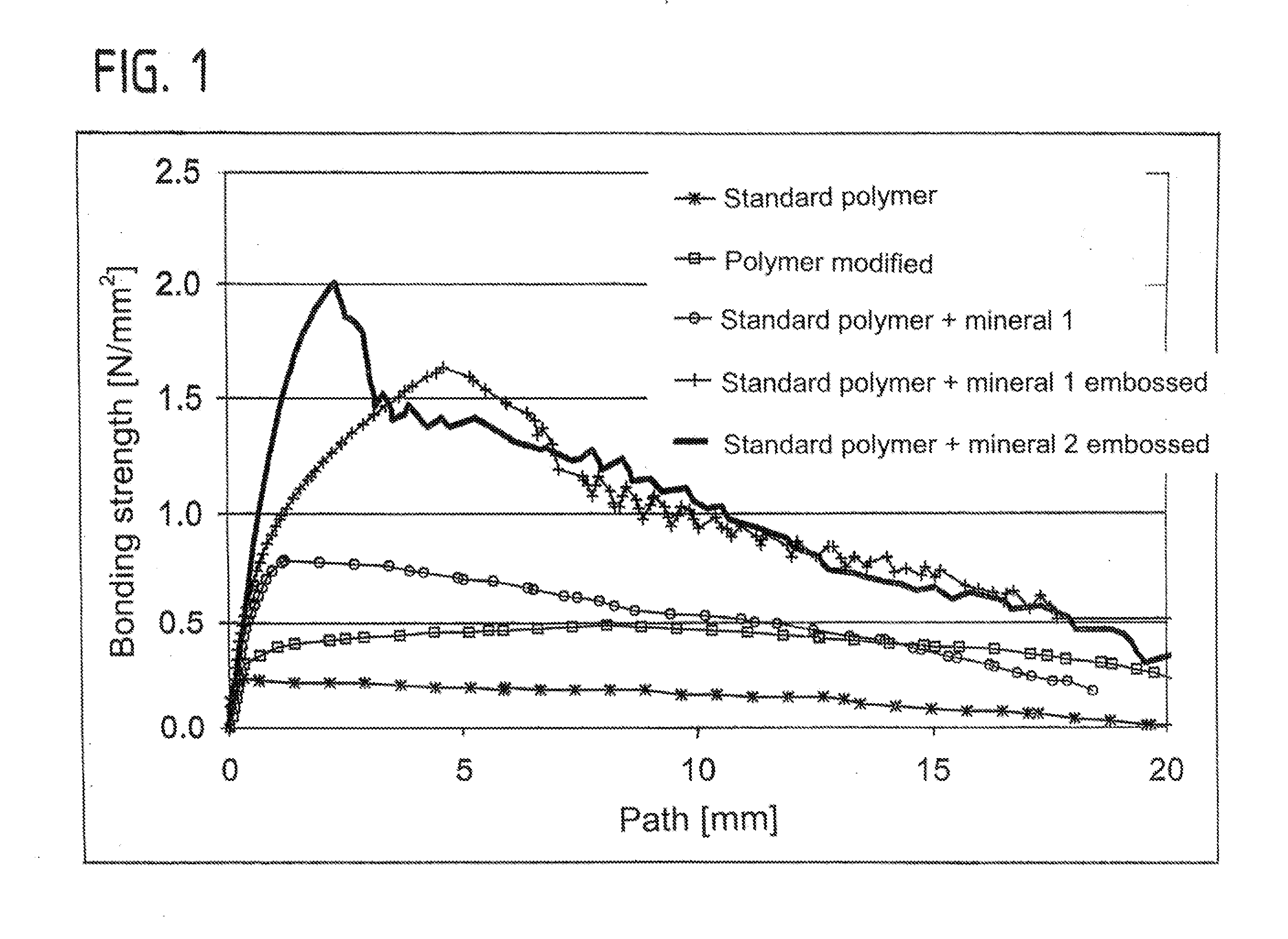

Bi-Component Plastic Fibers For Application in Cement-Bonded Building Materials

InactiveUS20120146254A1Low costHigh tensile strengthSynthetic resin layered productsBuilding reinforcementsPolymer scienceFiber diameter

Method for making plastic fiber for application in concrete with largest grain diameters >4 mm, with an average diameter of 0.15 to 2 mm, corresponding to approximately 160 to 28,000 dtex. Using a co-extrusion process, a bi-component fiber is formed having a central core and a casing around the central core, the central core and the casing contain different pure polymers or polymer mixtures, and then the co-extruded bi-component fiber is stretched by a factor of 5 to 15, and thereafter a structured or grooved surface is embossed onto the co-extruded stretched bi-component fiber. The embossing is performed such that a depth of the embossing is more than 10% of an average fiber diameter, and a maximal distances of structure tips within incorporated structures of the embossing in an axial direction lie in a region between 0.5 mm and 3 mm.

Owner:EMPA EIDGENOESSISCHE MATERIALPRFUNGS & FORSCHUNGSANSTALT +1

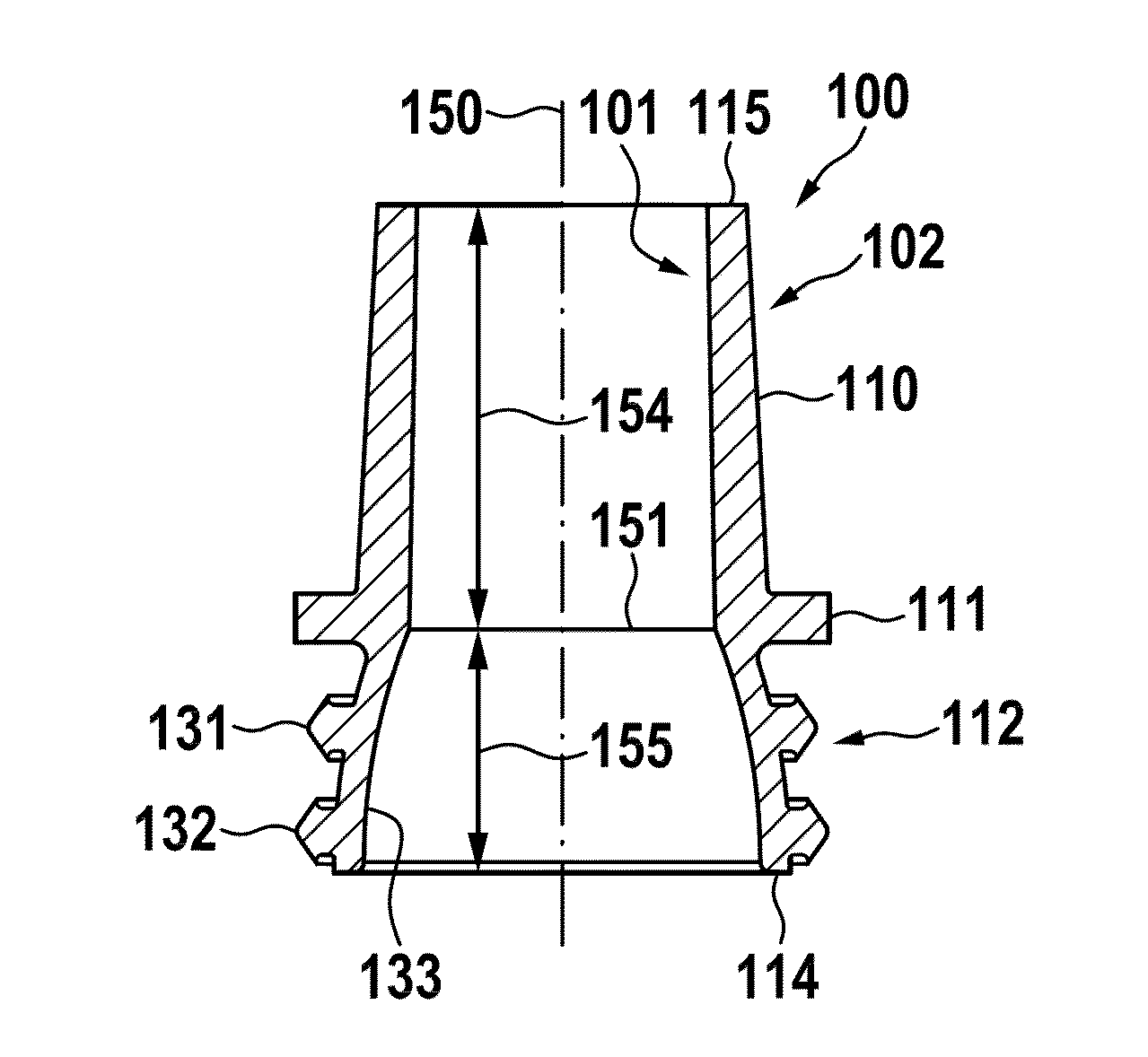

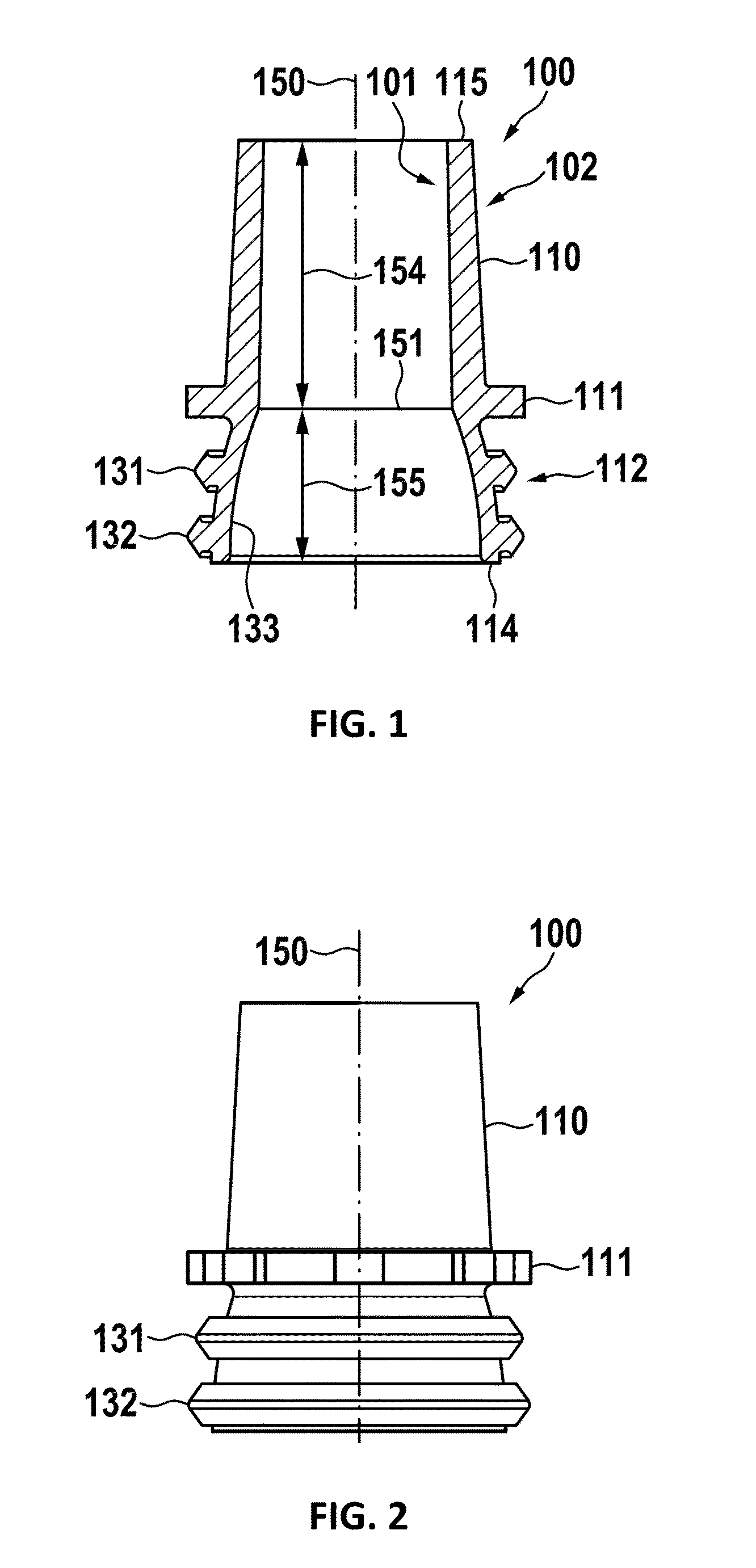

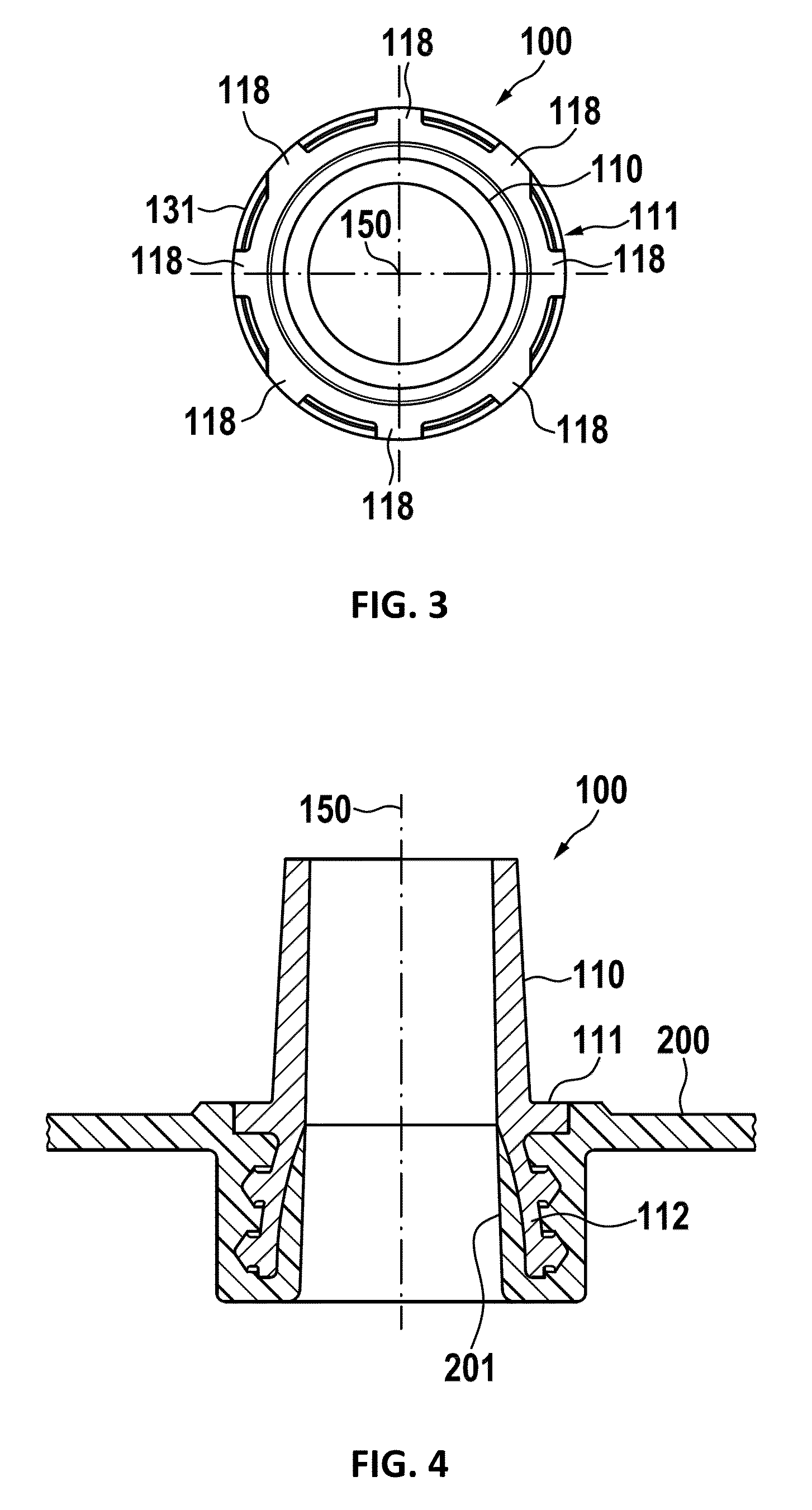

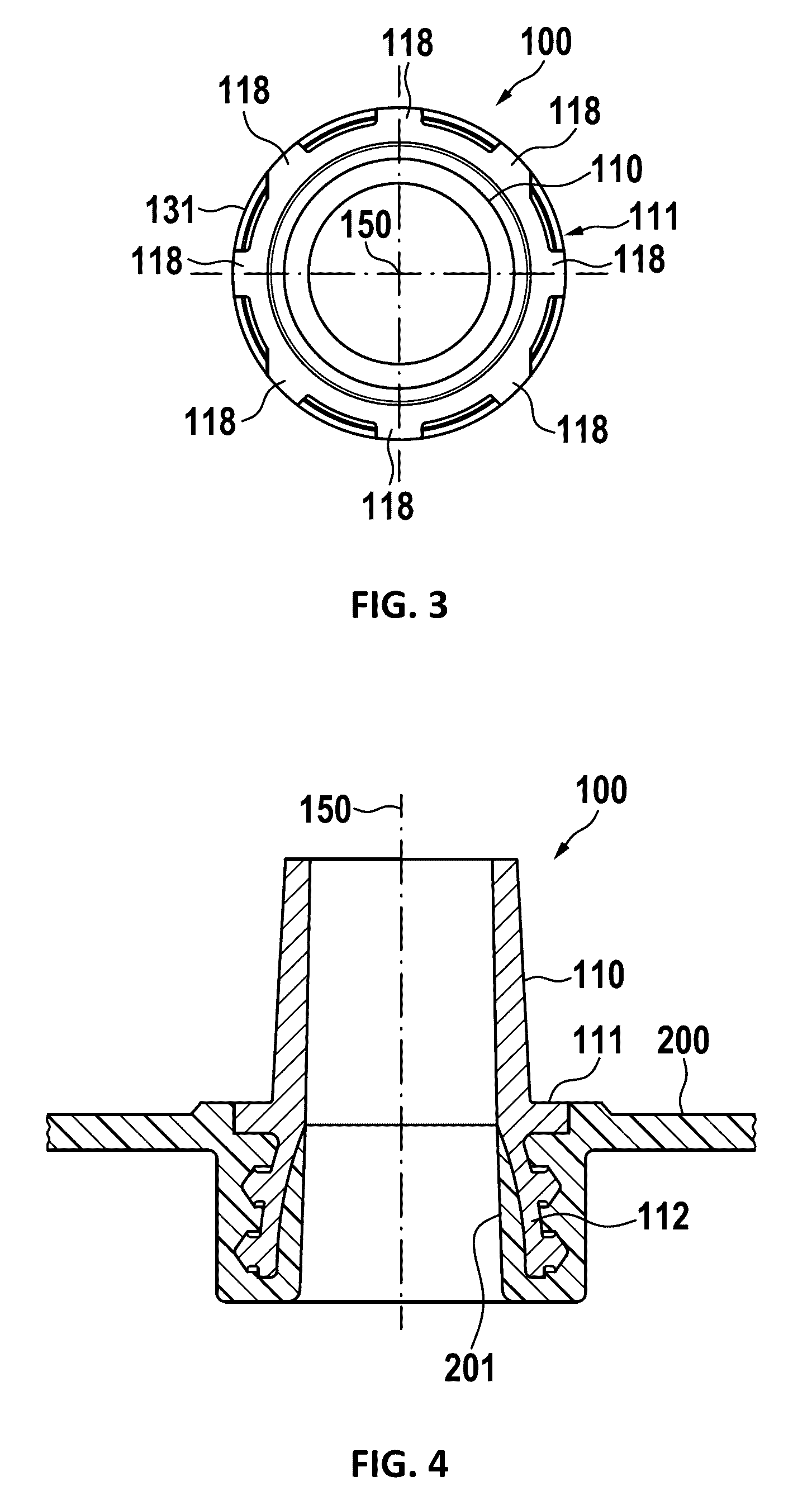

Sealable Terminal for Rechargeable Battery

ActiveUS20160043377A1Improve sealingImprove mechanical stabilityFinal product manufacturePrimary cellsRechargeable cellEngineering

Owner:WEGMANN AUTOMOTIVE GMBH & CO KG

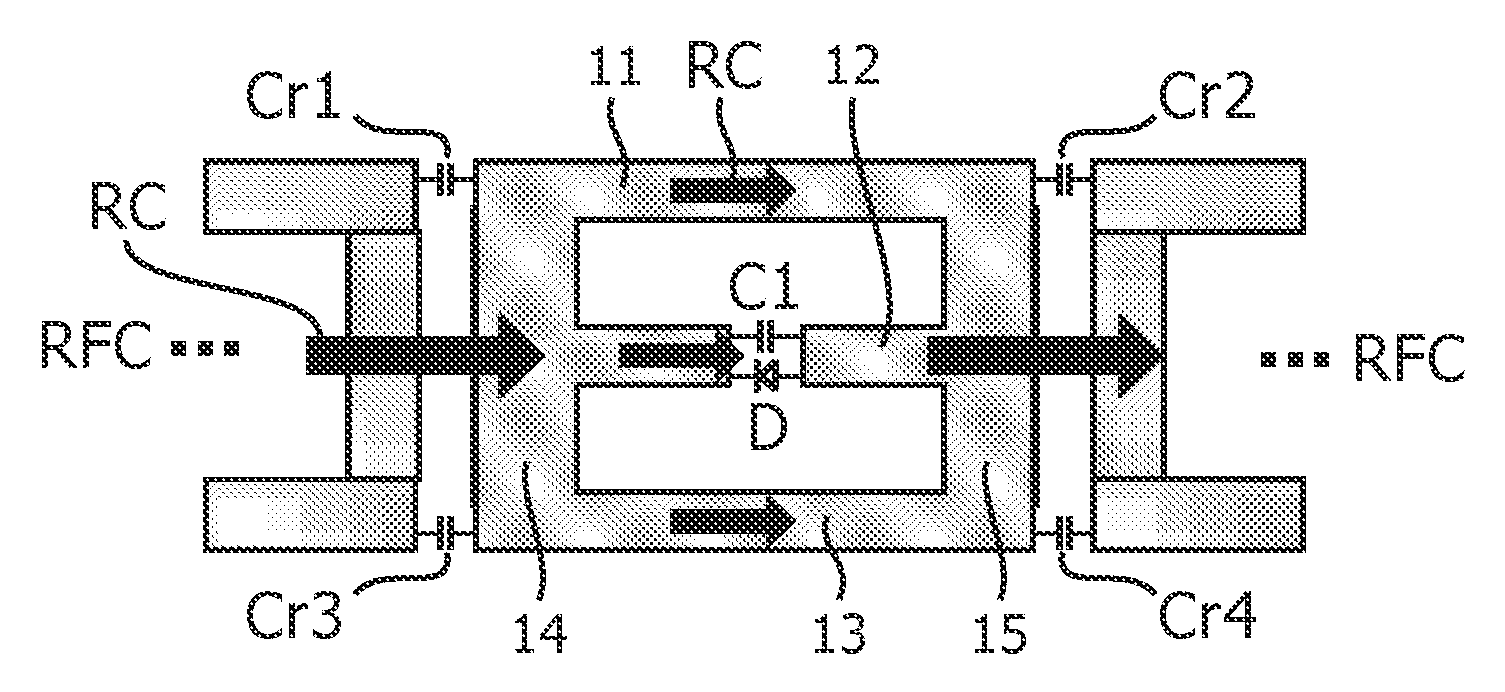

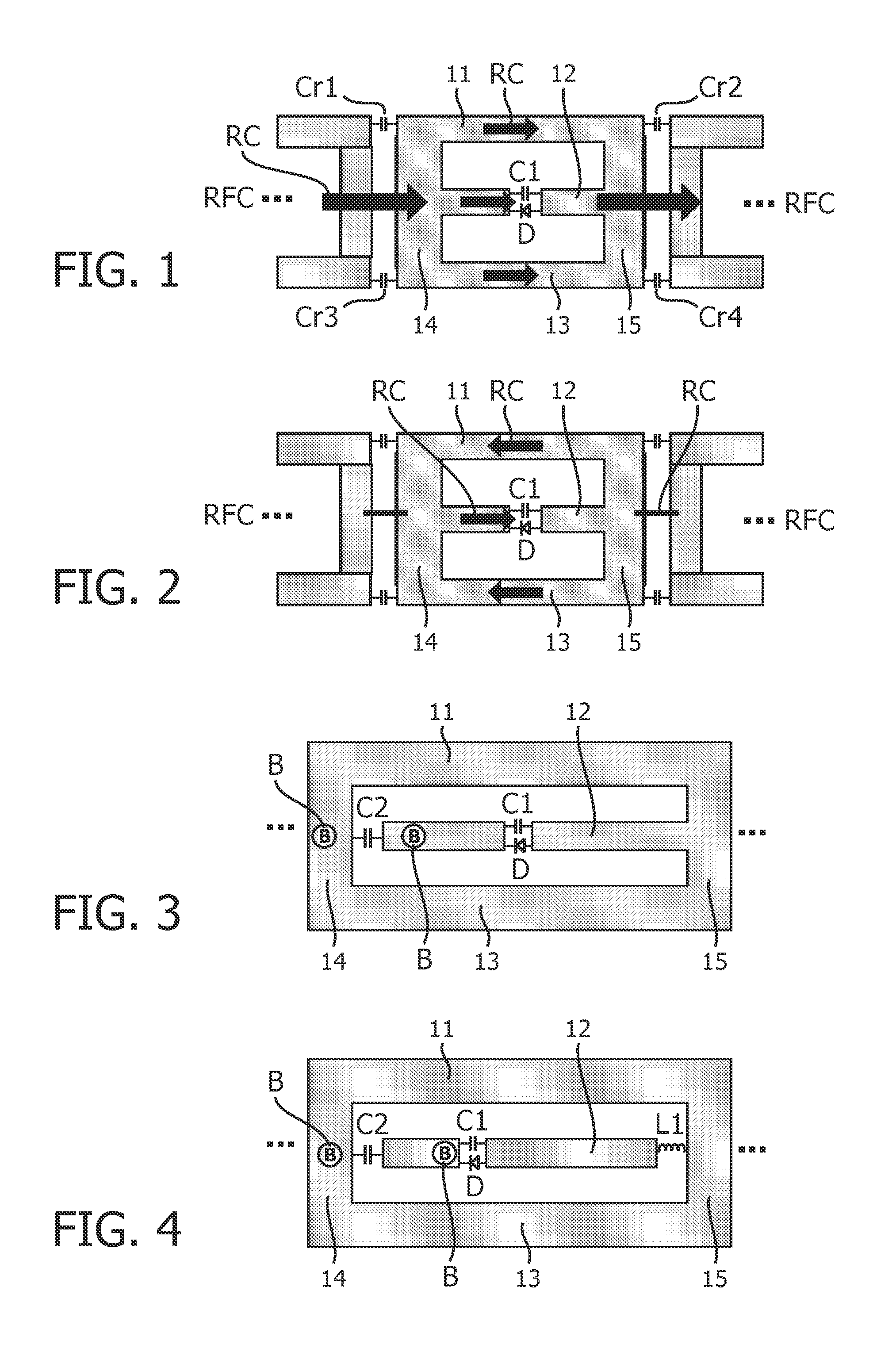

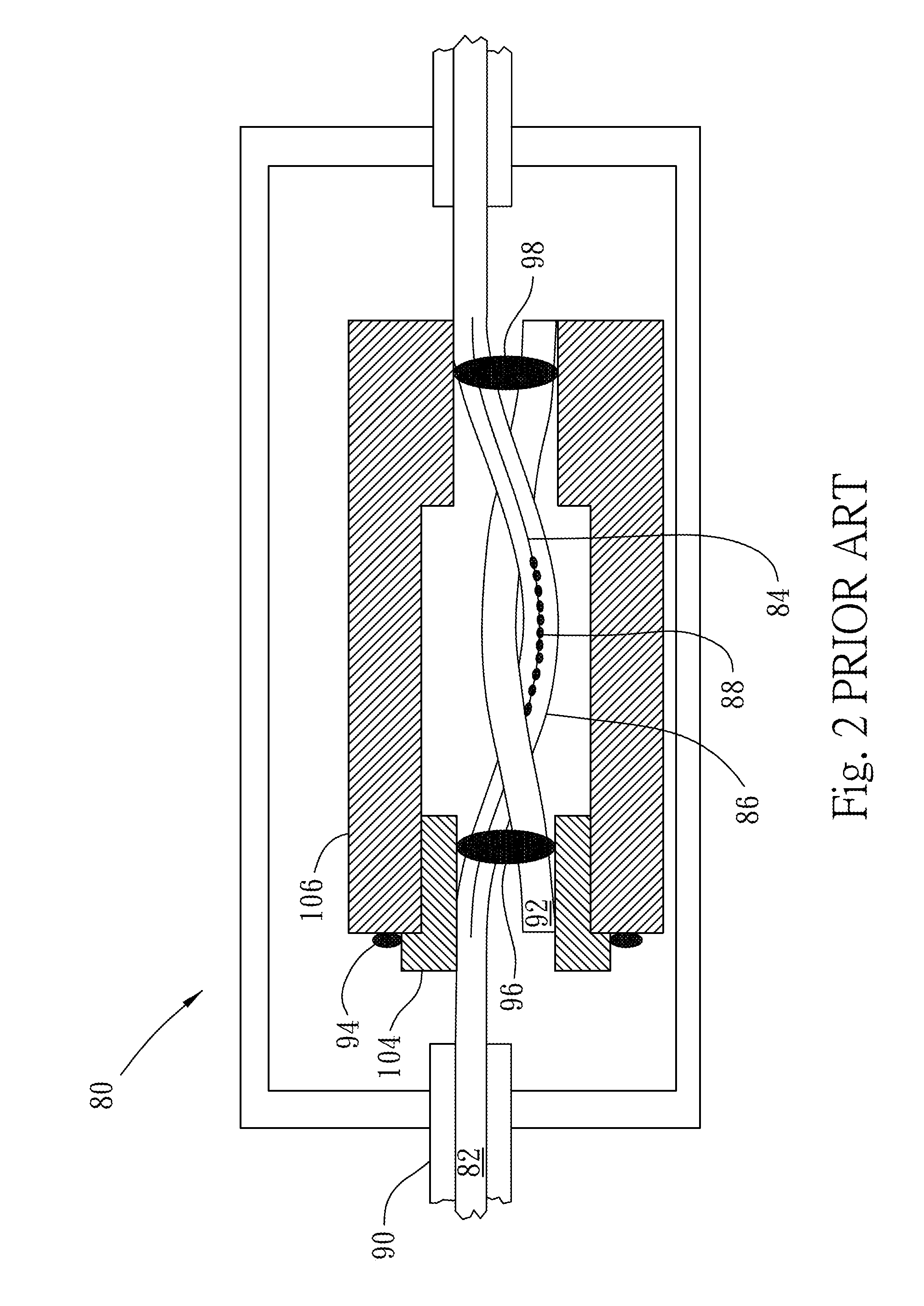

RF antenna arrangement for MRI comprising a trap circuit

InactiveUS20130207660A1Improved detuningTotal current dropElectric/magnetic detectionMeasurements using magnetic resonanceResonanceCoupling

An RF antenna or coil comprising a decoupling circuit including a parallel resonant trap circuit is disclosed for electromagnetically decoupling the RF antenna or coil when both RF antennas or coils are arranged in such proximity to each other that without a decoupling circuit couplings between both RF antennas or coils have to be expected which might lead to a decrease of the signal to noise ratio of received and / or transmitted RF signals or which couplings might lead other detrimental effects. Further, an RF transmit / receive antenna arrangement especially for an MR (magnetic resonance) imaging system or scanner is disclosed, wherein the RF transmit / receive antenna arrangement comprises an RF transmit antenna or coil which is preferably provided only for transmitting RF signals, and an RF receive antenna or coil which is preferably provided only for receiving MR signals (i.e. “dedicated” RF antennas or coils), wherein at least one of theses RF antennas or coils is provided with a decoupling circuit according to the invention.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Trench gate type semiconductor device and method of producing the same

ActiveUS20140141585A1Small extensionTransistorSemiconductor/solid-state device manufacturingMOSFETOhmic contact

A method of producing a trench gate type MOSFET is provided in which each intersection trench is formed as a two-stage trench structure. A gate trench is backfilled with a mask material and the mask material is then patterned to form a mask used for forming each intersection trench. The intersection trench intersecting the gate trench is provided so as to be deeper than the gate trench. A Schottky electrode is provided in the bottom of each intersection trench 10p. In this manner, there is provided a trench gate type semiconductor device and a method of producing the same, in which: the cell pitch can be reduced even when a wide band gap semiconductor is used as a main semiconductor substrate; good ohmic contacts can be obtained; and an excessive electric field is prevented from being applied to an insulating film in the bottom of each trench.

Owner:FUJI ELECTRIC CO LTD

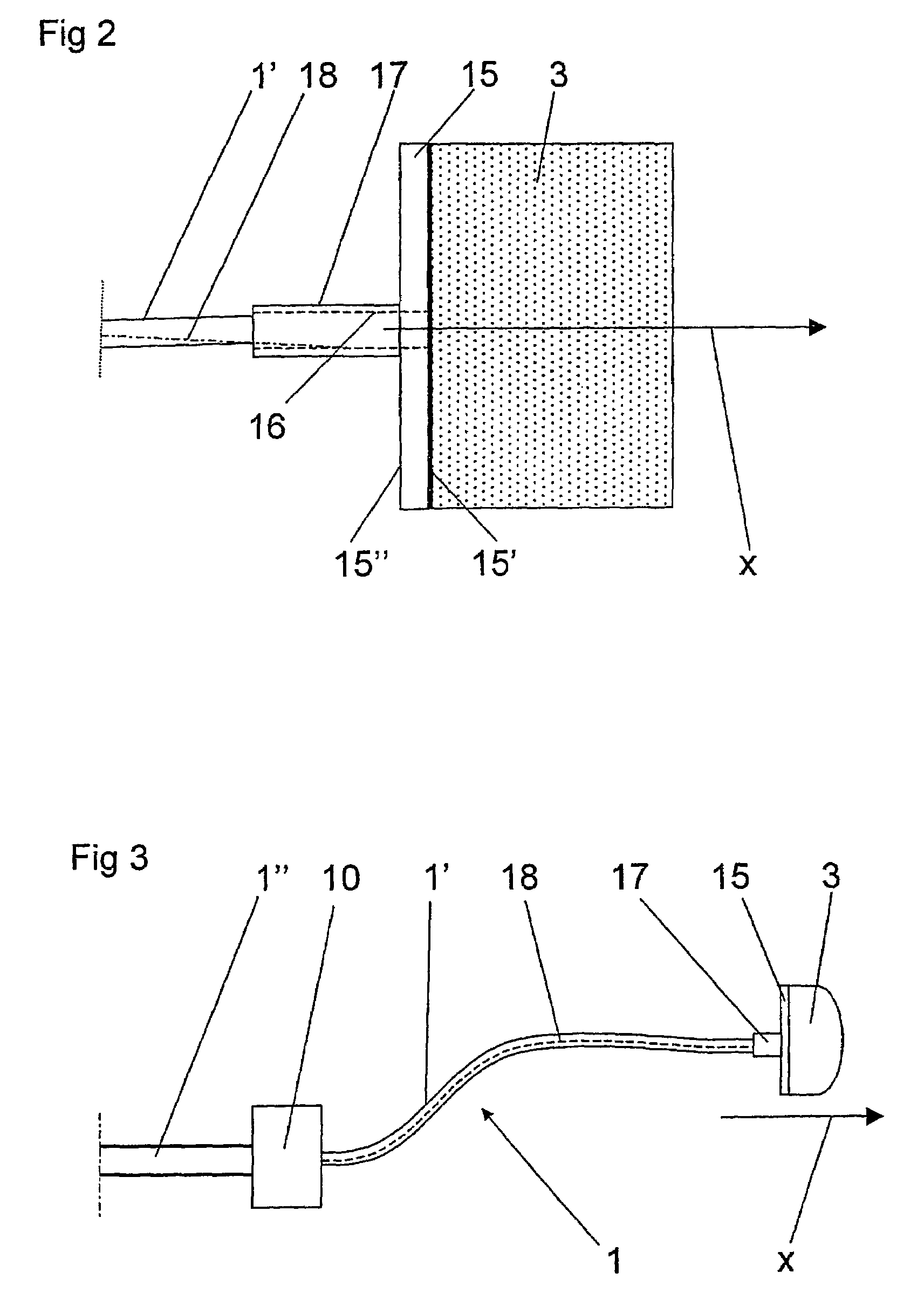

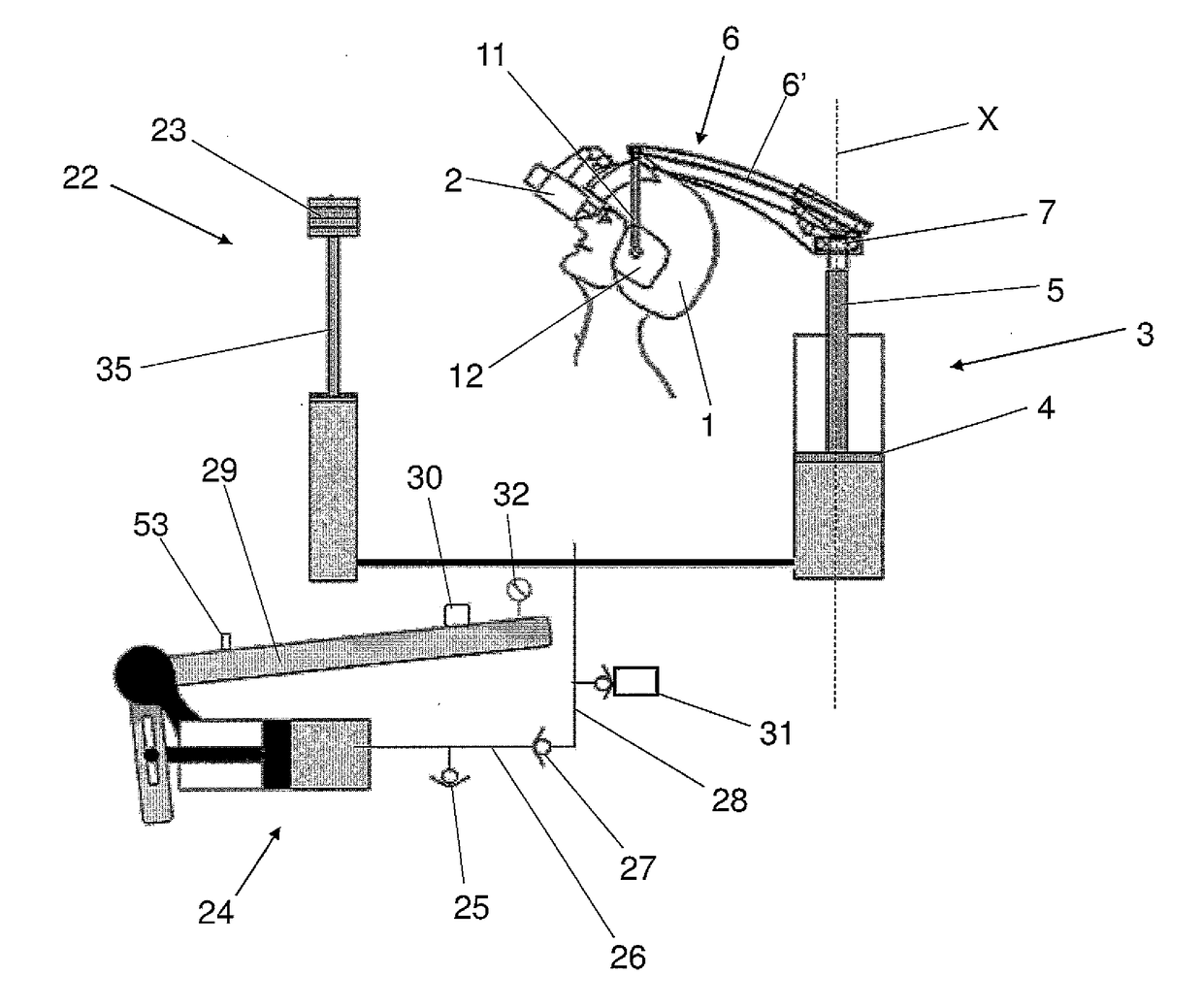

Device for the supply of a gas

InactiveUS7549973B2Increase the areaLess turbulenceOperating tablesDiagnosticsProduct gasEngineering

Owner:CARDIA INNOVATION

Acrylic fiber, ramie fiber and soybean protein fiber blended yarn

The invention provides an acrylic fiber, ramie fiber and soybean protein fiber blended yarn which comprises the following components by weight parts: 55-65 parts of acrylic fibers, 20-30 parts of ramie fibers and 10-20 parts of soybean protein fibers. The blended yarn disclosed by the invention can be sued for complementing the features of the acrylic fibers, the ramie fibers and the soybean protein fibers, and has the advantages of the acrylic fibers, the ramie fibers and the soybean protein fibers.

Owner:JIANGSU TONGHAI THREAD

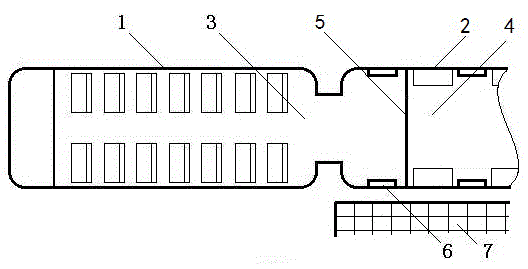

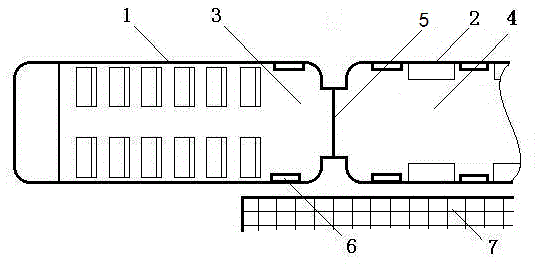

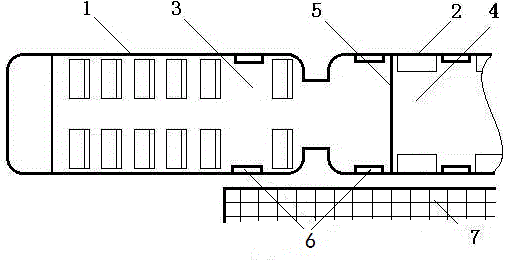

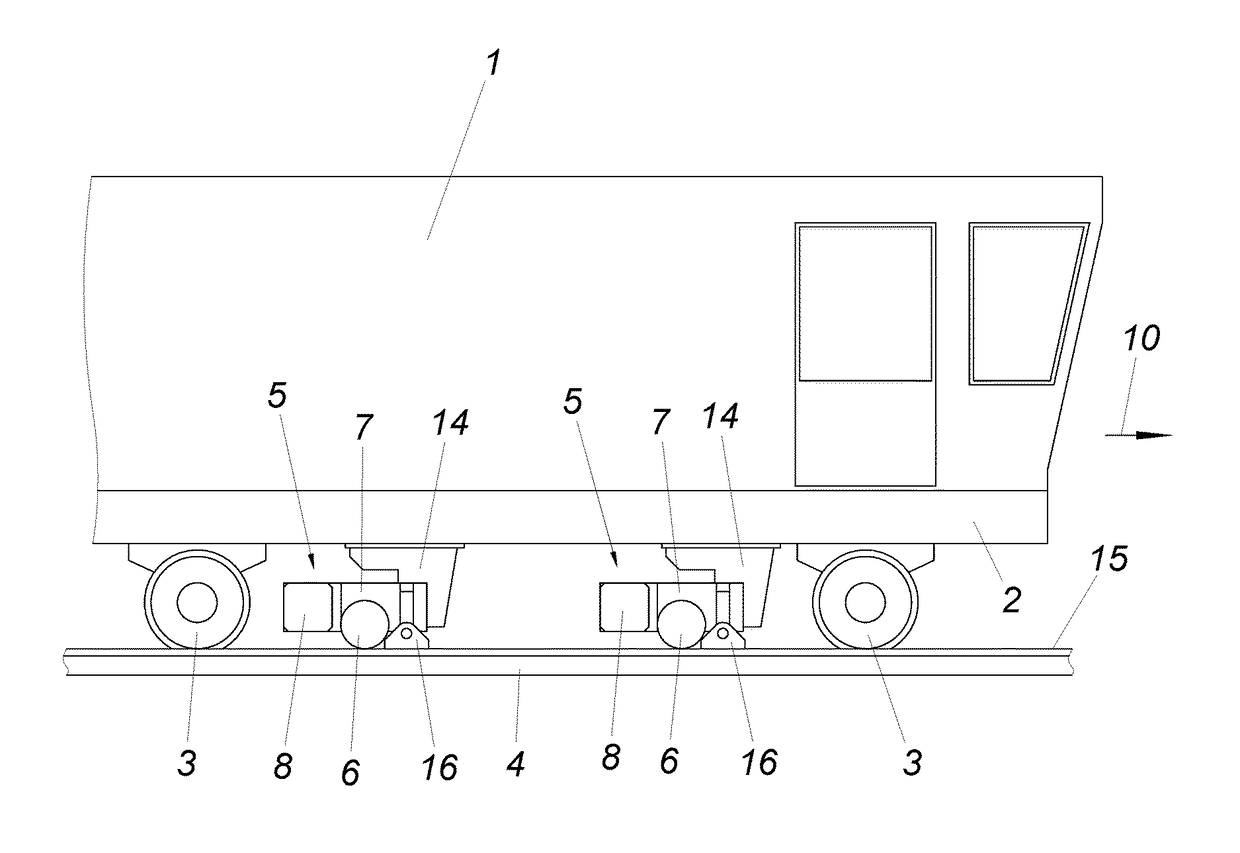

Subway mixed train

InactiveCN103818387ASmall extensionEase traffic pressureRailway componentsRailway stationTravel modePunctuality

Owner:侯庆生

Thermal compensated and tensed spring compact fiber bragg grating wavelength filter device

ActiveUS20160320555A1Small extensionIntimate initial tension strengthCladded optical fibreOptical waveguide light guideINCREASED EFFECTPre stressing

A thermal-compensated fiber Bragg grating wavelength filter comprises an outer low thermal expansion coefficient metallic tube and an inner high thermal expansion coefficient cylindrical coil spring jacketed by the outer metallic tube and pre-stressed beforehand. The thermal-induced length difference of the outer metallic tube and the inner spring generates a stress-relieving effect or stress-increasing effect on the pre-stressed high thermal expansion coefficient cylindrical coil spring, whereby to increase or decrease the refractive index and compensate for the thermal-induced wavelength shift of the fiber Bragg grating.

Owner:JINN HER ENTERPRISE

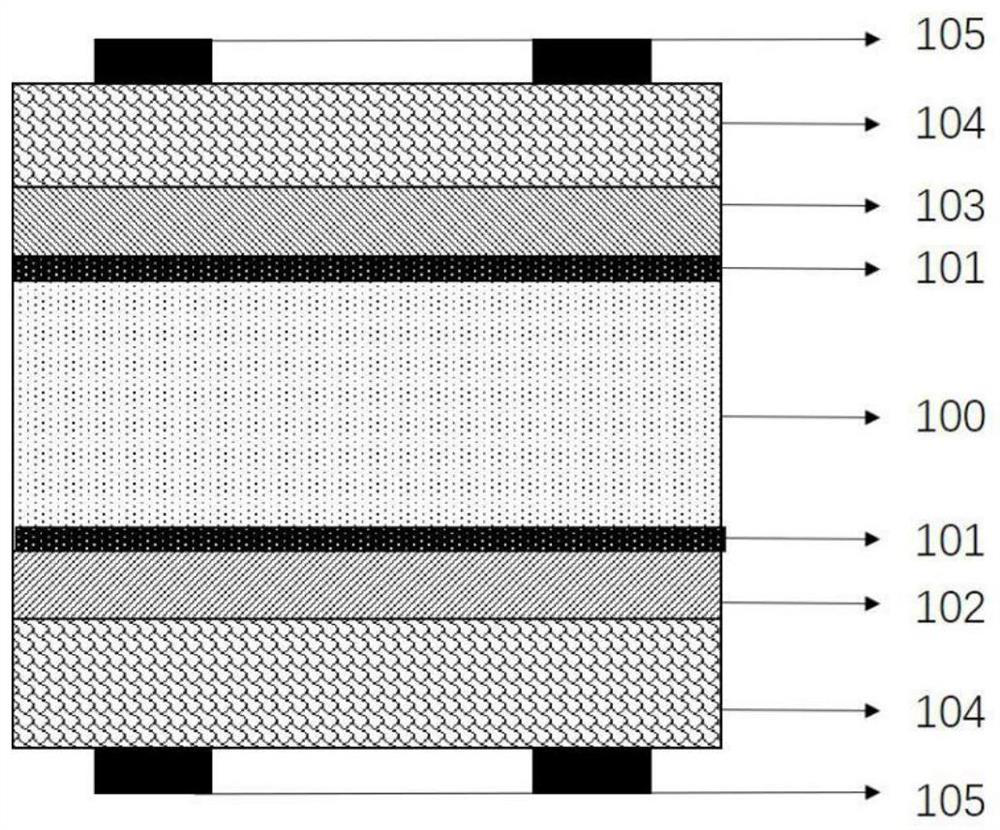

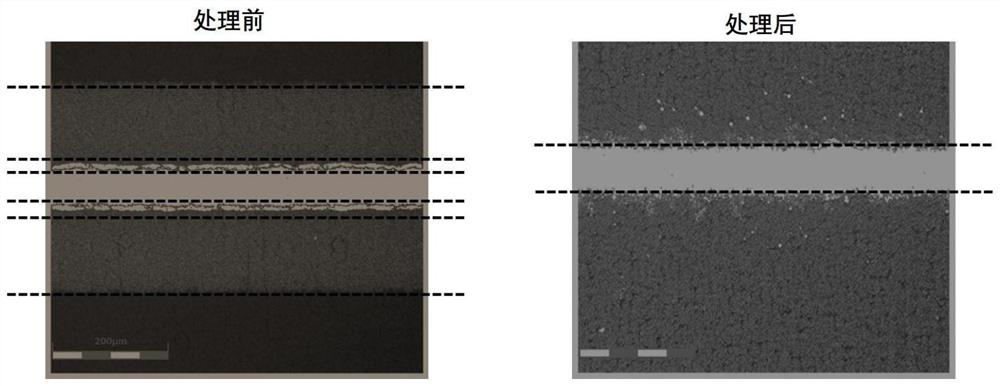

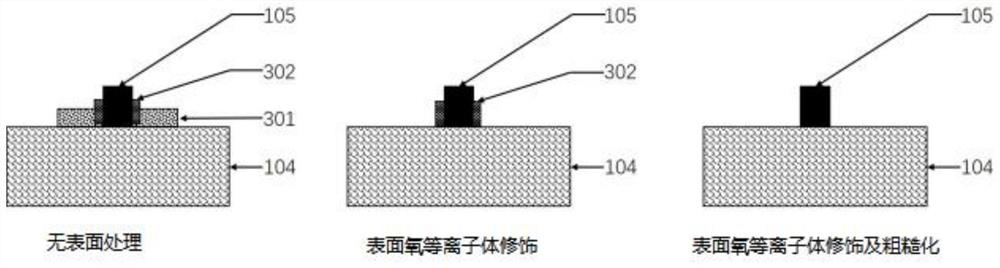

SHJ solar cell TCO film surface treatment method

ActiveCN111710759AHigh surface energyIncrease roughnessFinal product manufacturePhotovoltaic energy generationPhysicsThin membrane

The invention discloses an SHJ solar cell TCO film surface treatment method, which is used for solving the problem of poor contact between a TCO film and low-temperature silver paste in the prior art,and relates to the technical field of solar cells, and comprises the following steps: (1) depositing intrinsic amorphous silicon or amorphous silica films on the upper surface and the lower surface of a silicon wafer; (2) respectively depositing a P-type doped amorphous silicon film and an N-type doped amorphous silicon film on the upper surface and the lower surface of the silicon wafer obtainedin the step (1), or depositing amorphous silica films on the upper surface and the lower surface of the silicon wafer; (3) depositing TCO films on the upper surface and the lower surface of the silicon wafer obtained in the step (2); (4) carrying out surface treatment on the TCO film by adopting plasma, wherein the surface treatment comprises roughening treatment and modification treatment. According to the method, the contact between the low-temperature silver paste and the surface of the TCO thin film is better, the extension amount of the edge of the paste is low, the extension amount of organic matters in a paste system is small, the conversion efficiency of the SHJ solar cell is effectively improved, and the stability and the product yield of large-scale production of the SHJ solar cell are improved.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

Thermal insulation mortar with long service life

InactiveCN106082814AGuaranteed aestheticsGuaranteed thermal protectionSolid waste managementCalcium formatePolyvinyl alcohol

The invention discloses thermal insulation mortar with long service life. The thermal insulation mortar is prepared from, by weight, 1-2 parts of melamine, 0.3-1.8 parts of sulfamic acid, 2-3 parts of sodium fluosilicate, 10-16 parts of calcium carbonate, 1-2 parts of polyvinyl alcohol, 10-15 parts of carborundum, 10-15 parts of coal cinder powder, 4-6 parts of ground pumice, 45-55 parts of cement, 10-12 parts of microcapsule thermal storage and insulation materials, 3-5 parts of ramie, 0.2-0.4 part of calcium formate, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of glass fiber, 2-4 parts of wood flour and an appropriate amount of water.

Owner:ANHUI FUNAN LVYUAN CHEM

Hybrid core rope

ActiveUS8943789B2Reduce maintenance tasksNot easy to produceRope making machinesYarnFiber bundleMechanical engineering

The present invention is to provide a hybrid core rope which does not require maintenance or a hybrid core rope capable of reducing a maintenance task. The hybrid core rope includes a resin solid core in which a plurality of spiral grooves is formed in the longitudinal direction on an outer peripheral surface thereof, a plurality of fiber bundles respectively spirally wound around the outer peripheral surface of the resin solid core along the plurality of spiral grooves, the fiber bundles having thickness to fill the spiral grooves, and a plurality of steel strands spirally wound around the outer peripheral surface of the resin solid core around which the fiber bundles are wound. The fiber bundles and the strands are respectively wound so as to have angles which are not parallel to each other.

Owner:TOKYO ROPE MFG

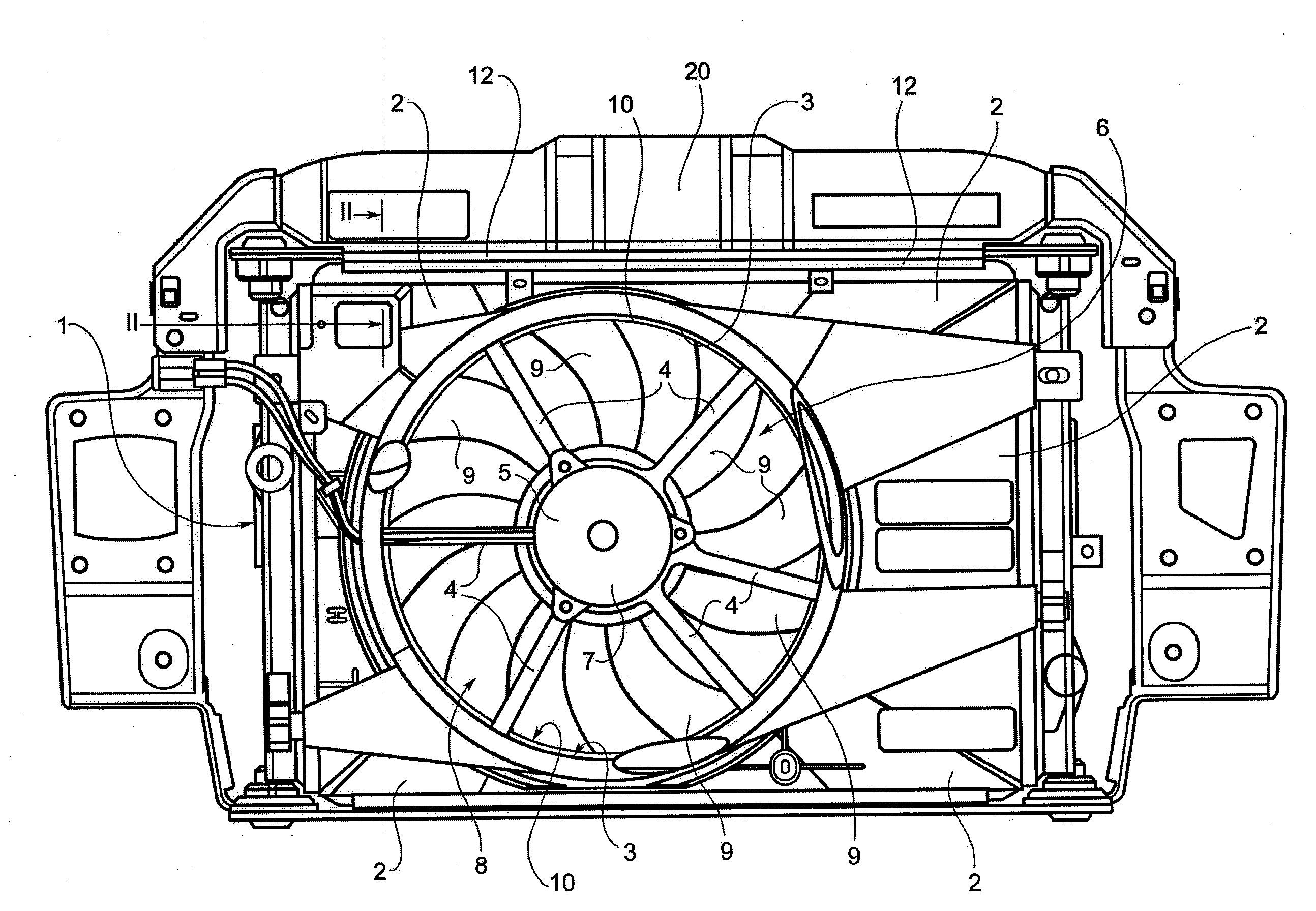

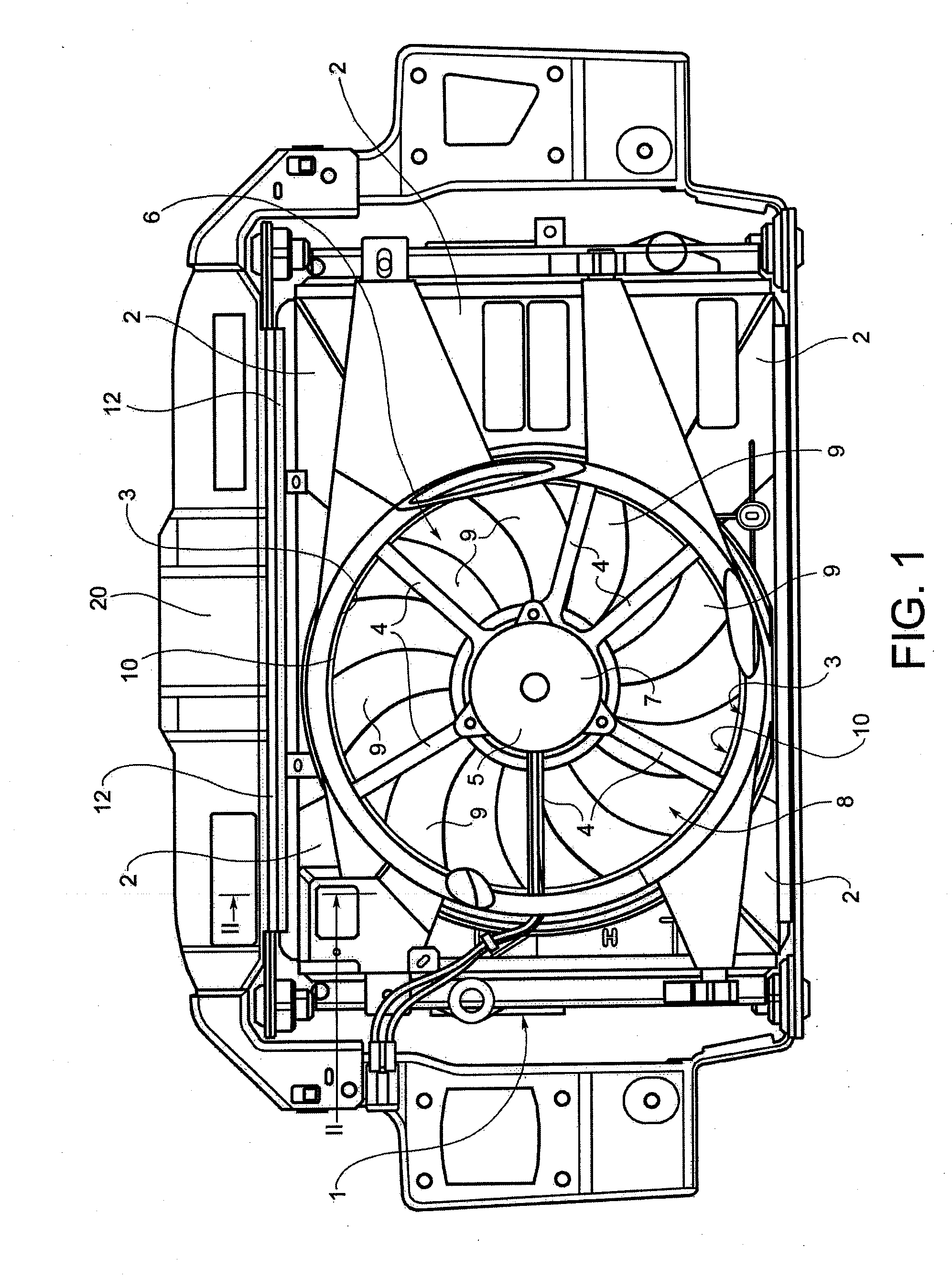

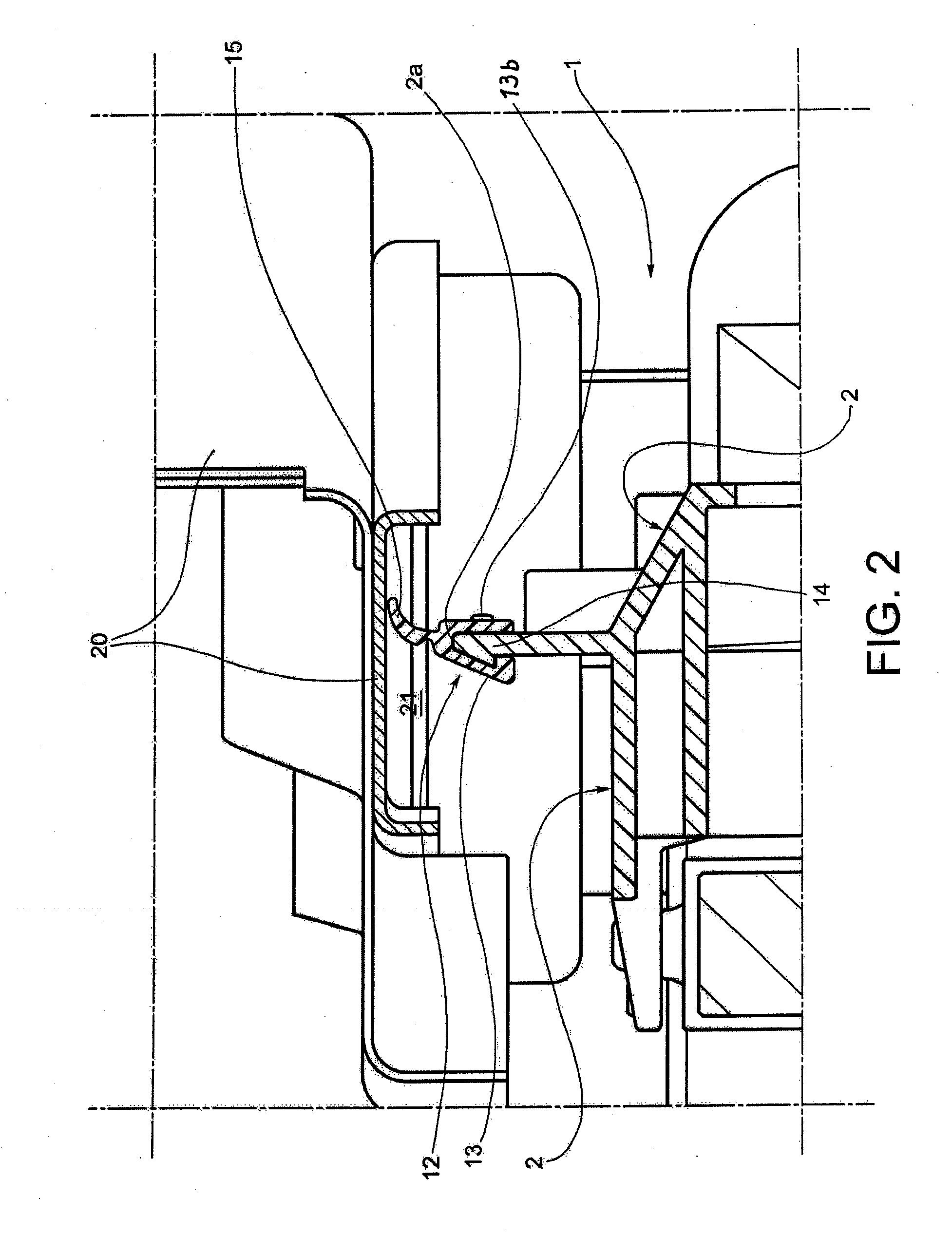

Fan unit for a heat exchanger

A fan unit for a heat exchanger of a vehicle, has a plate-like support structure or shroud which has a main opening defining a passage for a flow of air for ventilation of the heat exchanger, and an electric fan arranged to cause the flow of air. The fan has a drive motor and an impeller connected to the motor. The support structure or shroud has a top side intended to extend at a small distance from a horizontal cross-member of the heat exchanger or the vehicle, so that an interspace is defined between them. This top side of the support structure or shroud has a flexible sealing gasket which has a configuration such that, in the assembled operating condition of the fan unit, the gasket is able to close off the interspace.

Owner:JOHNSON ELECTRIC SA

Electrical conductor cable and method for forming the same

InactiveCN101006527AEasy to joinEfficient manufacturingNon-insulated conductorsPower cables with screens/conductive layersElectrical conductorEngineering

An electrical conductor came for long distance transmission of electrical current is provided. The conductor came includes a plurality of individual cylindrically shaped non-conductive components. The conductor cable further includes an electrically conductive m tuber located on an exterior of the core. A method for forming such a conductor cable is also provided.

Owner:GIFT TECH LP

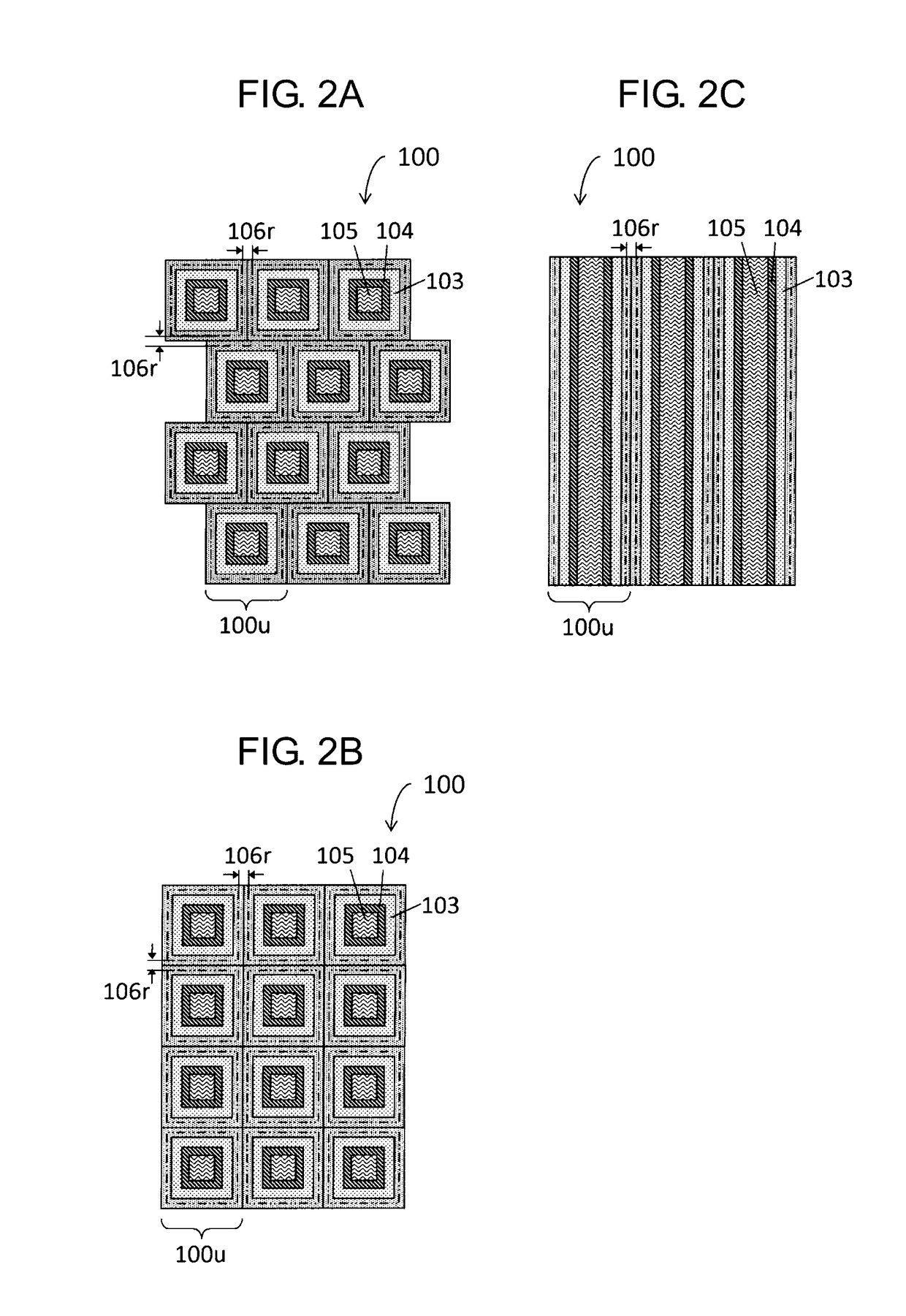

Silicon carbide semiconductor element and method for manufacturing the same

ActiveUS20170125575A1Reduce conduction lossReduce switch lossTransistorSolid-state devicesBody regionHigh concentration

In the silicon carbide semiconductor element, a second silicon carbide semiconductor layer that is in contact with the surface of a first silicon carbide semiconductor layer has at least an upper layer including a dopant of a first conductivity type at a high concentration. Above a junction field effect transistor (JFET) region interposed between body regions that are disposed in the first silicon carbide semiconductor layer so as to be spaced from each other, the silicon carbide semiconductor element has a channel removed region, which is a cutout formed by removing a high concentration layer from the front surface side of the second silicon carbide semiconductor layer, the high concentration layer having a higher dopant concentration than at least the dopant concentration of the JFET region. The width of the channel removed region is smaller than that of the JFET region.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

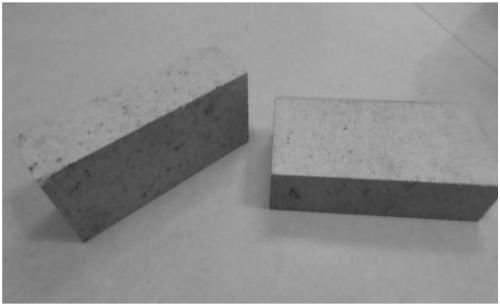

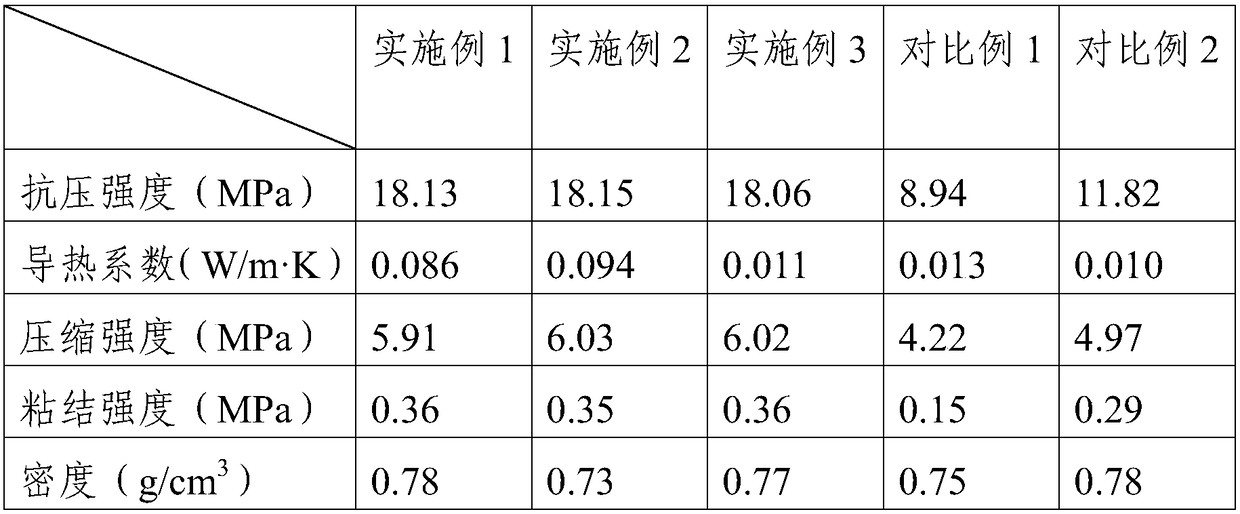

Method for preparing insulation bricks by using ramie fiber and riverway sludge

The invention provides a method for preparing insulation bricks by using ramie fiber and riverway sludge, and relates to the field of building materials. The method comprises the following steps: preparing the ramie fiber; heating trichloromethane to 75-85 DEG C, adding PVC while stirring, continuing stirring until the PVC is completely dissolved, cooling to room temperature, then immersing the ramie fiber for 15-20min, then taking out, and drying to obtain PVC-coated ramie fiber; excavating the riverway sludge, then flushing by using river water till a flow state, then conveying into a sludgetank by using a pressure pump, adding carbon powder, leaving to stand, then extracting a supernatant, excavating soil in the bottom layer, drying, then crushing, adding into a mixing tank, adding tapwater, fly ash, the PVC-coated ramie fiber, a polycarboxylate water reducer and Portland cement, heating up to 40-60 DEG C and uniformly stirring; sending a mixed material into a brick press, pressing into brick blanks, performing steam curing on the brick blanks in an autoclave for 5-6 hours, then drying till the moisture content is lower than or equal to 12%, and curing for 15-30 days. The prepared insulation bricks have the characteristics of high strength, no cracking, good insulation and the like and have extremely high economic and social benefits.

Owner:郑辉

Sealable terminal for rechargeable battery

ActiveUS9520590B2Improve sealingImprove mechanical stabilityFinal product manufactureCell lids/coversRechargeable cellInjection moulding

Owner:WEGMANN AUTOMOTIVE GMBH & CO KG

SBS (Styrene-Butadiene-Styrene) modified asphalt and production method thereof

InactiveCN101962482BReduce manufacturing costEnhanced interactionBuilding insulationsButadiene DioxideSolvent

The invention discloses SBS (Styrene-Butadiene-Styrene) modified asphalt and a production method thereof. The SBS modified asphalt mainly comprises the components of matrix asphalt No.70, linear SBS, a solubilizer and a stabilizer, wherein the linear SBS accounts for 3.6% to 4.2% be weight of the of matrix asphalt No.70, the solubilizer accounts for 2.0% to 3.0% by weight of the matrix asphalt No.70, and the stabilizer accounts for 0.16-0.18% be weight of the matrix asphalt No.70. The production method of the SBS modified asphalt comprises the following steps of: (1) heating the matrix asphalt No.70 to 175 DEG C to 185 DEG C; (2) adding the linear SBS and uniformly stirring; and (3) adding the solubilizer and the stabilizer and thoroughly grinding twice by using a colloid mill to obtain the SBS modified asphalt. The production method adopted in the invention effectively shortens the modified time and is low in production cost.

Owner:XUZHOU CITY LUXING HIGHWAY ENG

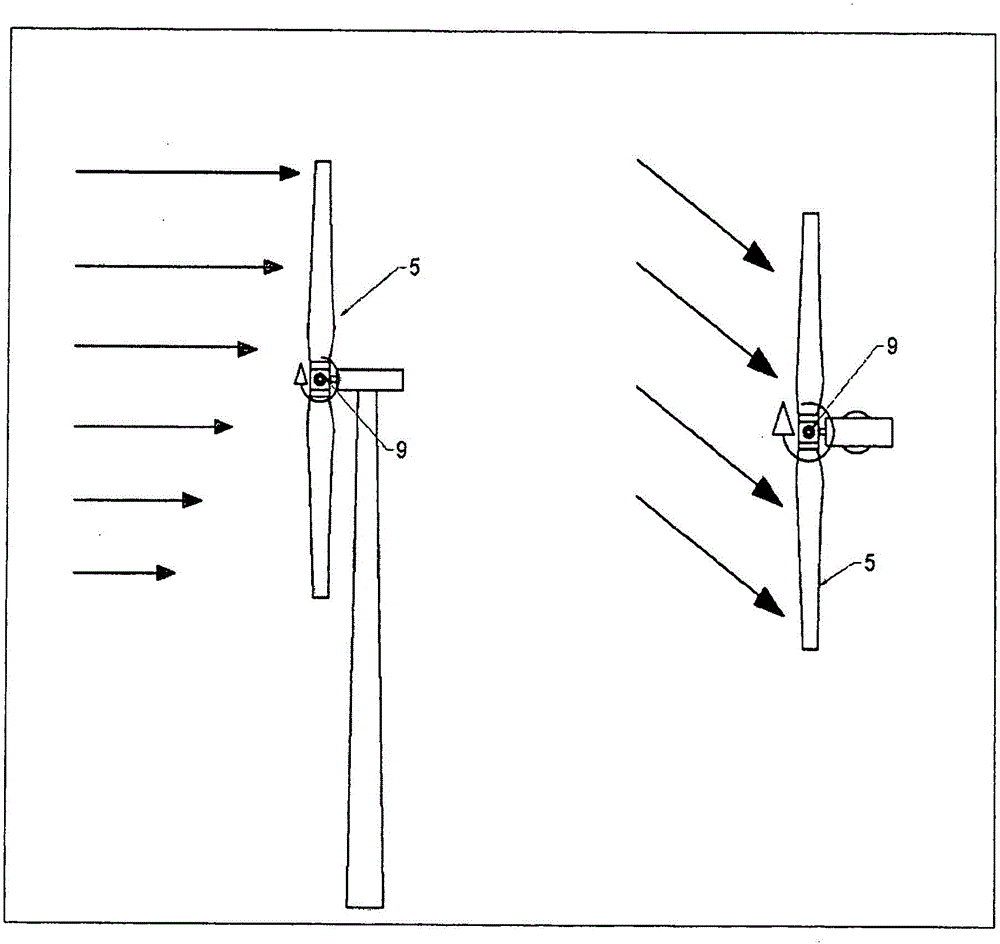

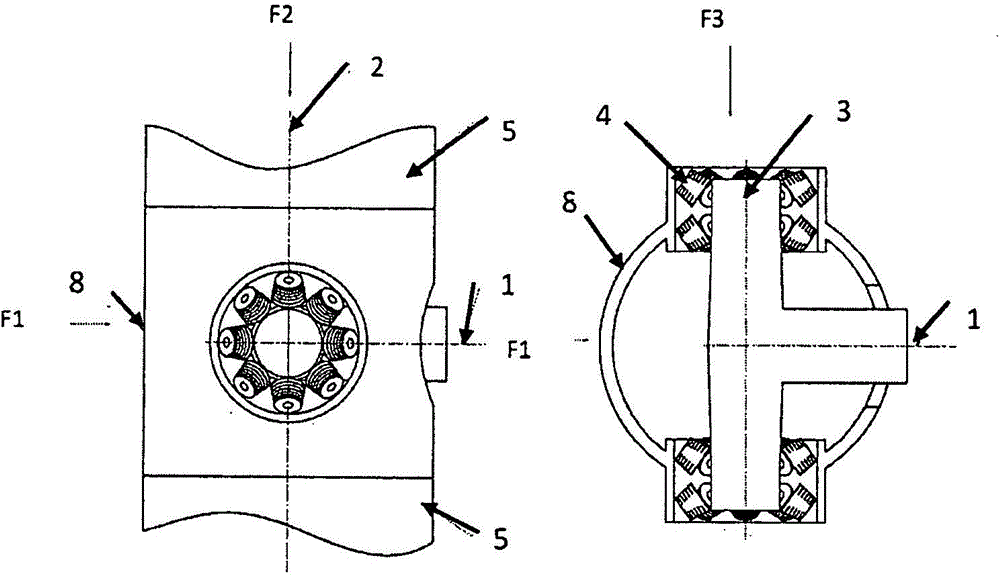

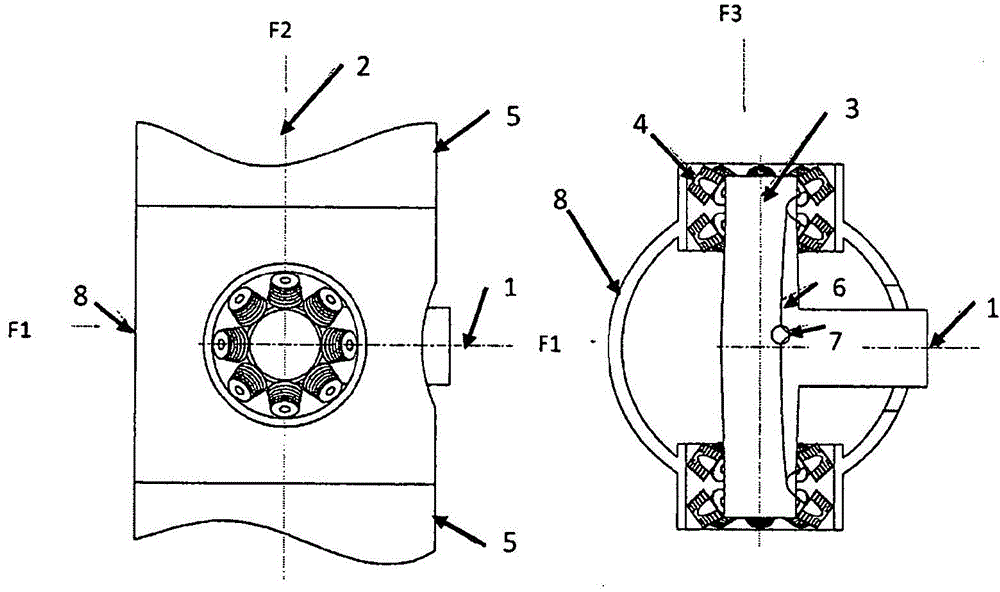

Elastic self-aligning bearing

ActiveCN104797844AEasy to produceEasy to pretensionWind motor controlNon-rotating vibration suppressionEngineeringMechanical engineering

Owner:ESM ENERGIE UND SCHWINGUNGSTECHN MITSCH GMBH

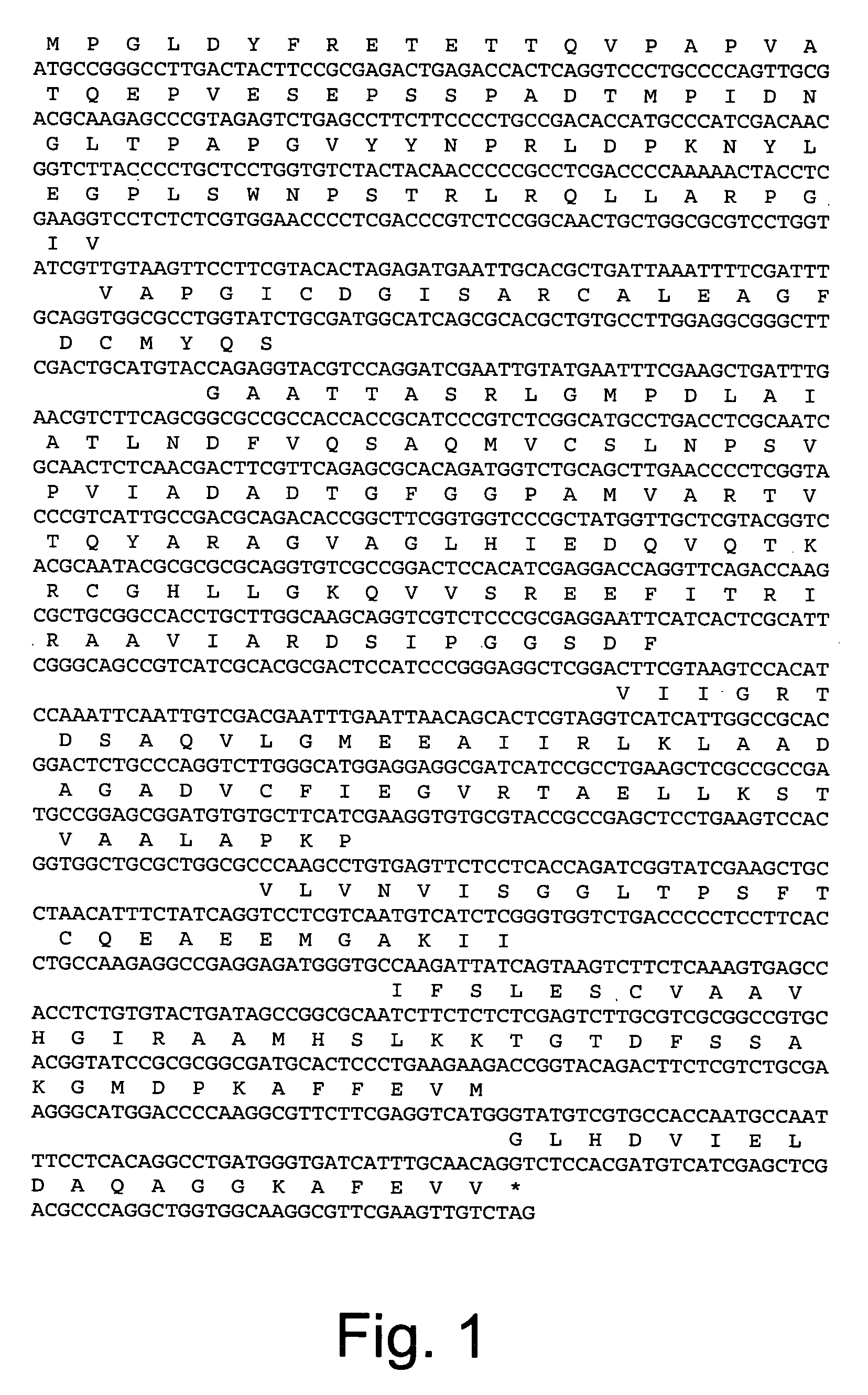

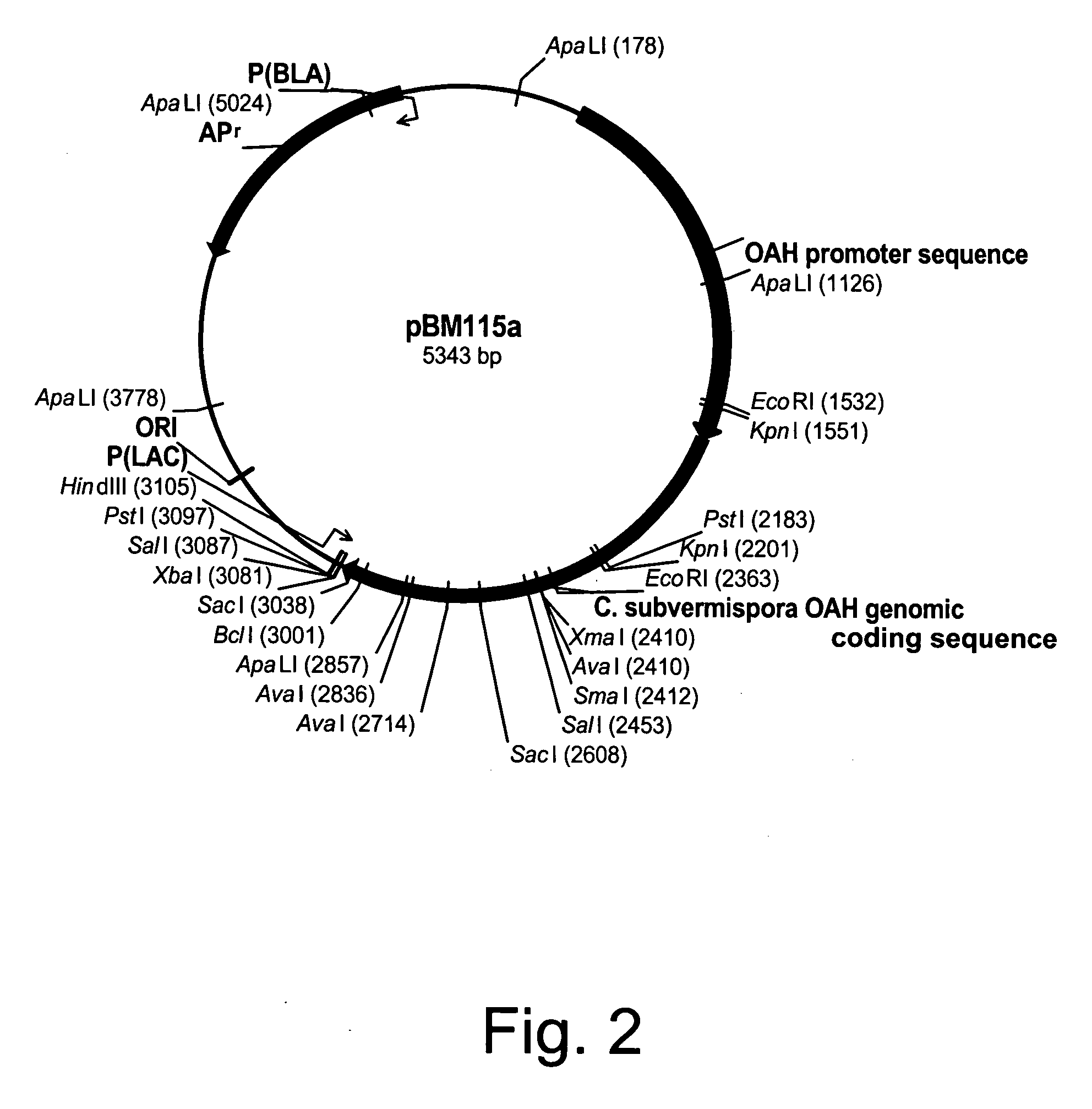

Polypeptides having oxaloacetate hydrolase activity and nucleic acids encoding same

InactiveUS20050048635A1Improve purification effectSmall extensionBacteriaSugar derivativesBiotechnologyNucleotide

The present invention relates to isolated polypeptides having oxaloacetate hydrolase activity and isolated polynucleotides encoding the polypeptides. The invention also relates to nucleic acid constructs, vectors, and host cells comprising the polynucleotides as well as methods for producing and using the polypeptides.

Owner:NOVO NORDISKBIOTECH INC

Silicon carbide semiconductor element and method for manufacturing the same

ActiveUS9923090B2Reduce conduction lossIncrease capacitanceTransistorSolid-state devicesDopantHigh concentration

In the silicon carbide semiconductor element, a second silicon carbide semiconductor layer that is in contact with the surface of a first silicon carbide semiconductor layer has at least an upper layer including a dopant of a first conductivity type at a high concentration. Above a junction field effect transistor (JFET) region interposed between body regions that are disposed in the first silicon carbide semiconductor layer so as to be spaced from each other, the silicon carbide semiconductor element has a channel removed region, which is a cutout formed by removing a high concentration layer from the front surface side of the second silicon carbide semiconductor layer, the high concentration layer having a higher dopant concentration than at least the dopant concentration of the JFET region. The width of the channel removed region is smaller than that of the JFET region.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

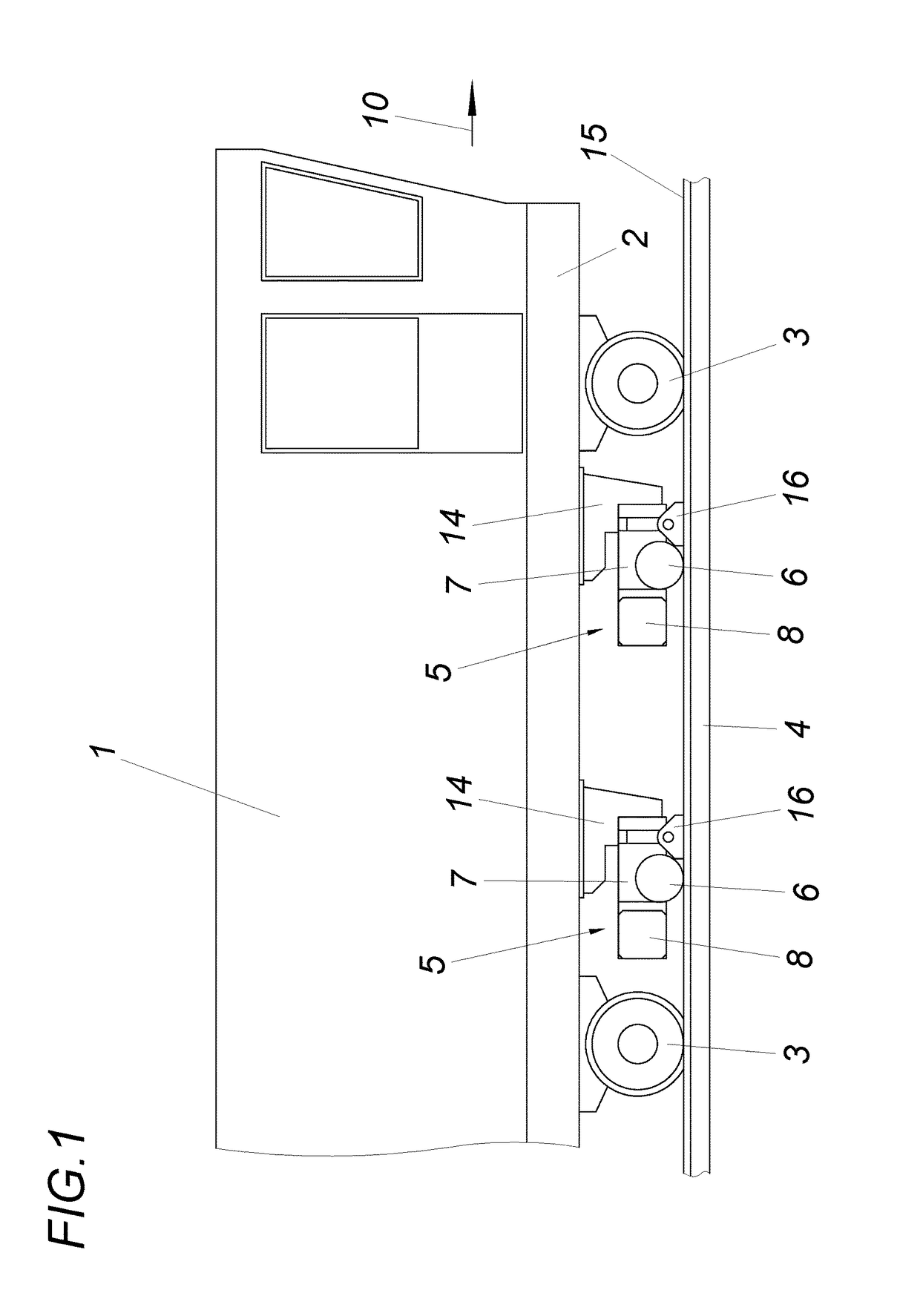

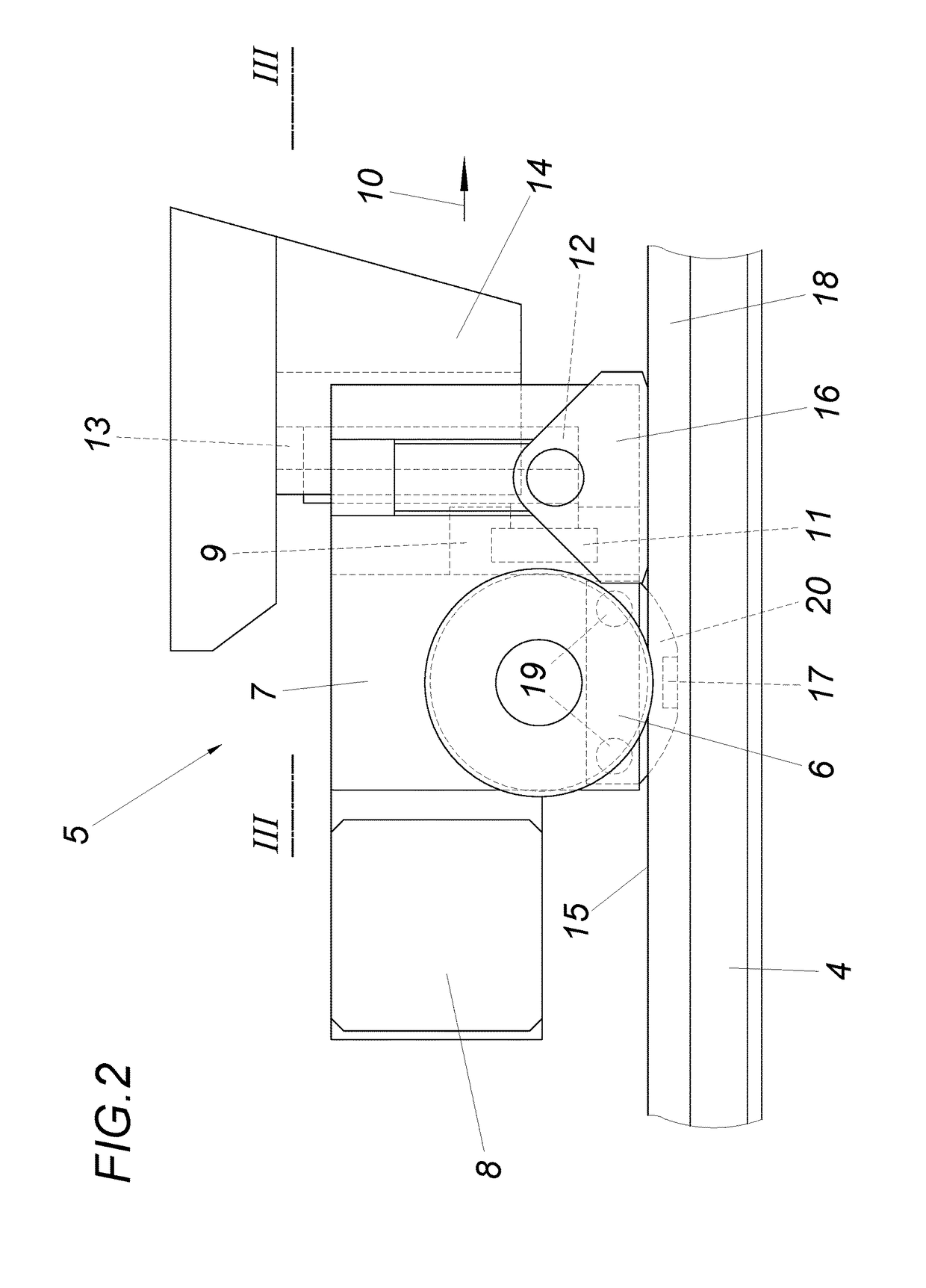

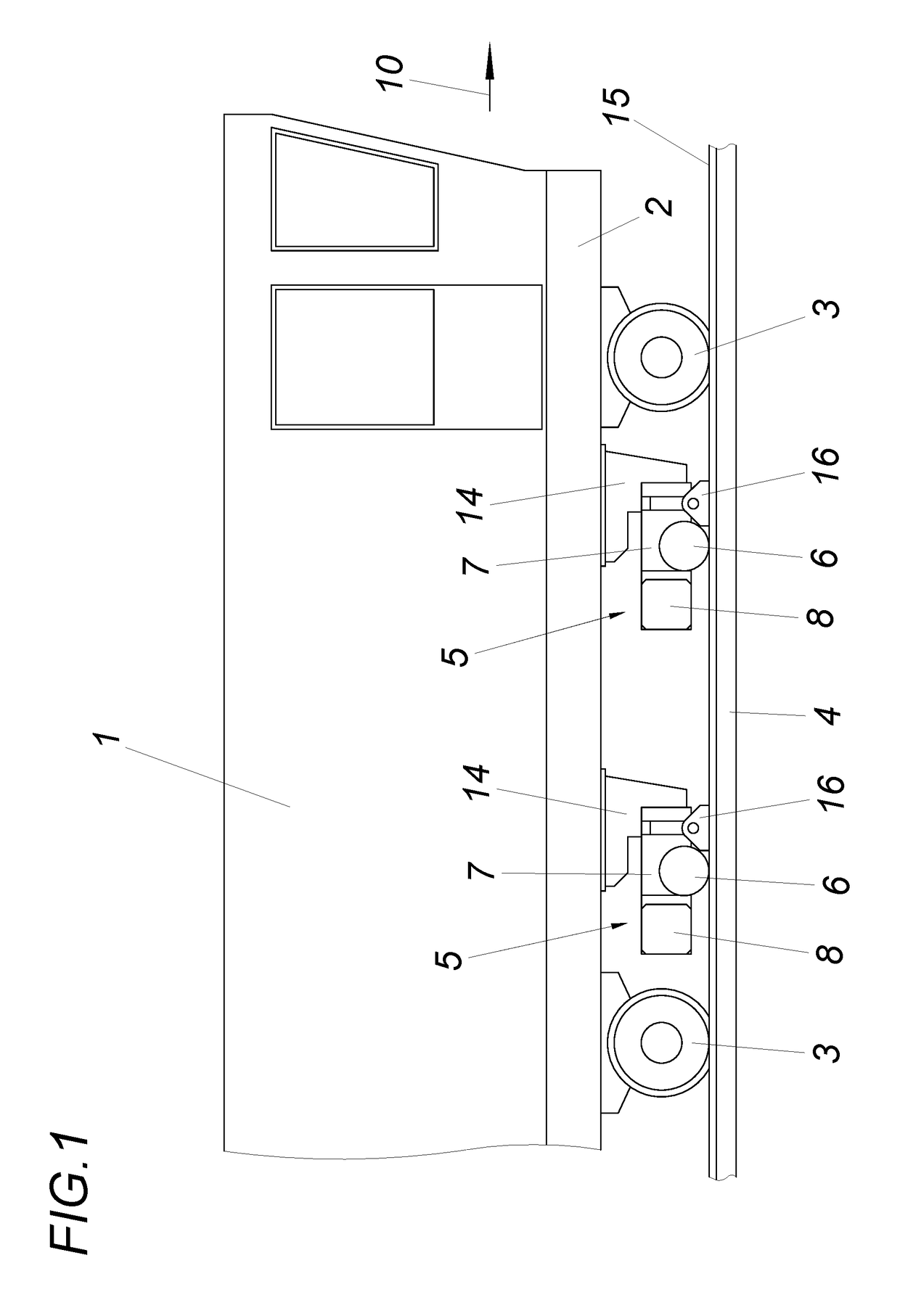

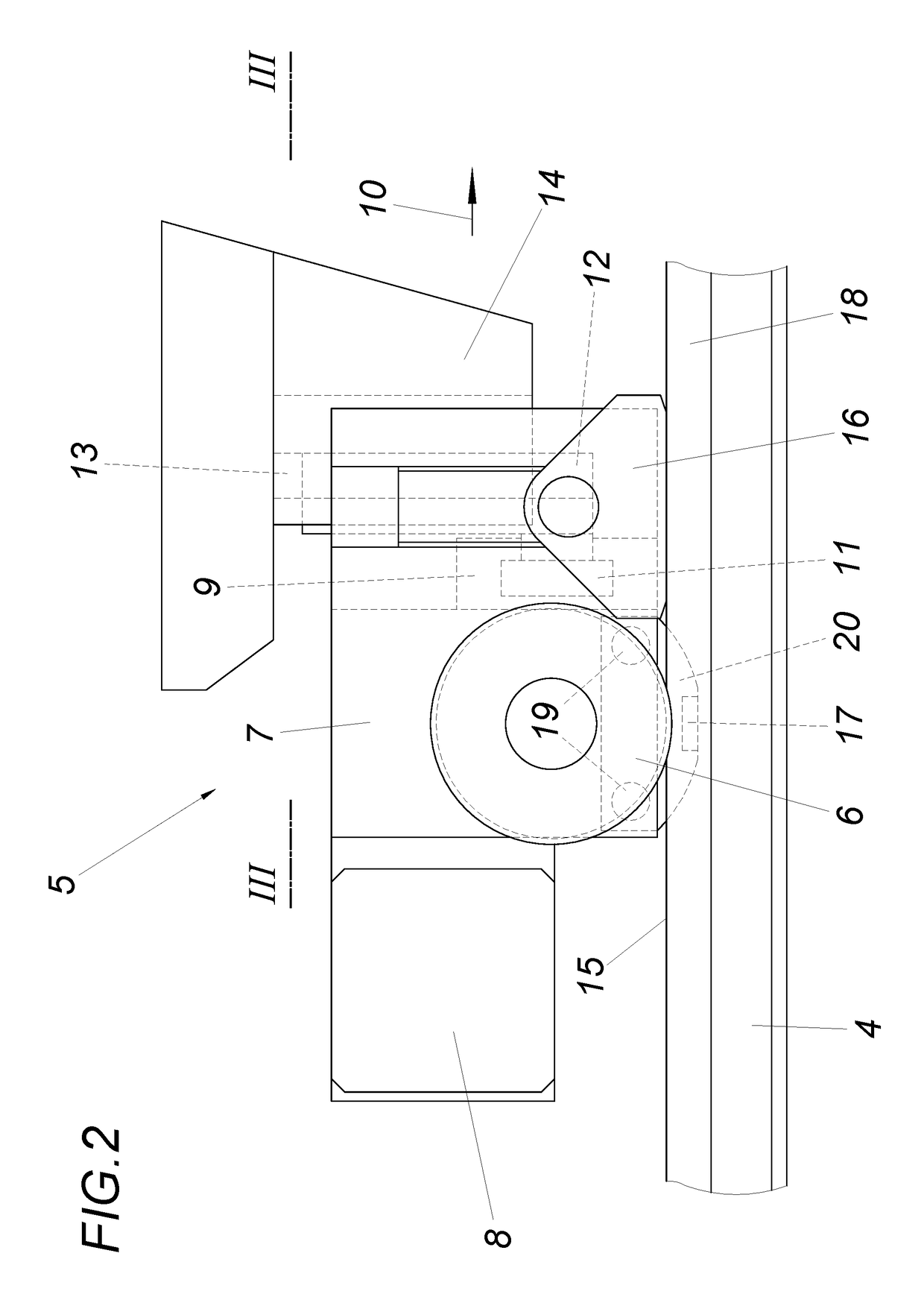

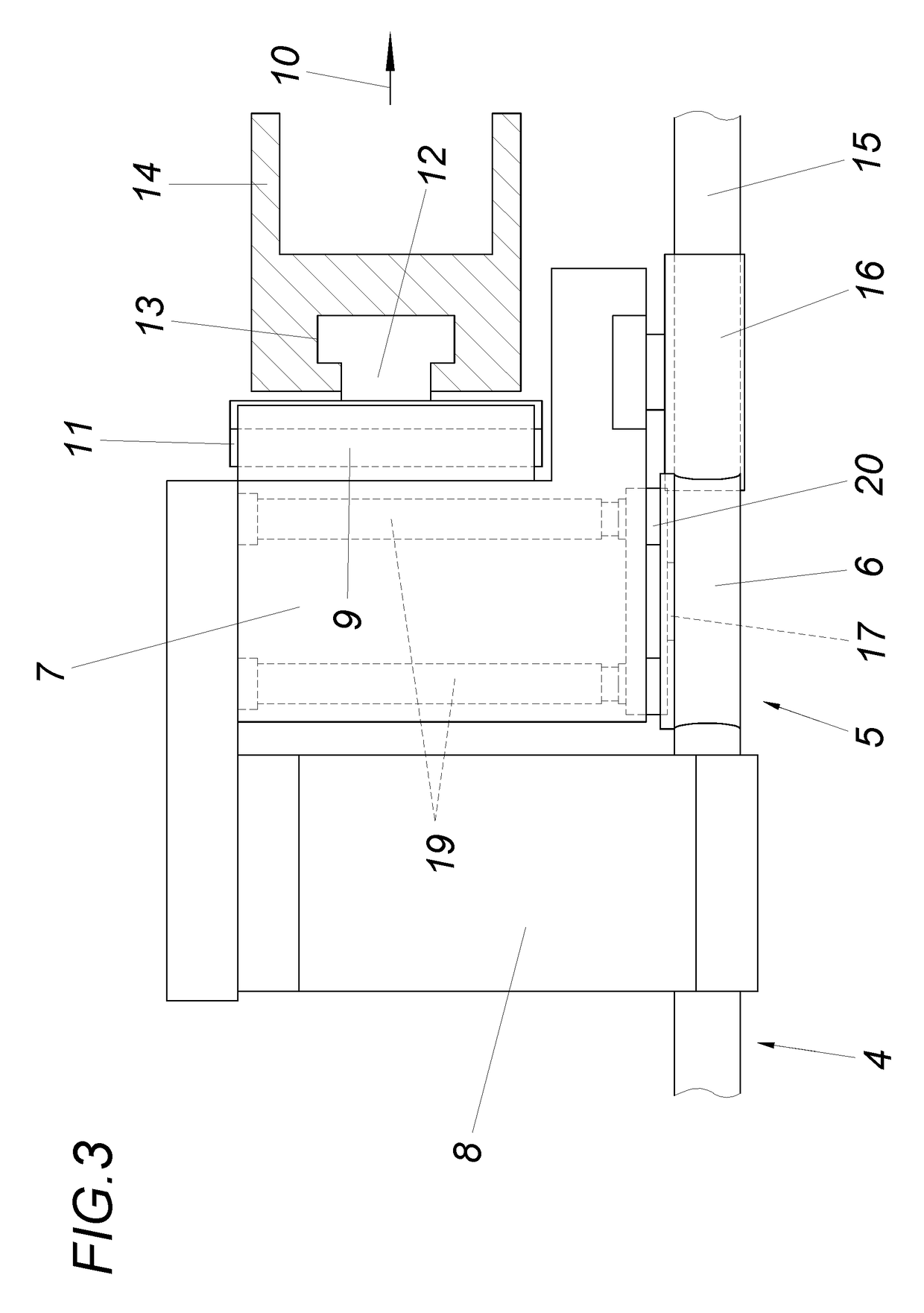

Rail vehicle having a device for finishing the running surface of track rails

A rail vehicle includes a milling device for finishing the running surface of track rails during the travel of the rail vehicle along the track rails. The rail vehicle has a chassis frame having wheel sets. The milling device is provided with a milling head, and includes a framework arranged on the chassis frame having a milling head receptacle, which is displaceable vertically and transversely in relation thereto. The milling head receptacle can be supported for the vertical guiding via a guide shoe on the running surface and for transverse guiding in parallel to the milling head shaft via a guide stop laterally on the railhead. The milling head receptacle forms a transverse carriage, which supports the guide shoe and the guide stop, and the guide path of which, which is vertically displaceable, is provided on the side of the milling head receptacle facing toward the guide shoe.

Owner:LINSINGER MASCHENBAU GES

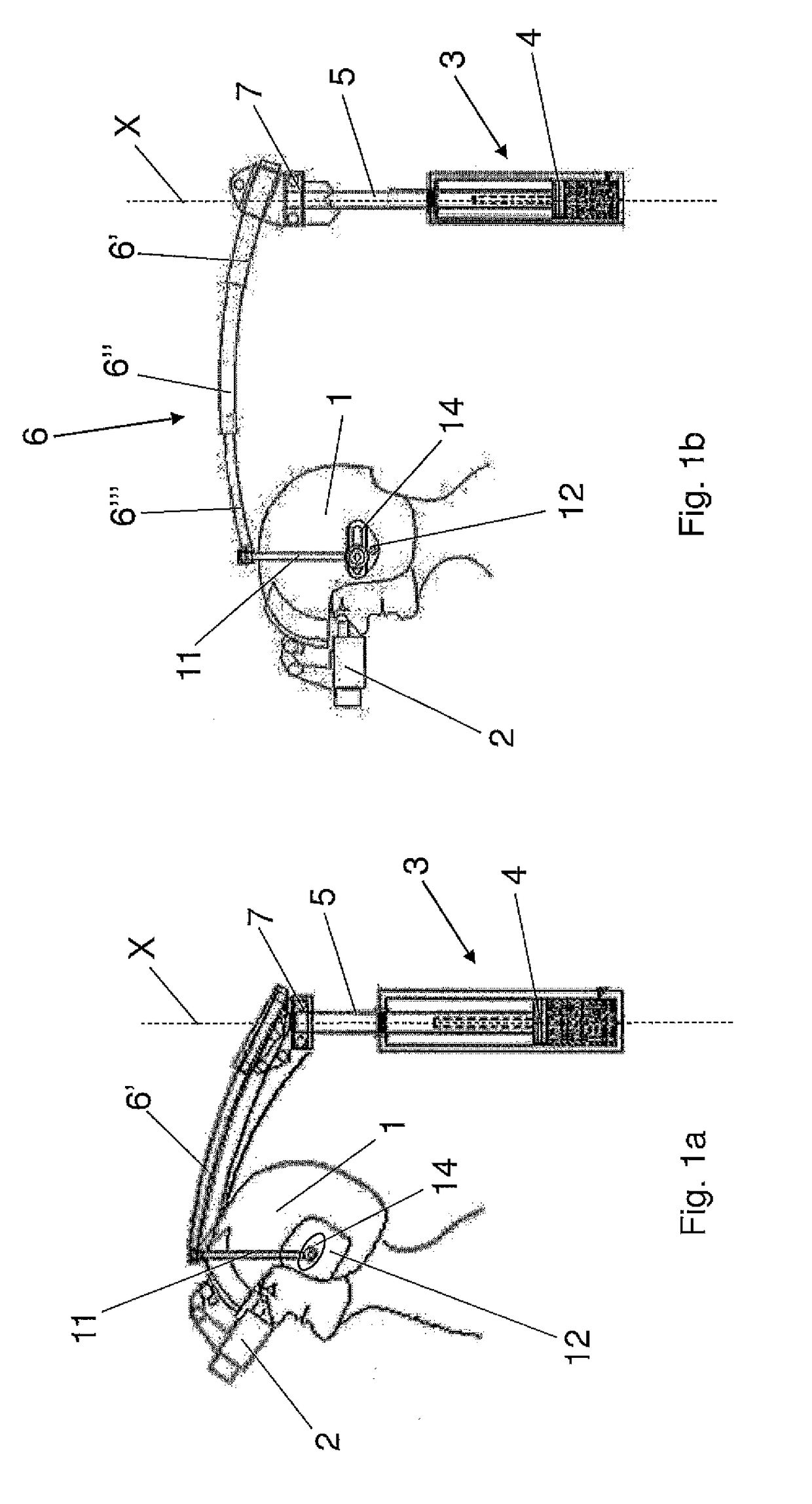

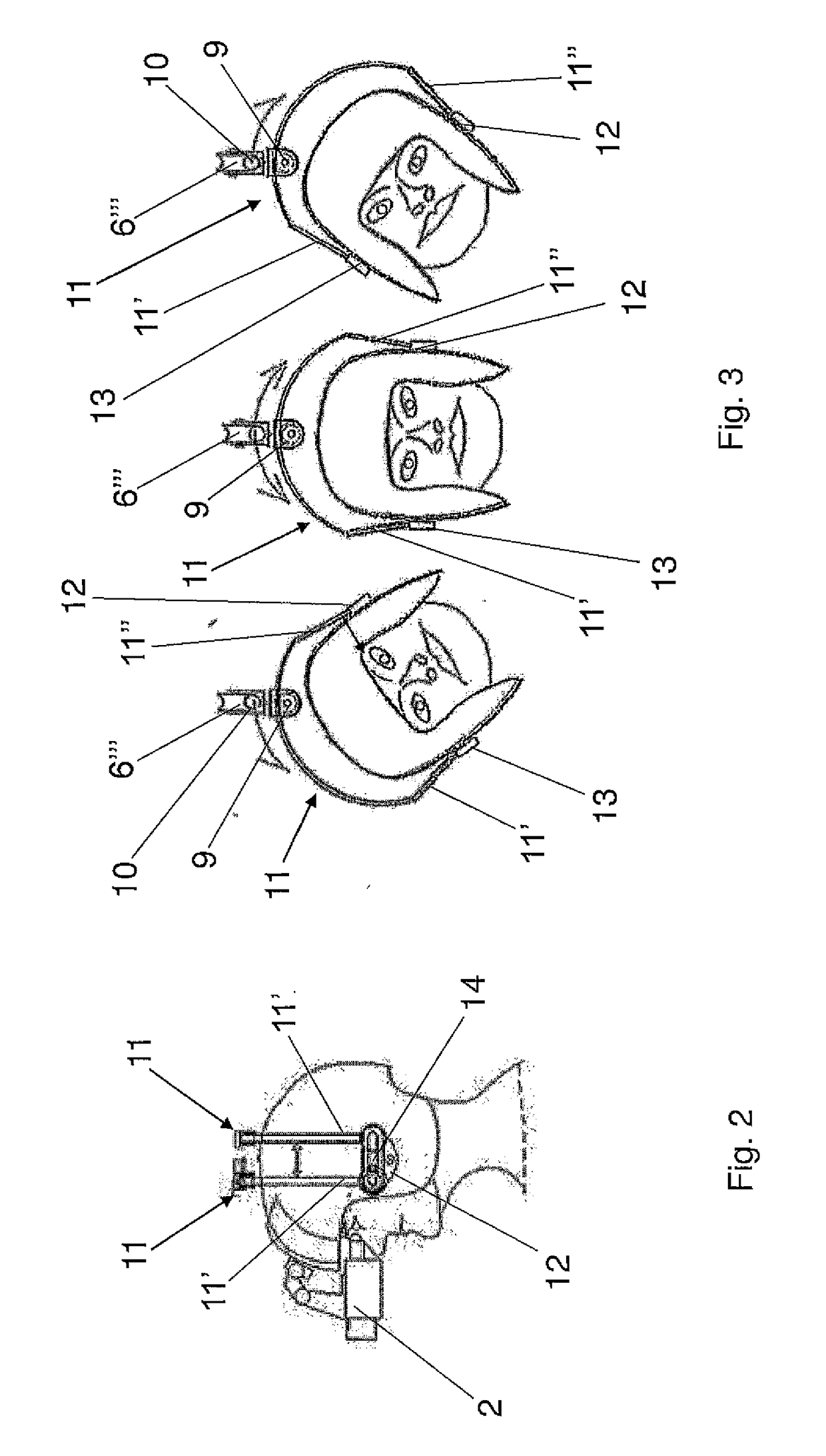

System for supporting the head-helmet unit of a passenger inside a vehicle

ActiveUS20180140035A1Limited space insideLower the volumePlug valvesHelmetsAutomotive engineeringCenter of mass

A system for lifting the head of an individual in a vehicle who is wearing a helmet, the system comprising suspension means for suspending the helmet and adjustment means for balancing the head of the individual as a function of the center of mass of the head of the individual, of the helmet and of any further equipment.

Owner:B M A BUIZZA MAZZEI AGENCY

Rail vehicle having a device for finishing the running surface of track rails

Owner:LINSINGER MASCHENBAU GES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com