SHJ solar cell TCO film surface treatment method

A surface treatment and solar cell technology, applied in the field of solar cells, can solve problems such as sewage discharge and mask cost, silver-clad copper low-temperature paste printability, and product cost that do not meet the requirements of industrialization promotion, etc., to achieve easy control of the process, The effect of improving stability and product yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment takes the PECVE coating technology as an example to provide a surface treatment method for TCO thin films of SHJ solar cells, including the following steps:

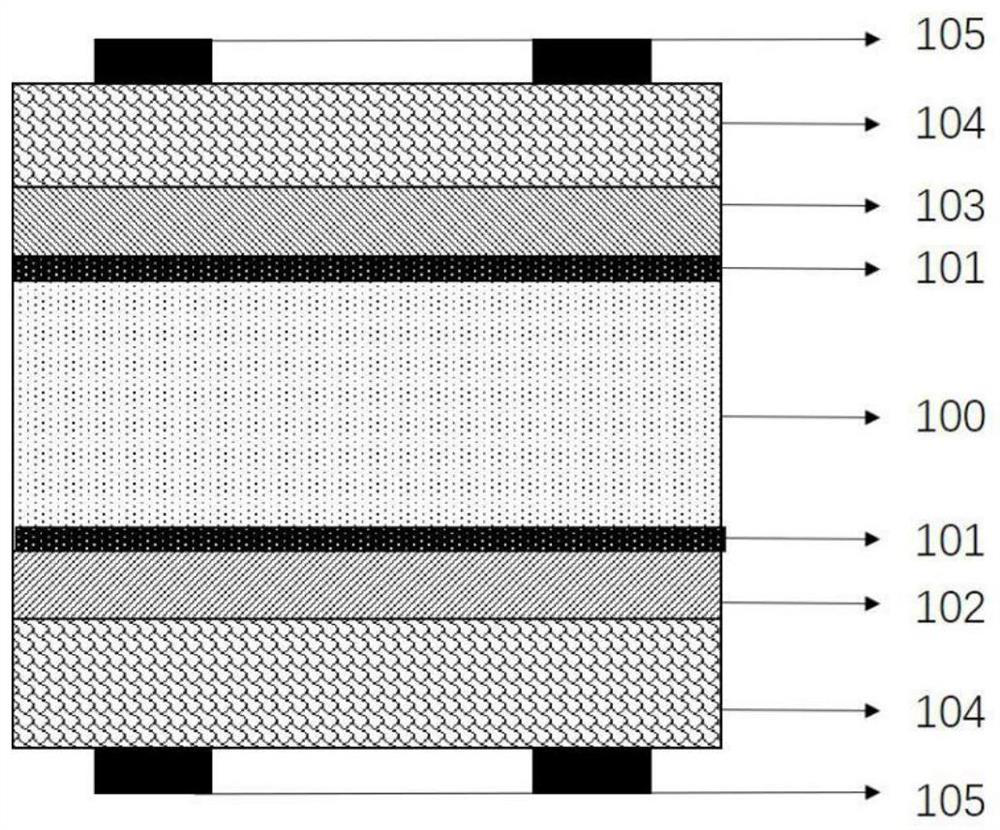

[0033] (1) Using an n-type single crystal silicon wafer 100 as a substrate, first carry out surface texturing and chemical cleaning on the silicon wafer to form a pyramidal concave-convex structure that can improve light absorption on the surface, and then form an ultra-clean surface after chemical cleaning again, Then utilize the PECVD method to deposit intrinsic amorphous silicon film 101 on the upper and lower surfaces of the silicon wafer respectively, deposit a P-type doped silicon thin film 102 stack on the lower surface intrinsic amorphous silicon thin film 101, and deposit the intrinsic amorphous silicon thin film 101 on the upper surface Deposit an N-type doped amorphous silicon thin film 103 stack on the top, and then deposit a TCO thin film 104 on both sides respectively.

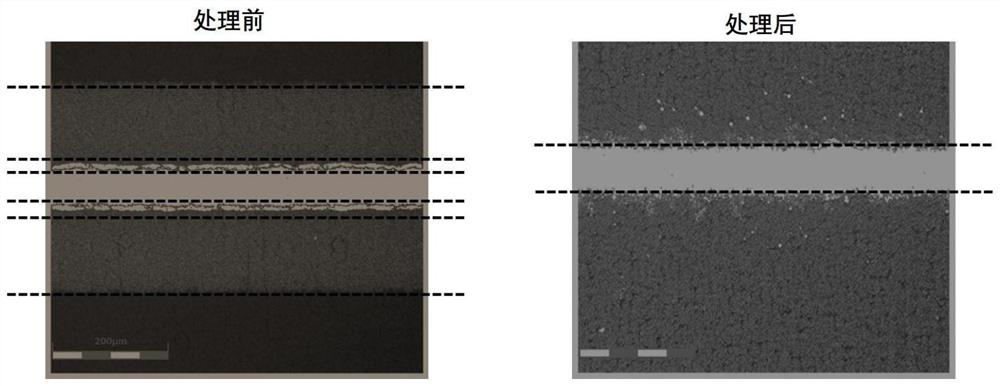

[0034](2) Aft...

Embodiment 2

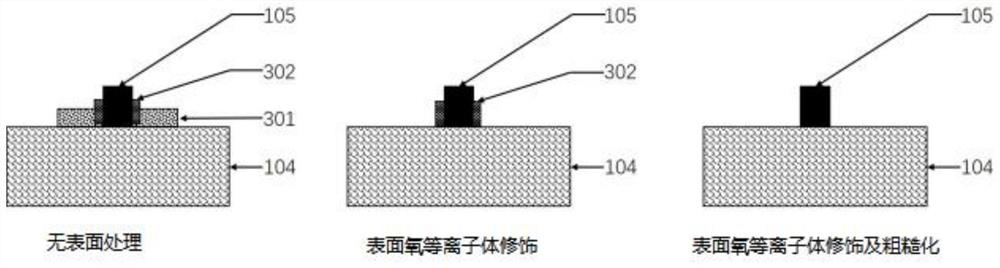

[0037] The difference between this embodiment and embodiment 1 is that, with O 2 As the plasma gas source, the surface of the TCO film was modified, but the roughening treatment was omitted, and the rest of the steps were the same.

Embodiment 3

[0039] The difference between this embodiment and embodiment 1 is that, with CCl 4 and Ar as the plasma gas source to roughen the surface of the TCO film. 2 and SF 6 Perform modification treatment for the plasma gas source, and the rest of the steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com