Patents

Literature

53results about How to "Shorten modification time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

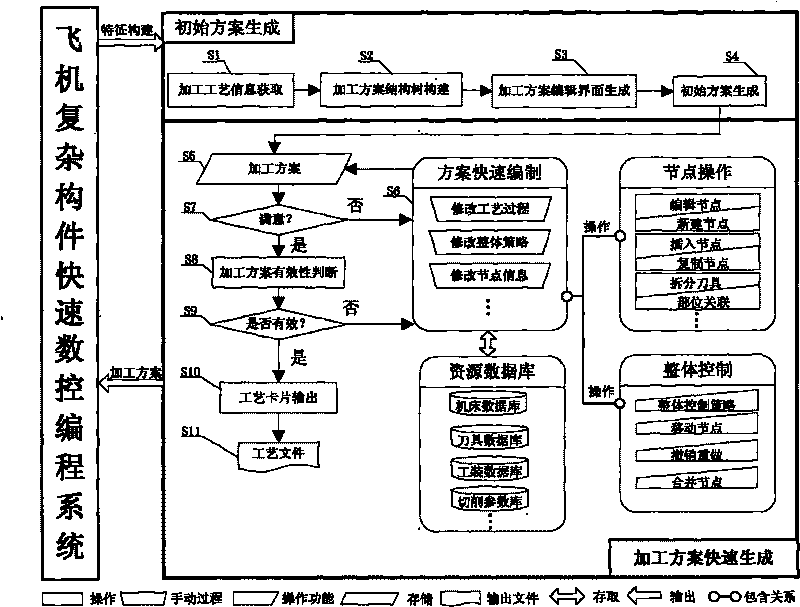

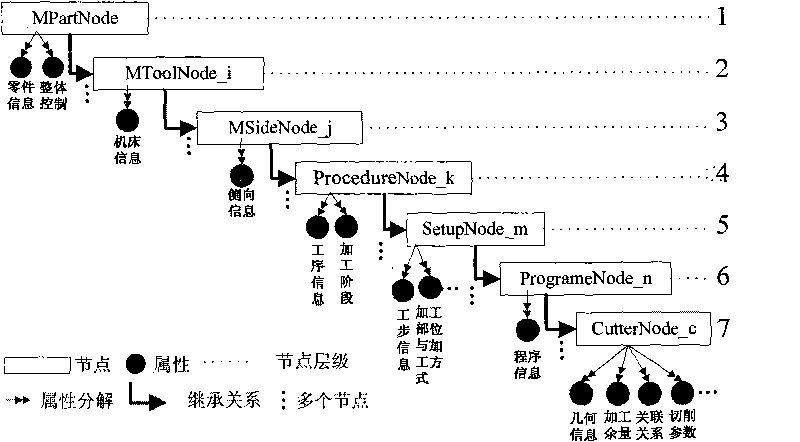

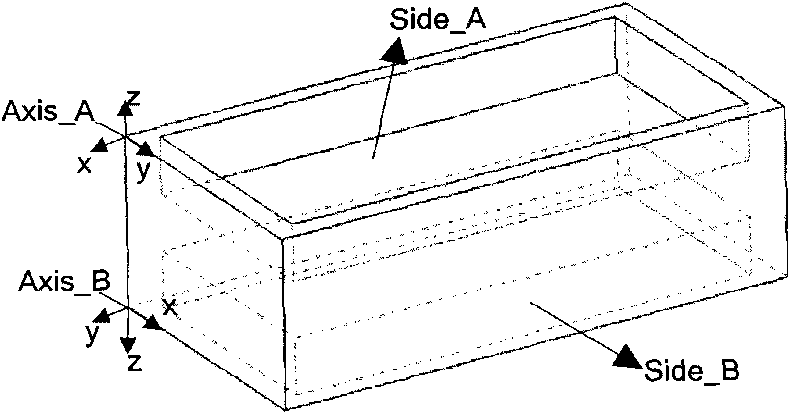

Quick generation method of numerical control machining scheme of complex parts of airplane

InactiveCN101763067AImprove efficiencyImprove accuracyProgramme controlComputer controlNumerical controlReusability

The invention discloses a quick generation method of a numerical control machining scheme of complex parts of an airplane, which mainly comprises the steps of: 1) obtaining machining technology information; 2) building the structural tree of the machining scheme; 3) generating the interaction display of the machining scheme; 4) quickly coding the machining scheme; 5) testing the effectiveness of the machining scheme; and 6) outputting the scheme. The method educates, normalizes and standardizes the machining scheme of the complex parts of the airplane, and improves the unitarity of the machining scheme, the reusability and the programming quickness, thereby shortening the programming period of numerical control machining scheme of the complex parts of the airplane, and improving the numerical control machining preparing efficiency and the machining quality.

Owner:SHENYANG AIRCRAFT CORP +1

SBS (Styrene-Butadiene-Styrene) modified asphalt and production method thereof

The invention discloses SBS (Styrene-Butadiene-Styrene) modified asphalt and a production method thereof. The SBS modified asphalt mainly comprises the components of matrix asphalt No.70, linear SBS, a solubilizer and a stabilizer, wherein the linear SBS accounts for 3.6% to 4.2% be weight of the of matrix asphalt No.70, the solubilizer accounts for 2.0% to 3.0% by weight of the matrix asphalt No.70, and the stabilizer accounts for 0.16-0.18% be weight of the matrix asphalt No.70. The production method of the SBS modified asphalt comprises the following steps of: (1) heating the matrix asphalt No.70 to 175 DEG C to 185 DEG C; (2) adding the linear SBS and uniformly stirring; and (3) adding the solubilizer and the stabilizer and thoroughly grinding twice by using a colloid mill to obtain the SBS modified asphalt. The production method adopted in the invention effectively shortens the modified time and is low in production cost.

Owner:XUZHOU CITY LUXING HIGHWAY ENG

Method for electrochemically modifying surface of ultrasonic-enhanced carbon fiber

The invention provides a method for electrochemically modifying surface of ultrasonic-enhanced carbon fiber. The method comprises the following steps of: firstly, pretreating the surface of the carbon fiber material, secondarily, soaking the pretreated carbon fiber material into an electrolytic bath filled with strong electrolyte solution; and by taking the carbon fiber material as an electrochemically oxidized anode and graphite as an electrochemically oxidized cathode, guiding in current through control of a voltage-stabilizing power supply, wherein the current intensity is 1A / g-2A / g; and under the conditions of ultrasonic power of 200W-2000W, ultrasonic frequency of 20kHz-100kHz, and water bath temperature of 20 DEG C-70 DEG C, carrying out ultrasonic oscillation for three minutes to 15 minutes to produce surface modification, and finally washing and drying to obtain surface-modified carbon fiber. With the method, the surface roughness of the carbon fiber can be increased, the wetting property of the carbon fiber can also be improved due to introduction of polar group into the surface of the fiber, the binding property between the carbon fiber and a resin matrix can be enhanced, and the interface property of binding the carbon fiber with other materials can be increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Modified coal ash used for treating ammonia nitrogen waste water and preparation method thereof

InactiveCN102188953ADestruction of the material structureLarge specific surface areaOther chemical processesAluminium silicatesAmmoniacal nitrogenResource utilization

The invention relates to modified coal ash used for treating ammonia nitrogen waste water, which is prepared by the following steps of: calcining NaOH and coal ash at a low temperature after NaOH and coal ash are uniformly mixed in proportion, cooling, grinding and sieving, then adding 1-5 times of water by weight, mixing, stirring, heating to the temperature of 70 DEG C and stopping stirring, gelling for 1.5-2 hours at constant temperature, then heating to the temperature of 100 DEG C, crystallizing for 3-4 hours at constant temperature, carrying out suction filtering, washing to be neutral with water, drying, cooling and then grinding and sieving, thus the modified coal ash is obtained. In the invention, NaOH low temperature calcining hydrothermal synthesis is adopted to modify the coal ash, the physical structure of the coal ash is destroyed, the modification time is shortened and a new zeolite mineral phase is generated under the condition of low alkali addition amount, the specific area of the coal ash is increased, and the cation exchange performance of the coal ash is improved. The modified coal ash provided by the invention is used for treating the ammonia nitrogen waste water, and the removing effect is obvious. By adopting the modified coal ash provided by the invention, wastes are treated with wastes, the resource utilization of wastes is realized, and the utilization factor of the coal ash is improved.

Owner:SHANXI UNIV

Surface modification method of carbon fiber by plasma treatment and coating of nano graphene

The invention relates to a surface modification method of carbon fiber by plasma treatment and coating of nano graphene, which is characterized in that nano graphene and a carbon fiber material are used as raw materials, and a nano graphene coating is coated on the surface of the carbon fiber material by a plasma treatment and coating method. The method comprises the steps of: (1) preparing 0.5-10% organic solvent or water sol solution of nano graphene by utilizing an ultrasonic oscillating technology; (2) coating the graphene solution on the surface of carbon fiber and drying; and (3) placing the carbon fiber on a plasma device, and spraying the plasma to the surface of the carbon fiber for surface modification, wherein the treatment power is 100-1000W and the time is 10-900s. By adopting the method, a high-performance composite material can be formed, and the mechanical property, conductivity and heat resistance of the carbon fiber are further improved. The method is low in cost, simple in operation, strong in applicability, good in treatment effect and not likely to cause environmental pollution, and is suitable for industrial production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Surface modification method of carbon fibre plasma grafted carbon nano-tube

InactiveCN103321034AImprove surface roughnessImprove wettabilityPhysical treatmentCarbon fibresFiberCarbon fibers

The invention provides a surface modification method of a carbon fibre plasma grafted carbon nano-tube, and the method comprises the following steps of: putting a carbon fibre material in the plasma atmosphere, wherein the power of a plasma generation device is 100-1000 W, and the processing time is 10-900 s; drying the processed carbon fibre material in vacuum at 40-60 DEG C to constant weight; then, adding amination carbon nano-tube into organic solution, and ultrasonically processing for 10-50 min to obtain sol solution with the concentration of 0.01-10 g / L; finally, adding the carbon fibre material into the carbon nano-tube sol solution, adding a surface active agent to mix, wherein the mass ratio of the surface active agent to the amination carbon nano-tube is 1:1, ultrasonically processing the obtained mixed solution for 10-50 minutes, increasing the temperature to 50-100 DEG C, carrying out constant-temperature reaction for 9-12 hours, and washing and drying. According to the invention, the carbon nano-tube is used as the surface grafting material of carbon fibre; the surface of carbon fibre is modified through plasma; a lot of polar groups are introduced into the surface of fibre, therefore, carbon fibre is grafted with the amination carbon nano-tube well; then, the carbon nano-tube well is grafted.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

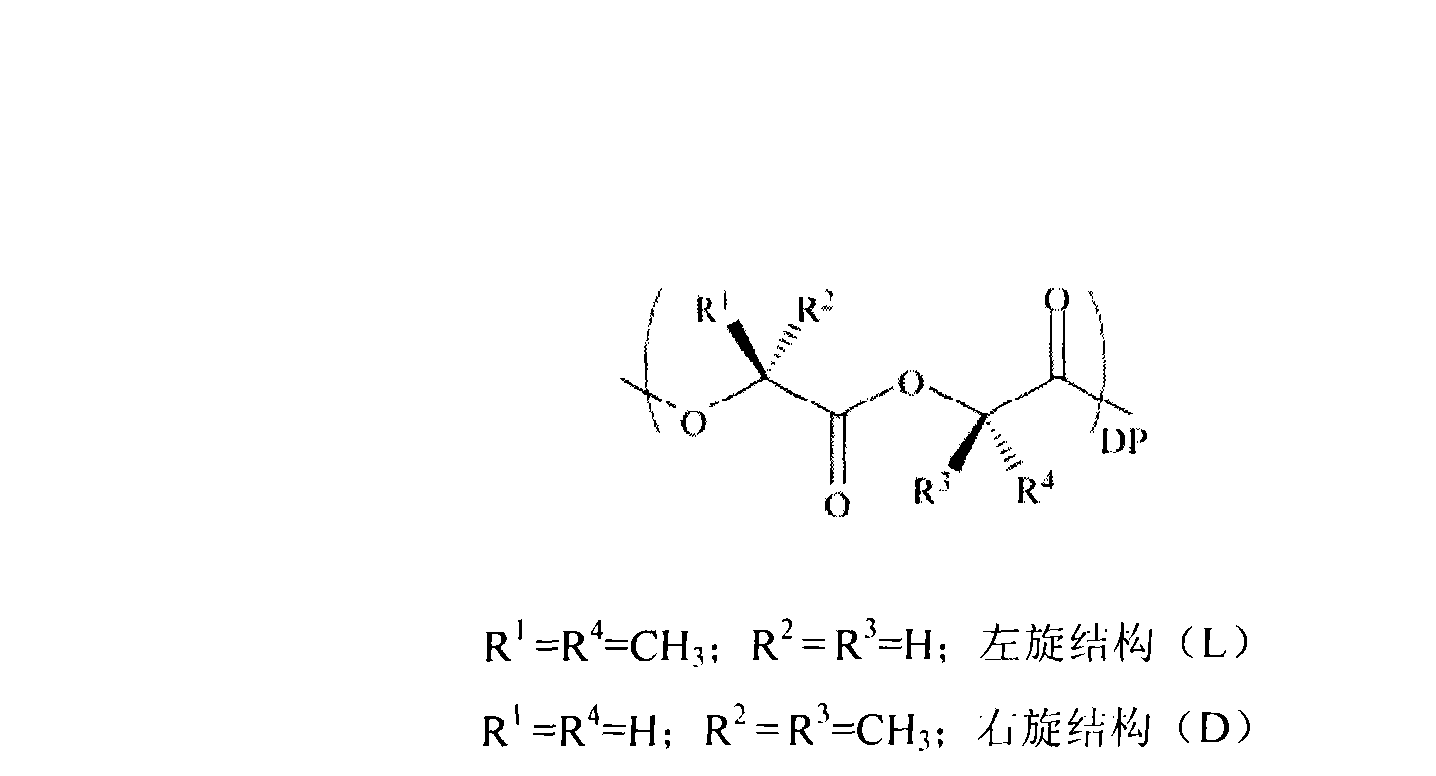

Composite material of shell micro powder filling bio-based resin and method for preparing same

ActiveCN101633775AImprove mechanical propertiesImproved Vicat softening temperatureChemical LinkageUltrasonic cavitation

The invention provides a composite material of shell micro powder filling bio-based resin and a method for preparing the same. The composite material comprises the following component in percentage by mass: (1) 20 to 60 percent of shell micro powder, 40 to 80 percent of bio-based resin, 1.5 to 8 percent of coupling agent and 0.2 to 0.4 percent of anti-oxidant; and or 20 to 60 percent of shell micro powder, 40 to 80 percent of bio-based resin, 0.6 to 3 percent of isocyanate, 0.05 to 0.1 percent of organic tin or organic stannous catalyst, and 0.2 to 0.4 percent of anti-oxidant. The invention also discloses a method for preparing the composite material. The method has the advantages of utilizing the ultrasonic cavitation to grind and disperse the shell micro powder, simultaneously accelerating the grafting or chemical bonding of the coupling agent or isocyanate on the surface of the shell micro powder, greatly shortening the modification time of the shell micro powder and the forming period of the composite material, and improving the interface compatibility and the bonding strength of the shell micro powder and the bio-based resin. The composite material is widely applied in fields of the production and consumption of automobile interior parts, stationery, road blocks, sporting goods, food bags, refuse bags, disposable tablecloth, outdoor flower pots, canteens, knives and forks and the like.

Owner:SHENZHEN HONGCAI NEW MATERIAL TECH

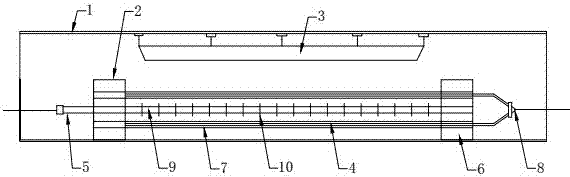

Method for improving activated carbon performances by self-assembling low-temperature plasma modification

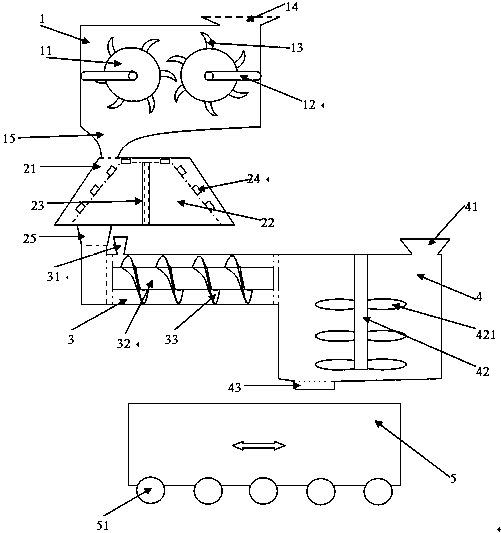

InactiveCN106984269AImprove modification efficiencyShorten modification timeOther chemical processesActivated carbonSorbent

The invention discloses a method for improving activated carbon performances by self-assembling low-temperature plasma modification, and belongs to the technical field of activated carbon modification. A self-assembling low-temperature plasma modification reaction device used in the invention mainly comprises a box body, a plasma generator, a gas distribution and exhaust gas treatment system, an auxiliary facility and the like. The activated carbon modification is taken as an aim, and the activated carbon modification is realized via four processes of activated carbon screening treatment, reactor detection and setting, activated carbon modification, and exhaust gas treatment. The method for improving the activated carbon performances by the self-assembling low-temperature plasma modification can effectively reduce the loss of activated carbon, shorten the modification time and improve the modification efficiency of the activated carbon, takes air as an air source which is cheap in price and easily obtained and is simple to operate, free of ozone dissipation and waste liquid to be treated, and environmentally friendly. The method for improving the activated carbon performances by the self-assembling low-temperature plasma modification can be widely used in the activated carbon modification, and further can be popularized and applied to the modification of adsorbents of kaolin and montmorillonite.

Owner:CHONGQING TECH & BUSINESS UNIV

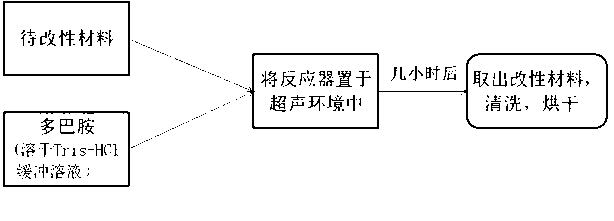

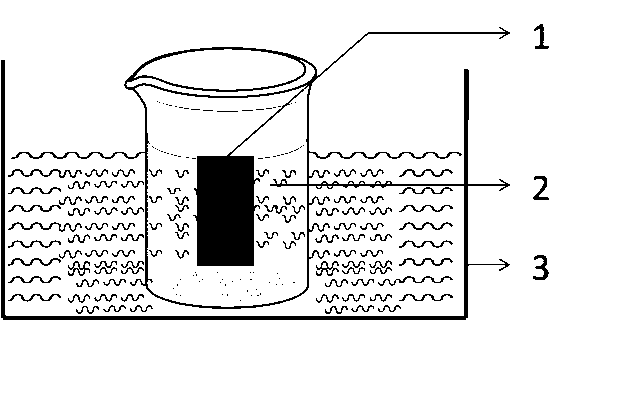

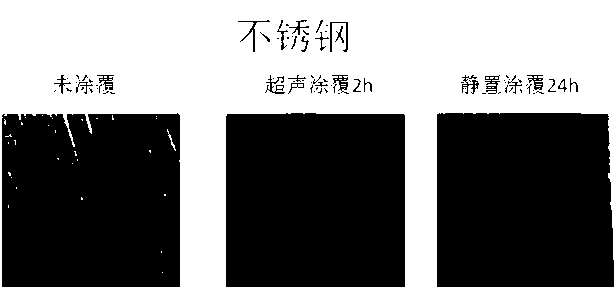

Method for coating dopamine on surface of ultrasonic reinforced material

InactiveCN102698950AStrong adhesionUniform particle sizeLiquid surface applicatorsLiquid spraying apparatusPolyethylene terephthalatePolyethylene terephthalate glycol

The invention relates to a method for coating dopamine on the surface of an ultrasonic reinforced material. The method comprises the following steps: preparing alkaline buffered solution containing dopamine capable of coating the surface of a material, immersing a material to be modified in the buffered solution, and modifying the surface of the material with the media in the solution in an ultrasonic environment. With respect to the defects of long modification time, poor adhesion and non-uniform surface of a coating and the like of the conventional standing coating modification process, the method greatly shortens the modification time, and the obtained coating has strong adhesion and uniform surface. The effects of modifying a 305 stainless steel, a glass slide, and a polyethylene terephthalate PET plastic by the conventional process and the method are respectively compared to prove the advantages of the method.

Owner:SHANGHAI UNIV

A kind of eco-environmental protection soil remediation method

ActiveCN110038890BImprove responseImprove hydrophobicityContaminated soil reclamationOrganic fertilisersEcological environmentMicrobial agent

Owner:中植同汇集团有限公司

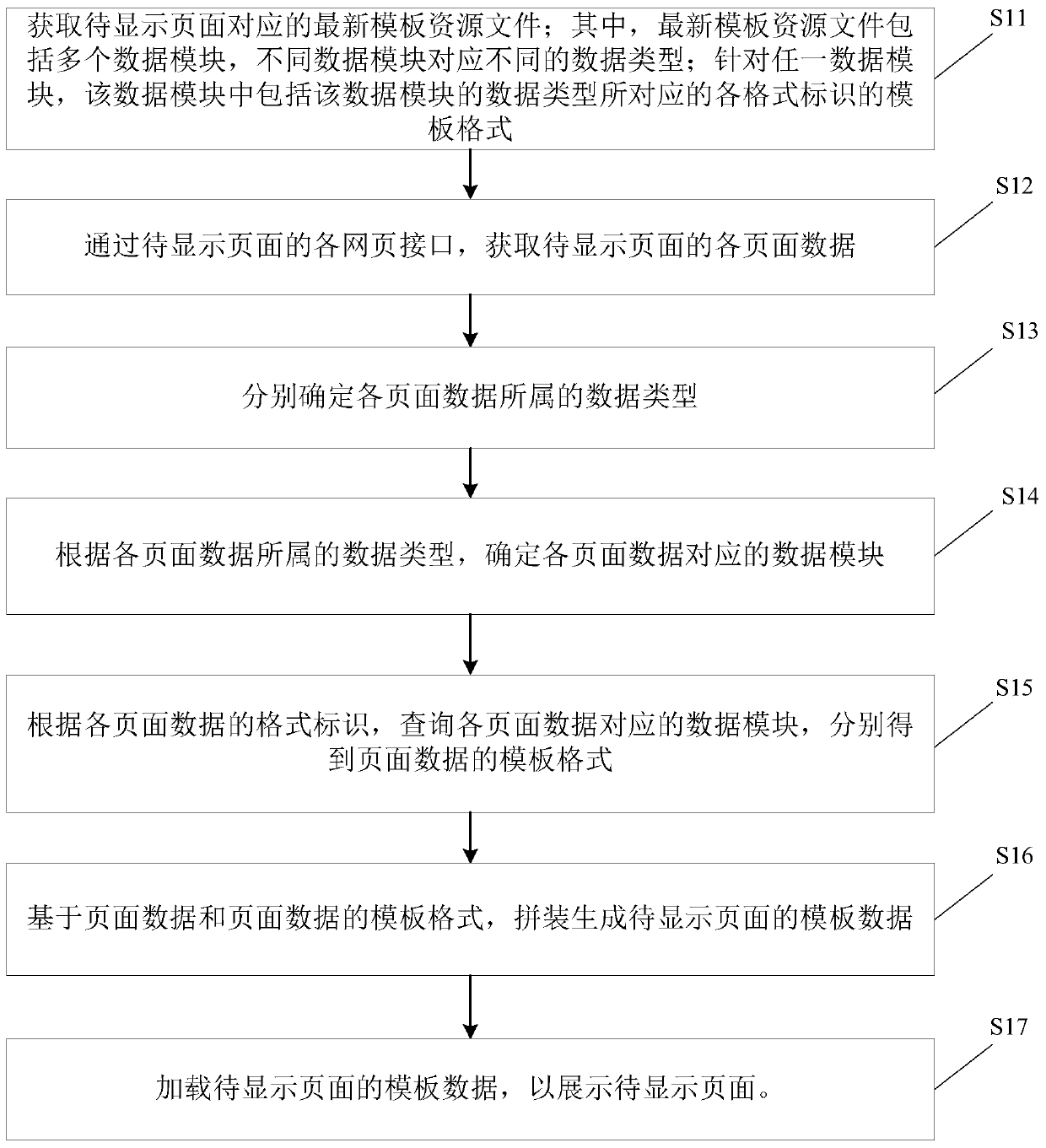

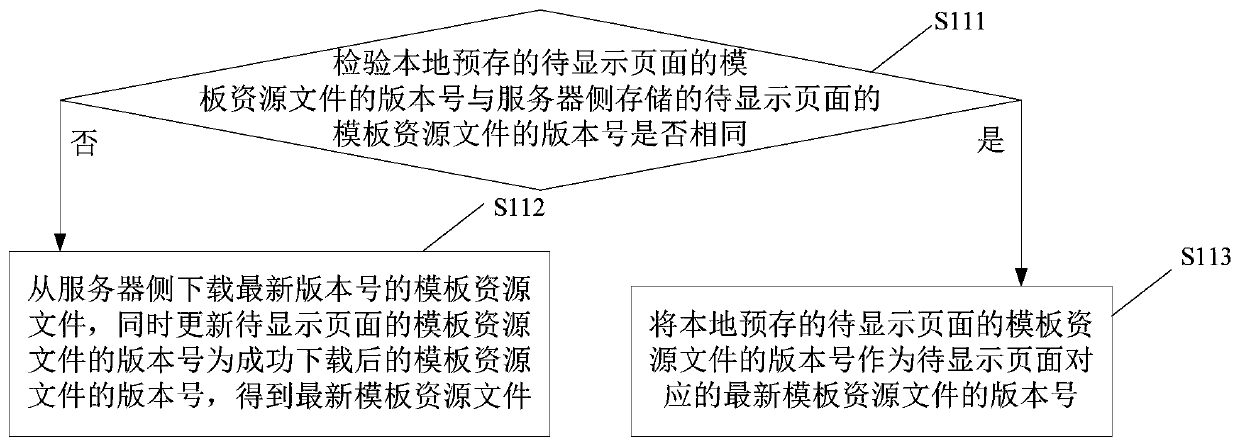

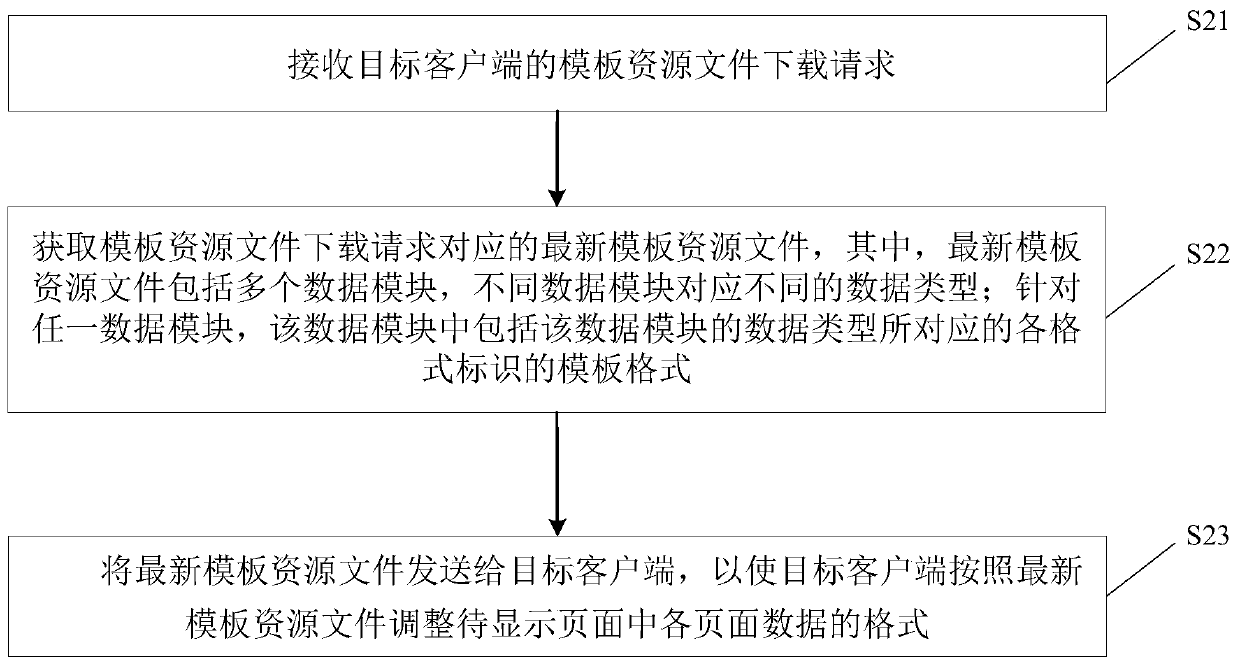

Mobile application localized loading method and device and electronic equipment

ActiveCN110321177AImprove the display effectShorten modification timeProgram loading/initiatingExecution for user interfacesWeb pageData type

Embodiments of the invention provide a mobile application localized loading method and device, and electronic equipment. The method comprises the steps of obtaining a latest template resource file corresponding to a to-be-displayed page; acquiring page data of the to-be-displayed page through each webpage interface of the to-be-displayed page; respectively determining a data type to which each piece of page data belongs; determining a data module corresponding to each piece of page data according to the data type to which each piece of page data belongs; querying a data module corresponding toeach piece of page data according to the format identifier of each piece of page data to respectively obtain a template format of the page data; based on the page data and the template format of thepage data, splicing to generate template data of the page to be displayed; and loading the template data of the to-be-displayed page to display the to-be-displayed page. According to the mobile application localized loading method provided by the embodiment of the invention, the online new style is dynamically displayed in real time, the time for modifying the page content is shortened, and the development cost is reduced.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

Novel method for producing carragheen

The production method of carragheen uses marine alga as raw material and includes the following steps: alkalu modification procedure treatment, cooking, rfiniting, salting out, dewatering and drying so as to obtain the invented finished product. The alkali modification procedure adopts the potassium hydroxide as modification agent, and uses pure water to prepare the potassium hydroxide into the potassium hydroxide solution, its concentration is 5-25%, and the potassium borohydride is added, and its added amount is 1-5% of potassium hydroxide. Said invention raises the gel strength and recovery rate of the prdoucts and can shorten production period and reduce its production cost.

Owner:MAOMING COLLEGE

Method for preparing functional carbon fibers

InactiveCN106283600AReduce performance lossReduce dosageCarbon fibresUltrasonic/sonic fibre treatmentFiberCarbon fibers

The invention relates to a method for preparing functional carbon fibers. Thermoplastic resin is used as a surface grafting material of the carbon fibers, surface modification is carried out on the carbon fibers by plasma, and the thermoplastic resin is grafted to form a high-performance composite material. The method provided by the invention has the advantages of low investment cost of surface modification equipment of the carbon fibers, low cost, simple operation, strong applicability, good treatment effect, small loss of fiber performance and reliable quality. The modification time is greatly shortened, the amount of chemicals is reduced, the product cost is lowered, the environmental pollution is reduced, and industrial production is applicable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Surface modification method for treating and coating nanometer graphene by carbon fiber plasmas

InactiveCN106283601AImprove performanceLow costCarbon fibresUltrasonic/sonic fibre treatmentFiberCarbon fibers

The invention relates to a surface modification method for treating and coating nanometer graphene by carbon fiber plasmas. Graphene is used as a surface coating material of carbon fiber; the carbon fiber surface is coated with nanometer graphene sol liquid; then, a composite material with high performance can be formed through plasma surface modification. The cost is low; the operation is simple; the applicability is high. The method has the advantages that the investment cost of equipment used by the carbon fiber surface modification is low; the invention cost is low; the operation is simple; the applicability is high; the treatment effect is good; the fiber performance loss is little; the quality is reliable; the modification time is greatly shortened; the chemical consumption and the product cost are reduced; the environment pollution is reduced; the method is suitable for industrial production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of amphiphilic silica flatting agent

InactiveCN106905751ALipophilicHydrophilicPolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSilanesMicroparticle

The invention discloses a preparation method of an amphiphilic silica flatting agent. The method comprises the following steps: silica powder is placed into a mixer and heated under stirring to 60-200 DEG C, and stirring is kept; a silane treating agent accounting for 2%-30% by mass of the silica powder is uniformly sprayed into the mixer in an atomized manner and sufficiently mixed with the powder, the mixture is heated to 70-250 DEG C, stirred for 0.5-3 h at the temperature and dried finally, the temperature is controlled at 50-250 DEG C, discharging is performed after drying for 0.5-6 h, natural cooling is performed, and the amphiphilic silica flatting agent is obtained. The obtained amphiphilic silica flatting agent is enabled to have lipophilicity and hydrophilicity by controlling temperature and reaction time under conditions of addition in proper proportion, certain temperature, cyclic motion state of microparticles and the like, the flatting agent is good in stability and is not prone to layering or production of hard precipitates, so that waste of the flatting agent and paint is reduced, ultrafine particles of the silica flatting agent are well arranged and uniform in luster, the visual effect is good, the flatting efficiency is increased, and the flatting performance is improved greatly.

Owner:成都聚鸿轩化学原料有限公司

Straw recycling treatment method

ActiveCN107787691ARealize one-stop productionImprove efficiencyChemical industryCuttersCasting moldPre treatment

The invention relates to a straw recycling treatment method. A straw recycling treatment device is adopted for production and comprises a crushing cavity, a fine grinding cylinder, a conveying cavity,a mixing cavity, a casting mold pressing machine and a steam chamber. The method comprises the steps of crushing, grinding, modifying, mixing with cement, casting mold, pressing, and aerated curing.By arranging equipment of a specific structure, the efficiency of the whole method is improved, and integrated equipment manufacturing from primary raw materials to final products is achieved withoutpretreating the raw materials, so that the overall production cost is reduced, and the production stability is improved.

Owner:ZHEJIANG KUNLUN ENVIRONMENTAL PROTECTION EQUIP

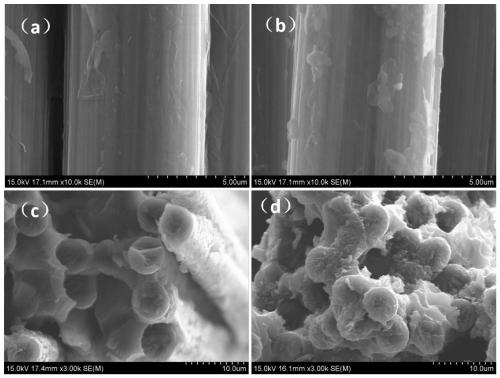

Method for surface modification by grafting carbon fiber to graphene oxide through plasma

InactiveCN106192363ALow costEasy to operateCarbon fibresUltrasonic/sonic fibre treatmentFiberCarbon fibers

The invention relates to a method for surface modification by grafting a carbon fiber to graphene oxide through plasma. The graphene oxide is used as a surface grafting material of the carbon fiber; the carbon fiber is subjected to surface modification through the plasma, and then the graphene oxide is grafted with the carbon fiber so as to form a high-performance composite material. The method is low in cost, easy to operate and high in practicability. The method has the advantages that equipment for carbon fiber surface modification is low in investment cost, and the method is low in cost, easy to operate, high in practicability, good in treatment effect, low in fiber performance loss and reliable in quality. The modification time can be greatly shortened, the use amount of chemicals and the product cost are reduced, the environmental pollution is reduced, and the method is applicable to the industrial production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

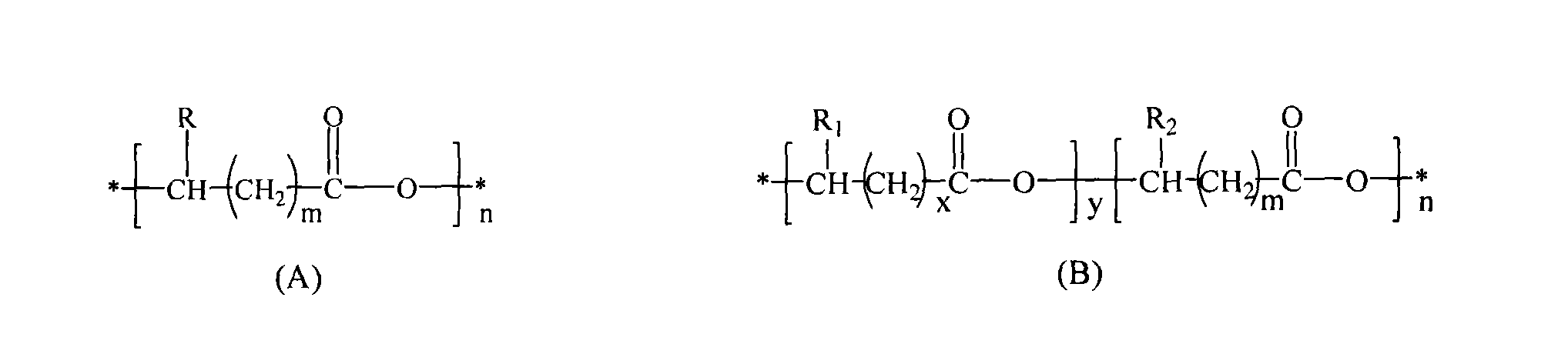

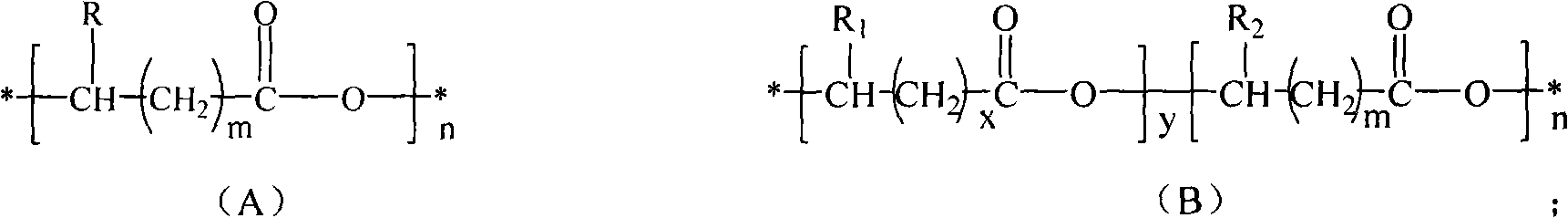

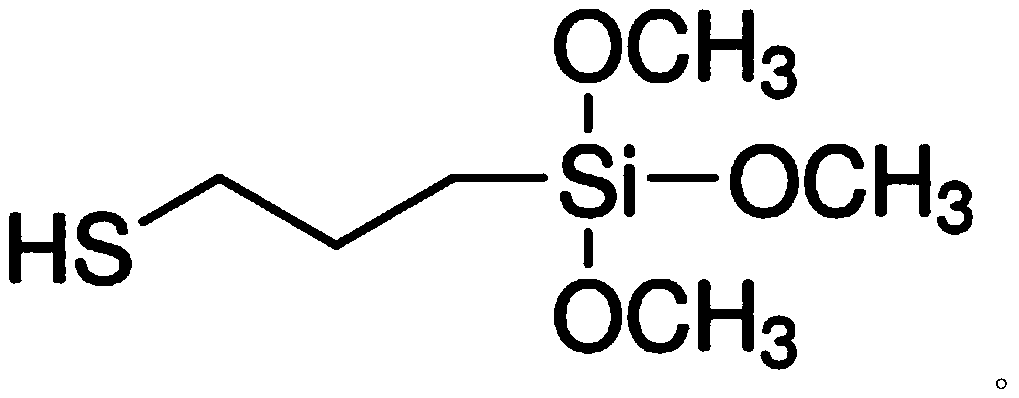

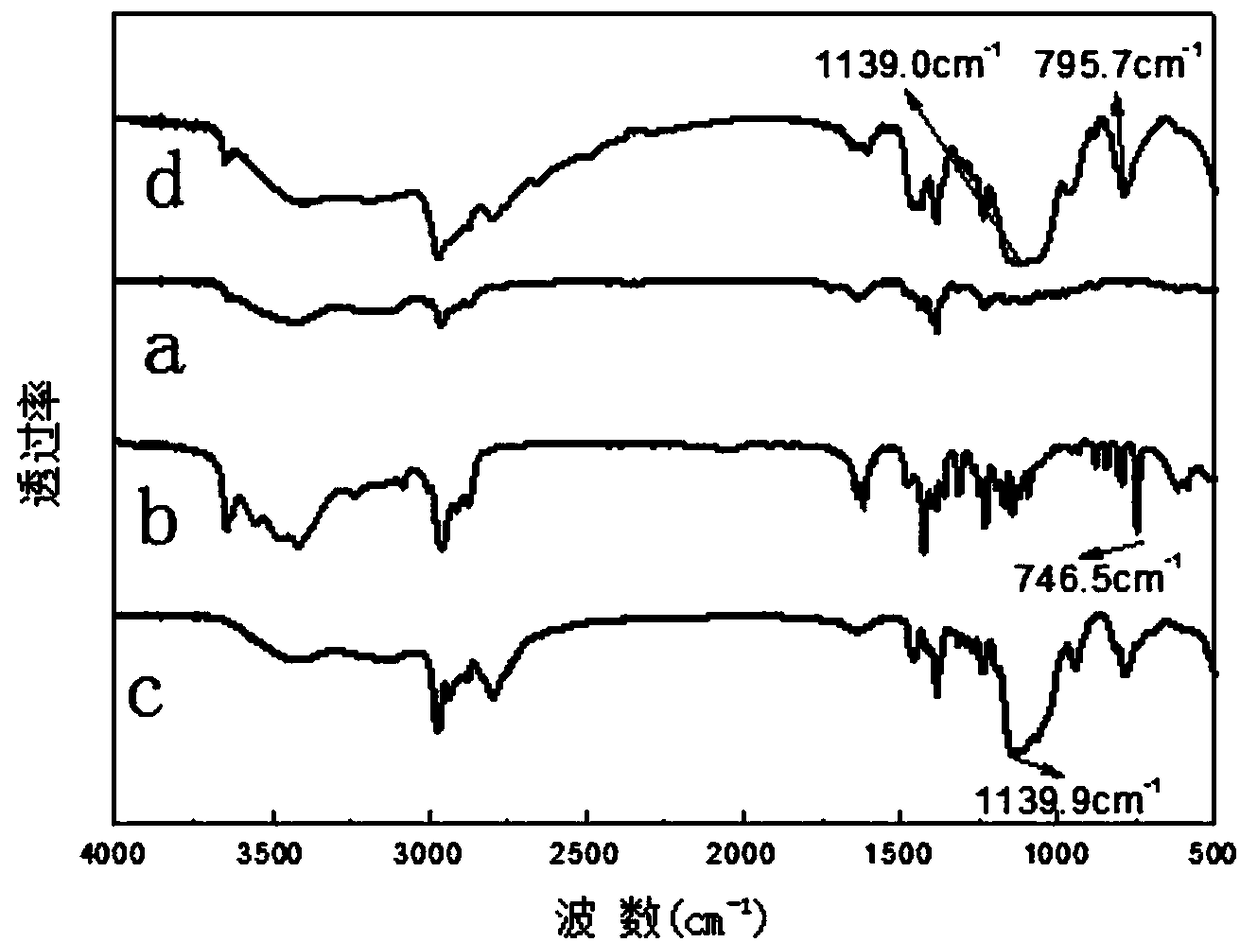

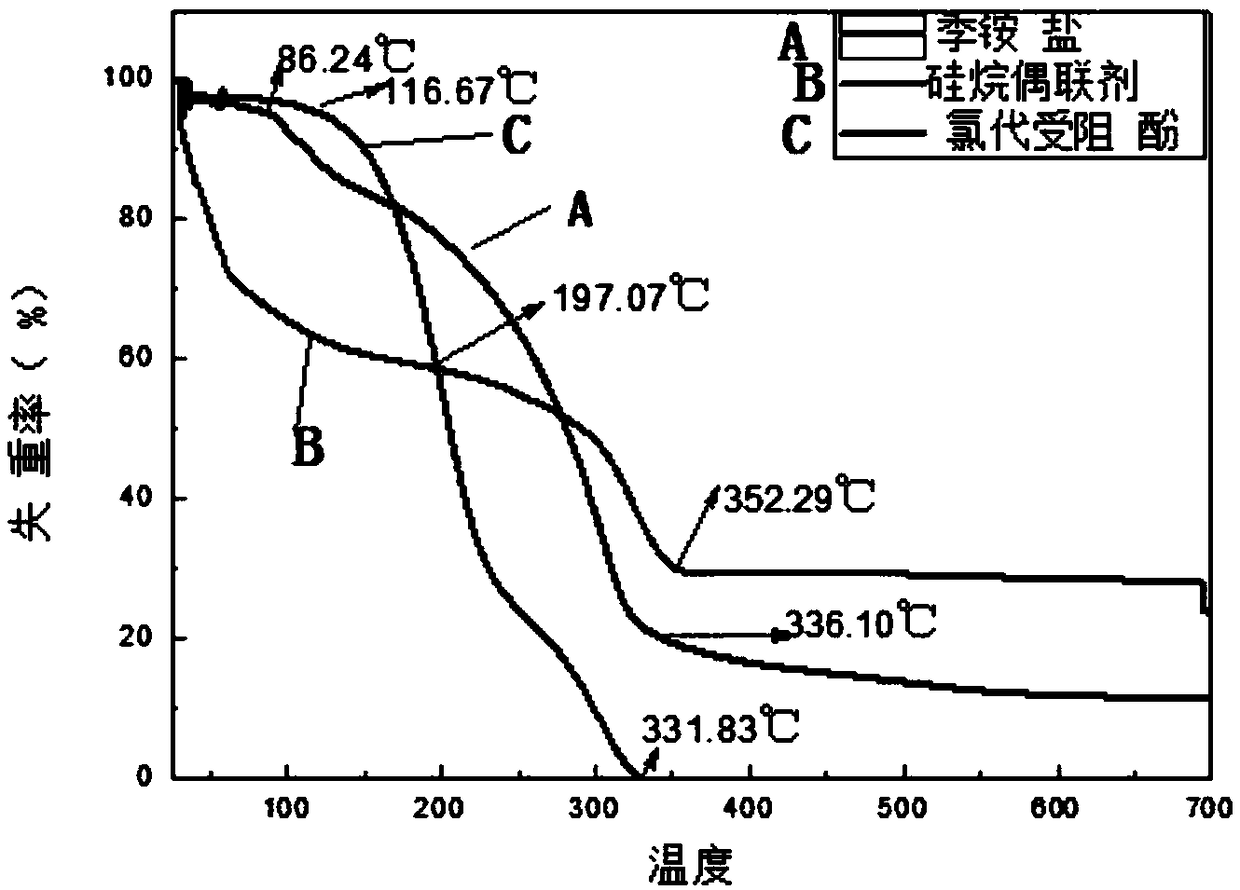

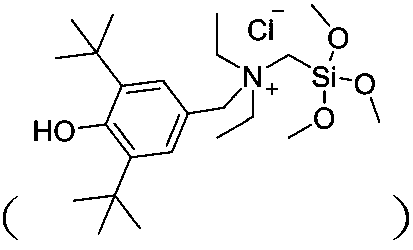

Novel antioxidation silane coupling agent containing hindered phenol structure and preparation method of novel antioxidation silane coupling agent

InactiveCN108440790ALower surface energyAntioxidant effectGroup 4/14 element organic compoundsDispersityNon toxicity

The invention discloses a novel antioxidation silane coupling agent containing a hindered phenol structure. The novel antioxidation silane coupling agent is characterized in that the structural formula of the silane coupling agent is shown in the description, wherein R<1> is methyl, ethyl or propyl; R<2> is methyl, ethyl, propyl or cyclohexyl; n is in a range of 1-4. Through combination of inorganic filler modification with antioxidant addition, the novel antioxidation silane coupling agent containing the hindered phenol structure not only has the advantages such as good antioxidation effect,little pollution, low probability of color change and low toxicity or non-toxicity of a hindered-phenol antioxidant, but also has the unique structure and performance such as adhesion, compatibility,dispersity and the like of the silane coupling agent, and compatibility of the antioxidant with a polymer material is improved greatly.

Owner:GUIZHOU NORMAL UNIVERSITY

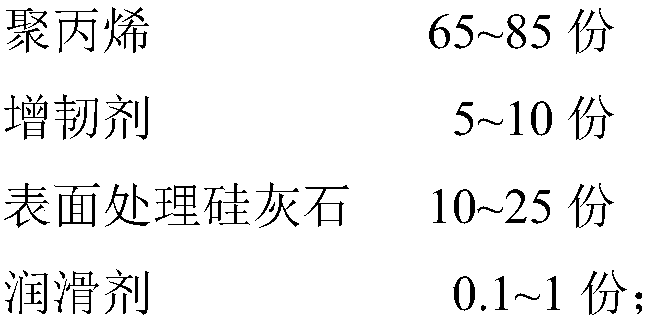

Wollastonite/polypropylene composite material and preparation method thereof

The invention discloses a wollastonite / polypropylene composite material and a preparation method thereof. The wollastonite / polypropylene composite material comprises, by weight, 65-85 parts of polypropylene, 5-10 parts of flexibilizers, 10-25 parts of surface treatment wollastonite and 0.1-1 part of lubricants, wherein the surface treatment wollastonite is prepared by the preparation method including the steps: adding wollastonite and surface treatment agents into a powder surface modification device according to the weight ratio of 100:(0.5-3) and performing surface coating treatment on the wollastonite. The surface treatment agents are selected from one or more of suberic acid, terephthalic acid and phthalic acid. The wollastonite / polypropylene composite material has excellent flowability and mechanical property.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

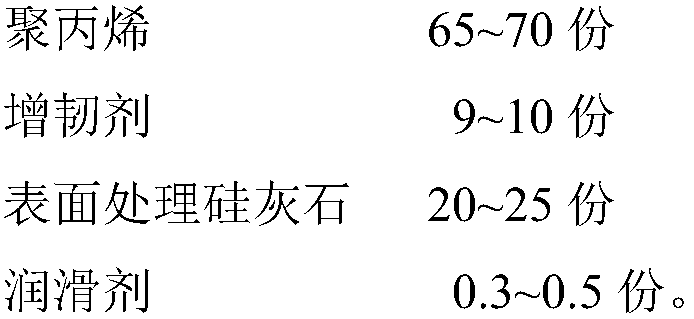

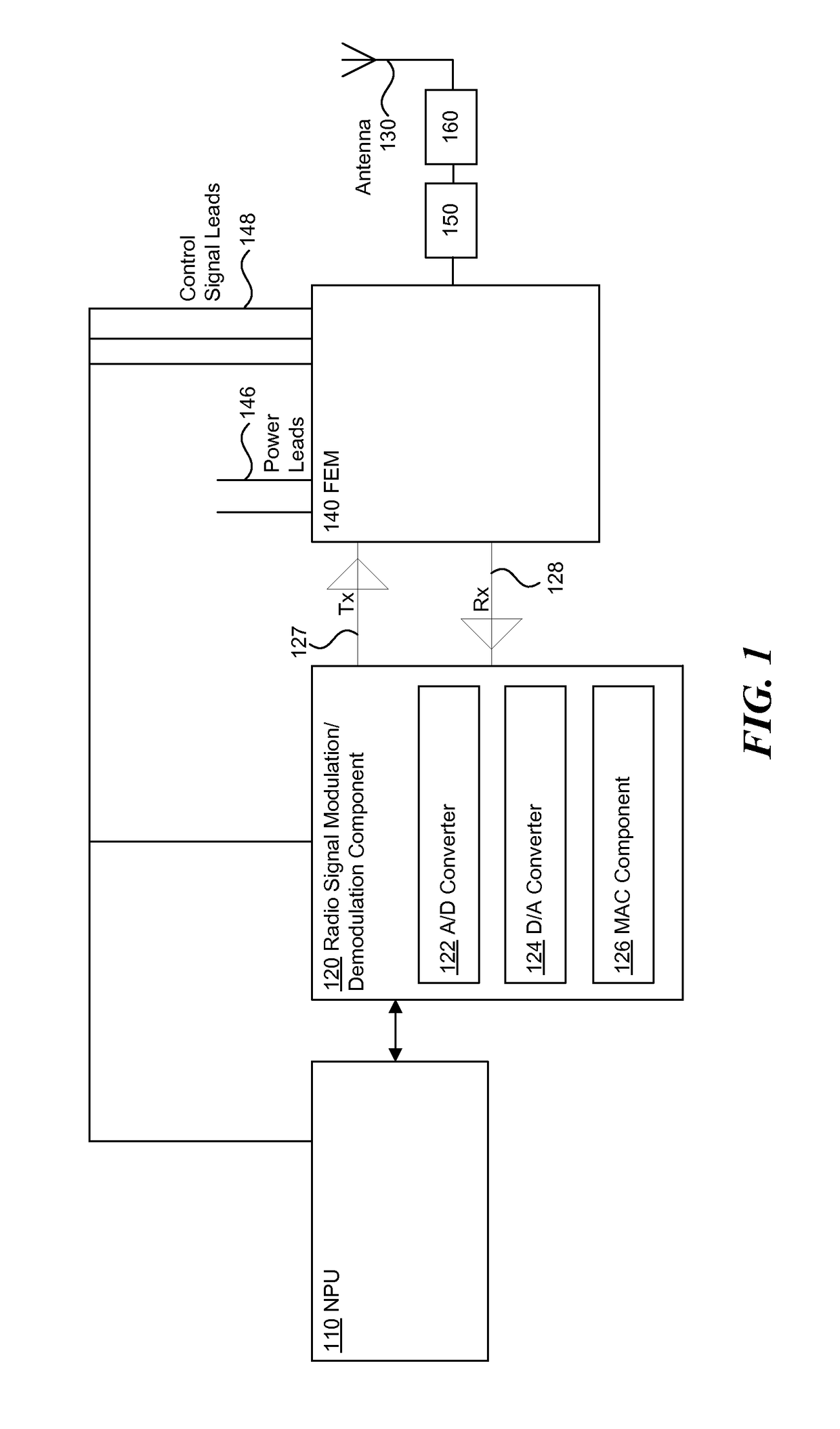

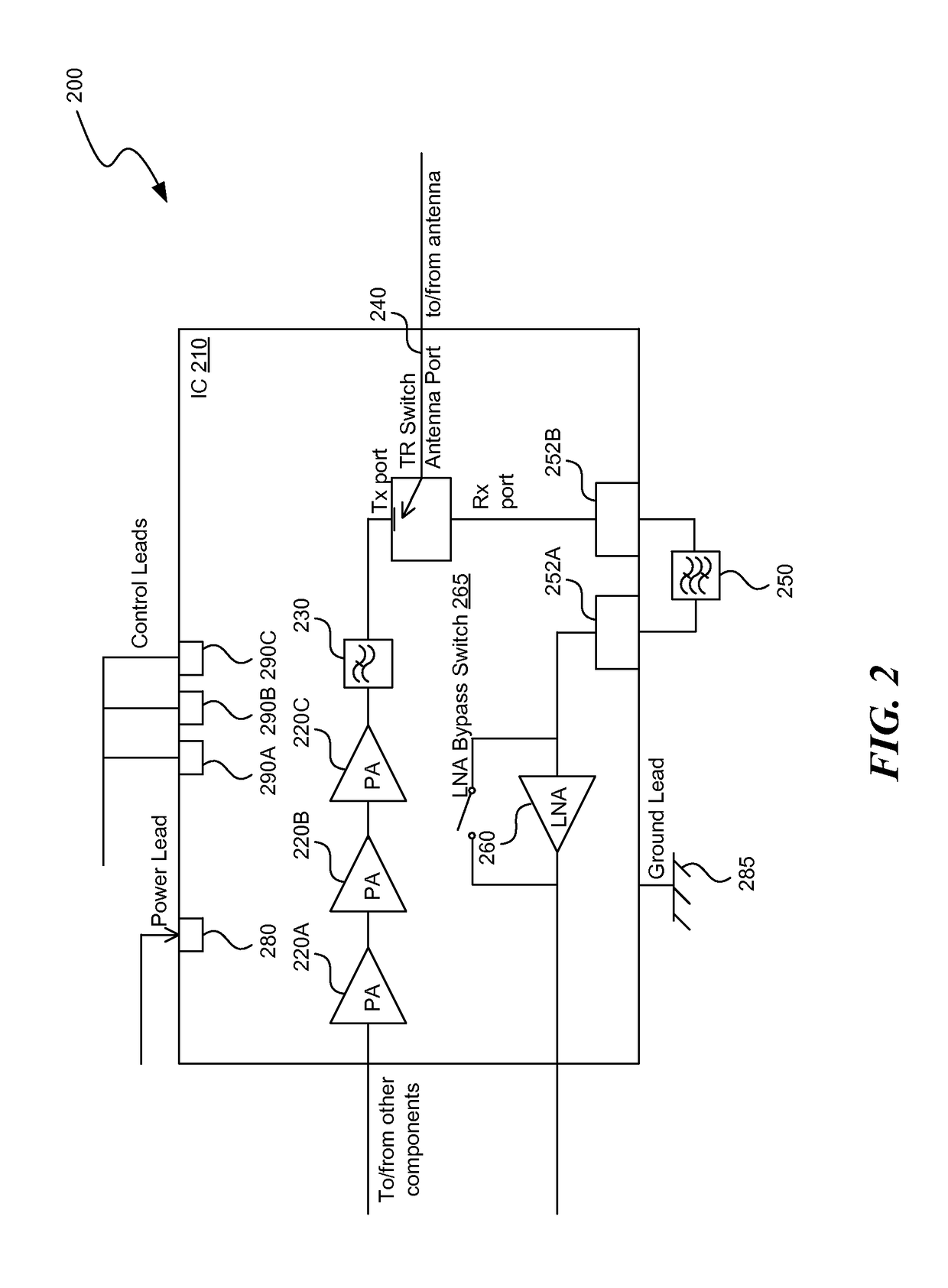

Radio frequency front end module with high band selectivity

Owner:NETGEAR INC

SBS (Styrene-Butadiene-Styrene) modified asphalt and production method thereof

InactiveCN101962482BReduce manufacturing costEnhanced interactionBuilding insulationsButadiene DioxideSolvent

The invention discloses SBS (Styrene-Butadiene-Styrene) modified asphalt and a production method thereof. The SBS modified asphalt mainly comprises the components of matrix asphalt No.70, linear SBS, a solubilizer and a stabilizer, wherein the linear SBS accounts for 3.6% to 4.2% be weight of the of matrix asphalt No.70, the solubilizer accounts for 2.0% to 3.0% by weight of the matrix asphalt No.70, and the stabilizer accounts for 0.16-0.18% be weight of the matrix asphalt No.70. The production method of the SBS modified asphalt comprises the following steps of: (1) heating the matrix asphalt No.70 to 175 DEG C to 185 DEG C; (2) adding the linear SBS and uniformly stirring; and (3) adding the solubilizer and the stabilizer and thoroughly grinding twice by using a colloid mill to obtain the SBS modified asphalt. The production method adopted in the invention effectively shortens the modified time and is low in production cost.

Owner:XUZHOU CITY LUXING HIGHWAY ENG

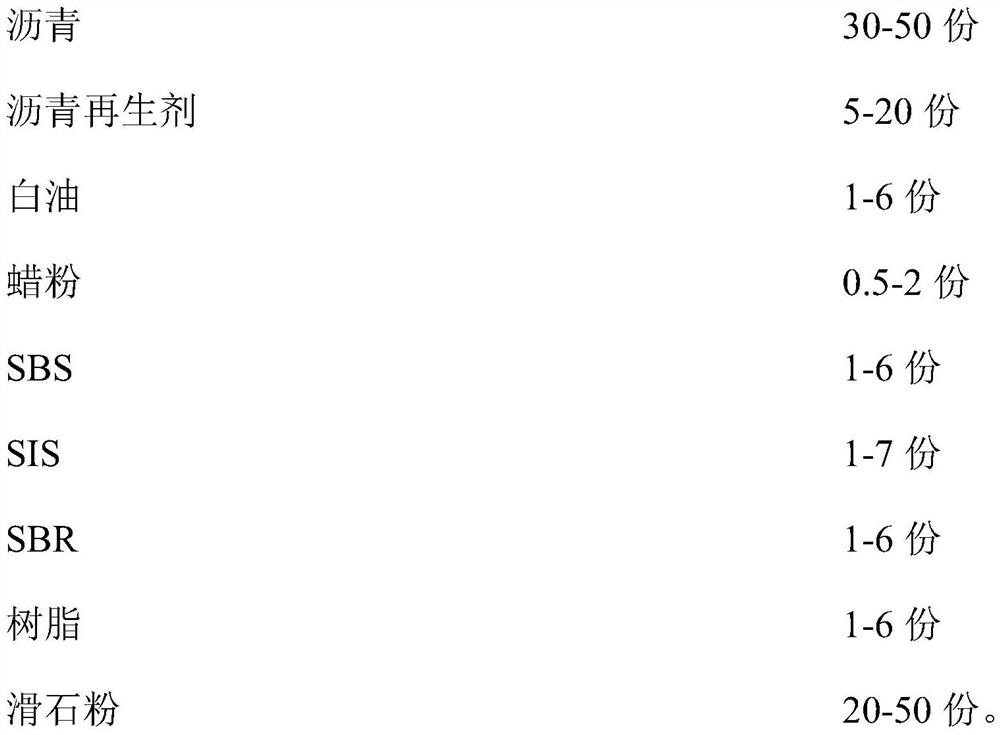

Modified asphalt and preparation method and application thereof

PendingCN113999537ATo achieve the effect of dissolutionShorten modification timeBuilding insulationsAsphaltPitch

The invention relates to modified asphalt and a preparation method and application thereof, and the modified asphalt is prepared from the following raw materials in parts by weight: 30-50 parts of asphalt, 5-20 parts of an asphalt regenerant, 1-6 parts of white oil, 0.5-2 parts of wax powder, 4-25 parts of a modifier and 20-50 parts of talcum powder. The preparation method comprises the following steps: mixing asphalt, an asphalt regenerant and white oil according to a formula ratio, and preserving heat to obtain premixed asphalt; shearing, grinding and mixing the modifier and the premixed asphalt according to the formula ratio to obtain a first shearing material; adding talcum powder into the first shearing material, stirring and mixing, preserving heat, and then shearing, grinding and mixing to obtain the modified asphalt. Through shearing, grinding and mixing in the preparation process, the modification time of asphalt is shortened, and the adverse effect of carbides generated in the high-temperature modification process on coiled material preparation is also avoided.

Owner:SHENZHEN ZHUOBAO TECH +1

Method for improving silicon dioxide aerogel water phase dispersibility thorugh atomization absorption

ActiveCN106866013AAdsorption amount controllableEvenly dispersedSolid waste managementPigment physical treatmentOrganic solventAqueous solution

The invention discloses a method for improving silicon dioxide aerogel water phase dispersibility through atomization absorption. The method comprises the following steps of fining and sieving silicon dioxide aerogel powder to obtain refined aerogel; atomizing organic solvents with the density being greater than the density of the water; forming a film coating reagent in a sealed container; uniformly dispersing the refined aerogel into a sealed container to form powder fog; adsorbing the film coating reagent by the powder fog to obtain coated aerogel; charging dispersing agent water solution into the bottom of a sealed container, wherein the sealed container is provided with a stirring device and an air blowing device; after the coated aerogel sinks down to the surface of the dispersing agent water solution, stirring and dispersing the coated aerogel with the density being greater than or equal to the density of the water into the water solution; blowing up the coated aerogel with the density being smaller than the density of water so that the coated aerogel is in contact with the film coating reagent again for adsorption. The method for improving silicon dioxide aerogel water phase dispersibility through atomization absorption provided by the invention has the advantages that the inherent structure and characteristics of the silicon dioxide aerogel are remained; the stable dispersion of the silicon dioxide aerogel in the water phase is realized; the work procedures are simple; the cost is low.

Owner:ECONANO TECH LTD BEIJING

Ecological and environment-friendly soil remedying agent

ActiveCN110028975AAchieve graftingImprove responseContaminated soil reclamationOrganic fertilisersMicrobial agentSoil remediation

The invention relates to an ecological and environment-friendly soil remedying agent. The soil remedying agent is formed by mixing 55-65 parts of modified hectorite, 20-30 parts of an organic fertilizer, 10-20 parts of humic acid and 1-3 parts of a microbial agent by weight, wherein the modified hectorite is prepared by a method comprising the following steps: calcinating hectorite, then adding amixed modifier, reacting while stirring, performing microwave irradiation treatment while stirring, and finally grinding into granules or powder. The soil remedying agent is applicable to remediationof heavy metal-contaminated soil, and has the advantages of low cost, ecological protection, a short remedying cycle, a good remedying effect, high remedying efficiency and the like.

Owner:河北田加力生物科技股份有限公司

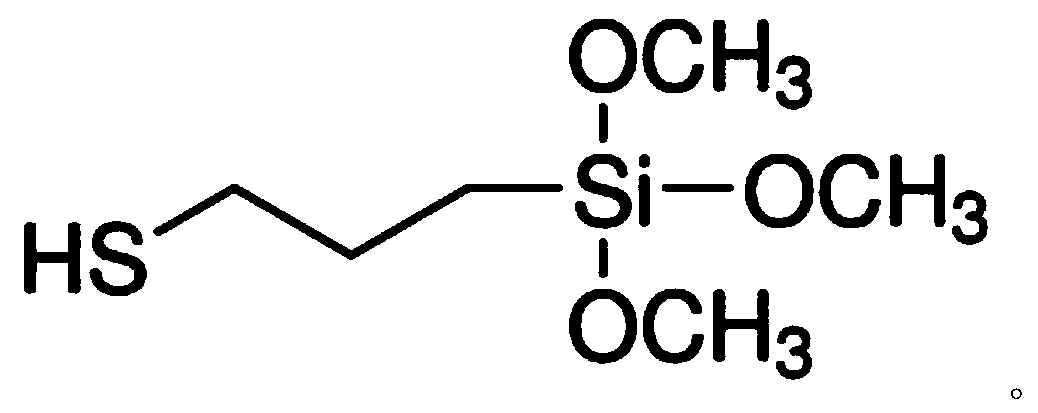

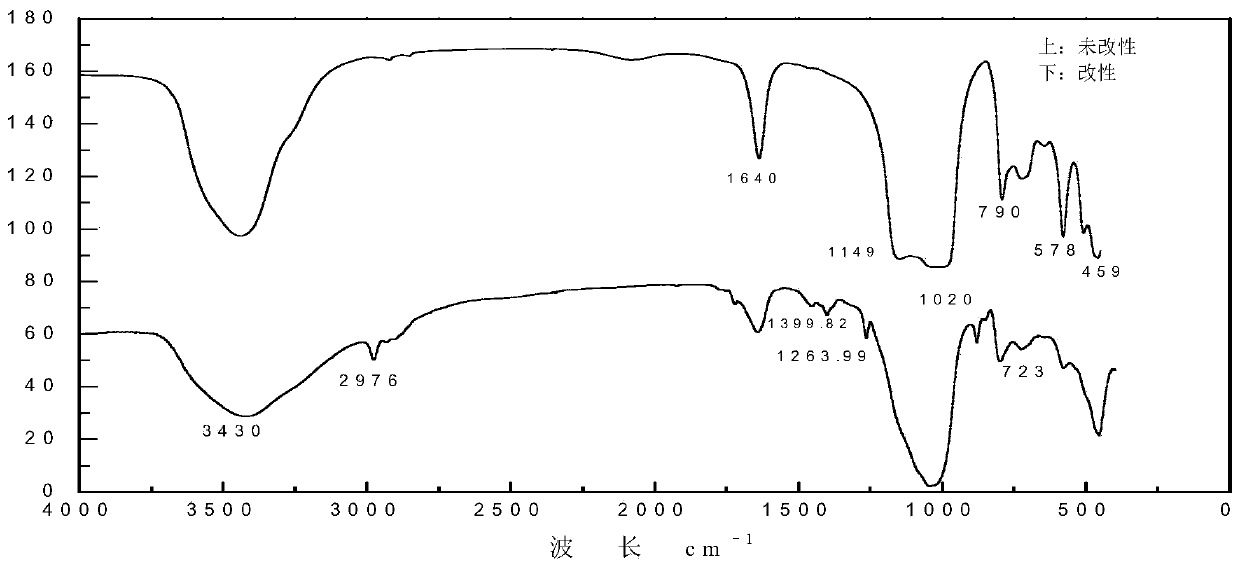

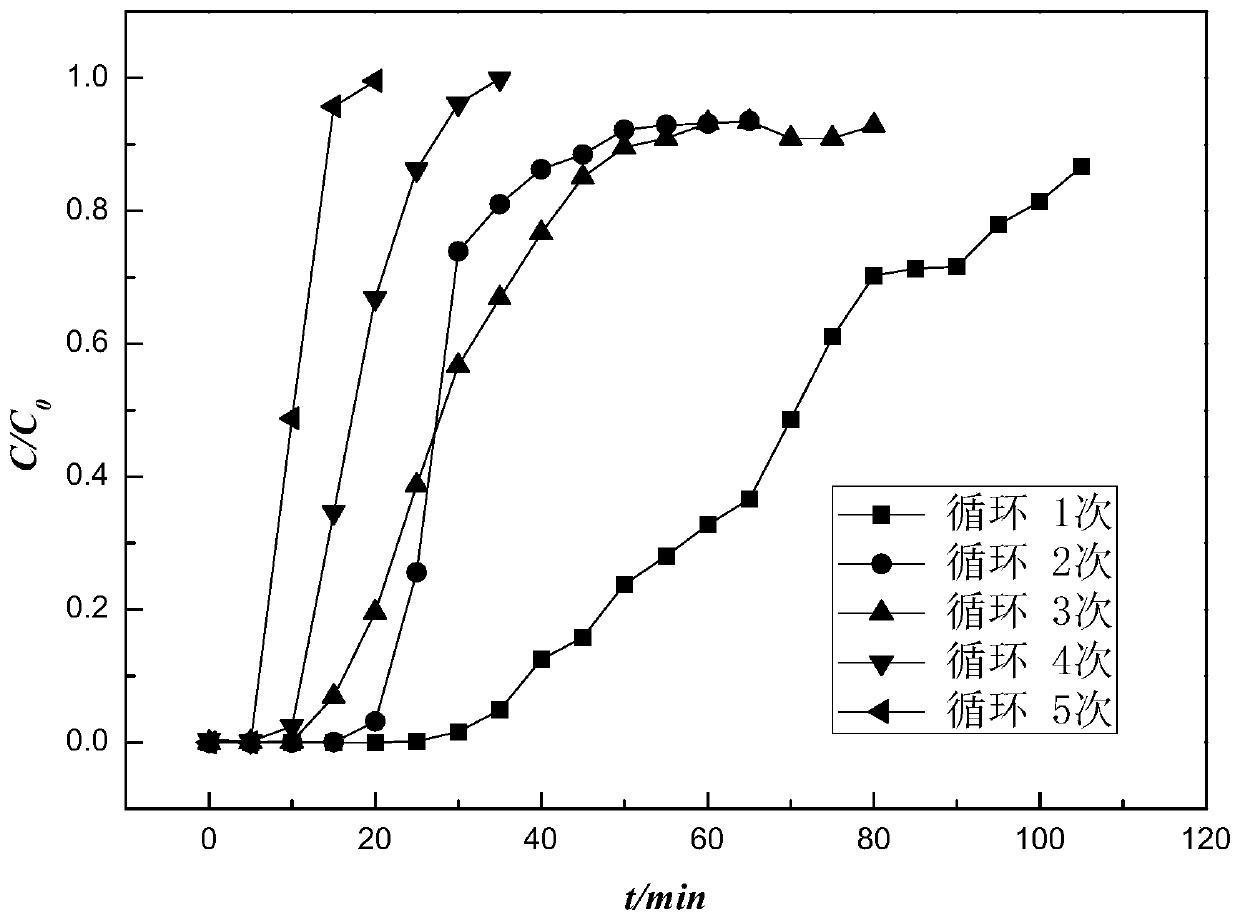

Preparation method of hydrophobic Y-type molecular sieve and hydrophobic Y-type molecular sieve

ActiveCN111302356AImprove modification efficiencyShorten modification timeGas treatmentOther chemical processesMolecular sieveIndustrial waste

The invention provides a preparation method of a hydrophobic Y-type molecular sieve and the hydrophobic Y-type molecular sieve. The preparation method mainly comprises an activation pretreatment process, a modification process and a water washing process, and specifically comprises the following steps: crushing an NAY molecular sieve screen, roasting, adding an organic solvent, adding a silanization reagent while carrying out ultrasonic treatment, stirring to fully react, filtering, washing, drying and the like, thereby obtaining the hydrophobic Y-type molecular sieve. The preparation method of the hydrophobic Y-type molecular sieve is short in reaction time and high in efficiency, and the prepared hydrophobic Y-type molecular sieve is applied to adsorption treatment on industrial waste gas, can be repeatedly used for multiple times, and has relatively good cycle performance, long adsorption penetration time and a wide application range, so that the economic cost is reduced.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

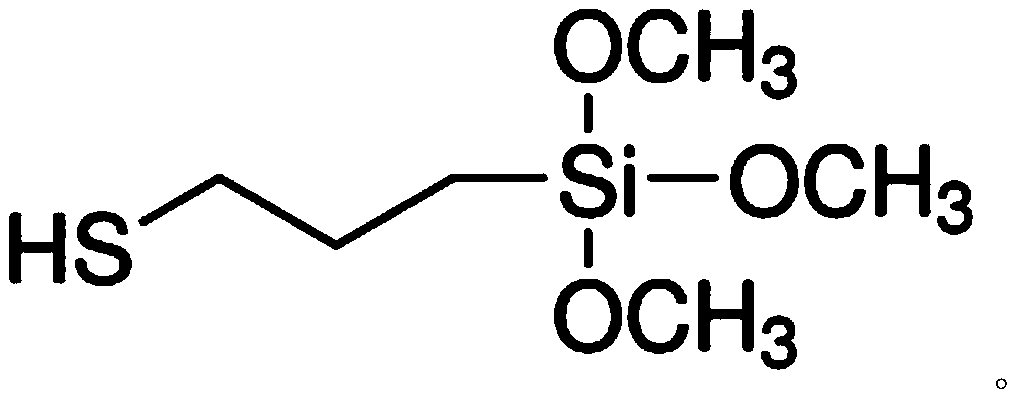

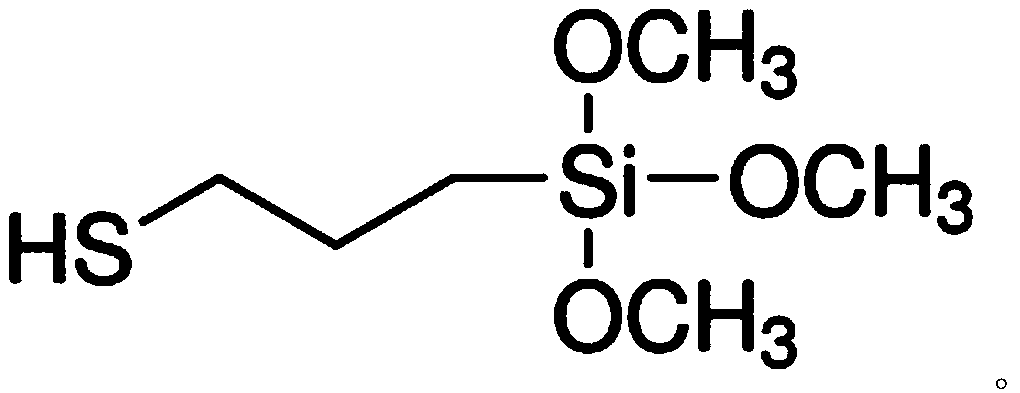

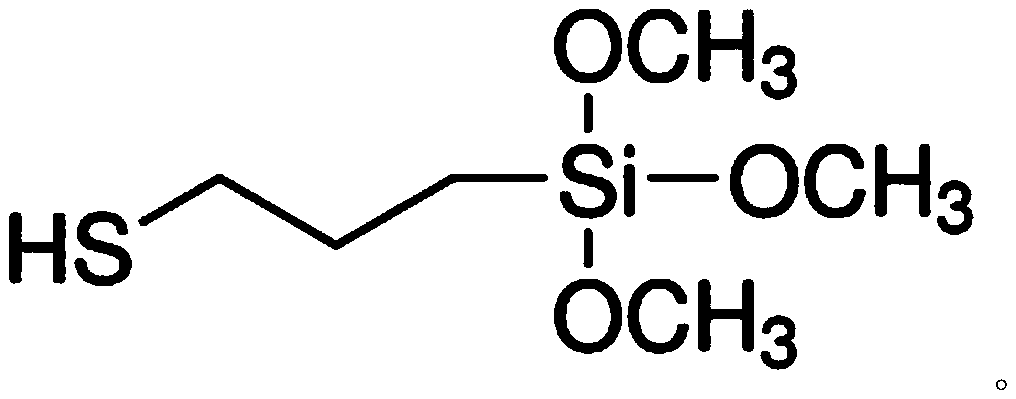

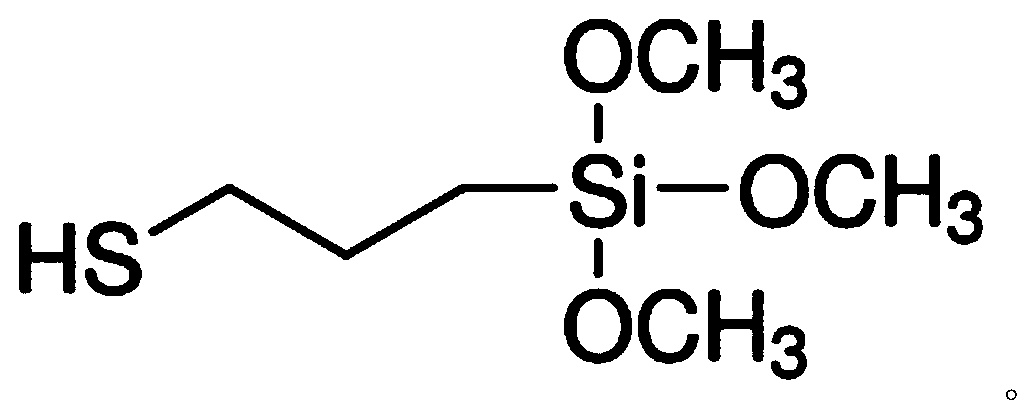

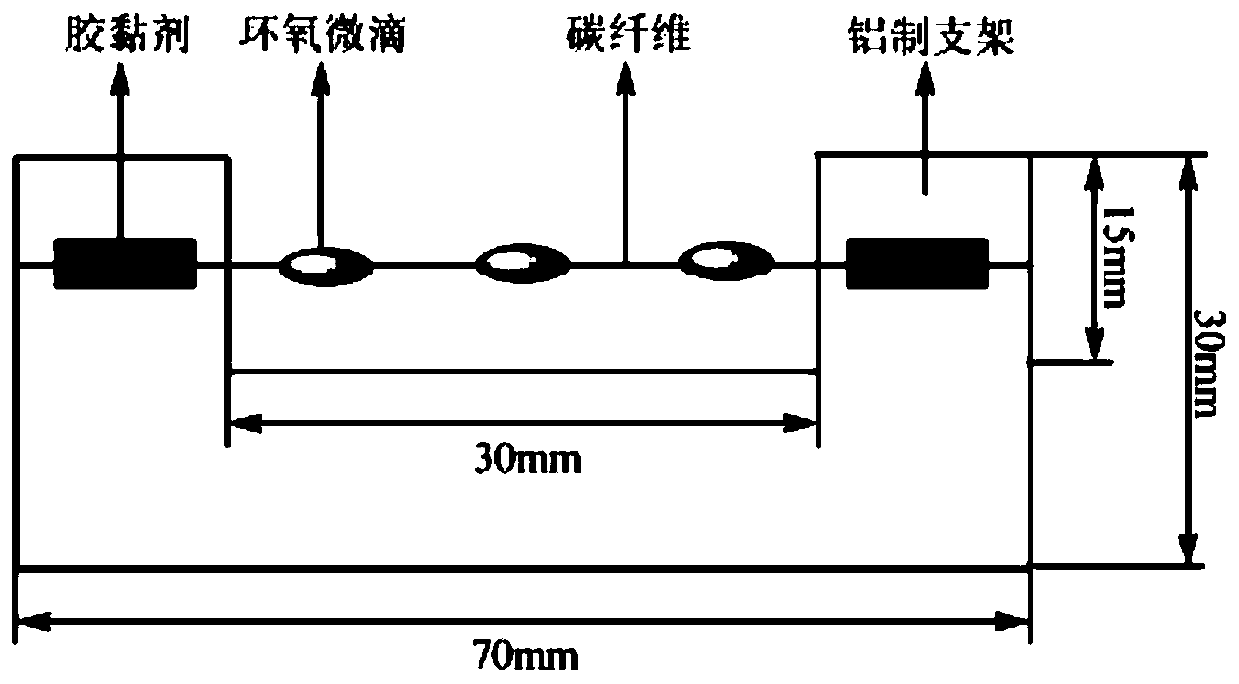

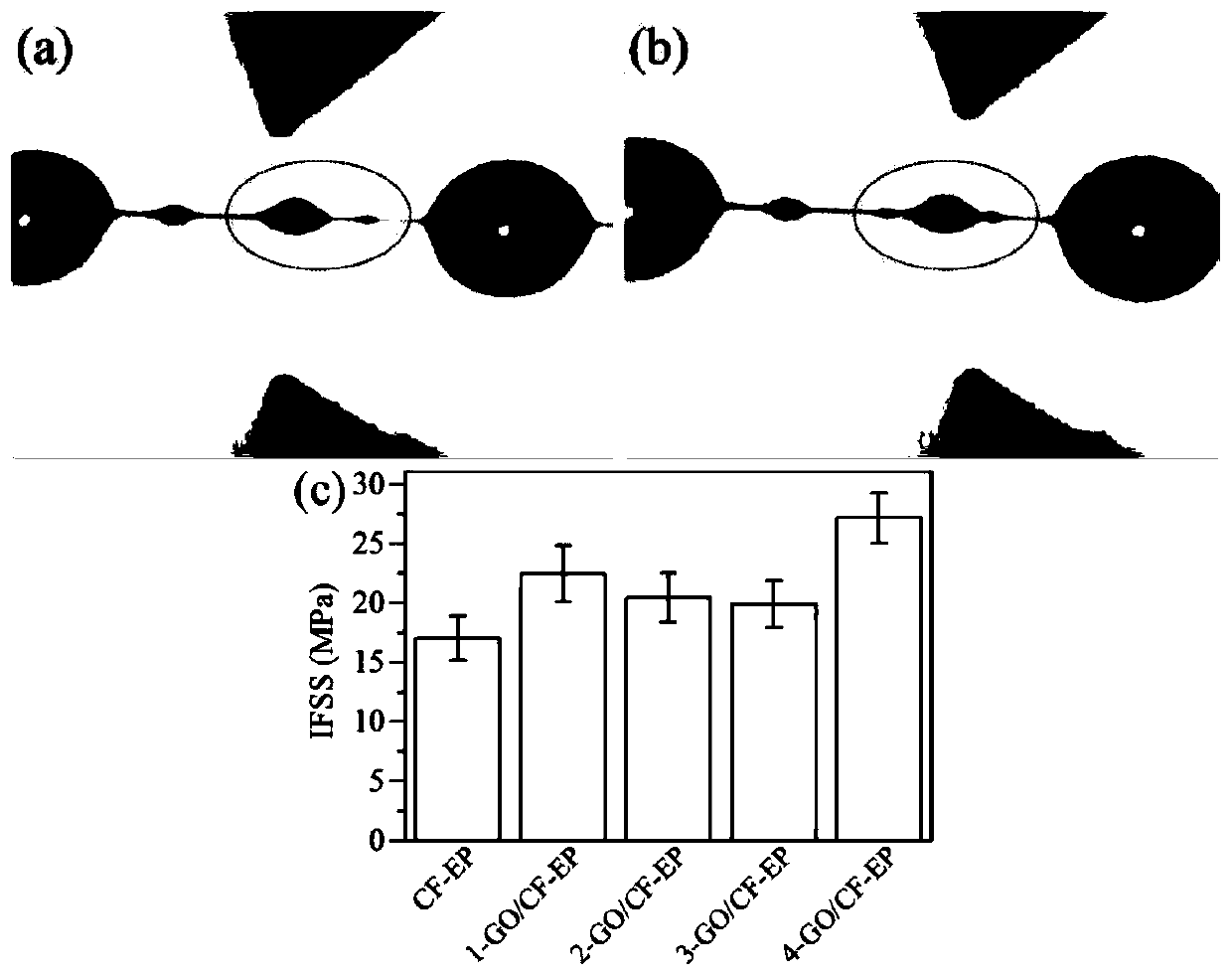

A preparation method of graphene oxide modified carbon fiber initiated by silane coupling agent-assisted electrophoretic deposition

ActiveCN108286187BRetain mechanical propertiesSolve reunionCarbon fibresCarbon fibersModified carbon

The invention discloses a preparation method of silane coupling agent assisted electrophoresis deposition initiated graphene oxide modified carbon fibers. The preparation method comprises the following steps: placing desized carbon fibers into an aqueous solution which contains amino propyl triethoxysilane (APTES) and ethanol for hydrolysis amination pretreatment to obtain carbon fibers treated bya silane coupling agent, connecting the carbon fibers treated by the silane coupling agent to a positive electrode of a power supply, connecting a copper sheet to a negative electrode of the power supply, and performing electrophoresis deposition by a graphene oxide aqueous solution used as an electrophoresis deposition solution to obtain the silane coupling agent assisted electrophoresis deposition initiated graphene oxide modified carbon fibers. The preparation method can effectively enhance the interfacial shear strength of a carbon fiber enhanced resin-based composite material, and can beapplied to a surface modification process of homemade carbon fiber.

Owner:SHANDONG UNIV

Method for preparing silicon dioxide aerogel by using bagasse ash

InactiveCN108358211ASolving Green Disposal ProblemsSolve the problem of production sourceSilicon compoundsTrimethylsilyl chlorideBis(trimethylsilyl)amine

The invention provides a method for preparing silicon dioxide aerogel by using bagasse ash. The method is characterized by comprising the following steps: (1) mixing the bagasse ash with a sodium hydroxide solution, carrying out heating boiling, carrying out continuous stirring, and carrying out filtering so as to obtain sodium silicate filter liquor; (2) mixing the sodium silicate filter liquor with acidic ion exchange resin, and carrying out continuous stirring so as to obtain a silicic acid solution; (3) adding trimethylchlorosilane into the silicic acid solution, and carrying out stirringfor 10 to 40 minutes, so as to obtain a primary modified solution; (4) adding hexamethyldisilazane into the primary modified solution, and carrying out stirring for 10 to 40 minutes, so as to obtain asecondary modified solution; (5) adjusting the pH of the secondary modified solution to 4 with an ammonium hydroxide solution, so as to obtain silicon dioxide aquagel; (6) subjecting the silicon dioxide aquagel to standing heat-preserving treatment, so as to obtain gel; (7) drying the gel under ordinary pressure, thereby obtaining the silicon dioxide aerogel.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

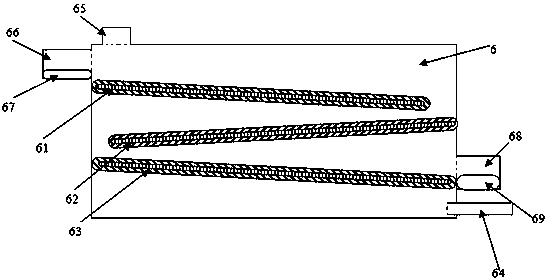

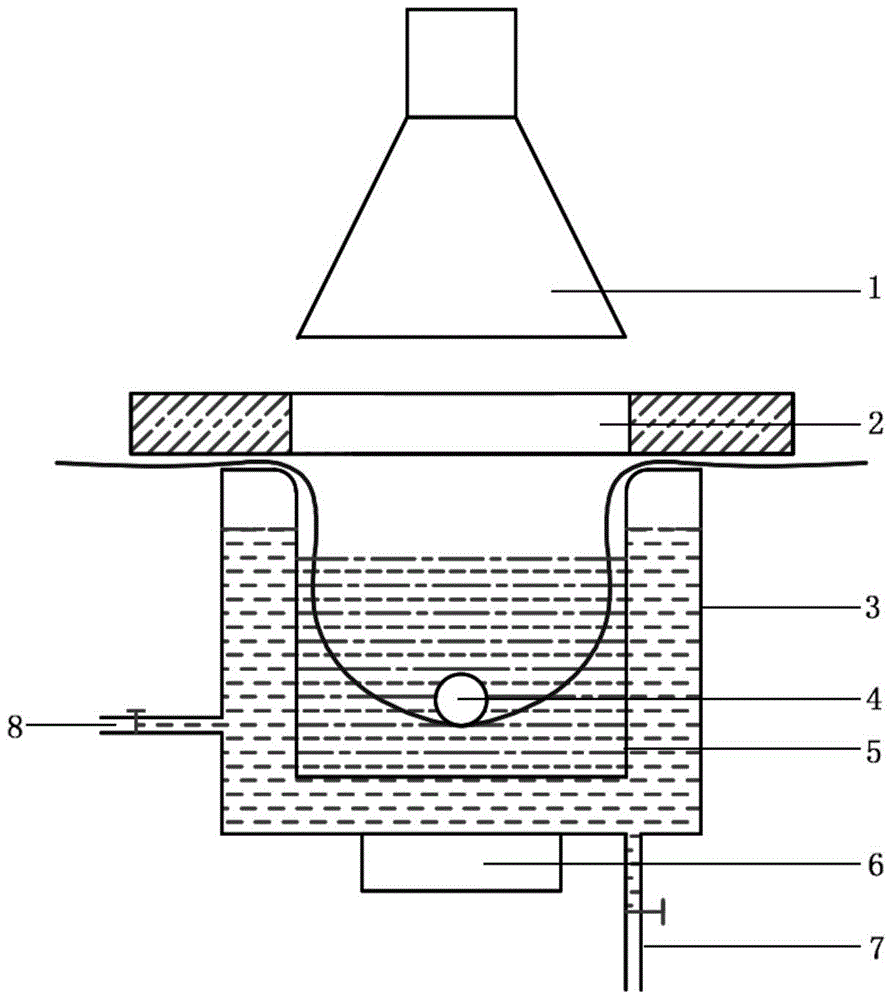

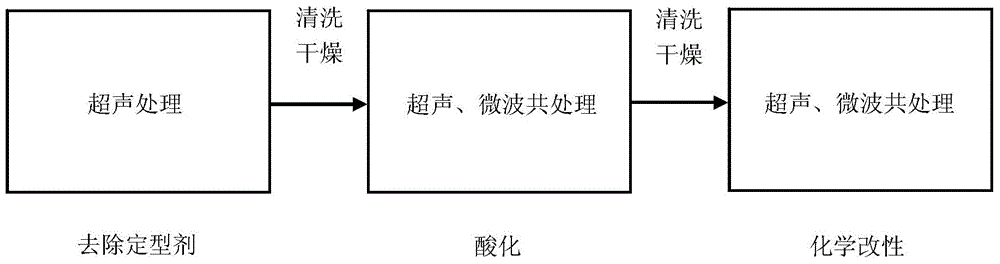

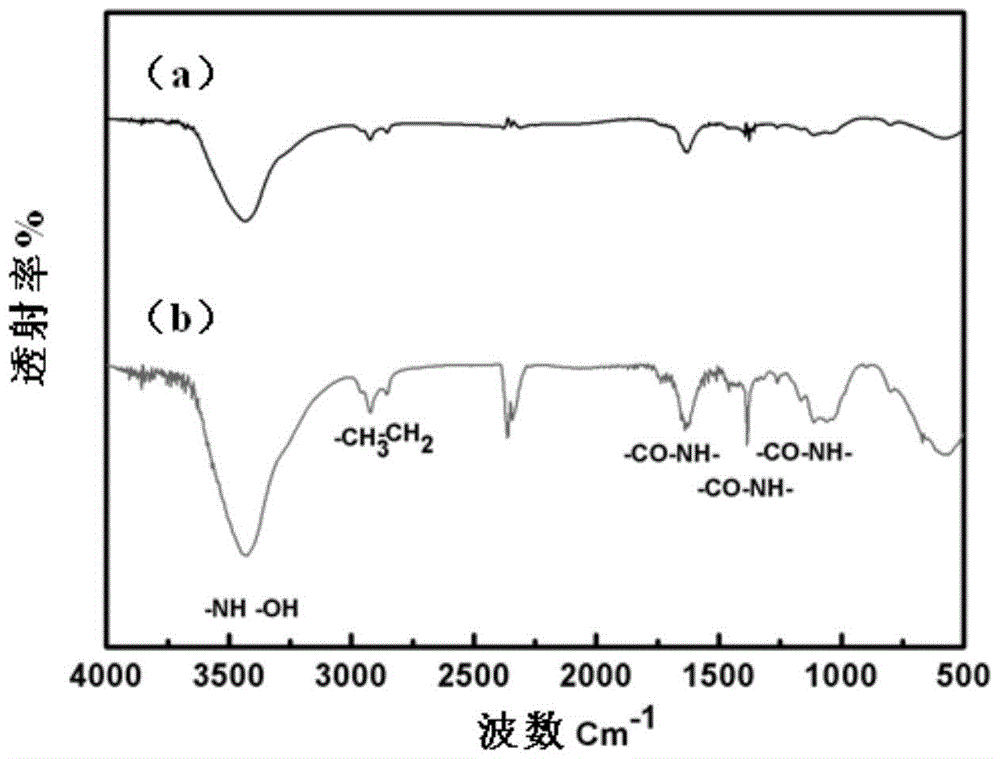

A chemical modification method and device for microwave and ultrasonic co-treatment of carbon fiber surface

InactiveCN104032565BImprove wettabilityIncrease speedUltrasonic/sonic fibre treatmentFiberTemperature control

The invention discloses a chemical modification method and device for co-treating the surface of carbon fiber with microwave and ultrasonic. In the method, the carbon fiber is pretreated to remove the sizing agent in the carbon fiber; acidification treatment is carried out; the acidified carbon fiber is added to the chemical modification solution In the process, ultrasonic pre-dispersion, then adding reaction initiator, and carrying out microwave radiation, the chemical modification is completed. The device includes a water tank with a temperature control system, the water tank is provided with a cavity for chemical modification solution, the bottom of the water tank is provided with an ultrasonic generator, the upper part of the water tank is provided with a microwave-transmissible closing cover, and the upper part of the closing cover is provided There is a microwave generator. The invention has the advantages of low cost, simple operation, strong applicability, high efficiency, and excellent treatment effect. It can not only increase the surface roughness of carbon fibers, but also introduce specific reactive functional groups on the surface of carbon fibers, improve the wettability of carbon fiber surfaces, and increase the contact between carbon fibers and resins. The bonding strength improves the performance of carbon fiber composite materials.

Owner:XI AN JIAOTONG UNIV

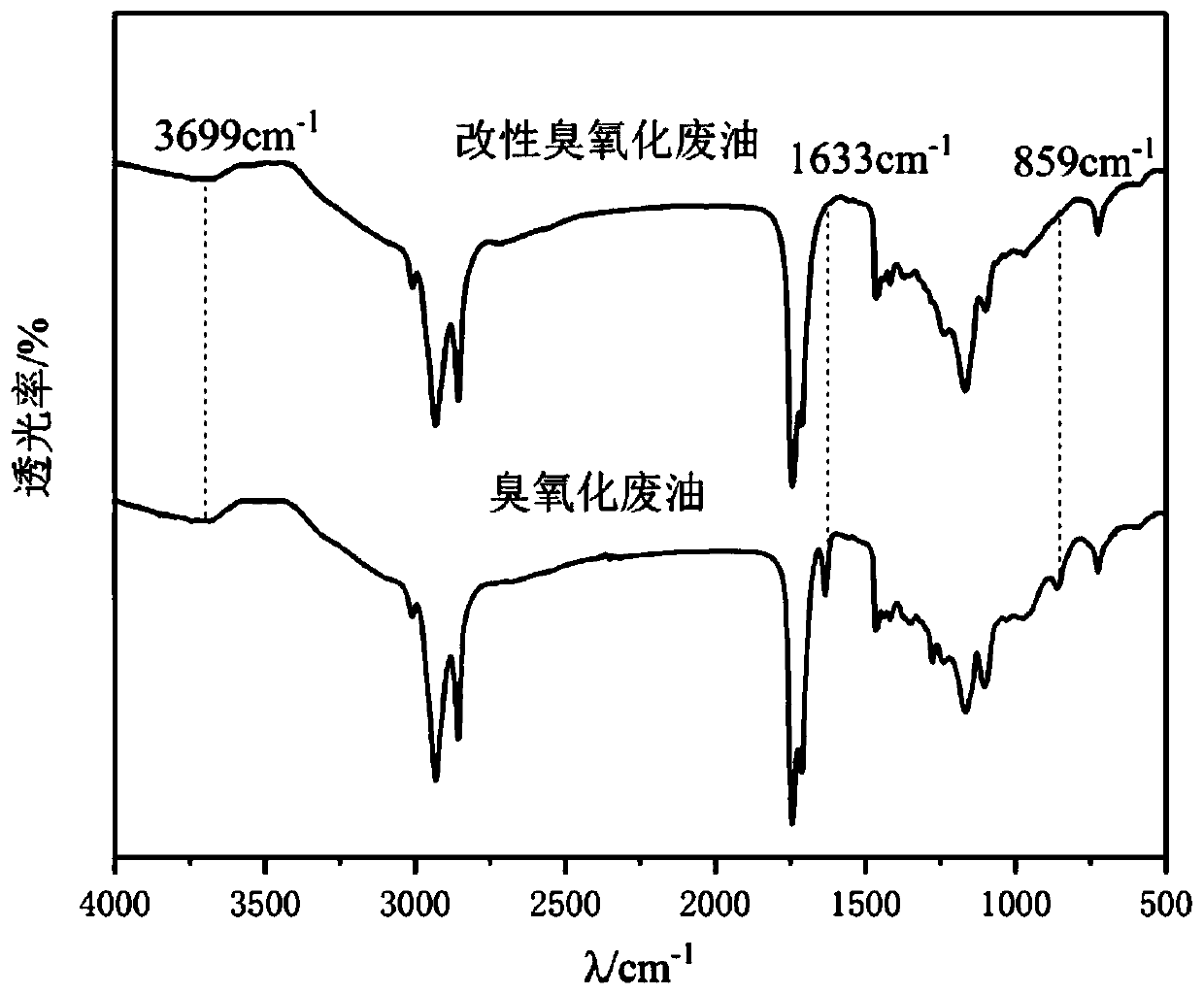

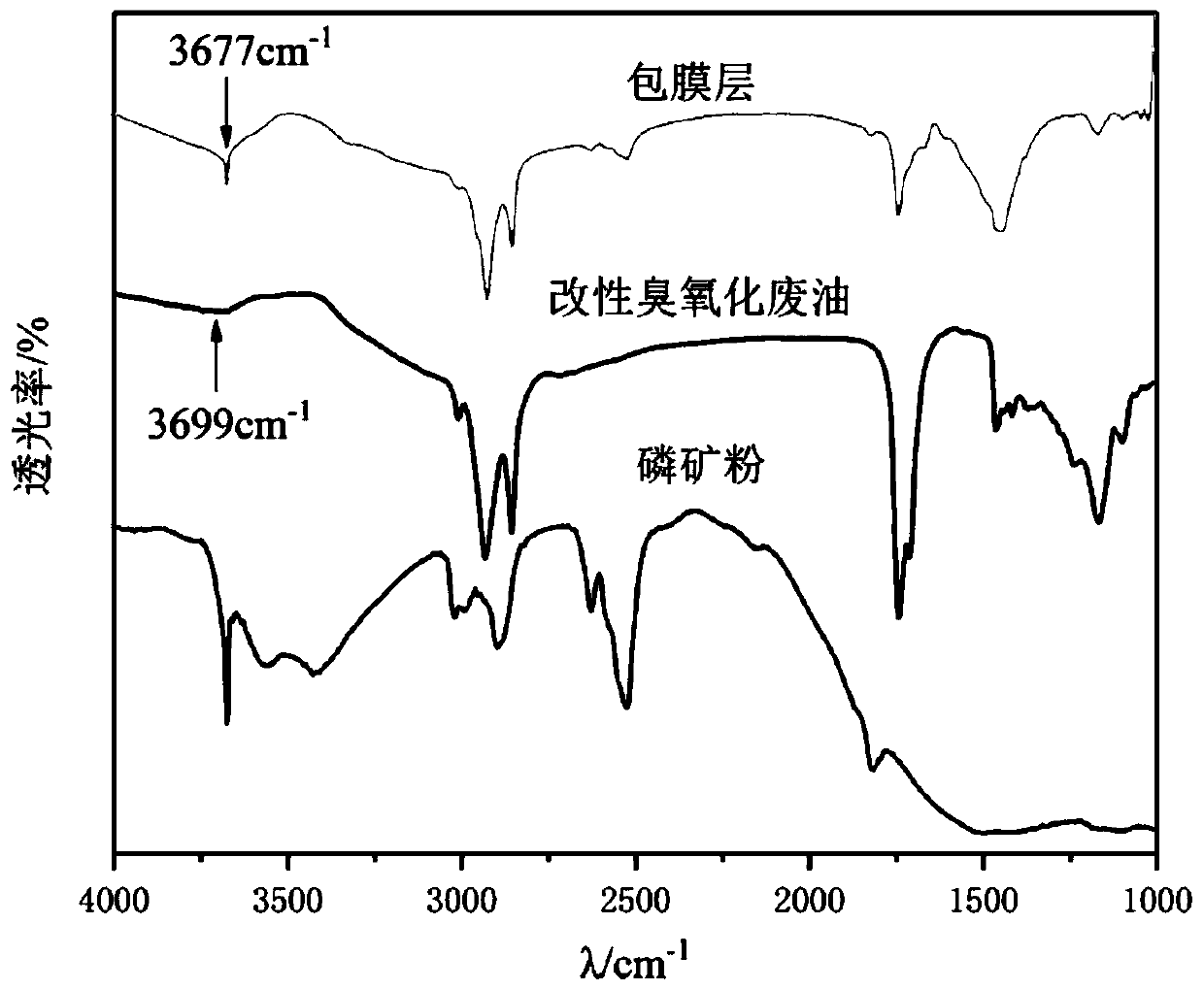

Method for modifying oil and fat and application of method

ActiveCN110343574AImprove stabilityImprove hydrophobicityFatty acid oxidationSolid/semi-solid fertilisersOil and greaseControlled release

The invention discloses a method for modifying oil and fat and application of the method. The method for modifying oil and fat comprises the steps that first the oil and fat is modified with ozone, and then a catalyst is added, and re-modification is carried out on the mixture under heating. Any solvent or other additives are not required, and modification is carried out by waste oil and fat, a degradation product is phytonutrients, the ozone consumption is small, and the ozone is a clean renewable resource, and the method can be realized under normal temperature and normal pressure. Expensiveequipment is not required to be used, and less equipment is used, so cost control is facilitated, new environmental pollution is not caused, and the method for modifying oil and fat is suitable for large-scale green environmental protection production; and the oil-fat modified material prepared by the method is applied to slow release fertilizer or control-release fertilizer, and the release of nutrients of the initial stage can be as low as 5.36% within 24 hours.

Owner:ZHONGKAI UNIV OF AGRI & ENG

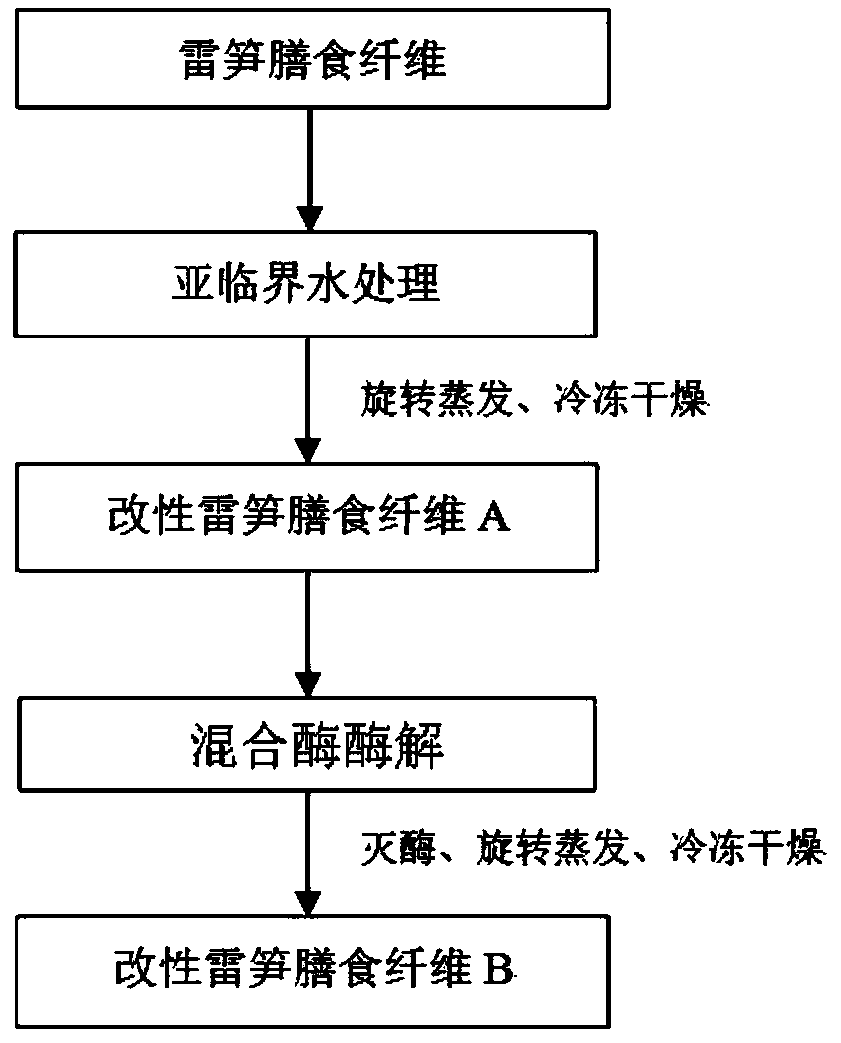

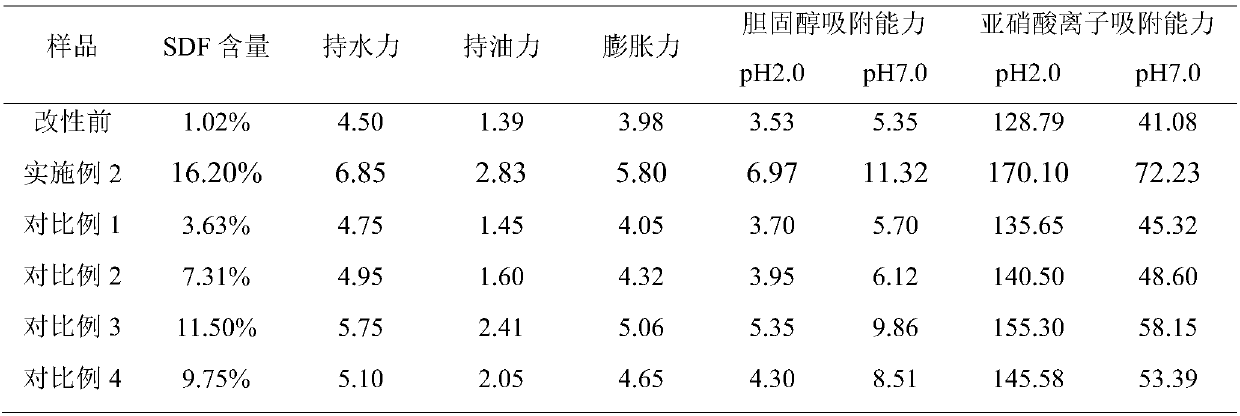

Modification method of dietary fibers and product thereof

PendingCN110916199AImprove enzymatic hydrolysis efficiencyShorten modification timeFermentationFood ingredient functionsDietary fibresEnzymatic hydrolysis

The invention belongs to the technical field of food processing, and relates to a modification method of dietary fibers. The modification method of the dietary fibers comprises the following steps: (1) uniformly mixing an extracted dietary fiber with distilled water so as to obtain a mixture, putting the mixture into subcritical water equipment so as to be subjected to processing at 105-160 DEG Cfor 10-60 minutes, carrying out concentration so as to obtain a concentrate, performing freeze-drying on the concentrate together with residues, and carrying out crushing so as to obtain a modified dietary fiber A; (2) adding distilled water into the modified dietary fiber A, adjusting the pH value to 3-8, and adding 0.1-1.0% of mixed enzymes composed of cellulase and xylanase so as to be subjected to enzymatic hydrolysis at 30-60 DEG C for 1-6 hours, thereby obtaining an enzymatic hydrolyzate; and (3) performing enzyme inactivation on the enzymatic hydrolyzate, and carrying out evaporating-concentrating, freeze-drying and crushing so as to obtain a modified dietary fiber B. The modification method of the dietary fibers disclosed by the invention is capable of significantly increasing content of soluble dietary fibers in total dietary fibers; and moreover, the obtained modified dietary fibers have significantly improved water-holding capacity, oil-holding capacity, expansive force, cholesterol adsorption capacity and nitrite ion adsorption capacity.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com