Straw recycling treatment method

A technology of recycling and processing straw, which is applied in the field of agricultural and sideline product recycling and new building materials, can solve the problems of large equipment cost investment, unobvious economic motivation, environmental problems, etc., and achieve the effects of improving efficiency, avoiding repeated processing, and stabilizing heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

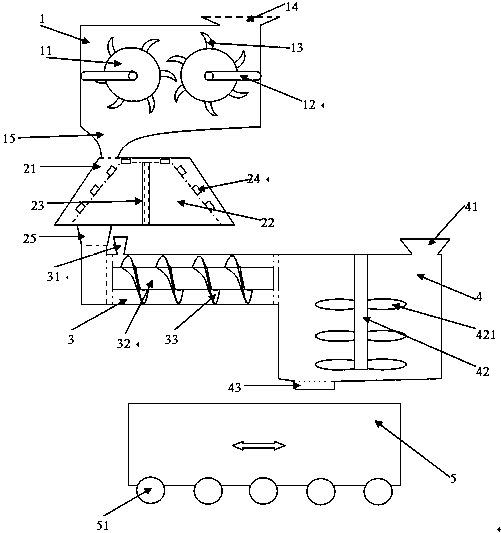

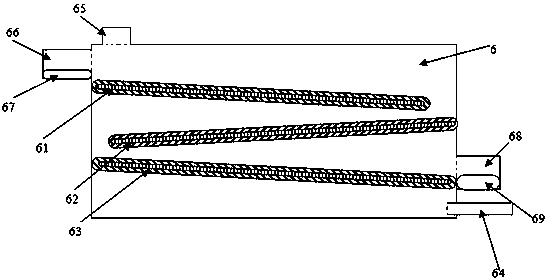

[0040] A straw recycling and processing method is produced by a straw recycling and processing device, and the straw recycling and processing device includes a crushing chamber, a fine grinding cylinder, a conveying chamber, a mixing chamber, a mold pressing machine and a steam chamber.

[0041]The crushing chamber includes a crushing chamber casing, a crushing roller assembly, a straw inlet and a crushing chamber outlet; the crushing chamber casing is arranged in a cuboid structure as a whole, and two crushing roller assemblies are arranged inside it, and the crushing roller assembly includes a transverse circular The cylindrical crushing roller is provided with a crushing knife with the same width on the side wall of the crushing roller. The crushing roller can rotate around its shaft, and a support rod is connected to the shaft through a bearing. The other end of the support rod is connected to the The inside of the side wall of the crushing chamber shell is fixed; the top s...

Embodiment 2

[0062] A straw recycling and processing method is produced by a straw recycling and processing device, and the straw recycling and processing device includes a crushing chamber, a fine grinding cylinder, a conveying chamber, a mixing chamber, a mold pressing machine and a steam chamber.

[0063] The crushing chamber includes a crushing chamber casing, a crushing roller assembly, a straw inlet and a crushing chamber outlet; the crushing chamber casing is arranged in a cuboid structure as a whole, and a plurality of crushing roller assemblies are arranged inside it, and the crushing roller assembly includes a transverse circular The cylindrical crushing roller is provided with a crushing knife with the same width on the side wall of the crushing roller. The crushing roller can rotate around its shaft, and a support rod is connected to the shaft through a bearing. The other end of the support rod is connected to the The inside of the side wall of the crushing chamber shell is fixe...

Embodiment 3

[0083] A straw recycling and processing method is produced by a straw recycling and processing device, and the straw recycling and processing device includes a crushing chamber, a fine grinding cylinder, a conveying chamber, a mixing chamber, a mold pressing machine and a steam chamber.

[0084] The crushing chamber includes a crushing chamber casing, a crushing roller assembly, a straw inlet and a crushing chamber outlet; the crushing chamber casing is arranged in a cuboid structure as a whole, and a plurality of crushing roller assemblies are arranged inside it, and the crushing roller assembly includes a transverse circular The cylindrical crushing roller is provided with a crushing knife with the same width on the side wall of the crushing roller. The crushing roller can rotate around its shaft, and a support rod is connected to the shaft through a bearing. The other end of the support rod is connected to the The inside of the side wall of the crushing chamber shell is fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com