Ecological and environment-friendly soil remedying agent

A soil remediation agent and environmental protection technology, which is applied in the restoration of polluted soil, soil conditioning materials, organic fertilizers, etc., can solve the problems of difficult to meet high-quality soil and high effective concentration, so as to improve adsorption and immobilization, and improve Modification effect, effect of widening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An ecological and environmentally friendly soil remediation agent, in parts by weight, the soil remediation agent is composed of 55 parts of modified hectorite, 20 parts of organic fertilizer, 10 parts of humic acid, and 1 part of microbial agent. Hectorite is prepared by the following method: calcining the hectorite, then adding a mixed modifier and stirring the reaction, microwave irradiation treatment while stirring, and finally grinding into particles or powder. The stirring reaction is at a temperature of 280°C. Execute under one hour;

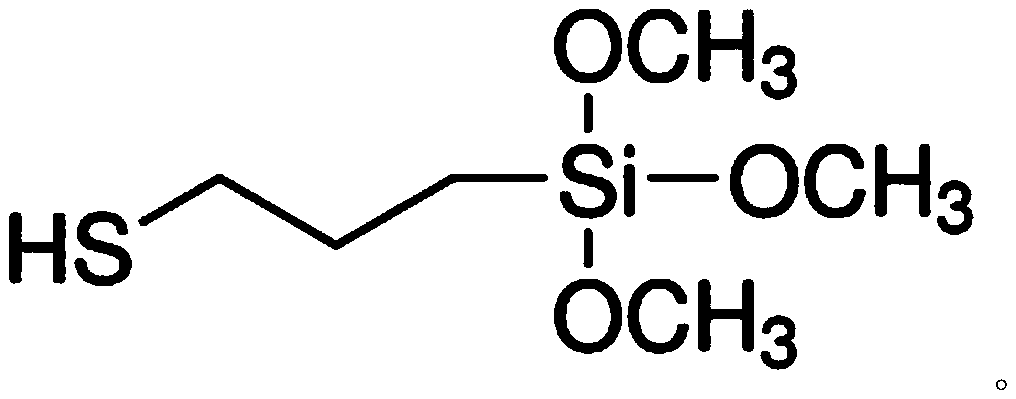

[0024] The amount of the mixed modifier accounts for 10wt% of the modified hectorite. The mixed modifier is composed of calcium polysulfide and modifier I in a mass ratio of 2:1. The structural formula of the modifier I as follows:

[0025]

[0026] Wherein, the microwave irradiation power is 750W, the organic fertilizer is chicken manure, the microbial agent is Bacillus, and the particle size of the modified hectorite is between 150 m...

Embodiment 2

[0028] An ecological and environmentally friendly soil remediation agent, in parts by weight, the soil remediation agent is mixed by 60 parts of modified hectorite, 25 parts of organic fertilizer, 15 parts of humic acid and 2 parts of microbial inoculants. Hectorite is prepared by the following method: calcining the hectorite, then adding a mixed modifier and stirring the reaction, microwave irradiation treatment while stirring, and finally grinding into particles or powder, the stirring reaction is at a temperature of 300°C Execute under one hour;

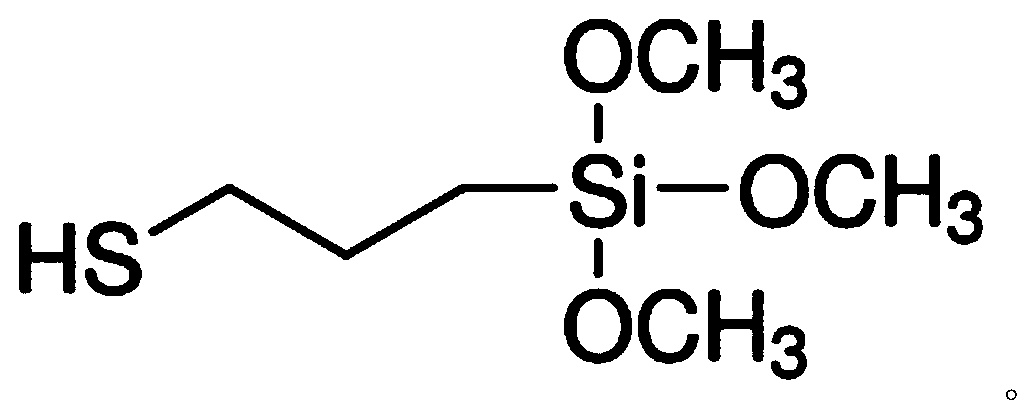

[0029] The amount of the mixed modifier accounts for 10wt% of the modified hectorite. The mixed modifier is composed of calcium polysulfide and modifier I in a mass ratio of 2:1. The structural formula of the modifier I as follows:

[0030]

[0031] Wherein, the microwave irradiation power is 800W, the organic fertilizer is pig manure, the microbial agent is Bacillus, and the particle size of the modified hectorite is between 200 mesh...

Embodiment 3

[0033] An ecological and environmentally friendly soil remediation agent, in parts by weight, the soil remediation agent is made up of 65 parts of modified hectorite, 30 parts of organic fertilizer, 20 parts of humic acid and 3 parts of microbial agents. Hectorite is prepared by the following method: calcining the hectorite, then adding a mixed modifier and stirring reaction, microwave irradiation treatment while stirring, and finally grinding into particles or powder, the stirring reaction is at a temperature of 320°C Execute under one hour;

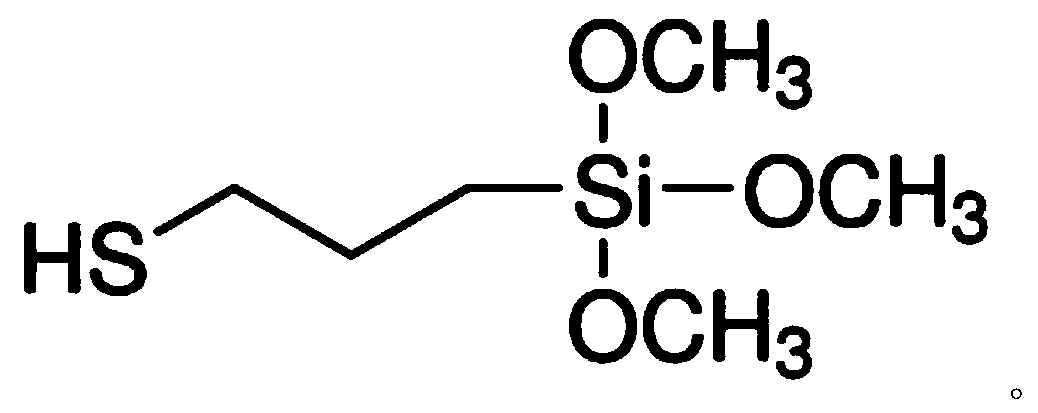

[0034] The amount of the mixed modifier accounts for 10wt% of the modified hectorite. The mixed modifier is composed of calcium polysulfide and modifier I in a mass ratio of 2:1. The structural formula of the modifier I as follows:

[0035]

[0036] Wherein, the microwave irradiation power is 850W, the organic fertilizer is cow dung, the microbial agent is Bacillus, and the particle size of the modified hectorite is between 250 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com