Catalyst with rewritable performance and its preparation method and application

A catalyst and writing performance technology, applied in the field of heterogeneous catalysts, can solve problems such as difficulty in changing catalytic performance, and achieve the effects of being beneficial to recycling, increasing stability, and improving catalytic desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

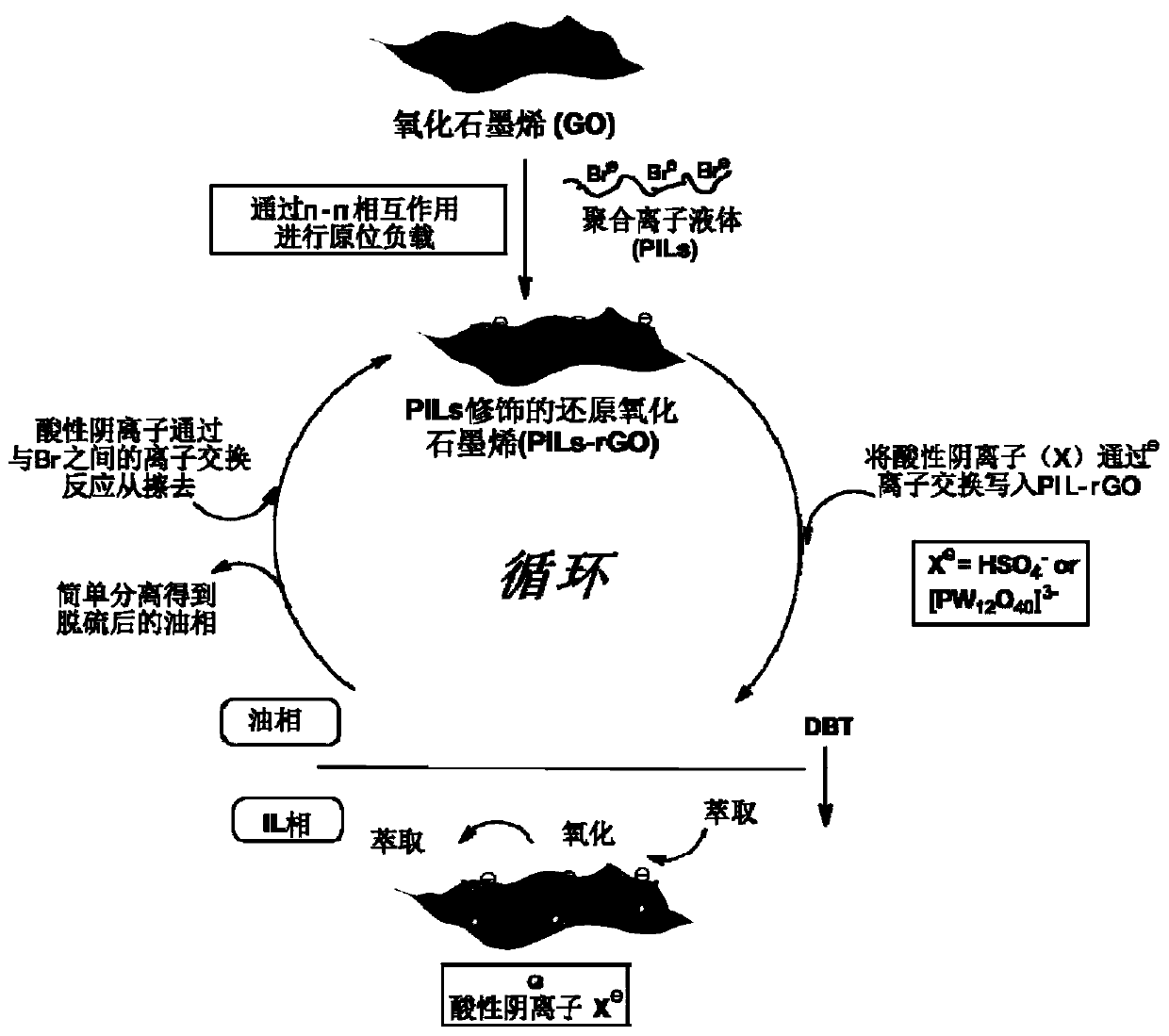

[0059] Example 1 Catalyst carrier PIL-rGO with rewritable properties

[0060] The preparation method is as follows:

[0061] 1) Preparation of polymeric ionic liquid 1-vinyl-3-ethylimidazolium bromide Poly[ViBIm]Br(PIL-Br)

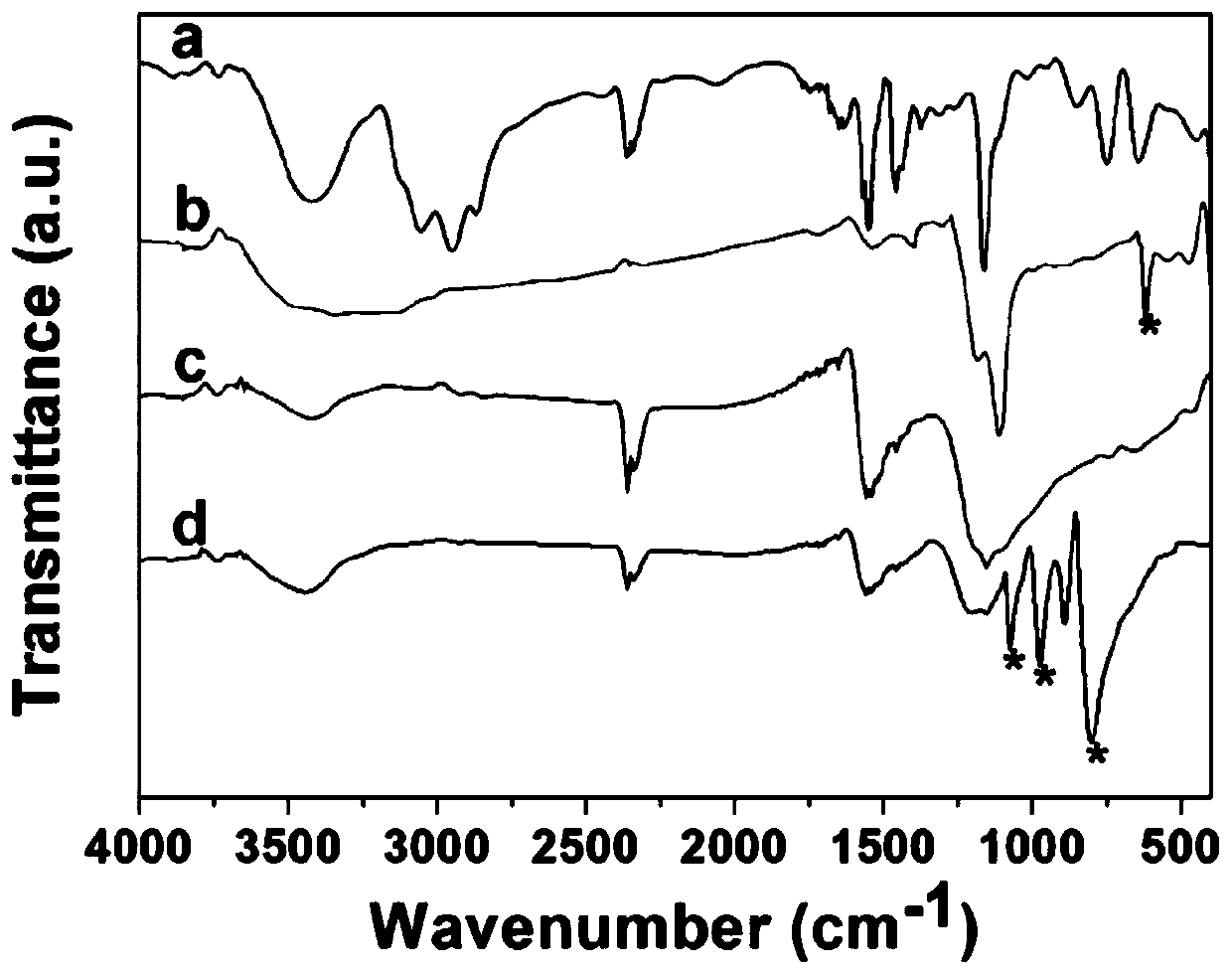

[0062] Accurately weigh 20 g of 1-vinyl-3-ethylimidazolium bromide monomer, and add it into a 250 mL round bottom flask, dissolve it with chloroform, add 0.4 g of AIBN, and stir to dissolve. After filling the above system with nitrogen for 30 minutes, under the protection of nitrogen, the reaction was refluxed for 5 hours. After the reaction was completed, it was cooled to room temperature, the product was washed three times with chloroform, and then dried in vacuo to obtain a yellow solid, Poly[ViBIm]Br(PIL-Br).

[0063] 2) load Br - Preparation of catalyst carrier (PIL-rGO) with rewritable performance

[0064] Add 0.1 g of graphene oxide (GO) to a round bottom flask containing 100 mL of deionized water, obtain a black GO dispersion system after ultra...

Embodiment 2

[0065] Example 2 Research on the rewritable performance of PIL-rGO

[0066] Based on the ion exchange property of PIL-Br, this example examines the relationship between different anions and Br in PIL-rGO - The reversible exchange between, that is, the rewritable performance of PIL-rGO.

[0067] 1) Acidic anion [HSO 4 ] - The writing process

[0068] Add 120mL sodium bisulfate saturated aqueous solution to the round bottom flask, weigh 0.1g loaded Br - The catalyst carrier PIL-rGO with rewritable properties was dissolved in a small amount of deionized water, and a black dispersion system was obtained after ultrasonic dispersion. The obtained black dispersion system was transferred to a round bottom flask and reacted for 24 h under magnetic stirring. After the reaction, the product was filtered through a filter membrane, washed three times with water, and freeze-dried to obtain the loaded acidic anion [HSO 4 ] - acidic anion catalyst ([HSO 4 ] - -PIL-rGO).

[0069] 2) ...

Embodiment 3

[0078] Synthesis of PIL-rGO catalysts modified by different heteropolyacid anions in embodiment 3

[0079] (1) [PW 12 o 40 ] 3- - Preparation of PIL-rGO

[0080] Add 120mL of phosphotungstic acid aqueous solution to the round bottom flask, weigh 0.1g of PIL-rGO prepared in Example 1 and dissolve in a small amount of deionized water, and obtain a black dispersion system after ultrasonication. The PIL-rGO dispersion was transferred to a round bottom flask and reacted for 24 h under magnetic stirring. After the reaction, the product was filtered with a filter membrane, washed three times with water, and after freeze-drying, the loaded acidic anion [PW12 o 40 ] 3- The acidic anion catalyst ([PW 12 o 40 ] 3- -PIL-rGO).

[0081] (2) [PMo 12 o 40 ] 3- - Preparation of PIL-rGO

[0082] Add 120 mL of phosphomolybdic acid aqueous solution into the round bottom flask, weigh 0.1 g of PIL-rGO prepared in Example 1, dissolve it in a small amount of deionized water, and obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com