A three-dimensional hybrid conductive binder for lithium batteries and batteries containing the binder

A binder, three-dimensional technology, applied in the field of three-dimensional hybrid conductive binder for lithium batteries and batteries containing the binder, can solve the problems of limited effect, poor adhesion and softness, and poor expansion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

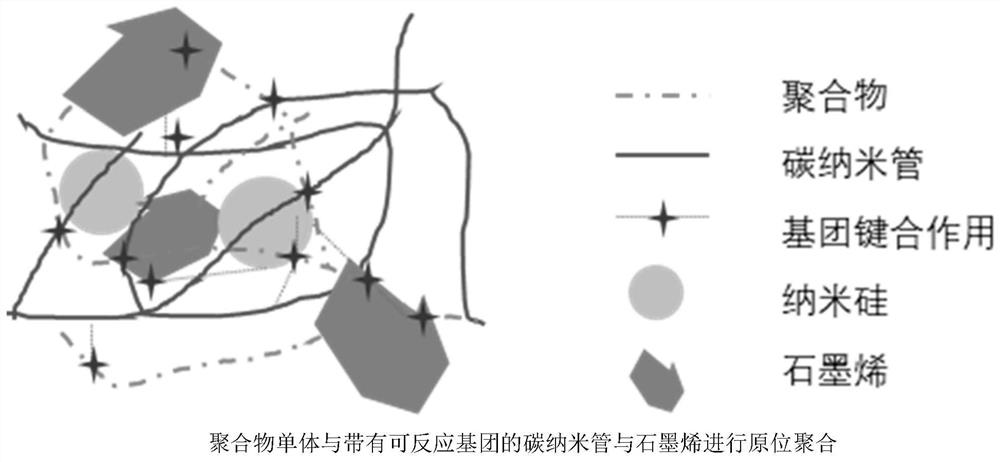

Method used

Image

Examples

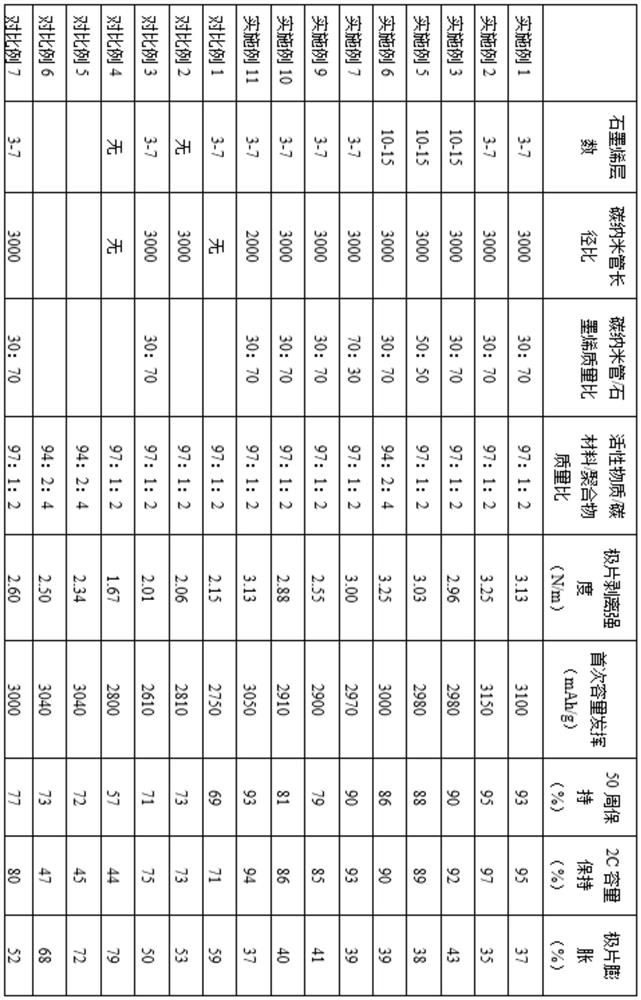

Embodiment 1

[0027] 5g carboxymethylcellulose, 5g acrylic acid, 0.025g ammonium persulfate, 3.5g hydroxyl and carboxyl few-layer graphene (3-7), 1.5g single-walled carbon nanotubes with an aspect ratio of 3000, 200ml deionized water To form a mixture, put it into the reaction kettle, stir at 30°C until fully mixed, the stirring revolution speed is 20rpm, the dispersion speed is 2000rpm, and high-purity nitrogen gas is introduced to drive oxygen for 2 hours. After vacuumizing and degassing the reactor, heat it to 80° C. with a stirring speed of 20 rpm. After reacting for 2 hours, a binder with a three-dimensional conductive network is obtained.

[0028] The composite binder is mixed with nano-silicon particles for beating, and the ratio of the weight of the binder except moisture to nano-silicon powder is 3:97. The above slurry is evenly coated on the copper foil current collector to obtain an electrode membrane. With metal lithium sheet as counter electrode, polypropylene microporous memb...

Embodiment 2

[0030] Compared with Example 1, the difference is that the raw materials are 10g acrylamide, 0.025g ammonium persulfate, 0.01g N-N methylene bisacrylamide, 0.025g ethylenediaminetetraacetic acid is added before heating and stirring, and the test results are listed in Table 1 .

Embodiment 3

[0032] Compared with Example 1, the difference is that the raw material adopts 10-15 layers of graphene. List the test results in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com