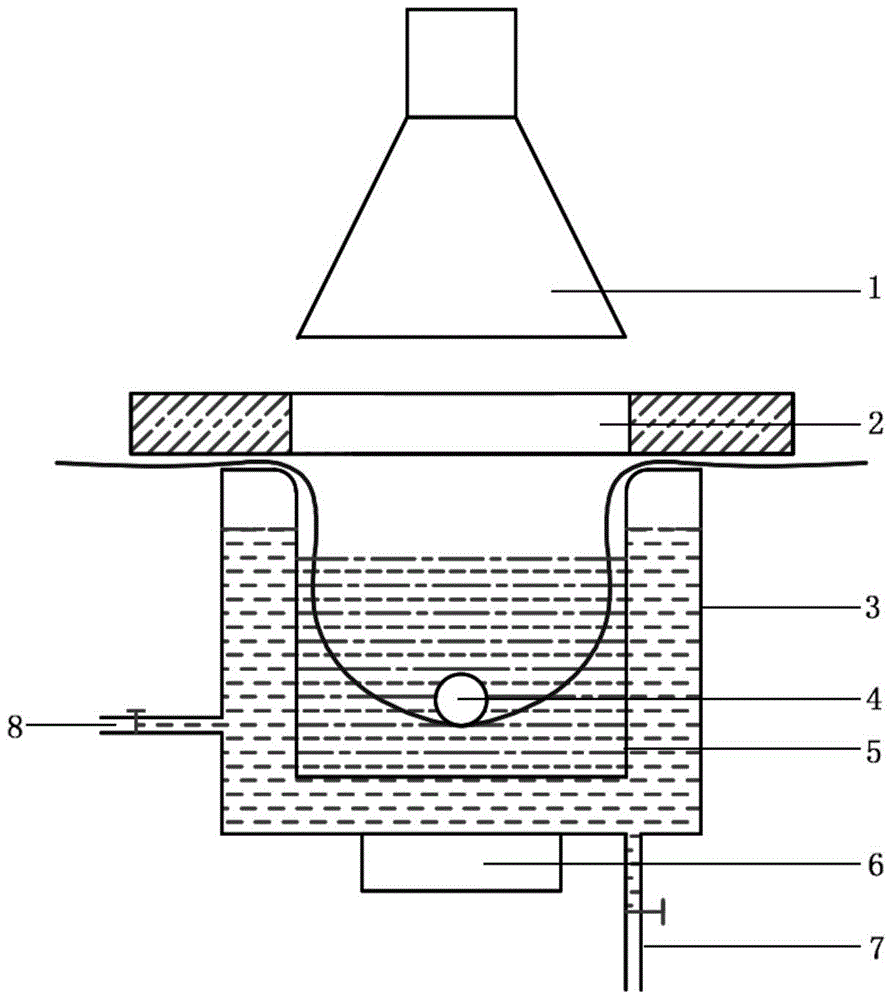

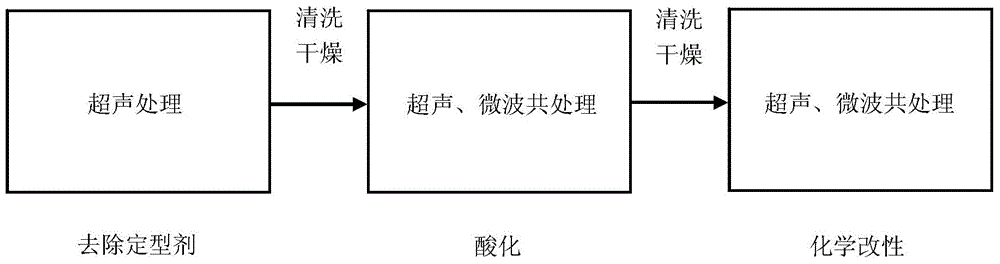

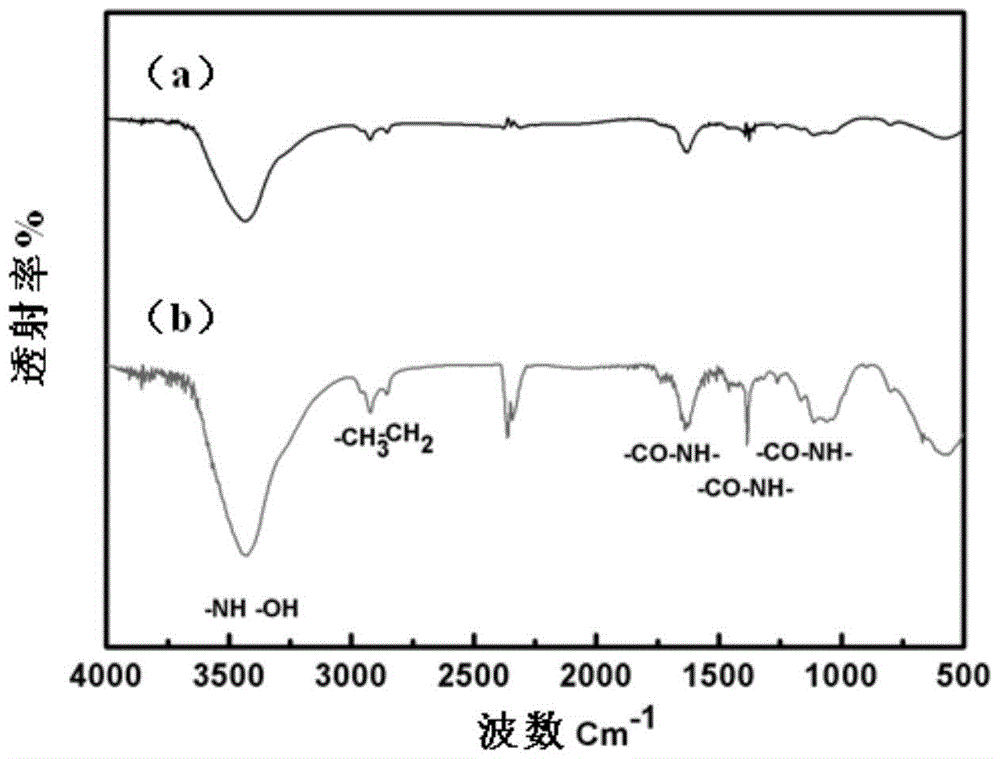

A chemical modification method and device for microwave and ultrasonic co-treatment of carbon fiber surface

A chemical modification and microwave ultrasonic technology, which is applied in ultrasonic/acoustic fiber treatment, fiber treatment, physical treatment, etc., can solve the problems of carbon fiber mechanical properties, single functional group, low reaction efficiency, etc., and achieve excellent treatment effect, The effect of low investment cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Immerse carbon fiber (raw material is pitch fiber, form is prepreg) into acetone, ultrasonically disperse for 10h at 800W power, 40kHz frequency and 60°C temperature to remove the sizing agent in the carbon fiber, and then in Wash in deionized water for 12 hours, and finally vacuum-dry at 100°C and -0.1MPa vacuum for 4 hours to obtain carbon fibers after removing the sizing agent.

[0035] Step 2: Add the carbon fiber after removing the sizing agent in step 1 into concentrated nitric acid with a mass concentration of 69% at a mass ratio of 0.4:100, and ultrasonically treat it for 30 minutes at a power of 400W and a frequency of 40kHz. 100W microwave generator with a frequency of 2.45GHz irradiated for 40 minutes, then took out the carbon fiber and washed it with deionized water until the eluate was neutral, then dried the carbon fiber at 80°C and a vacuum of -0.1MPa for 4 hours, that is Acidified carbon fibers are obtained.

[0036] Step 3: Add the acidified ca...

Embodiment 2

[0038]Step 1: Soak the carbon fiber (the raw material is polypropylene base, in the form of fiber tow) in petroleum ether, ultrasonically disperse for 6 hours at a power of 600W, a frequency of 60kHz, and a temperature of 80°C to remove the sizing agent in the carbon fiber, and then Wash in deionized water for 10 hours, and finally vacuum-dry at 100°C and -0.1MPa vacuum for 4 hours to obtain carbon fibers after removing the sizing agent.

[0039] Step 2: Add the carbon fiber after removing the sizing agent in step 1 into concentrated nitric acid with a mass concentration of 63% at a mass ratio of 0.6:100, and ultrasonically treat it for 40 minutes at a power of 600W and a frequency of 80kHz. 200W microwave generator with a frequency of 2.45GHz irradiates for 40min, then take out the carbon fiber and wash it with deionized water until the eluate is neutral, then dry the carbon fiber at 80°C and vacuum degree of -0.1MPa for 4h, that is Acidified carbon fibers are obtained.

[0...

Embodiment 3

[0042] Step 1: Immerse carbon fiber (raw material is viscose yarn, in the form of fiber tow) in methanol, ultrasonically disperse for 3 hours at a power of 200W, a frequency of 80kHz, and a temperature of 80°C to remove the sizing agent in the carbon fiber, and then Wash in deionized water for 12 hours, and finally vacuum-dry at 100°C and -0.1MPa vacuum for 4 hours to obtain carbon fibers after removing the sizing agent.

[0043] Step 2: Add the carbon fiber after removing the sizing agent in step 1 into concentrated nitric acid with a mass concentration of 64% at a mass ratio of 1:100, and ultrasonically treat it for 40 minutes at a power of 400W and a frequency of 80kHz. A 300W microwave generator with a frequency of 10GHz irradiates microwaves for 20min, then takes out the carbon fiber and washes it with deionized water until the eluate is neutral, and then dries the carbon fiber at 80°C and a vacuum of -0.1MPa for 4h to obtain Acidified carbon fiber.

[0044] Step 3: Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com