Method for modifying oil and fat and application of method

A grease and modification technology, applied in the field of grease modification, can solve the problems of high price of polyisocyanate, increase of agricultural production cost, unfavorable cost control, etc., achieve strong hydrophobicity, beneficial to cost control, and short preparation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] A method for modifying grease, comprising the steps of:

[0089] Take 80mL of waste oil (acid value 46.45mgKOH / g, water mass fraction less than 5%), and use an air source ozone machine to continuously inject ozone at a flow rate of 10g / h for 5h at 20-30°C to obtain ozonated waste oil ;

[0090] 2) Preparation of modified ozonated waste oil:

[0091] Add CuSO to 30mL ozonated waste oil 4 , to get the reaction solution, CuSO in the reaction solution 4 The concentration was 0.033 mol / L, and the reaction solution was heated at 120°C for 12 hours to obtain modified ozonated waste oil.

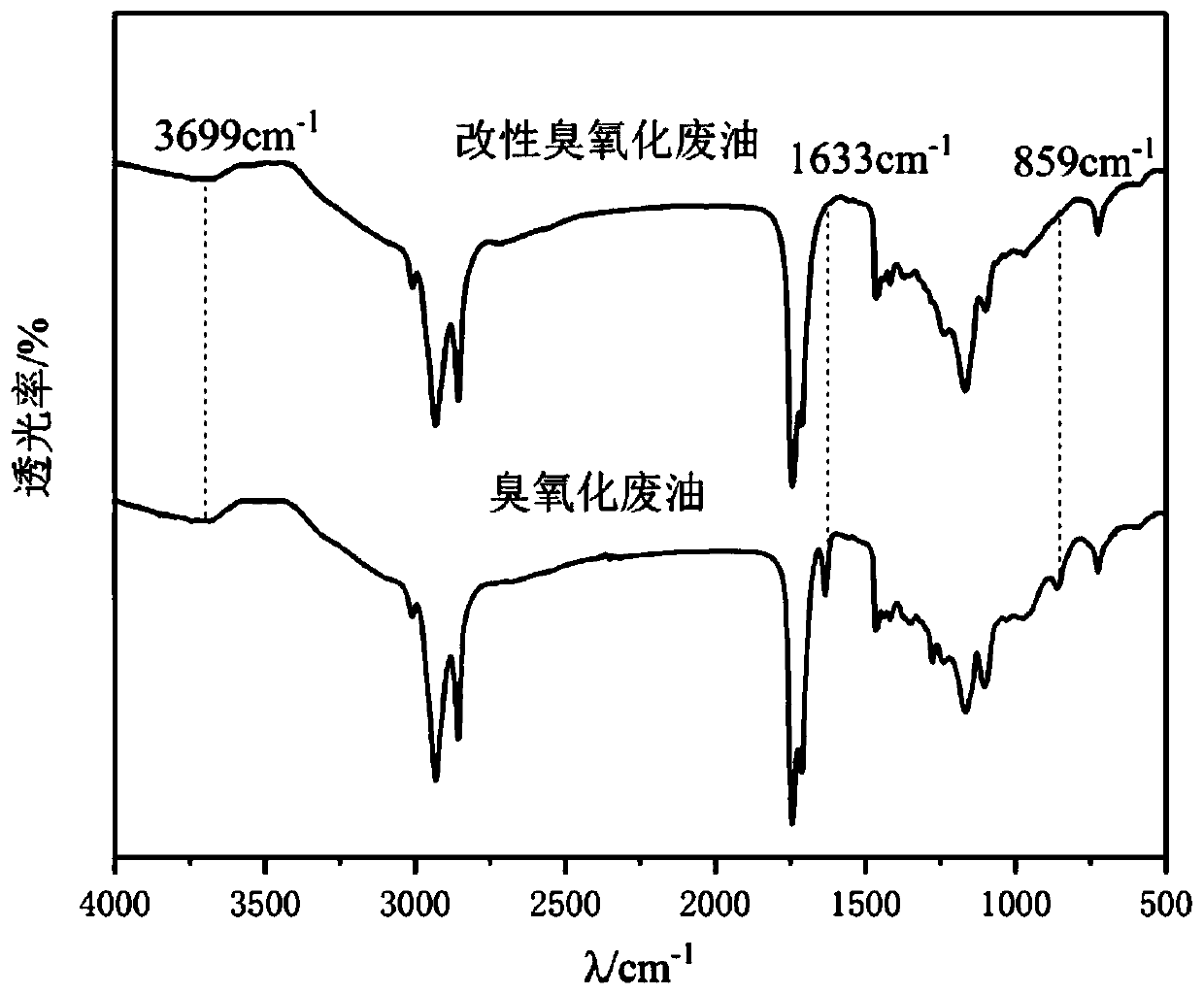

[0092] In order to clarify the effect of heating and adding catalyst on the structure of ozonated waste oil, the infrared comparison of ozonated waste oil and modified ozonated waste oil was carried out, and the results are as follows figure 1 shown. Depend on figure 1 It can be seen that compared with the ozonated waste oil, the modified ozonated waste oil is 3699cm -1 The absorption ...

Embodiment 2~5

[0094] The preparation method of Examples 2-5 is the same as that of Example 1, except that the heating time of the ozonated waste oil in Step 2) of Examples 2-5 is 24h, 36h, 48h, and 60h, respectively.

Embodiment 6

[0096] A method for modifying grease, comprising the steps of:

[0097] Take 80mL of waste oil (acid value 46.45mgKOH / g, water mass fraction less than 5%), and use an air source ozone machine to continuously inject ozone at a flow rate of 10g / h for 5h at 20-30°C to obtain ozonated waste oil ;

[0098] 2) Preparation of modified ozonated waste oil:

[0099] Add Fe to 30mL ozonated waste oil 2 (SO 4 ) 3 , to get the reaction solution, Fe in the reaction solution 2 (SO 4 ) 3 The concentration is 0.033mol / L, and then the reaction solution is heated at 120°C for 12 hours to obtain modified ozonated waste oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com